wheel alignment DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 48 of 2895

NOTE: Extreme pressure lubrication must be used

on the threaded portions of the tool. This will

increase the longevity of the tool and insure proper

operation during the removal and installation pro-

cess.

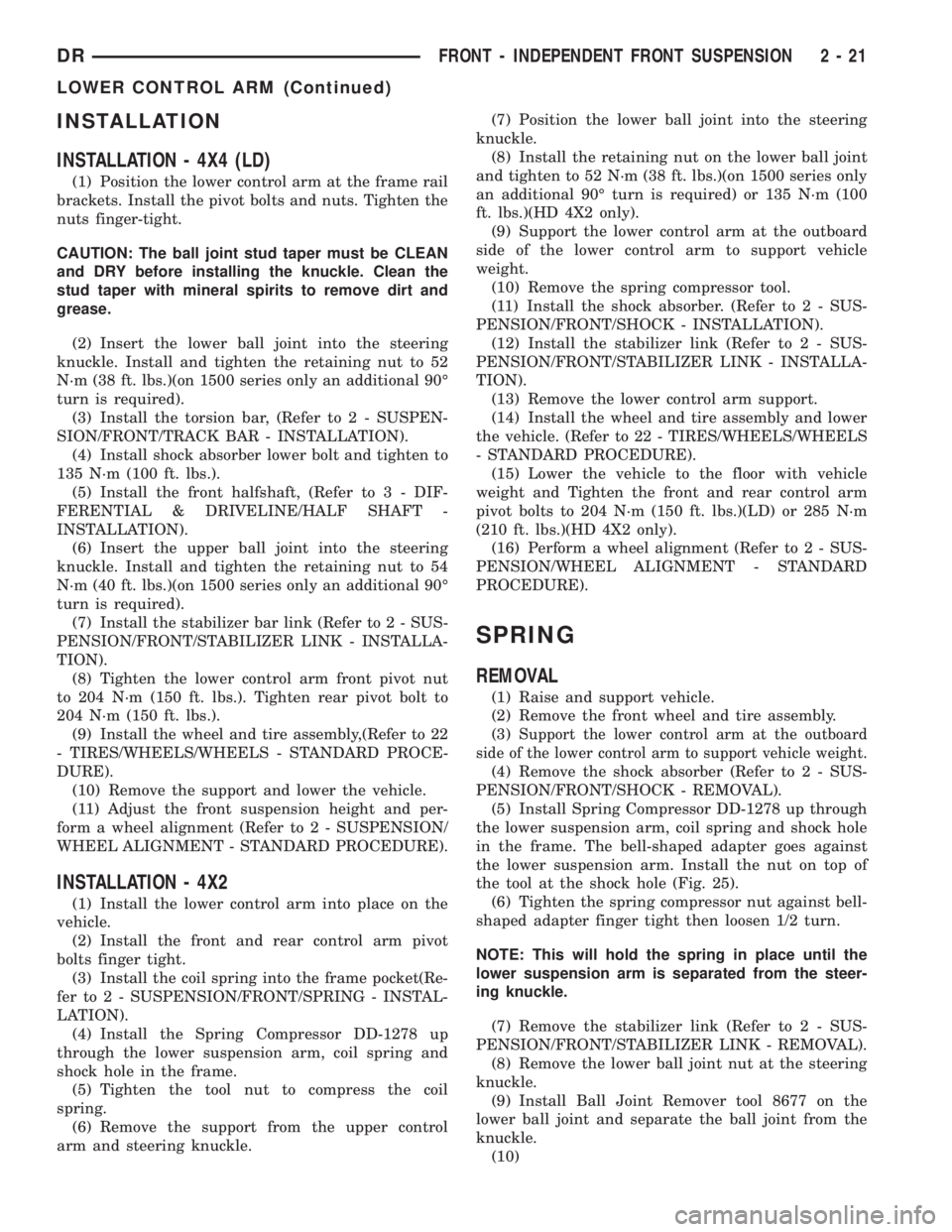

(7) Press the ball joint from the lower control arm

using special tools C-4212±F (PRESS), 8698-2

(RECEIVER) and 8698-3 (DRIVER) (Fig. 21).

INSTALLATION

NOTE: Extreme pressure lubrication must be used on

the threaded portions of the tool. This will increase

the longevity of the tool and insure proper operation

during the removal and installation process.

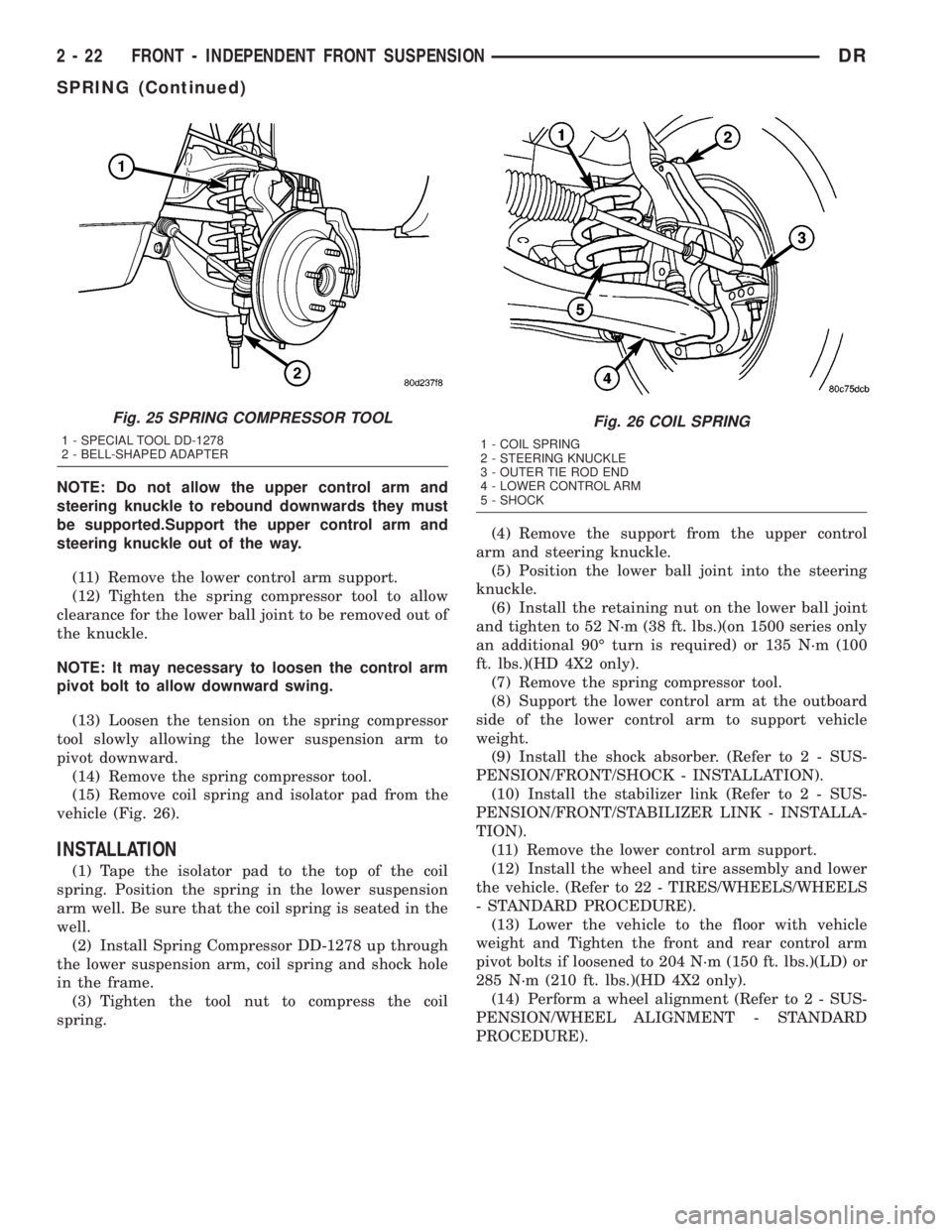

(1) Install the ball joint into the control arm and

press in using special tools C-4212±F (press), 8698-1

(driver) and 8698-3 (receiver) (Fig. 22).

(2) Install the ball joint boot.

(3) Stake the ball joint flange in four evenly

spaced places around the ball joint flange, using a

chisel and hammer (LD only).

(4) Replace the snap ring (HD 4X2 only)

(5) Remove the support for the halfshaft and

install into position (If Equipped).

(6) Install the steering knuckle (Refer to 2 - SUS-

PENSION/FRONT/KNUCKLE - INSTALLATION).

(7) Install the tie rod end into the steering knuckle

(Refer to 19 - STEERING/LINKAGE/TIE ROD END -

INSTALLATION).

(8) Install and tighten the halfshaft nut to 251

N´m (185 ft. lbs.). (If Equipped).

(9) Install the brake caliper and rotor (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

INSTALLATION).

(10) Install the tire and wheel assembly (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(11) Check the vehicle ride height (Refer to 2 -

SUSPENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

(12) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

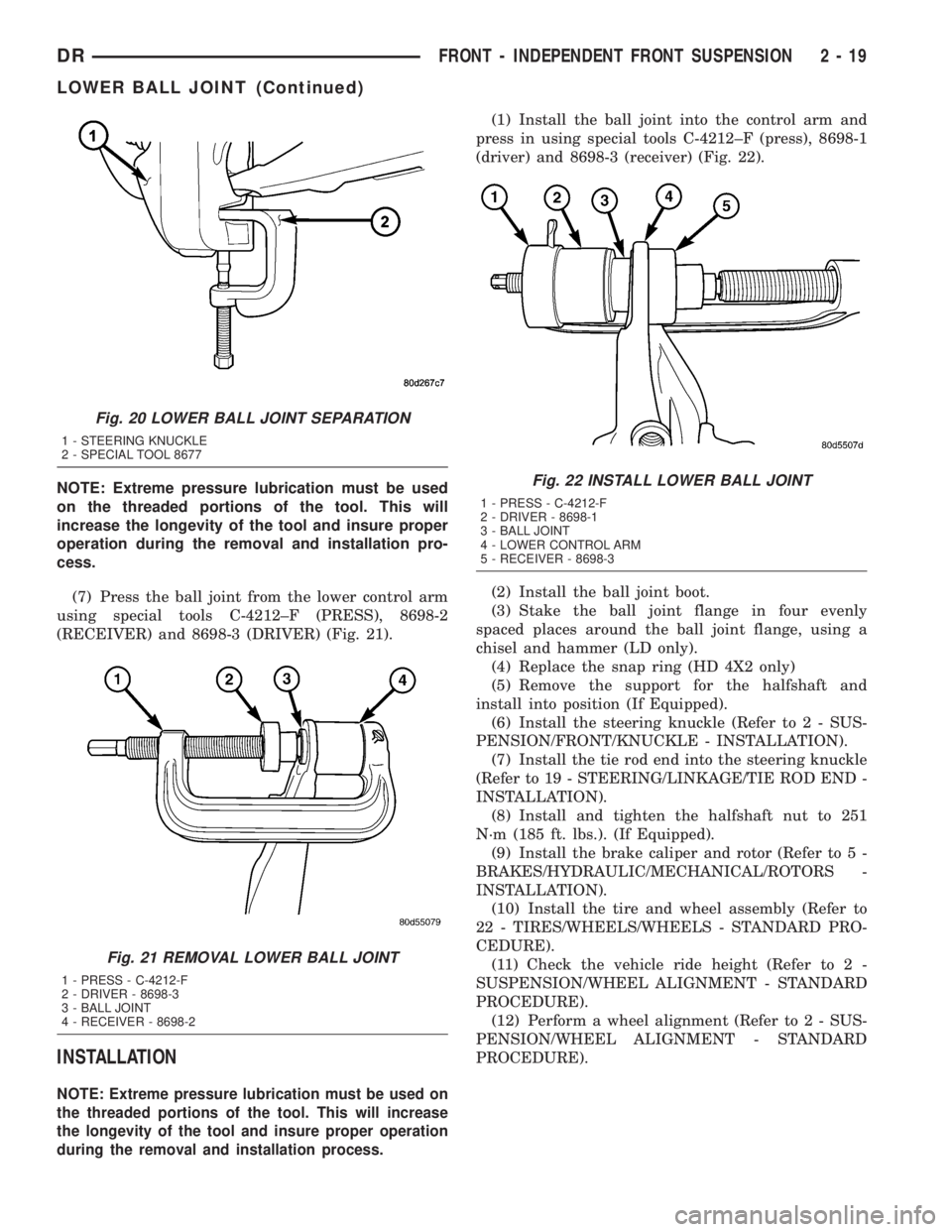

Fig. 20 LOWER BALL JOINT SEPARATION

1 - STEERING KNUCKLE

2 - SPECIAL TOOL 8677

Fig. 21 REMOVAL LOWER BALL JOINT

1 - PRESS - C-4212-F

2 - DRIVER - 8698-3

3 - BALL JOINT

4 - RECEIVER - 8698-2

Fig. 22 INSTALL LOWER BALL JOINT

1 - PRESS - C-4212-F

2 - DRIVER - 8698-1

3 - BALL JOINT

4 - LOWER CONTROL ARM

5 - RECEIVER - 8698-3

DRFRONT - INDEPENDENT FRONT SUSPENSION 2 - 19

LOWER BALL JOINT (Continued)

Page 50 of 2895

INSTALLATION

INSTALLATION - 4X4 (LD)

(1) Position the lower control arm at the frame rail

brackets. Install the pivot bolts and nuts. Tighten the

nuts finger-tight.

CAUTION: The ball joint stud taper must be CLEAN

and DRY before installing the knuckle. Clean the

stud taper with mineral spirits to remove dirt and

grease.

(2) Insert the lower ball joint into the steering

knuckle. Install and tighten the retaining nut to 52

N´m (38 ft. lbs.)(on 1500 series only an additional 90É

turn is required).

(3) Install the torsion bar, (Refer to 2 - SUSPEN-

SION/FRONT/TRACK BAR - INSTALLATION).

(4) Install shock absorber lower bolt and tighten to

135 N´m (100 ft. lbs.).

(5) Install the front halfshaft, (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/HALF SHAFT -

INSTALLATION).

(6) Insert the upper ball joint into the steering

knuckle. Install and tighten the retaining nut to 54

N´m (40 ft. lbs.)(on 1500 series only an additional 90É

turn is required).

(7) Install the stabilizer bar link (Refer to 2 - SUS-

PENSION/FRONT/STABILIZER LINK - INSTALLA-

TION).

(8) Tighten the lower control arm front pivot nut

to 204 N´m (150 ft. lbs.). Tighten rear pivot bolt to

204 N´m (150 ft. lbs.).

(9) Install the wheel and tire assembly,(Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(10) Remove the support and lower the vehicle.

(11) Adjust the front suspension height and per-

form a wheel alignment (Refer to 2 - SUSPENSION/

WHEEL ALIGNMENT - STANDARD PROCEDURE).

INSTALLATION - 4X2

(1) Install the lower control arm into place on the

vehicle.

(2) Install the front and rear control arm pivot

bolts finger tight.

(3) Install the coil spring into the frame pocket(Re-

fer to 2 - SUSPENSION/FRONT/SPRING - INSTAL-

LATION).

(4) Install the Spring Compressor DD-1278 up

through the lower suspension arm, coil spring and

shock hole in the frame.

(5) Tighten the tool nut to compress the coil

spring.

(6) Remove the support from the upper control

arm and steering knuckle.(7) Position the lower ball joint into the steering

knuckle.

(8) Install the retaining nut on the lower ball joint

and tighten to 52 N´m (38 ft. lbs.)(on 1500 series only

an additional 90É turn is required) or 135 N´m (100

ft. lbs.)(HD 4X2 only).

(9) Support the lower control arm at the outboard

side of the lower control arm to support vehicle

weight.

(10) Remove the spring compressor tool.

(11) Install the shock absorber. (Refer to 2 - SUS-

PENSION/FRONT/SHOCK - INSTALLATION).

(12) Install the stabilizer link (Refer to 2 - SUS-

PENSION/FRONT/STABILIZER LINK - INSTALLA-

TION).

(13) Remove the lower control arm support.

(14) Install the wheel and tire assembly and lower

the vehicle. (Refer to 22 - TIRES/WHEELS/WHEELS

- STANDARD PROCEDURE).

(15) Lower the vehicle to the floor with vehicle

weight and Tighten the front and rear control arm

pivot bolts to 204 N´m (150 ft. lbs.)(LD) or 285 N´m

(210 ft. lbs.)(HD 4X2 only).

(16) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

SPRING

REMOVAL

(1) Raise and support vehicle.

(2) Remove the front wheel and tire assembly.

(3)

Support the lower control arm at the outboard

side of the lower control arm to support vehicle weight.

(4) Remove the shock absorber (Refer to 2 - SUS-

PENSION/FRONT/SHOCK - REMOVAL).

(5) Install Spring Compressor DD-1278 up through

the lower suspension arm, coil spring and shock hole

in the frame. The bell-shaped adapter goes against

the lower suspension arm. Install the nut on top of

the tool at the shock hole (Fig. 25).

(6) Tighten the spring compressor nut against bell-

shaped adapter finger tight then loosen 1/2 turn.

NOTE: This will hold the spring in place until the

lower suspension arm is separated from the steer-

ing knuckle.

(7) Remove the stabilizer link (Refer to 2 - SUS-

PENSION/FRONT/STABILIZER LINK - REMOVAL).

(8) Remove the lower ball joint nut at the steering

knuckle.

(9) Install Ball Joint Remover tool 8677 on the

lower ball joint and separate the ball joint from the

knuckle.

(10)

DRFRONT - INDEPENDENT FRONT SUSPENSION 2 - 21

LOWER CONTROL ARM (Continued)

Page 51 of 2895

NOTE: Do not allow the upper control arm and

steering knuckle to rebound downwards they must

be supported.Support the upper control arm and

steering knuckle out of the way.

(11) Remove the lower control arm support.

(12) Tighten the spring compressor tool to allow

clearance for the lower ball joint to be removed out of

the knuckle.

NOTE: It may necessary to loosen the control arm

pivot bolt to allow downward swing.

(13) Loosen the tension on the spring compressor

tool slowly allowing the lower suspension arm to

pivot downward.

(14) Remove the spring compressor tool.

(15) Remove coil spring and isolator pad from the

vehicle (Fig. 26).

INSTALLATION

(1) Tape the isolator pad to the top of the coil

spring. Position the spring in the lower suspension

arm well. Be sure that the coil spring is seated in the

well.

(2) Install Spring Compressor DD-1278 up through

the lower suspension arm, coil spring and shock hole

in the frame.

(3) Tighten the tool nut to compress the coil

spring.(4) Remove the support from the upper control

arm and steering knuckle.

(5) Position the lower ball joint into the steering

knuckle.

(6) Install the retaining nut on the lower ball joint

and tighten to 52 N´m (38 ft. lbs.)(on 1500 series only

an additional 90É turn is required) or 135 N´m (100

ft. lbs.)(HD 4X2 only).

(7) Remove the spring compressor tool.

(8) Support the lower control arm at the outboard

side of the lower control arm to support vehicle

weight.

(9) Install the shock absorber. (Refer to 2 - SUS-

PENSION/FRONT/SHOCK - INSTALLATION).

(10) Install the stabilizer link (Refer to 2 - SUS-

PENSION/FRONT/STABILIZER LINK - INSTALLA-

TION).

(11) Remove the lower control arm support.

(12) Install the wheel and tire assembly and lower

the vehicle. (Refer to 22 - TIRES/WHEELS/WHEELS

- STANDARD PROCEDURE).

(13) Lower the vehicle to the floor with vehicle

weight and Tighten the front and rear control arm

pivot bolts if loosened to 204 N´m (150 ft. lbs.)(LD) or

285 N´m (210 ft. lbs.)(HD 4X2 only).

(14) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

Fig. 25 SPRING COMPRESSOR TOOL

1 - SPECIAL TOOL DD-1278

2 - BELL-SHAPED ADAPTER

Fig. 26 COIL SPRING

1 - COIL SPRING

2 - STEERING KNUCKLE

3 - OUTER TIE ROD END

4 - LOWER CONTROL ARM

5 - SHOCK

2 - 22 FRONT - INDEPENDENT FRONT SUSPENSIONDR

SPRING (Continued)

Page 55 of 2895

INSTALLATION

CAUTION: The left and right side torsion bars are

NOT interchangeable. The bars are identified and

stamped R or L, for right or left. The bars do not

have a front or rear end and can be installed with

either end facing forward.

(1) Insert torsion bar ends into anchor and suspen-

sion arm.

(2) Position the anchor in the frame crossmember.

(3) Install Special Tool - 8686 to the anchor and

the crossmember (Fig. 30).

(4) Increase the tension on the anchor in order to

load the torsion bar.

(5) Install the adjustment bolt and the adjuster

nut.

(6) Turn adjustment bolt clockwise the recorded

amount of turns.

(7) Remove tool - 8686 from the torsion bar cross-

member (Fig. 30).

(8) Install the transfer case skid plate (Refer to 13

- FRAME & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - INSTALLATION).

(9) Lower vehicle and adjust the front suspension

height (Refer to 2 - SUSPENSION/WHEEL ALIGN-

MENT - STANDARD PROCEDURE).

(10) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

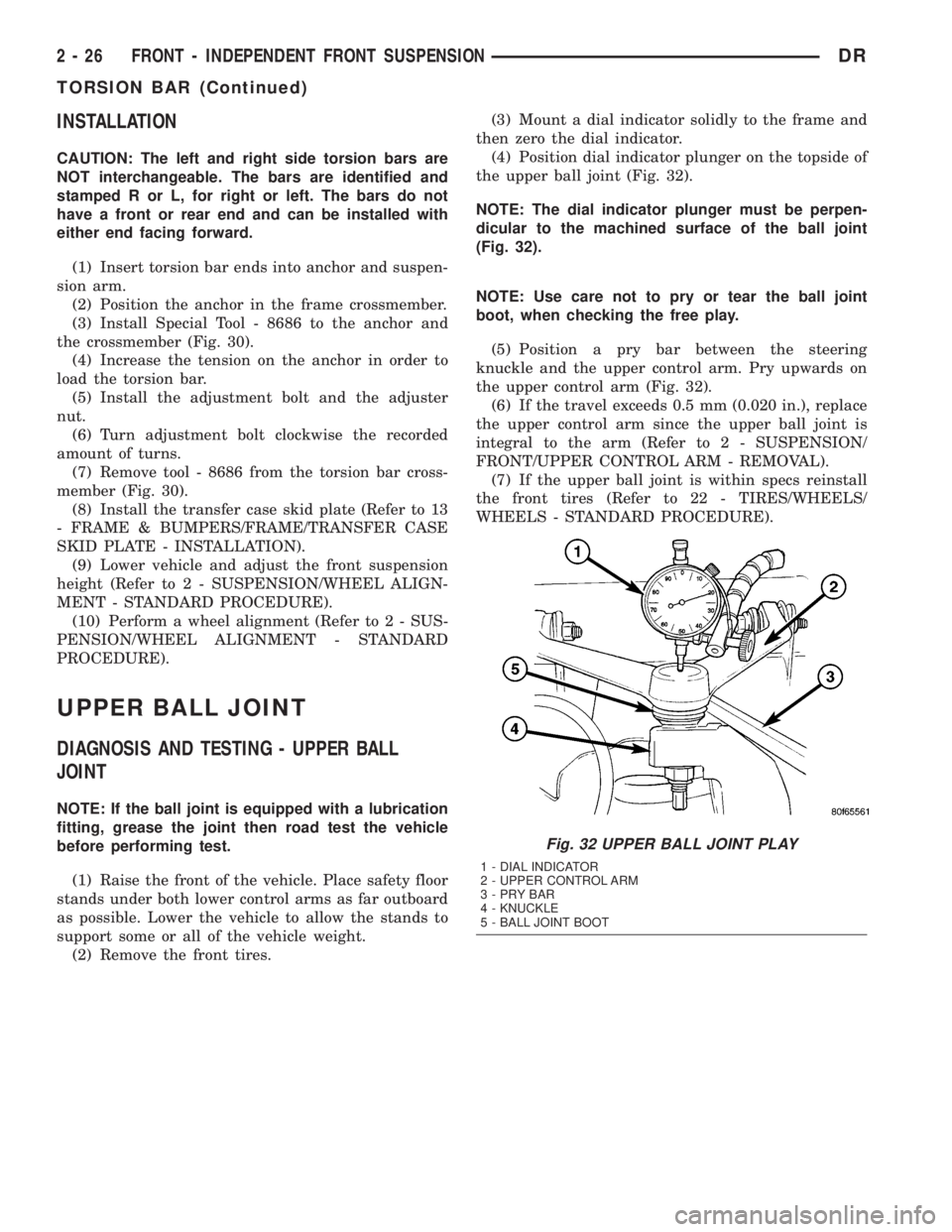

UPPER BALL JOINT

DIAGNOSIS AND TESTING - UPPER BALL

JOINT

NOTE: If the ball joint is equipped with a lubrication

fitting, grease the joint then road test the vehicle

before performing test.

(1) Raise the front of the vehicle. Place safety floor

stands under both lower control arms as far outboard

as possible. Lower the vehicle to allow the stands to

support some or all of the vehicle weight.

(2) Remove the front tires.(3) Mount a dial indicator solidly to the frame and

then zero the dial indicator.

(4) Position dial indicator plunger on the topside of

the upper ball joint (Fig. 32).

NOTE: The dial indicator plunger must be perpen-

dicular to the machined surface of the ball joint

(Fig. 32).

NOTE: Use care not to pry or tear the ball joint

boot, when checking the free play.

(5) Position a pry bar between the steering

knuckle and the upper control arm. Pry upwards on

the upper control arm (Fig. 32).

(6) If the travel exceeds 0.5 mm (0.020 in.), replace

the upper control arm since the upper ball joint is

integral to the arm (Refer to 2 - SUSPENSION/

FRONT/UPPER CONTROL ARM - REMOVAL).

(7) If the upper ball joint is within specs reinstall

the front tires (Refer to 22 - TIRES/WHEELS/

WHEELS - STANDARD PROCEDURE).

Fig. 32 UPPER BALL JOINT PLAY

1 - DIAL INDICATOR

2 - UPPER CONTROL ARM

3-PRYBAR

4 - KNUCKLE

5 - BALL JOINT BOOT

2 - 26 FRONT - INDEPENDENT FRONT SUSPENSIONDR

TORSION BAR (Continued)

Page 56 of 2895

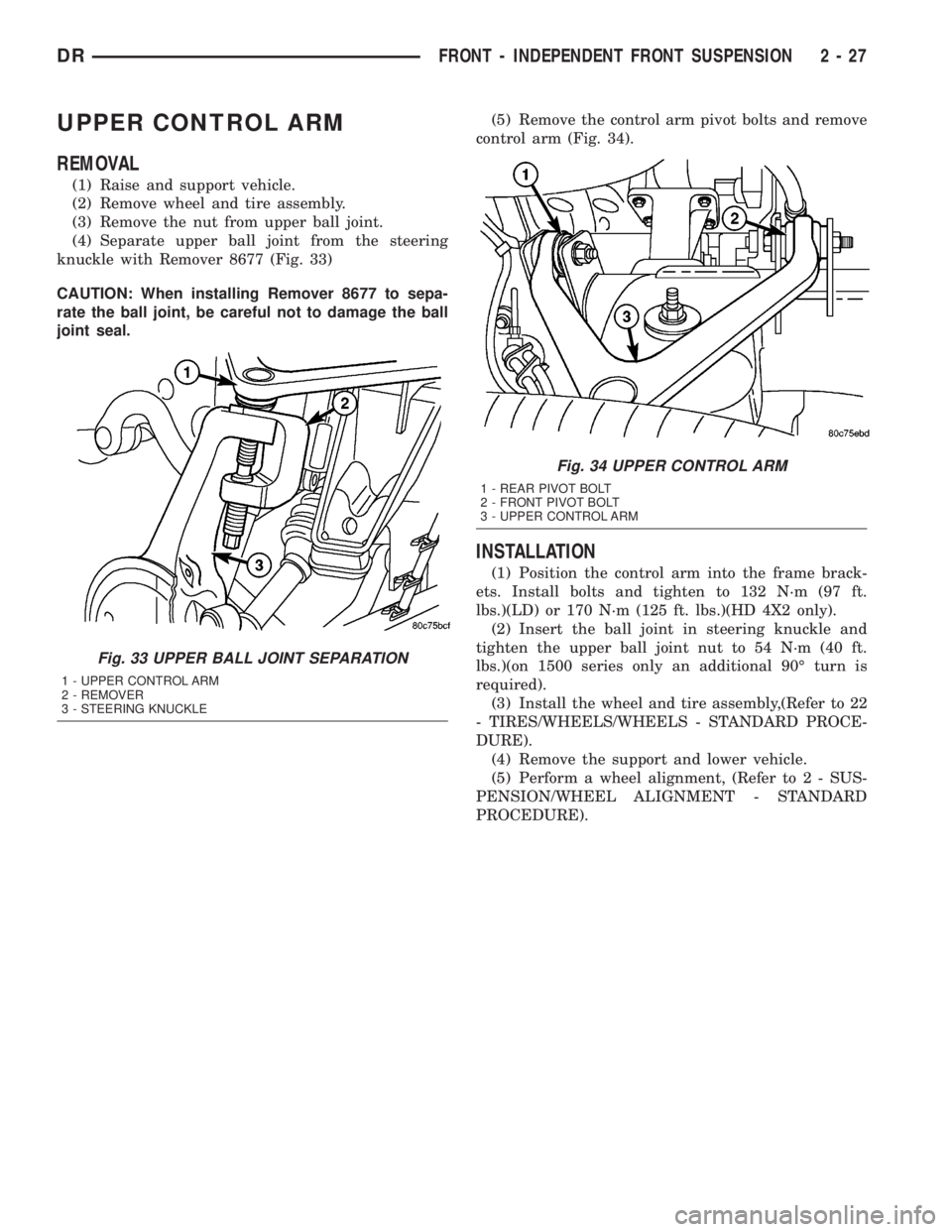

UPPER CONTROL ARM

REMOVAL

(1) Raise and support vehicle.

(2) Remove wheel and tire assembly.

(3) Remove the nut from upper ball joint.

(4) Separate upper ball joint from the steering

knuckle with Remover 8677 (Fig. 33)

CAUTION: When installing Remover 8677 to sepa-

rate the ball joint, be careful not to damage the ball

joint seal.(5) Remove the control arm pivot bolts and remove

control arm (Fig. 34).

INSTALLATION

(1) Position the control arm into the frame brack-

ets. Install bolts and tighten to 132 N´m (97 ft.

lbs.)(LD) or 170 N´m (125 ft. lbs.)(HD 4X2 only).

(2) Insert the ball joint in steering knuckle and

tighten the upper ball joint nut to 54 N´m (40 ft.

lbs.)(on 1500 series only an additional 90É turn is

required).

(3) Install the wheel and tire assembly,(Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(4) Remove the support and lower vehicle.

(5) Perform a wheel alignment, (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

Fig. 33 UPPER BALL JOINT SEPARATION

1 - UPPER CONTROL ARM

2 - REMOVER

3 - STEERING KNUCKLE

Fig. 34 UPPER CONTROL ARM

1 - REAR PIVOT BOLT

2 - FRONT PIVOT BOLT

3 - UPPER CONTROL ARM

DRFRONT - INDEPENDENT FRONT SUSPENSION 2 - 27

Page 76 of 2895

(15) If the vibration remains unacceptable, apply

the same steps to the front end of the propeller shaft.

(16) Install the wheel and tires. Lower the vehicle.

PROPELLER SHAFT RUNOUT

(1) Remove dirt, rust, paint and undercoating from

the propeller shaft surface where the dial indicator

will contact the shaft.

(2) The dial indicator must be installed perpendic-

ular to the shaft surface.

(3) Measure runout at the center and ends of the

shaft sufficiently far away from weld areas to ensure

that the effects of the weld process will not enter into

the measurements.

(4) Refer to Runout Specifications chart.

(5) If the propeller shaft runout is out of specifica-

tion, remove the propeller shaft, index the shaft 180É,

and re-install the propeller shaft. Measure shaft

runout again.

(6) If the propeller shaft runout is now within

specifications, mark the shaft and yokes for proper

orientation.

(7) If the propeller shaft runout is not within spec-

ifications, verify that the runout of the transmission/

transfer case and axle are within specifications.

Correct as necessary and re-measure propeller shaft

runout.

(8) Replace the propeller shaft if the runout still

exceeds the limits.

RUNOUT SPECIFICATIONS

Front of Shaft 0.020 in. (0.50 mm)

Center of Shaft 0.025 in. (0.63 mm)

Rear of Shaft 0.020 in. (0.50 mm)

note:

Measure front/rear runout approximately 3 inches (76

mm) from the weld seam at each end of the shaft

tube for tube lengths over 30 inches. For tube lengths

under 30 inches, the maximum allowed runout is

0.020 in. (0.50 mm) for the full length of the tube.

STANDARD PROCEDURE

PROPELLER SHAFT ANGLE

This procedure applies to both the front/rear pro-

peller shafts. To obtain the front output angle (A) on

the front propeller shaft, place the inclinometer the

machined surface of the C/V joint.

(1) To check driveline alignment, raise and support

the vehicle at the axles as level as possible. Allow the

wheels and propeller shaft to turn.

(2) Remove any external bearing snap rings, if

equipped from universal joint so protractor base sits

flat.

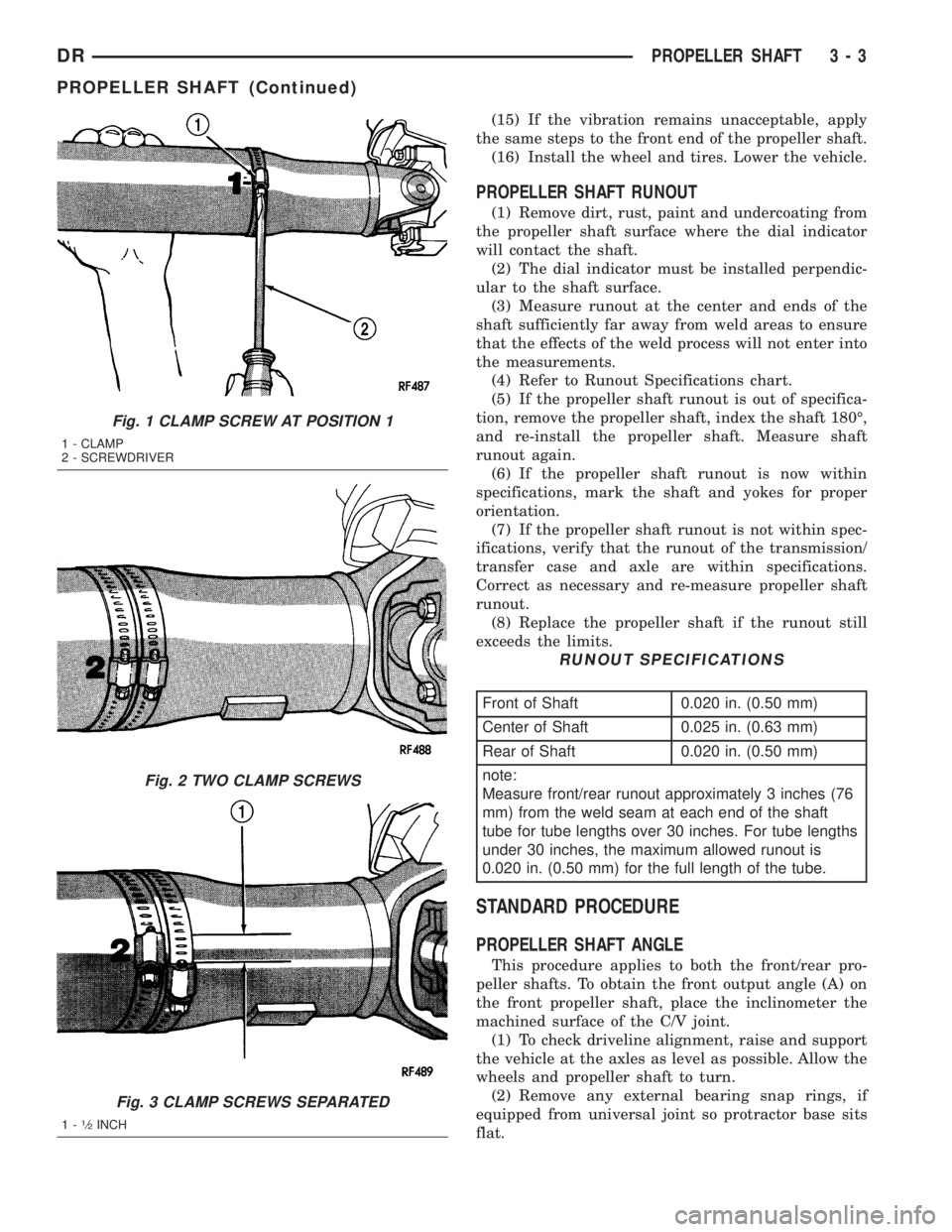

Fig. 1 CLAMP SCREW AT POSITION 1

1 - CLAMP

2 - SCREWDRIVER

Fig. 2 TWO CLAMP SCREWS

Fig. 3 CLAMP SCREWS SEPARATED

1-1¤2INCH

DRPROPELLER SHAFT 3 - 3

PROPELLER SHAFT (Continued)

Page 84 of 2895

HALF SHAFT

TABLE OF CONTENTS

page page

HALF SHAFT

CAUTION.............................11

DIAGNOSIS AND TESTING................11

REMOVAL.............................11

INSTALLATION.........................12

SPECIFICATIONS.......................12

SPECIAL TOOLS.......................12CV JOINT-OUTER

REMOVAL.............................13

INSTALLATION.........................13

CV JOINT-INNER

REMOVAL.............................16

INSTALLATION.........................16

HALF SHAFT

CAUTION

CAUTION:: Never grasp half shaft assembly by the

boots. This may cause the boot to pucker or crease

and reduce the service life of the boot.

Avoid over angulating or stroking the C/V joints

when handling the half shaft.

Half shafts exposed to battery acid, transmission

fluid, brake fluid, differential fluid or gasoline may

cause the boots to deteriorate.

DIAGNOSIS AND TESTING

Check for grease at the inboard and outboard C/V

joint. This is a sign of boot or boot clamp damage.

NOISE/VIBRATION IN TURNS

A clicking noise or a vibration in turns could be

caused by a damaged outer C/V or inner tripod joint

seal boot or seal boot clamps. This will result in the

loss/contamination of the joint grease, resulting in

inadequate lubrication of the joint. Noise could also

be caused by another component of the vehicle com-

ing in contact with the half shafts.

CLUNKING NOISE DURING ACCELERATION

This noise may be a result of a damaged or worn

C/V joint. A torn boot or loose/missing clamp on the

inner/outer joint which has allowed the grease to be

lost will damage the C/V joint.

SHUDDER/VIBRATION DURING ACCELERATION

This problem could be a result of a worn/damaged

inner tripod joint or a sticking tripod joint. Improper

wheel alignment may also cause a shudder or vibra-

tion.

VIBRATION AT HIGHWAY SPEEDS

This problem could be a result of out of balance

front tires or tire/wheel runout. Foreign material

(mud, etc.) packed on the backside of the wheel(s)

will also cause a vibration.

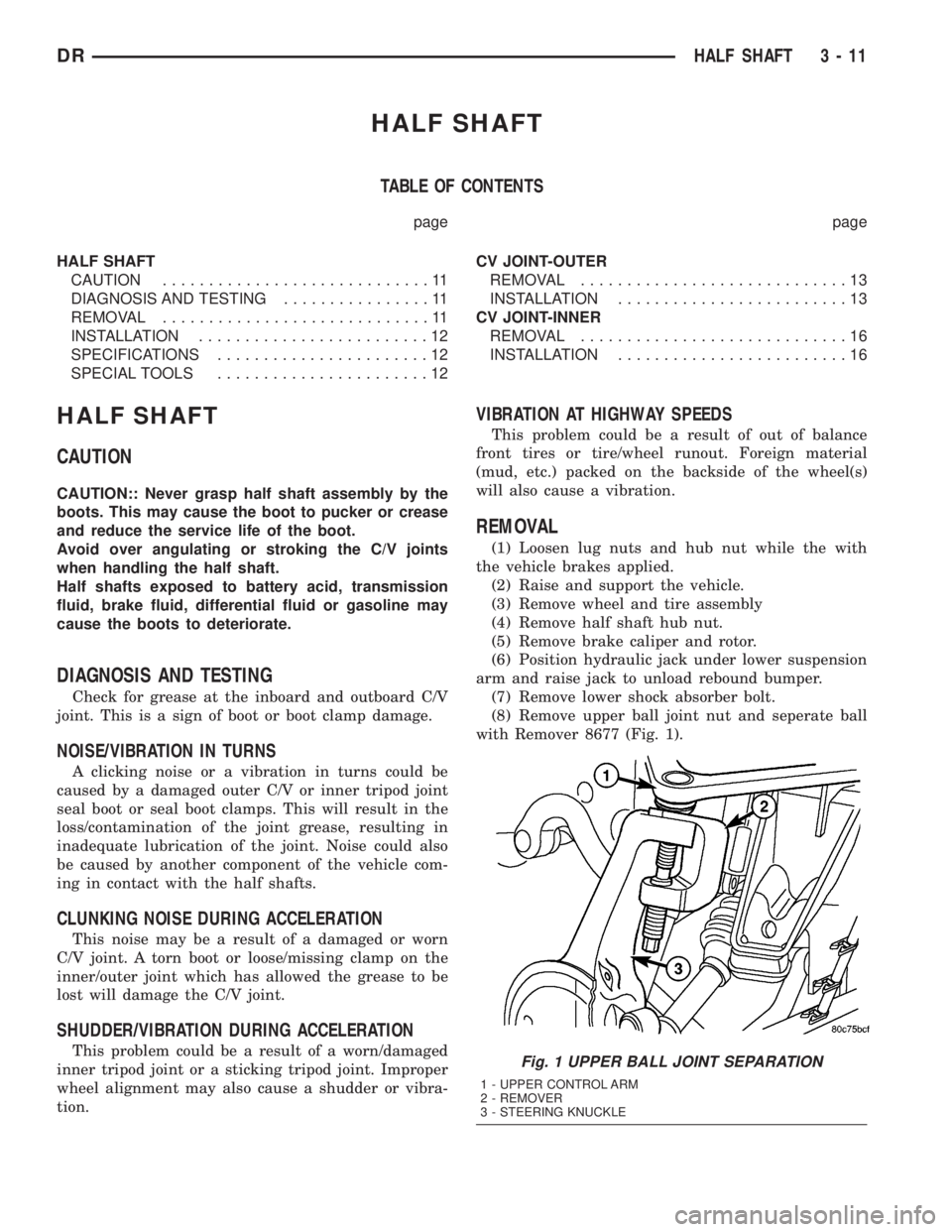

REMOVAL

(1) Loosen lug nuts and hub nut while the with

the vehicle brakes applied.

(2) Raise and support the vehicle.

(3) Remove wheel and tire assembly

(4) Remove half shaft hub nut.

(5) Remove brake caliper and rotor.

(6) Position hydraulic jack under lower suspension

arm and raise jack to unload rebound bumper.

(7) Remove lower shock absorber bolt.

(8) Remove upper ball joint nut and seperate ball

with Remover 8677 (Fig. 1).

Fig. 1 UPPER BALL JOINT SEPARATION

1 - UPPER CONTROL ARM

2 - REMOVER

3 - STEERING KNUCKLE

DRHALF SHAFT 3 - 11

Page 86 of 2895

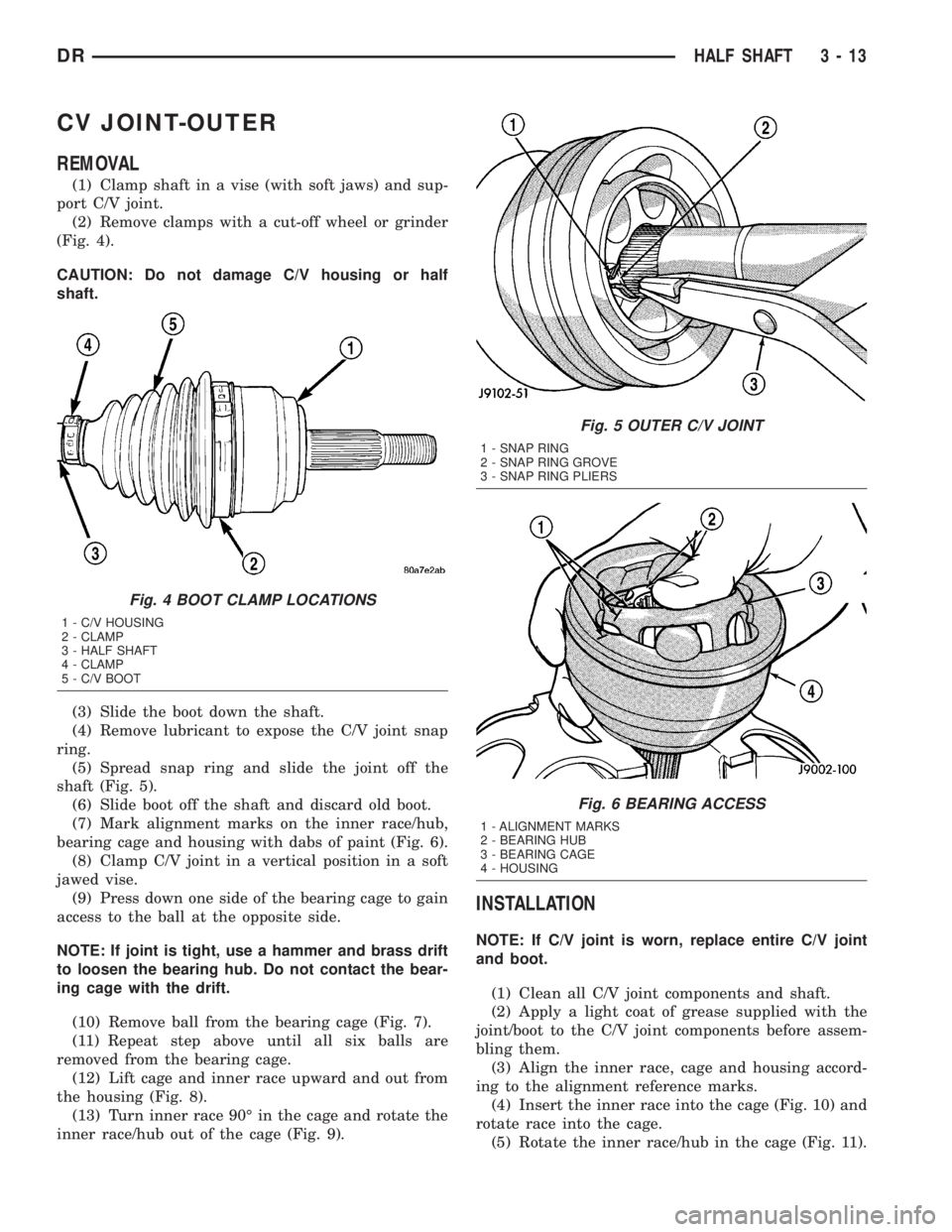

CV JOINT-OUTER

REMOVAL

(1) Clamp shaft in a vise (with soft jaws) and sup-

port C/V joint.

(2) Remove clamps with a cut-off wheel or grinder

(Fig. 4).

CAUTION: Do not damage C/V housing or half

shaft.

(3) Slide the boot down the shaft.

(4) Remove lubricant to expose the C/V joint snap

ring.

(5) Spread snap ring and slide the joint off the

shaft (Fig. 5).

(6) Slide boot off the shaft and discard old boot.

(7) Mark alignment marks on the inner race/hub,

bearing cage and housing with dabs of paint (Fig. 6).

(8) Clamp C/V joint in a vertical position in a soft

jawed vise.

(9) Press down one side of the bearing cage to gain

access to the ball at the opposite side.

NOTE: If joint is tight, use a hammer and brass drift

to loosen the bearing hub. Do not contact the bear-

ing cage with the drift.

(10) Remove ball from the bearing cage (Fig. 7).

(11) Repeat step above until all six balls are

removed from the bearing cage.

(12) Lift cage and inner race upward and out from

the housing (Fig. 8).

(13) Turn inner race 90É in the cage and rotate the

inner race/hub out of the cage (Fig. 9).

INSTALLATION

NOTE: If C/V joint is worn, replace entire C/V joint

and boot.

(1) Clean all C/V joint components and shaft.

(2) Apply a light coat of grease supplied with the

joint/boot to the C/V joint components before assem-

bling them.

(3) Align the inner race, cage and housing accord-

ing to the alignment reference marks.

(4) Insert the inner race into the cage (Fig. 10) and

rotate race into the cage.

(5) Rotate the inner race/hub in the cage (Fig. 11).

Fig. 4 BOOT CLAMP LOCATIONS

1 - C/V HOUSING

2 - CLAMP

3 - HALF SHAFT

4 - CLAMP

5 - C/V BOOT

Fig. 5 OUTER C/V JOINT

1 - SNAP RING

2 - SNAP RING GROVE

3 - SNAP RING PLIERS

Fig. 6 BEARING ACCESS

1 - ALIGNMENT MARKS

2 - BEARING HUB

3 - BEARING CAGE

4 - HOUSING

DRHALF SHAFT 3 - 13

Page 92 of 2895

tial bearing noise is also constant and varies only

with vehicle speed.

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side-gear thrust washers. A worn

pinion shaft bore will also cause low speed knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).

²Worn or out of balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).

²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).Check for loose or damaged front end components

or engine/transmission mounts. These components

can contribute to what appears to be a rear end

vibration. Do not overlook engine accessories, brack-

ets and drive belts.

All driveline components should be examined

before starting any repair.

(Refer to 22 - TIRES/WHEELS - DIAGNOSIS AND

TESTING)

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged) can be caused by:

²High engine idle speed.

²Transmission shift operation.

²Loose engine/transmission/transfer case mounts.

²Worn U-joints.

²Loose spring mounts.

²Loose pinion gear nut and yoke.

²Excessive ring gear backlash.

²Excessive side gear to case clearance.

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the vehi-

cle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear. Listen

for the noise, a mechanics stethoscope is helpful in

isolating the source of a noise.

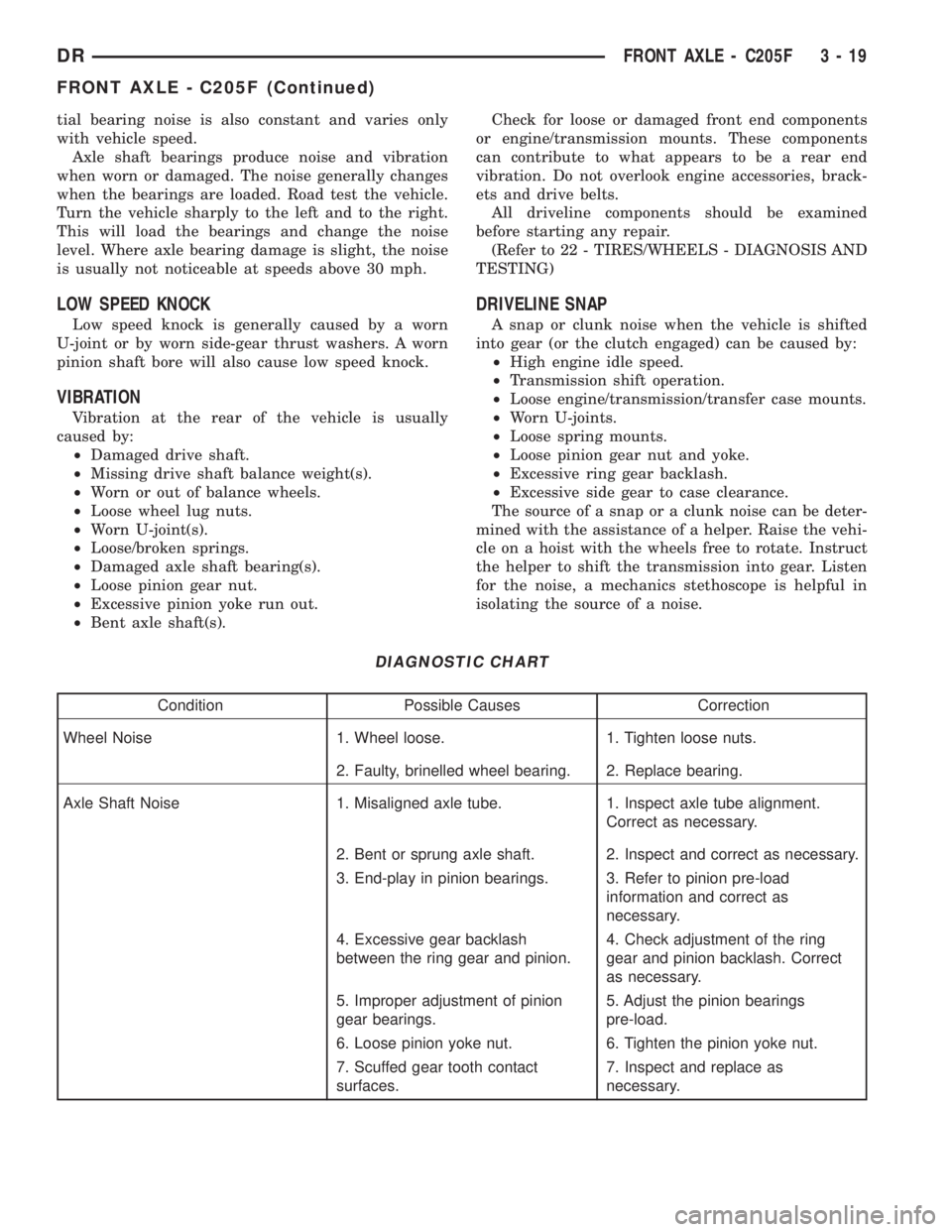

DIAGNOSTIC CHART

Condition Possible Causes Correction

Wheel Noise 1. Wheel loose. 1. Tighten loose nuts.

2. Faulty, brinelled wheel bearing. 2. Replace bearing.

Axle Shaft Noise 1. Misaligned axle tube. 1. Inspect axle tube alignment.

Correct as necessary.

2. Bent or sprung axle shaft. 2. Inspect and correct as necessary.

3. End-play in pinion bearings. 3. Refer to pinion pre-load

information and correct as

necessary.

4. Excessive gear backlash

between the ring gear and pinion.4. Check adjustment of the ring

gear and pinion backlash. Correct

as necessary.

5. Improper adjustment of pinion

gear bearings.5. Adjust the pinion bearings

pre-load.

6. Loose pinion yoke nut. 6. Tighten the pinion yoke nut.

7. Scuffed gear tooth contact

surfaces.7. Inspect and replace as

necessary.

DRFRONT AXLE - C205F 3 - 19

FRONT AXLE - C205F (Continued)

Page 93 of 2895

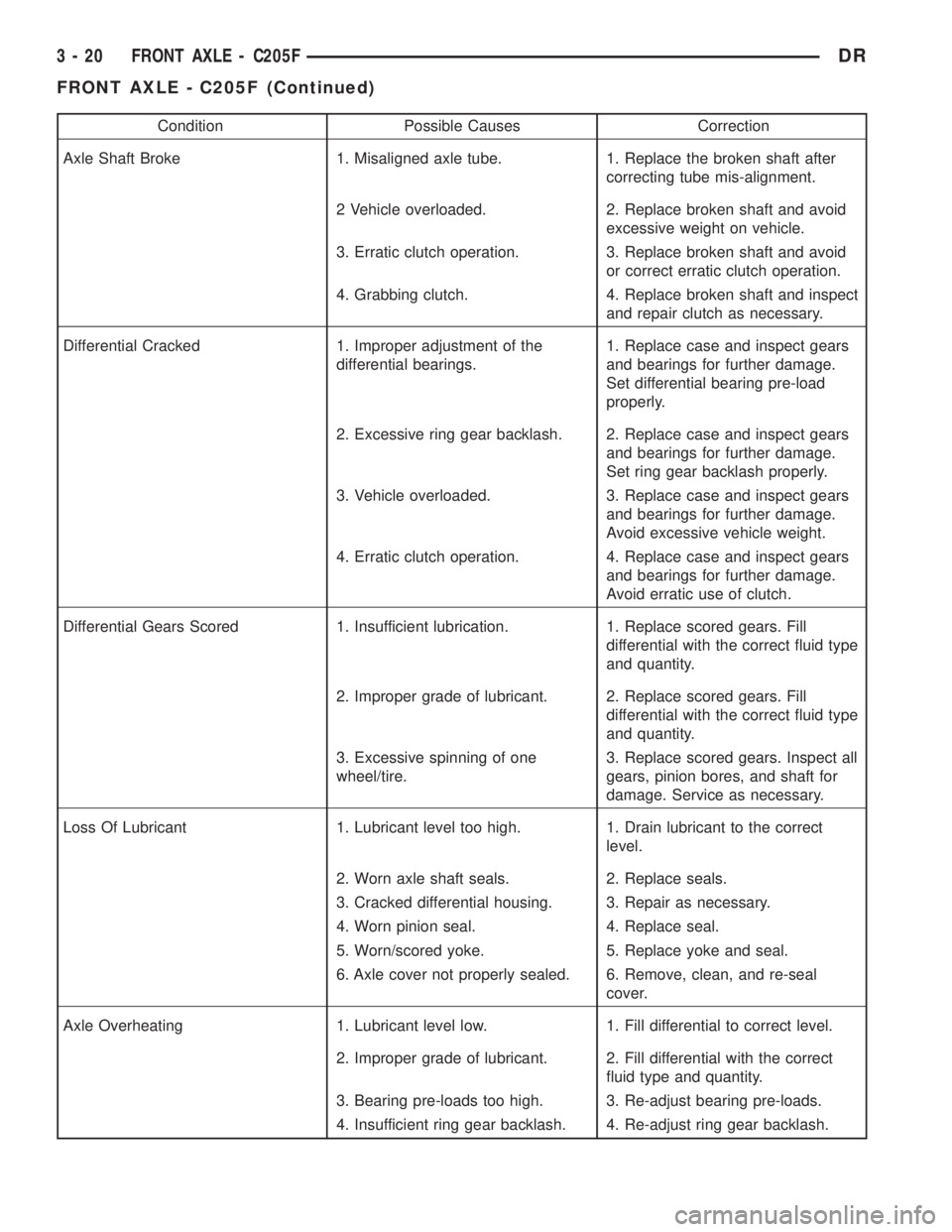

Condition Possible Causes Correction

Axle Shaft Broke 1. Misaligned axle tube. 1. Replace the broken shaft after

correcting tube mis-alignment.

2 Vehicle overloaded. 2. Replace broken shaft and avoid

excessive weight on vehicle.

3. Erratic clutch operation. 3. Replace broken shaft and avoid

or correct erratic clutch operation.

4. Grabbing clutch. 4. Replace broken shaft and inspect

and repair clutch as necessary.

Differential Cracked 1. Improper adjustment of the

differential bearings.1. Replace case and inspect gears

and bearings for further damage.

Set differential bearing pre-load

properly.

2. Excessive ring gear backlash. 2. Replace case and inspect gears

and bearings for further damage.

Set ring gear backlash properly.

3. Vehicle overloaded. 3. Replace case and inspect gears

and bearings for further damage.

Avoid excessive vehicle weight.

4. Erratic clutch operation. 4. Replace case and inspect gears

and bearings for further damage.

Avoid erratic use of clutch.

Differential Gears Scored 1. Insufficient lubrication. 1. Replace scored gears. Fill

differential with the correct fluid type

and quantity.

2. Improper grade of lubricant. 2. Replace scored gears. Fill

differential with the correct fluid type

and quantity.

3. Excessive spinning of one

wheel/tire.3. Replace scored gears. Inspect all

gears, pinion bores, and shaft for

damage. Service as necessary.

Loss Of Lubricant 1. Lubricant level too high. 1. Drain lubricant to the correct

level.

2. Worn axle shaft seals. 2. Replace seals.

3. Cracked differential housing. 3. Repair as necessary.

4. Worn pinion seal. 4. Replace seal.

5. Worn/scored yoke. 5. Replace yoke and seal.

6. Axle cover not properly sealed. 6. Remove, clean, and re-seal

cover.

Axle Overheating 1. Lubricant level low. 1. Fill differential to correct level.

2. Improper grade of lubricant. 2. Fill differential with the correct

fluid type and quantity.

3. Bearing pre-loads too high. 3. Re-adjust bearing pre-loads.

4. Insufficient ring gear backlash. 4. Re-adjust ring gear backlash.

3 - 20 FRONT AXLE - C205FDR

FRONT AXLE - C205F (Continued)