DODGE RAM 2003 Service Repair Manual

Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1881 of 2895

MANUAL TRANSMISSION - NV4500

TABLE OF CONTENTS

page page

MANUAL TRANSMISSION - NV4500

DESCRIPTION.........................42

OPERATION...........................42

DIAGNOSIS AND TESTING................43

REMOVAL.............................43

DISASSEMBLY.........................44

CLEANING............................60

INSPECTION..........................60

ASSEMBLY............................61

INSTALLATION.........................77

SPECIFICATIONS.......................79

SPECIAL TOOLS.......................79ADAPTER HOUSING SEAL

REMOVAL.............................83

INSTALLATION.........................83

EXTENSION HOUSING SEAL

REMOVAL.............................83

INSTALLATION.........................83

SHIFT MECHANISM

REMOVAL.............................84

INSTALLATION.........................85

SHIFT COVER

REMOVAL.............................86

INSTALLATION.........................86

MANUAL TRANSMISSION -

NV4500

DESCRIPTION

The NV4500 is a five speed constant mesh manual

transmission. All gear ranges including reverse are

synchronized. Fifth gear is an overdrive range. The

transmission has a cast iron gear case and aluminum

shift cover.

Two versions are used, a standard duty for 5.7L

applications and a heavy duty for V10 and Cummins

diesel applications. Main difference is a larger diam-

eter input shaft, for the heavy duty model.

Tapered roller bearings support the drive gear,

mainshaft and countershaft in the gear case. Roller

bearings in the drive gear support the forward end of

the mainshaft. The mainshaft gears are all supported

on caged type roller bearings. Drive gear thrust reac-

tion is controlled by a needle type thrust bearing.

The bearing is located at the forward end of the

mainshaft.

The transmission is a top loader style. The shift

lever is located in a shifter tower which is bolted to

the shift cover and operates the shift forks and rails

directly. The shift forks and rails are all located

within the aluminum cover which is bolted to the top

of the gear case.

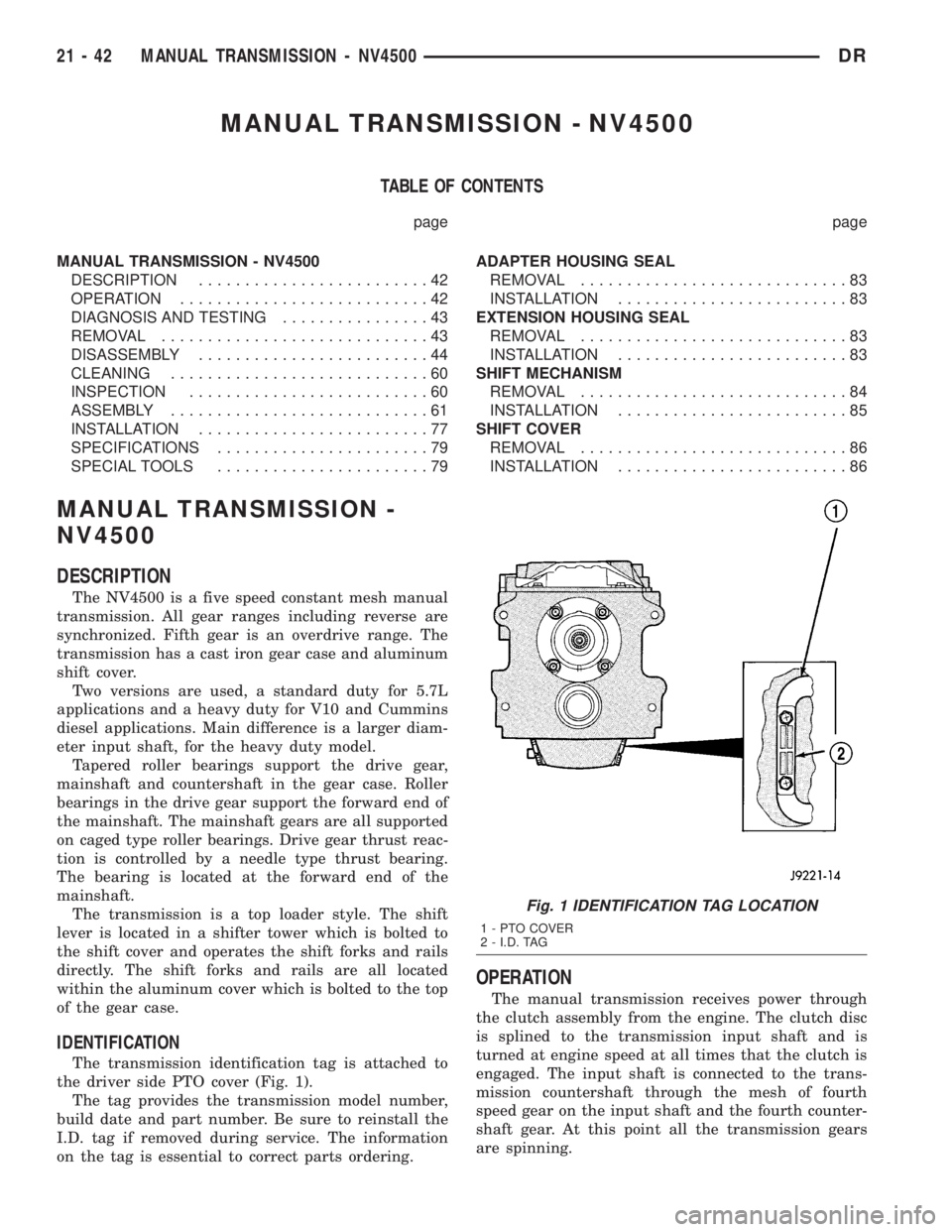

IDENTIFICATION

The transmission identification tag is attached to

the driver side PTO cover (Fig. 1).

The tag provides the transmission model number,

build date and part number. Be sure to reinstall the

I.D. tag if removed during service. The information

on the tag is essential to correct parts ordering.

OPERATION

The manual transmission receives power through

the clutch assembly from the engine. The clutch disc

is splined to the transmission input shaft and is

turned at engine speed at all times that the clutch is

engaged. The input shaft is connected to the trans-

mission countershaft through the mesh of fourth

speed gear on the input shaft and the fourth counter-

shaft gear. At this point all the transmission gears

are spinning.

Fig. 1 IDENTIFICATION TAG LOCATION

1 - PTO COVER

2 - I.D. TAG

21 - 42 MANUAL TRANSMISSION - NV4500DR

Page 1882 of 2895

The driver selects a particular gear by moving the

shift lever to the desired gear position. This move-

ment moves the internal transmission shift compo-

nents to begin the shift sequence. As the shift lever

moves the selected shift rail, the shift fork attached

to that rail begins to move. The fork is positioned in

a groove in the outer circumference of the synchro-

nizer sleeve. As the shift fork moves the synchronizer

sleeve, the synchronizer begins to speed-up or slow

down the selected gear (depending on whether the

driver is up-shifting or down-shifting). The synchro-

nizer does this by having the synchronizer hub

splined to the mainshaft, or the countershaft in some

cases, and moving the blocker ring into contact with

the gear's friction cone. As the blocker ring and fric-

tion cone come together, the gear speed is brought up

or down to the speed of the synchronizer. As the two

speeds match, the splines on the inside of the syn-

chronizer sleeve become aligned with the teeth on

the blocker ring and the friction cone and eventually

will slide over the teeth, locking the gear to the

mainshaft, or countershaft, through the synchronizer.

DIAGNOSIS AND TESTING

LOW LUBRICANT LEVEL

A low transmission lubricant level is generally the

result of a leak, inadequate lubricant fill or an incor-

rect lubricant level check. A correct lubricant level

check can only be made when the vehicle is level.

Also allow the lubricant to settle for a minute or so

before checking. These recommendations will ensure

an accurate check and avoid an underfill or overfill

condition. Always check the lubricant level after any

addition of fluid to avoid an incorrect lubricant level

condition.

Leaks can occur at the mating surfaces of the gear

case, adaptor or extension housing, or from the front/

rear seals. A suspected leak could also be the result

of an overfill condition. Leaks at the rear of the

extension or adapter housing will be from the hous-

ing oil seals. Leaks at component mating surfaces

will probably be the result of inadequate sealer, gaps

in the sealer, incorrect bolt tightening or use of a

non-recommended sealer. A leak at the front of the

transmission will be from either the front bearing

retainer or retainer seal. Lubricant may be seen drip-

ping from the clutch housing after extended opera-

tion. If the leak is severe, it may also contaminate

the clutch disc causing the disc to slip, grab and or

chatter.

HARD SHIFTING

Hard shifting is usually caused by a low lubricant

level, improper or contaminated lubricants. The con-

sequence of using non-recommended lubricants isnoise, excessive wear, internal bind and hard shift-

ing. Substantial lubricant leaks can result in gear,

shift rail, synchro, and bearing damage. If a leak

goes undetected for an extended period, the first indi-

cations of component damage are usually hard shift-

ing and noise.

Component damage, incorrect clutch adjustment or

damaged clutch pressure plate or disc are additional

probable causes of increased shift effort. Incorrect

adjustment or a worn/damaged pressure plate or disc

can cause incorrect release. If clutch problem is

advanced, gear clash during shifts can result. Worn

or damaged synchro rings can cause gear clash when

shifting into any forward gear. In some new or

rebuilt transmissions, new synchro rings may tend to

stick slightly causing hard or noisy shifts. In most

cases this condition will decline as the rings wear-in.

TRANSMISSION NOISE

Most manual transmissions make some noise dur-

ing normal operation. Rotating gears generate a mild

whine that is audible, but generally only at extreme

speeds. Severe highly audible transmission noise is

generally the initial indicator of a lubricant problem.

Insufficient, improper or contaminated lubricant

will promote rapid wear of gears, synchros, shift

rails, forks and bearings. The overheating caused by

a lubricant problem, can also lead to gear breakage.

REMOVAL

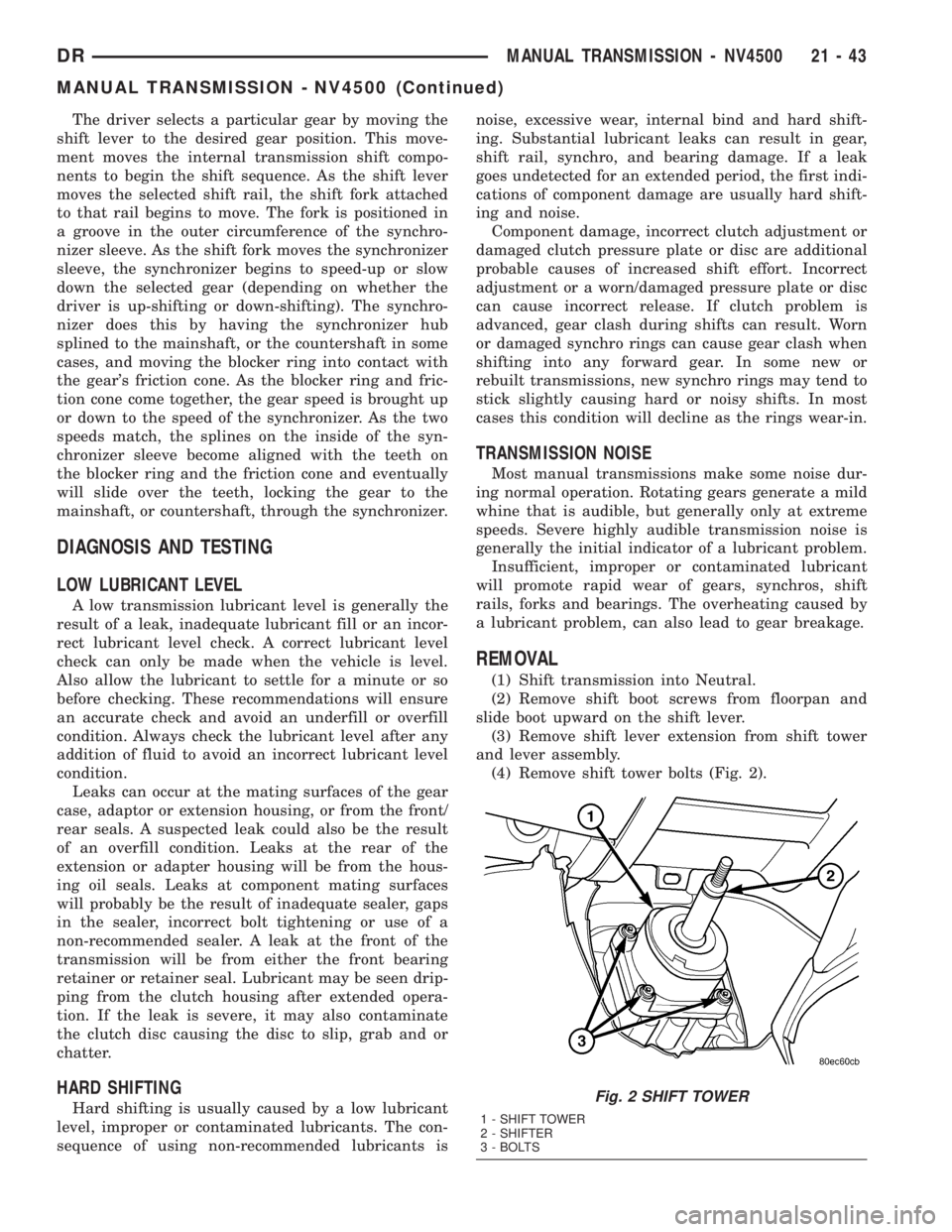

(1) Shift transmission into Neutral.

(2) Remove shift boot screws from floorpan and

slide boot upward on the shift lever.

(3) Remove shift lever extension from shift tower

and lever assembly.

(4) Remove shift tower bolts (Fig. 2).

Fig. 2 SHIFT TOWER

1 - SHIFT TOWER

2 - SHIFTER

3 - BOLTS

DRMANUAL TRANSMISSION - NV4500 21 - 43

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1883 of 2895

(5) Remove shift tower and isolator plate from

transmission shift cover.

(6) Raise and support vehicle.

(7) Remove skid plate, if equipped.

(8) Mark propeller shaft and axle yokes for instal-

lation reference and remove shaft/shafts.

(9) Remove exhaust system Y-pipe.

(10) Disconnect speed sensor and backup light

switch connectors.

(11) Support engine with safety stand and a wood

block.

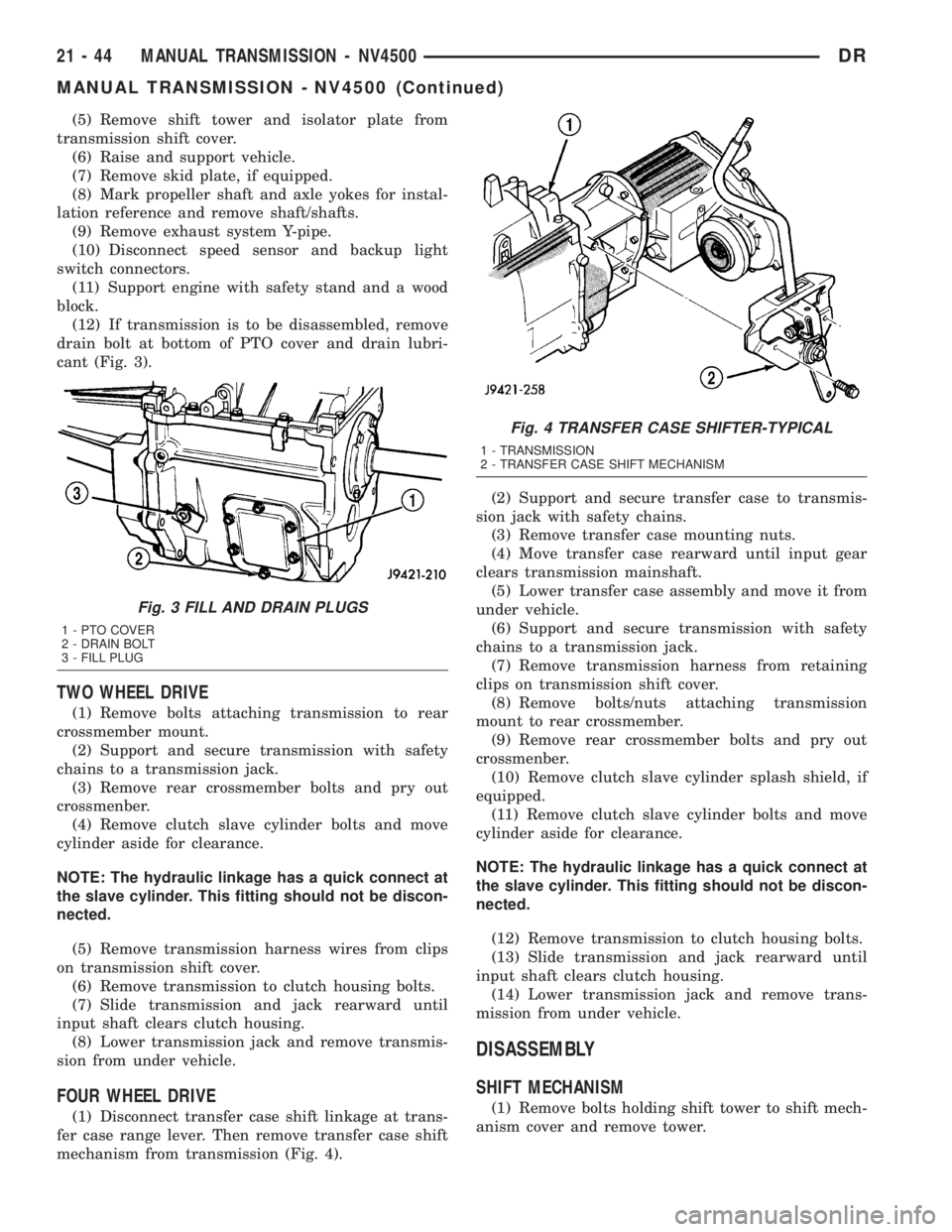

(12) If transmission is to be disassembled, remove

drain bolt at bottom of PTO cover and drain lubri-

cant (Fig. 3).

TWO WHEEL DRIVE

(1) Remove bolts attaching transmission to rear

crossmember mount.

(2) Support and secure transmission with safety

chains to a transmission jack.

(3) Remove rear crossmember bolts and pry out

crossmenber.

(4) Remove clutch slave cylinder bolts and move

cylinder aside for clearance.

NOTE: The hydraulic linkage has a quick connect at

the slave cylinder. This fitting should not be discon-

nected.

(5) Remove transmission harness wires from clips

on transmission shift cover.

(6) Remove transmission to clutch housing bolts.

(7) Slide transmission and jack rearward until

input shaft clears clutch housing.

(8) Lower transmission jack and remove transmis-

sion from under vehicle.

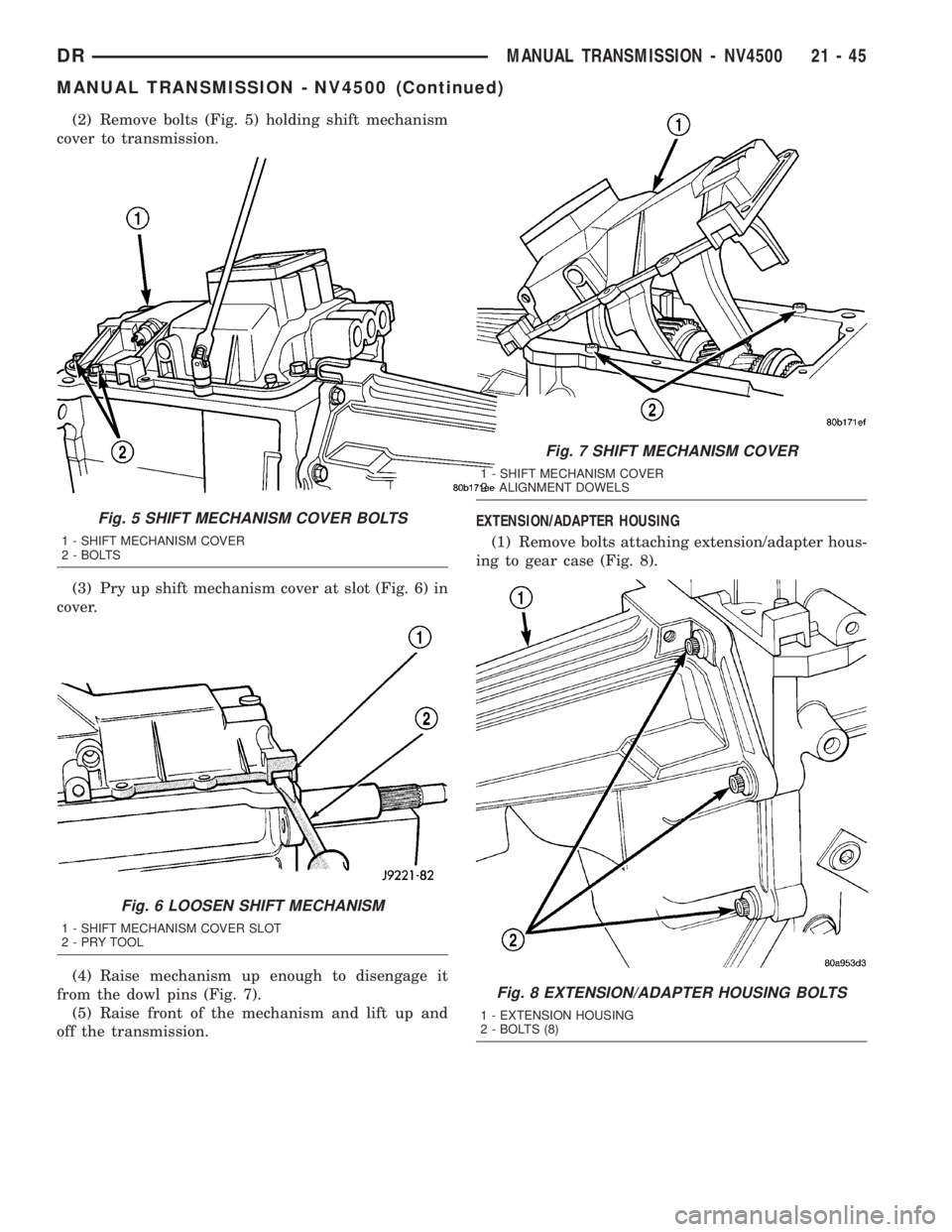

FOUR WHEEL DRIVE

(1) Disconnect transfer case shift linkage at trans-

fer case range lever. Then remove transfer case shift

mechanism from transmission (Fig. 4).(2) Support and secure transfer case to transmis-

sion jack with safety chains.

(3) Remove transfer case mounting nuts.

(4) Move transfer case rearward until input gear

clears transmission mainshaft.

(5) Lower transfer case assembly and move it from

under vehicle.

(6) Support and secure transmission with safety

chains to a transmission jack.

(7) Remove transmission harness from retaining

clips on transmission shift cover.

(8) Remove bolts/nuts attaching transmission

mount to rear crossmember.

(9) Remove rear crossmember bolts and pry out

crossmenber.

(10) Remove clutch slave cylinder splash shield, if

equipped.

(11) Remove clutch slave cylinder bolts and move

cylinder aside for clearance.

NOTE: The hydraulic linkage has a quick connect at

the slave cylinder. This fitting should not be discon-

nected.

(12) Remove transmission to clutch housing bolts.

(13) Slide transmission and jack rearward until

input shaft clears clutch housing.

(14) Lower transmission jack and remove trans-

mission from under vehicle.

DISASSEMBLY

SHIFT MECHANISM

(1) Remove bolts holding shift tower to shift mech-

anism cover and remove tower.

Fig. 3 FILL AND DRAIN PLUGS

1 - PTO COVER

2 - DRAIN BOLT

3 - FILL PLUG

Fig. 4 TRANSFER CASE SHIFTER-TYPICAL

1 - TRANSMISSION

2 - TRANSFER CASE SHIFT MECHANISM

21 - 44 MANUAL TRANSMISSION - NV4500DR

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1884 of 2895

(2) Remove bolts (Fig. 5) holding shift mechanism

cover to transmission.

(3) Pry up shift mechanism cover at slot (Fig. 6) in

cover.

(4) Raise mechanism up enough to disengage it

from the dowl pins (Fig. 7).

(5) Raise front of the mechanism and lift up and

off the transmission.EXTENSION/ADAPTER HOUSING

(1) Remove bolts attaching extension/adapter hous-

ing to gear case (Fig. 8).

Fig. 5 SHIFT MECHANISM COVER BOLTS

1 - SHIFT MECHANISM COVER

2 - BOLTS

Fig. 6 LOOSEN SHIFT MECHANISM

1 - SHIFT MECHANISM COVER SLOT

2-PRYTOOL

Fig. 7 SHIFT MECHANISM COVER

1 - SHIFT MECHANISM COVER

2 - ALIGNMENT DOWELS

Fig. 8 EXTENSION/ADAPTER HOUSING BOLTS

1 - EXTENSION HOUSING

2 - BOLTS (8)

DRMANUAL TRANSMISSION - NV4500 21 - 45

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1885 of 2895

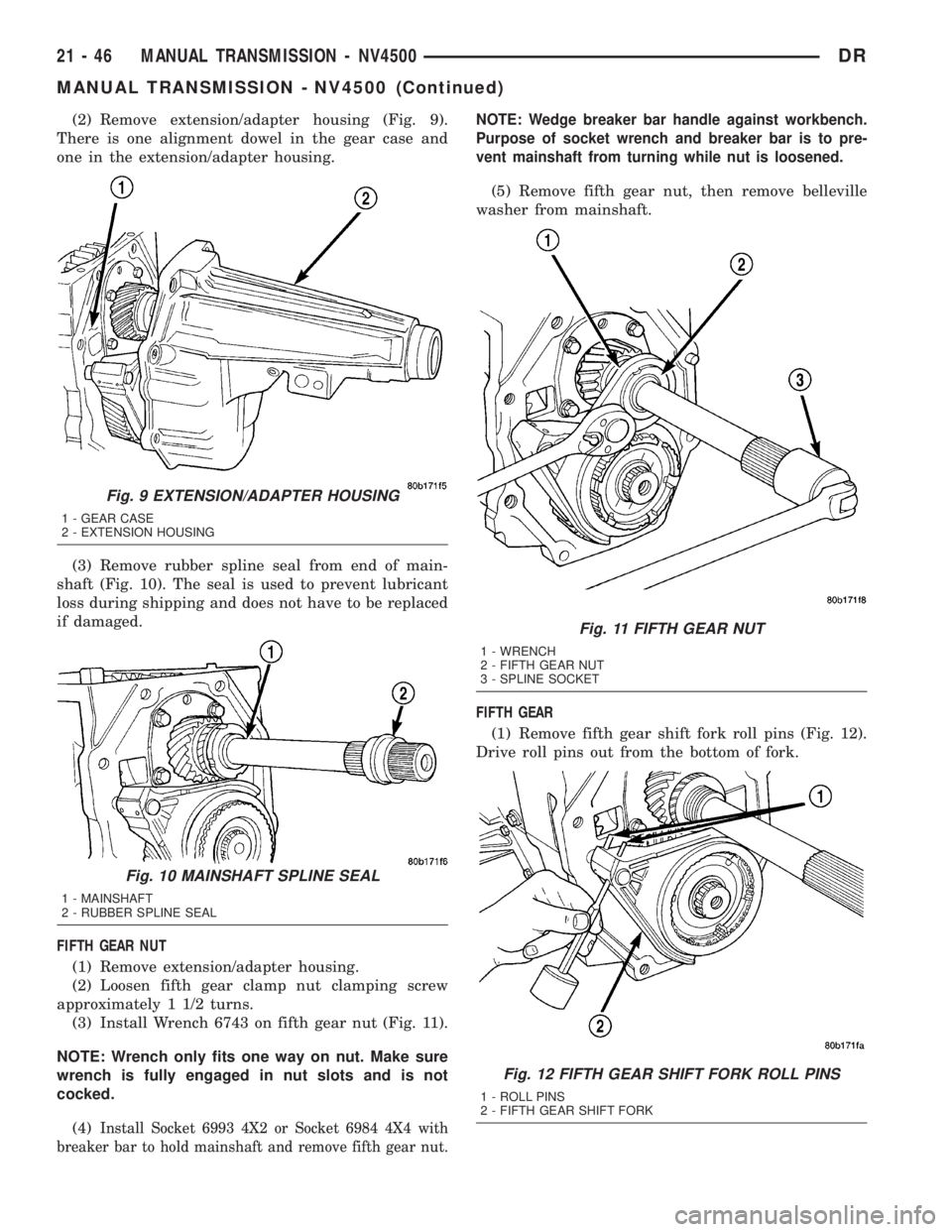

(2) Remove extension/adapter housing (Fig. 9).

There is one alignment dowel in the gear case and

one in the extension/adapter housing.

(3) Remove rubber spline seal from end of main-

shaft (Fig. 10). The seal is used to prevent lubricant

loss during shipping and does not have to be replaced

if damaged.

FIFTH GEAR NUT

(1) Remove extension/adapter housing.

(2) Loosen fifth gear clamp nut clamping screw

approximately 1 1/2 turns.

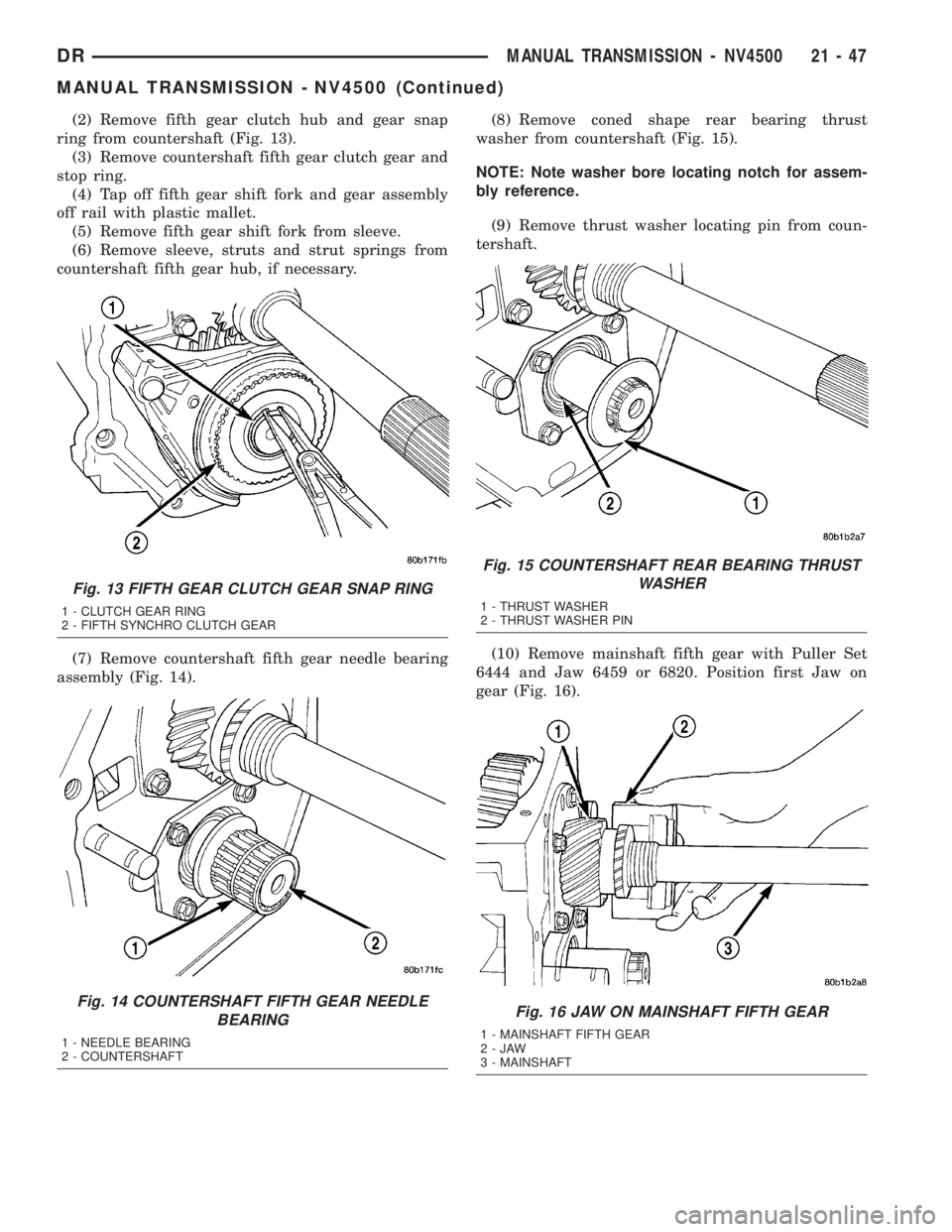

(3) Install Wrench 6743 on fifth gear nut (Fig. 11).

NOTE: Wrench only fits one way on nut. Make sure

wrench is fully engaged in nut slots and is not

cocked.

(4)

Install Socket 6993 4X2 or Socket 6984 4X4 with

breaker bar to hold mainshaft and remove fifth gear nut.

NOTE: Wedge breaker bar handle against workbench.

Purpose of socket wrench and breaker bar is to pre-

vent mainshaft from turning while nut is loosened.

(5) Remove fifth gear nut, then remove belleville

washer from mainshaft.

FIFTH GEAR

(1) Remove fifth gear shift fork roll pins (Fig. 12).

Drive roll pins out from the bottom of fork.

Fig. 9 EXTENSION/ADAPTER HOUSING

1 - GEAR CASE

2 - EXTENSION HOUSING

Fig. 10 MAINSHAFT SPLINE SEAL

1 - MAINSHAFT

2 - RUBBER SPLINE SEAL

Fig. 11 FIFTH GEAR NUT

1 - WRENCH

2 - FIFTH GEAR NUT

3 - SPLINE SOCKET

Fig. 12 FIFTH GEAR SHIFT FORK ROLL PINS

1 - ROLL PINS

2 - FIFTH GEAR SHIFT FORK

21 - 46 MANUAL TRANSMISSION - NV4500DR

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1886 of 2895

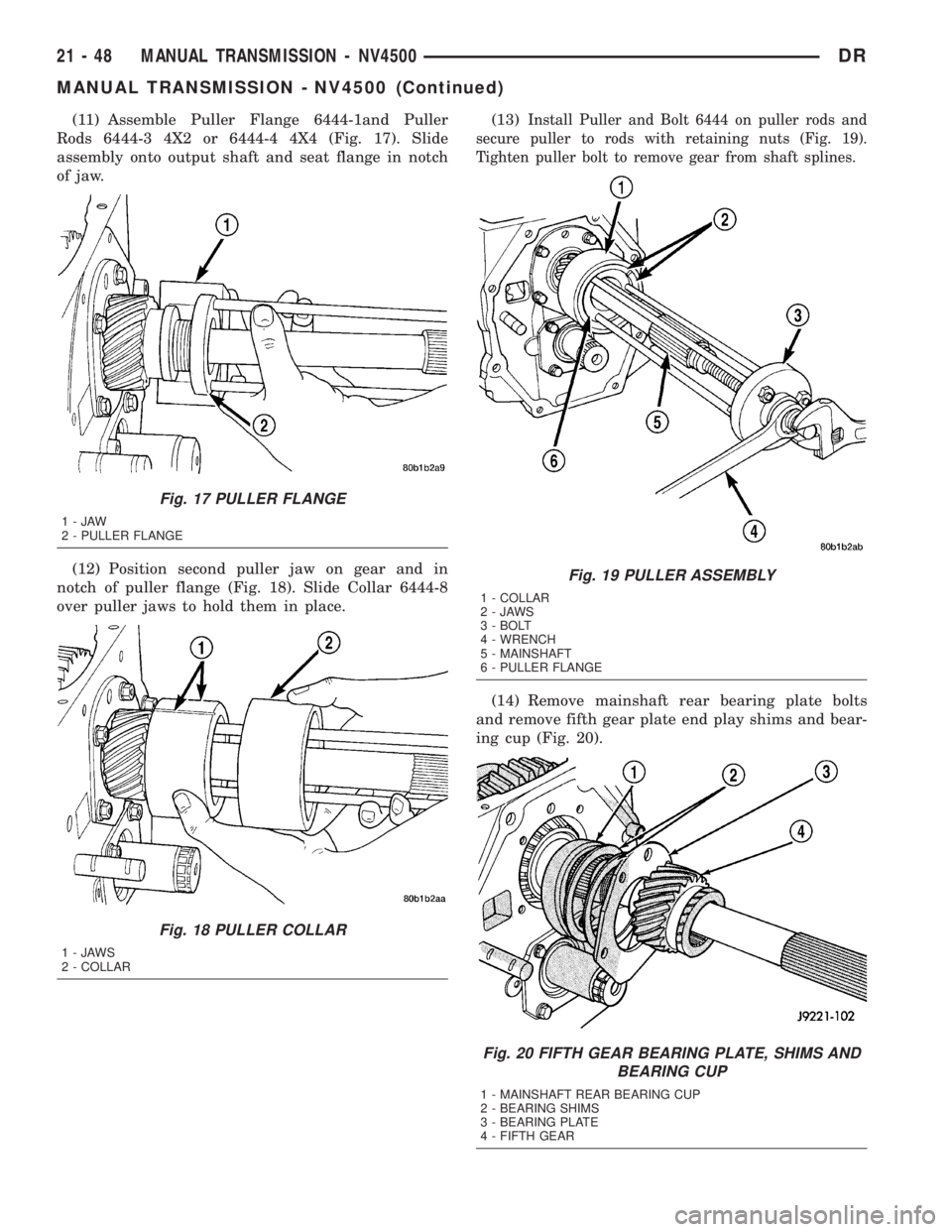

(2) Remove fifth gear clutch hub and gear snap

ring from countershaft (Fig. 13).

(3) Remove countershaft fifth gear clutch gear and

stop ring.

(4) Tap off fifth gear shift fork and gear assembly

off rail with plastic mallet.

(5) Remove fifth gear shift fork from sleeve.

(6) Remove sleeve, struts and strut springs from

countershaft fifth gear hub, if necessary.

(7) Remove countershaft fifth gear needle bearing

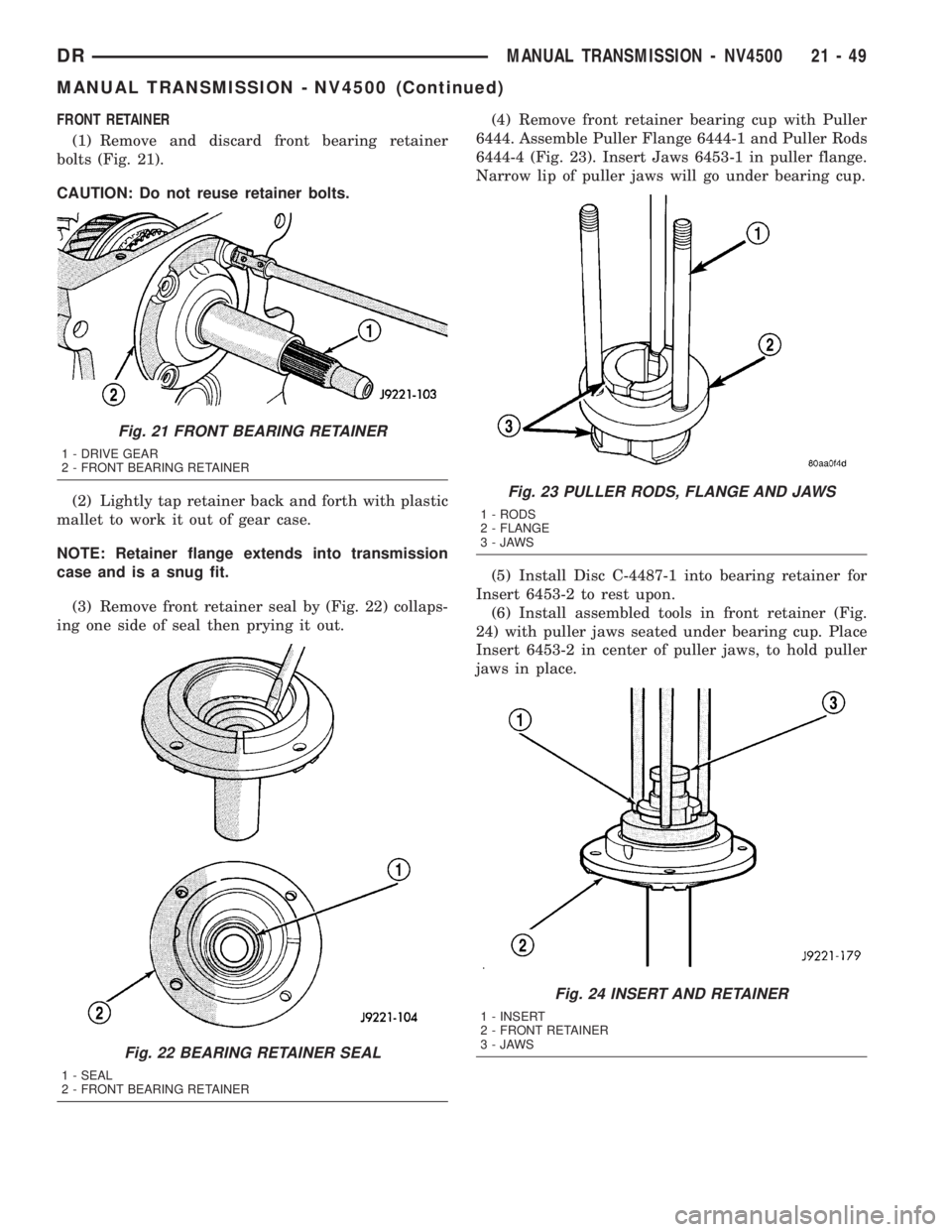

assembly (Fig. 14).(8) Remove coned shape rear bearing thrust

washer from countershaft (Fig. 15).

NOTE: Note washer bore locating notch for assem-

bly reference.

(9) Remove thrust washer locating pin from coun-

tershaft.

(10) Remove mainshaft fifth gear with Puller Set

6444 and Jaw 6459 or 6820. Position first Jaw on

gear (Fig. 16).

Fig. 13 FIFTH GEAR CLUTCH GEAR SNAP RING

1 - CLUTCH GEAR RING

2 - FIFTH SYNCHRO CLUTCH GEAR

Fig. 14 COUNTERSHAFT FIFTH GEAR NEEDLE

BEARING

1 - NEEDLE BEARING

2 - COUNTERSHAFT

Fig. 15 COUNTERSHAFT REAR BEARING THRUST

WASHER

1 - THRUST WASHER

2 - THRUST WASHER PIN

Fig. 16 JAW ON MAINSHAFT FIFTH GEAR

1 - MAINSHAFT FIFTH GEAR

2-JAW

3 - MAINSHAFT

DRMANUAL TRANSMISSION - NV4500 21 - 47

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1887 of 2895

(11) Assemble Puller Flange 6444-1and Puller

Rods 6444-3 4X2 or 6444-4 4X4 (Fig. 17). Slide

assembly onto output shaft and seat flange in notch

of jaw.

(12) Position second puller jaw on gear and in

notch of puller flange (Fig. 18). Slide Collar 6444-8

over puller jaws to hold them in place.(13)Install Puller and Bolt 6444 on puller rods and

secure puller to rods with retaining nuts (Fig. 19).

Tighten puller bolt to remove gear from shaft splines.

(14) Remove mainshaft rear bearing plate bolts

and remove fifth gear plate end play shims and bear-

ing cup (Fig. 20).

Fig. 17 PULLER FLANGE

1-JAW

2 - PULLER FLANGE

Fig. 18 PULLER COLLAR

1-JAWS

2 - COLLAR

Fig. 19 PULLER ASSEMBLY

1 - COLLAR

2-JAWS

3 - BOLT

4 - WRENCH

5 - MAINSHAFT

6 - PULLER FLANGE

Fig. 20 FIFTH GEAR BEARING PLATE, SHIMS AND

BEARING CUP

1 - MAINSHAFT REAR BEARING CUP

2 - BEARING SHIMS

3 - BEARING PLATE

4 - FIFTH GEAR

21 - 48 MANUAL TRANSMISSION - NV4500DR

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1888 of 2895

FRONT RETAINER

(1) Remove and discard front bearing retainer

bolts (Fig. 21).

CAUTION: Do not reuse retainer bolts.

(2) Lightly tap retainer back and forth with plastic

mallet to work it out of gear case.

NOTE: Retainer flange extends into transmission

case and is a snug fit.

(3) Remove front retainer seal by (Fig. 22) collaps-

ing one side of seal then prying it out.(4) Remove front retainer bearing cup with Puller

6444. Assemble Puller Flange 6444-1 and Puller Rods

6444-4 (Fig. 23). Insert Jaws 6453-1 in puller flange.

Narrow lip of puller jaws will go under bearing cup.

(5) Install Disc C-4487-1 into bearing retainer for

Insert 6453-2 to rest upon.

(6) Install assembled tools in front retainer (Fig.

24) with puller jaws seated under bearing cup. Place

Insert 6453-2 in center of puller jaws, to hold puller

jaws in place.

Fig. 21 FRONT BEARING RETAINER

1 - DRIVE GEAR

2 - FRONT BEARING RETAINER

Fig. 22 BEARING RETAINER SEAL

1 - SEAL

2 - FRONT BEARING RETAINER

Fig. 23 PULLER RODS, FLANGE AND JAWS

1 - RODS

2 - FLANGE

3-JAWS

Fig. 24 INSERT AND RETAINER

1 - INSERT

2 - FRONT RETAINER

3-JAWS

DRMANUAL TRANSMISSION - NV4500 21 - 49

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1889 of 2895

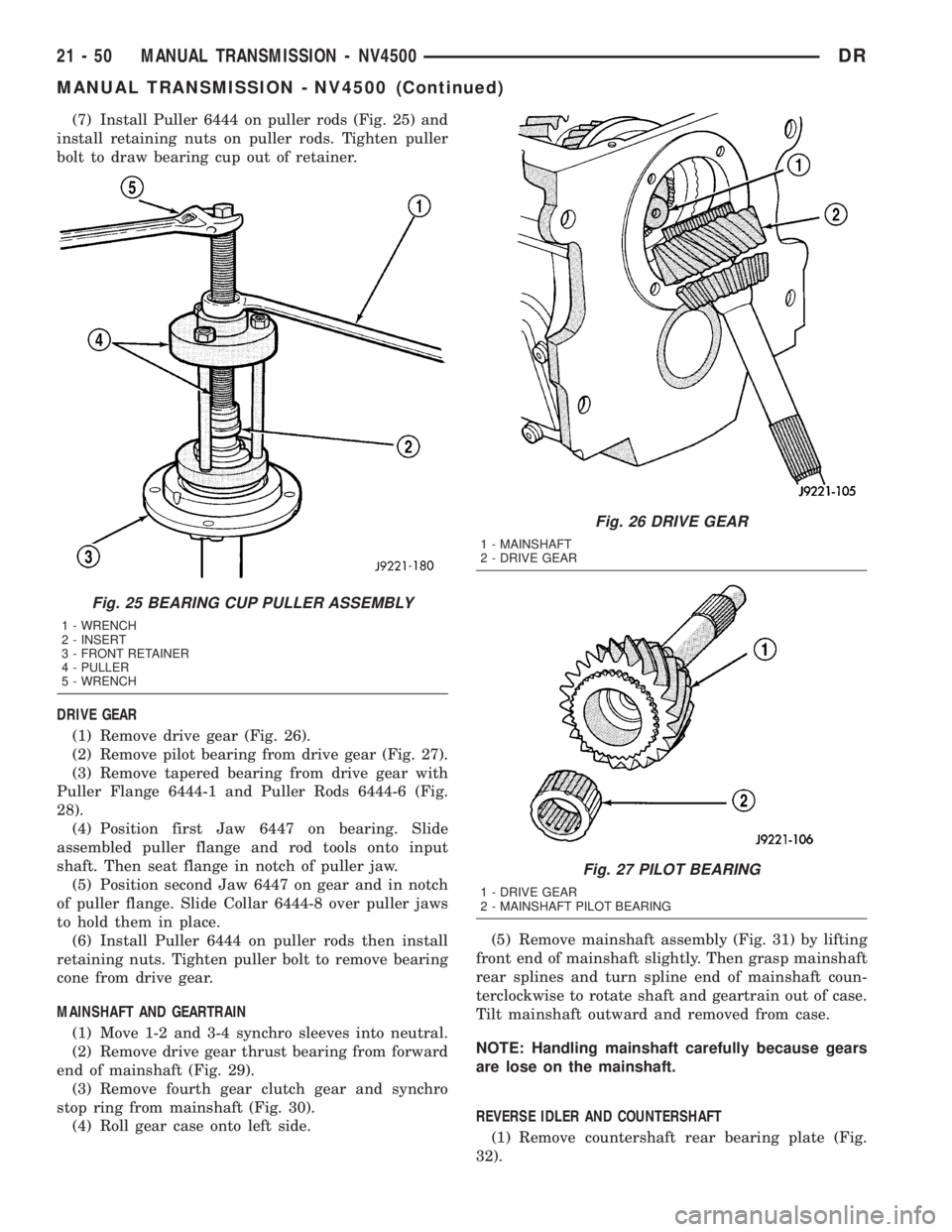

(7) Install Puller 6444 on puller rods (Fig. 25) and

install retaining nuts on puller rods. Tighten puller

bolt to draw bearing cup out of retainer.

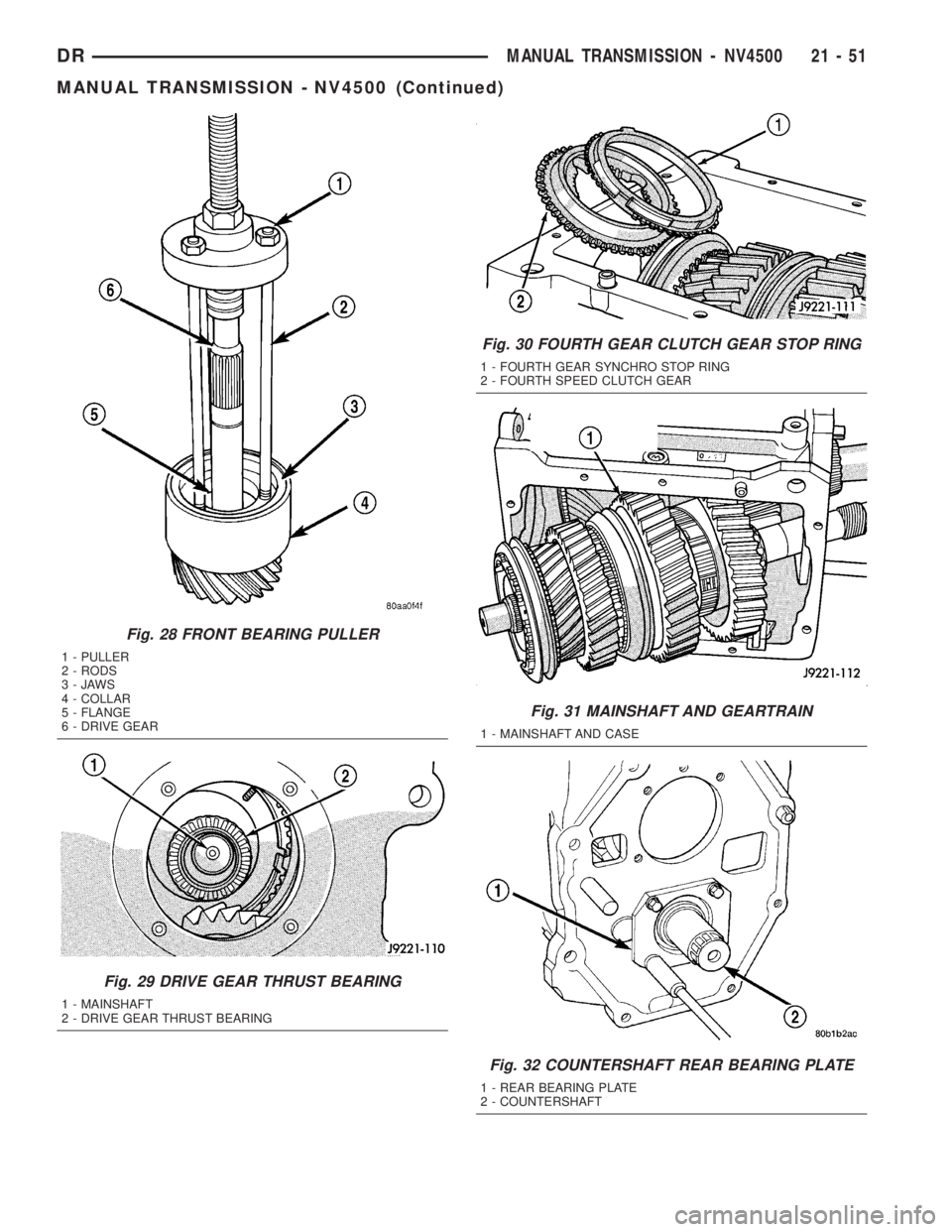

DRIVE GEAR

(1) Remove drive gear (Fig. 26).

(2) Remove pilot bearing from drive gear (Fig. 27).

(3) Remove tapered bearing from drive gear with

Puller Flange 6444-1 and Puller Rods 6444-6 (Fig.

28).

(4) Position first Jaw 6447 on bearing. Slide

assembled puller flange and rod tools onto input

shaft. Then seat flange in notch of puller jaw.

(5) Position second Jaw 6447 on gear and in notch

of puller flange. Slide Collar 6444-8 over puller jaws

to hold them in place.

(6) Install Puller 6444 on puller rods then install

retaining nuts. Tighten puller bolt to remove bearing

cone from drive gear.

MAINSHAFT AND GEARTRAIN

(1) Move 1-2 and 3-4 synchro sleeves into neutral.

(2) Remove drive gear thrust bearing from forward

end of mainshaft (Fig. 29).

(3) Remove fourth gear clutch gear and synchro

stop ring from mainshaft (Fig. 30).

(4) Roll gear case onto left side.(5) Remove mainshaft assembly (Fig. 31) by lifting

front end of mainshaft slightly. Then grasp mainshaft

rear splines and turn spline end of mainshaft coun-

terclockwise to rotate shaft and geartrain out of case.

Tilt mainshaft outward and removed from case.

NOTE: Handling mainshaft carefully because gears

are lose on the mainshaft.

REVERSE IDLER AND COUNTERSHAFT

(1) Remove countershaft rear bearing plate (Fig.

32).

Fig. 25 BEARING CUP PULLER ASSEMBLY

1 - WRENCH

2 - INSERT

3 - FRONT RETAINER

4 - PULLER

5 - WRENCH

Fig. 26 DRIVE GEAR

1 - MAINSHAFT

2 - DRIVE GEAR

Fig. 27 PILOT BEARING

1 - DRIVE GEAR

2 - MAINSHAFT PILOT BEARING

21 - 50 MANUAL TRANSMISSION - NV4500DR

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1890 of 2895

Fig. 28 FRONT BEARING PULLER

1 - PULLER

2 - RODS

3-JAWS

4 - COLLAR

5 - FLANGE

6 - DRIVE GEAR

Fig. 29 DRIVE GEAR THRUST BEARING

1 - MAINSHAFT

2 - DRIVE GEAR THRUST BEARING

Fig. 30 FOURTH GEAR CLUTCH GEAR STOP RING

1 - FOURTH GEAR SYNCHRO STOP RING

2 - FOURTH SPEED CLUTCH GEAR

Fig. 31 MAINSHAFT AND GEARTRAIN

1 - MAINSHAFT AND CASE

Fig. 32 COUNTERSHAFT REAR BEARING PLATE

1 - REAR BEARING PLATE

2 - COUNTERSHAFT

DRMANUAL TRANSMISSION - NV4500 21 - 51

MANUAL TRANSMISSION - NV4500 (Continued)