DODGE RAM 2003 Service Repair Manual

Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 251 of 2895

(10) Install the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION).

(11) Reconnect the negative battery cable.

ADJUSTABLE PEDAL MOTOR

DESCRIPTION

The Adjustable Pedals System (APS) is designed to

enable the fore and aft repositioning of the brake and

accelerator pedals. This results in improved ergonom-

ics in relation to the steering wheel for taller and

shorter drivers. Being able to adjust the pedal posi-

tions also allows the driver to set steering wheel tilt

and seat position to the most comfortable position.

The position of the brake and accelerator pedals can

be adjusted without compromising safety or comfort

in actuating the pedals.

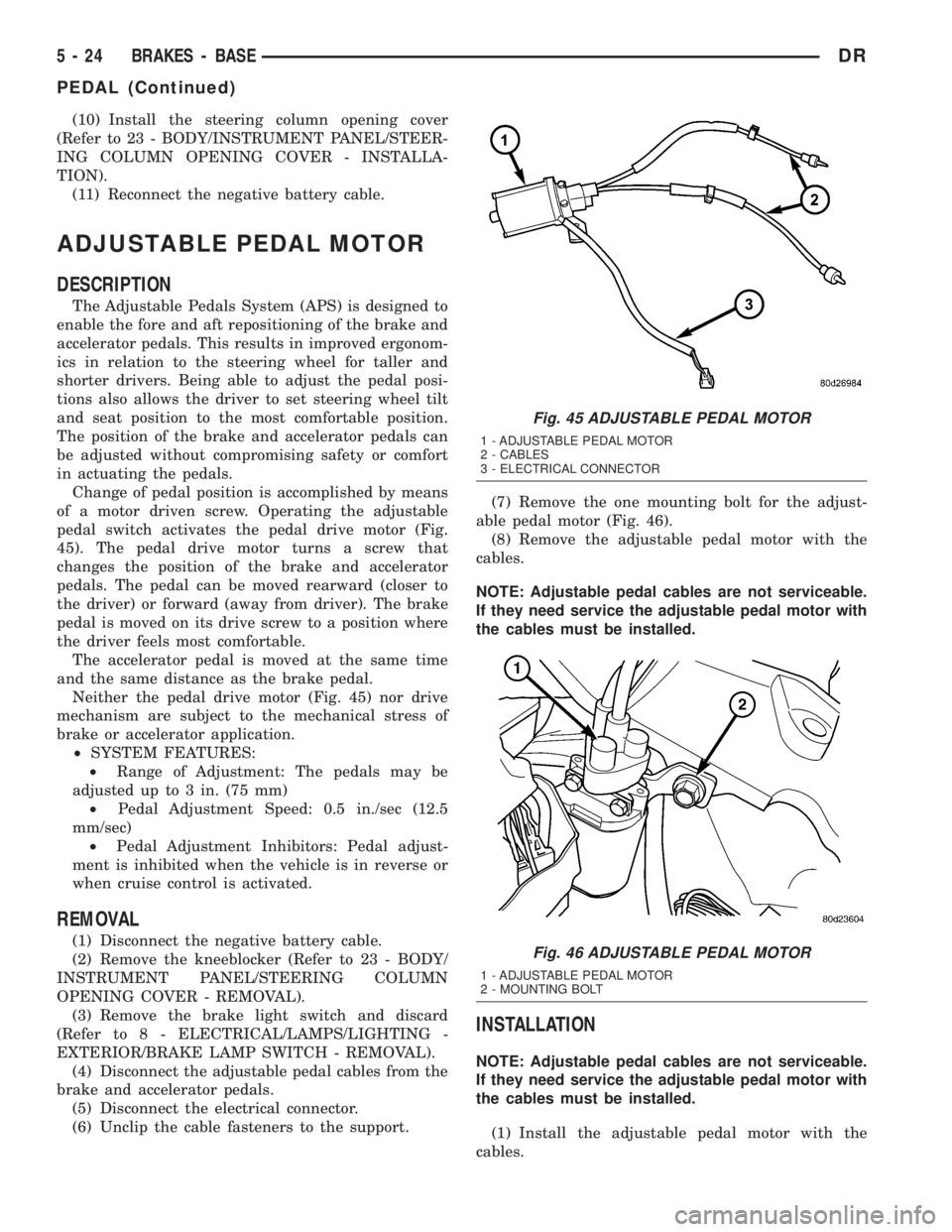

Change of pedal position is accomplished by means

of a motor driven screw. Operating the adjustable

pedal switch activates the pedal drive motor (Fig.

45). The pedal drive motor turns a screw that

changes the position of the brake and accelerator

pedals. The pedal can be moved rearward (closer to

the driver) or forward (away from driver). The brake

pedal is moved on its drive screw to a position where

the driver feels most comfortable.

The accelerator pedal is moved at the same time

and the same distance as the brake pedal.

Neither the pedal drive motor (Fig. 45) nor drive

mechanism are subject to the mechanical stress of

brake or accelerator application.

²SYSTEM FEATURES:

²Range of Adjustment: The pedals may be

adjusted up to 3 in. (75 mm)

²Pedal Adjustment Speed: 0.5 in./sec (12.5

mm/sec)

²Pedal Adjustment Inhibitors: Pedal adjust-

ment is inhibited when the vehicle is in reverse or

when cruise control is activated.

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the kneeblocker (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - REMOVAL).

(3) Remove the brake light switch and discard

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/BRAKE LAMP SWITCH - REMOVAL).

(4) Disconnect the adjustable pedal cables from the

brake and accelerator pedals.

(5) Disconnect the electrical connector.

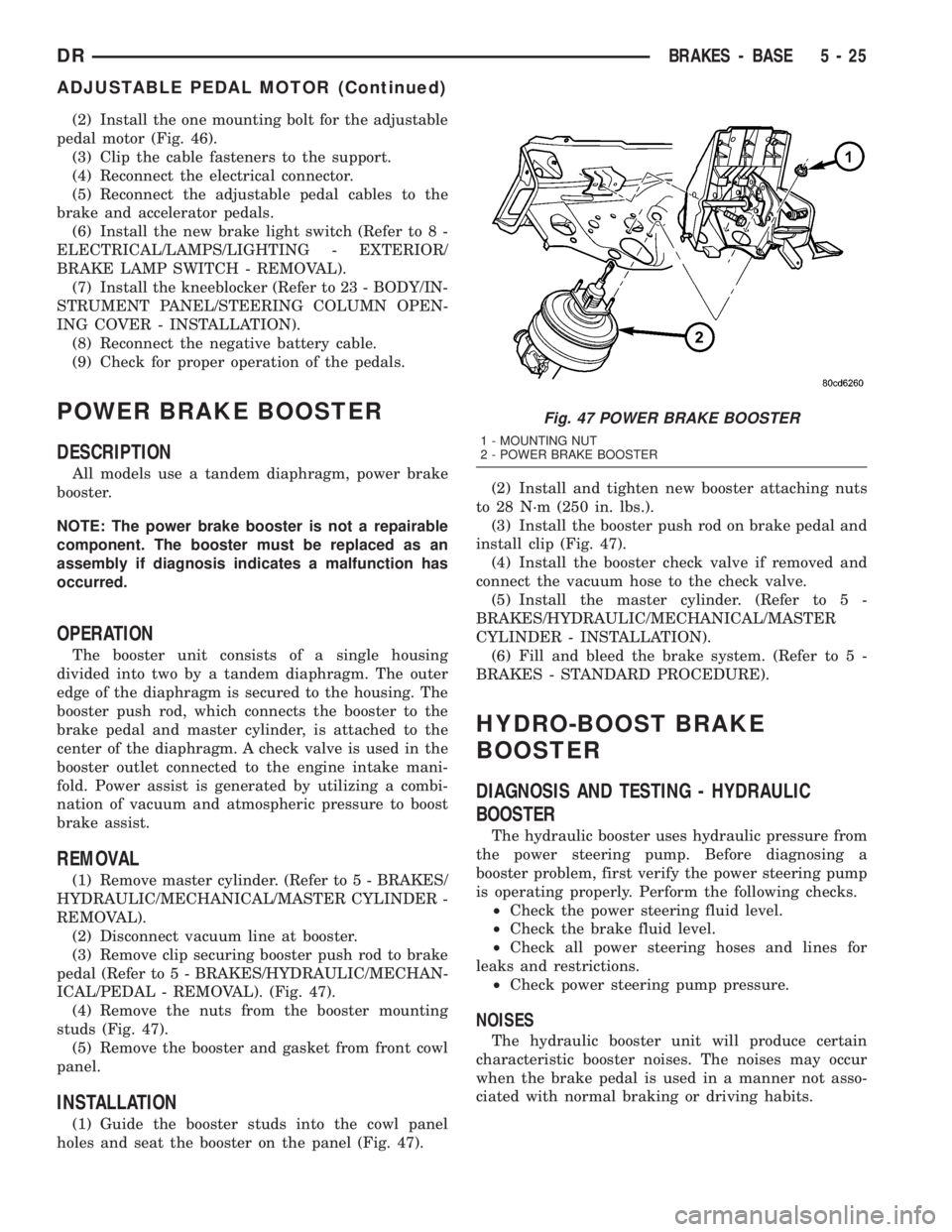

(6) Unclip the cable fasteners to the support.(7) Remove the one mounting bolt for the adjust-

able pedal motor (Fig. 46).

(8) Remove the adjustable pedal motor with the

cables.

NOTE: Adjustable pedal cables are not serviceable.

If they need service the adjustable pedal motor with

the cables must be installed.

INSTALLATION

NOTE: Adjustable pedal cables are not serviceable.

If they need service the adjustable pedal motor with

the cables must be installed.

(1) Install the adjustable pedal motor with the

cables.

Fig. 45 ADJUSTABLE PEDAL MOTOR

1 - ADJUSTABLE PEDAL MOTOR

2 - CABLES

3 - ELECTRICAL CONNECTOR

Fig. 46 ADJUSTABLE PEDAL MOTOR

1 - ADJUSTABLE PEDAL MOTOR

2 - MOUNTING BOLT

5 - 24 BRAKES - BASEDR

PEDAL (Continued)

Page 252 of 2895

(2) Install the one mounting bolt for the adjustable

pedal motor (Fig. 46).

(3) Clip the cable fasteners to the support.

(4) Reconnect the electrical connector.

(5) Reconnect the adjustable pedal cables to the

brake and accelerator pedals.

(6) Install the new brake light switch (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - REMOVAL).

(7) Install the kneeblocker (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - INSTALLATION).

(8) Reconnect the negative battery cable.

(9) Check for proper operation of the pedals.

POWER BRAKE BOOSTER

DESCRIPTION

All models use a tandem diaphragm, power brake

booster.

NOTE: The power brake booster is not a repairable

component. The booster must be replaced as an

assembly if diagnosis indicates a malfunction has

occurred.

OPERATION

The booster unit consists of a single housing

divided into two by a tandem diaphragm. The outer

edge of the diaphragm is secured to the housing. The

booster push rod, which connects the booster to the

brake pedal and master cylinder, is attached to the

center of the diaphragm. A check valve is used in the

booster outlet connected to the engine intake mani-

fold. Power assist is generated by utilizing a combi-

nation of vacuum and atmospheric pressure to boost

brake assist.

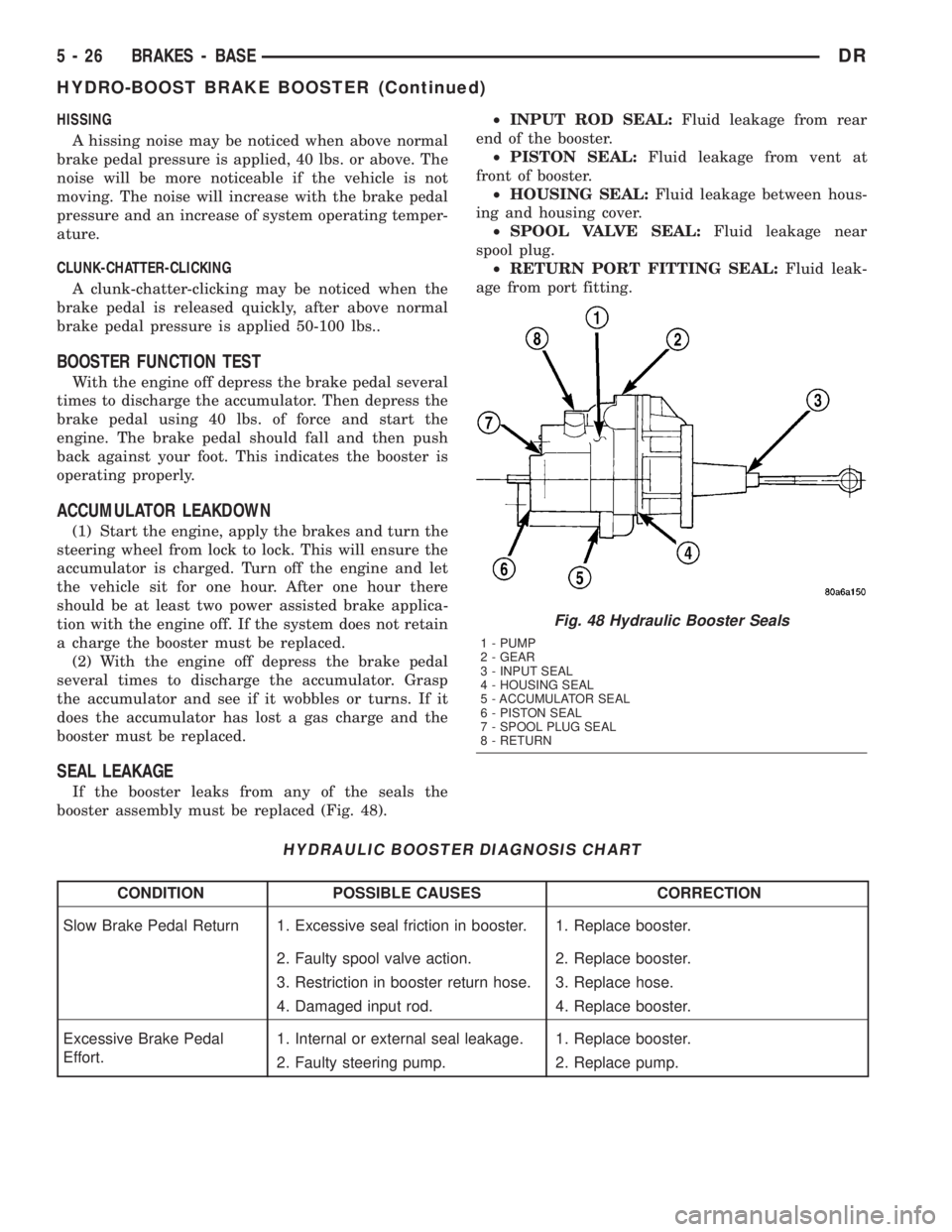

REMOVAL

(1) Remove master cylinder. (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/MASTER CYLINDER -

REMOVAL).

(2) Disconnect vacuum line at booster.

(3) Remove clip securing booster push rod to brake

pedal (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/PEDAL - REMOVAL). (Fig. 47).

(4) Remove the nuts from the booster mounting

studs (Fig. 47).

(5) Remove the booster and gasket from front cowl

panel.

INSTALLATION

(1) Guide the booster studs into the cowl panel

holes and seat the booster on the panel (Fig. 47).(2) Install and tighten new booster attaching nuts

to 28 N´m (250 in. lbs.).

(3) Install the booster push rod on brake pedal and

install clip (Fig. 47).

(4) Install the booster check valve if removed and

connect the vacuum hose to the check valve.

(5) Install the master cylinder. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/MASTER

CYLINDER - INSTALLATION).

(6) Fill and bleed the brake system. (Refer to 5 -

BRAKES - STANDARD PROCEDURE).

HYDRO-BOOST BRAKE

BOOSTER

DIAGNOSIS AND TESTING - HYDRAULIC

BOOSTER

The hydraulic booster uses hydraulic pressure from

the power steering pump. Before diagnosing a

booster problem, first verify the power steering pump

is operating properly. Perform the following checks.

²Check the power steering fluid level.

²Check the brake fluid level.

²Check all power steering hoses and lines for

leaks and restrictions.

²Check power steering pump pressure.

NOISES

The hydraulic booster unit will produce certain

characteristic booster noises. The noises may occur

when the brake pedal is used in a manner not asso-

ciated with normal braking or driving habits.

Fig. 47 POWER BRAKE BOOSTER

1 - MOUNTING NUT

2 - POWER BRAKE BOOSTER

DRBRAKES - BASE 5 - 25

ADJUSTABLE PEDAL MOTOR (Continued)

Page 253 of 2895

HISSING

A hissing noise may be noticed when above normal

brake pedal pressure is applied, 40 lbs. or above. The

noise will be more noticeable if the vehicle is not

moving. The noise will increase with the brake pedal

pressure and an increase of system operating temper-

ature.

CLUNK-CHATTER-CLICKING

A clunk-chatter-clicking may be noticed when the

brake pedal is released quickly, after above normal

brake pedal pressure is applied 50-100 lbs..

BOOSTER FUNCTION TEST

With the engine off depress the brake pedal several

times to discharge the accumulator. Then depress the

brake pedal using 40 lbs. of force and start the

engine. The brake pedal should fall and then push

back against your foot. This indicates the booster is

operating properly.

ACCUMULATOR LEAKDOWN

(1) Start the engine, apply the brakes and turn the

steering wheel from lock to lock. This will ensure the

accumulator is charged. Turn off the engine and let

the vehicle sit for one hour. After one hour there

should be at least two power assisted brake applica-

tion with the engine off. If the system does not retain

a charge the booster must be replaced.

(2) With the engine off depress the brake pedal

several times to discharge the accumulator. Grasp

the accumulator and see if it wobbles or turns. If it

does the accumulator has lost a gas charge and the

booster must be replaced.

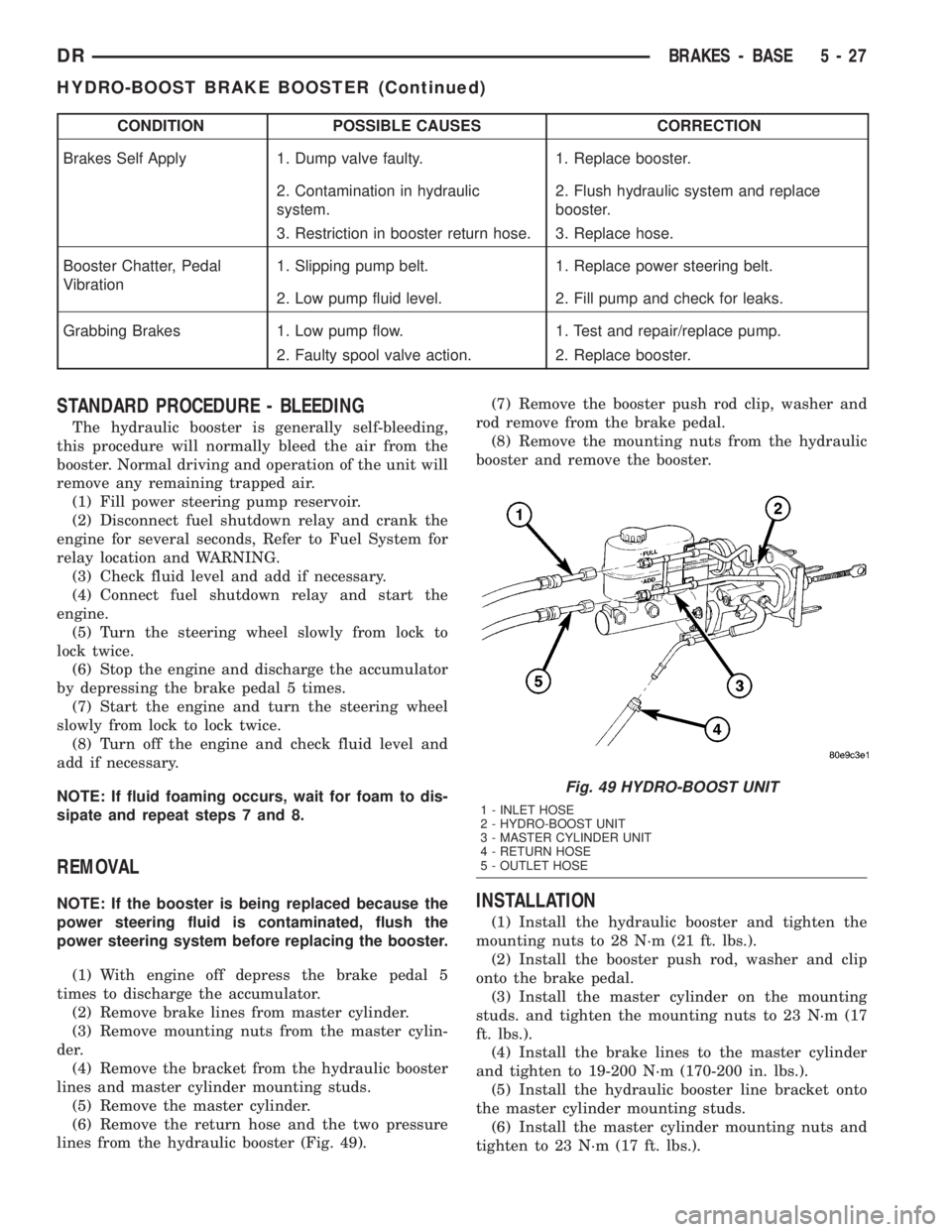

SEAL LEAKAGE

If the booster leaks from any of the seals the

booster assembly must be replaced (Fig. 48).²INPUT ROD SEAL:Fluid leakage from rear

end of the booster.

²PISTON SEAL:Fluid leakage from vent at

front of booster.

²HOUSING SEAL:Fluid leakage between hous-

ing and housing cover.

²SPOOL VALVE SEAL:Fluid leakage near

spool plug.

²RETURN PORT FITTING SEAL:Fluid leak-

age from port fitting.

HYDRAULIC BOOSTER DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

Slow Brake Pedal Return 1. Excessive seal friction in booster. 1. Replace booster.

2. Faulty spool valve action. 2. Replace booster.

3. Restriction in booster return hose. 3. Replace hose.

4. Damaged input rod. 4. Replace booster.

Excessive Brake Pedal

Effort.1. Internal or external seal leakage. 1. Replace booster.

2. Faulty steering pump. 2. Replace pump.

Fig. 48 Hydraulic Booster Seals

1 - PUMP

2 - GEAR

3 - INPUT SEAL

4 - HOUSING SEAL

5 - ACCUMULATOR SEAL

6 - PISTON SEAL

7 - SPOOL PLUG SEAL

8 - RETURN

5 - 26 BRAKES - BASEDR

HYDRO-BOOST BRAKE BOOSTER (Continued)

Page 254 of 2895

CONDITION POSSIBLE CAUSES CORRECTION

Brakes Self Apply 1. Dump valve faulty. 1. Replace booster.

2. Contamination in hydraulic

system.2. Flush hydraulic system and replace

booster.

3. Restriction in booster return hose. 3. Replace hose.

Booster Chatter, Pedal

Vibration1. Slipping pump belt. 1. Replace power steering belt.

2. Low pump fluid level. 2. Fill pump and check for leaks.

Grabbing Brakes 1. Low pump flow. 1. Test and repair/replace pump.

2. Faulty spool valve action. 2. Replace booster.

STANDARD PROCEDURE - BLEEDING

The hydraulic booster is generally self-bleeding,

this procedure will normally bleed the air from the

booster. Normal driving and operation of the unit will

remove any remaining trapped air.

(1) Fill power steering pump reservoir.

(2) Disconnect fuel shutdown relay and crank the

engine for several seconds, Refer to Fuel System for

relay location and WARNING.

(3) Check fluid level and add if necessary.

(4) Connect fuel shutdown relay and start the

engine.

(5) Turn the steering wheel slowly from lock to

lock twice.

(6) Stop the engine and discharge the accumulator

by depressing the brake pedal 5 times.

(7) Start the engine and turn the steering wheel

slowly from lock to lock twice.

(8) Turn off the engine and check fluid level and

add if necessary.

NOTE: If fluid foaming occurs, wait for foam to dis-

sipate and repeat steps 7 and 8.

REMOVAL

NOTE: If the booster is being replaced because the

power steering fluid is contaminated, flush the

power steering system before replacing the booster.

(1) With engine off depress the brake pedal 5

times to discharge the accumulator.

(2) Remove brake lines from master cylinder.

(3) Remove mounting nuts from the master cylin-

der.

(4) Remove the bracket from the hydraulic booster

lines and master cylinder mounting studs.

(5) Remove the master cylinder.

(6) Remove the return hose and the two pressure

lines from the hydraulic booster (Fig. 49).(7) Remove the booster push rod clip, washer and

rod remove from the brake pedal.

(8) Remove the mounting nuts from the hydraulic

booster and remove the booster.INSTALLATION

(1) Install the hydraulic booster and tighten the

mounting nuts to 28 N´m (21 ft. lbs.).

(2) Install the booster push rod, washer and clip

onto the brake pedal.

(3) Install the master cylinder on the mounting

studs. and tighten the mounting nuts to 23 N´m (17

ft. lbs.).

(4) Install the brake lines to the master cylinder

and tighten to 19-200 N´m (170-200 in. lbs.).

(5) Install the hydraulic booster line bracket onto

the master cylinder mounting studs.

(6) Install the master cylinder mounting nuts and

tighten to 23 N´m (17 ft. lbs.).

Fig. 49 HYDRO-BOOST UNIT

1 - INLET HOSE

2 - HYDRO-BOOST UNIT

3 - MASTER CYLINDER UNIT

4 - RETURN HOSE

5 - OUTLET HOSE

DRBRAKES - BASE 5 - 27

HYDRO-BOOST BRAKE BOOSTER (Continued)

Page 255 of 2895

(7) Install the hydraulic booster pressure lines to

the bracket and booster.

(8) Tighten the pressure lines to 41 N´m (30 ft.

lbs.).

NOTE: Inspect o-rings on the pressure line fittings

to insure they are in good condition before installa-

tion. Replace o-rings if necessary.

(9) Install the return hose to the booster.

(10) Bleed base brake system, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL - STAN-

DARD PROCEDURE).

(11) Fill the power steering pump with fluid,

(Refer to 19 - STEERING/PUMP - STANDARD PRO-

CEDURE).

CAUTION: MOPAR (MS-9602) ATF+4 is to be used in

the power steering system. No other power steering

or automatic transmission fluid is to be used in the

system. Damage may result to the power steering

pump and system if any other fluid is used, and do

not overfill.

(12) Bleed the hydraulic booster (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/POWER

BRAKE BOOSTER - STANDARD PROCEDURE).

ROTORS

REMOVAL

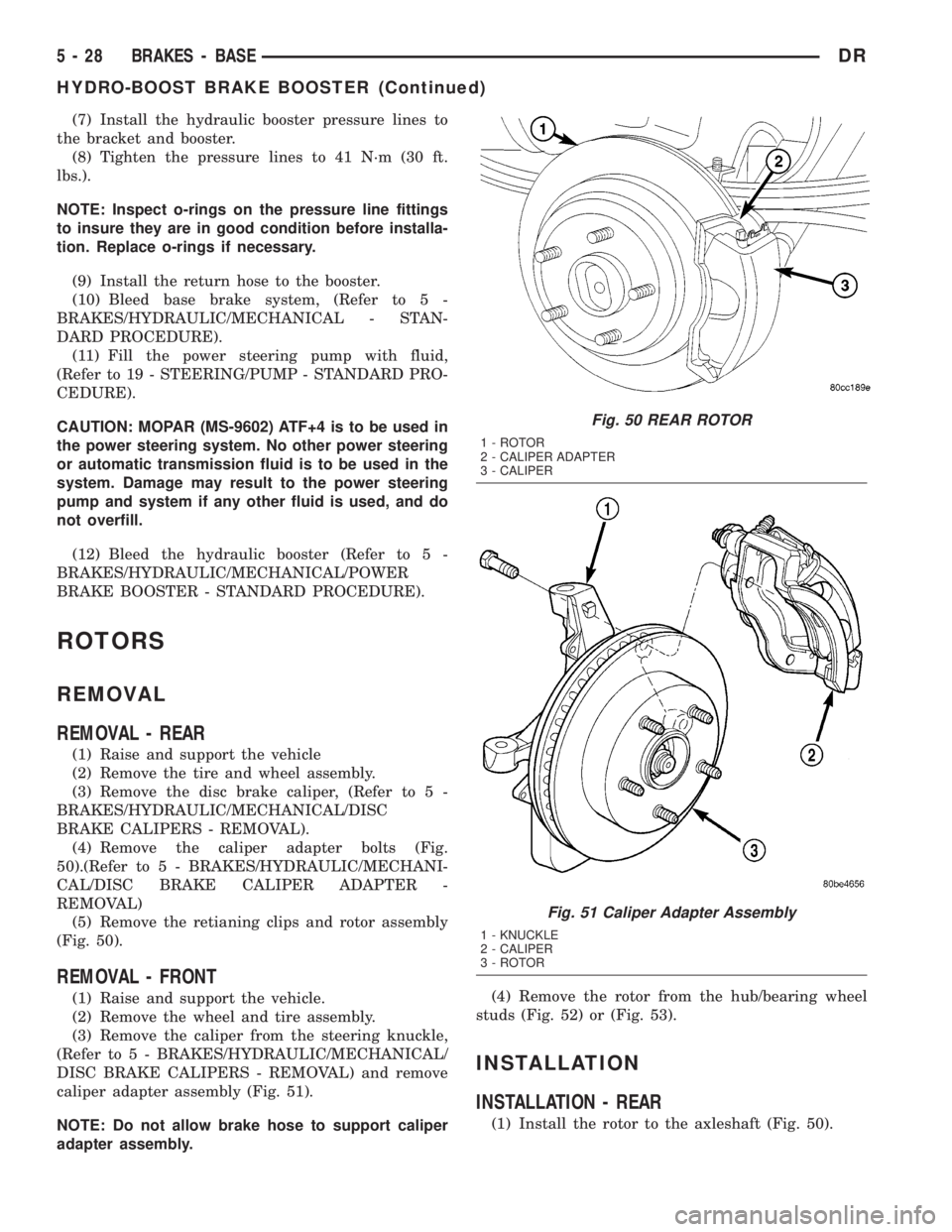

REMOVAL - REAR

(1) Raise and support the vehicle

(2) Remove the tire and wheel assembly.

(3) Remove the disc brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(4) Remove the caliper adapter bolts (Fig.

50).(Refer to 5 - BRAKES/HYDRAULIC/MECHANI-

CAL/DISC BRAKE CALIPER ADAPTER -

REMOVAL)

(5) Remove the retianing clips and rotor assembly

(Fig. 50).

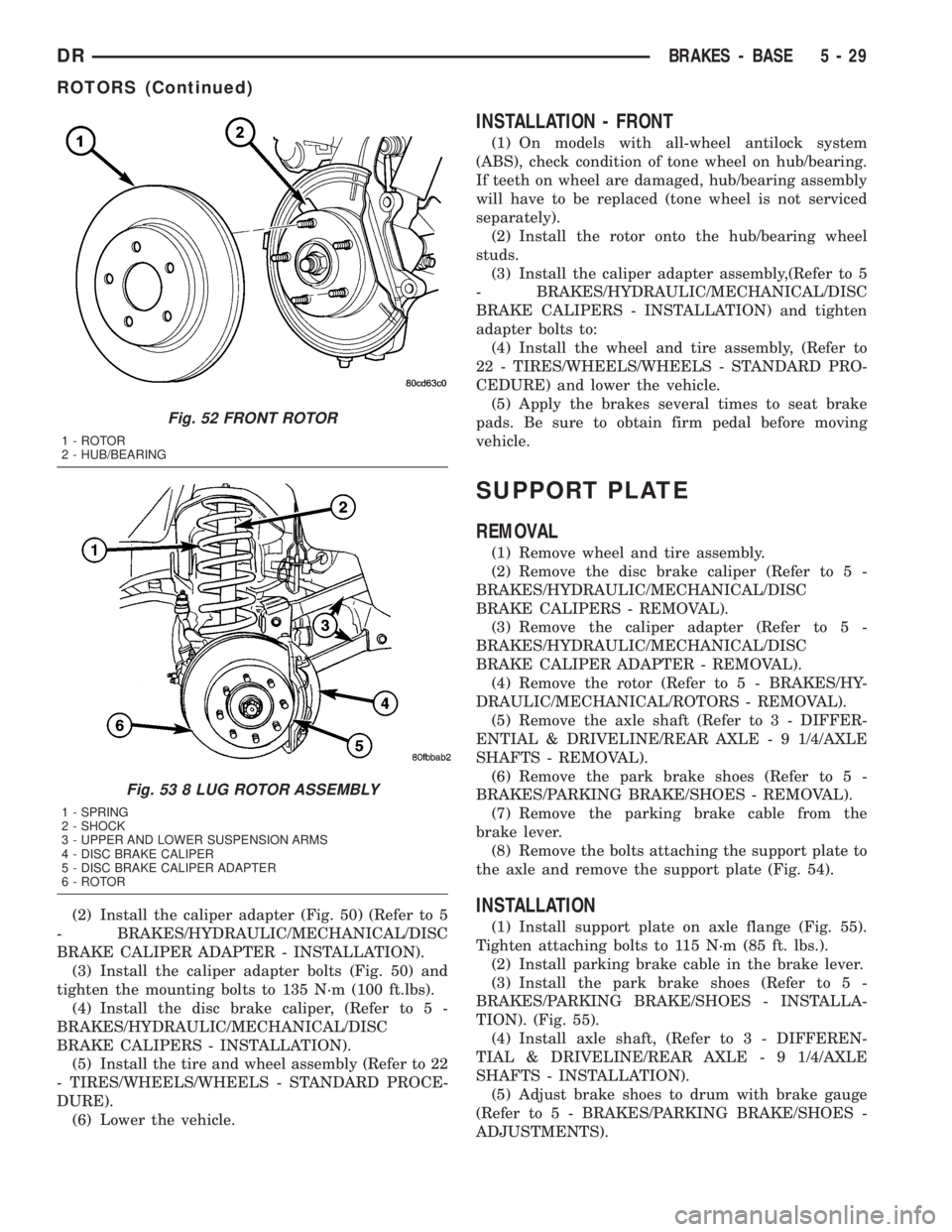

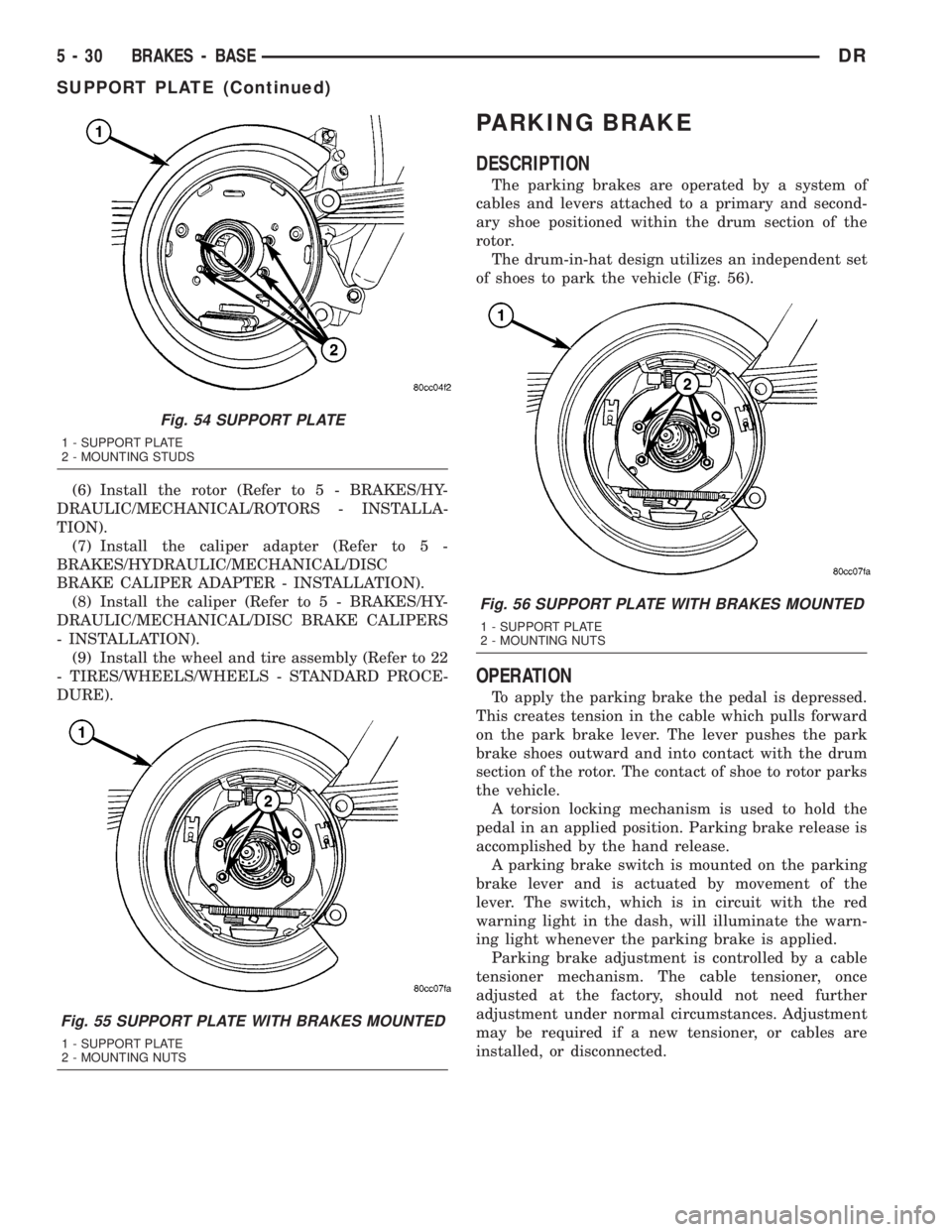

REMOVAL - FRONT

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Remove the caliper from the steering knuckle,

(Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

DISC BRAKE CALIPERS - REMOVAL) and remove

caliper adapter assembly (Fig. 51).

NOTE: Do not allow brake hose to support caliper

adapter assembly.(4) Remove the rotor from the hub/bearing wheel

studs (Fig. 52) or (Fig. 53).

INSTALLATION

INSTALLATION - REAR

(1) Install the rotor to the axleshaft (Fig. 50).

Fig. 50 REAR ROTOR

1 - ROTOR

2 - CALIPER ADAPTER

3 - CALIPER

Fig. 51 Caliper Adapter Assembly

1 - KNUCKLE

2 - CALIPER

3 - ROTOR

5 - 28 BRAKES - BASEDR

HYDRO-BOOST BRAKE BOOSTER (Continued)

Page 256 of 2895

(2) Install the caliper adapter (Fig. 50) (Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - INSTALLATION).

(3) Install the caliper adapter bolts (Fig. 50) and

tighten the mounting bolts to 135 N´m (100 ft.lbs).

(4) Install the disc brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION).

(5) Install the tire and wheel assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(6) Lower the vehicle.

INSTALLATION - FRONT

(1) On models with all-wheel antilock system

(ABS), check condition of tone wheel on hub/bearing.

If teeth on wheel are damaged, hub/bearing assembly

will have to be replaced (tone wheel is not serviced

separately).

(2) Install the rotor onto the hub/bearing wheel

studs.

(3) Install the caliper adapter assembly,(Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION) and tighten

adapter bolts to:

(4) Install the wheel and tire assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE) and lower the vehicle.

(5) Apply the brakes several times to seat brake

pads. Be sure to obtain firm pedal before moving

vehicle.

SUPPORT PLATE

REMOVAL

(1) Remove wheel and tire assembly.

(2) Remove the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(3) Remove the caliper adapter (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - REMOVAL).

(4) Remove the rotor (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - REMOVAL).

(5) Remove the axle shaft (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE

SHAFTS - REMOVAL).

(6) Remove the park brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - REMOVAL).

(7) Remove the parking brake cable from the

brake lever.

(8) Remove the bolts attaching the support plate to

the axle and remove the support plate (Fig. 54).

INSTALLATION

(1) Install support plate on axle flange (Fig. 55).

Tighten attaching bolts to 115 N´m (85 ft. lbs.).

(2) Install parking brake cable in the brake lever.

(3) Install the park brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - INSTALLA-

TION). (Fig. 55).

(4) Install axle shaft, (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE

SHAFTS - INSTALLATION).

(5) Adjust brake shoes to drum with brake gauge

(Refer to 5 - BRAKES/PARKING BRAKE/SHOES -

ADJUSTMENTS).

Fig. 52 FRONT ROTOR

1 - ROTOR

2 - HUB/BEARING

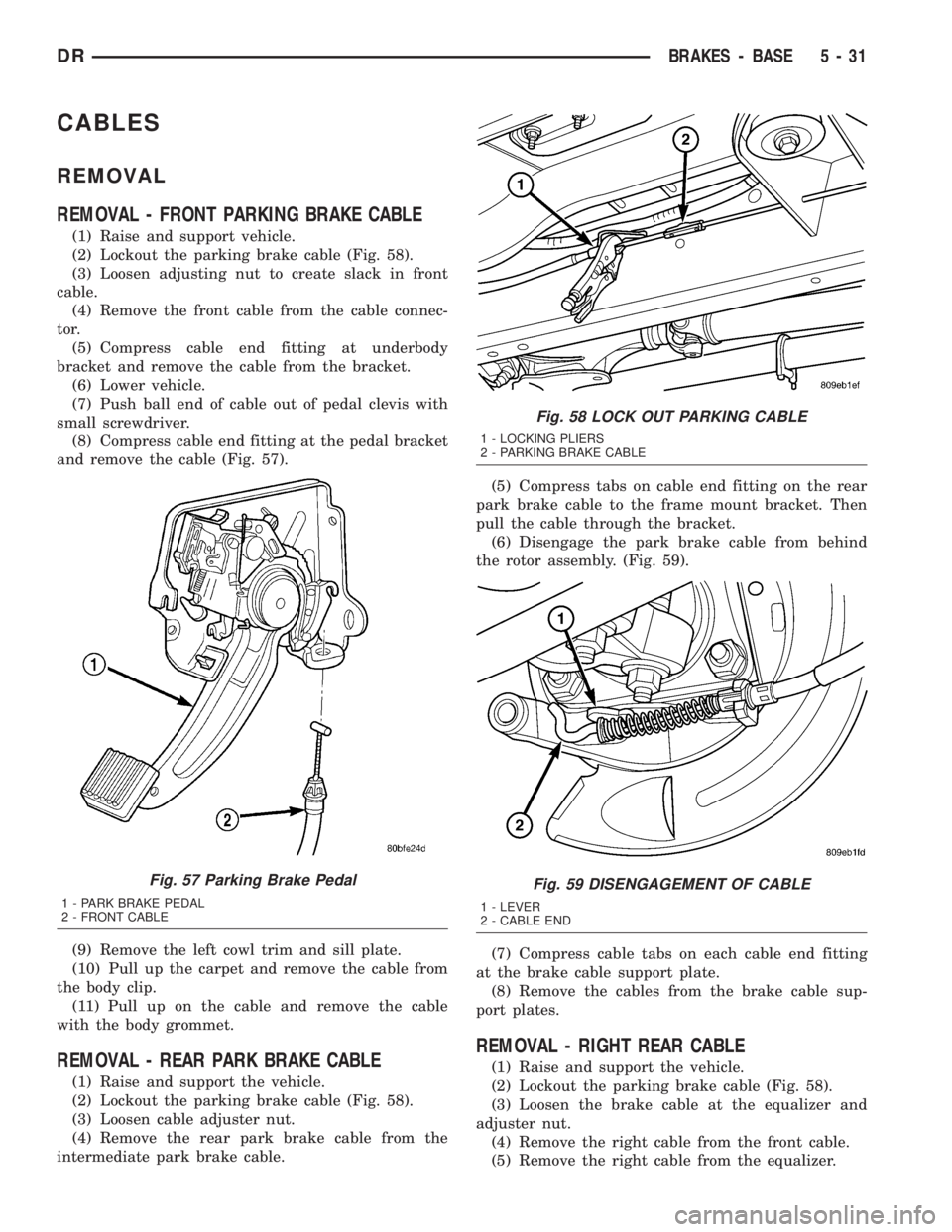

Fig. 53 8 LUG ROTOR ASSEMBLY

1 - SPRING

2 - SHOCK

3 - UPPER AND LOWER SUSPENSION ARMS

4 - DISC BRAKE CALIPER

5 - DISC BRAKE CALIPER ADAPTER

6 - ROTOR

DRBRAKES - BASE 5 - 29

ROTORS (Continued)

Page 257 of 2895

(6) Install the rotor (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - INSTALLA-

TION).

(7) Install the caliper adapter (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - INSTALLATION).

(8) Install the caliper (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/DISC BRAKE CALIPERS

- INSTALLATION).

(9) Install the wheel and tire assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

PARKING BRAKE

DESCRIPTION

The parking brakes are operated by a system of

cables and levers attached to a primary and second-

ary shoe positioned within the drum section of the

rotor.

The drum-in-hat design utilizes an independent set

of shoes to park the vehicle (Fig. 56).

OPERATION

To apply the parking brake the pedal is depressed.

This creates tension in the cable which pulls forward

on the park brake lever. The lever pushes the park

brake shoes outward and into contact with the drum

section of the rotor. The contact of shoe to rotor parks

the vehicle.

A torsion locking mechanism is used to hold the

pedal in an applied position. Parking brake release is

accomplished by the hand release.

A parking brake switch is mounted on the parking

brake lever and is actuated by movement of the

lever. The switch, which is in circuit with the red

warning light in the dash, will illuminate the warn-

ing light whenever the parking brake is applied.

Parking brake adjustment is controlled by a cable

tensioner mechanism. The cable tensioner, once

adjusted at the factory, should not need further

adjustment under normal circumstances. Adjustment

may be required if a new tensioner, or cables are

installed, or disconnected.

Fig. 54 SUPPORT PLATE

1 - SUPPORT PLATE

2 - MOUNTING STUDS

Fig. 55 SUPPORT PLATE WITH BRAKES MOUNTED

1 - SUPPORT PLATE

2 - MOUNTING NUTS

Fig. 56 SUPPORT PLATE WITH BRAKES MOUNTED

1 - SUPPORT PLATE

2 - MOUNTING NUTS

5 - 30 BRAKES - BASEDR

SUPPORT PLATE (Continued)

Page 258 of 2895

CABLES

REMOVAL

REMOVAL - FRONT PARKING BRAKE CABLE

(1) Raise and support vehicle.

(2) Lockout the parking brake cable (Fig. 58).

(3) Loosen adjusting nut to create slack in front

cable.

(4) Remove the front cable from the cable connec-

tor.

(5) Compress cable end fitting at underbody

bracket and remove the cable from the bracket.

(6) Lower vehicle.

(7) Push ball end of cable out of pedal clevis with

small screwdriver.

(8) Compress cable end fitting at the pedal bracket

and remove the cable (Fig. 57).

(9) Remove the left cowl trim and sill plate.

(10) Pull up the carpet and remove the cable from

the body clip.

(11) Pull up on the cable and remove the cable

with the body grommet.

REMOVAL - REAR PARK BRAKE CABLE

(1) Raise and support the vehicle.

(2) Lockout the parking brake cable (Fig. 58).

(3) Loosen cable adjuster nut.

(4) Remove the rear park brake cable from the

intermediate park brake cable.(5) Compress tabs on cable end fitting on the rear

park brake cable to the frame mount bracket. Then

pull the cable through the bracket.

(6) Disengage the park brake cable from behind

the rotor assembly. (Fig. 59).

(7) Compress cable tabs on each cable end fitting

at the brake cable support plate.

(8) Remove the cables from the brake cable sup-

port plates.

REMOVAL - RIGHT REAR CABLE

(1) Raise and support the vehicle.

(2) Lockout the parking brake cable (Fig. 58).

(3) Loosen the brake cable at the equalizer and

adjuster nut.

(4) Remove the right cable from the front cable.

(5) Remove the right cable from the equalizer.

Fig. 57 Parking Brake Pedal

1 - PARK BRAKE PEDAL

2 - FRONT CABLE

Fig. 58 LOCK OUT PARKING CABLE

1 - LOCKING PLIERS

2 - PARKING BRAKE CABLE

Fig. 59 DISENGAGEMENT OF CABLE

1 - LEVER

2 - CABLE END

DRBRAKES - BASE 5 - 31

Page 259 of 2895

(6) Remove the cable from the frame bracket.

(7) Remove the cable from the axle bracket.

(8) Remove the cable bracket from the shock

bracket.

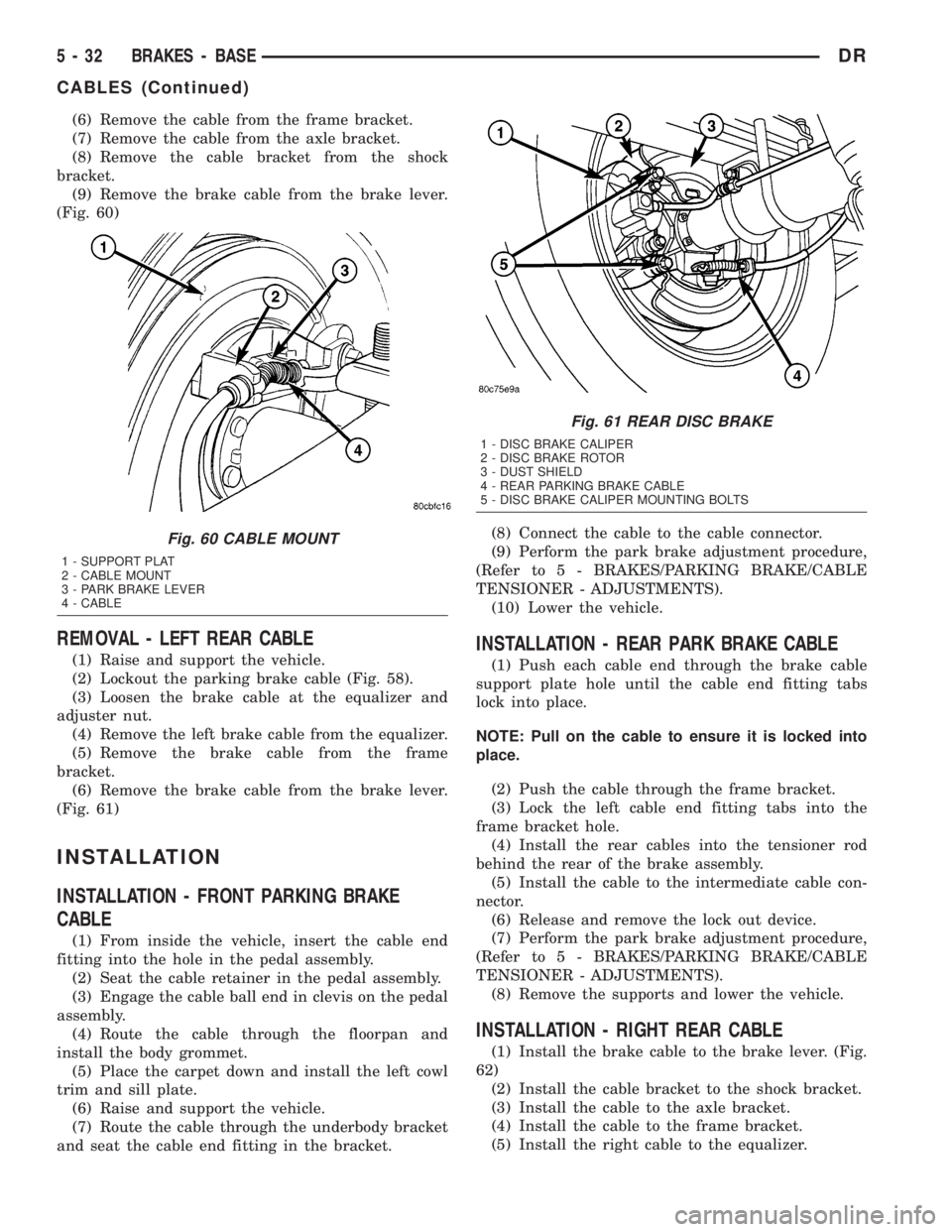

(9) Remove the brake cable from the brake lever.

(Fig. 60)

REMOVAL - LEFT REAR CABLE

(1) Raise and support the vehicle.

(2) Lockout the parking brake cable (Fig. 58).

(3) Loosen the brake cable at the equalizer and

adjuster nut.

(4) Remove the left brake cable from the equalizer.

(5) Remove the brake cable from the frame

bracket.

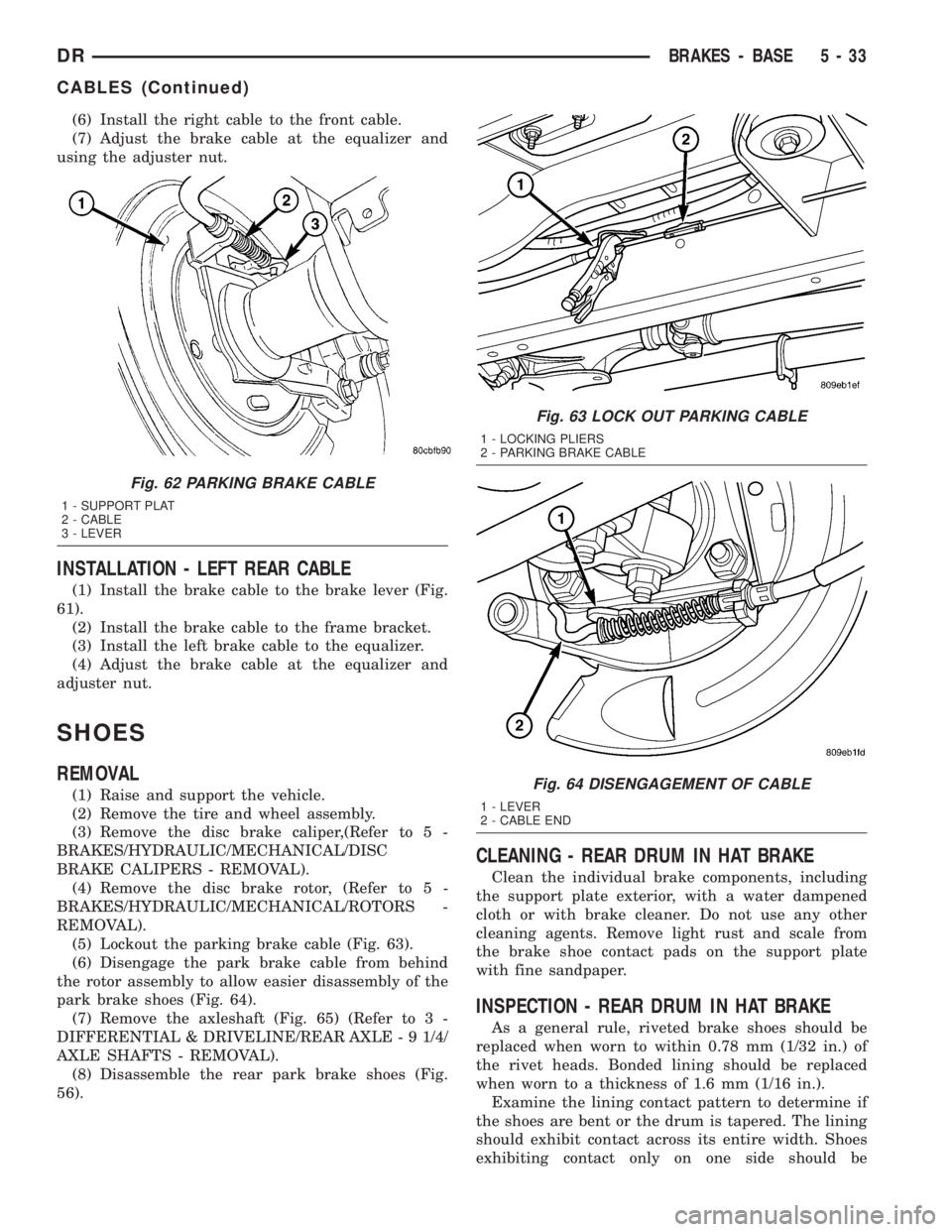

(6) Remove the brake cable from the brake lever.

(Fig. 61)

INSTALLATION

INSTALLATION - FRONT PARKING BRAKE

CABLE

(1) From inside the vehicle, insert the cable end

fitting into the hole in the pedal assembly.

(2) Seat the cable retainer in the pedal assembly.

(3) Engage the cable ball end in clevis on the pedal

assembly.

(4) Route the cable through the floorpan and

install the body grommet.

(5) Place the carpet down and install the left cowl

trim and sill plate.

(6) Raise and support the vehicle.

(7) Route the cable through the underbody bracket

and seat the cable end fitting in the bracket.(8) Connect the cable to the cable connector.

(9) Perform the park brake adjustment procedure,

(Refer to 5 - BRAKES/PARKING BRAKE/CABLE

TENSIONER - ADJUSTMENTS).

(10) Lower the vehicle.

INSTALLATION - REAR PARK BRAKE CABLE

(1) Push each cable end through the brake cable

support plate hole until the cable end fitting tabs

lock into place.

NOTE: Pull on the cable to ensure it is locked into

place.

(2) Push the cable through the frame bracket.

(3) Lock the left cable end fitting tabs into the

frame bracket hole.

(4) Install the rear cables into the tensioner rod

behind the rear of the brake assembly.

(5) Install the cable to the intermediate cable con-

nector.

(6) Release and remove the lock out device.

(7) Perform the park brake adjustment procedure,

(Refer to 5 - BRAKES/PARKING BRAKE/CABLE

TENSIONER - ADJUSTMENTS).

(8) Remove the supports and lower the vehicle.

INSTALLATION - RIGHT REAR CABLE

(1) Install the brake cable to the brake lever. (Fig.

62)

(2) Install the cable bracket to the shock bracket.

(3) Install the cable to the axle bracket.

(4) Install the cable to the frame bracket.

(5) Install the right cable to the equalizer.

Fig. 60 CABLE MOUNT

1 - SUPPORT PLAT

2 - CABLE MOUNT

3 - PARK BRAKE LEVER

4 - CABLE

Fig. 61 REAR DISC BRAKE

1 - DISC BRAKE CALIPER

2 - DISC BRAKE ROTOR

3 - DUST SHIELD

4 - REAR PARKING BRAKE CABLE

5 - DISC BRAKE CALIPER MOUNTING BOLTS

5 - 32 BRAKES - BASEDR

CABLES (Continued)

Page 260 of 2895

(6) Install the right cable to the front cable.

(7) Adjust the brake cable at the equalizer and

using the adjuster nut.

INSTALLATION - LEFT REAR CABLE

(1) Install the brake cable to the brake lever (Fig.

61).

(2) Install the brake cable to the frame bracket.

(3) Install the left brake cable to the equalizer.

(4) Adjust the brake cable at the equalizer and

adjuster nut.

SHOES

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the tire and wheel assembly.

(3) Remove the disc brake caliper,(Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(4) Remove the disc brake rotor, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

REMOVAL).

(5) Lockout the parking brake cable (Fig. 63).

(6) Disengage the park brake cable from behind

the rotor assembly to allow easier disassembly of the

park brake shoes (Fig. 64).

(7) Remove the axleshaft (Fig. 65) (Refer to 3 -

DIFFERENTIAL & DRIVELINE/REAR AXLE - 9 1/4/

AXLE SHAFTS - REMOVAL).

(8) Disassemble the rear park brake shoes (Fig.

56).

CLEANING - REAR DRUM IN HAT BRAKE

Clean the individual brake components, including

the support plate exterior, with a water dampened

cloth or with brake cleaner. Do not use any other

cleaning agents. Remove light rust and scale from

the brake shoe contact pads on the support plate

with fine sandpaper.

INSPECTION - REAR DRUM IN HAT BRAKE

As a general rule, riveted brake shoes should be

replaced when worn to within 0.78 mm (1/32 in.) of

the rivet heads. Bonded lining should be replaced

when worn to a thickness of 1.6 mm (1/16 in.).

Examine the lining contact pattern to determine if

the shoes are bent or the drum is tapered. The lining

should exhibit contact across its entire width. Shoes

exhibiting contact only on one side should be

Fig. 62 PARKING BRAKE CABLE

1 - SUPPORT PLAT

2 - CABLE

3 - LEVER

Fig. 63 LOCK OUT PARKING CABLE

1 - LOCKING PLIERS

2 - PARKING BRAKE CABLE

Fig. 64 DISENGAGEMENT OF CABLE

1 - LEVER

2 - CABLE END

DRBRAKES - BASE 5 - 33

CABLES (Continued)