ignition DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3550 of 5267

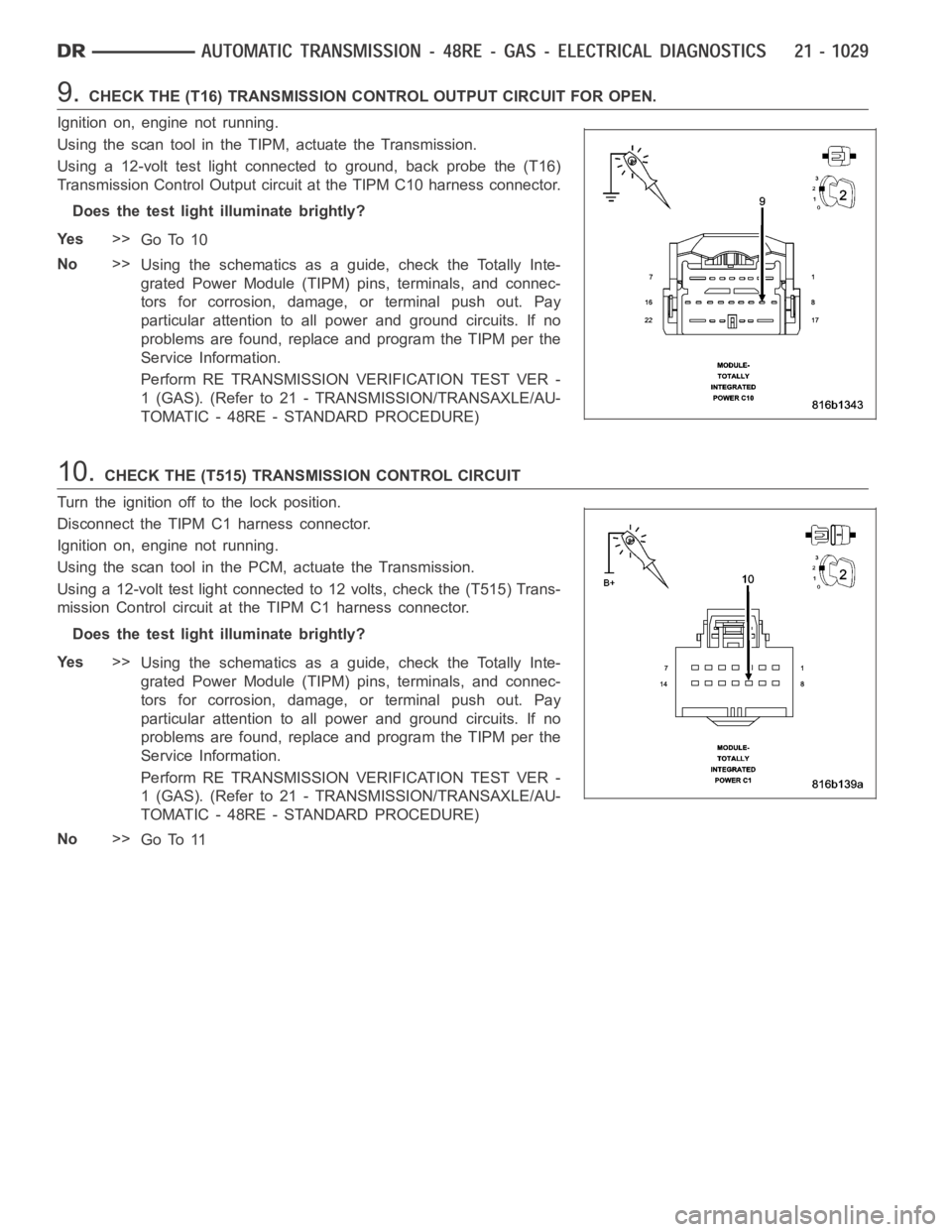

9.CHECK THE (T16) TRANSMISSION CONTROL OUTPUT CIRCUIT FOR OPEN.

Ignition on, engine not running.

Using the scan tool in the TIPM, actuate the Transmission.

Using a 12-volt test light connected to ground, back probe the (T16)

Transmission Control Output circuit at the TIPM C10 harness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 10

No>>

Using the schematics as a guide, check the Totally Inte-

grated Power Module (TIPM) pins, terminals, and connec-

tors for corrosion, damage, or terminal push out. Pay

particular attention to all power and ground circuits. If no

problems are found, replace and program the TIPM per the

Service Information.

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (GAS). (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 48RE - STANDARD PROCEDURE)

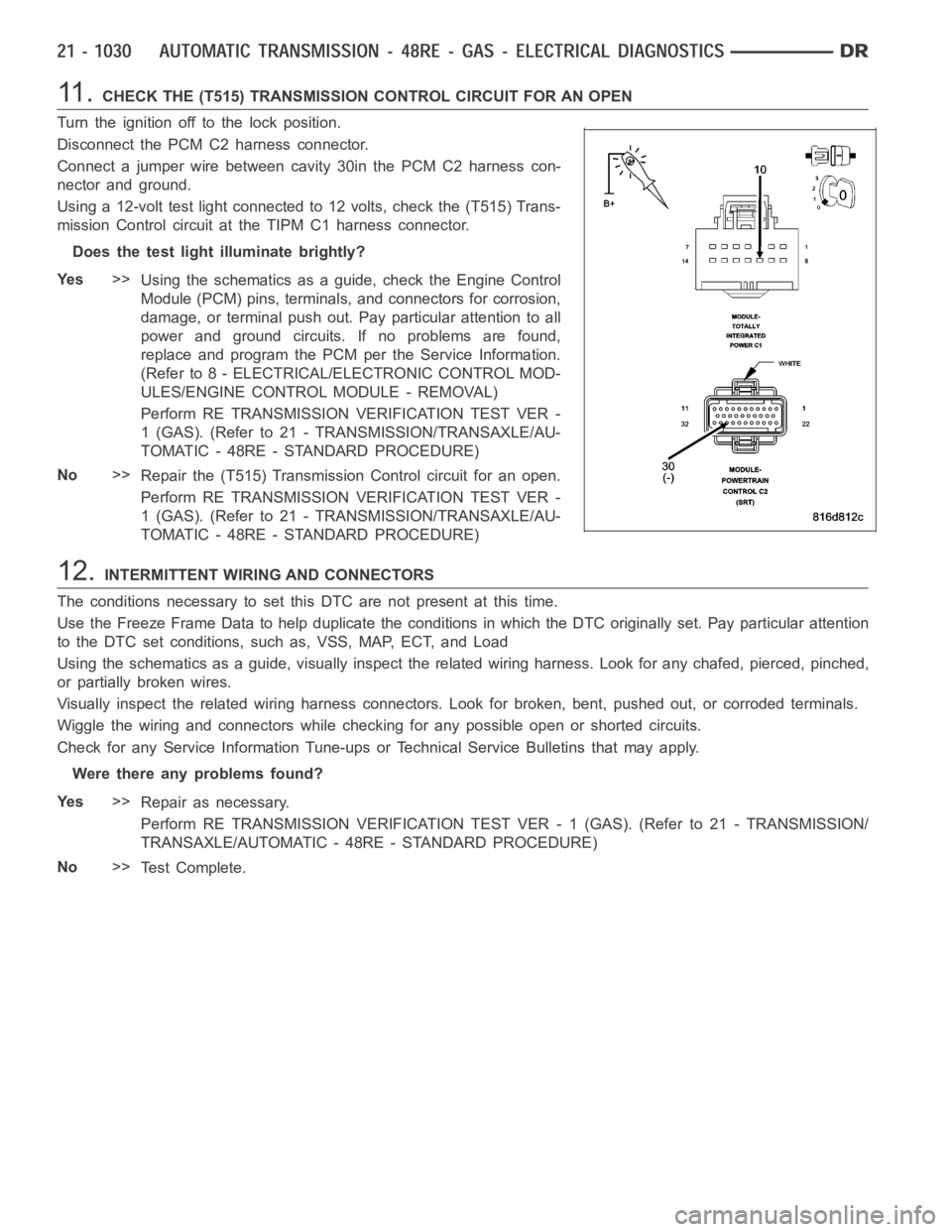

10.CHECK THE (T515) TRANSMISSION CONTROL CIRCUIT

Turn the ignition off to the lock position.

Disconnect the TIPM C1 harness connector.

Ignition on, engine not running.

Using the scan tool in the PCM, actuate the Transmission.

Using a 12-volt test light connected to 12 volts, check the (T515) Trans-

mission Control circuit at the TIPM C1 harness connector.

Does the test light illuminate brightly?

Ye s>>

Using the schematics as a guide, check the Totally Inte-

grated Power Module (TIPM) pins, terminals, and connec-

tors for corrosion, damage, or terminal push out. Pay

particular attention to all power and ground circuits. If no

problems are found, replace and program the TIPM per the

Service Information.

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (GAS). (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Go To 11

Page 3551 of 5267

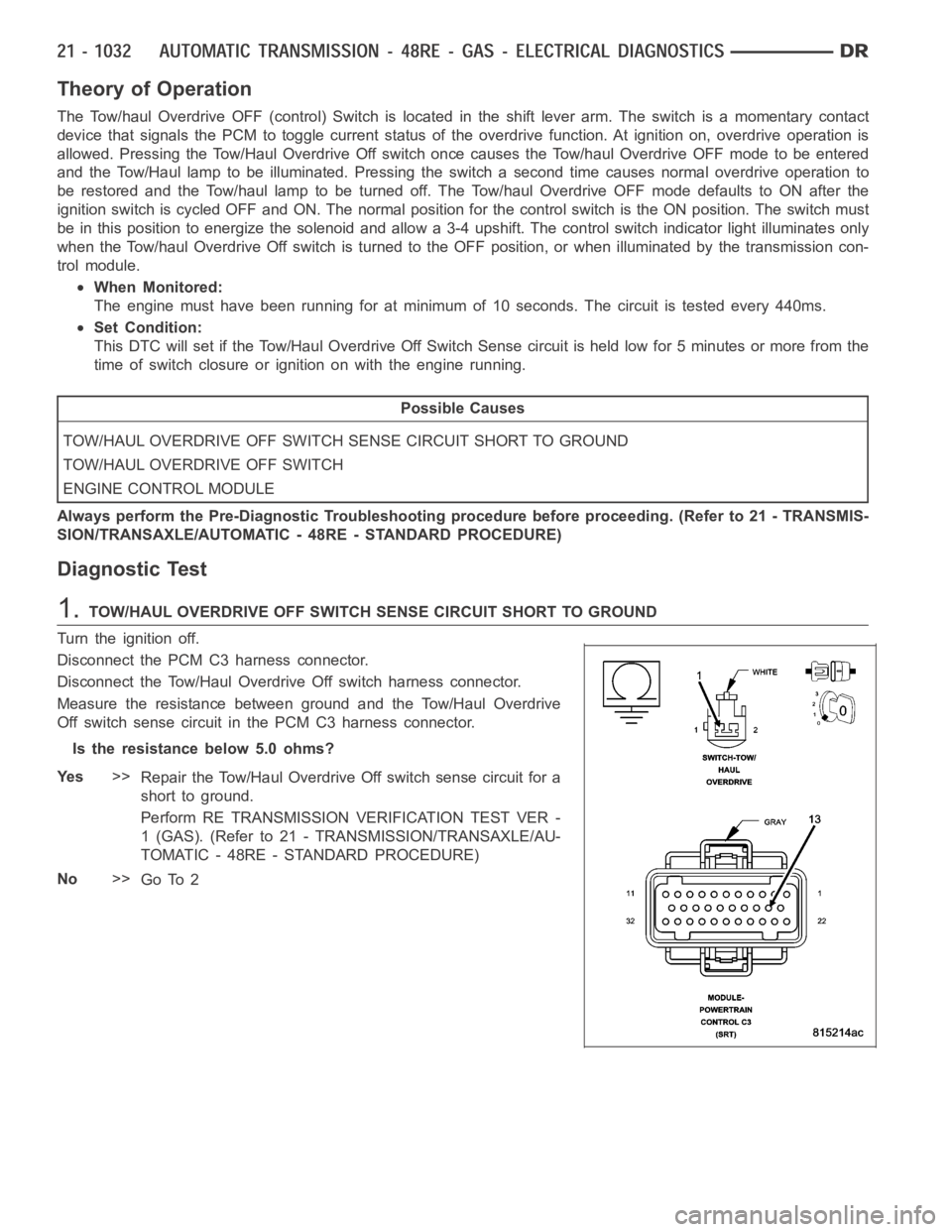

11 .CHECK THE (T515) TRANSMISSION CONTROL CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Disconnect the PCM C2 harness connector.

Connect a jumper wire between cavity 30in the PCM C2 harness con-

nector and ground.

Using a 12-volt test light connected to 12 volts, check the (T515) Trans-

mission Control circuit at the TIPM C1 harness connector.

Does the test light illuminate brightly?

Ye s>>

Using the schematics as a guide, check the Engine Control

Module (PCM) pins, terminals, and connectors for corrosion,

damage, or terminal push out. Pay particular attention to all

power and ground circuits. If no problems are found,

replace and program the PCM per the Service Information.

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/ENGINE CONTROL MODULE - REMOVAL)

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (GAS). (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Repair the (T515) Transmission Control circuit for an open.

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (GAS). (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 48RE - STANDARD PROCEDURE)

12.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Use the Freeze Frame Data to help duplicate the conditions in which the DTC originally set. Pay particular attention

to the DTC set conditions, such as, VSS, MAP, ECT, and Load

Using the schematics as a guide, visually inspect the related wiring harness. Look for any chafed, pierced, pinched,

or partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken,bent, pushed out, or corroded terminals.

Wiggle the wiring and connectors while checking for any possible open or shorted circuits.

Check for any Service Information Tune-ups or Technical Service Bulletins that may apply.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (GAS). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 3553 of 5267

Theory of Operation

The Tow/haul Overdrive OFF (control) Switch is located in the shift lever arm. The switch is a momentary contact

device that signals the PCM to toggle current status of the overdrive function. At ignition on, overdrive operation is

allowed. Pressing the Tow/Haul Overdrive Off switch once causes the Tow/haul Overdrive OFF mode to be entered

and the Tow/Haul lamp to be illuminated. Pressing the switch a second time causes normal overdrive operation to

be restored and the Tow/haul lamp to be turned off. The Tow/haul Overdrive OFF mode defaults to ON after the

ignition switch is cycled OFF and ON. Thenormal position for the control switch is the ON position. The switch must

be in this position to energize the solenoid and allow a 3-4 upshift. The control switch indicator light illuminates only

when the Tow/haul Overdrive Off switch is turned to the OFF position, or when illuminated by the transmission con-

trol module.

When Monitored:

The engine must have been running for at minimum of 10 seconds. The circuit is tested every 440ms.

Set Condition:

This DTC will set if the Tow/Haul Overdrive Off Switch Sense circuit is heldlow for 5 minutes or more from the

time of switch closure or ignition on with the engine running.

Possible Causes

TOW/HAUL OVERDRIVE OFF SWITCH SENSE CIRCUIT SHORT TO GROUND

TOW/HAUL OVERDRIVE OFF SWITCH

ENGINE CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Diagnostic Test

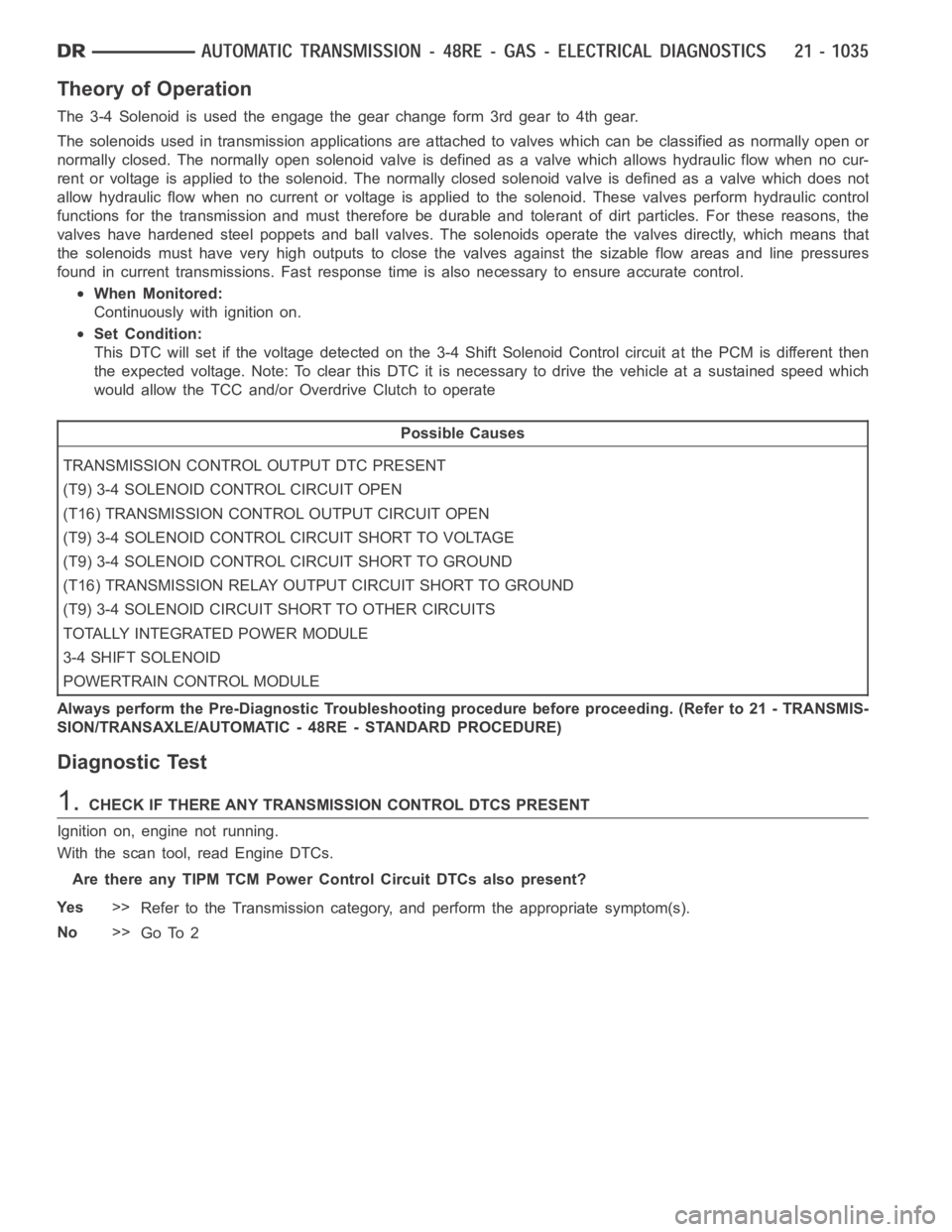

1.TOW/HAUL OVERDRIVE OFF SWITCH SENSE CIRCUIT SHORT TO GROUND

Turn the ignition off.

Disconnect the PCM C3 harness connector.

Disconnect the Tow/Haul OverdriveOff switch harness connector.

Measure the resistance between ground and the Tow/Haul Overdrive

Off switch sense circuit in the PCM C3 harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the Tow/Haul Overdrive Off switch sense circuit for a

short to ground.

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (GAS). (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Go To 2

Page 3556 of 5267

Theory of Operation

The 3-4 Solenoid is used the engage the gear change form 3rd gear to 4th gear.

The solenoids used in transmission applications are attached to valves which can be classified as normally open or

normally closed. The normally open solenoid valve is defined as a valve which allows hydraulic flow when no cur-

rent or voltage is applied to the solenoid. The normally closed solenoid valve is defined as a valve which does not

allow hydraulic flow when no current or voltage is applied to the solenoid.These valves perform hydraulic control

functions for the transmission and must therefore be durable and tolerantof dirt particles. For these reasons, the

valves have hardened steel poppets and ball valves. The solenoids operatethe valves directly, which means that

the solenoids must have very high outputs to close the valves against the sizable flow areas and line pressures

found in current transmissions. Fastresponse time is also necessary to ensure accurate control.

When Monitored:

Continuously with ignition on.

Set Condition:

This DTC will set if the voltage detected on the 3-4 Shift Solenoid Control circuit at the PCM is different then

the expected voltage. Note: To clear this DTC it is necessary to drive the vehicle at a sustained speed which

would allow the TCC and/or Overdrive Clutch to operate

Possible Causes

TRANSMISSION CONTROL OUTPUT DTC PRESENT

(T9) 3-4 SOLENOID CONTROL CIRCUIT OPEN

(T16) TRANSMISSION CONTROL OUTPUT CIRCUIT OPEN

(T9) 3-4 SOLENOID CONTROL CIRCUIT SHORT TO VOLTAGE

(T9) 3-4 SOLENOID CONTROL CIRCUIT SHORT TO GROUND

(T16) TRANSMISSION RELAY OUTPUT CIRCUIT SHORT TO GROUND

(T9) 3-4 SOLENOID CIRCUIT SHORT TO OTHER CIRCUITS

TOTALLY INTEGRATED POWER MODULE

3-4 SHIFT SOLENOID

POWERTRAIN CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Diagnostic Test

1.CHECK IF THERE ANY TRANSMISSION CONTROL DTCS PRESENT

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Are there any TIPM TCM Power Control Circuit DTCs also present?

Ye s>>

Refer to the Transmission category, and perform the appropriate symptom(s).

No>>

Go To 2

Page 3557 of 5267

2.CHECK IF THE DTC IS CURRENT

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Record the Freeze Frame data for the reported DTC.

With the scan tool, erase DTCs.

Turn the ignition off to the lock position.

Using the Freeze Frame data recorded earlier, try to duplicate the conditions in which the DTC originally set.

NOTE: It may be necessary to road test the vehicle to duplicate the originalset conditions.

With the scan tool, read Engine DTCs.

Did the DTC reset?

Ye s>>

Go To 3

No>>

Go To 12

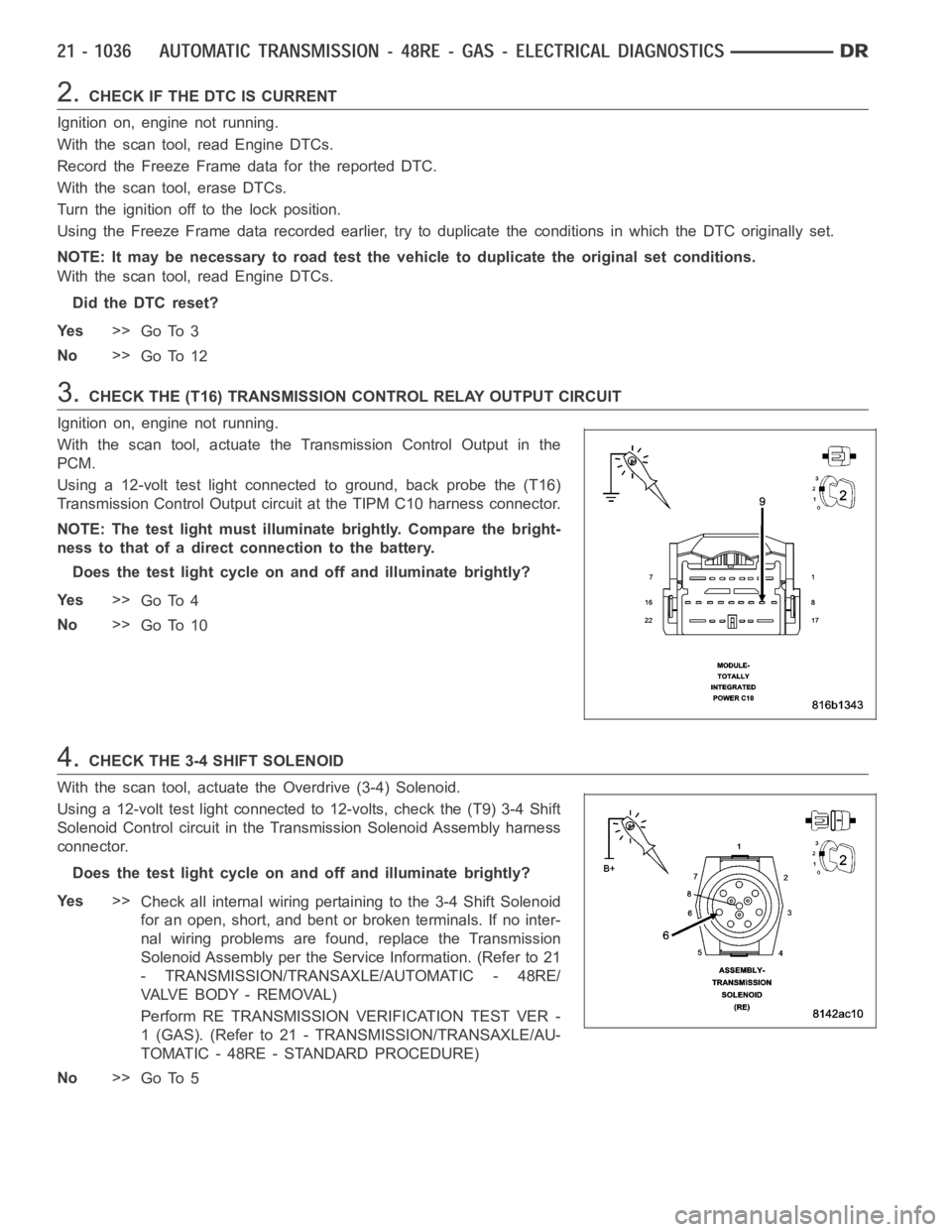

3.CHECK THE (T16) TRANSMISSION CONTROL RELAY OUTPUT CIRCUIT

Ignition on, engine not running.

With the scan tool, actuate the Transmission Control Output in the

PCM.

Using a 12-volt test light connected to ground, back probe the (T16)

Transmission Control Output circuit at the TIPM C10 harness connector.

NOTE: The test light must illuminate brightly. Compare the bright-

ness to that of a direct connection to the battery.

Does the test light cycle on and off and illuminate brightly?

Ye s>>

Go To 4

No>>

Go To 10

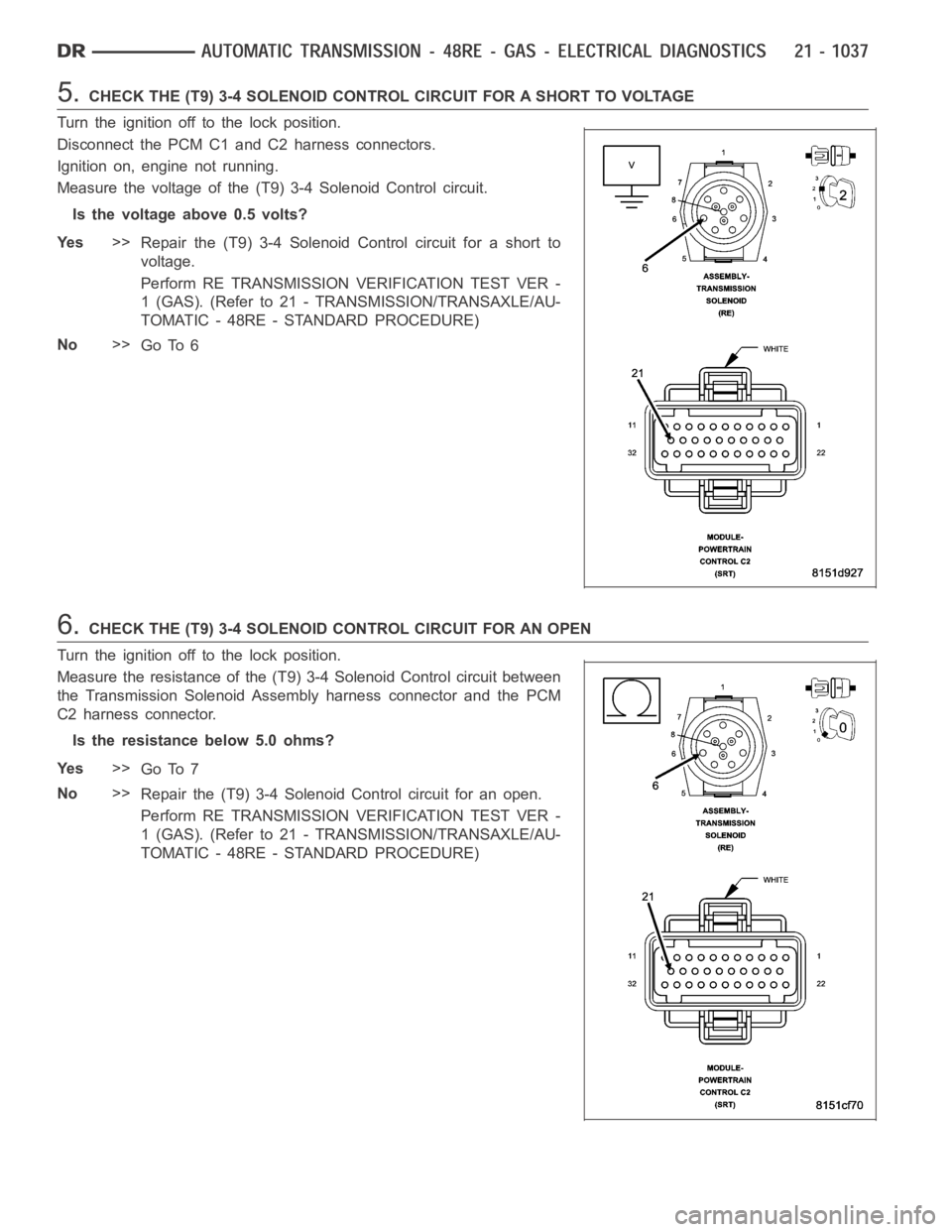

4.CHECK THE 3-4 SHIFT SOLENOID

With the scan tool, actuate the Overdrive (3-4) Solenoid.

Using a 12-volt test light connected to 12-volts, check the (T9) 3-4 Shift

Solenoid Control circuit in the Transmission Solenoid Assembly harness

connector.

Does the test light cycle on and off and illuminate brightly?

Ye s>>

Check all internal wiring pertaining to the 3-4 Shift Solenoid

for an open, short, and bent or broken terminals. If no inter-

nal wiring problems are found, replace the Transmission

Solenoid Assembly per the Service Information. (Refer to 21

- TRANSMISSION/TRANSAXLE/AUTOMATIC - 48RE/

VA LV E B O D Y - R E M O VA L )

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (GAS). (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Go To 5

Page 3558 of 5267

5.CHECK THE (T9) 3-4 SOLENOID CONTROL CIRCUIT FOR A SHORT TO VOLTAGE

Turn the ignition off to the lock position.

Disconnect the PCM C1 and C2 harness connectors.

Ignition on, engine not running.

Measure the voltage of the (T9) 3-4 Solenoid Control circuit.

Is the voltage above 0.5 volts?

Ye s>>

Repair the (T9) 3-4 Solenoid Control circuit for a short to

voltage.

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (GAS). (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Go To 6

6.CHECK THE (T9) 3-4 SOLENOID CONTROL CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Measure the resistance of the (T9) 3-4 Solenoid Control circuit between

the Transmission Solenoid Assembly harness connector and the PCM

C2 harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 7

No>>

Repair the (T9) 3-4 Solenoid Control circuit for an open.

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (GAS). (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 48RE - STANDARD PROCEDURE)

Page 3560 of 5267

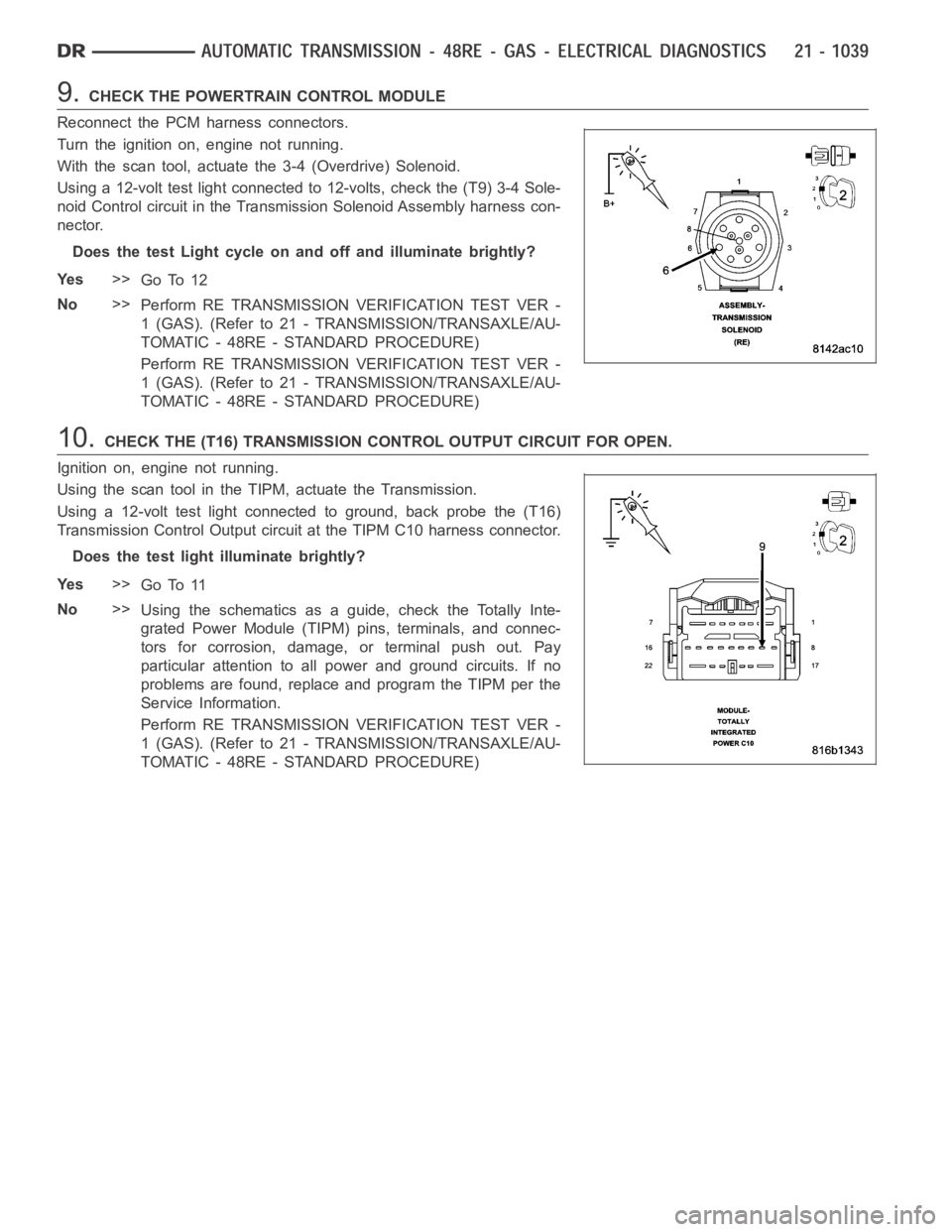

9.CHECK THE POWERTRAIN CONTROL MODULE

Reconnect the PCM harness connectors.

Turn the ignition on, engine not running.

With the scan tool, actuate the 3-4 (Overdrive) Solenoid.

Using a 12-volt test light connected to 12-volts, check the (T9) 3-4 Sole-

noid Control circuit in the Transmission Solenoid Assembly harness con-

nector.

Does the test Light cycle on and off and illuminate brightly?

Ye s>>

Go To 12

No>>

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (GAS). (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 48RE - STANDARD PROCEDURE)

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (GAS). (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 48RE - STANDARD PROCEDURE)

10.CHECK THE (T16) TRANSMISSION CONTROL OUTPUT CIRCUIT FOR OPEN.

Ignition on, engine not running.

Using the scan tool in the TIPM, actuate the Transmission.

Using a 12-volt test light connected to ground, back probe the (T16)

Transmission Control Output circuit at the TIPM C10 harness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 11

No>>

Using the schematics as a guide, check the Totally Inte-

grated Power Module (TIPM) pins, terminals, and connec-

tors for corrosion, damage, or terminal push out. Pay

particular attention to all power and ground circuits. If no

problems are found, replace and program the TIPM per the

Service Information.

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (GAS). (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 48RE - STANDARD PROCEDURE)

Page 3561 of 5267

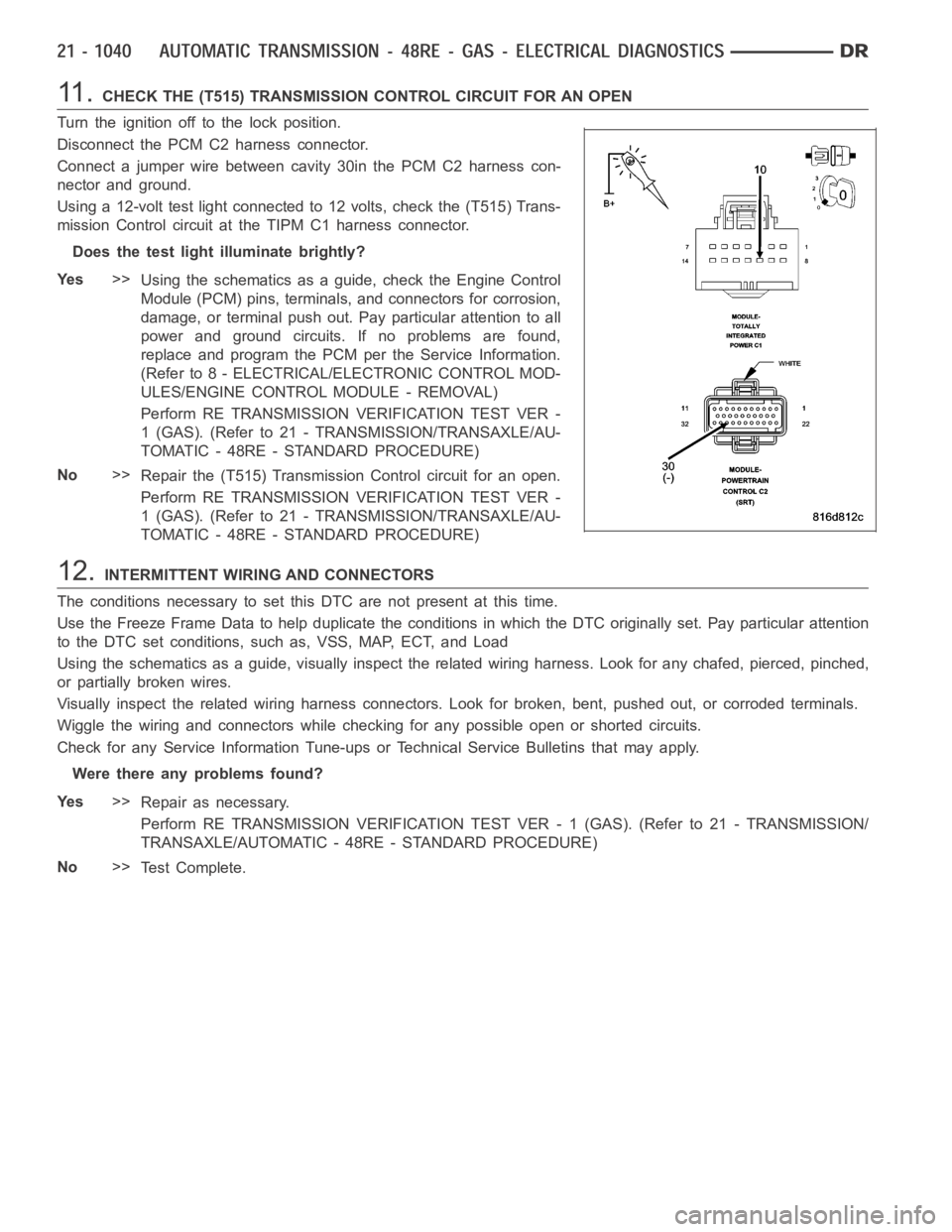

11 .CHECK THE (T515) TRANSMISSION CONTROL CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Disconnect the PCM C2 harness connector.

Connect a jumper wire between cavity 30in the PCM C2 harness con-

nector and ground.

Using a 12-volt test light connected to 12 volts, check the (T515) Trans-

mission Control circuit at the TIPM C1 harness connector.

Does the test light illuminate brightly?

Ye s>>

Using the schematics as a guide, check the Engine Control

Module (PCM) pins, terminals, and connectors for corrosion,

damage, or terminal push out. Pay particular attention to all

power and ground circuits. If no problems are found,

replace and program the PCM per the Service Information.

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/ENGINE CONTROL MODULE - REMOVAL)

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (GAS). (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Repair the (T515) Transmission Control circuit for an open.

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (GAS). (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 48RE - STANDARD PROCEDURE)

12.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Use the Freeze Frame Data to help duplicate the conditions in which the DTC originally set. Pay particular attention

to the DTC set conditions, such as, VSS, MAP, ECT, and Load

Using the schematics as a guide, visually inspect the related wiring harness. Look for any chafed, pierced, pinched,

or partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken,bent, pushed out, or corroded terminals.

Wiggle the wiring and connectors while checking for any possible open or shorted circuits.

Check for any Service Information Tune-ups or Technical Service Bulletins that may apply.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (GAS). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 3563 of 5267

Theory of Operation

The Torque Converter Clutch (TCC) Solenoid is used to engage the TCC which improves fuel economy. The Over-

drive Solenoid is used to engage the gear change from third to Overdrive.

When Monitored:

Continuously with the ignition on and the engine running.

Set Condition:

This DTC will set if the expected engine RPM drop does not occur within 4 seconds of the gear change being

requested by the PCM three consecutive failed tests.

Possible Causes

FLUID LEVEL AND CONDITION - EXCESSIVE DEBRIS OR BURNT

3-4 SHIFT SOLENOID

INTERNAL TRANSMISSION FAILURE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Diagnostic Test

1.CHECK IF THERE ANY TRANSMISSION CONTROL DTCS PRESENT

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Are there any TIPM TCM Power Control Circuit DTCs also present?

Ye s>>

Refer to the Transmission or Engine category and perform the appropriate symptom(s).

No>>

Go To 2

2.CHECK IF THE DTC IS CURRENT

With the scan tool, read Engine DTCs.

Record the Freeze Frame data for the reported DTC.

With the scan tool, erase DTCs.

Turn the ignition off to the lock position.

Using the Freeze Frame data recorded earlier, try to duplicate the conditions in which the DTC originally set.

NOTE: It may be necessary to road test the vehicle to duplicate the originalset conditions.

With the scan tool, read Engine DTCs.

Did the DTC reset?

Ye s>>

Go To 3

No>>

Go To 6

3.CHECK THE GOVERNOR AND OVERDRIVE PRESSURE

Turn the ignition off to the lock position.

Connect a 0 - 2068 KPa (0 - 300 PSI) pressure gauge to the Overdrive Clutch test port.

Connect another 0 - 2068 KPa (0 - 300 PSI) pressure gauge to the Governor Pressure test port. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 48RE - DIAGNOSIS AND TESTING)

Start the engine and allow the transmission temperature to rise to normal operating temperature.

CAUTION: Apply the parking brake.

Firmly apply the brakesand place the gear selector in Drive.

While observing the pressure gauges, with the scan tool, select 4th gear from the Gov and 3-4 Shift Valve Test.

Page 3564 of 5267

NOTE: The governor pressure should rise above 138 kPa (20 PSI). Shortly after the O/D pressure should

rise above 276 kPa (40 PSI).

Did the pressures act as previously described?

Ye s>>

Go To 4

No>>

Go To 5

4.CHECK THE TRANSMISSION OIL CONDITION

Turn the ignition off to the lock position.

Remove the transmission oil pan and inspect for excessive debris and burntoil.

Is the oil burnt or does the transmission oil pan contain excessive debris?

Ye s>>

Repair the transmission as necessary. Refer to the Service Informtion forthe proper repair procedures.

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 48RE - DIAGNOSIS AND TESTING)

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (GAS). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Go To 6

5.CHECK THE GOVERNOR AND OVERDRIVE PRESSURE AFTER REPLACEMENT OF THE 3-4 SHIFT

SOLENOID

Turn the ignition off to the lock position.

Replace the 3-4 Shift Solenoid per the Service Information. (Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 48RE/VALVE BODY - DISASSEMBLY)

With the pressure gauges still attached, start the engine and allow the transmission temperature to rise to normal

operating temperature.

CAUTION: Apply the parking brake.

Firmly apply the brakesand place the gear selector in Drive.

While observing the pressure gauges, with the scan tool, select 4th gear from the Gov and 3-4 Shift Valve Test.

NOTE: The governor pressure should rise to above 138 kPa (20 PSI). Shortly after the O/D pressure should

rise above 276 kPa (40 PSI).

Did the pressures act as previously described?

Ye s>>

Te s t C o m p l e t e .

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (DIESEL). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Overhaul the transmission per the Service Information. Pay attention to seals and clutches related to the

OD clutch.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (GAS). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)