Oil pump DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2452 of 2895

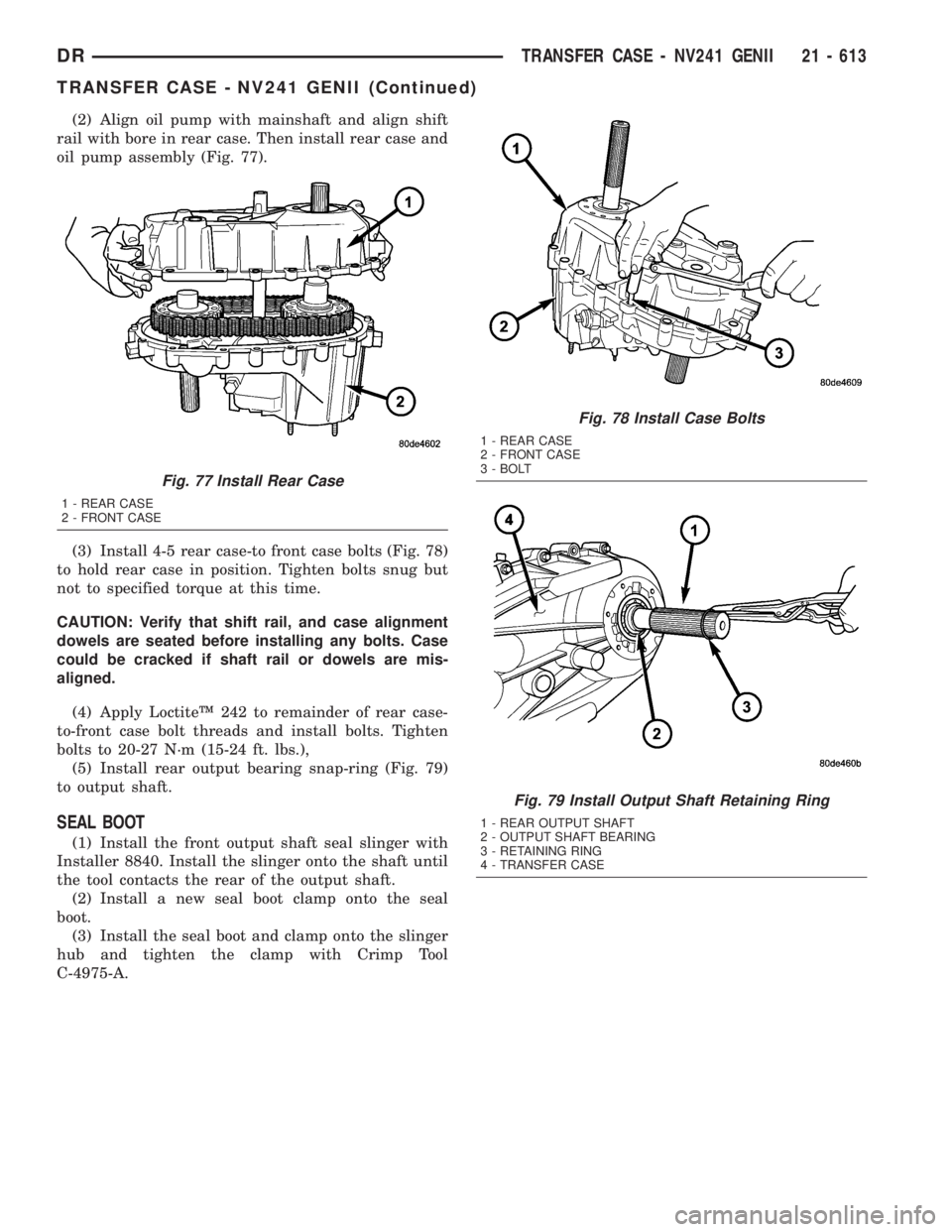

(2) Align oil pump with mainshaft and align shift

rail with bore in rear case. Then install rear case and

oil pump assembly (Fig. 77).

(3) Install 4-5 rear case-to front case bolts (Fig. 78)

to hold rear case in position. Tighten bolts snug but

not to specified torque at this time.

CAUTION: Verify that shift rail, and case alignment

dowels are seated before installing any bolts. Case

could be cracked if shaft rail or dowels are mis-

aligned.

(4) Apply LoctiteŸ 242 to remainder of rear case-

to-front case bolt threads and install bolts. Tighten

bolts to 20-27 N´m (15-24 ft. lbs.),

(5) Install rear output bearing snap-ring (Fig. 79)

to output shaft.

SEAL BOOT

(1) Install the front output shaft seal slinger with

Installer 8840. Install the slinger onto the shaft until

the tool contacts the rear of the output shaft.

(2) Install a new seal boot clamp onto the seal

boot.

(3) Install the seal boot and clamp onto the slinger

hub and tighten the clamp with Crimp Tool

C-4975-A.

Fig. 77 Install Rear Case

1 - REAR CASE

2 - FRONT CASE

Fig. 78 Install Case Bolts

1 - REAR CASE

2 - FRONT CASE

3 - BOLT

Fig. 79 Install Output Shaft Retaining Ring

1 - REAR OUTPUT SHAFT

2 - OUTPUT SHAFT BEARING

3 - RETAINING RING

4 - TRANSFER CASE

DRTRANSFER CASE - NV241 GENII 21 - 613

TRANSFER CASE - NV241 GENII (Continued)

Page 2453 of 2895

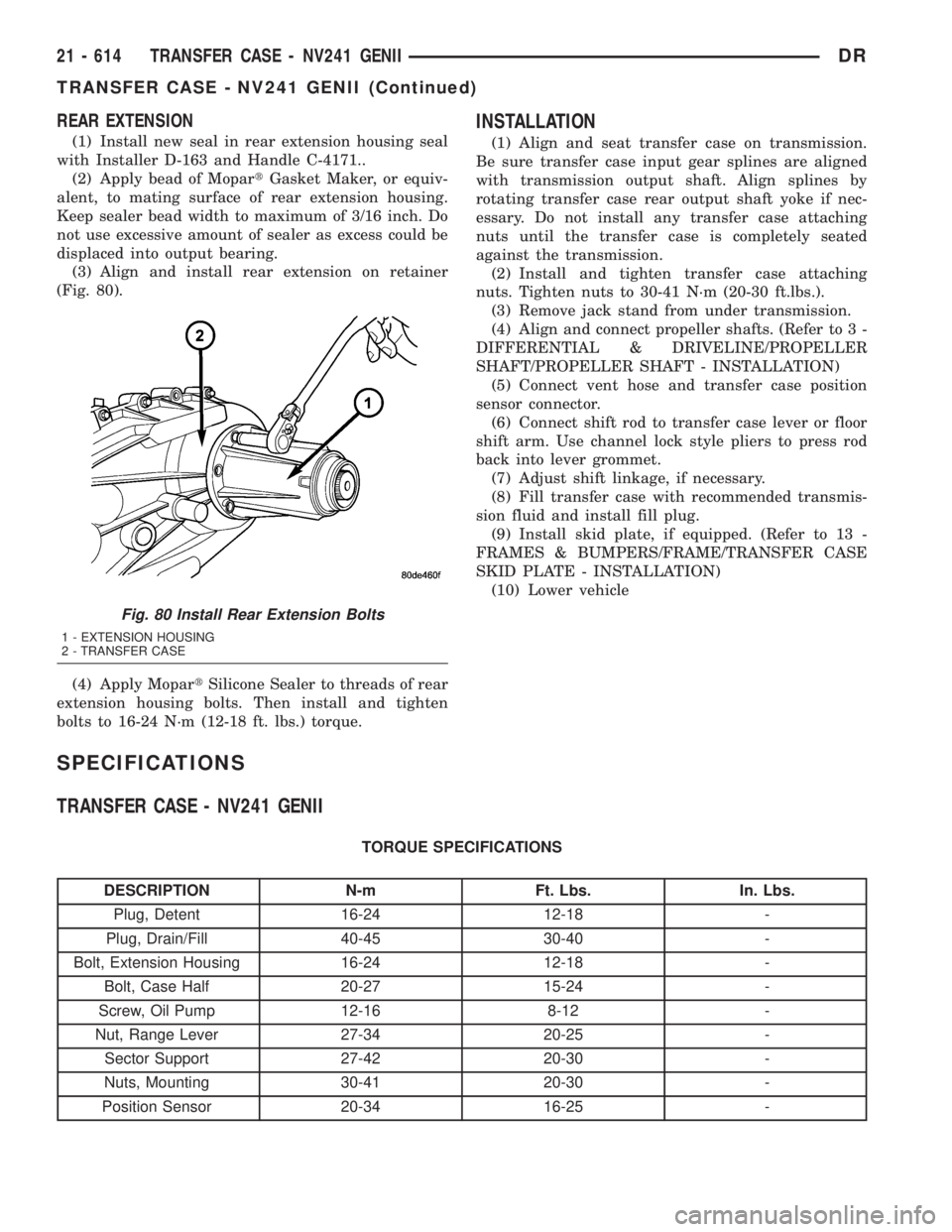

REAR EXTENSION

(1) Install new seal in rear extension housing seal

with Installer D-163 and Handle C-4171..

(2) Apply bead of MopartGasket Maker, or equiv-

alent, to mating surface of rear extension housing.

Keep sealer bead width to maximum of 3/16 inch. Do

not use excessive amount of sealer as excess could be

displaced into output bearing.

(3) Align and install rear extension on retainer

(Fig. 80).

(4) Apply MopartSilicone Sealer to threads of rear

extension housing bolts. Then install and tighten

bolts to 16-24 N´m (12-18 ft. lbs.) torque.

INSTALLATION

(1) Align and seat transfer case on transmission.

Be sure transfer case input gear splines are aligned

with transmission output shaft. Align splines by

rotating transfer case rear output shaft yoke if nec-

essary. Do not install any transfer case attaching

nuts until the transfer case is completely seated

against the transmission.

(2) Install and tighten transfer case attaching

nuts. Tighten nuts to 30-41 N´m (20-30 ft.lbs.).

(3) Remove jack stand from under transmission.

(4) Align and connect propeller shafts. (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - INSTALLATION)

(5) Connect vent hose and transfer case position

sensor connector.

(6) Connect shift rod to transfer case lever or floor

shift arm. Use channel lock style pliers to press rod

back into lever grommet.

(7) Adjust shift linkage, if necessary.

(8) Fill transfer case with recommended transmis-

sion fluid and install fill plug.

(9) Install skid plate, if equipped. (Refer to 13 -

FRAMES & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - INSTALLATION)

(10) Lower vehicle

SPECIFICATIONS

TRANSFER CASE - NV241 GENII

TORQUE SPECIFICATIONS

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Plug, Detent 16-24 12-18 -

Plug, Drain/Fill 40-45 30-40 -

Bolt, Extension Housing 16-24 12-18 -

Bolt, Case Half 20-27 15-24 -

Screw, Oil Pump 12-16 8-12 -

Nut, Range Lever 27-34 20-25 -

Sector Support 27-42 20-30 -

Nuts, Mounting 30-41 20-30 -

Position Sensor 20-34 16-25 -

Fig. 80 Install Rear Extension Bolts

1 - EXTENSION HOUSING

2 - TRANSFER CASE

21 - 614 TRANSFER CASE - NV241 GENIIDR

TRANSFER CASE - NV241 GENII (Continued)

Page 2466 of 2895

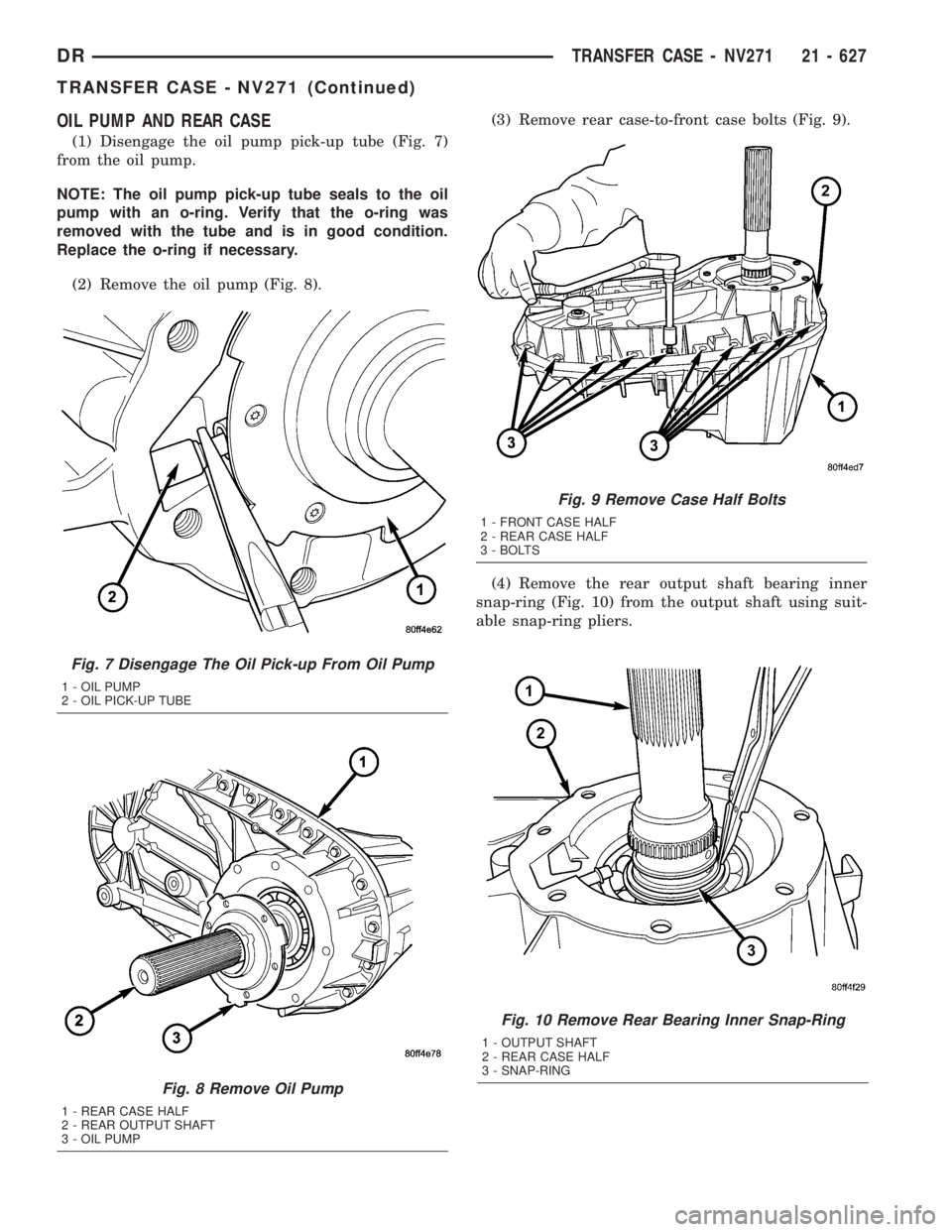

OIL PUMP AND REAR CASE

(1) Disengage the oil pump pick-up tube (Fig. 7)

from the oil pump.

NOTE: The oil pump pick-up tube seals to the oil

pump with an o-ring. Verify that the o-ring was

removed with the tube and is in good condition.

Replace the o-ring if necessary.

(2) Remove the oil pump (Fig. 8).(3) Remove rear case-to-front case bolts (Fig. 9).

(4) Remove the rear output shaft bearing inner

snap-ring (Fig. 10) from the output shaft using suit-

able snap-ring pliers.

Fig. 10 Remove Rear Bearing Inner Snap-Ring

1 - OUTPUT SHAFT

2 - REAR CASE HALF

3 - SNAP-RING

Fig. 7 Disengage The Oil Pick-up From Oil Pump

1 - OIL PUMP

2 - OIL PICK-UP TUBE

Fig. 8 Remove Oil Pump

1 - REAR CASE HALF

2 - REAR OUTPUT SHAFT

3 - OIL PUMP

Fig. 9 Remove Case Half Bolts

1 - FRONT CASE HALF

2 - REAR CASE HALF

3 - BOLTS

DRTRANSFER CASE - NV271 21 - 627

TRANSFER CASE - NV271 (Continued)

Page 2475 of 2895

Examine the carrier body and pinion gears for

wear or damage. Check the pinion gear thrust wash-

ers on the pinon pins for damage. The carrier will

have to be replaced as an assembly if the body, pin-

ion pins, or pinion gears are damaged.

Check the lock ring and both thrust washers for

wear or cracks. Replace them if necessary. Also

replace the lock retaining ring if bent, distorted, or

broken.

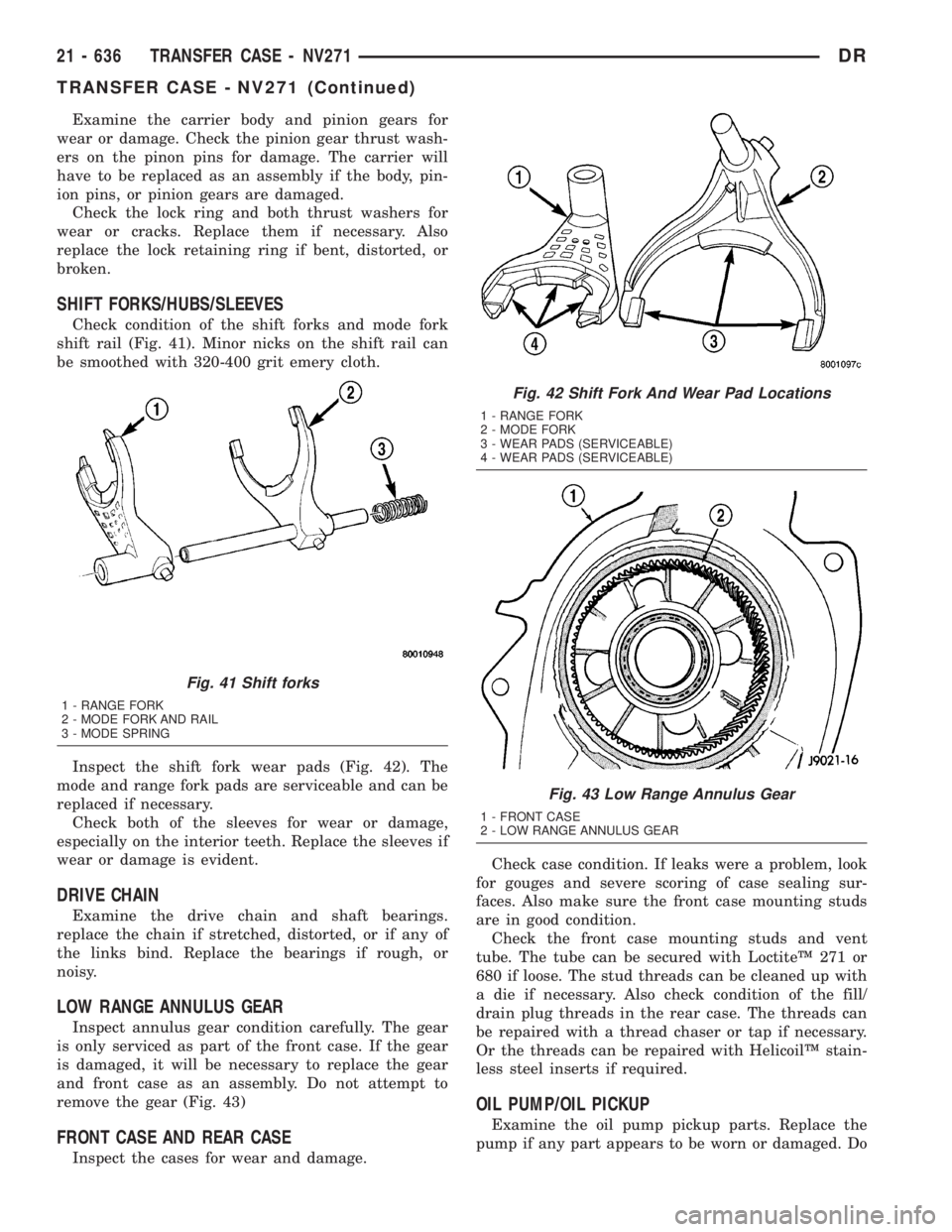

SHIFT FORKS/HUBS/SLEEVES

Check condition of the shift forks and mode fork

shift rail (Fig. 41). Minor nicks on the shift rail can

be smoothed with 320-400 grit emery cloth.

Inspect the shift fork wear pads (Fig. 42). The

mode and range fork pads are serviceable and can be

replaced if necessary.

Check both of the sleeves for wear or damage,

especially on the interior teeth. Replace the sleeves if

wear or damage is evident.

DRIVE CHAIN

Examine the drive chain and shaft bearings.

replace the chain if stretched, distorted, or if any of

the links bind. Replace the bearings if rough, or

noisy.

LOW RANGE ANNULUS GEAR

Inspect annulus gear condition carefully. The gear

is only serviced as part of the front case. If the gear

is damaged, it will be necessary to replace the gear

and front case as an assembly. Do not attempt to

remove the gear (Fig. 43)

FRONT CASE AND REAR CASE

Inspect the cases for wear and damage.Check case condition. If leaks were a problem, look

for gouges and severe scoring of case sealing sur-

faces. Also make sure the front case mounting studs

are in good condition.

Check the front case mounting studs and vent

tube. The tube can be secured with LoctiteŸ 271 or

680 if loose. The stud threads can be cleaned up with

a die if necessary. Also check condition of the fill/

drain plug threads in the rear case. The threads can

be repaired with a thread chaser or tap if necessary.

Or the threads can be repaired with HelicoilŸ stain-

less steel inserts if required.

OIL PUMP/OIL PICKUP

Examine the oil pump pickup parts. Replace the

pump if any part appears to be worn or damaged. Do

Fig. 41 Shift forks

1 - RANGE FORK

2 - MODE FORK AND RAIL

3 - MODE SPRING

Fig. 42 Shift Fork And Wear Pad Locations

1 - RANGE FORK

2 - MODE FORK

3 - WEAR PADS (SERVICEABLE)

4 - WEAR PADS (SERVICEABLE)

Fig. 43 Low Range Annulus Gear

1 - FRONT CASE

2 - LOW RANGE ANNULUS GEAR

21 - 636 TRANSFER CASE - NV271DR

TRANSFER CASE - NV271 (Continued)

Page 2478 of 2895

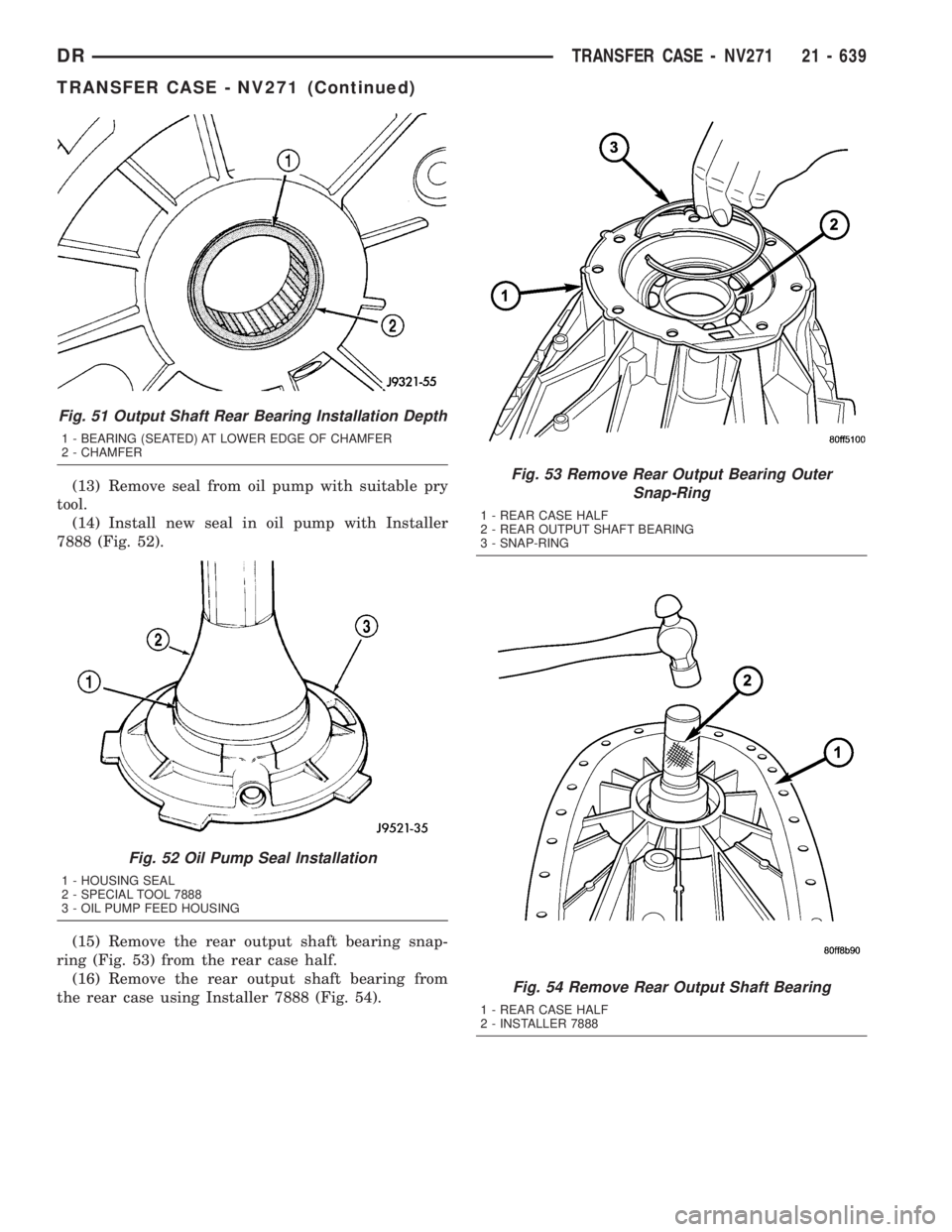

(13) Remove seal from oil pump with suitable pry

tool.

(14) Install new seal in oil pump with Installer

7888 (Fig. 52).

(15) Remove the rear output shaft bearing snap-

ring (Fig. 53) from the rear case half.

(16) Remove the rear output shaft bearing from

the rear case using Installer 7888 (Fig. 54).Fig. 53 Remove Rear Output Bearing Outer

Snap-Ring

1 - REAR CASE HALF

2 - REAR OUTPUT SHAFT BEARING

3 - SNAP-RING

Fig. 54 Remove Rear Output Shaft Bearing

1 - REAR CASE HALF

2 - INSTALLER 7888

Fig. 51 Output Shaft Rear Bearing Installation Depth

1 - BEARING (SEATED) AT LOWER EDGE OF CHAMFER

2 - CHAMFER

Fig. 52 Oil Pump Seal Installation

1 - HOUSING SEAL

2 - SPECIAL TOOL 7888

3 - OIL PUMP FEED HOUSING

DRTRANSFER CASE - NV271 21 - 639

TRANSFER CASE - NV271 (Continued)

Page 2486 of 2895

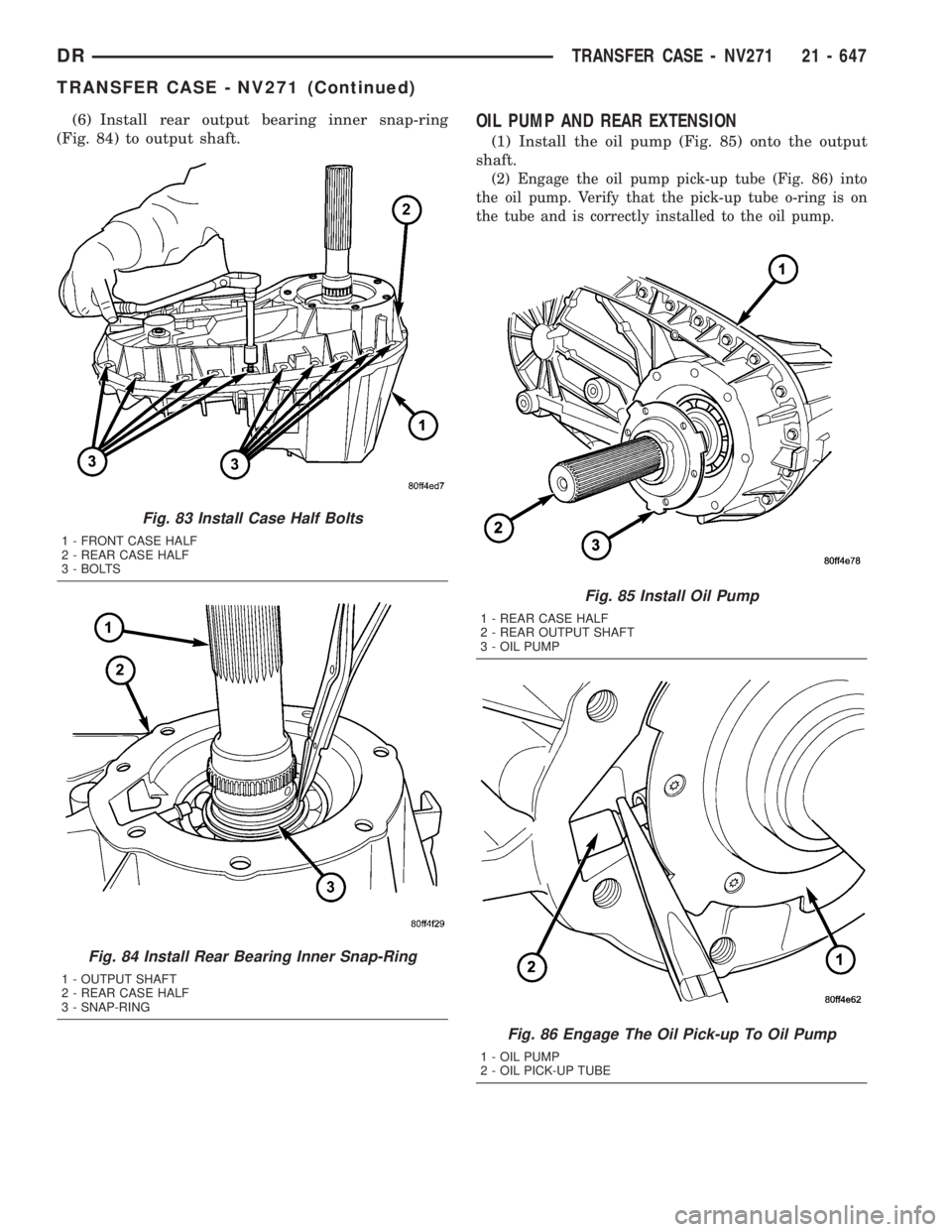

(6) Install rear output bearing inner snap-ring

(Fig. 84) to output shaft.OIL PUMP AND REAR EXTENSION

(1) Install the oil pump (Fig. 85) onto the output

shaft.

(2) Engage the oil pump pick-up tube (Fig. 86) into

the oil pump. Verify that the pick-up tube o-ring is on

the tube and is correctly installed to the oil pump.

Fig. 83 Install Case Half Bolts

1 - FRONT CASE HALF

2 - REAR CASE HALF

3 - BOLTS

Fig. 84 Install Rear Bearing Inner Snap-Ring

1 - OUTPUT SHAFT

2 - REAR CASE HALF

3 - SNAP-RING

Fig. 85 Install Oil Pump

1 - REAR CASE HALF

2 - REAR OUTPUT SHAFT

3 - OIL PUMP

Fig. 86 Engage The Oil Pick-up To Oil Pump

1 - OIL PUMP

2 - OIL PICK-UP TUBE

DRTRANSFER CASE - NV271 21 - 647

TRANSFER CASE - NV271 (Continued)

Page 2501 of 2895

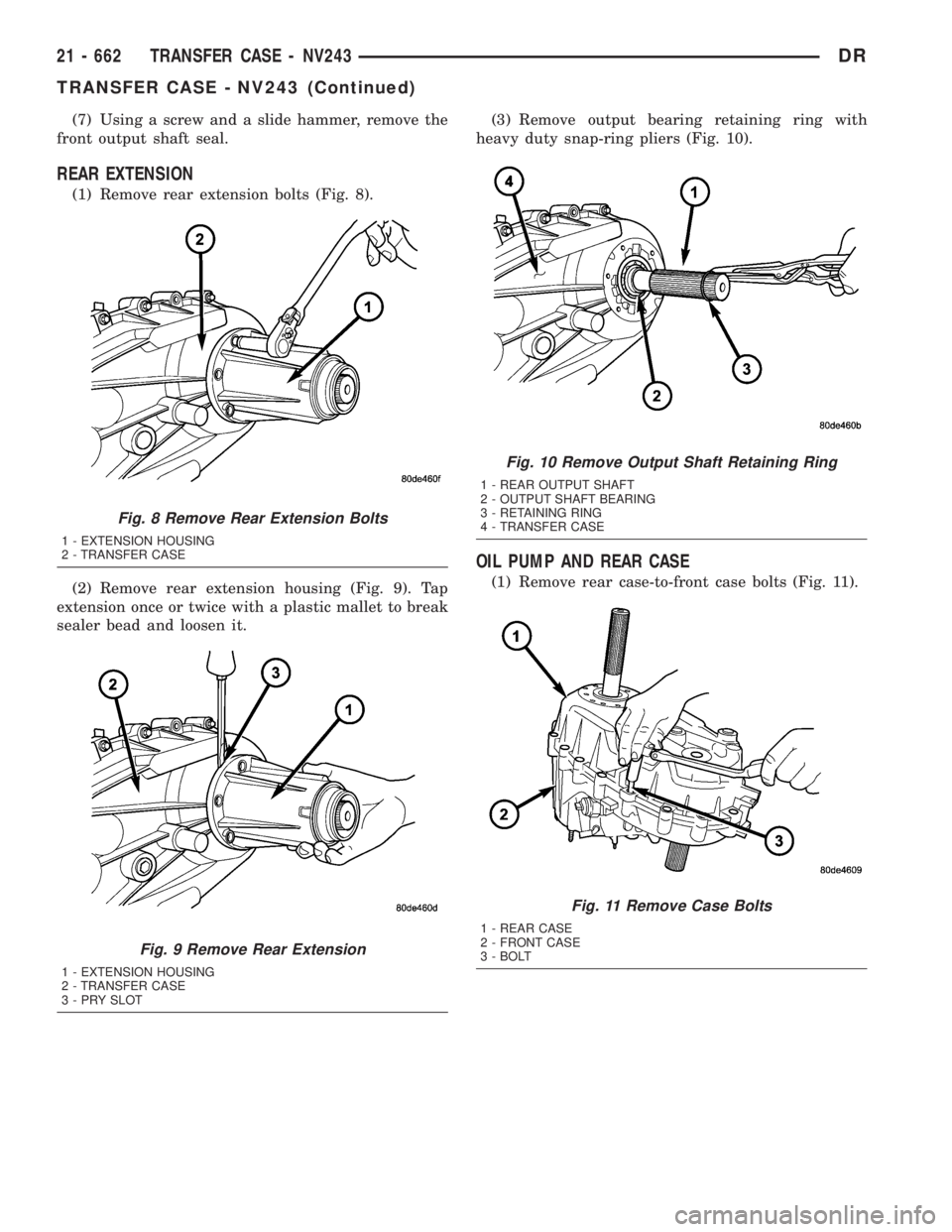

(7) Using a screw and a slide hammer, remove the

front output shaft seal.

REAR EXTENSION

(1) Remove rear extension bolts (Fig. 8).

(2) Remove rear extension housing (Fig. 9). Tap

extension once or twice with a plastic mallet to break

sealer bead and loosen it.(3) Remove output bearing retaining ring with

heavy duty snap-ring pliers (Fig. 10).

OIL PUMP AND REAR CASE

(1) Remove rear case-to-front case bolts (Fig. 11).

Fig. 8 Remove Rear Extension Bolts

1 - EXTENSION HOUSING

2 - TRANSFER CASE

Fig. 9 Remove Rear Extension

1 - EXTENSION HOUSING

2 - TRANSFER CASE

3 - PRY SLOT

Fig. 10 Remove Output Shaft Retaining Ring

1 - REAR OUTPUT SHAFT

2 - OUTPUT SHAFT BEARING

3 - RETAINING RING

4 - TRANSFER CASE

Fig. 11 Remove Case Bolts

1 - REAR CASE

2 - FRONT CASE

3 - BOLT

21 - 662 TRANSFER CASE - NV243DR

TRANSFER CASE - NV243 (Continued)

Page 2502 of 2895

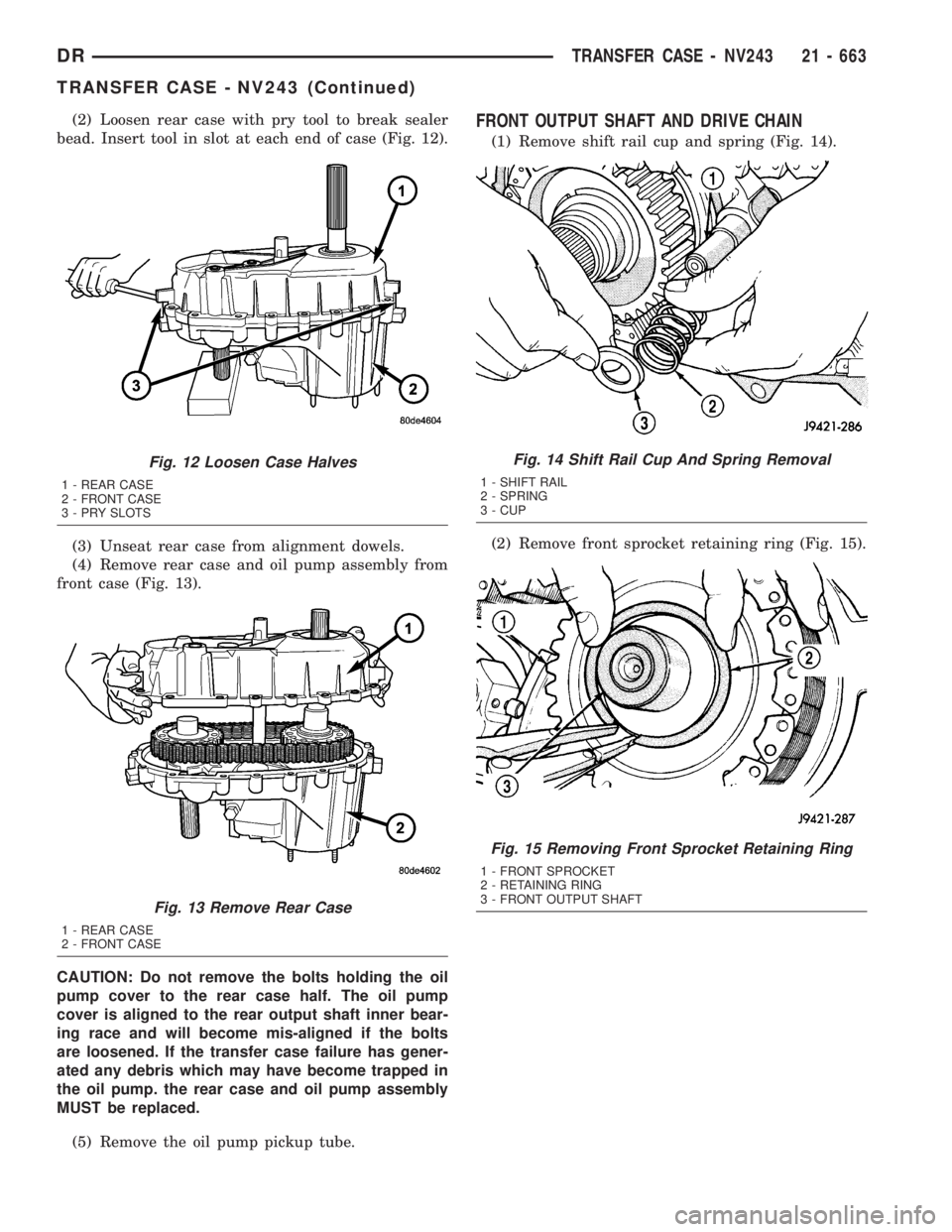

(2) Loosen rear case with pry tool to break sealer

bead. Insert tool in slot at each end of case (Fig. 12).

(3) Unseat rear case from alignment dowels.

(4) Remove rear case and oil pump assembly from

front case (Fig. 13).

CAUTION: Do not remove the bolts holding the oil

pump cover to the rear case half. The oil pump

cover is aligned to the rear output shaft inner bear-

ing race and will become mis-aligned if the bolts

are loosened. If the transfer case failure has gener-

ated any debris which may have become trapped in

the oil pump. the rear case and oil pump assembly

MUST be replaced.

(5) Remove the oil pump pickup tube.FRONT OUTPUT SHAFT AND DRIVE CHAIN

(1) Remove shift rail cup and spring (Fig. 14).

(2) Remove front sprocket retaining ring (Fig. 15).

Fig. 12 Loosen Case Halves

1 - REAR CASE

2 - FRONT CASE

3 - PRY SLOTS

Fig. 13 Remove Rear Case

1 - REAR CASE

2 - FRONT CASE

Fig. 14 Shift Rail Cup And Spring Removal

1 - SHIFT RAIL

2 - SPRING

3 - CUP

Fig. 15 Removing Front Sprocket Retaining Ring

1 - FRONT SPROCKET

2 - RETAINING RING

3 - FRONT OUTPUT SHAFT

DRTRANSFER CASE - NV243 21 - 663

TRANSFER CASE - NV243 (Continued)

Page 2509 of 2895

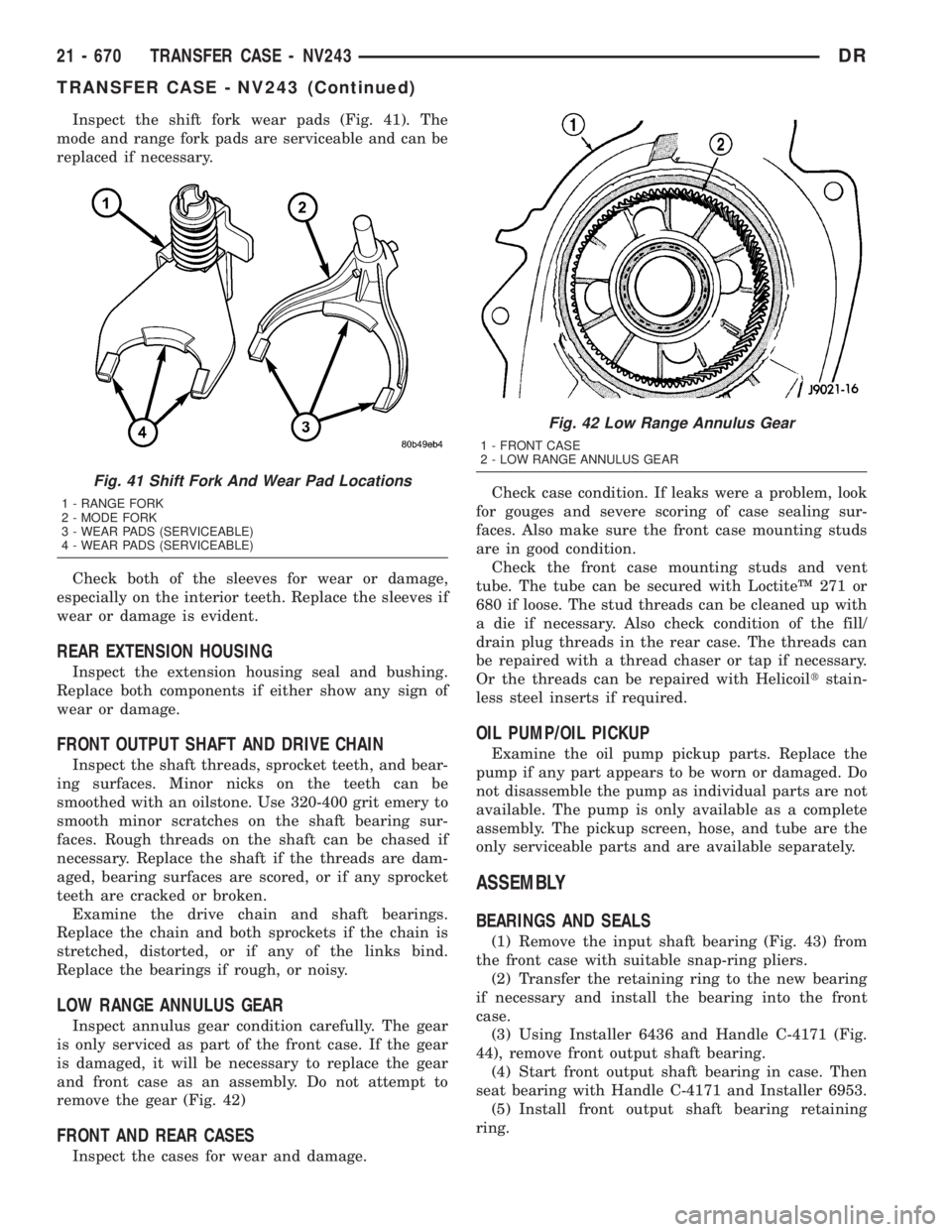

Inspect the shift fork wear pads (Fig. 41). The

mode and range fork pads are serviceable and can be

replaced if necessary.

Check both of the sleeves for wear or damage,

especially on the interior teeth. Replace the sleeves if

wear or damage is evident.

REAR EXTENSION HOUSING

Inspect the extension housing seal and bushing.

Replace both components if either show any sign of

wear or damage.

FRONT OUTPUT SHAFT AND DRIVE CHAIN

Inspect the shaft threads, sprocket teeth, and bear-

ing surfaces. Minor nicks on the teeth can be

smoothed with an oilstone. Use 320-400 grit emery to

smooth minor scratches on the shaft bearing sur-

faces. Rough threads on the shaft can be chased if

necessary. Replace the shaft if the threads are dam-

aged, bearing surfaces are scored, or if any sprocket

teeth are cracked or broken.

Examine the drive chain and shaft bearings.

Replace the chain and both sprockets if the chain is

stretched, distorted, or if any of the links bind.

Replace the bearings if rough, or noisy.

LOW RANGE ANNULUS GEAR

Inspect annulus gear condition carefully. The gear

is only serviced as part of the front case. If the gear

is damaged, it will be necessary to replace the gear

and front case as an assembly. Do not attempt to

remove the gear (Fig. 42)

FRONT AND REAR CASES

Inspect the cases for wear and damage.Check case condition. If leaks were a problem, look

for gouges and severe scoring of case sealing sur-

faces. Also make sure the front case mounting studs

are in good condition.

Check the front case mounting studs and vent

tube. The tube can be secured with LoctiteŸ 271 or

680 if loose. The stud threads can be cleaned up with

a die if necessary. Also check condition of the fill/

drain plug threads in the rear case. The threads can

be repaired with a thread chaser or tap if necessary.

Or the threads can be repaired with Helicoiltstain-

less steel inserts if required.

OIL PUMP/OIL PICKUP

Examine the oil pump pickup parts. Replace the

pump if any part appears to be worn or damaged. Do

not disassemble the pump as individual parts are not

available. The pump is only available as a complete

assembly. The pickup screen, hose, and tube are the

only serviceable parts and are available separately.

ASSEMBLY

BEARINGS AND SEALS

(1) Remove the input shaft bearing (Fig. 43) from

the front case with suitable snap-ring pliers.

(2) Transfer the retaining ring to the new bearing

if necessary and install the bearing into the front

case.

(3) Using Installer 6436 and Handle C-4171 (Fig.

44), remove front output shaft bearing.

(4) Start front output shaft bearing in case. Then

seat bearing with Handle C-4171 and Installer 6953.

(5) Install front output shaft bearing retaining

ring.

Fig. 41 Shift Fork And Wear Pad Locations

1 - RANGE FORK

2 - MODE FORK

3 - WEAR PADS (SERVICEABLE)

4 - WEAR PADS (SERVICEABLE)

Fig. 42 Low Range Annulus Gear

1 - FRONT CASE

2 - LOW RANGE ANNULUS GEAR

21 - 670 TRANSFER CASE - NV243DR

TRANSFER CASE - NV243 (Continued)

Page 2517 of 2895

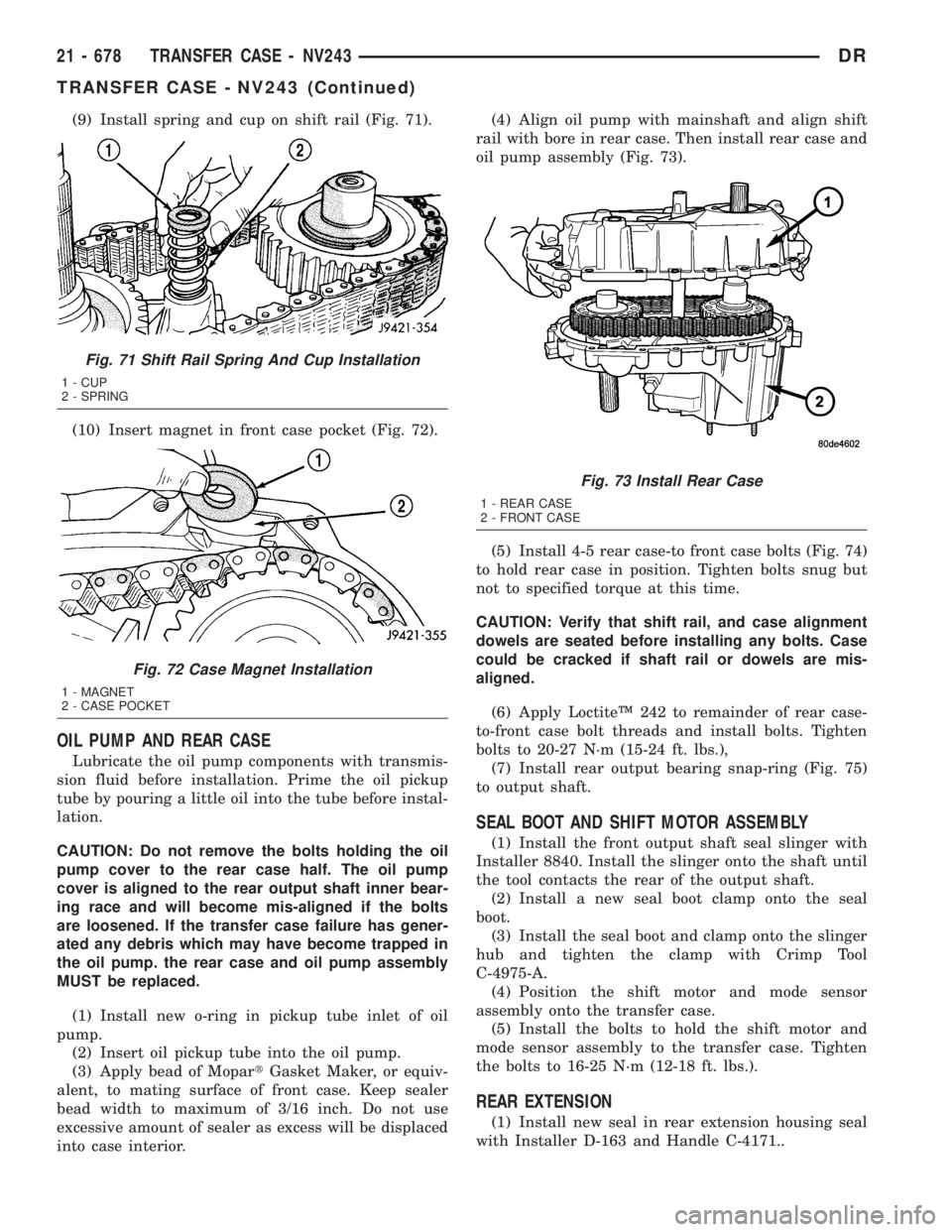

(9) Install spring and cup on shift rail (Fig. 71).

(10) Insert magnet in front case pocket (Fig. 72).

OIL PUMP AND REAR CASE

Lubricate the oil pump components with transmis-

sion fluid before installation. Prime the oil pickup

tube by pouring a little oil into the tube before instal-

lation.

CAUTION: Do not remove the bolts holding the oil

pump cover to the rear case half. The oil pump

cover is aligned to the rear output shaft inner bear-

ing race and will become mis-aligned if the bolts

are loosened. If the transfer case failure has gener-

ated any debris which may have become trapped in

the oil pump. the rear case and oil pump assembly

MUST be replaced.

(1) Install new o-ring in pickup tube inlet of oil

pump.

(2) Insert oil pickup tube into the oil pump.

(3) Apply bead of MopartGasket Maker, or equiv-

alent, to mating surface of front case. Keep sealer

bead width to maximum of 3/16 inch. Do not use

excessive amount of sealer as excess will be displaced

into case interior.(4) Align oil pump with mainshaft and align shift

rail with bore in rear case. Then install rear case and

oil pump assembly (Fig. 73).

(5) Install 4-5 rear case-to front case bolts (Fig. 74)

to hold rear case in position. Tighten bolts snug but

not to specified torque at this time.

CAUTION: Verify that shift rail, and case alignment

dowels are seated before installing any bolts. Case

could be cracked if shaft rail or dowels are mis-

aligned.

(6) Apply LoctiteŸ 242 to remainder of rear case-

to-front case bolt threads and install bolts. Tighten

bolts to 20-27 N´m (15-24 ft. lbs.),

(7) Install rear output bearing snap-ring (Fig. 75)

to output shaft.

SEAL BOOT AND SHIFT MOTOR ASSEMBLY

(1) Install the front output shaft seal slinger with

Installer 8840. Install the slinger onto the shaft until

the tool contacts the rear of the output shaft.

(2) Install a new seal boot clamp onto the seal

boot.

(3) Install the seal boot and clamp onto the slinger

hub and tighten the clamp with Crimp Tool

C-4975-A.

(4) Position the shift motor and mode sensor

assembly onto the transfer case.

(5) Install the bolts to hold the shift motor and

mode sensor assembly to the transfer case. Tighten

the bolts to 16-25 N´m (12-18 ft. lbs.).

REAR EXTENSION

(1) Install new seal in rear extension housing seal

with Installer D-163 and Handle C-4171..

Fig. 71 Shift Rail Spring And Cup Installation

1 - CUP

2 - SPRING

Fig. 72 Case Magnet Installation

1 - MAGNET

2 - CASE POCKET

Fig. 73 Install Rear Case

1 - REAR CASE

2 - FRONT CASE

21 - 678 TRANSFER CASE - NV243DR

TRANSFER CASE - NV243 (Continued)