DODGE RAM 2003 Service Repair Manual

Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2251 of 2895

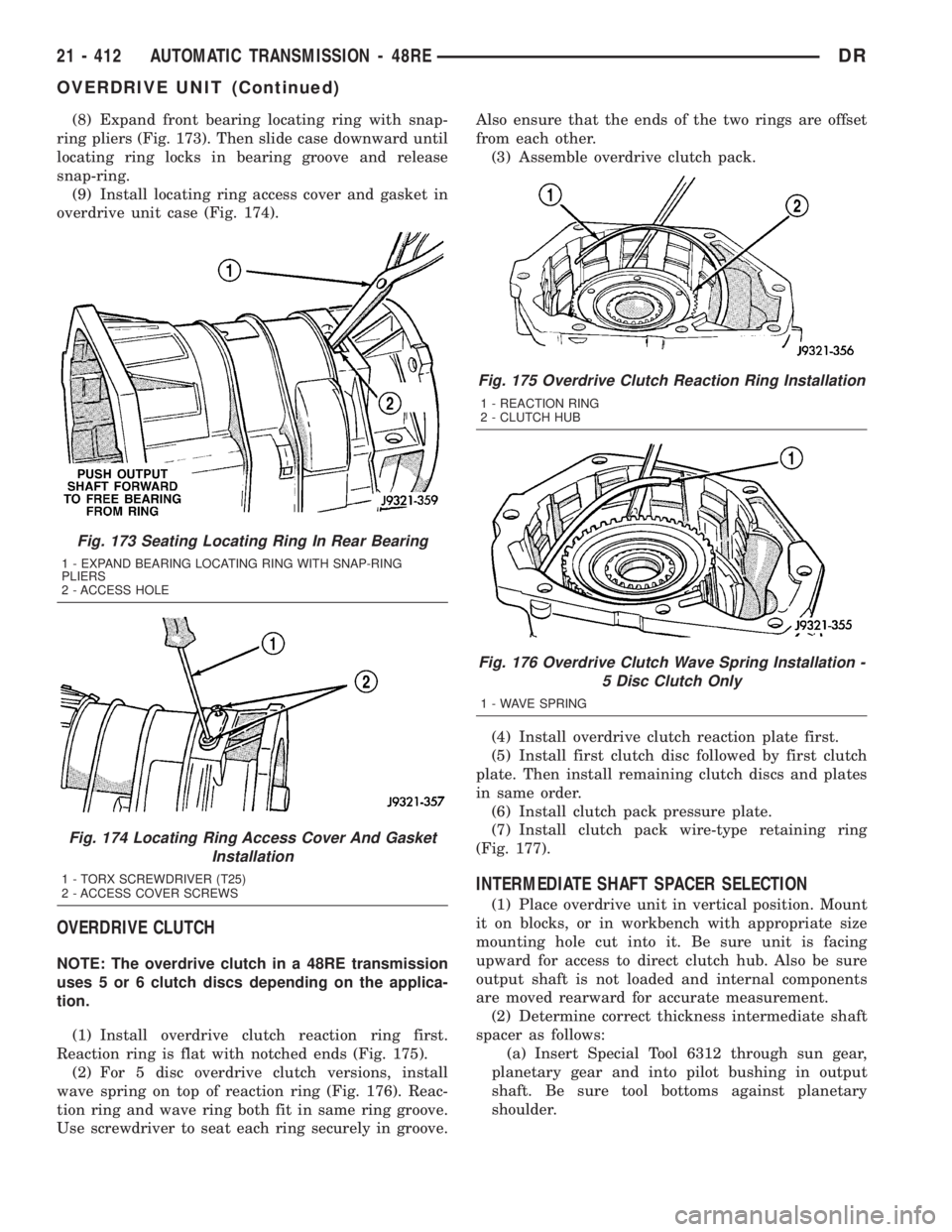

(8) Expand front bearing locating ring with snap-

ring pliers (Fig. 173). Then slide case downward until

locating ring locks in bearing groove and release

snap-ring.

(9) Install locating ring access cover and gasket in

overdrive unit case (Fig. 174).

OVERDRIVE CLUTCH

NOTE: The overdrive clutch in a 48RE transmission

uses 5 or 6 clutch discs depending on the applica-

tion.

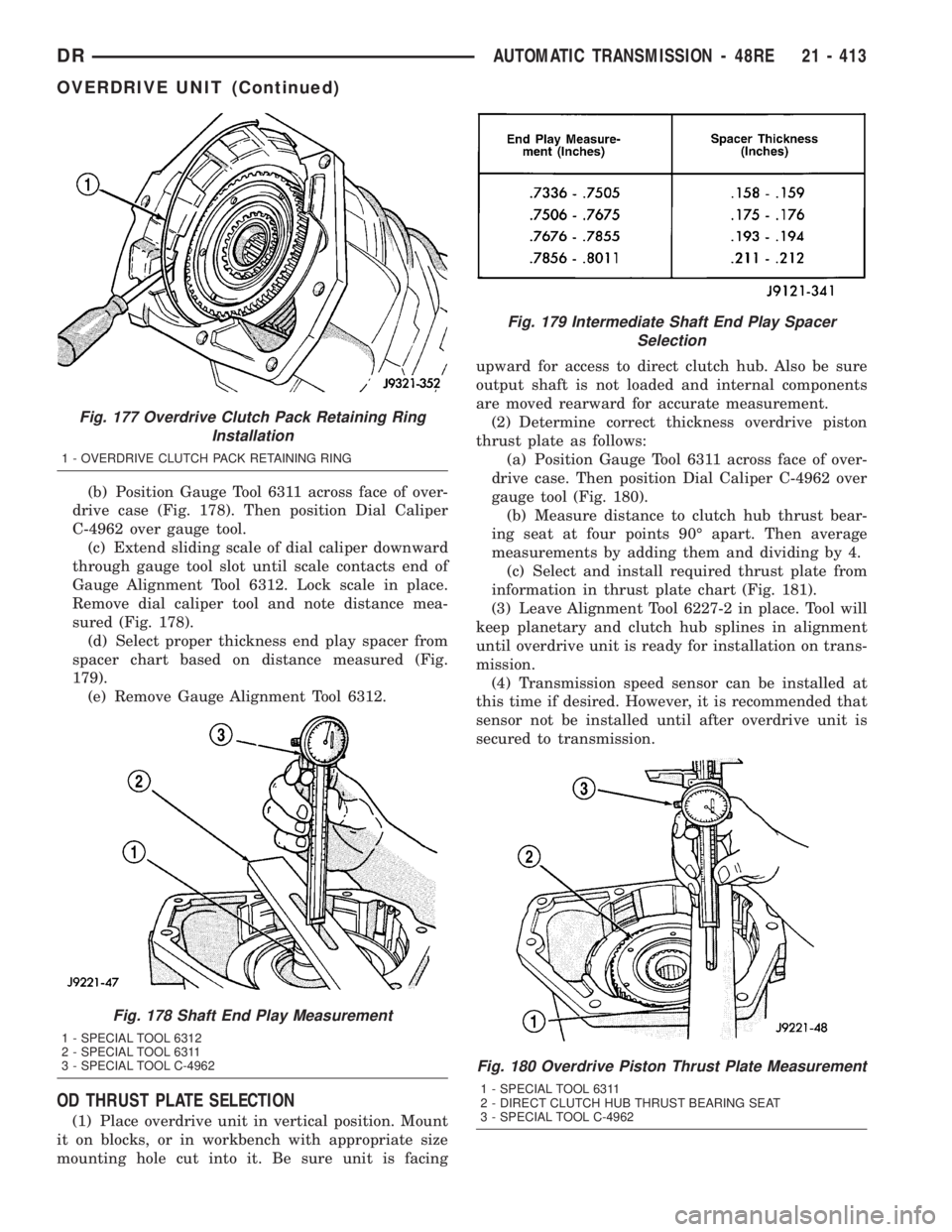

(1) Install overdrive clutch reaction ring first.

Reaction ring is flat with notched ends (Fig. 175).

(2) For 5 disc overdrive clutch versions, install

wave spring on top of reaction ring (Fig. 176). Reac-

tion ring and wave ring both fit in same ring groove.

Use screwdriver to seat each ring securely in groove.Also ensure that the ends of the two rings are offset

from each other.

(3) Assemble overdrive clutch pack.

(4) Install overdrive clutch reaction plate first.

(5) Install first clutch disc followed by first clutch

plate. Then install remaining clutch discs and plates

in same order.

(6) Install clutch pack pressure plate.

(7) Install clutch pack wire-type retaining ring

(Fig. 177).

INTERMEDIATE SHAFT SPACER SELECTION

(1) Place overdrive unit in vertical position. Mount

it on blocks, or in workbench with appropriate size

mounting hole cut into it. Be sure unit is facing

upward for access to direct clutch hub. Also be sure

output shaft is not loaded and internal components

are moved rearward for accurate measurement.

(2) Determine correct thickness intermediate shaft

spacer as follows:

(a) Insert Special Tool 6312 through sun gear,

planetary gear and into pilot bushing in output

shaft. Be sure tool bottoms against planetary

shoulder.

Fig. 173 Seating Locating Ring In Rear Bearing

1 - EXPAND BEARING LOCATING RING WITH SNAP-RING

PLIERS

2 - ACCESS HOLE

Fig. 174 Locating Ring Access Cover And Gasket

Installation

1 - TORX SCREWDRIVER (T25)

2 - ACCESS COVER SCREWS

Fig. 175 Overdrive Clutch Reaction Ring Installation

1 - REACTION RING

2 - CLUTCH HUB

Fig. 176 Overdrive Clutch Wave Spring Installation -

5 Disc Clutch Only

1 - WAVE SPRING

21 - 412 AUTOMATIC TRANSMISSION - 48REDR

OVERDRIVE UNIT (Continued)

Page 2252 of 2895

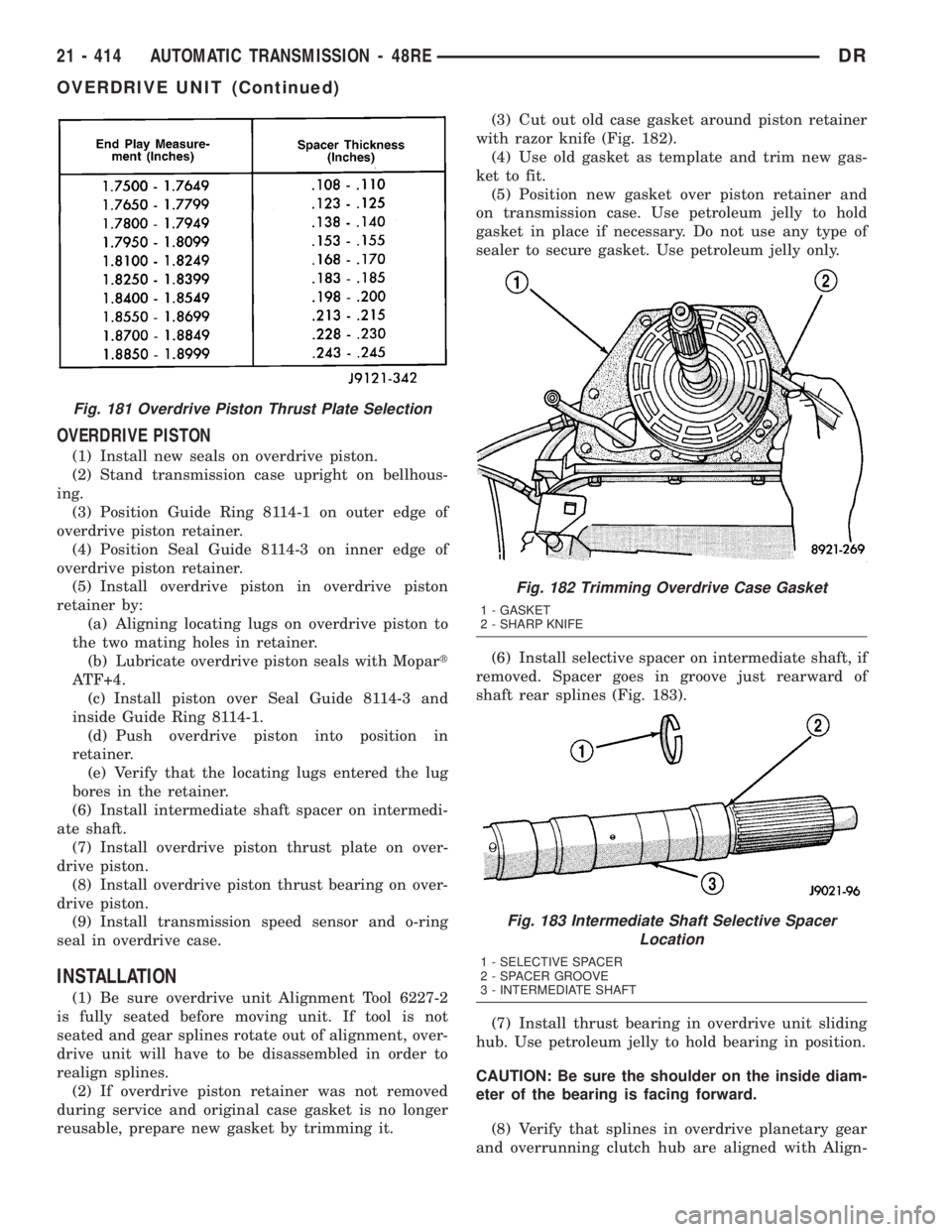

(b) Position Gauge Tool 6311 across face of over-

drive case (Fig. 178). Then position Dial Caliper

C-4962 over gauge tool.

(c) Extend sliding scale of dial caliper downward

through gauge tool slot until scale contacts end of

Gauge Alignment Tool 6312. Lock scale in place.

Remove dial caliper tool and note distance mea-

sured (Fig. 178).

(d) Select proper thickness end play spacer from

spacer chart based on distance measured (Fig.

179).

(e) Remove Gauge Alignment Tool 6312.

OD THRUST PLATE SELECTION

(1) Place overdrive unit in vertical position. Mount

it on blocks, or in workbench with appropriate size

mounting hole cut into it. Be sure unit is facingupward for access to direct clutch hub. Also be sure

output shaft is not loaded and internal components

are moved rearward for accurate measurement.

(2) Determine correct thickness overdrive piston

thrust plate as follows:

(a) Position Gauge Tool 6311 across face of over-

drive case. Then position Dial Caliper C-4962 over

gauge tool (Fig. 180).

(b) Measure distance to clutch hub thrust bear-

ing seat at four points 90É apart. Then average

measurements by adding them and dividing by 4.

(c) Select and install required thrust plate from

information in thrust plate chart (Fig. 181).

(3) Leave Alignment Tool 6227-2 in place. Tool will

keep planetary and clutch hub splines in alignment

until overdrive unit is ready for installation on trans-

mission.

(4) Transmission speed sensor can be installed at

this time if desired. However, it is recommended that

sensor not be installed until after overdrive unit is

secured to transmission.

Fig. 177 Overdrive Clutch Pack Retaining Ring

Installation

1 - OVERDRIVE CLUTCH PACK RETAINING RING

Fig. 178 Shaft End Play Measurement

1 - SPECIAL TOOL 6312

2 - SPECIAL TOOL 6311

3 - SPECIAL TOOL C-4962

Fig. 179 Intermediate Shaft End Play Spacer

Selection

Fig. 180 Overdrive Piston Thrust Plate Measurement

1 - SPECIAL TOOL 6311

2 - DIRECT CLUTCH HUB THRUST BEARING SEAT

3 - SPECIAL TOOL C-4962

DRAUTOMATIC TRANSMISSION - 48RE 21 - 413

OVERDRIVE UNIT (Continued)

Page 2253 of 2895

OVERDRIVE PISTON

(1) Install new seals on overdrive piston.

(2) Stand transmission case upright on bellhous-

ing.

(3) Position Guide Ring 8114-1 on outer edge of

overdrive piston retainer.

(4) Position Seal Guide 8114-3 on inner edge of

overdrive piston retainer.

(5) Install overdrive piston in overdrive piston

retainer by:

(a) Aligning locating lugs on overdrive piston to

the two mating holes in retainer.

(b) Lubricate overdrive piston seals with Mopart

ATF+4.

(c) Install piston over Seal Guide 8114-3 and

inside Guide Ring 8114-1.

(d) Push overdrive piston into position in

retainer.

(e) Verify that the locating lugs entered the lug

bores in the retainer.

(6) Install intermediate shaft spacer on intermedi-

ate shaft.

(7) Install overdrive piston thrust plate on over-

drive piston.

(8) Install overdrive piston thrust bearing on over-

drive piston.

(9) Install transmission speed sensor and o-ring

seal in overdrive case.

INSTALLATION

(1) Be sure overdrive unit Alignment Tool 6227-2

is fully seated before moving unit. If tool is not

seated and gear splines rotate out of alignment, over-

drive unit will have to be disassembled in order to

realign splines.

(2) If overdrive piston retainer was not removed

during service and original case gasket is no longer

reusable, prepare new gasket by trimming it.(3) Cut out old case gasket around piston retainer

with razor knife (Fig. 182).

(4) Use old gasket as template and trim new gas-

ket to fit.

(5) Position new gasket over piston retainer and

on transmission case. Use petroleum jelly to hold

gasket in place if necessary. Do not use any type of

sealer to secure gasket. Use petroleum jelly only.

(6) Install selective spacer on intermediate shaft, if

removed. Spacer goes in groove just rearward of

shaft rear splines (Fig. 183).

(7) Install thrust bearing in overdrive unit sliding

hub. Use petroleum jelly to hold bearing in position.

CAUTION: Be sure the shoulder on the inside diam-

eter of the bearing is facing forward.

(8) Verify that splines in overdrive planetary gear

and overrunning clutch hub are aligned with Align-

Fig. 181 Overdrive Piston Thrust Plate Selection

Fig. 182 Trimming Overdrive Case Gasket

1 - GASKET

2 - SHARP KNIFE

Fig. 183 Intermediate Shaft Selective Spacer

Location

1 - SELECTIVE SPACER

2 - SPACER GROOVE

3 - INTERMEDIATE SHAFT

21 - 414 AUTOMATIC TRANSMISSION - 48REDR

OVERDRIVE UNIT (Continued)

Page 2254 of 2895

ment Tool 6227-2. Overdrive unit cannot be installed

if splines are not aligned. If splines have rotated out

of alignment, unit will have to be disassembled to

realign splines.

(9)

Carefully slide Alignment Tool 6227-2 out of over-

drive planetary gear and overrunning clutch splines.

(10) Raise overdrive unit and carefully slide it

straight onto intermediate shaft. Insert park rod into

park lock reaction plug at same time. Avoid tilting

overdrive during installation as this could cause

planetary gear and overrunning clutch splines to

rotate out of alignment. If this occurs, it will be nec-

essary to remove and disassemble overdrive unit to

realign splines.

(11) Work overdrive unit forward on intermediate

shaft until seated against transmission case.

(12) Install bolts attaching overdrive unit to trans-

mission unit. Tighten bolts in diagonal pattern to 34

N´m (25 ft-lbs).

(13) Connect the transmission speed sensor and

overdrive wiring connectors.

(14) Install the transfer case, if equipped.

(15) Align and install rear propeller shaft, if nec-

essary. (Refer to 3 - DIFFERENTIAL & DRIVELINE/

PROPELLER SHAFT/PROPELLER SHAFT -

INSTALLATION)

OVERRUNNING CLUTCH

CAM/OVERDRIVE PISTON

RETAINER

DESCRIPTION

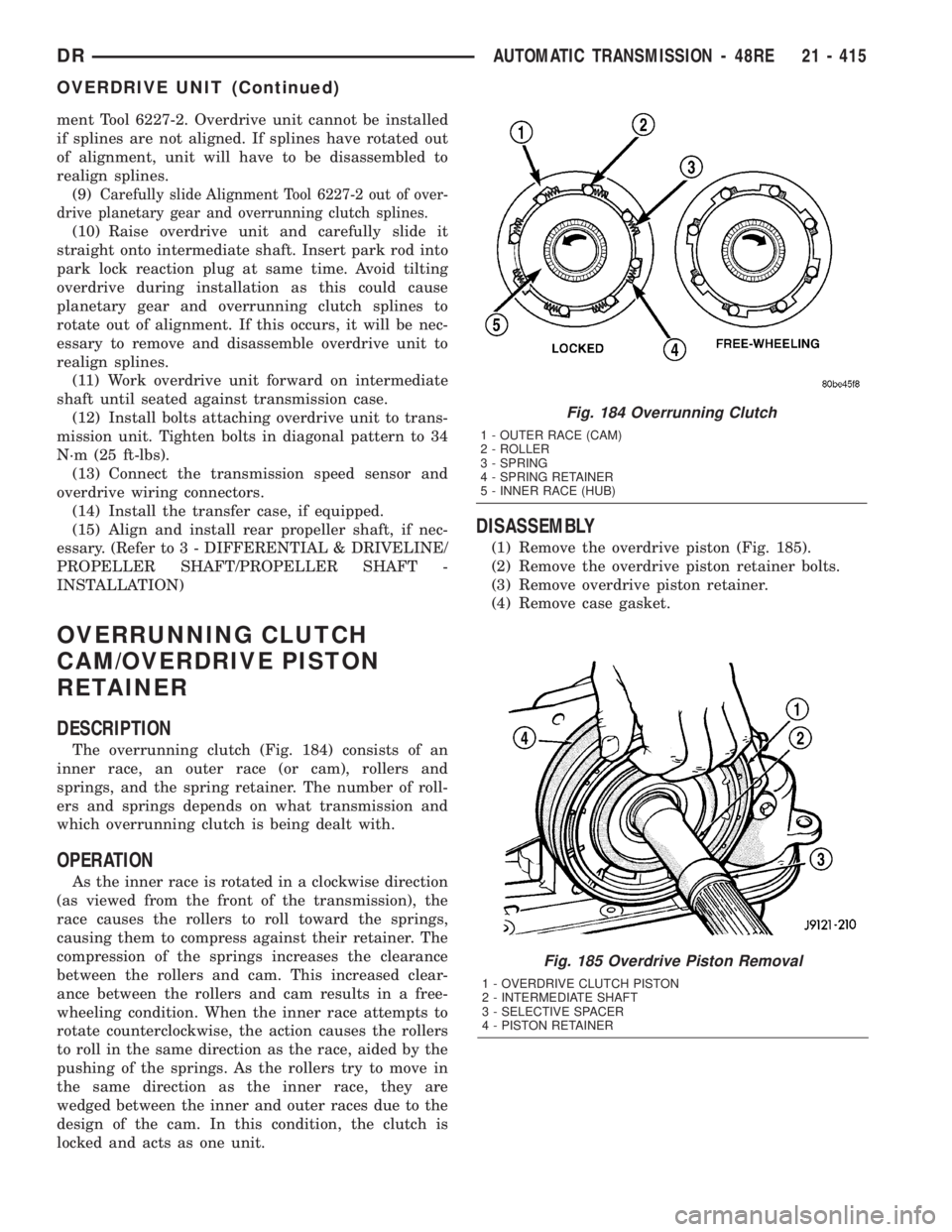

The overrunning clutch (Fig. 184) consists of an

inner race, an outer race (or cam), rollers and

springs, and the spring retainer. The number of roll-

ers and springs depends on what transmission and

which overrunning clutch is being dealt with.

OPERATION

As the inner race is rotated in a clockwise direction

(as viewed from the front of the transmission), the

race causes the rollers to roll toward the springs,

causing them to compress against their retainer. The

compression of the springs increases the clearance

between the rollers and cam. This increased clear-

ance between the rollers and cam results in a free-

wheeling condition. When the inner race attempts to

rotate counterclockwise, the action causes the rollers

to roll in the same direction as the race, aided by the

pushing of the springs. As the rollers try to move in

the same direction as the inner race, they are

wedged between the inner and outer races due to the

design of the cam. In this condition, the clutch is

locked and acts as one unit.

DISASSEMBLY

(1) Remove the overdrive piston (Fig. 185).

(2) Remove the overdrive piston retainer bolts.

(3) Remove overdrive piston retainer.

(4) Remove case gasket.

Fig. 185 Overdrive Piston Removal

1 - OVERDRIVE CLUTCH PISTON

2 - INTERMEDIATE SHAFT

3 - SELECTIVE SPACER

4 - PISTON RETAINER

Fig. 184 Overrunning Clutch

1 - OUTER RACE (CAM)

2 - ROLLER

3 - SPRING

4 - SPRING RETAINER

5 - INNER RACE (HUB)

DRAUTOMATIC TRANSMISSION - 48RE 21 - 415

OVERDRIVE UNIT (Continued)

Page 2255 of 2895

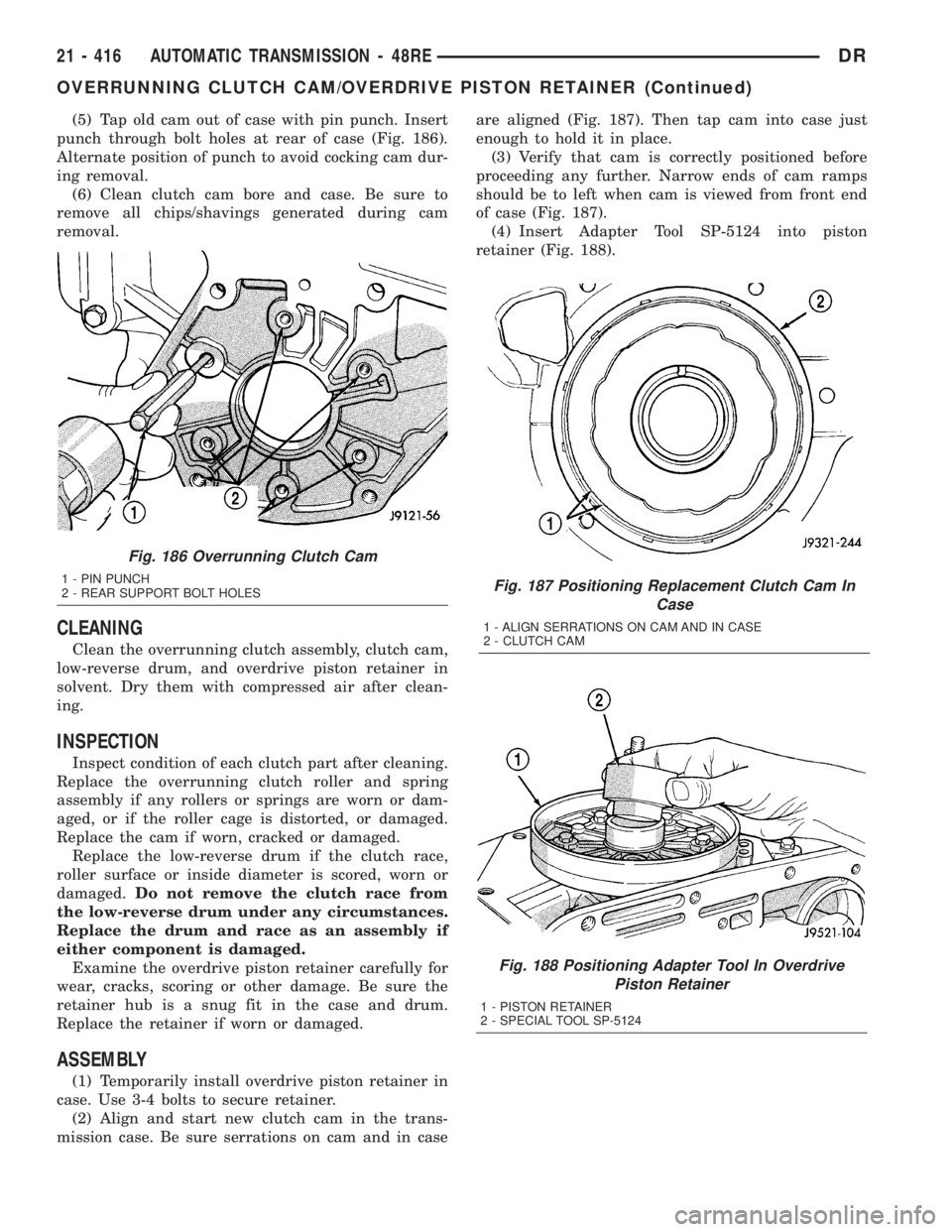

(5) Tap old cam out of case with pin punch. Insert

punch through bolt holes at rear of case (Fig. 186).

Alternate position of punch to avoid cocking cam dur-

ing removal.

(6) Clean clutch cam bore and case. Be sure to

remove all chips/shavings generated during cam

removal.

CLEANING

Clean the overrunning clutch assembly, clutch cam,

low-reverse drum, and overdrive piston retainer in

solvent. Dry them with compressed air after clean-

ing.

INSPECTION

Inspect condition of each clutch part after cleaning.

Replace the overrunning clutch roller and spring

assembly if any rollers or springs are worn or dam-

aged, or if the roller cage is distorted, or damaged.

Replace the cam if worn, cracked or damaged.

Replace the low-reverse drum if the clutch race,

roller surface or inside diameter is scored, worn or

damaged.Do not remove the clutch race from

the low-reverse drum under any circumstances.

Replace the drum and race as an assembly if

either component is damaged.

Examine the overdrive piston retainer carefully for

wear, cracks, scoring or other damage. Be sure the

retainer hub is a snug fit in the case and drum.

Replace the retainer if worn or damaged.

ASSEMBLY

(1) Temporarily install overdrive piston retainer in

case. Use 3-4 bolts to secure retainer.

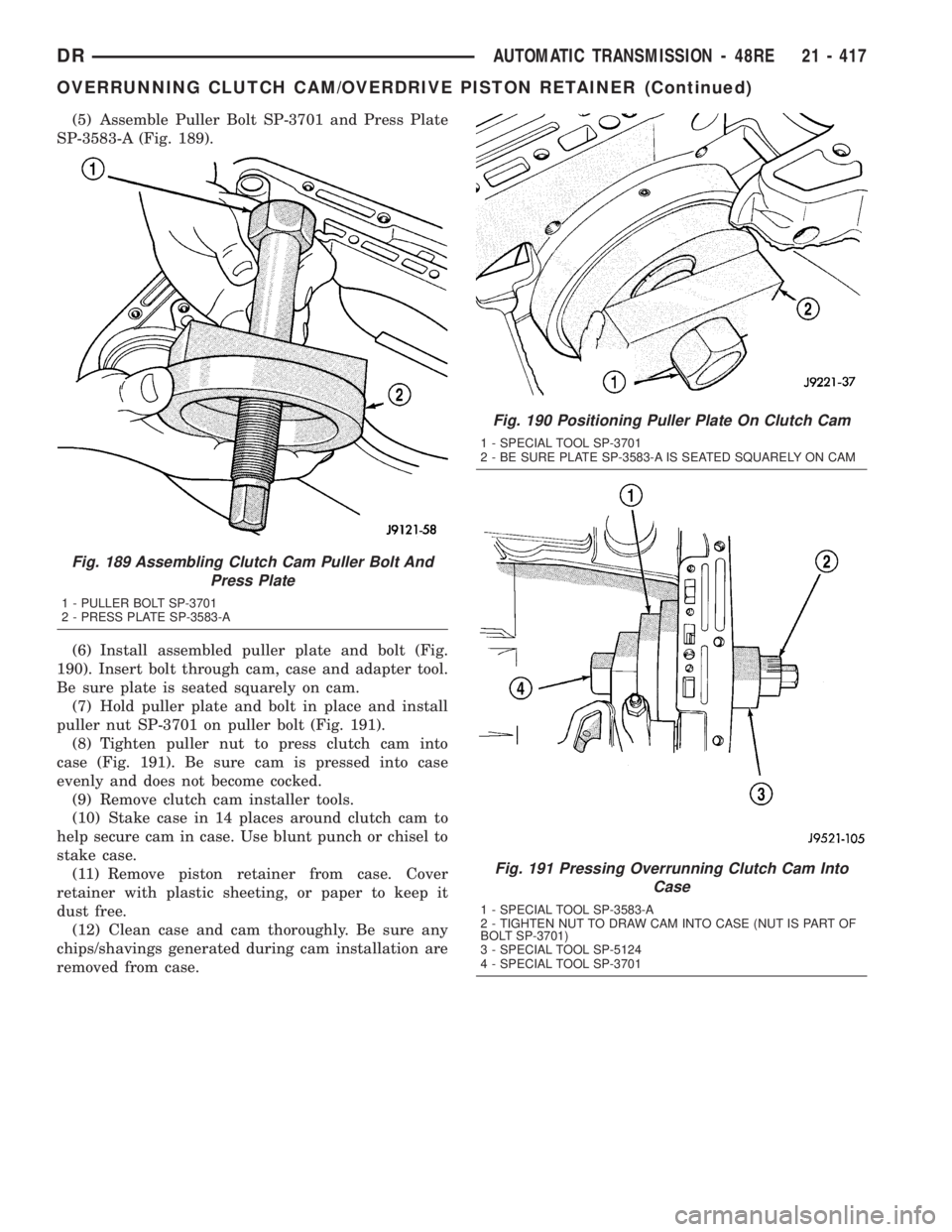

(2) Align and start new clutch cam in the trans-

mission case. Be sure serrations on cam and in caseare aligned (Fig. 187). Then tap cam into case just

enough to hold it in place.

(3) Verify that cam is correctly positioned before

proceeding any further. Narrow ends of cam ramps

should be to left when cam is viewed from front end

of case (Fig. 187).

(4) Insert Adapter Tool SP-5124 into piston

retainer (Fig. 188).

Fig. 187 Positioning Replacement Clutch Cam In

Case

1 - ALIGN SERRATIONS ON CAM AND IN CASE

2 - CLUTCH CAM

Fig. 188 Positioning Adapter Tool In Overdrive

Piston Retainer

1 - PISTON RETAINER

2 - SPECIAL TOOL SP-5124

Fig. 186 Overrunning Clutch Cam

1 - PIN PUNCH

2 - REAR SUPPORT BOLT HOLES

21 - 416 AUTOMATIC TRANSMISSION - 48REDR

OVERRUNNING CLUTCH CAM/OVERDRIVE PISTON RETAINER (Continued)

Page 2256 of 2895

(5) Assemble Puller Bolt SP-3701 and Press Plate

SP-3583-A (Fig. 189).

(6) Install assembled puller plate and bolt (Fig.

190). Insert bolt through cam, case and adapter tool.

Be sure plate is seated squarely on cam.

(7) Hold puller plate and bolt in place and install

puller nut SP-3701 on puller bolt (Fig. 191).

(8) Tighten puller nut to press clutch cam into

case (Fig. 191). Be sure cam is pressed into case

evenly and does not become cocked.

(9) Remove clutch cam installer tools.

(10) Stake case in 14 places around clutch cam to

help secure cam in case. Use blunt punch or chisel to

stake case.

(11) Remove piston retainer from case. Cover

retainer with plastic sheeting, or paper to keep it

dust free.

(12) Clean case and cam thoroughly. Be sure any

chips/shavings generated during cam installation are

removed from case.

Fig. 189 Assembling Clutch Cam Puller Bolt And

Press Plate

1 - PULLER BOLT SP-3701

2 - PRESS PLATE SP-3583-A

Fig. 190 Positioning Puller Plate On Clutch Cam

1 - SPECIAL TOOL SP-3701

2 - BE SURE PLATE SP-3583-A IS SEATED SQUARELY ON CAM

Fig. 191 Pressing Overrunning Clutch Cam Into

Case

1 - SPECIAL TOOL SP-3583-A

2 - TIGHTEN NUT TO DRAW CAM INTO CASE (NUT IS PART OF

BOLT SP-3701)

3 - SPECIAL TOOL SP-5124

4 - SPECIAL TOOL SP-3701

DRAUTOMATIC TRANSMISSION - 48RE 21 - 417

OVERRUNNING CLUTCH CAM/OVERDRIVE PISTON RETAINER (Continued)

Page 2257 of 2895

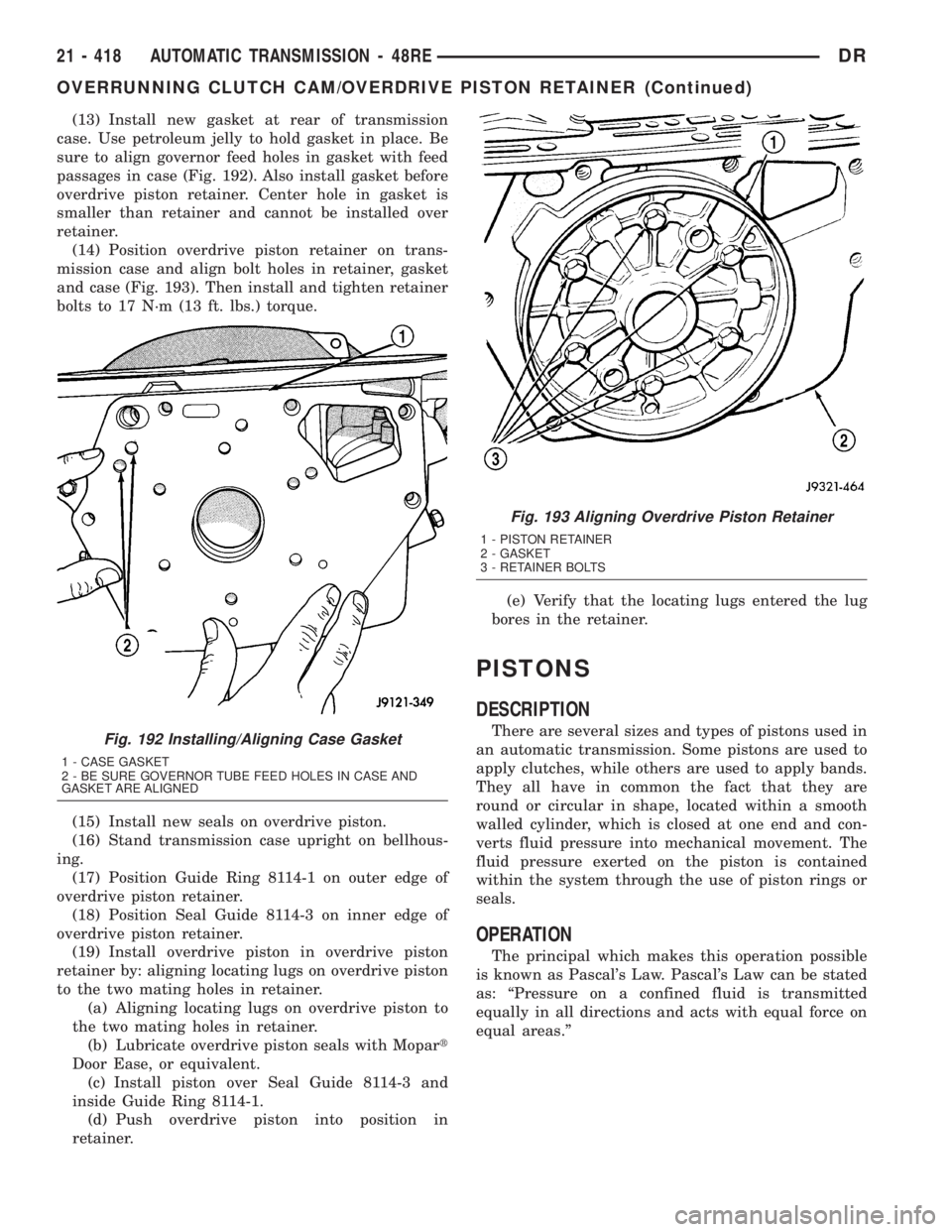

(13) Install new gasket at rear of transmission

case. Use petroleum jelly to hold gasket in place. Be

sure to align governor feed holes in gasket with feed

passages in case (Fig. 192). Also install gasket before

overdrive piston retainer. Center hole in gasket is

smaller than retainer and cannot be installed over

retainer.

(14) Position overdrive piston retainer on trans-

mission case and align bolt holes in retainer, gasket

and case (Fig. 193). Then install and tighten retainer

bolts to 17 N´m (13 ft. lbs.) torque.

(15) Install new seals on overdrive piston.

(16) Stand transmission case upright on bellhous-

ing.

(17) Position Guide Ring 8114-1 on outer edge of

overdrive piston retainer.

(18) Position Seal Guide 8114-3 on inner edge of

overdrive piston retainer.

(19) Install overdrive piston in overdrive piston

retainer by: aligning locating lugs on overdrive piston

to the two mating holes in retainer.

(a) Aligning locating lugs on overdrive piston to

the two mating holes in retainer.

(b) Lubricate overdrive piston seals with Mopart

Door Ease, or equivalent.

(c) Install piston over Seal Guide 8114-3 and

inside Guide Ring 8114-1.

(d) Push overdrive piston into position in

retainer.(e) Verify that the locating lugs entered the lug

bores in the retainer.

PISTONS

DESCRIPTION

There are several sizes and types of pistons used in

an automatic transmission. Some pistons are used to

apply clutches, while others are used to apply bands.

They all have in common the fact that they are

round or circular in shape, located within a smooth

walled cylinder, which is closed at one end and con-

verts fluid pressure into mechanical movement. The

fluid pressure exerted on the piston is contained

within the system through the use of piston rings or

seals.

OPERATION

The principal which makes this operation possible

is known as Pascal's Law. Pascal's Law can be stated

as: ªPressure on a confined fluid is transmitted

equally in all directions and acts with equal force on

equal areas.º

Fig. 192 Installing/Aligning Case Gasket

1 - CASE GASKET

2 - BE SURE GOVERNOR TUBE FEED HOLES IN CASE AND

GASKET ARE ALIGNED

Fig. 193 Aligning Overdrive Piston Retainer

1 - PISTON RETAINER

2 - GASKET

3 - RETAINER BOLTS

21 - 418 AUTOMATIC TRANSMISSION - 48REDR

OVERRUNNING CLUTCH CAM/OVERDRIVE PISTON RETAINER (Continued)

Page 2258 of 2895

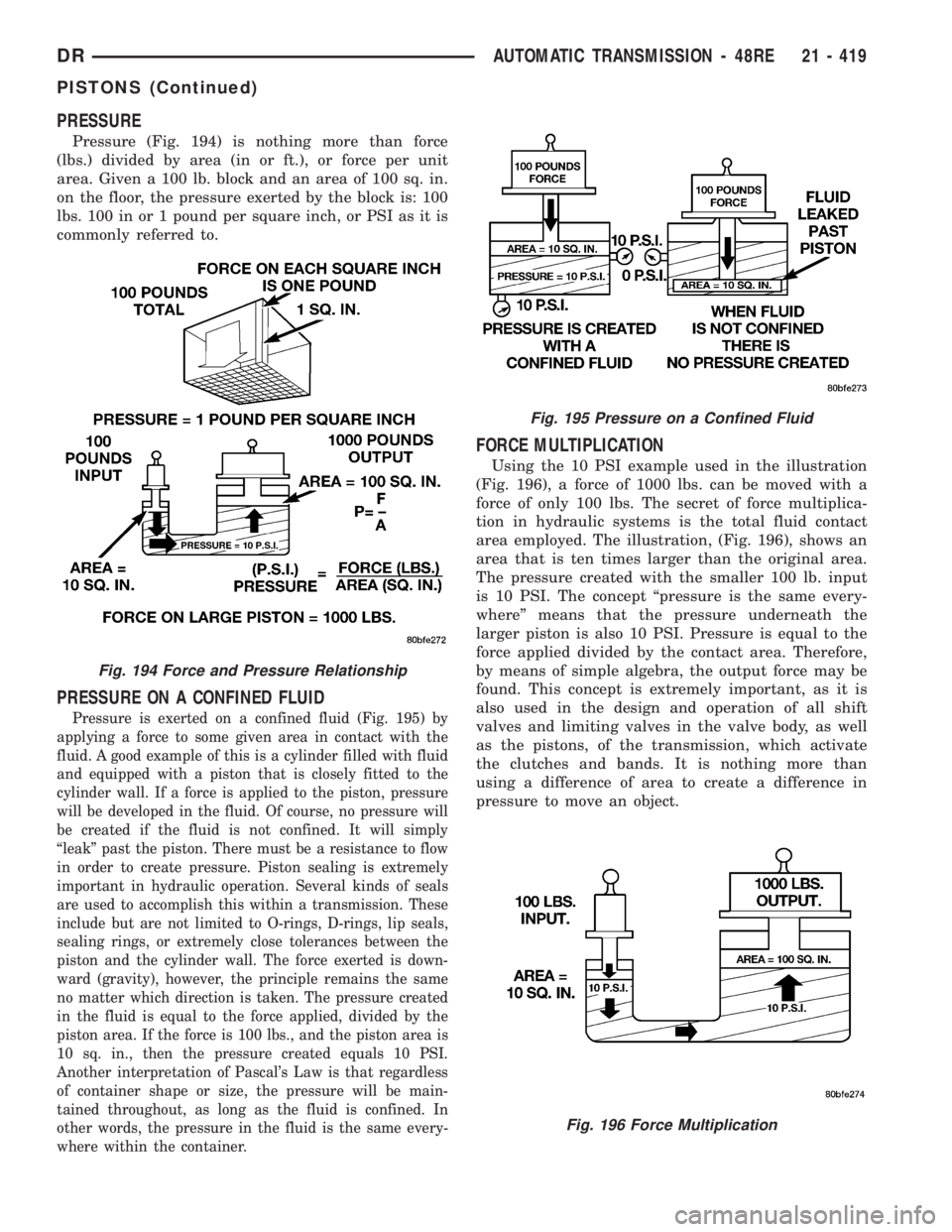

PRESSURE

Pressure (Fig. 194) is nothing more than force

(lbs.) divided by area (in or ft.), or force per unit

area. Given a 100 lb. block and an area of 100 sq. in.

on the floor, the pressure exerted by the block is: 100

lbs. 100 in or 1 pound per square inch, or PSI as it is

commonly referred to.

PRESSURE ON A CONFINED FLUID

Pressure is exerted on a confined fluid (Fig. 195) by

applying a force to some given area in contact with the

fluid. A good example of this is a cylinder filled with fluid

and equipped with a piston that is closely fitted to the

cylinder wall. If a force is applied to the piston, pressure

will be developed in the fluid. Of course, no pressure will

be created if the fluid is not confined. It will simply

ªleakº past the piston. There must be a resistance to flow

in order to create pressure. Piston sealing is extremely

important in hydraulic operation. Several kinds of seals

are used to accomplish this within a transmission. These

include but are not limited to O-rings, D-rings, lip seals,

sealing rings, or extremely close tolerances between the

piston and the cylinder wall. The force exerted is down-

ward (gravity), however, the principle remains the same

no matter which direction is taken. The pressure created

in the fluid is equal to the force applied, divided by the

piston area. If the force is 100 lbs., and the piston area is

10 sq. in., then the pressure created equals 10 PSI.

Another interpretation of Pascal's Law is that regardless

of container shape or size, the pressure will be main-

tained throughout, as long as the fluid is confined. In

other words, the pressure in the fluid is the same every-

where within the container.

FORCE MULTIPLICATION

Using the 10 PSI example used in the illustration

(Fig. 196), a force of 1000 lbs. can be moved with a

force of only 100 lbs. The secret of force multiplica-

tion in hydraulic systems is the total fluid contact

area employed. The illustration, (Fig. 196), shows an

area that is ten times larger than the original area.

The pressure created with the smaller 100 lb. input

is 10 PSI. The concept ªpressure is the same every-

whereº means that the pressure underneath the

larger piston is also 10 PSI. Pressure is equal to the

force applied divided by the contact area. Therefore,

by means of simple algebra, the output force may be

found. This concept is extremely important, as it is

also used in the design and operation of all shift

valves and limiting valves in the valve body, as well

as the pistons, of the transmission, which activate

the clutches and bands. It is nothing more than

using a difference of area to create a difference in

pressure to move an object.

Fig. 194 Force and Pressure Relationship

Fig. 195 Pressure on a Confined Fluid

Fig. 196 Force Multiplication

DRAUTOMATIC TRANSMISSION - 48RE 21 - 419

PISTONS (Continued)

Page 2259 of 2895

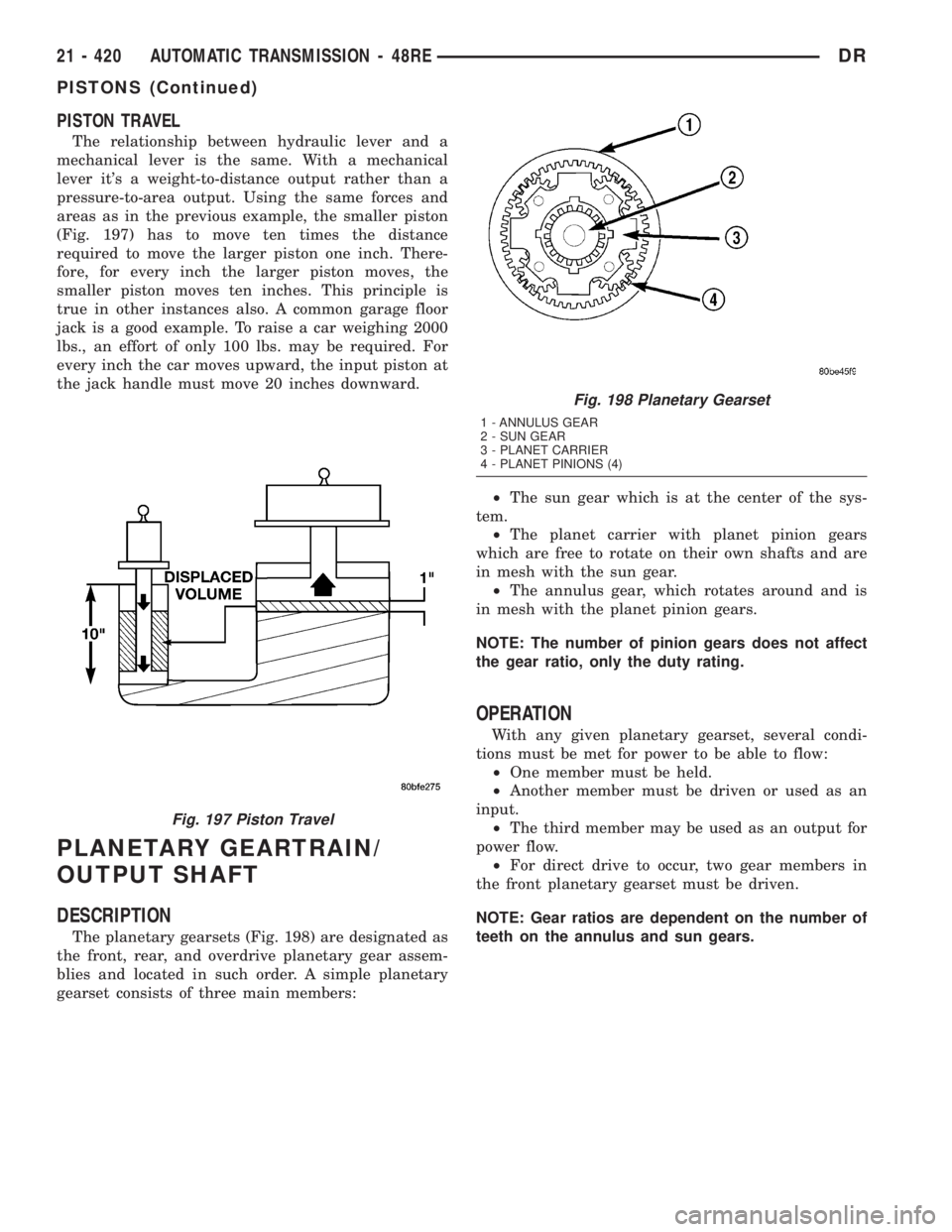

PISTON TRAVEL

The relationship between hydraulic lever and a

mechanical lever is the same. With a mechanical

lever it's a weight-to-distance output rather than a

pressure-to-area output. Using the same forces and

areas as in the previous example, the smaller piston

(Fig. 197) has to move ten times the distance

required to move the larger piston one inch. There-

fore, for every inch the larger piston moves, the

smaller piston moves ten inches. This principle is

true in other instances also. A common garage floor

jack is a good example. To raise a car weighing 2000

lbs., an effort of only 100 lbs. may be required. For

every inch the car moves upward, the input piston at

the jack handle must move 20 inches downward.

PLANETARY GEARTRAIN/

OUTPUT SHAFT

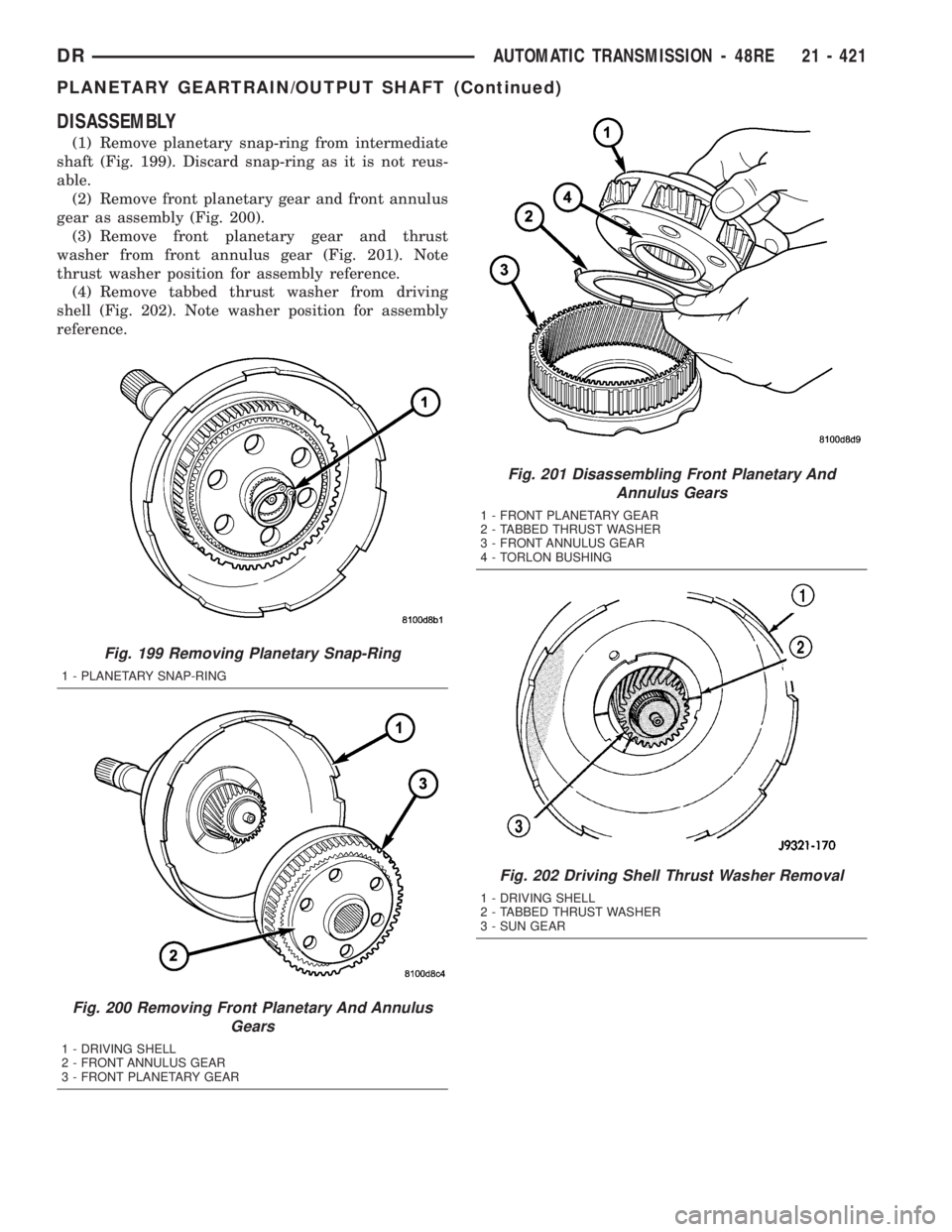

DESCRIPTION

The planetary gearsets (Fig. 198) are designated as

the front, rear, and overdrive planetary gear assem-

blies and located in such order. A simple planetary

gearset consists of three main members:²The sun gear which is at the center of the sys-

tem.

²The planet carrier with planet pinion gears

which are free to rotate on their own shafts and are

in mesh with the sun gear.

²The annulus gear, which rotates around and is

in mesh with the planet pinion gears.

NOTE: The number of pinion gears does not affect

the gear ratio, only the duty rating.

OPERATION

With any given planetary gearset, several condi-

tions must be met for power to be able to flow:

²One member must be held.

²Another member must be driven or used as an

input.

²The third member may be used as an output for

power flow.

²For direct drive to occur, two gear members in

the front planetary gearset must be driven.

NOTE: Gear ratios are dependent on the number of

teeth on the annulus and sun gears.

Fig. 197 Piston Travel

Fig. 198 Planetary Gearset

1 - ANNULUS GEAR

2 - SUN GEAR

3 - PLANET CARRIER

4 - PLANET PINIONS (4)

21 - 420 AUTOMATIC TRANSMISSION - 48REDR

PISTONS (Continued)

Page 2260 of 2895

DISASSEMBLY

(1) Remove planetary snap-ring from intermediate

shaft (Fig. 199). Discard snap-ring as it is not reus-

able.

(2) Remove front planetary gear and front annulus

gear as assembly (Fig. 200).

(3) Remove front planetary gear and thrust

washer from front annulus gear (Fig. 201). Note

thrust washer position for assembly reference.

(4) Remove tabbed thrust washer from driving

shell (Fig. 202). Note washer position for assembly

reference.

Fig. 199 Removing Planetary Snap-Ring

1 - PLANETARY SNAP-RING

Fig. 200 Removing Front Planetary And Annulus

Gears

1 - DRIVING SHELL

2 - FRONT ANNULUS GEAR

3 - FRONT PLANETARY GEAR

Fig. 201 Disassembling Front Planetary And

Annulus Gears

1 - FRONT PLANETARY GEAR

2 - TABBED THRUST WASHER

3 - FRONT ANNULUS GEAR

4 - TORLON BUSHING

Fig. 202 Driving Shell Thrust Washer Removal

1 - DRIVING SHELL

2 - TABBED THRUST WASHER

3 - SUN GEAR

DRAUTOMATIC TRANSMISSION - 48RE 21 - 421

PLANETARY GEARTRAIN/OUTPUT SHAFT (Continued)