ABS DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2085 of 2895

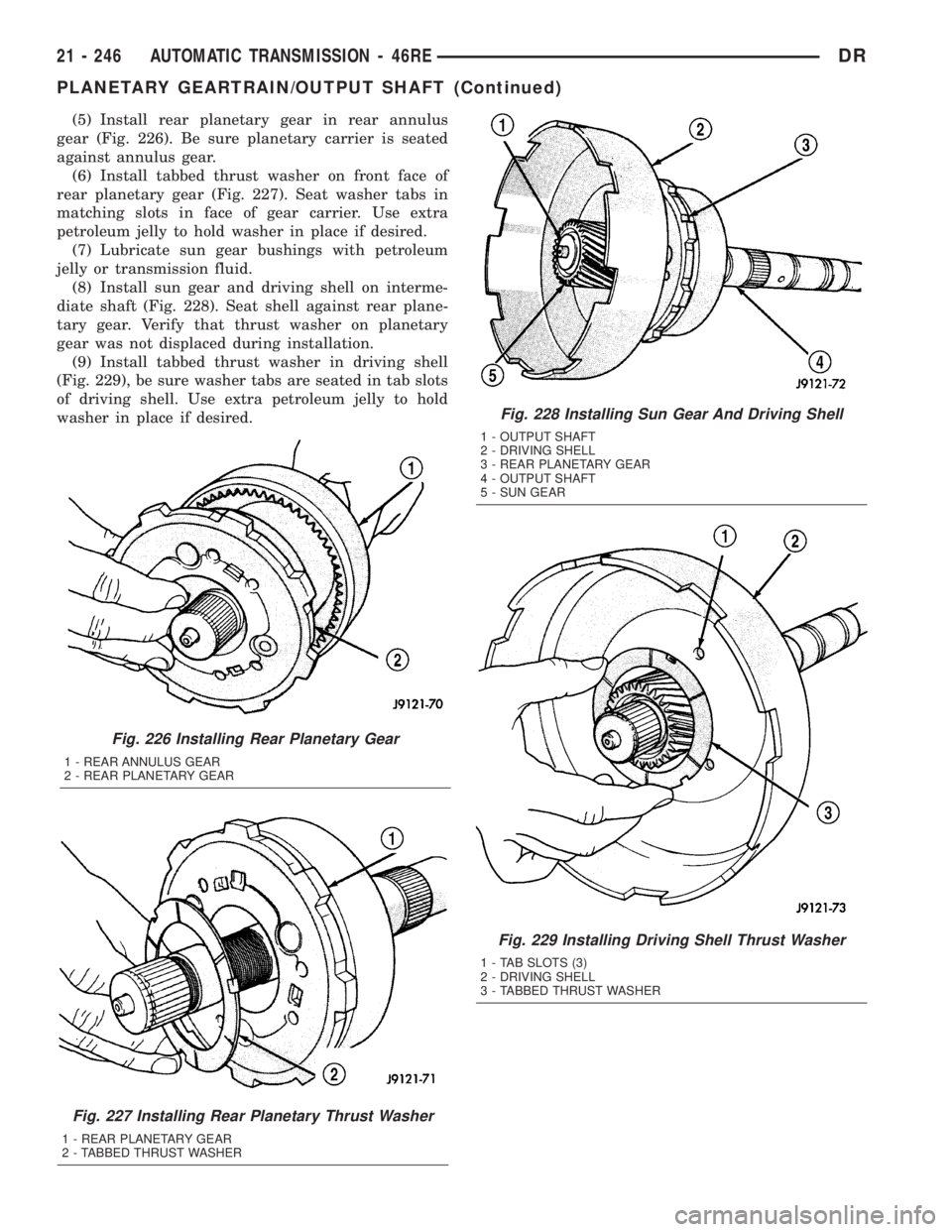

(5) Install rear planetary gear in rear annulus

gear (Fig. 226). Be sure planetary carrier is seated

against annulus gear.

(6) Install tabbed thrust washer on front face of

rear planetary gear (Fig. 227). Seat washer tabs in

matching slots in face of gear carrier. Use extra

petroleum jelly to hold washer in place if desired.

(7) Lubricate sun gear bushings with petroleum

jelly or transmission fluid.

(8) Install sun gear and driving shell on interme-

diate shaft (Fig. 228). Seat shell against rear plane-

tary gear. Verify that thrust washer on planetary

gear was not displaced during installation.

(9) Install tabbed thrust washer in driving shell

(Fig. 229), be sure washer tabs are seated in tab slots

of driving shell. Use extra petroleum jelly to hold

washer in place if desired.

Fig. 226 Installing Rear Planetary Gear

1 - REAR ANNULUS GEAR

2 - REAR PLANETARY GEAR

Fig. 227 Installing Rear Planetary Thrust Washer

1 - REAR PLANETARY GEAR

2 - TABBED THRUST WASHER

Fig. 228 Installing Sun Gear And Driving Shell

1 - OUTPUT SHAFT

2 - DRIVING SHELL

3 - REAR PLANETARY GEAR

4 - OUTPUT SHAFT

5 - SUN GEAR

Fig. 229 Installing Driving Shell Thrust Washer

1 - TAB SLOTS (3)

2 - DRIVING SHELL

3 - TABBED THRUST WASHER

21 - 246 AUTOMATIC TRANSMISSION - 46REDR

PLANETARY GEARTRAIN/OUTPUT SHAFT (Continued)

Page 2086 of 2895

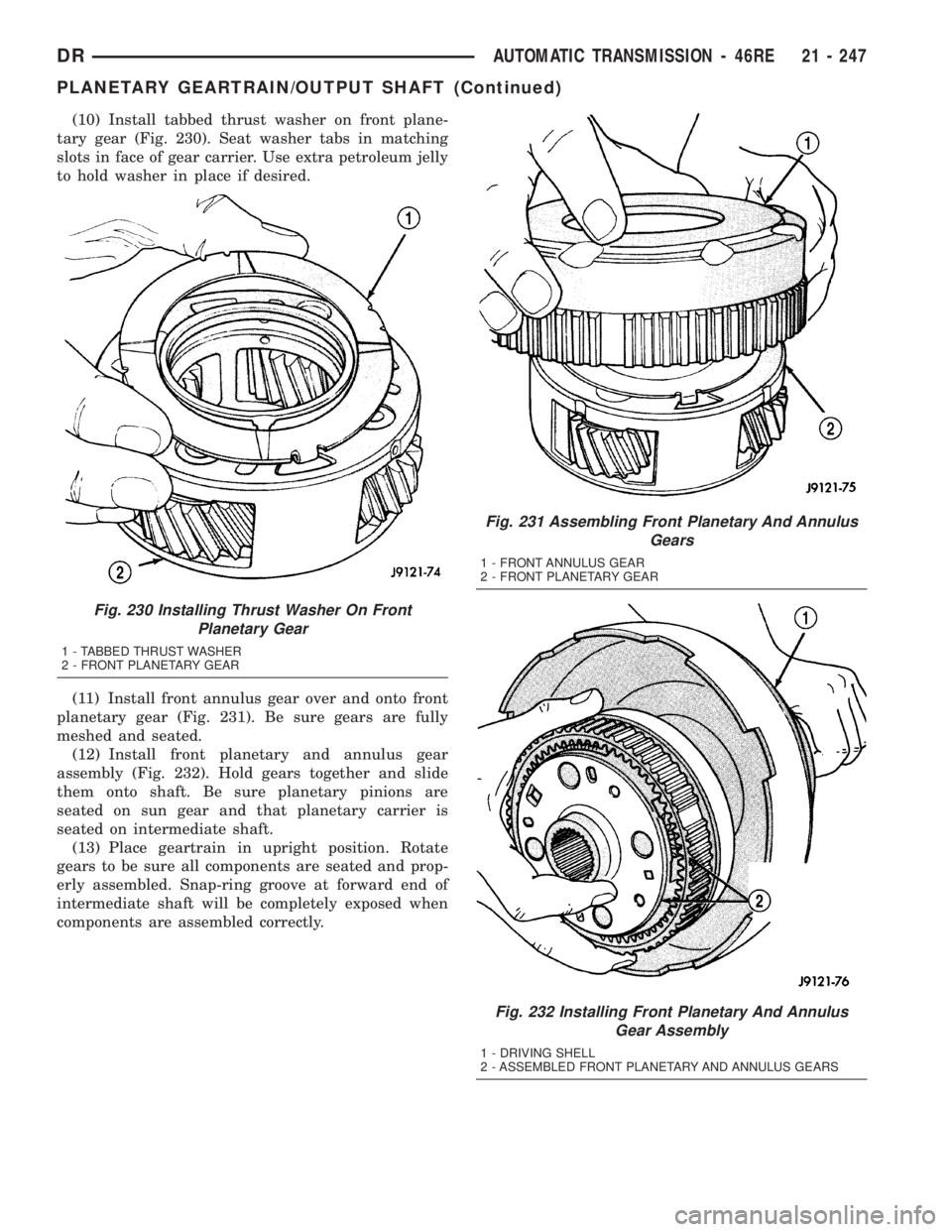

(10) Install tabbed thrust washer on front plane-

tary gear (Fig. 230). Seat washer tabs in matching

slots in face of gear carrier. Use extra petroleum jelly

to hold washer in place if desired.

(11) Install front annulus gear over and onto front

planetary gear (Fig. 231). Be sure gears are fully

meshed and seated.

(12) Install front planetary and annulus gear

assembly (Fig. 232). Hold gears together and slide

them onto shaft. Be sure planetary pinions are

seated on sun gear and that planetary carrier is

seated on intermediate shaft.

(13) Place geartrain in upright position. Rotate

gears to be sure all components are seated and prop-

erly assembled. Snap-ring groove at forward end of

intermediate shaft will be completely exposed when

components are assembled correctly.

Fig. 231 Assembling Front Planetary And Annulus

Gears

1 - FRONT ANNULUS GEAR

2 - FRONT PLANETARY GEAR

Fig. 232 Installing Front Planetary And Annulus

Gear Assembly

1 - DRIVING SHELL

2 - ASSEMBLED FRONT PLANETARY AND ANNULUS GEARS

Fig. 230 Installing Thrust Washer On Front

Planetary Gear

1 - TABBED THRUST WASHER

2 - FRONT PLANETARY GEAR

DRAUTOMATIC TRANSMISSION - 46RE 21 - 247

PLANETARY GEARTRAIN/OUTPUT SHAFT (Continued)

Page 2131 of 2895

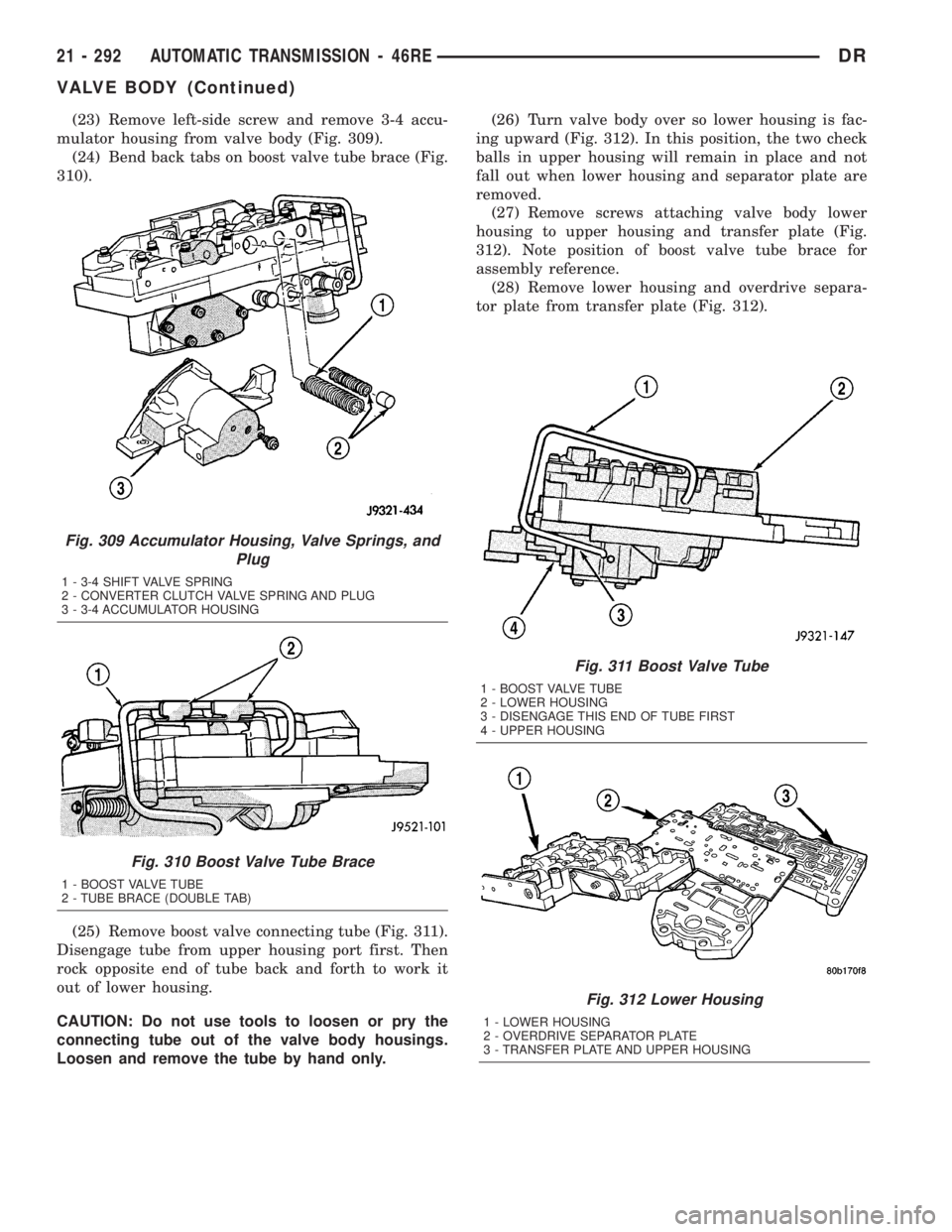

(23) Remove left-side screw and remove 3-4 accu-

mulator housing from valve body (Fig. 309).

(24) Bend back tabs on boost valve tube brace (Fig.

310).

(25) Remove boost valve connecting tube (Fig. 311).

Disengage tube from upper housing port first. Then

rock opposite end of tube back and forth to work it

out of lower housing.

CAUTION: Do not use tools to loosen or pry the

connecting tube out of the valve body housings.

Loosen and remove the tube by hand only.(26) Turn valve body over so lower housing is fac-

ing upward (Fig. 312). In this position, the two check

balls in upper housing will remain in place and not

fall out when lower housing and separator plate are

removed.

(27) Remove screws attaching valve body lower

housing to upper housing and transfer plate (Fig.

312). Note position of boost valve tube brace for

assembly reference.

(28) Remove lower housing and overdrive separa-

tor plate from transfer plate (Fig. 312).

Fig. 311 Boost Valve Tube

1 - BOOST VALVE TUBE

2 - LOWER HOUSING

3 - DISENGAGE THIS END OF TUBE FIRST

4 - UPPER HOUSING

Fig. 312 Lower Housing

1 - LOWER HOUSING

2 - OVERDRIVE SEPARATOR PLATE

3 - TRANSFER PLATE AND UPPER HOUSING

Fig. 309 Accumulator Housing, Valve Springs, and

Plug

1 - 3-4 SHIFT VALVE SPRING

2 - CONVERTER CLUTCH VALVE SPRING AND PLUG

3 - 3-4 ACCUMULATOR HOUSING

Fig. 310 Boost Valve Tube Brace

1 - BOOST VALVE TUBE

2 - TUBE BRACE (DOUBLE TAB)

21 - 292 AUTOMATIC TRANSMISSION - 46REDR

VALVE BODY (Continued)

Page 2143 of 2895

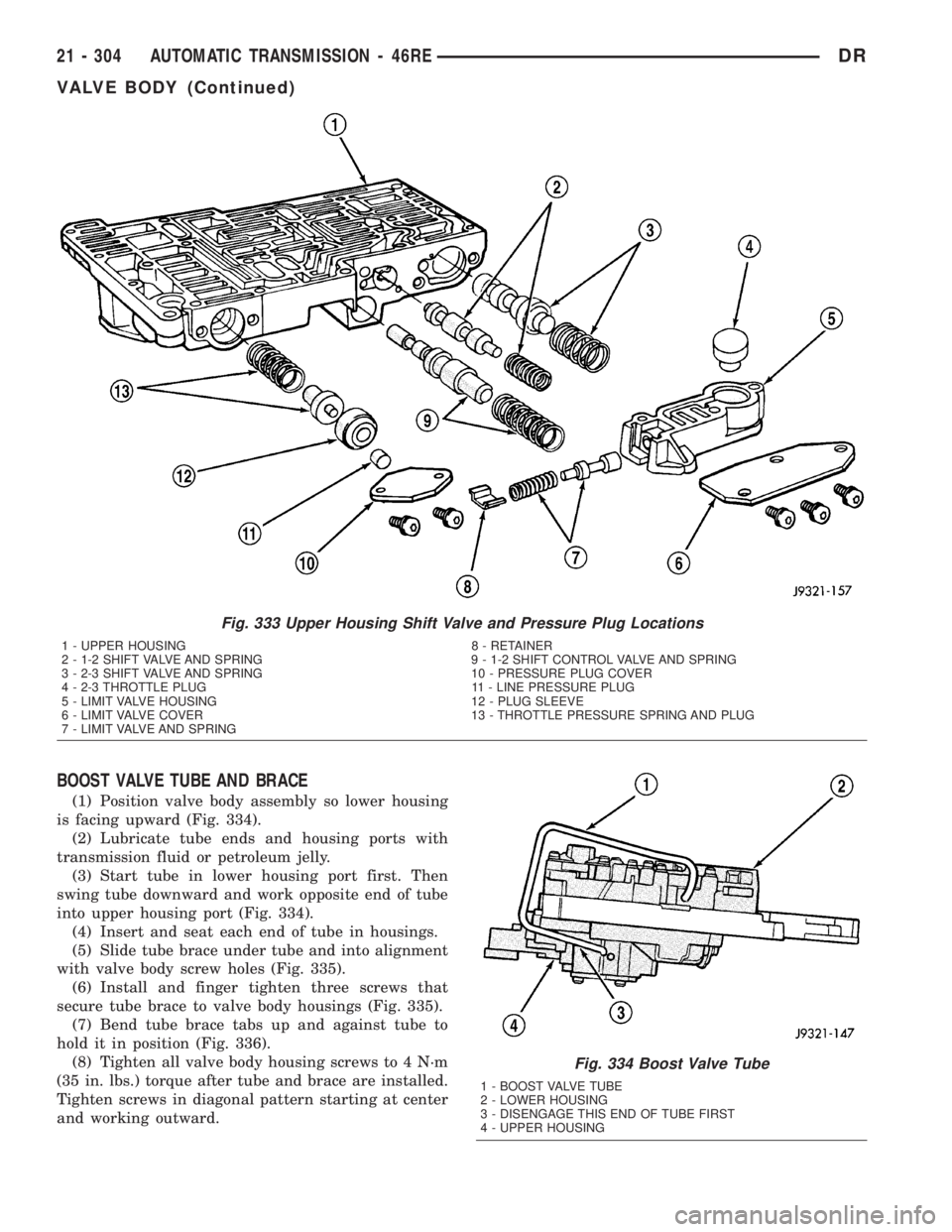

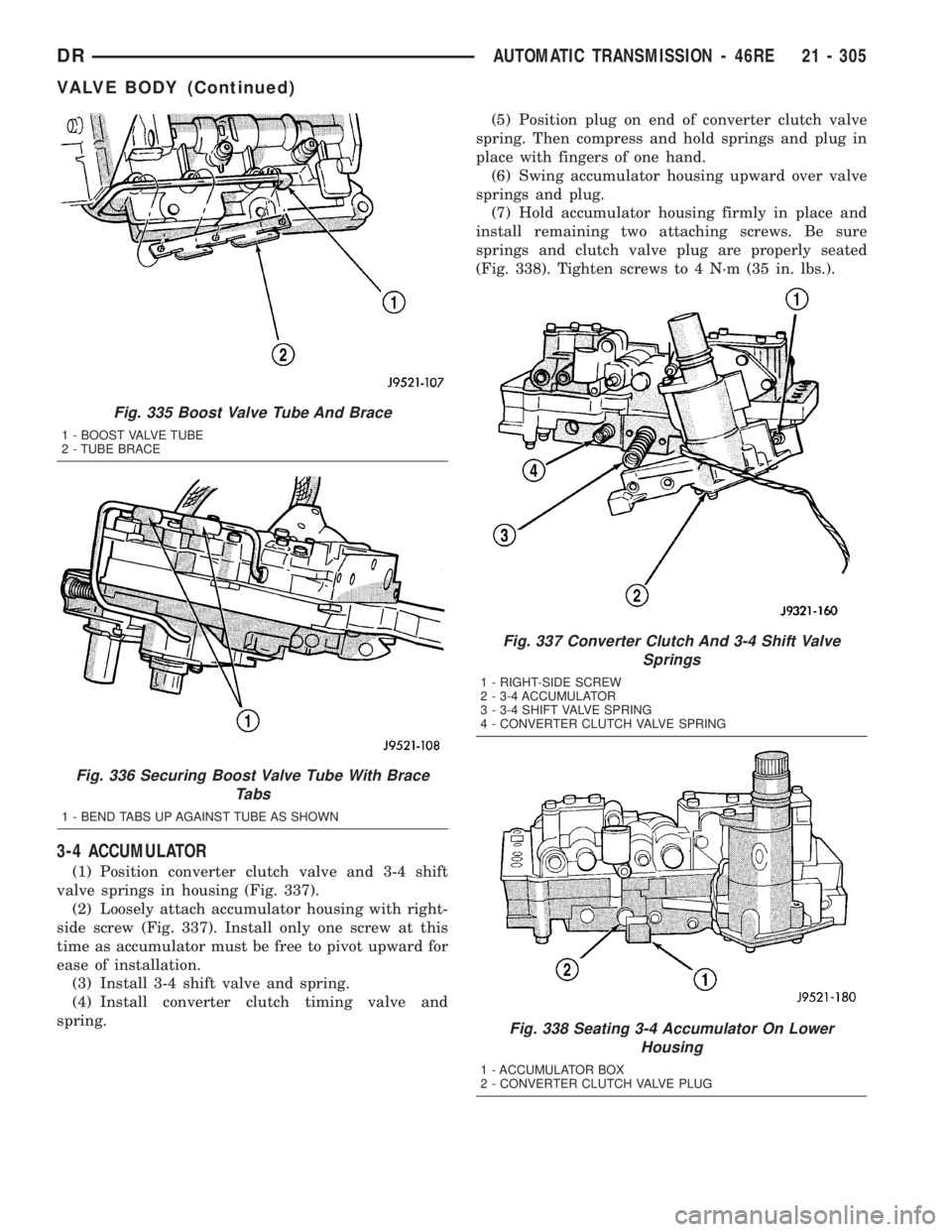

BOOST VALVE TUBE AND BRACE

(1) Position valve body assembly so lower housing

is facing upward (Fig. 334).

(2) Lubricate tube ends and housing ports with

transmission fluid or petroleum jelly.

(3) Start tube in lower housing port first. Then

swing tube downward and work opposite end of tube

into upper housing port (Fig. 334).

(4) Insert and seat each end of tube in housings.

(5) Slide tube brace under tube and into alignment

with valve body screw holes (Fig. 335).

(6) Install and finger tighten three screws that

secure tube brace to valve body housings (Fig. 335).

(7) Bend tube brace tabs up and against tube to

hold it in position (Fig. 336).

(8) Tighten all valve body housing screws to 4 N´m

(35 in. lbs.) torque after tube and brace are installed.

Tighten screws in diagonal pattern starting at center

and working outward.

Fig. 333 Upper Housing Shift Valve and Pressure Plug Locations

1 - UPPER HOUSING 8 - RETAINER

2 - 1-2 SHIFT VALVE AND SPRING 9 - 1-2 SHIFT CONTROL VALVE AND SPRING

3 - 2-3 SHIFT VALVE AND SPRING 10 - PRESSURE PLUG COVER

4 - 2-3 THROTTLE PLUG 11 - LINE PRESSURE PLUG

5 - LIMIT VALVE HOUSING 12 - PLUG SLEEVE

6 - LIMIT VALVE COVER 13 - THROTTLE PRESSURE SPRING AND PLUG

7 - LIMIT VALVE AND SPRING

Fig. 334 Boost Valve Tube

1 - BOOST VALVE TUBE

2 - LOWER HOUSING

3 - DISENGAGE THIS END OF TUBE FIRST

4 - UPPER HOUSING

21 - 304 AUTOMATIC TRANSMISSION - 46REDR

VALVE BODY (Continued)

Page 2144 of 2895

3-4 ACCUMULATOR

(1) Position converter clutch valve and 3-4 shift

valve springs in housing (Fig. 337).

(2) Loosely attach accumulator housing with right-

side screw (Fig. 337). Install only one screw at this

time as accumulator must be free to pivot upward for

ease of installation.

(3) Install 3-4 shift valve and spring.

(4) Install converter clutch timing valve and

spring.(5) Position plug on end of converter clutch valve

spring. Then compress and hold springs and plug in

place with fingers of one hand.

(6) Swing accumulator housing upward over valve

springs and plug.

(7) Hold accumulator housing firmly in place and

install remaining two attaching screws. Be sure

springs and clutch valve plug are properly seated

(Fig. 338). Tighten screws to 4 N´m (35 in. lbs.).

Fig. 335 Boost Valve Tube And Brace

1 - BOOST VALVE TUBE

2 - TUBE BRACE

Fig. 336 Securing Boost Valve Tube With Brace

Tabs

1 - BEND TABS UP AGAINST TUBE AS SHOWN

Fig. 337 Converter Clutch And 3-4 Shift Valve

Springs

1 - RIGHT-SIDE SCREW

2 - 3-4 ACCUMULATOR

3 - 3-4 SHIFT VALVE SPRING

4 - CONVERTER CLUTCH VALVE SPRING

Fig. 338 Seating 3-4 Accumulator On Lower

Housing

1 - ACCUMULATOR BOX

2 - CONVERTER CLUTCH VALVE PLUG

DRAUTOMATIC TRANSMISSION - 46RE 21 - 305

VALVE BODY (Continued)

Page 2216 of 2895

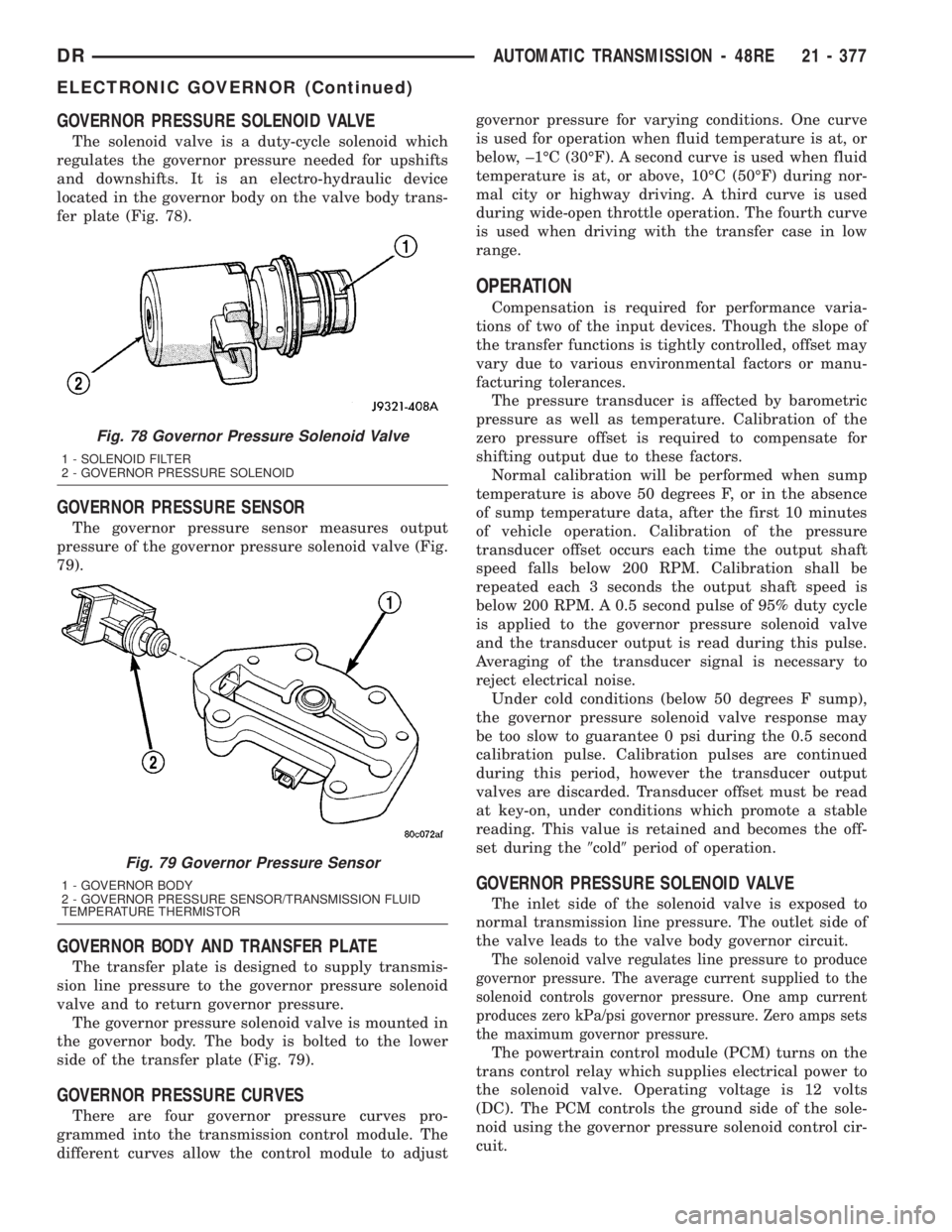

GOVERNOR PRESSURE SOLENOID VALVE

The solenoid valve is a duty-cycle solenoid which

regulates the governor pressure needed for upshifts

and downshifts. It is an electro-hydraulic device

located in the governor body on the valve body trans-

fer plate (Fig. 78).

GOVERNOR PRESSURE SENSOR

The governor pressure sensor measures output

pressure of the governor pressure solenoid valve (Fig.

79).

GOVERNOR BODY AND TRANSFER PLATE

The transfer plate is designed to supply transmis-

sion line pressure to the governor pressure solenoid

valve and to return governor pressure.

The governor pressure solenoid valve is mounted in

the governor body. The body is bolted to the lower

side of the transfer plate (Fig. 79).

GOVERNOR PRESSURE CURVES

There are four governor pressure curves pro-

grammed into the transmission control module. The

different curves allow the control module to adjustgovernor pressure for varying conditions. One curve

is used for operation when fluid temperature is at, or

below, ±1ÉC (30ÉF). A second curve is used when fluid

temperature is at, or above, 10ÉC (50ÉF) during nor-

mal city or highway driving. A third curve is used

during wide-open throttle operation. The fourth curve

is used when driving with the transfer case in low

range.

OPERATION

Compensation is required for performance varia-

tions of two of the input devices. Though the slope of

the transfer functions is tightly controlled, offset may

vary due to various environmental factors or manu-

facturing tolerances.

The pressure transducer is affected by barometric

pressure as well as temperature. Calibration of the

zero pressure offset is required to compensate for

shifting output due to these factors.

Normal calibration will be performed when sump

temperature is above 50 degrees F, or in the absence

of sump temperature data, after the first 10 minutes

of vehicle operation. Calibration of the pressure

transducer offset occurs each time the output shaft

speed falls below 200 RPM. Calibration shall be

repeated each 3 seconds the output shaft speed is

below 200 RPM. A 0.5 second pulse of 95% duty cycle

is applied to the governor pressure solenoid valve

and the transducer output is read during this pulse.

Averaging of the transducer signal is necessary to

reject electrical noise.

Under cold conditions (below 50 degrees F sump),

the governor pressure solenoid valve response may

be too slow to guarantee 0 psi during the 0.5 second

calibration pulse. Calibration pulses are continued

during this period, however the transducer output

valves are discarded. Transducer offset must be read

at key-on, under conditions which promote a stable

reading. This value is retained and becomes the off-

set during the9cold9period of operation.

GOVERNOR PRESSURE SOLENOID VALVE

The inlet side of the solenoid valve is exposed to

normal transmission line pressure. The outlet side of

the valve leads to the valve body governor circuit.

The solenoid valve regulates line pressure to produce

governor pressure. The average current supplied to the

solenoid controls governor pressure. One amp current

produces zero kPa/psi governor pressure. Zero amps sets

the maximum governor pressure.

The powertrain control module (PCM) turns on the

trans control relay which supplies electrical power to

the solenoid valve. Operating voltage is 12 volts

(DC). The PCM controls the ground side of the sole-

noid using the governor pressure solenoid control cir-

cuit.

Fig. 78 Governor Pressure Solenoid Valve

1 - SOLENOID FILTER

2 - GOVERNOR PRESSURE SOLENOID

Fig. 79 Governor Pressure Sensor

1 - GOVERNOR BODY

2 - GOVERNOR PRESSURE SENSOR/TRANSMISSION FLUID

TEMPERATURE THERMISTOR

DRAUTOMATIC TRANSMISSION - 48RE 21 - 377

ELECTRONIC GOVERNOR (Continued)

Page 2262 of 2895

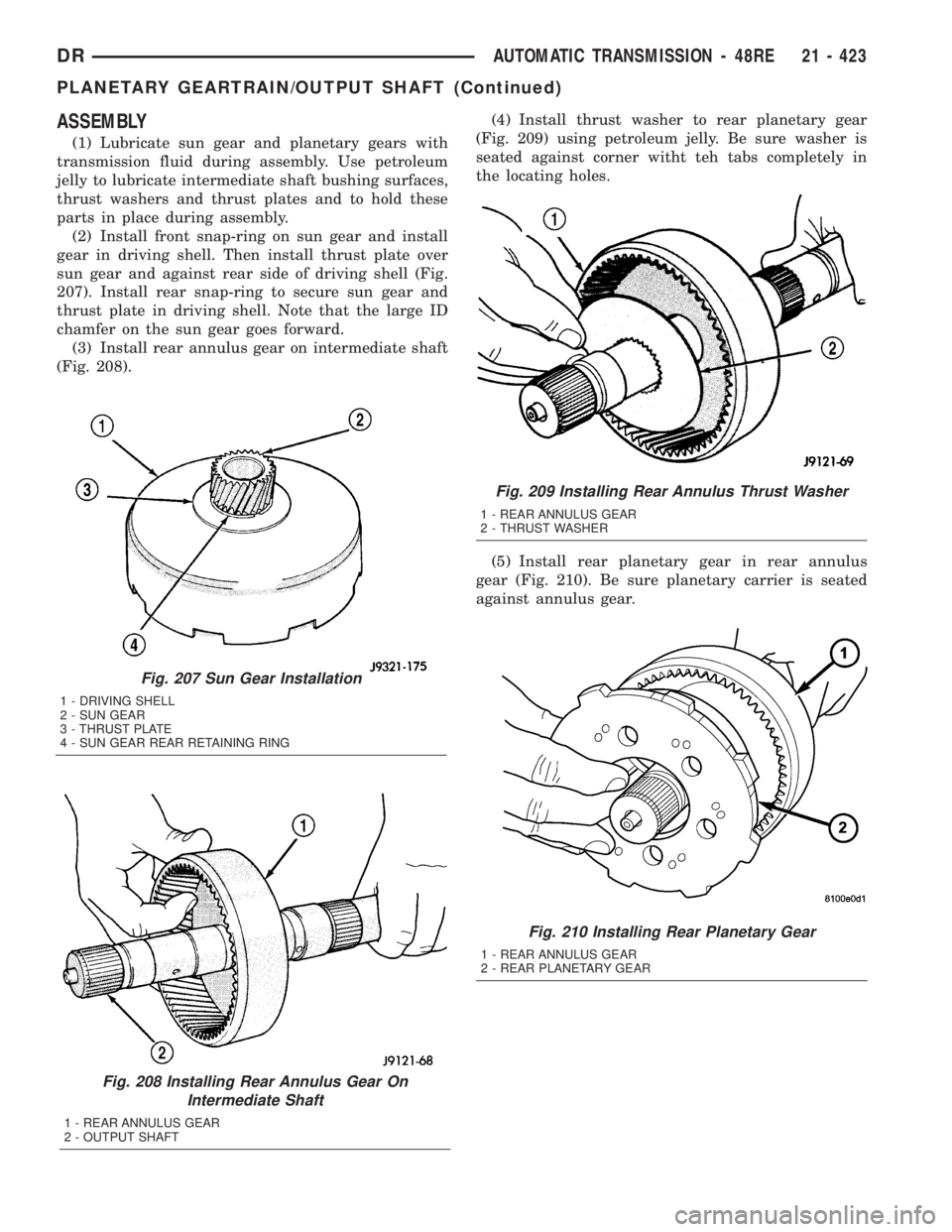

ASSEMBLY

(1) Lubricate sun gear and planetary gears with

transmission fluid during assembly. Use petroleum

jelly to lubricate intermediate shaft bushing surfaces,

thrust washers and thrust plates and to hold these

parts in place during assembly.

(2) Install front snap-ring on sun gear and install

gear in driving shell. Then install thrust plate over

sun gear and against rear side of driving shell (Fig.

207). Install rear snap-ring to secure sun gear and

thrust plate in driving shell. Note that the large ID

chamfer on the sun gear goes forward.

(3) Install rear annulus gear on intermediate shaft

(Fig. 208).(4) Install thrust washer to rear planetary gear

(Fig. 209) using petroleum jelly. Be sure washer is

seated against corner witht teh tabs completely in

the locating holes.

(5) Install rear planetary gear in rear annulus

gear (Fig. 210). Be sure planetary carrier is seated

against annulus gear.

Fig. 207 Sun Gear Installation

1 - DRIVING SHELL

2 - SUN GEAR

3 - THRUST PLATE

4 - SUN GEAR REAR RETAINING RING

Fig. 208 Installing Rear Annulus Gear On

Intermediate Shaft

1 - REAR ANNULUS GEAR

2 - OUTPUT SHAFT

Fig. 210 Installing Rear Planetary Gear

1 - REAR ANNULUS GEAR

2 - REAR PLANETARY GEAR

Fig. 209 Installing Rear Annulus Thrust Washer

1 - REAR ANNULUS GEAR

2 - THRUST WASHER

DRAUTOMATIC TRANSMISSION - 48RE 21 - 423

PLANETARY GEARTRAIN/OUTPUT SHAFT (Continued)

Page 2263 of 2895

(6) Install tabbed thrust washer on front face of

rear planetary gear (Fig. 211). Seat washer tabs in

matching slots in face of gear carrier. Use extra

petroleum jelly to hold washer in place if desired.

(7) Lubricate sun gear bushings with petroleum

jelly or transmission fluid.

(8) Install sun gear and driving shell on interme-

diate shaft (Fig. 212). Seat shell against rear plane-

tary gear. Verify that thrust washer on planetary

gear was not displaced during installation.

(9) Install tabbed thrust washer in driving shell

(Fig. 213), be sure washer tabs are seated in tab slots

of driving shell. Use extra petroleum jelly to hold

washer in place if desired.(10) Install tabbed thrust washer on front plane-

tary gear (Fig. 214). Seat washer tabs in matching

Fig. 211 Installing Rear Planetary Thrust Washer

1 - REAR PLANETARY GEAR

2 - TABBED THRUST WASHER

Fig. 212 Installing Sun Gear And Driving Shell

1 - OUTPUT SHAFT

2 - DRIVING SHELL

3 - REAR PLANETARY GEAR

4 - OUTPUT SHAFT

5 - SUN GEAR

Fig. 213 Installing Driving Shell Thrust Washer

1 - TAB SLOTS (3)

2 - DRIVING SHELL

3 - TABBED THRUST WASHER

Fig. 214 Installing Thrust Washer On Front

Planetary Gear

1 - TABBED THRUST WASHER

2 - FRONT PLANETARY GEAR

21 - 424 AUTOMATIC TRANSMISSION - 48REDR

PLANETARY GEARTRAIN/OUTPUT SHAFT (Continued)

Page 2309 of 2895

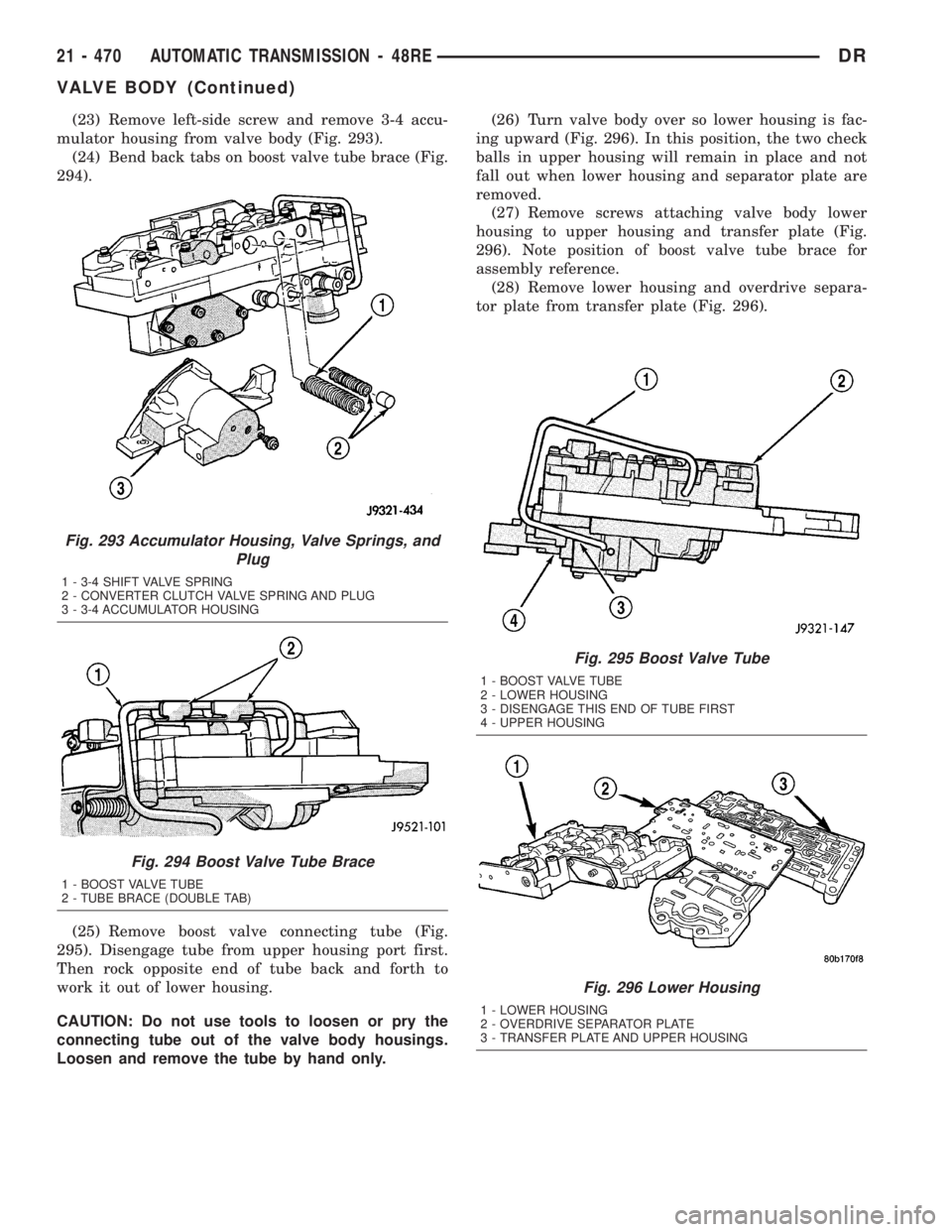

(23) Remove left-side screw and remove 3-4 accu-

mulator housing from valve body (Fig. 293).

(24) Bend back tabs on boost valve tube brace (Fig.

294).

(25) Remove boost valve connecting tube (Fig.

295). Disengage tube from upper housing port first.

Then rock opposite end of tube back and forth to

work it out of lower housing.

CAUTION: Do not use tools to loosen or pry the

connecting tube out of the valve body housings.

Loosen and remove the tube by hand only.(26) Turn valve body over so lower housing is fac-

ing upward (Fig. 296). In this position, the two check

balls in upper housing will remain in place and not

fall out when lower housing and separator plate are

removed.

(27) Remove screws attaching valve body lower

housing to upper housing and transfer plate (Fig.

296). Note position of boost valve tube brace for

assembly reference.

(28) Remove lower housing and overdrive separa-

tor plate from transfer plate (Fig. 296).

Fig. 295 Boost Valve Tube

1 - BOOST VALVE TUBE

2 - LOWER HOUSING

3 - DISENGAGE THIS END OF TUBE FIRST

4 - UPPER HOUSING

Fig. 296 Lower Housing

1 - LOWER HOUSING

2 - OVERDRIVE SEPARATOR PLATE

3 - TRANSFER PLATE AND UPPER HOUSING

Fig. 293 Accumulator Housing, Valve Springs, and

Plug

1 - 3-4 SHIFT VALVE SPRING

2 - CONVERTER CLUTCH VALVE SPRING AND PLUG

3 - 3-4 ACCUMULATOR HOUSING

Fig. 294 Boost Valve Tube Brace

1 - BOOST VALVE TUBE

2 - TUBE BRACE (DOUBLE TAB)

21 - 470 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 2323 of 2895

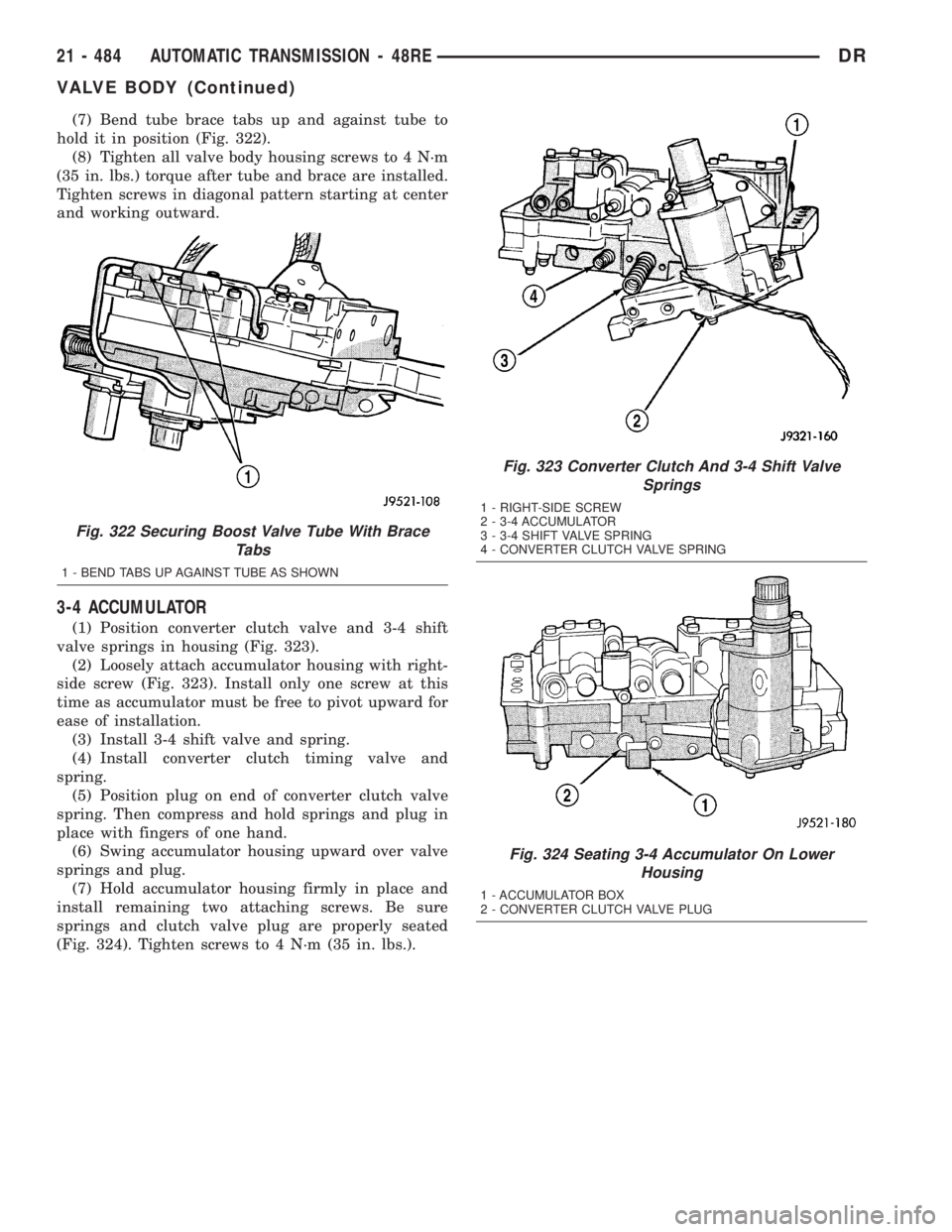

(7) Bend tube brace tabs up and against tube to

hold it in position (Fig. 322).

(8) Tighten all valve body housing screws to 4 N´m

(35 in. lbs.) torque after tube and brace are installed.

Tighten screws in diagonal pattern starting at center

and working outward.

3-4 ACCUMULATOR

(1) Position converter clutch valve and 3-4 shift

valve springs in housing (Fig. 323).

(2) Loosely attach accumulator housing with right-

side screw (Fig. 323). Install only one screw at this

time as accumulator must be free to pivot upward for

ease of installation.

(3) Install 3-4 shift valve and spring.

(4) Install converter clutch timing valve and

spring.

(5) Position plug on end of converter clutch valve

spring. Then compress and hold springs and plug in

place with fingers of one hand.

(6) Swing accumulator housing upward over valve

springs and plug.

(7) Hold accumulator housing firmly in place and

install remaining two attaching screws. Be sure

springs and clutch valve plug are properly seated

(Fig. 324). Tighten screws to 4 N´m (35 in. lbs.).

Fig. 322 Securing Boost Valve Tube With Brace

Tabs

1 - BEND TABS UP AGAINST TUBE AS SHOWN

Fig. 323 Converter Clutch And 3-4 Shift Valve

Springs

1 - RIGHT-SIDE SCREW

2 - 3-4 ACCUMULATOR

3 - 3-4 SHIFT VALVE SPRING

4 - CONVERTER CLUTCH VALVE SPRING

Fig. 324 Seating 3-4 Accumulator On Lower

Housing

1 - ACCUMULATOR BOX

2 - CONVERTER CLUTCH VALVE PLUG

21 - 484 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)