ABS DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2653 of 2895

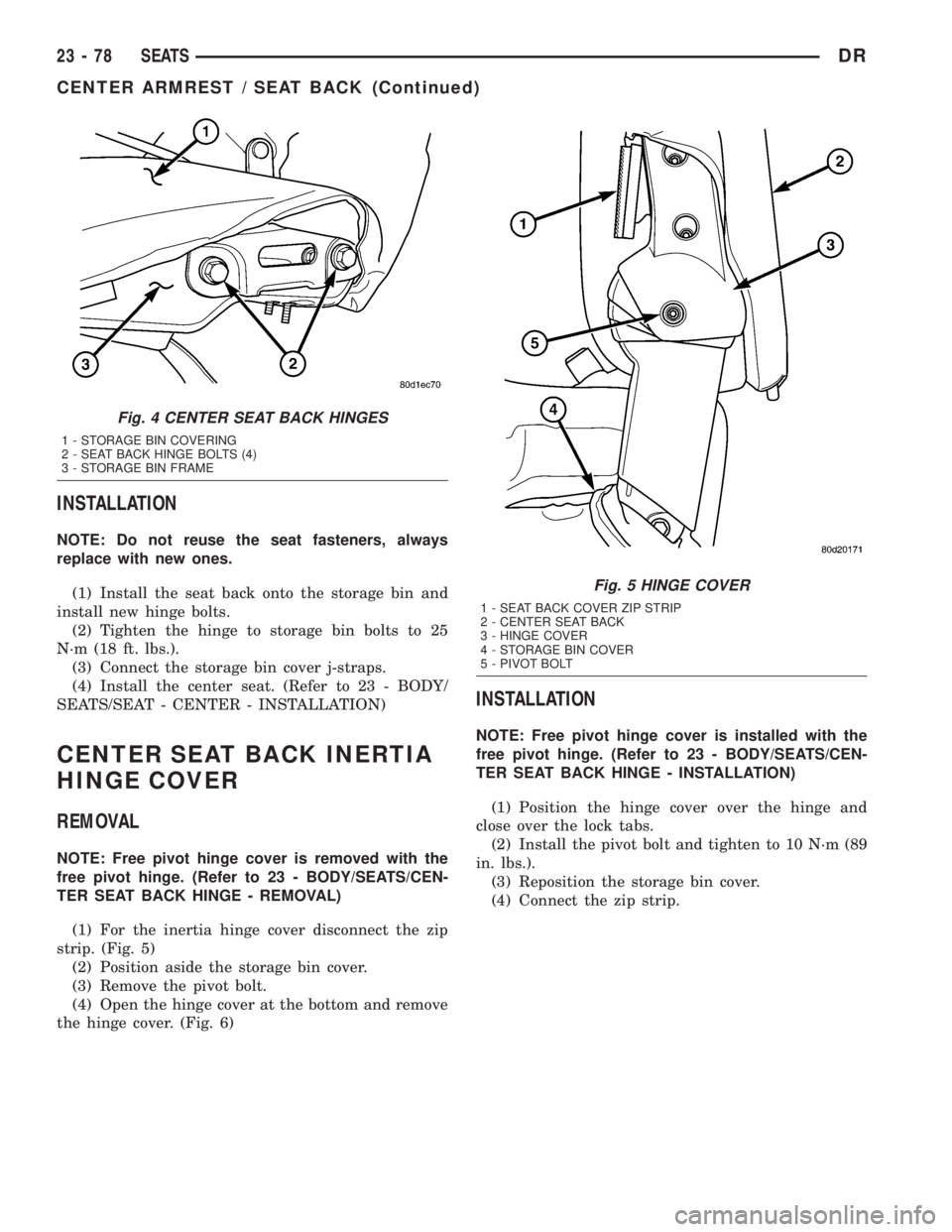

INSTALLATION

NOTE: Do not reuse the seat fasteners, always

replace with new ones.

(1) Install the seat back onto the storage bin and

install new hinge bolts.

(2) Tighten the hinge to storage bin bolts to 25

N´m (18 ft. lbs.).

(3) Connect the storage bin cover j-straps.

(4) Install the center seat. (Refer to 23 - BODY/

SEATS/SEAT - CENTER - INSTALLATION)

CENTER SEAT BACK INERTIA

HINGE COVER

REMOVAL

NOTE: Free pivot hinge cover is removed with the

free pivot hinge. (Refer to 23 - BODY/SEATS/CEN-

TER SEAT BACK HINGE - REMOVAL)

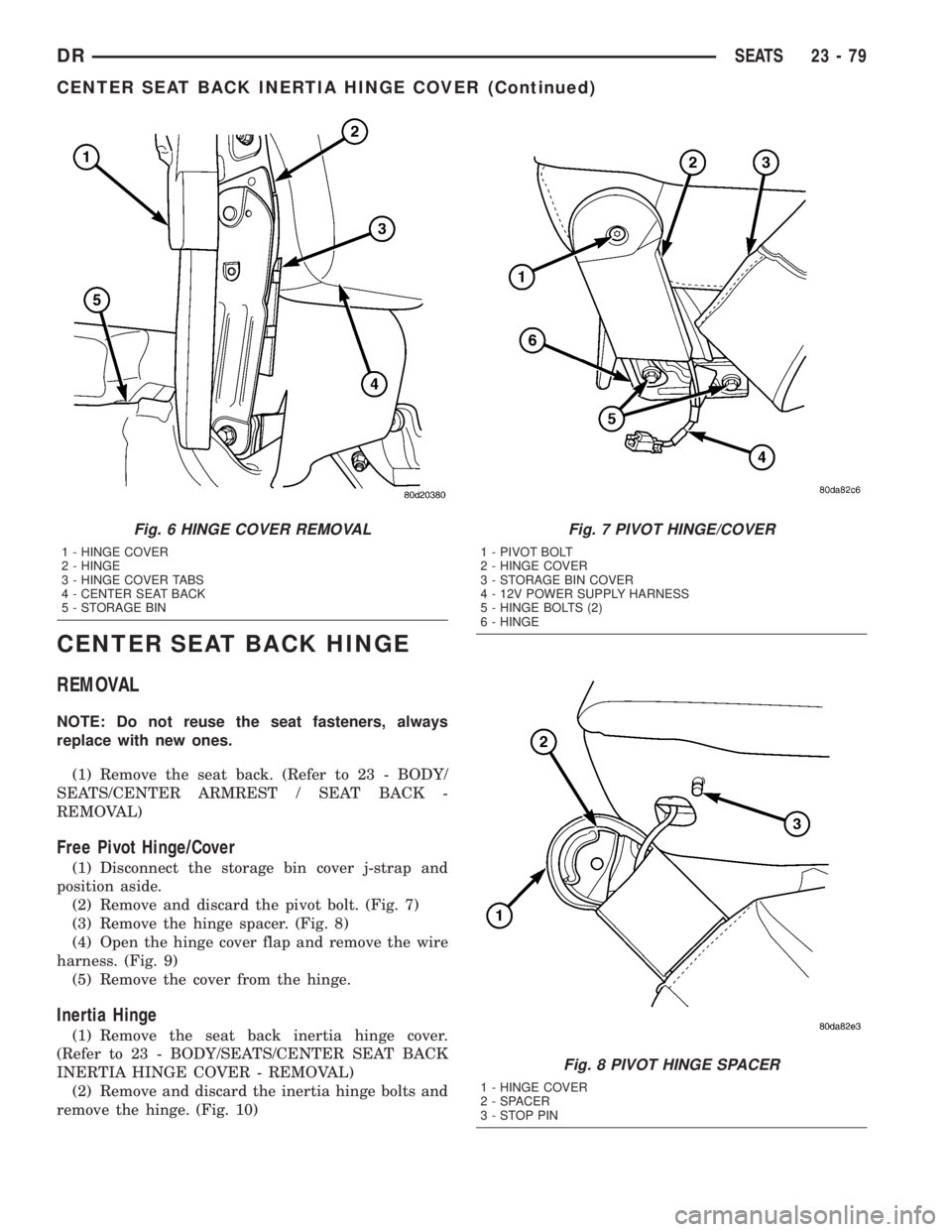

(1) For the inertia hinge cover disconnect the zip

strip. (Fig. 5)

(2) Position aside the storage bin cover.

(3) Remove the pivot bolt.

(4) Open the hinge cover at the bottom and remove

the hinge cover. (Fig. 6)

INSTALLATION

NOTE: Free pivot hinge cover is installed with the

free pivot hinge. (Refer to 23 - BODY/SEATS/CEN-

TER SEAT BACK HINGE - INSTALLATION)

(1) Position the hinge cover over the hinge and

close over the lock tabs.

(2) Install the pivot bolt and tighten to 10 N´m (89

in. lbs.).

(3) Reposition the storage bin cover.

(4) Connect the zip strip.

Fig. 4 CENTER SEAT BACK HINGES

1 - STORAGE BIN COVERING

2 - SEAT BACK HINGE BOLTS (4)

3 - STORAGE BIN FRAME

Fig. 5 HINGE COVER

1 - SEAT BACK COVER ZIP STRIP

2 - CENTER SEAT BACK

3 - HINGE COVER

4 - STORAGE BIN COVER

5 - PIVOT BOLT

23 - 78 SEATSDR

CENTER ARMREST / SEAT BACK (Continued)

Page 2654 of 2895

CENTER SEAT BACK HINGE

REMOVAL

NOTE: Do not reuse the seat fasteners, always

replace with new ones.

(1) Remove the seat back. (Refer to 23 - BODY/

SEATS/CENTER ARMREST / SEAT BACK -

REMOVAL)

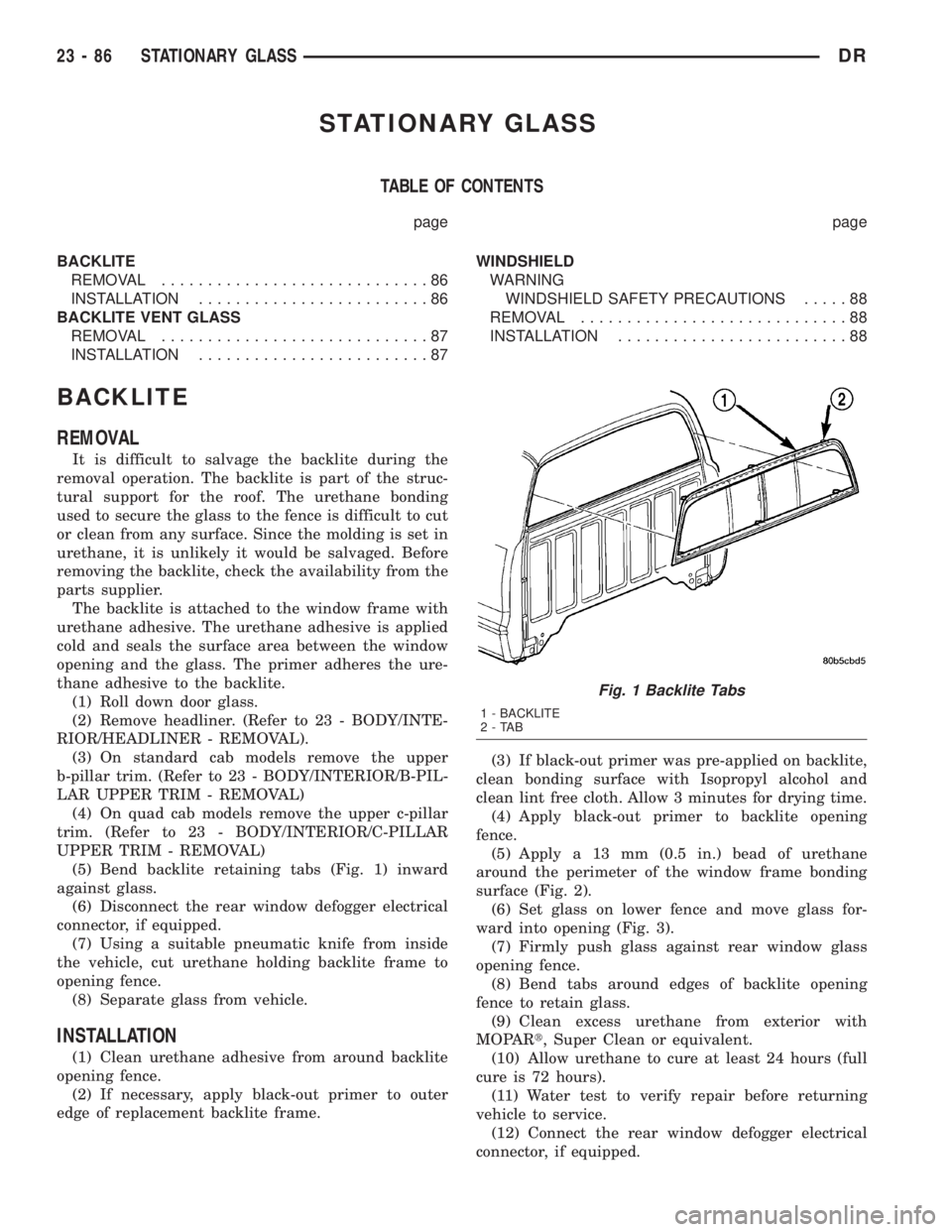

Free Pivot Hinge/Cover

(1) Disconnect the storage bin cover j-strap and

position aside.

(2) Remove and discard the pivot bolt. (Fig. 7)

(3) Remove the hinge spacer. (Fig. 8)

(4) Open the hinge cover flap and remove the wire

harness. (Fig. 9)

(5) Remove the cover from the hinge.

Inertia Hinge

(1) Remove the seat back inertia hinge cover.

(Refer to 23 - BODY/SEATS/CENTER SEAT BACK

INERTIA HINGE COVER - REMOVAL)

(2) Remove and discard the inertia hinge bolts and

remove the hinge. (Fig. 10)

Fig. 6 HINGE COVER REMOVAL

1 - HINGE COVER

2 - HINGE

3 - HINGE COVER TABS

4 - CENTER SEAT BACK

5 - STORAGE BIN

Fig. 7 PIVOT HINGE/COVER

1 - PIVOT BOLT

2 - HINGE COVER

3 - STORAGE BIN COVER

4 - 12V POWER SUPPLY HARNESS

5 - HINGE BOLTS (2)

6 - HINGE

Fig. 8 PIVOT HINGE SPACER

1 - HINGE COVER

2 - SPACER

3-STOPPIN

DRSEATS 23 - 79

CENTER SEAT BACK INERTIA HINGE COVER (Continued)

Page 2661 of 2895

STATIONARY GLASS

TABLE OF CONTENTS

page page

BACKLITE

REMOVAL.............................86

INSTALLATION.........................86

BACKLITE VENT GLASS

REMOVAL.............................87

INSTALLATION.........................87WINDSHIELD

WARNING

WINDSHIELD SAFETY PRECAUTIONS.....88

REMOVAL.............................88

INSTALLATION.........................88

BACKLITE

REMOVAL

It is difficult to salvage the backlite during the

removal operation. The backlite is part of the struc-

tural support for the roof. The urethane bonding

used to secure the glass to the fence is difficult to cut

or clean from any surface. Since the molding is set in

urethane, it is unlikely it would be salvaged. Before

removing the backlite, check the availability from the

parts supplier.

The backlite is attached to the window frame with

urethane adhesive. The urethane adhesive is applied

cold and seals the surface area between the window

opening and the glass. The primer adheres the ure-

thane adhesive to the backlite.

(1) Roll down door glass.

(2) Remove headliner. (Refer to 23 - BODY/INTE-

RIOR/HEADLINER - REMOVAL).

(3) On standard cab models remove the upper

b-pillar trim. (Refer to 23 - BODY/INTERIOR/B-PIL-

LAR UPPER TRIM - REMOVAL)

(4) On quad cab models remove the upper c-pillar

trim. (Refer to 23 - BODY/INTERIOR/C-PILLAR

UPPER TRIM - REMOVAL)

(5) Bend backlite retaining tabs (Fig. 1) inward

against glass.

(6) Disconnect the rear window defogger electrical

connector, if equipped.

(7) Using a suitable pneumatic knife from inside

the vehicle, cut urethane holding backlite frame to

opening fence.

(8) Separate glass from vehicle.

INSTALLATION

(1) Clean urethane adhesive from around backlite

opening fence.

(2) If necessary, apply black-out primer to outer

edge of replacement backlite frame.(3) If black-out primer was pre-applied on backlite,

clean bonding surface with Isopropyl alcohol and

clean lint free cloth. Allow 3 minutes for drying time.

(4) Apply black-out primer to backlite opening

fence.

(5) Apply a 13 mm (0.5 in.) bead of urethane

around the perimeter of the window frame bonding

surface (Fig. 2).

(6) Set glass on lower fence and move glass for-

ward into opening (Fig. 3).

(7) Firmly push glass against rear window glass

opening fence.

(8) Bend tabs around edges of backlite opening

fence to retain glass.

(9) Clean excess urethane from exterior with

MOPARt, Super Clean or equivalent.

(10) Allow urethane to cure at least 24 hours (full

cure is 72 hours).

(11) Water test to verify repair before returning

vehicle to service.

(12) Connect the rear window defogger electrical

connector, if equipped.

Fig. 1 Backlite Tabs

1 - BACKLITE

2-TAB

23 - 86 STATIONARY GLASSDR

Page 2777 of 2895

coil. To maintain minimum evaporator temperature

and prevent evaporator freezing, the A/C Fin Probe

which is located in the evaporator cycles the com-

pressor clutch by sending an A/C request to the

JTEC which in turn processes this piece of informa-

tion and if all conditions are met cycles the compres-

sor clutch.

OPERATION - REFRIGERANT SYSTEM SERVICE

PORT

The low pressure service port is located on the suc-

tion refrigerant line, near the accumulator. The high

pressure service port is located on the liquid line at

the passenger side of the engine compartment, near

the condenser.

Each of the service ports has a threaded plastic

protective cap installed over it from the factory. After

servicing the refrigerant system, always reinstall

both of the service port caps.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE

The air conditioning system is designed to provide

the passenger compartment with low temperature

and low humidity air. The evaporator, located in the

HVAC housing on the dash panel below the instru-

ment panel, is cooled to temperatures near the freez-

ing point. As warm damp air passes through the

cooled evaporator, the air transfers its heat to the

refrigerant in the evaporator and the moisture in the

air condenses on the evaporator fins. During periods

of high heat and humidity, an air conditioning sys-

tem will be more effective in the Recirculation Mode.

With the system in the Recirculation Mode, only air

from the passenger compartment passes through the

evaporator. As the passenger compartment air dehu-

midifies, the air conditioning system performance

levels improve.

Humidity has an important bearing on the temper-

ature of the air delivered to the interior of the vehi-

cle. It is important to understand the effect that

humidity has on the performance of the air condition-

ing system. When humidity is high, the evaporator

has to perform a double duty. It must lower the air

temperature, and it must lower the temperature of

the moisture in the air that condenses on the evapo-

rator fins. Condensing the moisture in the air trans-

fers heat energy into the evaporator fins and tubing.

This reduces the amount of heat the evaporator can

absorb from the air. High humidity greatly reduces

the ability of the evaporator to lower the temperature

of the air.

However, evaporator capacity used to reduce the

amount of moisture in the air is not wasted. Remov-

ing some of the moisture out of the air entering the

vehicle adds to the comfort of the passengers.

Although, an owner may expect too much from the

air conditioning system on humid days. A perfor-

mance test is the best way to determine whether the

system is performing up to standard. This test also

provides valuable clues as to the possible cause of

trouble with the air conditioning system.

Before proceeding, (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNING) and

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - CAUTION). The air temperature in

the test room and in the vehicle must be a minimum

of 21É C (70É F) for this test.

(1) Connect a tachometer and a manifold gauge set

or A/C recycling/charging station.

(2) Set the A/C Heater mode control switch knob in

the Recirculation Mode position, the temperature

control knob in the full cool position, and the blower

motor switch knob in the highest speed position.

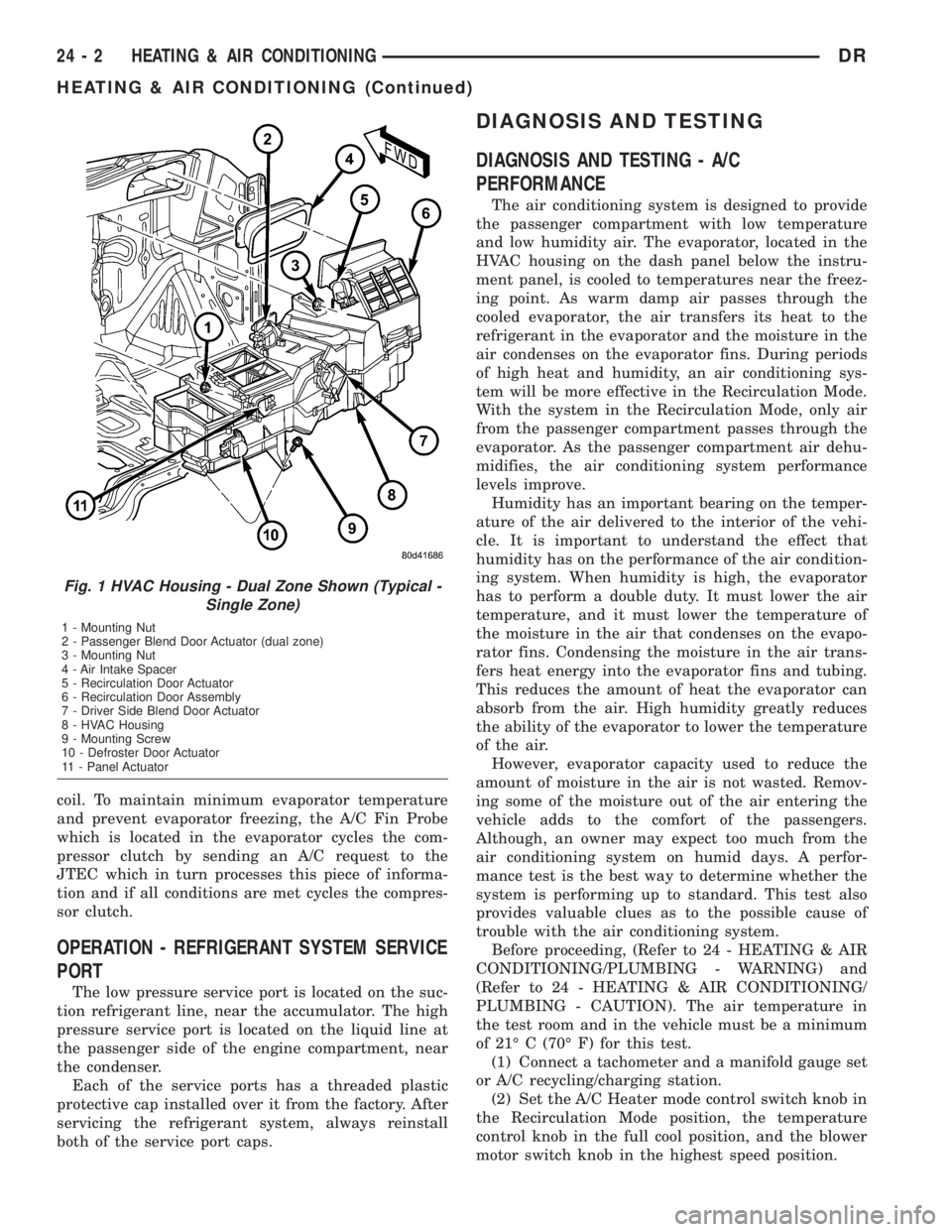

Fig. 1 HVAC Housing - Dual Zone Shown (Typical -

Single Zone)

1 - Mounting Nut

2 - Passenger Blend Door Actuator (dual zone)

3 - Mounting Nut

4 - Air Intake Spacer

5 - Recirculation Door Actuator

6 - Recirculation Door Assembly

7 - Driver Side Blend Door Actuator

8 - HVAC Housing

9 - Mounting Screw

10 - Defroster Door Actuator

11 - Panel Actuator

24 - 2 HEATING & AIR CONDITIONINGDR

HEATING & AIR CONDITIONING (Continued)

Page 2790 of 2895

INSTALLATION

(1) Plug the two wire harness connectors into the

back of the A/C Heater control.

(2) Position the A/C Heater control in the instru-

ment panel bezel and secure it with four screws.

Tighten the screws to 2.2 N´m (20 in. lbs.).

(3) Reinstall the center bezel onto the instrument

panel(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL CENTER BEZEL - INSTALLA-

TION).

(4) Connect the battery negative cable.

A/C PRESSURE TRANSDUCER

DESCRIPTION - A/C PRESSURE TRANSDUCER

The A/C pressure transducer is a switch that is

installed on a fitting located on the refrigerant dis-

charge line between the compressor and the conden-

sor in the front corner of the engine compartment. An

internally threaded hex fitting on the transducer con-

nects it to the externally threaded Schrader-type fit-

ting on the liquid line. A rubber O-ring seals the

connection between the transducer and the discharge

line fitting. Three terminals within a molded plastic

connector receptacle on the top of the transducer con-

nect it to the vehicle electrical system through a take

out and connector of the headlamp and dash wire

harness.

The A/C pressure transducer cannot be adjusted or

repaired and, if faulty or damaged, it must be

replaced.

OPERATION

The A/C pressure transducer monitors the pres-

sures in the high side of the refrigerant system

through its connection to a fitting on the discharge

line. The transducer will change its internal resis-

tance in response to the pressures it monitors. The

Powertrain Control Module (PCM) provides a five

volt reference signal and a sensor ground to the

transducer, then monitors the output voltage of the

transducer on a sensor return circuit to determine

refrigerant pressure. The PCM is programmed to

respond to this and other sensor inputs by controlling

the operation of the air conditioning compressor

clutch and the radiator cooling fan to help optimize

air conditioning system performance and to protect

the system components from damage. The A/C pres-

sure transducer input to the PCM will also prevent

the air conditioning compressor clutch from engaging

when ambient temperatures are below about 10É C

due to the pressure/temperature relationship of the

refrigerant. The Schrader-type valve in the discharge

line fitting permits the A/C pressure transducer to be

removed or installed without disturbing the refriger-

ant in the system. The A/C pressure transducer is

diagnosed using a DRBIIItscan tool. Refer to the

appropriate diagnostic information.

DIAGNOSIS AND TESTING - A/C PRESSURE

TRANSDUCER

The A/C pressure transducer is tested using a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information. Before testing the A/C pressure

transducer, be certain that the transducer wire har-

ness connection is clean of corrosion and properly

connected. For the air conditioning system to operate,

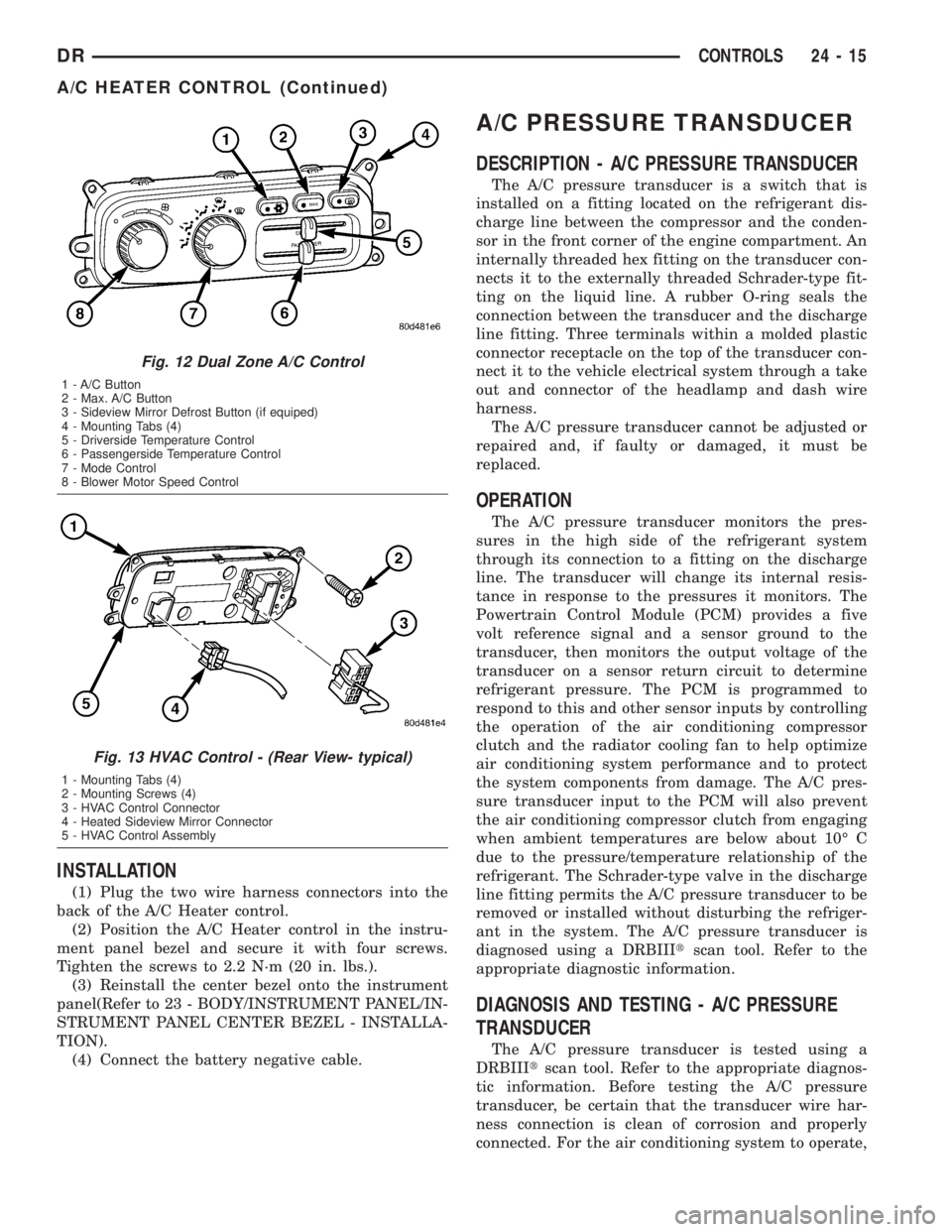

Fig. 12 Dual Zone A/C Control

1 - A/C Button

2 - Max. A/C Button

3 - Sideview Mirror Defrost Button (if equiped)

4 - Mounting Tabs (4)

5 - Driverside Temperature Control

6 - Passengerside Temperature Control

7 - Mode Control

8 - Blower Motor Speed Control

Fig. 13 HVAC Control - (Rear View- typical)

1 - Mounting Tabs (4)

2 - Mounting Screws (4)

3 - HVAC Control Connector

4 - Heated Sideview Mirror Connector

5 - HVAC Control Assembly

DRCONTROLS 24 - 15

A/C HEATER CONTROL (Continued)

Page 2791 of 2895

an A/C pressure transducer voltage reading between

0.451 and 4.519 volts is required. Voltages outside

this range indicate a low or high refrigerant system

pressure condition to the Powertrain Control Module

(PCM). The PCM is programmed to respond to a low

or high refrigerant system pressure by suppressing

operation of the compressor. Refer to the A/C Pres-

sure Transducer Voltage table for the possible condi-

tion indicated by the transducer voltage readings.

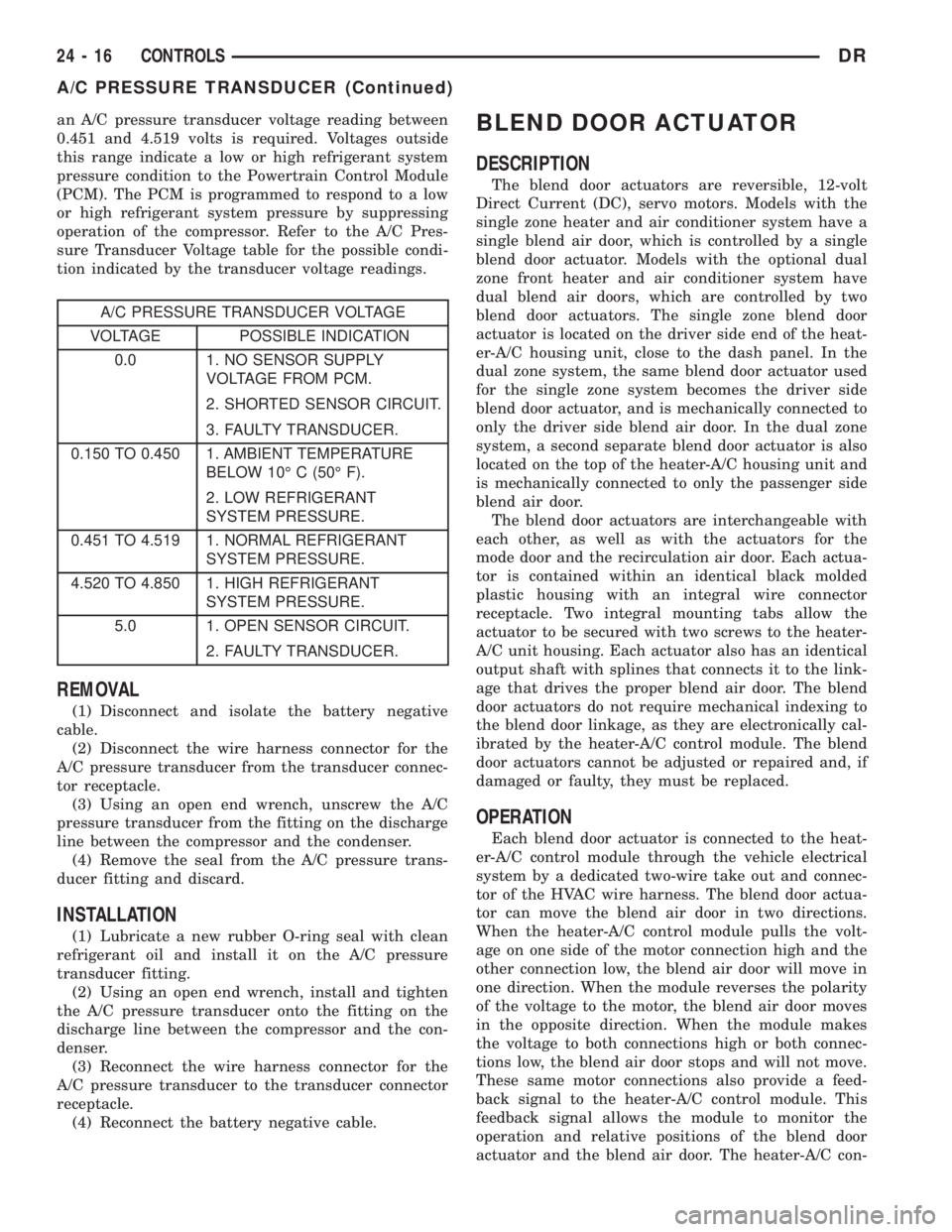

A/C PRESSURE TRANSDUCER VOLTAGE

VOLTAGE POSSIBLE INDICATION

0.0 1. NO SENSOR SUPPLY

VOLTAGE FROM PCM.

2. SHORTED SENSOR CIRCUIT.

3. FAULTY TRANSDUCER.

0.150 TO 0.450 1. AMBIENT TEMPERATURE

BELOW 10É C (50É F).

2. LOW REFRIGERANT

SYSTEM PRESSURE.

0.451 TO 4.519 1. NORMAL REFRIGERANT

SYSTEM PRESSURE.

4.520 TO 4.850 1. HIGH REFRIGERANT

SYSTEM PRESSURE.

5.0 1. OPEN SENSOR CIRCUIT.

2. FAULTY TRANSDUCER.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the wire harness connector for the

A/C pressure transducer from the transducer connec-

tor receptacle.

(3) Using an open end wrench, unscrew the A/C

pressure transducer from the fitting on the discharge

line between the compressor and the condenser.

(4) Remove the seal from the A/C pressure trans-

ducer fitting and discard.

INSTALLATION

(1) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the A/C pressure

transducer fitting.

(2) Using an open end wrench, install and tighten

the A/C pressure transducer onto the fitting on the

discharge line between the compressor and the con-

denser.

(3) Reconnect the wire harness connector for the

A/C pressure transducer to the transducer connector

receptacle.

(4) Reconnect the battery negative cable.

BLEND DOOR ACTUATOR

DESCRIPTION

The blend door actuators are reversible, 12-volt

Direct Current (DC), servo motors. Models with the

single zone heater and air conditioner system have a

single blend air door, which is controlled by a single

blend door actuator. Models with the optional dual

zone front heater and air conditioner system have

dual blend air doors, which are controlled by two

blend door actuators. The single zone blend door

actuator is located on the driver side end of the heat-

er-A/C housing unit, close to the dash panel. In the

dual zone system, the same blend door actuator used

for the single zone system becomes the driver side

blend door actuator, and is mechanically connected to

only the driver side blend air door. In the dual zone

system, a second separate blend door actuator is also

located on the top of the heater-A/C housing unit and

is mechanically connected to only the passenger side

blend air door.

The blend door actuators are interchangeable with

each other, as well as with the actuators for the

mode door and the recirculation air door. Each actua-

tor is contained within an identical black molded

plastic housing with an integral wire connector

receptacle. Two integral mounting tabs allow the

actuator to be secured with two screws to the heater-

A/C unit housing. Each actuator also has an identical

output shaft with splines that connects it to the link-

age that drives the proper blend air door. The blend

door actuators do not require mechanical indexing to

the blend door linkage, as they are electronically cal-

ibrated by the heater-A/C control module. The blend

door actuators cannot be adjusted or repaired and, if

damaged or faulty, they must be replaced.

OPERATION

Each blend door actuator is connected to the heat-

er-A/C control module through the vehicle electrical

system by a dedicated two-wire take out and connec-

tor of the HVAC wire harness. The blend door actua-

tor can move the blend air door in two directions.

When the heater-A/C control module pulls the volt-

age on one side of the motor connection high and the

other connection low, the blend air door will move in

one direction. When the module reverses the polarity

of the voltage to the motor, the blend air door moves

in the opposite direction. When the module makes

the voltage to both connections high or both connec-

tions low, the blend air door stops and will not move.

These same motor connections also provide a feed-

back signal to the heater-A/C control module. This

feedback signal allows the module to monitor the

operation and relative positions of the blend door

actuator and the blend air door. The heater-A/C con-

24 - 16 CONTROLSDR

A/C PRESSURE TRANSDUCER (Continued)

Page 2795 of 2895

(4) Remove the mounting screws from the actua-

tor.

(5) Remove the actuator from the HVAC housing.

INSTALLATION - FLOOR - DEFROST DOOR

ACTUATOR

(1) Install the floor-defrost door actuator to the

HVAC assembly.

(2) Install the mounting screws and tighten to 2.2

N´m (20 in. lbs.).

(3) Install the actuator electrical connector.

(4) Install the instrument panel assembly into the

vehicle(Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL ASSEMBLY - INSTALLA-

TION).

(5) Connect the battery negative cable.

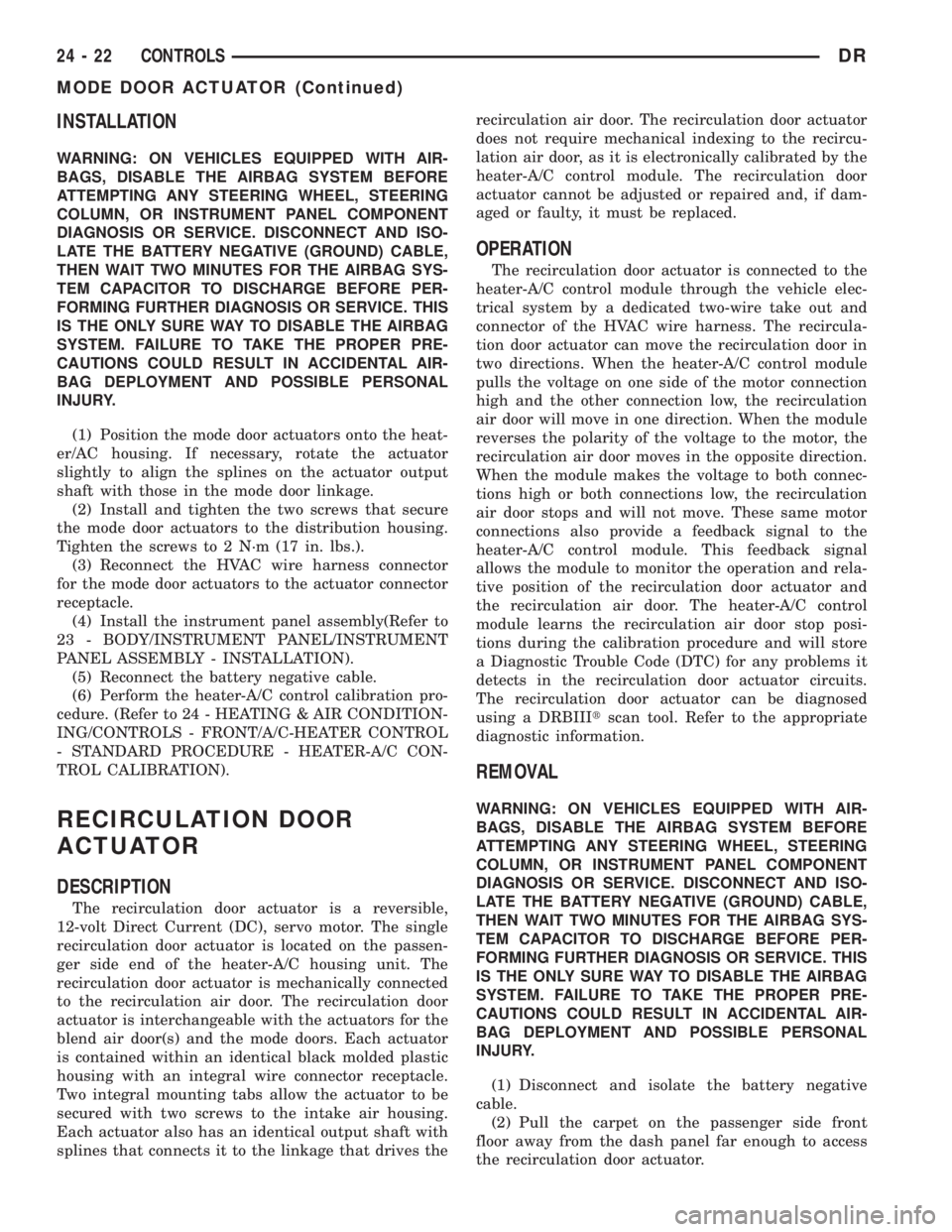

MODE DOOR ACTUATOR

DESCRIPTION

The mode door actuator is a reversible, 12-volt

Direct Current (DC), servo motor (Fig. 16). The sin-

gle mode door actuator is located on the driver side

end of the heater-A/C housing unit, close to the top of

the distribution housing. The mode door actuator is

mechanically connected to the mode door. The mode

door actuator is interchangeable with the actuators

for the blend air door(s) and the recirculation air

door. Each actuator is contained within an identical

black molded plastic housing with an integral wire

connector receptacle. Two integral mounting tabs

allow the actuator to be secured with two screws to

the heater-A/C unit housing. Each actuator also has

an identical output shaft with splines that connects

it to the linkage that drives the mode door. The mode

door actuator does not require mechanical indexing

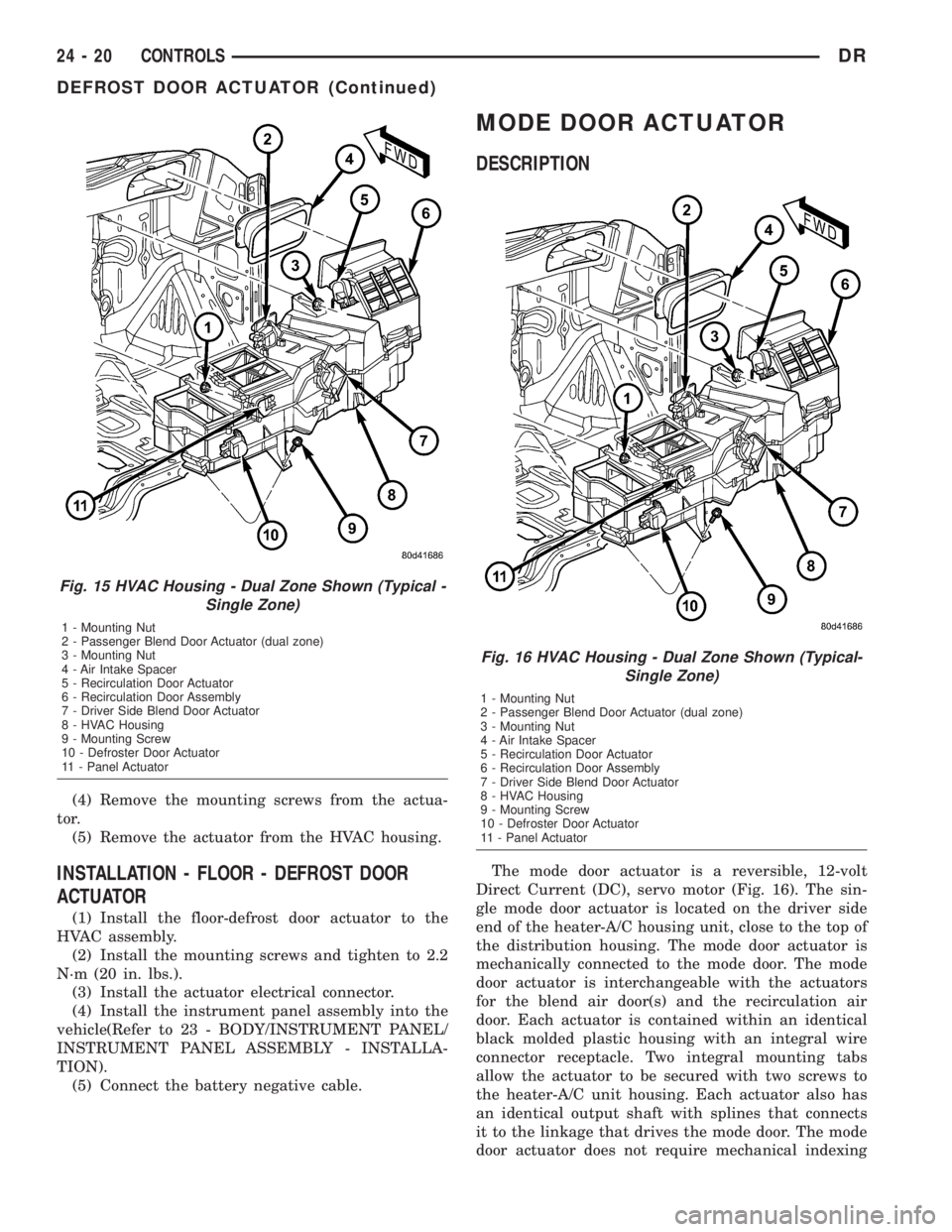

Fig. 15 HVAC Housing - Dual Zone Shown (Typical -

Single Zone)

1 - Mounting Nut

2 - Passenger Blend Door Actuator (dual zone)

3 - Mounting Nut

4 - Air Intake Spacer

5 - Recirculation Door Actuator

6 - Recirculation Door Assembly

7 - Driver Side Blend Door Actuator

8 - HVAC Housing

9 - Mounting Screw

10 - Defroster Door Actuator

11 - Panel Actuator

Fig. 16 HVAC Housing - Dual Zone Shown (Typical-

Single Zone)

1 - Mounting Nut

2 - Passenger Blend Door Actuator (dual zone)

3 - Mounting Nut

4 - Air Intake Spacer

5 - Recirculation Door Actuator

6 - Recirculation Door Assembly

7 - Driver Side Blend Door Actuator

8 - HVAC Housing

9 - Mounting Screw

10 - Defroster Door Actuator

11 - Panel Actuator

24 - 20 CONTROLSDR

DEFROST DOOR ACTUATOR (Continued)

Page 2797 of 2895

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the mode door actuators onto the heat-

er/AC housing. If necessary, rotate the actuator

slightly to align the splines on the actuator output

shaft with those in the mode door linkage.

(2) Install and tighten the two screws that secure

the mode door actuators to the distribution housing.

Tighten the screws to 2 N´m (17 in. lbs.).

(3) Reconnect the HVAC wire harness connector

for the mode door actuators to the actuator connector

receptacle.

(4) Install the instrument panel assembly(Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - INSTALLATION).

(5) Reconnect the battery negative cable.

(6) Perform the heater-A/C control calibration pro-

cedure. (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS - FRONT/A/C-HEATER CONTROL

- STANDARD PROCEDURE - HEATER-A/C CON-

TROL CALIBRATION).

RECIRCULATION DOOR

ACTUATOR

DESCRIPTION

The recirculation door actuator is a reversible,

12-volt Direct Current (DC), servo motor. The single

recirculation door actuator is located on the passen-

ger side end of the heater-A/C housing unit. The

recirculation door actuator is mechanically connected

to the recirculation air door. The recirculation door

actuator is interchangeable with the actuators for the

blend air door(s) and the mode doors. Each actuator

is contained within an identical black molded plastic

housing with an integral wire connector receptacle.

Two integral mounting tabs allow the actuator to be

secured with two screws to the intake air housing.

Each actuator also has an identical output shaft with

splines that connects it to the linkage that drives therecirculation air door. The recirculation door actuator

does not require mechanical indexing to the recircu-

lation air door, as it is electronically calibrated by the

heater-A/C control module. The recirculation door

actuator cannot be adjusted or repaired and, if dam-

aged or faulty, it must be replaced.

OPERATION

The recirculation door actuator is connected to the

heater-A/C control module through the vehicle elec-

trical system by a dedicated two-wire take out and

connector of the HVAC wire harness. The recircula-

tion door actuator can move the recirculation door in

two directions. When the heater-A/C control module

pulls the voltage on one side of the motor connection

high and the other connection low, the recirculation

air door will move in one direction. When the module

reverses the polarity of the voltage to the motor, the

recirculation air door moves in the opposite direction.

When the module makes the voltage to both connec-

tions high or both connections low, the recirculation

air door stops and will not move. These same motor

connections also provide a feedback signal to the

heater-A/C control module. This feedback signal

allows the module to monitor the operation and rela-

tive position of the recirculation door actuator and

the recirculation air door. The heater-A/C control

module learns the recirculation air door stop posi-

tions during the calibration procedure and will store

a Diagnostic Trouble Code (DTC) for any problems it

detects in the recirculation door actuator circuits.

The recirculation door actuator can be diagnosed

using a DRBIIItscan tool. Refer to the appropriate

diagnostic information.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Pull the carpet on the passenger side front

floor away from the dash panel far enough to access

the recirculation door actuator.

24 - 22 CONTROLSDR

MODE DOOR ACTUATOR (Continued)

Page 2808 of 2895

CAUTION

SERVICE CAUTIONS

CAUTION: Liquid refrigerant is corrosive to metal

surfaces. Follow the operating instructions supplied

with the service equipment being used.

Never add R-12 to a refrigerant system designed to

use R-134a. Damage to the system will result.

R-12 refrigerant oil must not be mixed with R-134a

refrigerant oil. They are not compatible.

Do not use R-12 equipment or parts on the R-134a

system. Damage to the system will result.

Do not overcharge the refrigerant system. This will

cause excessive compressor head pressure and

can cause noise and system failure.

Recover the refrigerant before opening any fitting

or connection. Open the fittings with caution, even

after the system has been discharged. Never open

or loosen a connection before recovering the refrig-

erant.

Do not remove the secondary retention clip from

any spring-lock coupler connection while the refrig-

erant system is under pressure. Recover the refrig-

erant before removing the secondary retention clip.

Open the fittings with caution, even after the sys-

tem has been discharged. Never open or loosen a

connection before recovering the refrigerant.

The refrigerant system must always be evacuated

before charging.

Do not open the refrigerant system or uncap a

replacement component until you are ready to ser-

vice the system. This will prevent contamination in

the system.

Before disconnecting a component, clean the out-

side of the fittings thoroughly to prevent contami-

nation from entering the refrigerant system.

Immediately after disconnecting a component from

the refrigerant system, seal the open fittings with a

cap or plug.

Before connecting an open refrigerant fitting,

always install a new seal or gasket. Coat the fitting

and seal with clean refrigerant oil before connect-

ing.

Do not remove the sealing caps from a replacement

component until it is to be installed.

When installing a refrigerant line, avoid sharp

bends that may restrict refrigerant flow. Position the

refrigerant lines away from exhaust system compo-

nents or any sharp edges, which may damage the

line.

Tighten refrigerant fittings only to the specified

torque. The aluminum fittings used in the refriger-

ant system will not tolerate overtightening.

When disconnecting a refrigerant fitting, use a

wrench on both halves of the fitting. This will pre-vent twisting of the refrigerant lines or tubes.

Refrigerant oil will absorb moisture from the atmo-

sphere if left uncapped. Do not open a container of

refrigerant oil until you are ready to use it. Replace

the cap on the oil container immediately after using.

Store refrigerant oil only in a clean, airtight, and

moisture-free container.

Keep service tools and the work area clean. Con-

tamination of the refrigerant system through care-

less work habits must be avoided.

CAUTION - REFRIGERANT HOSES/LINES/

TUBES PRECAUTIONS

Kinks or sharp bends in the refrigerant plumbing

will reduce the capacity of the entire system. High

pressures are produced in the system when it is oper-

ating. Extreme care must be exercised to make sure

that all refrigerant system connections are pressure

tight.

A good rule for the flexible hose refrigerant lines is

to keep the radius of all bends at least ten times the

diameter of the hose. Sharp bends will reduce the

flow of refrigerant. The flexible hose lines should be

routed so they are at least 80 millimeters (3 inches)

from the exhaust manifold. It is a good practice to

inspect all flexible refrigerant system hose lines at

least once a year to make sure they are in good con-

dition and properly routed.

There are two types of refrigerant fittings:

²All fittings with O-rings need to be coated with

refrigerant oil before installation. Use only O-rings

that are the correct size and approved for use with

R-134a refrigerant. Failure to do so may result in a

leak.

²Unified plumbing connections with gaskets can-

not be serviced with O-rings. The gaskets are not

reusable and new gaskets do not require lubrication

before installing.

Using the proper tools when making a refrigerant

plumbing connection is very important. Improper

tools or improper use of the tools can damage the

refrigerant fittings. Always use two wrenches when

loosening or tightening tube fittings. Use one wrench

to hold one side of the connection stationary, while

loosening or tightening the other side of the connec-

tion with a second wrench.

The refrigerant must be recovered completely from

the system before opening any fitting or connection.

Open the fittings with caution, even after the refrig-

erant has been recovered. If any pressure is noticed

as a fitting is loosened, tighten the fitting and

recover the refrigerant from the system again.

Do not discharge refrigerant into the atmosphere.

Use an R-134a refrigerant recovery/recycling device

that meets SAE Standard J2210.

DRPLUMBING 24 - 33

PLUMBING (Continued)

Page 2815 of 2895

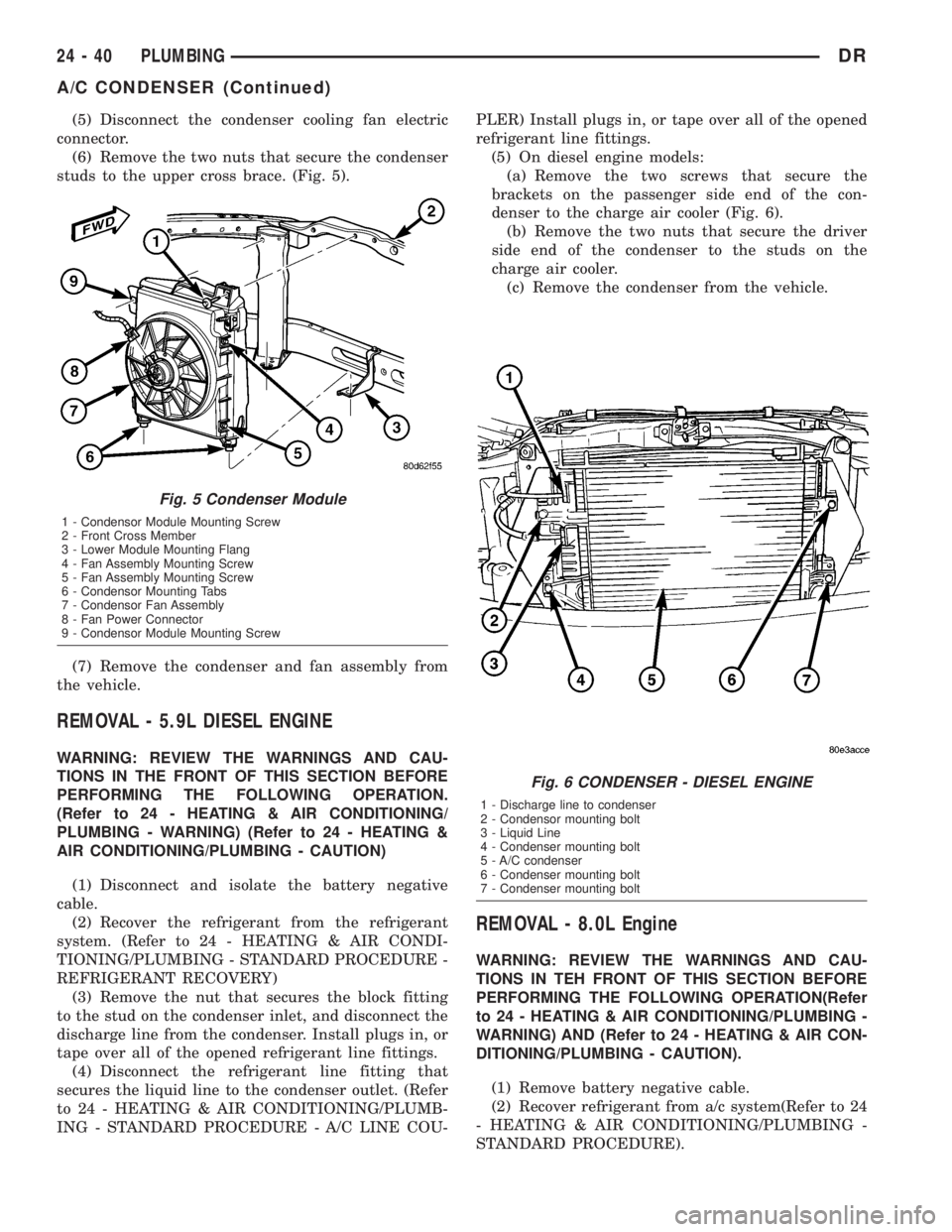

(5) Disconnect the condenser cooling fan electric

connector.

(6) Remove the two nuts that secure the condenser

studs to the upper cross brace. (Fig. 5).

(7) Remove the condenser and fan assembly from

the vehicle.

REMOVAL - 5.9L DIESEL ENGINE

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(3) Remove the nut that secures the block fitting

to the stud on the condenser inlet, and disconnect the

discharge line from the condenser. Install plugs in, or

tape over all of the opened refrigerant line fittings.

(4) Disconnect the refrigerant line fitting that

secures the liquid line to the condenser outlet. (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING - STANDARD PROCEDURE - A/C LINE COU-PLER) Install plugs in, or tape over all of the opened

refrigerant line fittings.

(5) On diesel engine models:

(a) Remove the two screws that secure the

brackets on the passenger side end of the con-

denser to the charge air cooler (Fig. 6).

(b) Remove the two nuts that secure the driver

side end of the condenser to the studs on the

charge air cooler.

(c) Remove the condenser from the vehicle.

REMOVAL - 8.0L Engine

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN TEH FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION(Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) AND (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

(1) Remove battery negative cable.

(2) Recover refrigerant from a/c system(Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

Fig. 5 Condenser Module

1 - Condensor Module Mounting Screw

2 - Front Cross Member

3 - Lower Module Mounting Flang

4 - Fan Assembly Mounting Screw

5 - Fan Assembly Mounting Screw

6 - Condensor Mounting Tabs

7 - Condensor Fan Assembly

8 - Fan Power Connector

9 - Condensor Module Mounting Screw

Fig. 6 CONDENSER - DIESEL ENGINE

1 - Discharge line to condenser

2 - Condensor mounting bolt

3 - Liquid Line

4 - Condenser mounting bolt

5 - A/C condenser

6 - Condenser mounting bolt

7 - Condenser mounting bolt

24 - 40 PLUMBINGDR

A/C CONDENSER (Continued)