DODGE RAM 2003 Service Repair Manual

Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2241 of 2895

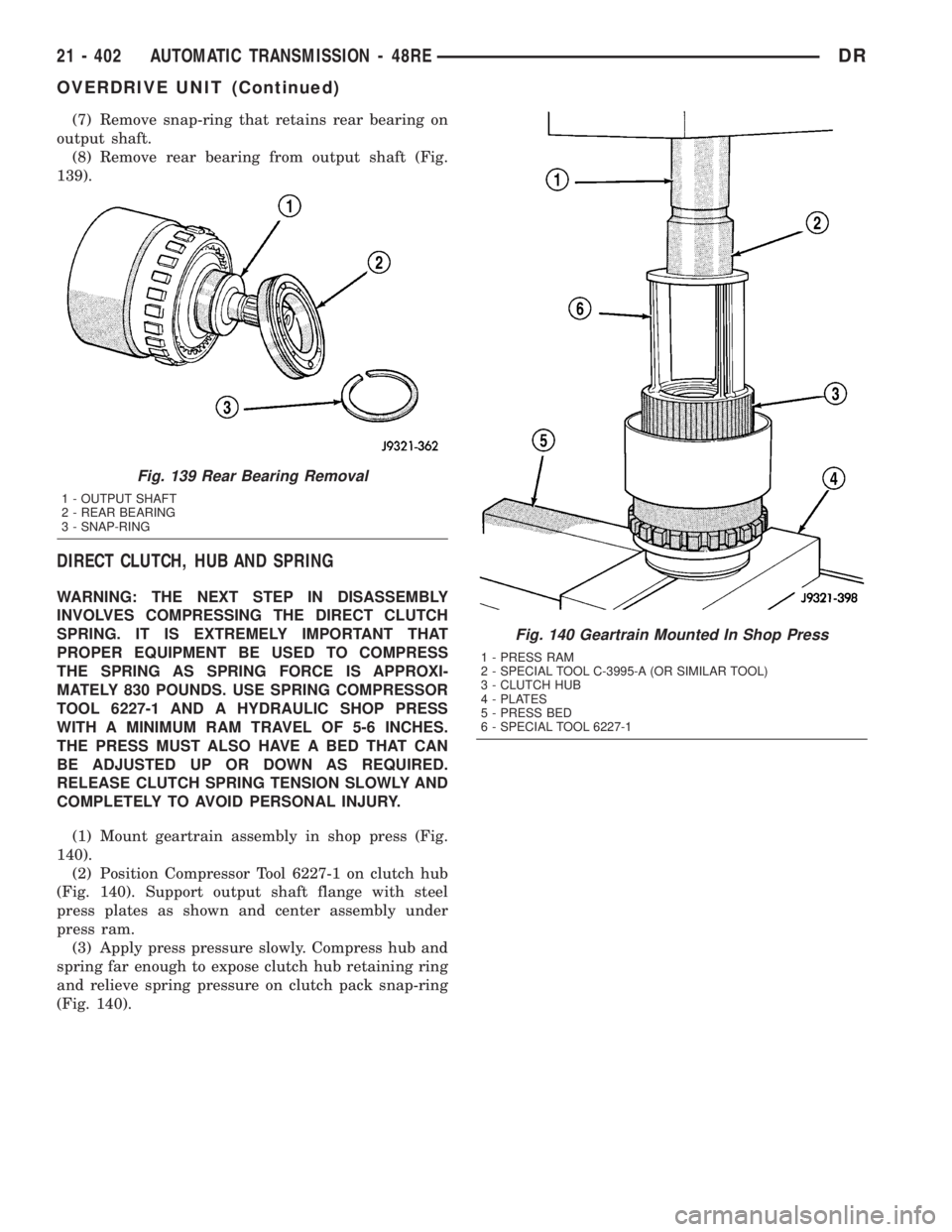

(7) Remove snap-ring that retains rear bearing on

output shaft.

(8) Remove rear bearing from output shaft (Fig.

139).

DIRECT CLUTCH, HUB AND SPRING

WARNING: THE NEXT STEP IN DISASSEMBLY

INVOLVES COMPRESSING THE DIRECT CLUTCH

SPRING. IT IS EXTREMELY IMPORTANT THAT

PROPER EQUIPMENT BE USED TO COMPRESS

THE SPRING AS SPRING FORCE IS APPROXI-

MATELY 830 POUNDS. USE SPRING COMPRESSOR

TOOL 6227-1 AND A HYDRAULIC SHOP PRESS

WITH A MINIMUM RAM TRAVEL OF 5-6 INCHES.

THE PRESS MUST ALSO HAVE A BED THAT CAN

BE ADJUSTED UP OR DOWN AS REQUIRED.

RELEASE CLUTCH SPRING TENSION SLOWLY AND

COMPLETELY TO AVOID PERSONAL INJURY.

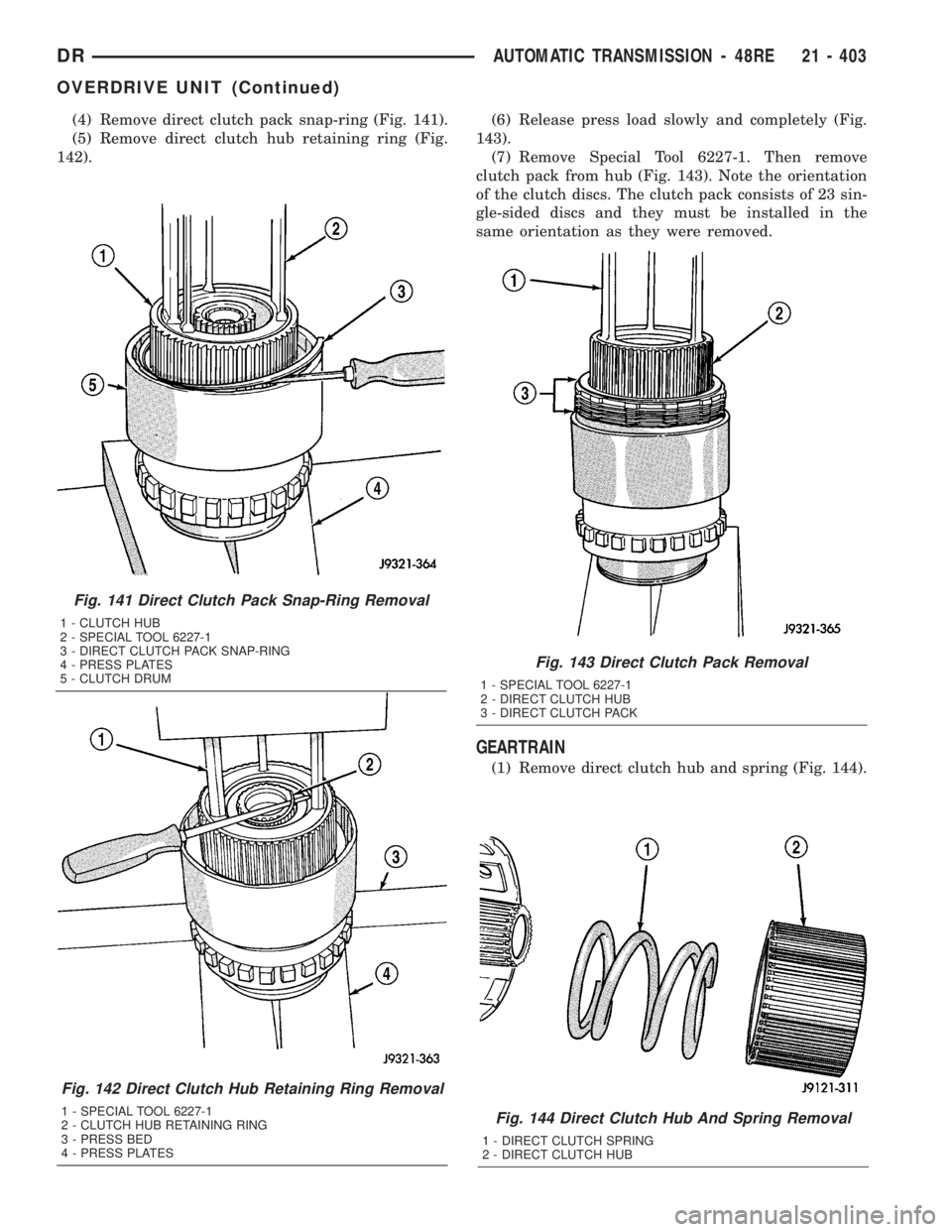

(1) Mount geartrain assembly in shop press (Fig.

140).

(2) Position Compressor Tool 6227-1 on clutch hub

(Fig. 140). Support output shaft flange with steel

press plates as shown and center assembly under

press ram.

(3) Apply press pressure slowly. Compress hub and

spring far enough to expose clutch hub retaining ring

and relieve spring pressure on clutch pack snap-ring

(Fig. 140).

Fig. 139 Rear Bearing Removal

1 - OUTPUT SHAFT

2 - REAR BEARING

3 - SNAP-RING

Fig. 140 Geartrain Mounted In Shop Press

1 - PRESS RAM

2 - SPECIAL TOOL C-3995-A (OR SIMILAR TOOL)

3 - CLUTCH HUB

4 - PLATES

5 - PRESS BED

6 - SPECIAL TOOL 6227-1

21 - 402 AUTOMATIC TRANSMISSION - 48REDR

OVERDRIVE UNIT (Continued)

Page 2242 of 2895

(4) Remove direct clutch pack snap-ring (Fig. 141).

(5) Remove direct clutch hub retaining ring (Fig.

142).(6) Release press load slowly and completely (Fig.

143).

(7) Remove Special Tool 6227-1. Then remove

clutch pack from hub (Fig. 143). Note the orientation

of the clutch discs. The clutch pack consists of 23 sin-

gle-sided discs and they must be installed in the

same orientation as they were removed.

GEARTRAIN

(1) Remove direct clutch hub and spring (Fig. 144).

Fig. 141 Direct Clutch Pack Snap-Ring Removal

1 - CLUTCH HUB

2 - SPECIAL TOOL 6227-1

3 - DIRECT CLUTCH PACK SNAP-RING

4 - PRESS PLATES

5 - CLUTCH DRUM

Fig. 142 Direct Clutch Hub Retaining Ring Removal

1 - SPECIAL TOOL 6227-1

2 - CLUTCH HUB RETAINING RING

3 - PRESS BED

4 - PRESS PLATESFig. 144 Direct Clutch Hub And Spring Removal

1 - DIRECT CLUTCH SPRING

2 - DIRECT CLUTCH HUB

Fig. 143 Direct Clutch Pack Removal

1 - SPECIAL TOOL 6227-1

2 - DIRECT CLUTCH HUB

3 - DIRECT CLUTCH PACK

DRAUTOMATIC TRANSMISSION - 48RE 21 - 403

OVERDRIVE UNIT (Continued)

Page 2243 of 2895

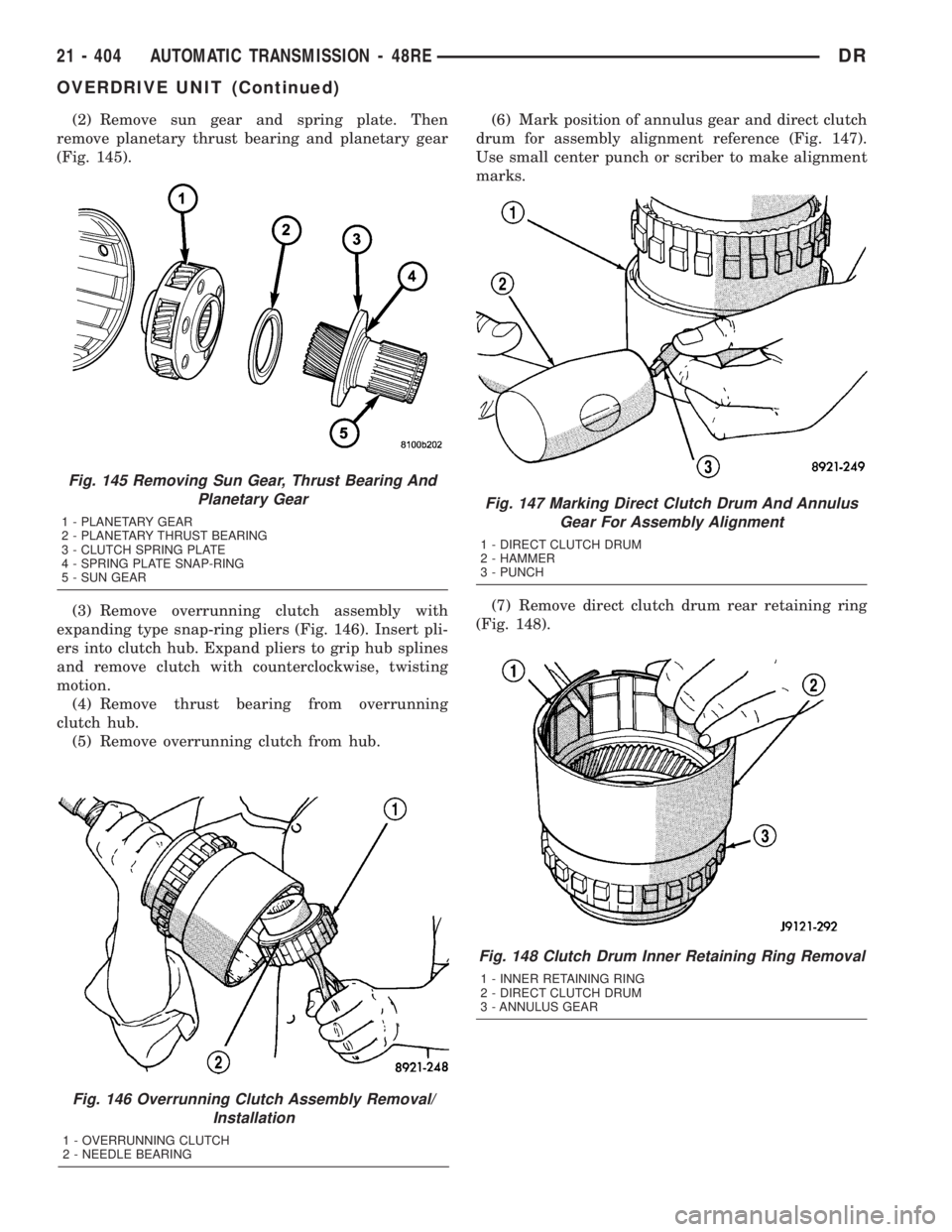

(2) Remove sun gear and spring plate. Then

remove planetary thrust bearing and planetary gear

(Fig. 145).

(3) Remove overrunning clutch assembly with

expanding type snap-ring pliers (Fig. 146). Insert pli-

ers into clutch hub. Expand pliers to grip hub splines

and remove clutch with counterclockwise, twisting

motion.

(4) Remove thrust bearing from overrunning

clutch hub.

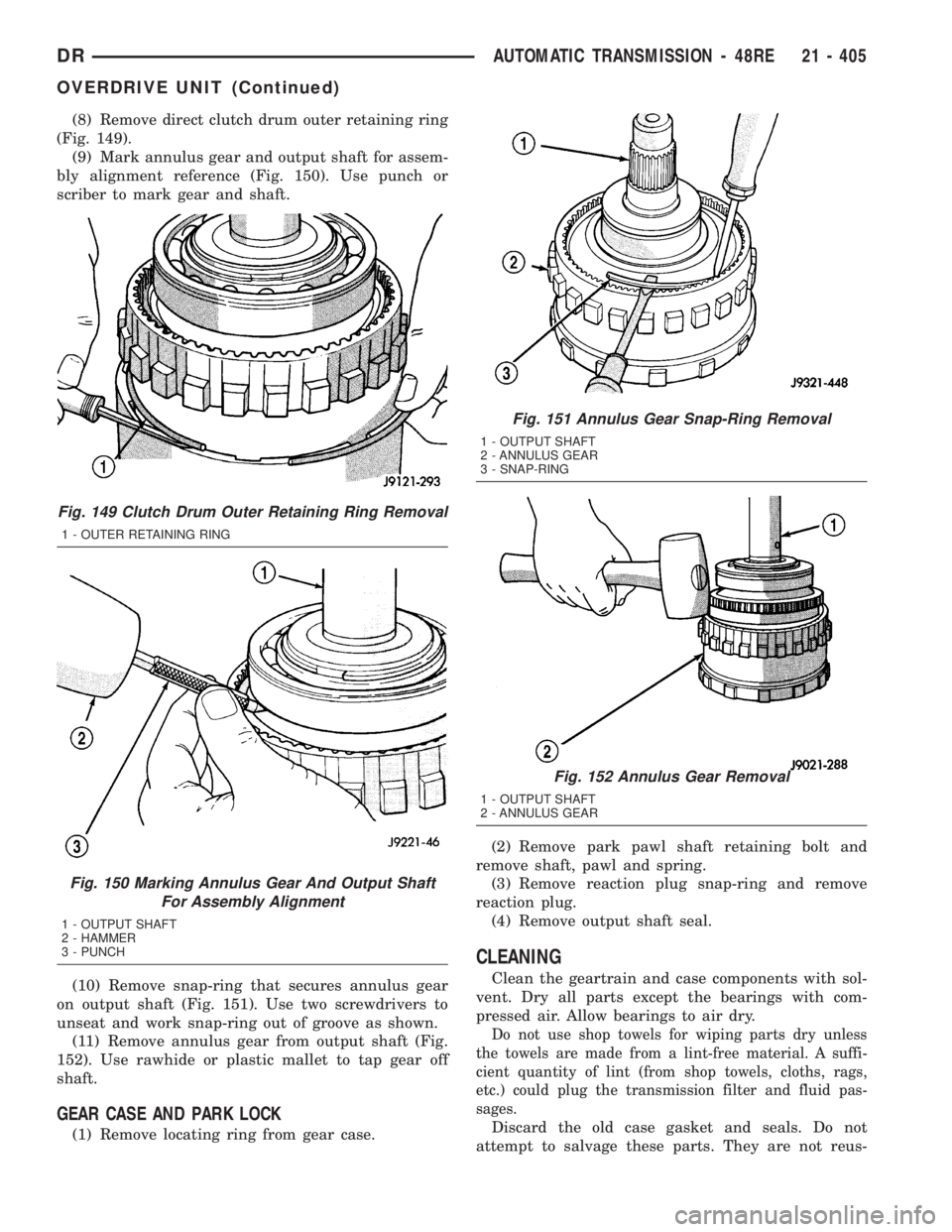

(5) Remove overrunning clutch from hub.(6) Mark position of annulus gear and direct clutch

drum for assembly alignment reference (Fig. 147).

Use small center punch or scriber to make alignment

marks.

(7) Remove direct clutch drum rear retaining ring

(Fig. 148).

Fig. 146 Overrunning Clutch Assembly Removal/

Installation

1 - OVERRUNNING CLUTCH

2 - NEEDLE BEARING

Fig. 148 Clutch Drum Inner Retaining Ring Removal

1 - INNER RETAINING RING

2 - DIRECT CLUTCH DRUM

3 - ANNULUS GEAR

Fig. 145 Removing Sun Gear, Thrust Bearing And

Planetary Gear

1 - PLANETARY GEAR

2 - PLANETARY THRUST BEARING

3 - CLUTCH SPRING PLATE

4 - SPRING PLATE SNAP-RING

5 - SUN GEAR

Fig. 147 Marking Direct Clutch Drum And Annulus

Gear For Assembly Alignment

1 - DIRECT CLUTCH DRUM

2 - HAMMER

3 - PUNCH

21 - 404 AUTOMATIC TRANSMISSION - 48REDR

OVERDRIVE UNIT (Continued)

Page 2244 of 2895

(8) Remove direct clutch drum outer retaining ring

(Fig. 149).

(9) Mark annulus gear and output shaft for assem-

bly alignment reference (Fig. 150). Use punch or

scriber to mark gear and shaft.

(10) Remove snap-ring that secures annulus gear

on output shaft (Fig. 151). Use two screwdrivers to

unseat and work snap-ring out of groove as shown.

(11) Remove annulus gear from output shaft (Fig.

152). Use rawhide or plastic mallet to tap gear off

shaft.

GEAR CASE AND PARK LOCK

(1) Remove locating ring from gear case.(2) Remove park pawl shaft retaining bolt and

remove shaft, pawl and spring.

(3) Remove reaction plug snap-ring and remove

reaction plug.

(4) Remove output shaft seal.

CLEANING

Clean the geartrain and case components with sol-

vent. Dry all parts except the bearings with com-

pressed air. Allow bearings to air dry.

Do not use shop towels for wiping parts dry unless

the towels are made from a lint-free material. A suffi-

cient quantity of lint (from shop towels, cloths, rags,

etc.) could plug the transmission filter and fluid pas-

sages.

Discard the old case gasket and seals. Do not

attempt to salvage these parts. They are not reus-

Fig. 149 Clutch Drum Outer Retaining Ring Removal

1 - OUTER RETAINING RING

Fig. 150 Marking Annulus Gear And Output Shaft

For Assembly Alignment

1 - OUTPUT SHAFT

2 - HAMMER

3 - PUNCH

Fig. 151 Annulus Gear Snap-Ring Removal

1 - OUTPUT SHAFT

2 - ANNULUS GEAR

3 - SNAP-RING

Fig. 152 Annulus Gear Removal

1 - OUTPUT SHAFT

2 - ANNULUS GEAR

DRAUTOMATIC TRANSMISSION - 48RE 21 - 405

OVERDRIVE UNIT (Continued)

Page 2245 of 2895

able. Replace any of the overdrive unit snap-rings if

distorted or damaged.

Minor nicks or scratches on components can be

smoothed with crocus cloth. However, do not attempt

to reduce severe scoring on any components with

abrasive materials. Replace severely scored compo-

nents; do not try to salvage them.

INSPECTION

Check condition of the park lock components and

the overdrive case.

Check the bushings in the overdrive case. Replace

the bushings if severely scored or worn. Also replace

the case seal if loose, distorted, or damaged.

Examine the overdrive and direct clutch discs and

plates. Replace the discs if the facing is worn,

severely scored, or burned and flaking off. Replace

the clutch plates if worn, heavily scored, or cracked.

Check the lugs on the clutch plates for wear. The

plates should slide freely in the drum. Replace the

plates or drum if binding occurs.

Check condition of the annulus gear, direct clutch

hub, clutch drum and clutch spring. Replace the gear,

hub and drum if worn or damaged. Replace the

spring if collapsed, distorted, or cracked.

Be sure the splines and lugs on the gear, drum and

hub are in good condition. The clutch plates and

discs should slide freely in these components.

Inspect the thrust bearings and spring plate.

Replace the plate if worn or scored. Replace the bear-

ings if rough, noisy, brinnelled, or worn.

Inspect the planetary gear assembly and the sun

gear and bushings. If either the sun gear or the

bushings are damaged, replace the gear and bush-

ings as an assembly. The gear and bushings are not

serviced separately.

The planetary carrier and pinions must be in good

condition. Also be sure the pinion pins are secure and in

good condition. Replace the carrier if worn or damaged.

Inspect the overrunning clutch and race. The race

surface should be smooth and free of scores. Replace

the overrunning clutch assembly or the race if either

assembly is worn or damaged in any way.

Replace the shaft pilot bushing and inner bushing

if damaged. Replace either shaft bearing if rough or

noisy. Replace the bearing snap-rings if distorted or

cracked.

Check the machined surfaces on the output shaft.

These surfaces should clean and smooth. Very minor

nicks or scratches can be smoothed with crocus cloth.

Replace the shaft if worn, scored or damaged in any way.

Inspect the output shaft bushings. The small bush-

ing is the intermediate shaft pilot bushing. The large

bushing is the overrunning clutch hub bushing.

Replace either bushing if scored, pitted, cracked, or

worn.

ASSEMBLY

GEARTRAIN AND DIRECT CLUTCH

(1) Soak direct clutch and overdrive clutch discs in

MopartATF +4, Automatic Transmission fluid. Allow

discs to soak for 10-20 minutes.

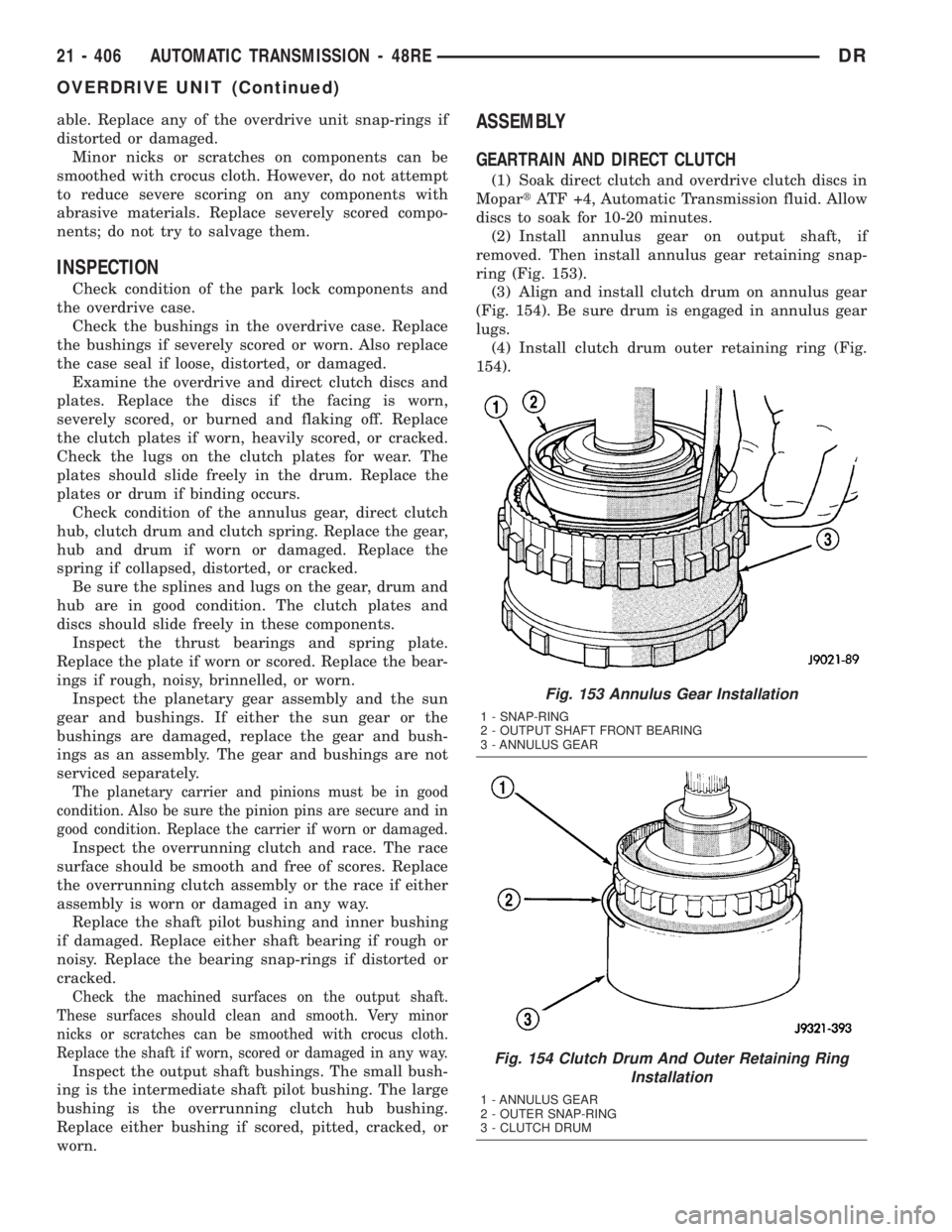

(2) Install annulus gear on output shaft, if

removed. Then install annulus gear retaining snap-

ring (Fig. 153).

(3) Align and install clutch drum on annulus gear

(Fig. 154). Be sure drum is engaged in annulus gear

lugs.

(4) Install clutch drum outer retaining ring (Fig.

154).

Fig. 153 Annulus Gear Installation

1 - SNAP-RING

2 - OUTPUT SHAFT FRONT BEARING

3 - ANNULUS GEAR

Fig. 154 Clutch Drum And Outer Retaining Ring

Installation

1 - ANNULUS GEAR

2 - OUTER SNAP-RING

3 - CLUTCH DRUM

21 - 406 AUTOMATIC TRANSMISSION - 48REDR

OVERDRIVE UNIT (Continued)

Page 2246 of 2895

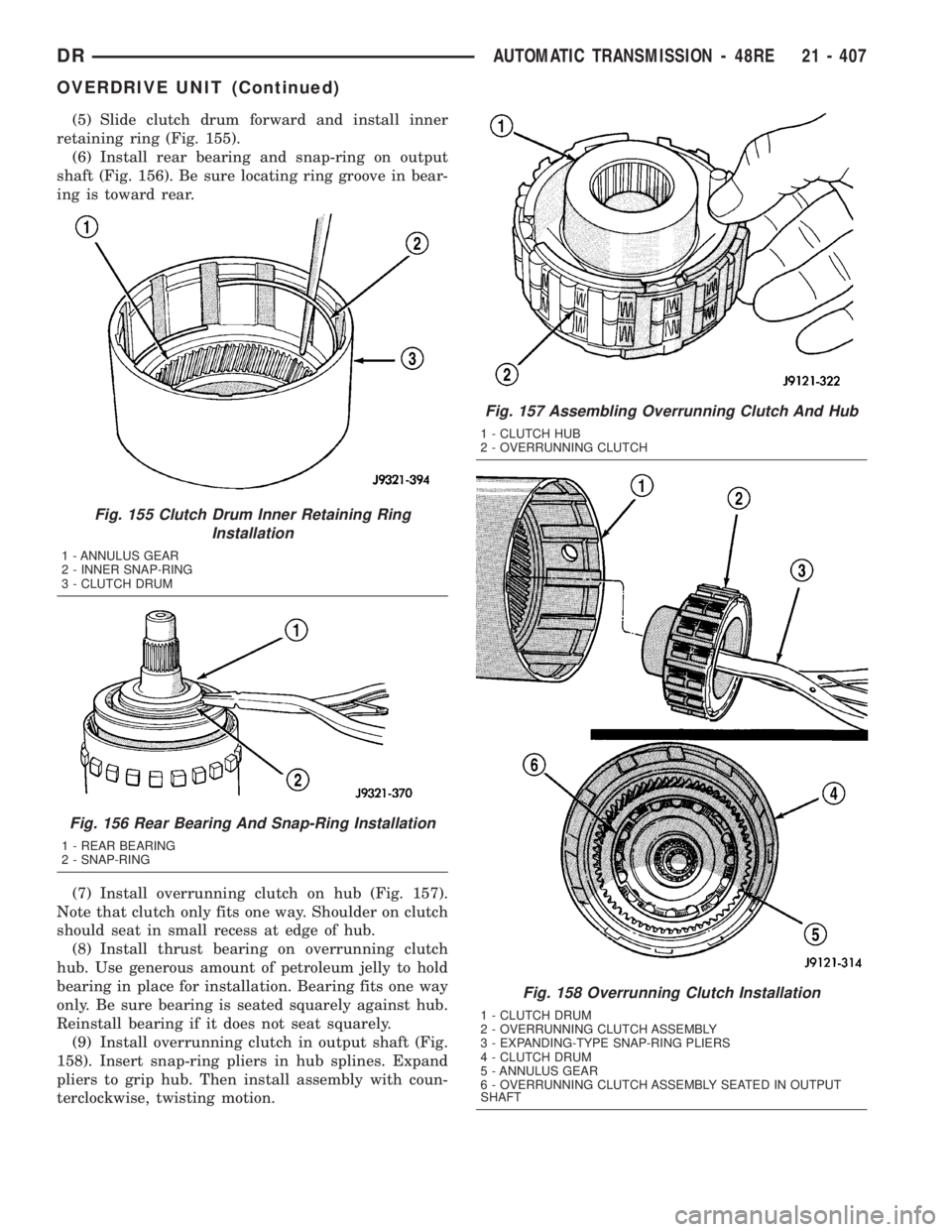

(5) Slide clutch drum forward and install inner

retaining ring (Fig. 155).

(6) Install rear bearing and snap-ring on output

shaft (Fig. 156). Be sure locating ring groove in bear-

ing is toward rear.

(7) Install overrunning clutch on hub (Fig. 157).

Note that clutch only fits one way. Shoulder on clutch

should seat in small recess at edge of hub.

(8) Install thrust bearing on overrunning clutch

hub. Use generous amount of petroleum jelly to hold

bearing in place for installation. Bearing fits one way

only. Be sure bearing is seated squarely against hub.

Reinstall bearing if it does not seat squarely.

(9) Install overrunning clutch in output shaft (Fig.

158). Insert snap-ring pliers in hub splines. Expand

pliers to grip hub. Then install assembly with coun-

terclockwise, twisting motion.

Fig. 158 Overrunning Clutch Installation

1 - CLUTCH DRUM

2 - OVERRUNNING CLUTCH ASSEMBLY

3 - EXPANDING-TYPE SNAP-RING PLIERS

4 - CLUTCH DRUM

5 - ANNULUS GEAR

6 - OVERRUNNING CLUTCH ASSEMBLY SEATED IN OUTPUT

SHAFT

Fig. 155 Clutch Drum Inner Retaining Ring

Installation

1 - ANNULUS GEAR

2 - INNER SNAP-RING

3 - CLUTCH DRUM

Fig. 156 Rear Bearing And Snap-Ring Installation

1 - REAR BEARING

2 - SNAP-RING

Fig. 157 Assembling Overrunning Clutch And Hub

1 - CLUTCH HUB

2 - OVERRUNNING CLUTCH

DRAUTOMATIC TRANSMISSION - 48RE 21 - 407

OVERDRIVE UNIT (Continued)

Page 2247 of 2895

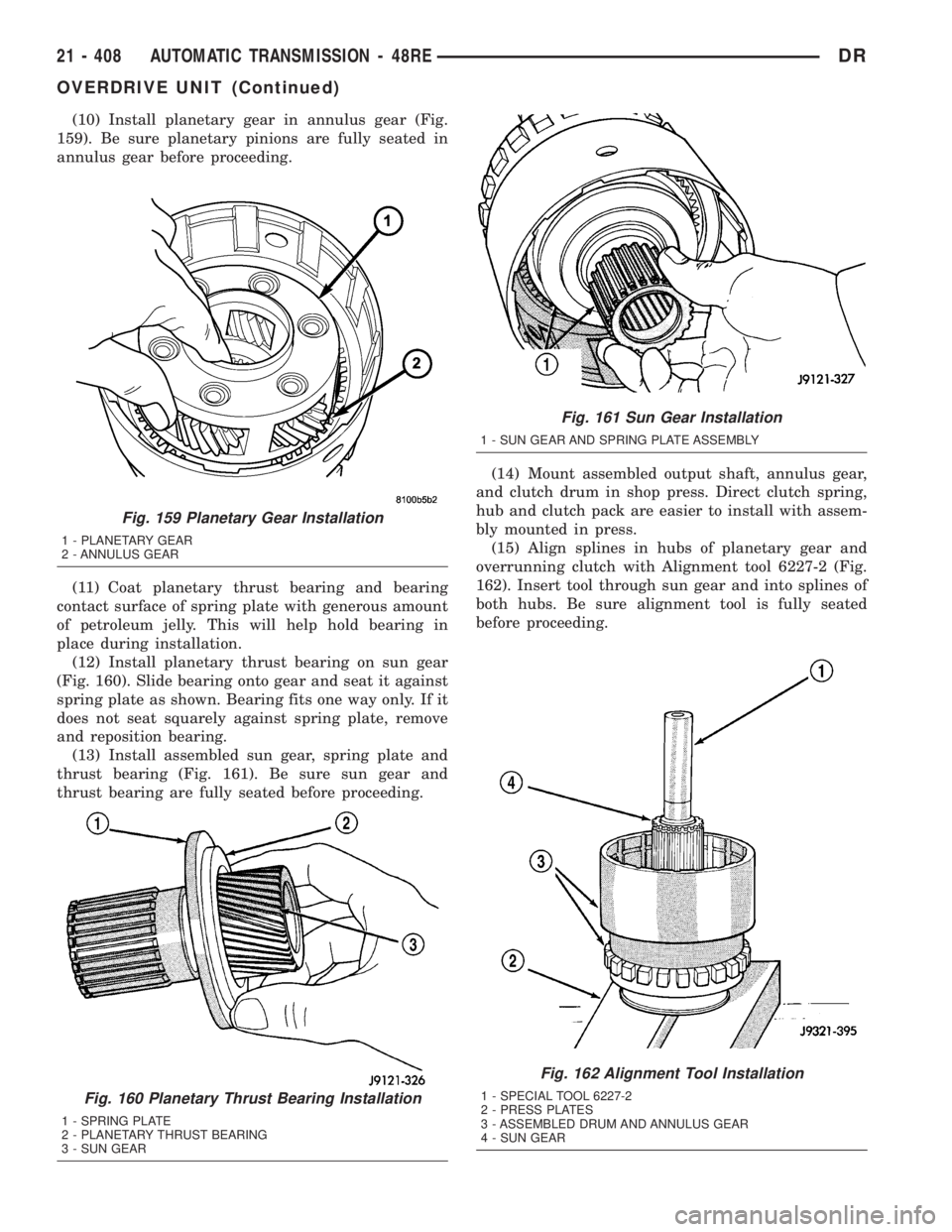

(10) Install planetary gear in annulus gear (Fig.

159). Be sure planetary pinions are fully seated in

annulus gear before proceeding.

(11) Coat planetary thrust bearing and bearing

contact surface of spring plate with generous amount

of petroleum jelly. This will help hold bearing in

place during installation.

(12) Install planetary thrust bearing on sun gear

(Fig. 160). Slide bearing onto gear and seat it against

spring plate as shown. Bearing fits one way only. If it

does not seat squarely against spring plate, remove

and reposition bearing.

(13) Install assembled sun gear, spring plate and

thrust bearing (Fig. 161). Be sure sun gear and

thrust bearing are fully seated before proceeding.(14) Mount assembled output shaft, annulus gear,

and clutch drum in shop press. Direct clutch spring,

hub and clutch pack are easier to install with assem-

bly mounted in press.

(15) Align splines in hubs of planetary gear and

overrunning clutch with Alignment tool 6227-2 (Fig.

162). Insert tool through sun gear and into splines of

both hubs. Be sure alignment tool is fully seated

before proceeding.

Fig. 162 Alignment Tool Installation

1 - SPECIAL TOOL 6227-2

2 - PRESS PLATES

3 - ASSEMBLED DRUM AND ANNULUS GEAR

4 - SUN GEAR

Fig. 159 Planetary Gear Installation

1 - PLANETARY GEAR

2 - ANNULUS GEAR

Fig. 160 Planetary Thrust Bearing Installation

1 - SPRING PLATE

2 - PLANETARY THRUST BEARING

3 - SUN GEAR

Fig. 161 Sun Gear Installation

1 - SUN GEAR AND SPRING PLATE ASSEMBLY

21 - 408 AUTOMATIC TRANSMISSION - 48REDR

OVERDRIVE UNIT (Continued)

Page 2248 of 2895

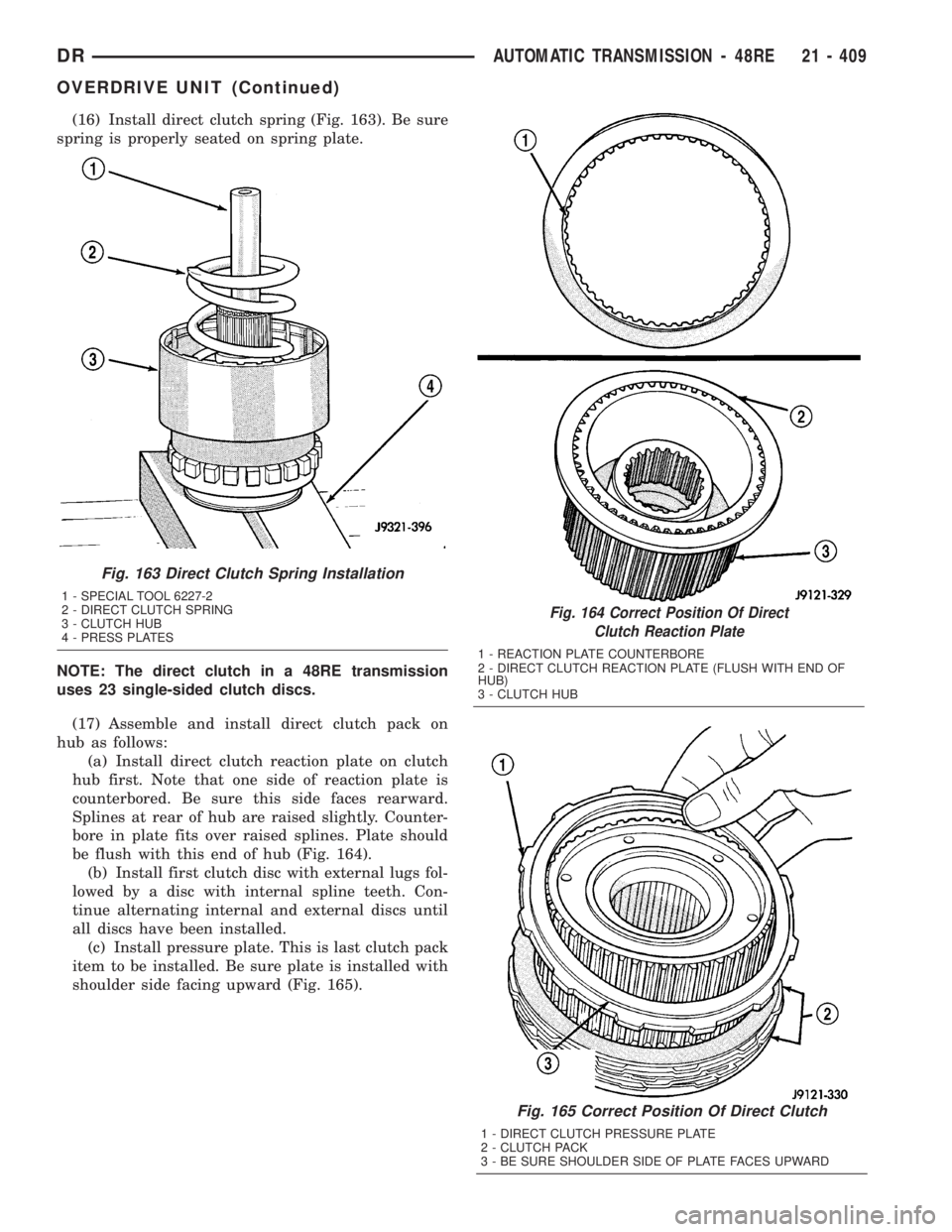

(16) Install direct clutch spring (Fig. 163). Be sure

spring is properly seated on spring plate.

NOTE: The direct clutch in a 48RE transmission

uses 23 single-sided clutch discs.

(17) Assemble and install direct clutch pack on

hub as follows:

(a) Install direct clutch reaction plate on clutch

hub first. Note that one side of reaction plate is

counterbored. Be sure this side faces rearward.

Splines at rear of hub are raised slightly. Counter-

bore in plate fits over raised splines. Plate should

be flush with this end of hub (Fig. 164).

(b) Install first clutch disc with external lugs fol-

lowed by a disc with internal spline teeth. Con-

tinue alternating internal and external discs until

all discs have been installed.

(c) Install pressure plate. This is last clutch pack

item to be installed. Be sure plate is installed with

shoulder side facing upward (Fig. 165).

Fig. 164 Correct Position Of Direct

Clutch Reaction Plate

1 - REACTION PLATE COUNTERBORE

2 - DIRECT CLUTCH REACTION PLATE (FLUSH WITH END OF

HUB)

3 - CLUTCH HUB

Fig. 165 Correct Position Of Direct Clutch

1 - DIRECT CLUTCH PRESSURE PLATE

2 - CLUTCH PACK

3 - BE SURE SHOULDER SIDE OF PLATE FACES UPWARD

Fig. 163 Direct Clutch Spring Installation

1 - SPECIAL TOOL 6227-2

2 - DIRECT CLUTCH SPRING

3 - CLUTCH HUB

4 - PRESS PLATES

DRAUTOMATIC TRANSMISSION - 48RE 21 - 409

OVERDRIVE UNIT (Continued)

Page 2249 of 2895

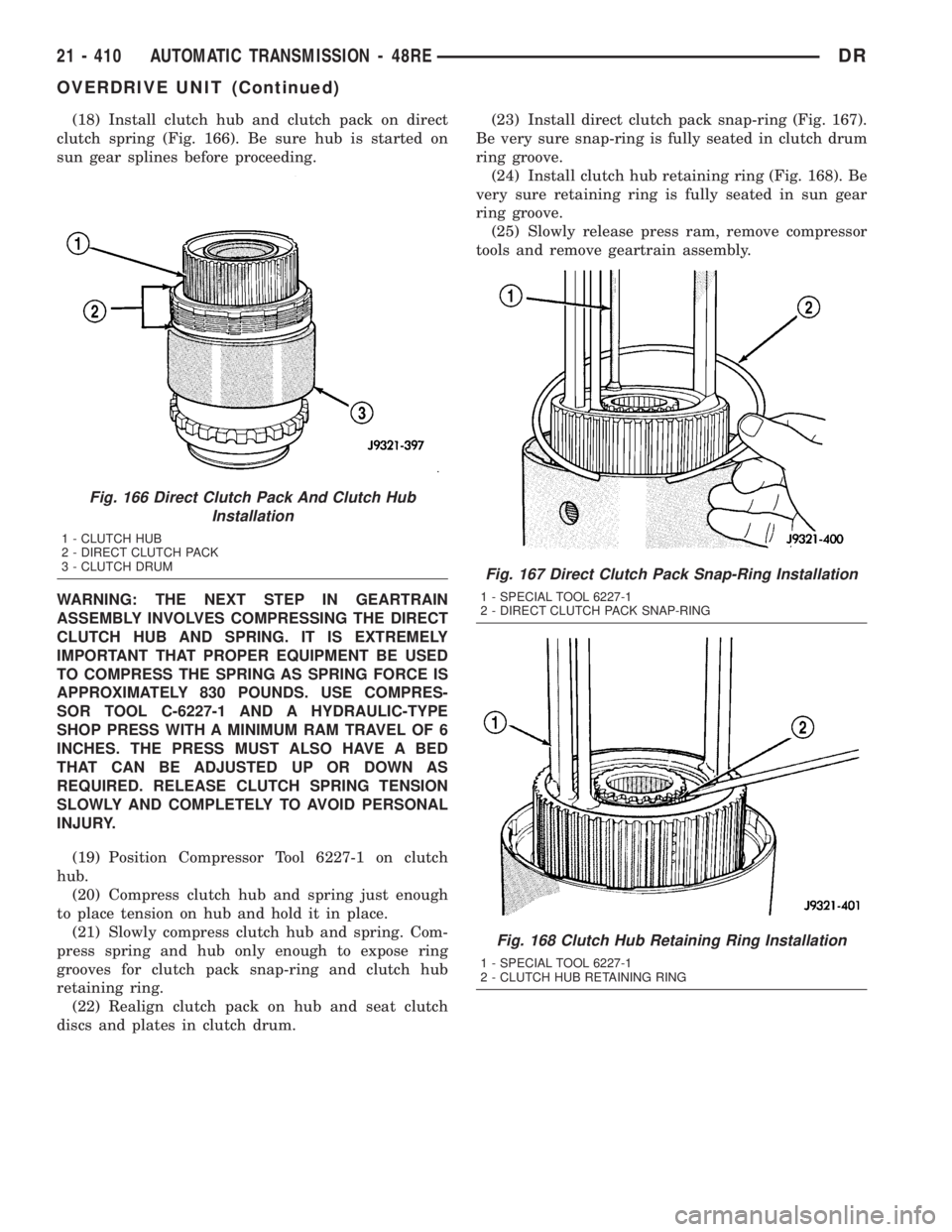

(18) Install clutch hub and clutch pack on direct

clutch spring (Fig. 166). Be sure hub is started on

sun gear splines before proceeding.

WARNING: THE NEXT STEP IN GEARTRAIN

ASSEMBLY INVOLVES COMPRESSING THE DIRECT

CLUTCH HUB AND SPRING. IT IS EXTREMELY

IMPORTANT THAT PROPER EQUIPMENT BE USED

TO COMPRESS THE SPRING AS SPRING FORCE IS

APPROXIMATELY 830 POUNDS. USE COMPRES-

SOR TOOL C-6227-1 AND A HYDRAULIC-TYPE

SHOP PRESS WITH A MINIMUM RAM TRAVEL OF 6

INCHES. THE PRESS MUST ALSO HAVE A BED

THAT CAN BE ADJUSTED UP OR DOWN AS

REQUIRED. RELEASE CLUTCH SPRING TENSION

SLOWLY AND COMPLETELY TO AVOID PERSONAL

INJURY.

(19) Position Compressor Tool 6227-1 on clutch

hub.

(20) Compress clutch hub and spring just enough

to place tension on hub and hold it in place.

(21) Slowly compress clutch hub and spring. Com-

press spring and hub only enough to expose ring

grooves for clutch pack snap-ring and clutch hub

retaining ring.

(22) Realign clutch pack on hub and seat clutch

discs and plates in clutch drum.(23) Install direct clutch pack snap-ring (Fig. 167).

Be very sure snap-ring is fully seated in clutch drum

ring groove.

(24) Install clutch hub retaining ring (Fig. 168). Be

very sure retaining ring is fully seated in sun gear

ring groove.

(25) Slowly release press ram, remove compressor

tools and remove geartrain assembly.

Fig. 166 Direct Clutch Pack And Clutch Hub

Installation

1 - CLUTCH HUB

2 - DIRECT CLUTCH PACK

3 - CLUTCH DRUM

Fig. 167 Direct Clutch Pack Snap-Ring Installation

1 - SPECIAL TOOL 6227-1

2 - DIRECT CLUTCH PACK SNAP-RING

Fig. 168 Clutch Hub Retaining Ring Installation

1 - SPECIAL TOOL 6227-1

2 - CLUTCH HUB RETAINING RING

21 - 410 AUTOMATIC TRANSMISSION - 48REDR

OVERDRIVE UNIT (Continued)

Page 2250 of 2895

GEAR CASE

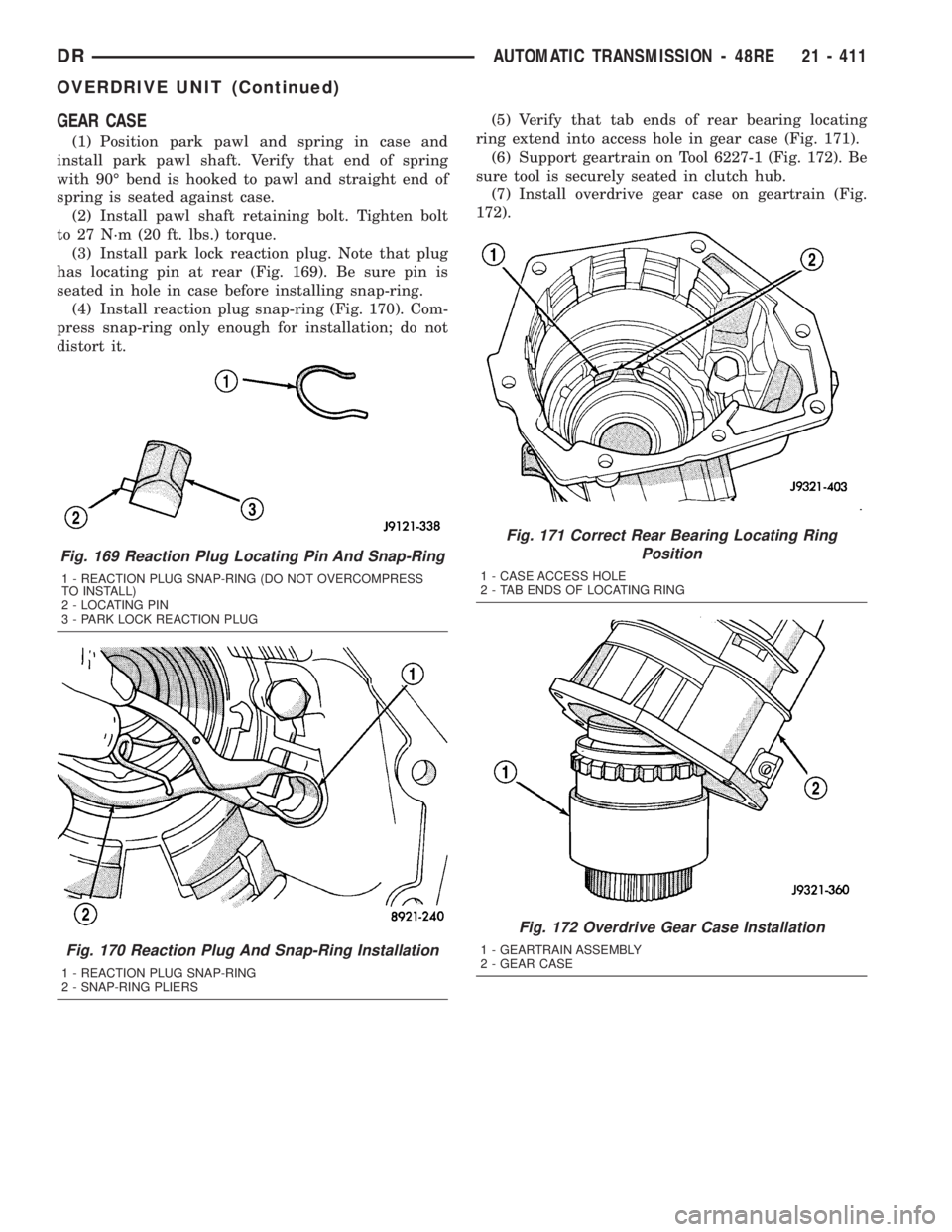

(1) Position park pawl and spring in case and

install park pawl shaft. Verify that end of spring

with 90É bend is hooked to pawl and straight end of

spring is seated against case.

(2) Install pawl shaft retaining bolt. Tighten bolt

to 27 N´m (20 ft. lbs.) torque.

(3) Install park lock reaction plug. Note that plug

has locating pin at rear (Fig. 169). Be sure pin is

seated in hole in case before installing snap-ring.

(4) Install reaction plug snap-ring (Fig. 170). Com-

press snap-ring only enough for installation; do not

distort it.(5) Verify that tab ends of rear bearing locating

ring extend into access hole in gear case (Fig. 171).

(6) Support geartrain on Tool 6227-1 (Fig. 172). Be

sure tool is securely seated in clutch hub.

(7) Install overdrive gear case on geartrain (Fig.

172).

Fig. 169 Reaction Plug Locating Pin And Snap-Ring

1 - REACTION PLUG SNAP-RING (DO NOT OVERCOMPRESS

TO INSTALL)

2 - LOCATING PIN

3 - PARK LOCK REACTION PLUG

Fig. 170 Reaction Plug And Snap-Ring Installation

1 - REACTION PLUG SNAP-RING

2 - SNAP-RING PLIERS

Fig. 171 Correct Rear Bearing Locating Ring

Position

1 - CASE ACCESS HOLE

2 - TAB ENDS OF LOCATING RING

Fig. 172 Overdrive Gear Case Installation

1 - GEARTRAIN ASSEMBLY

2 - GEAR CASE

DRAUTOMATIC TRANSMISSION - 48RE 21 - 411

OVERDRIVE UNIT (Continued)