ESP DODGE RAM 2003 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 685 of 2895

The washer fluid level switch is connected to the

vehicle electrical system through a dedicated take

out and connector of the right (except V-10 and diesel

engines) or left (V-10 and diesel engines only) head-

lamp and dash wire harness. The switch is connected

in series between a clean ground output of the Front

Control Module (FCM) on a sensor return circuit and

the washer fluid switch sense input to the FCM.

When the switch closes, the FMC senses the ground

on the washer fluid switch sense circuit. The FMC is

programmed to respond to this input by sending an

electronic washer fluid indicator lamp-on message to

the instrument cluster over the Programmable Com-

munications Interface (PCI) data bus. The instru-

ment cluster responds to this message by

illuminating the washer fluid indicator and by sound-

ing an audible chime tone warning.

The washer fluid level switch may be diagnosed

and tested using conventional diagnostic tools and

procedures. However, conventional diagnostic meth-

ods may not prove conclusive in the diagnosis of the

instrument cluster, the Front Control Module (FCM),

or the electronic message inputs to or outputs from

the instrument cluster and the FCM that control the

operation of the washer fluid visual and/or audible

indicators. The most reliable, efficient, and accurate

means to diagnose the washer fluid level indicator,

the instrument cluster, the FCM, or the electronic

message inputs and outputs related to the washer

fluid indicator requires the use of a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

REMOVAL

The washer fluid level switch can be removed from

the washer reservoir without removing the reservoir

from the vehicle.

(1) Unlatch and open the hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Disconnect the washer hose from the barbed

outlet nipple of the washer pump/motor unit and

allow the washer fluid to drain into a clean container

for reuse.

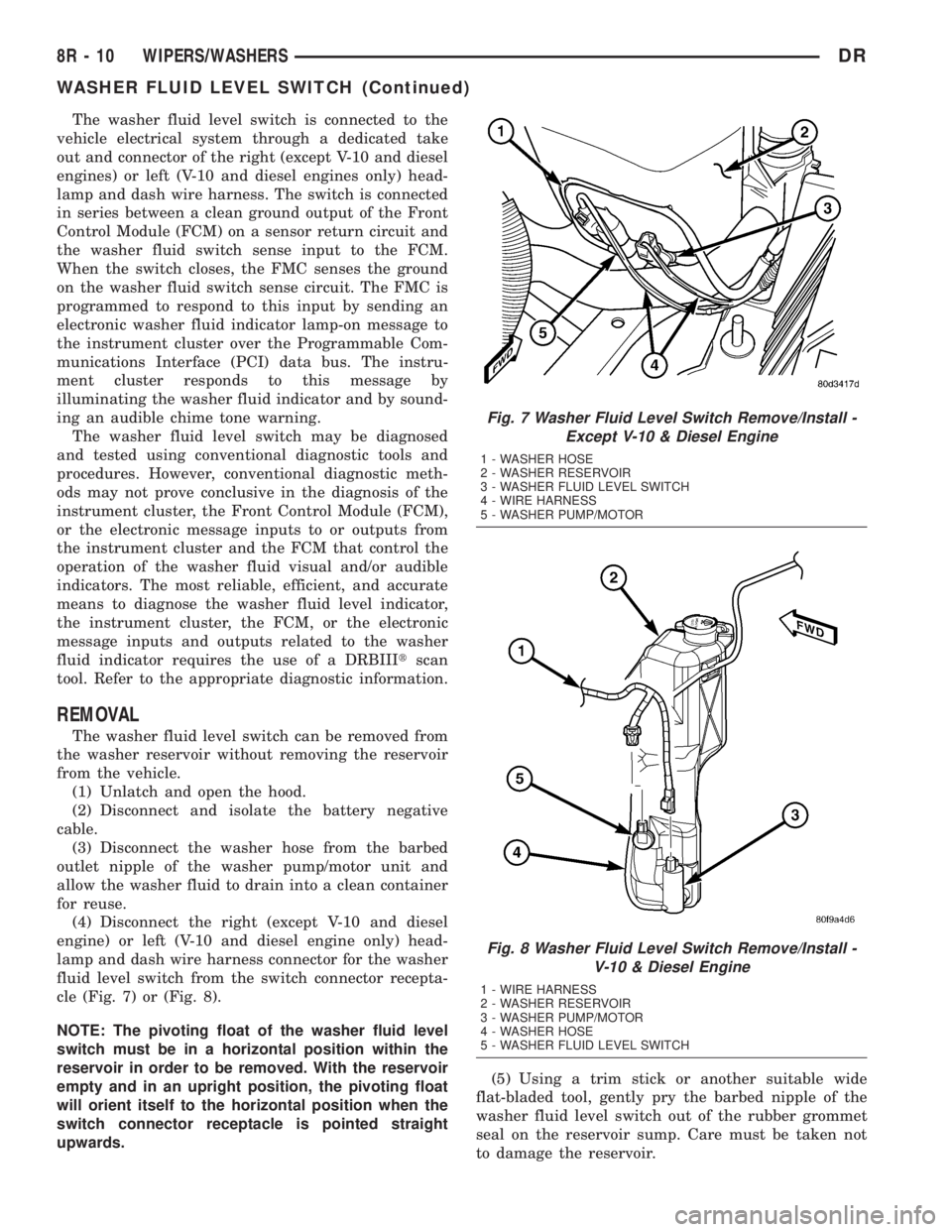

(4) Disconnect the right (except V-10 and diesel

engine) or left (V-10 and diesel engine only) head-

lamp and dash wire harness connector for the washer

fluid level switch from the switch connector recepta-

cle (Fig. 7) or (Fig. 8).

NOTE: The pivoting float of the washer fluid level

switch must be in a horizontal position within the

reservoir in order to be removed. With the reservoir

empty and in an upright position, the pivoting float

will orient itself to the horizontal position when the

switch connector receptacle is pointed straight

upwards.(5) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the barbed nipple of the

washer fluid level switch out of the rubber grommet

seal on the reservoir sump. Care must be taken not

to damage the reservoir.

Fig. 7 Washer Fluid Level Switch Remove/Install -

Except V-10 & Diesel Engine

1 - WASHER HOSE

2 - WASHER RESERVOIR

3 - WASHER FLUID LEVEL SWITCH

4 - WIRE HARNESS

5 - WASHER PUMP/MOTOR

Fig. 8 Washer Fluid Level Switch Remove/Install -

V-10 & Diesel Engine

1 - WIRE HARNESS

2 - WASHER RESERVOIR

3 - WASHER PUMP/MOTOR

4 - WASHER HOSE

5 - WASHER FLUID LEVEL SWITCH

8R - 10 WIPERS/WASHERSDR

WASHER FLUID LEVEL SWITCH (Continued)

Page 697 of 2895

WIPER MODULE

DESCRIPTION

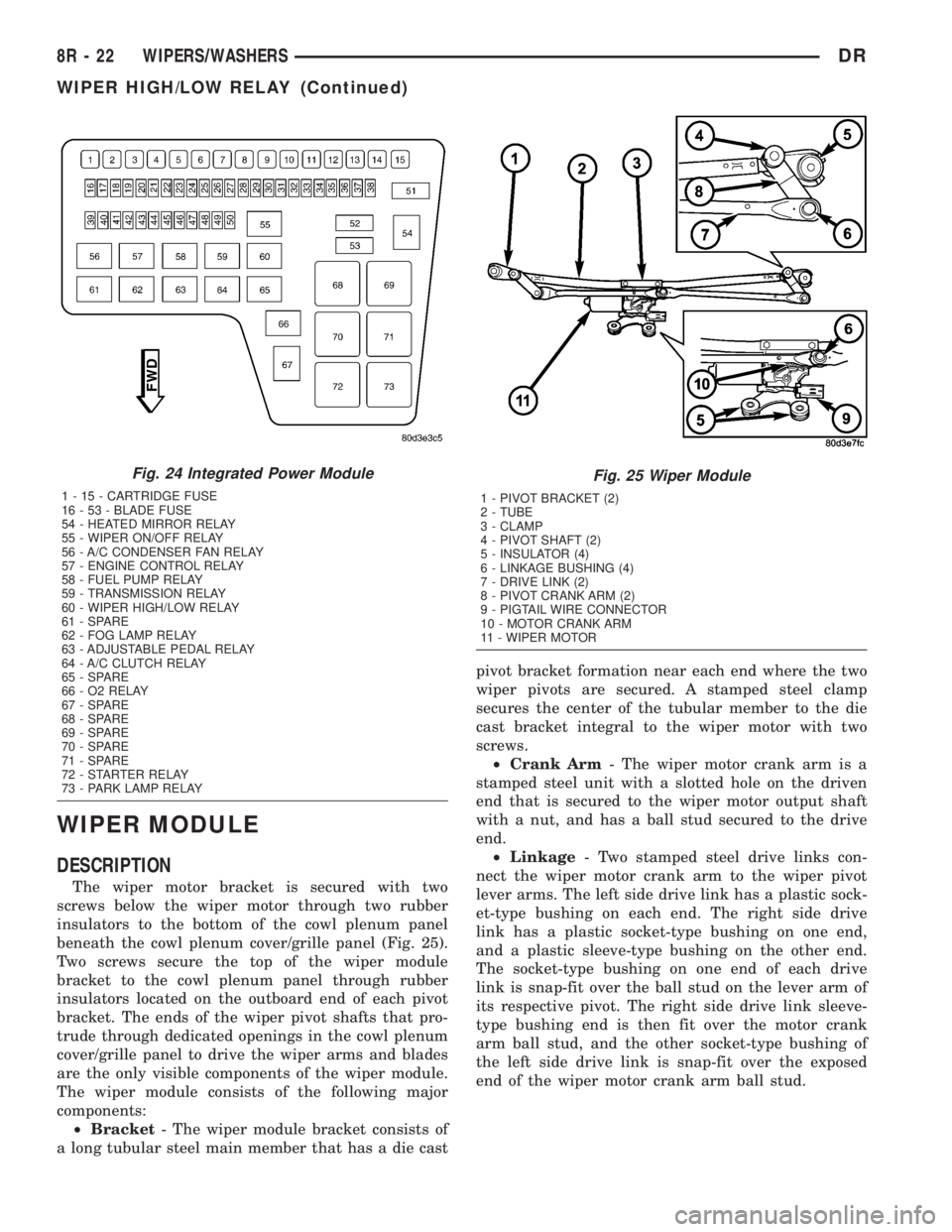

The wiper motor bracket is secured with two

screws below the wiper motor through two rubber

insulators to the bottom of the cowl plenum panel

beneath the cowl plenum cover/grille panel (Fig. 25).

Two screws secure the top of the wiper module

bracket to the cowl plenum panel through rubber

insulators located on the outboard end of each pivot

bracket. The ends of the wiper pivot shafts that pro-

trude through dedicated openings in the cowl plenum

cover/grille panel to drive the wiper arms and blades

are the only visible components of the wiper module.

The wiper module consists of the following major

components:

²Bracket- The wiper module bracket consists of

a long tubular steel main member that has a die castpivot bracket formation near each end where the two

wiper pivots are secured. A stamped steel clamp

secures the center of the tubular member to the die

cast bracket integral to the wiper motor with two

screws.

²Crank Arm- The wiper motor crank arm is a

stamped steel unit with a slotted hole on the driven

end that is secured to the wiper motor output shaft

with a nut, and has a ball stud secured to the drive

end.

²Linkage- Two stamped steel drive links con-

nect the wiper motor crank arm to the wiper pivot

lever arms. The left side drive link has a plastic sock-

et-type bushing on each end. The right side drive

link has a plastic socket-type bushing on one end,

and a plastic sleeve-type bushing on the other end.

The socket-type bushing on one end of each drive

link is snap-fit over the ball stud on the lever arm of

its respective pivot. The right side drive link sleeve-

type bushing end is then fit over the motor crank

arm ball stud, and the other socket-type bushing of

the left side drive link is snap-fit over the exposed

end of the wiper motor crank arm ball stud.

Fig. 24 Integrated Power Module

1 - 15 - CARTRIDGE FUSE

16 - 53 - BLADE FUSE

54 - HEATED MIRROR RELAY

55 - WIPER ON/OFF RELAY

56 - A/C CONDENSER FAN RELAY

57 - ENGINE CONTROL RELAY

58 - FUEL PUMP RELAY

59 - TRANSMISSION RELAY

60 - WIPER HIGH/LOW RELAY

61 - SPARE

62 - FOG LAMP RELAY

63 - ADJUSTABLE PEDAL RELAY

64 - A/C CLUTCH RELAY

65 - SPARE

66 - O2 RELAY

67 - SPARE

68 - SPARE

69 - SPARE

70 - SPARE

71 - SPARE

72 - STARTER RELAY

73 - PARK LAMP RELAY

Fig. 25 Wiper Module

1 - PIVOT BRACKET (2)

2 - TUBE

3 - CLAMP

4 - PIVOT SHAFT (2)

5 - INSULATOR (4)

6 - LINKAGE BUSHING (4)

7 - DRIVE LINK (2)

8 - PIVOT CRANK ARM (2)

9 - PIGTAIL WIRE CONNECTOR

10 - MOTOR CRANK ARM

11 - WIPER MOTOR

8R - 22 WIPERS/WASHERSDR

WIPER HIGH/LOW RELAY (Continued)

Page 710 of 2895

DESCRIPTION - CONNECTOR, GROUND AND

SPLICE INFORMATION

CAUTION: Not all connectors are serviced. Some

connectors are serviced only with a harness. A typ-

ical example might be the Supplemental Restraint

System connectors. Always check parts availability

before attempting a repair.

IDENTIFICATION

In-line connectors are identified by a number, as

follows:

²In-line connectors located in the engine compart-

ment are C100 series numbers

²In-line connectors located in the Instrument

Panel area are C200 series numbers.

²In-line connectors located in the body are C300

series numbers.

²Jumper harness connectors are C400 series

numbers.

²Grounds and ground connectors are identified

with a ªGº and follow the same series numbering as

the in-line connectors.

²Splices are identified with an ªSº and follow the

same series numbering as the in-line connectors.

²Component connectors are identified by the com-

ponent name instead of a number. Multiple connec-

tors on a component use a C1, C2, etc. identifier.

LOCATIONS

Section 8W-91 contains connector/ground/splice

location illustrations. The illustrations contain the

connector name (or number)/ground number/splice

number and component identification. Connector/

ground/splice location charts in section 8W-91 refer-

ence the figure numbers of the illustrations.

The abbreviation T/O is used in the component

location section to indicate a point in which the wir-

ing harness branches out to a component. The abbre-

viation N/S means Not Shown in the illustrations

WARNING

WARNINGS - GENERAL

WARNINGSprovide information to prevent per-

sonal injury and vehicle damage. Below is a list of

general warnings that should be followed any time a

vehicle is being serviced.

WARNING: ALWAYS WEAR SAFETY GLASSES FOR

EYE PROTECTION.

WARNING: USE SAFETY STANDS ANYTIME A PRO-

CEDURE REQUIRES BEING UNDER A VEHICLE.WARNING: BE SURE THAT THE IGNITION SWITCH

ALWAYS IS IN THE OFF POSITION, UNLESS THE

PROCEDURE REQUIRES IT TO BE ON.

WARNING: SET THE PARKING BRAKE WHEN

WORKING ON ANY VEHICLE. AN AUTOMATIC

TRANSMISSION SHOULD BE IN PARK. A MANUAL

TRANSMISSION SHOULD BE IN NEUTRAL.

WARNING: OPERATE THE ENGINE ONLY IN A

WELL-VENTILATED AREA.

WARNING: KEEP AWAY FROM MOVING PARTS

WHEN THE ENGINE IS RUNNING, ESPECIALLY THE

FAN AND BELTS.

WARNING: TO PREVENT SERIOUS BURNS, AVOID

CONTACT WITH HOT PARTS SUCH AS THE RADIA-

TOR, EXHAUST MANIFOLD(S), TAIL PIPE, CATA-

LYTIC CONVERTER AND MUFFLER.

WARNING: DO NOT ALLOW FLAME OR SPARKS

NEAR THE BATTERY. GASES ARE ALWAYS

PRESENT IN AND AROUND THE BATTERY.

WARNING: ALWAYS REMOVE RINGS, WATCHES,

LOOSE HANGING JEWELRY AND AVOID LOOSE

CLOTHING.

DIAGNOSIS AND TESTING - WIRING HARNESS

TROUBLESHOOTING TOOLS

When diagnosing a problem in an electrical circuit

there are several common tools necessary. These tools

are listed and explained below.

²Jumper Wire - This is a test wire used to con-

nect two points of a circuit. It can be used to bypass

an open in a circuit.

WARNING: NEVER USE A JUMPER WIRE ACROSS

A LOAD, SUCH AS A MOTOR, CONNECTED

BETWEEN A BATTERY FEED AND GROUND.

²Voltmeter - Used to check for voltage on a cir-

cuit. Always connect the black lead to a known good

ground and the red lead to the positive side of the

circuit.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

voltages in these circuits, use a meter with a 10 -

megohm or greater impedance rating.

DR8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 7

WIRING DIAGRAM INFORMATION (Continued)

Page 1259 of 2895

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier than using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

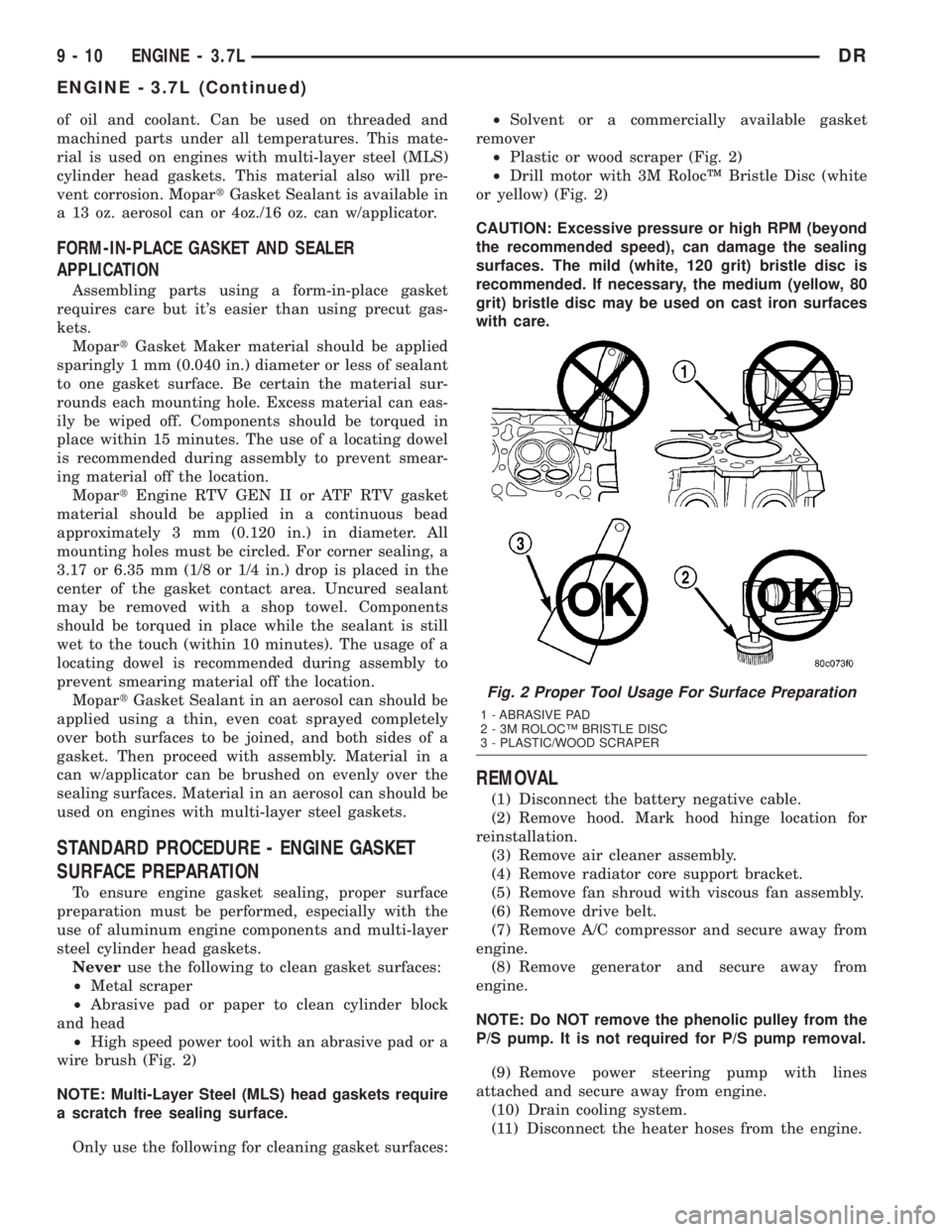

STANDARD PROCEDURE - ENGINE GASKET

SURFACE PREPARATION

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

Neveruse the following to clean gasket surfaces:

²Metal scraper

²Abrasive pad or paper to clean cylinder block

and head

²High speed power tool with an abrasive pad or a

wire brush (Fig. 2)

NOTE: Multi-Layer Steel (MLS) head gaskets require

a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:²Solvent or a commercially available gasket

remover

²Plastic or wood scraper (Fig. 2)

²Drill motor with 3M RolocŸ Bristle Disc (white

or yellow) (Fig. 2)

CAUTION: Excessive pressure or high RPM (beyond

the recommended speed), can damage the sealing

surfaces. The mild (white, 120 grit) bristle disc is

recommended. If necessary, the medium (yellow, 80

grit) bristle disc may be used on cast iron surfaces

with care.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove hood. Mark hood hinge location for

reinstallation.

(3) Remove air cleaner assembly.

(4) Remove radiator core support bracket.

(5) Remove fan shroud with viscous fan assembly.

(6) Remove drive belt.

(7) Remove A/C compressor and secure away from

engine.

(8) Remove generator and secure away from

engine.

NOTE: Do NOT remove the phenolic pulley from the

P/S pump. It is not required for P/S pump removal.

(9) Remove power steering pump with lines

attached and secure away from engine.

(10) Drain cooling system.

(11) Disconnect the heater hoses from the engine.

Fig. 2 Proper Tool Usage For Surface Preparation

1 - ABRASIVE PAD

2 - 3M ROLOCŸ BRISTLE DISC

3 - PLASTIC/WOOD SCRAPER

9 - 10 ENGINE - 3.7LDR

ENGINE - 3.7L (Continued)

Page 1292 of 2895

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDURE

MAIN BEARING FITTING

SELECT FIT IDENTIFICATION

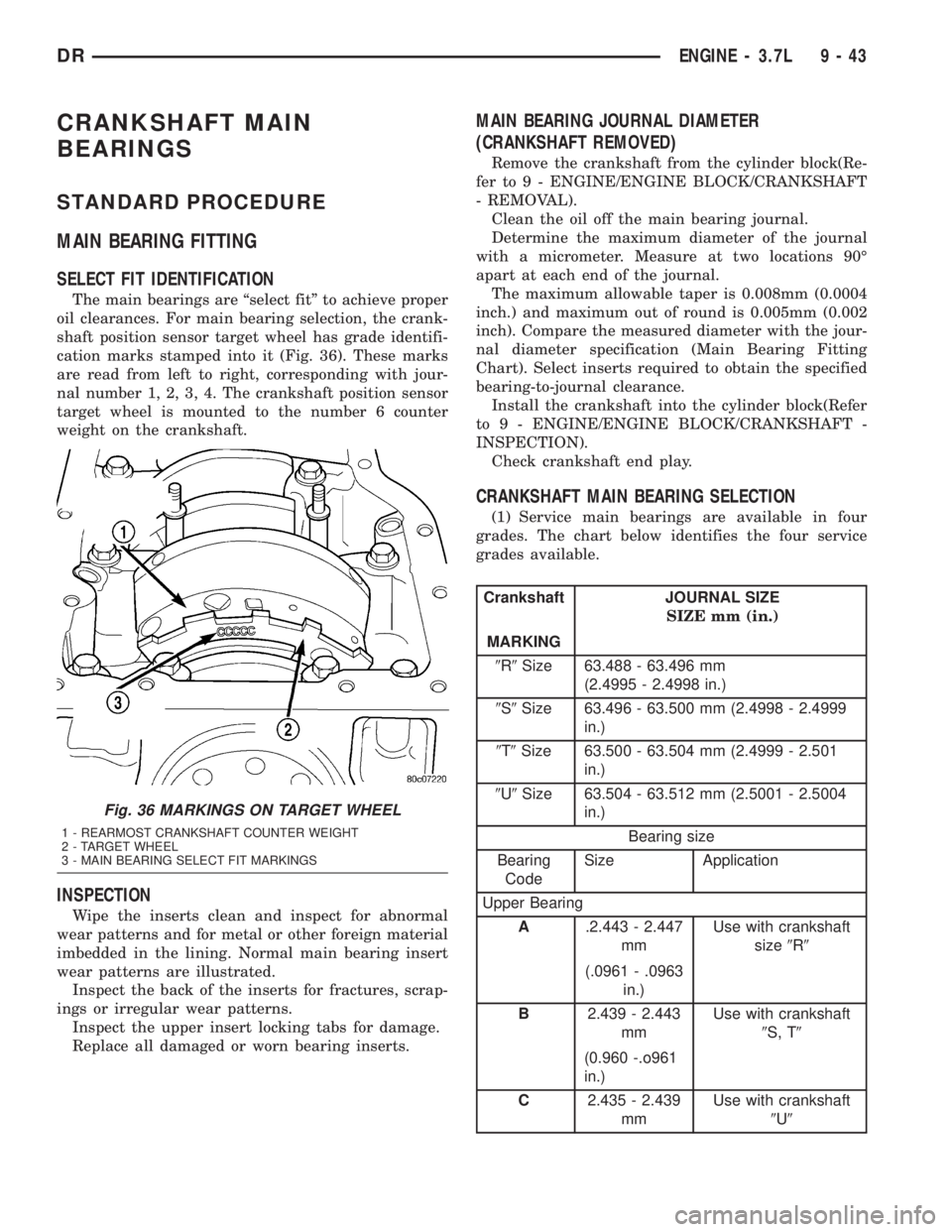

The main bearings are ªselect fitº to achieve proper

oil clearances. For main bearing selection, the crank-

shaft position sensor target wheel has grade identifi-

cation marks stamped into it (Fig. 36). These marks

are read from left to right, corresponding with jour-

nal number 1, 2, 3, 4. The crankshaft position sensor

target wheel is mounted to the number 6 counter

weight on the crankshaft.

INSPECTION

Wipe the inserts clean and inspect for abnormal

wear patterns and for metal or other foreign material

imbedded in the lining. Normal main bearing insert

wear patterns are illustrated.

Inspect the back of the inserts for fractures, scrap-

ings or irregular wear patterns.

Inspect the upper insert locking tabs for damage.

Replace all damaged or worn bearing inserts.

MAIN BEARING JOURNAL DIAMETER

(CRANKSHAFT REMOVED)

Remove the crankshaft from the cylinder block(Re-

fer to 9 - ENGINE/ENGINE BLOCK/CRANKSHAFT

- REMOVAL).

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper is 0.008mm (0.0004

inch.) and maximum out of round is 0.005mm (0.002

inch). Compare the measured diameter with the jour-

nal diameter specification (Main Bearing Fitting

Chart). Select inserts required to obtain the specified

bearing-to-journal clearance.

Install the crankshaft into the cylinder block(Refer

to 9 - ENGINE/ENGINE BLOCK/CRANKSHAFT -

INSPECTION).

Check crankshaft end play.

CRANKSHAFT MAIN BEARING SELECTION

(1) Service main bearings are available in four

grades. The chart below identifies the four service

grades available.

Crankshaft JOURNAL SIZE

SIZE mm (in.)

MARKING

9R9Size 63.488 - 63.496 mm

(2.4995 - 2.4998 in.)

9S9Size 63.496 - 63.500 mm (2.4998 - 2.4999

in.)

9T9Size 63.500 - 63.504 mm (2.4999 - 2.501

in.)

9U9Size 63.504 - 63.512 mm (2.5001 - 2.5004

in.)

Bearing size

Bearing

CodeSize Application

Upper Bearing

A.2.443 - 2.447

mmUse with crankshaft

size9R9

(.0961 - .0963

in.)

B2.439 - 2.443

mmUse with crankshaft

9S, T9

(0.960 -.o961

in.)

C2.435 - 2.439

mmUse with crankshaft

9U9

Fig. 36 MARKINGS ON TARGET WHEEL

1 - REARMOST CRANKSHAFT COUNTER WEIGHT

2 - TARGET WHEEL

3 - MAIN BEARING SELECT FIT MARKINGS

DRENGINE - 3.7L 9 - 43

Page 1312 of 2895

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐENGINE OIL LEAK

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24 km (15 miles), and

repeat inspection.If the oil leak source is not pos-

itively identified at this time, proceed with the air

leak detection test method.

Air Leak Detection Test Method

(1) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(2) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(3) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kPa (3 PSI) of test pressure.

(4) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(5) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(6) If no leaks are detected, turn off the air supply

and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose.(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs oil galley pipe plugs, oil

filter runoff, and main bearing cap to cylinder

block mating surfaces.

(4) If no leaks are detected, pressurize the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

DRENGINE - 3.7L 9 - 63

LUBRICATION (Continued)

Page 1346 of 2895

(9) Connect fuel supply line quick connect fitting

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

QUICK CONNECT FITTING - STANDARD PROCE-

DURE).

(10) Connect the vacuum lines at the throttle body

and intake manifold.

(11) Connect engine harness at the following

points (Fig. 3):

²Intake Air Temperature (IAT) Sensor

²Idle Air Control (IAC) Motor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure (MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

(12) Position and install heater hoses and tubes

onto intake manifold.

(13) Install the heater hoses onto the heater core

and the engine front cover.

(14) Install generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - INSTALLATION).

(15) Install A/C condenser (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/A/C CON-

DENSER - INSTALLATION), radiator (Refer to 7 -

COOLING/ENGINE/RADIATOR - INSTALLATION)

and transmission oil cooler.

(16) Connect radiator upper and lower hoses.

(17) Connect the transmission oil cooler lines to

the radiator.

(18) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION), fan assembly and shroud (Refer to

7 - COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - INSTALLATION).

(19) Install A/C compressor (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - INSTALLATION).

(20) Install both breathers. Connect tube to both

crankcase breathers (Fig. 2).(21) Connect throttle and speed control cables.

(22) Install throttle body resonator assembly and

air inlet hose. Tighten clamps 4 N´m (35 in. lbs.).

(23) Raise vehicle.

(24) Install transmission to engine mounting bolts.

Tighten the bolts to 41 N´m (30 ft. lbs.).

(25) Install torque converter bolts (Automatic

Transmission Only).

(26) Connect crankshaft position sensor (Fig. 1).

(27)4X4 vehiclesPosition and install the axle

isolator bracket onto the axle, transmission and

engine block. Tighten bolts to specification (Refer to 9

- ENGINE - SPECIFICATIONS).

(28) Install starter (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - INSTALLATION).

CAUTION: The structural cover requires a specific

torque sequence. Failure to follow this sequence

may cause severe damage to the cover.

(29) Install structural cover (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - INSTAL-

LATION).

(30) Install exhaust crossover pipe.

(31) Install engine block heater power cable, If

equipped.

(32)4X4 vehiclesConnect axle vent tube to left

side engine mount.

(33) Lower vehicle.

(34) Check and fill engine oil.

(35) Recharge the A/C system (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/REFRIG-

ERANT - STANDARD PROCEDURE).

(36) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(37) Install the battery tray and battery.

(38) Connect the battery positive and negative

cables.

(39) Start the engine and check for leaks.

DRENGINE - 4.7L 9 - 97

ENGINE - 4.7L (Continued)

Page 1359 of 2895

NOTE: The cylinder head is attached to the cylinder

block with fourteen bolts.

(21) Remove the cylinder head retaining bolts.

(22) Remove the cylinder head and gasket. Discard

the gasket.

CAUTION: Do not lay the cylinder head on its gas-

ket sealing surface, do to the design of the cylinder

head gasket any distortion to the cylinder head

sealing surface may prevent the gasket from prop-

erly sealing resulting in leaks.

CLEANING

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

INSPECTION

(1) Inspect the cylinder head for out-of-flatness,

using a straightedge and a feeler gauge. If tolerances

exceed 0.0508 mm (0.002 in.) replace the cylinder

head.

(2) Inspect the valve seats for damage. Service the

valve seats as necessary.

(3) Inspect the valve guides for wear, cracks or

looseness. If either condition exist, replace the cylin-

der head.

INSTALLATION

INSTALLATION - LEFT CYLINDER HEAD

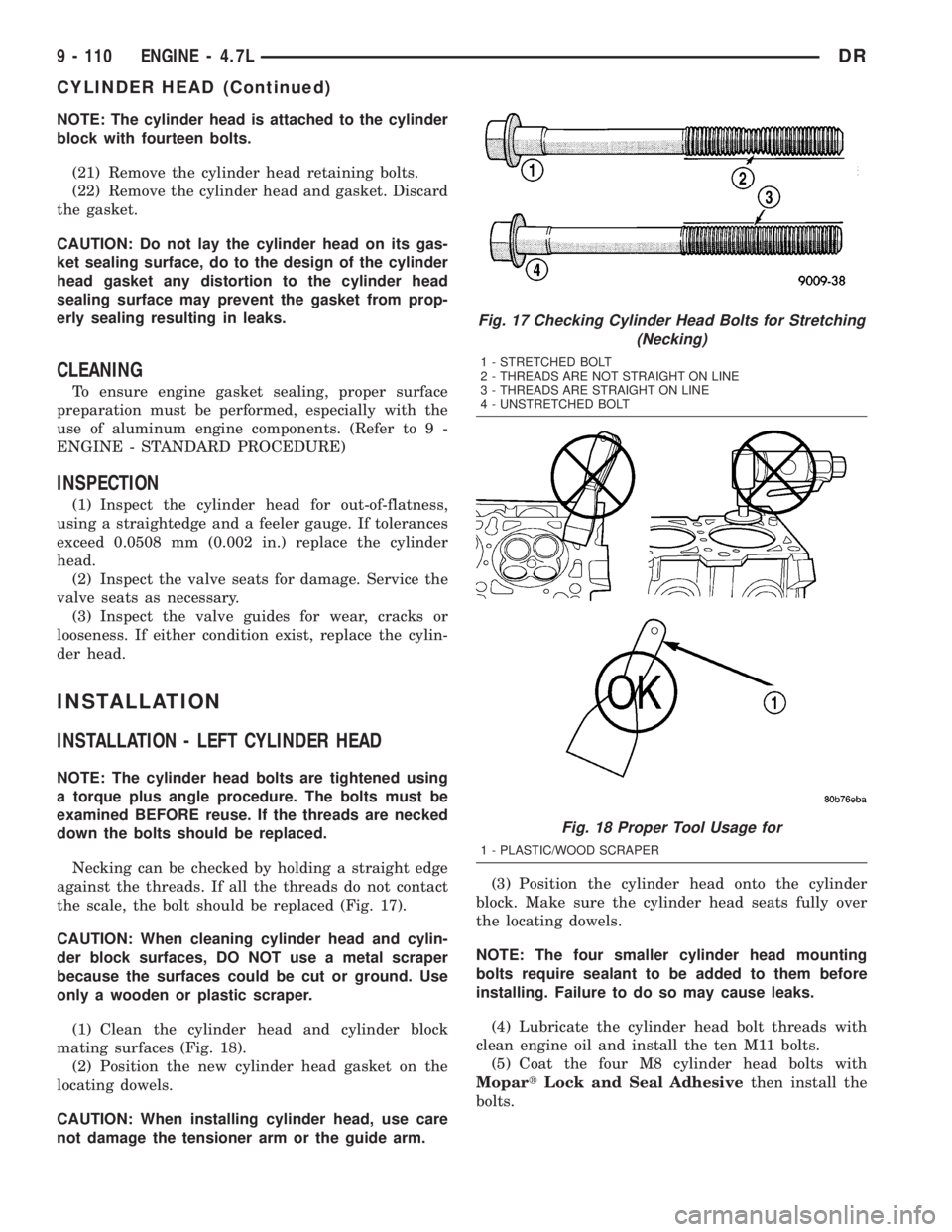

NOTE: The cylinder head bolts are tightened using

a torque plus angle procedure. The bolts must be

examined BEFORE reuse. If the threads are necked

down the bolts should be replaced.

Necking can be checked by holding a straight edge

against the threads. If all the threads do not contact

the scale, the bolt should be replaced (Fig. 17).

CAUTION: When cleaning cylinder head and cylin-

der block surfaces, DO NOT use a metal scraper

because the surfaces could be cut or ground. Use

only a wooden or plastic scraper.

(1) Clean the cylinder head and cylinder block

mating surfaces (Fig. 18).

(2) Position the new cylinder head gasket on the

locating dowels.

CAUTION: When installing cylinder head, use care

not damage the tensioner arm or the guide arm.(3) Position the cylinder head onto the cylinder

block. Make sure the cylinder head seats fully over

the locating dowels.

NOTE: The four smaller cylinder head mounting

bolts require sealant to be added to them before

installing. Failure to do so may cause leaks.

(4) Lubricate the cylinder head bolt threads with

clean engine oil and install the ten M11 bolts.

(5) Coat the four M8 cylinder head bolts with

MopartLock and Seal Adhesivethen install the

bolts.

Fig. 17 Checking Cylinder Head Bolts for Stretching

(Necking)

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

Fig. 18 Proper Tool Usage for

1 - PLASTIC/WOOD SCRAPER

9 - 110 ENGINE - 4.7LDR

CYLINDER HEAD (Continued)

Page 1382 of 2895

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDUREÐCRANKSHAFT MAIN

BEARING - FITTING

MAIN BEARING JOURNAL DIAMETER

(CRANKSHAFT REMOVED)

Crankshaft removed from the cylinder block.

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper is 0.008mm (0.0004

inch.) and maximum out of round is 0.005mm (0.002

inch). Compare the measured diameter with the jour-

nal diameter specification (Main Bearing Fitting

Chart). Select inserts required to obtain the specified

bearing-to-journal clearance.

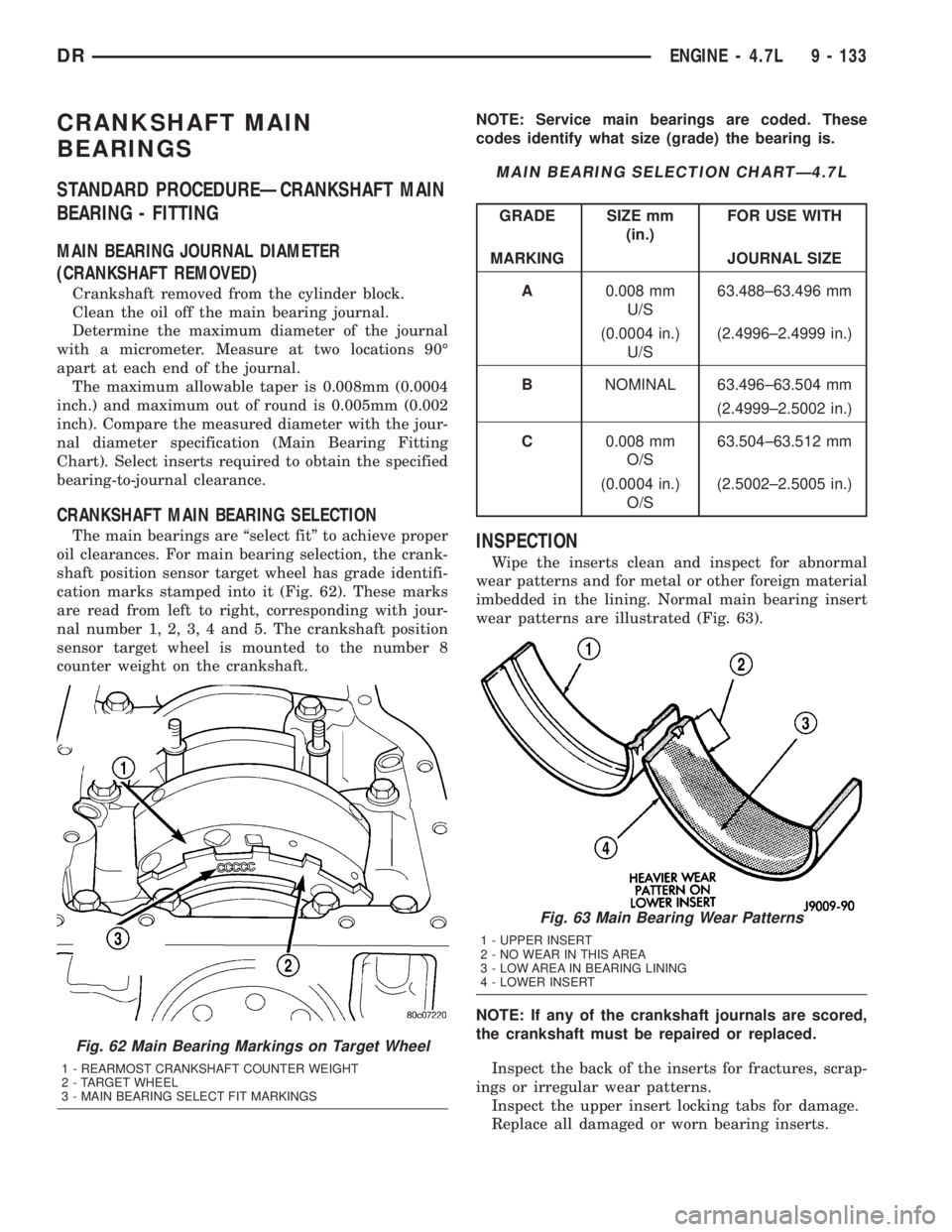

CRANKSHAFT MAIN BEARING SELECTION

The main bearings are ªselect fitº to achieve proper

oil clearances. For main bearing selection, the crank-

shaft position sensor target wheel has grade identifi-

cation marks stamped into it (Fig. 62). These marks

are read from left to right, corresponding with jour-

nal number 1, 2, 3, 4 and 5. The crankshaft position

sensor target wheel is mounted to the number 8

counter weight on the crankshaft.NOTE: Service main bearings are coded. These

codes identify what size (grade) the bearing is.

MAIN BEARING SELECTION CHARTÐ4.7L

GRADE SIZE mm

(in.)FOR USE WITH

MARKING JOURNAL SIZE

A0.008 mm

U/S63.488±63.496 mm

(0.0004 in.)

U/S(2.4996±2.4999 in.)

BNOMINAL 63.496±63.504 mm

(2.4999±2.5002 in.)

C0.008 mm

O/S63.504±63.512 mm

(0.0004 in.)

O/S(2.5002±2.5005 in.)

INSPECTION

Wipe the inserts clean and inspect for abnormal

wear patterns and for metal or other foreign material

imbedded in the lining. Normal main bearing insert

wear patterns are illustrated (Fig. 63).

NOTE: If any of the crankshaft journals are scored,

the crankshaft must be repaired or replaced.

Inspect the back of the inserts for fractures, scrap-

ings or irregular wear patterns.

Inspect the upper insert locking tabs for damage.

Replace all damaged or worn bearing inserts.

Fig. 62 Main Bearing Markings on Target Wheel

1 - REARMOST CRANKSHAFT COUNTER WEIGHT

2 - TARGET WHEEL

3 - MAIN BEARING SELECT FIT MARKINGS

Fig. 63 Main Bearing Wear Patterns

1 - UPPER INSERT

2 - NO WEAR IN THIS AREA

3 - LOW AREA IN BEARING LINING

4 - LOWER INSERT

DRENGINE - 4.7L 9 - 133

Page 1400 of 2895

camshaft bore cup plugs oil galley pipe plugs, oil

filter runoff, and main bearing cap to cylinder

block mating surfaces.

(4) If no leaks are detected, pressurize the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

OIL

STANDARD PROCEDURE - ENGINE OIL

SERVICE

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY.

ENGINE OIL SPECIFICATION

CAUTION: Do not use non-detergent or straight

mineral oil when adding or changing crankcase

lubricant. Engine failure can result.

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Service Grade Certi-

fied. MOPARtprovides engine oils that conform to

this service grade.

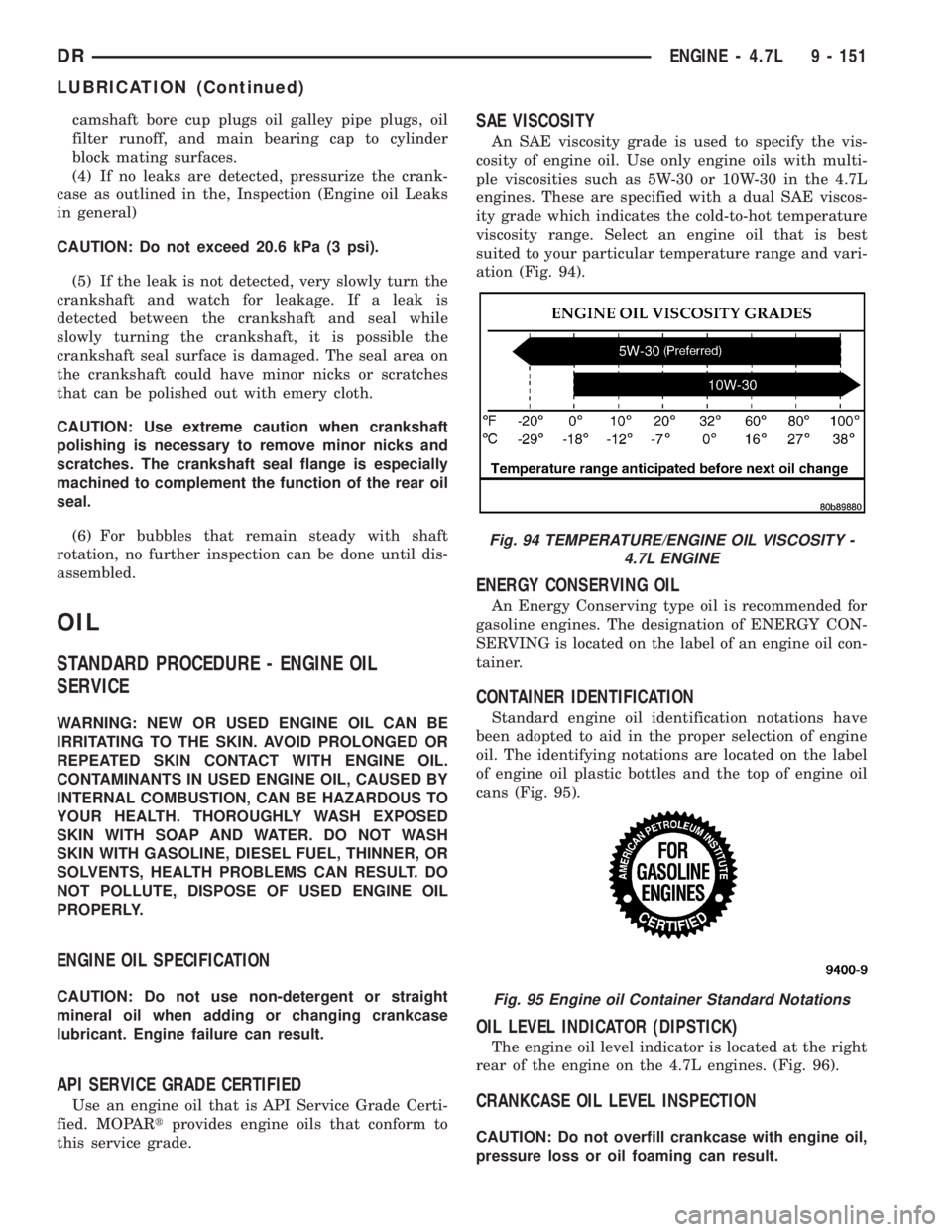

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. Use only engine oils with multi-

ple viscosities such as 5W-30 or 10W-30 in the 4.7L

engines. These are specified with a dual SAE viscos-

ity grade which indicates the cold-to-hot temperature

viscosity range. Select an engine oil that is best

suited to your particular temperature range and vari-

ation (Fig. 94).

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. The designation of ENERGY CON-

SERVING is located on the label of an engine oil con-

tainer.

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans (Fig. 95).

OIL LEVEL INDICATOR (DIPSTICK)

The engine oil level indicator is located at the right

rear of the engine on the 4.7L engines. (Fig. 96).

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

pressure loss or oil foaming can result.

Fig. 94 TEMPERATURE/ENGINE OIL VISCOSITY -

4.7L ENGINE

Fig. 95 Engine oil Container Standard Notations

DRENGINE - 4.7L 9 - 151

LUBRICATION (Continued)