ABS DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4625 of 5267

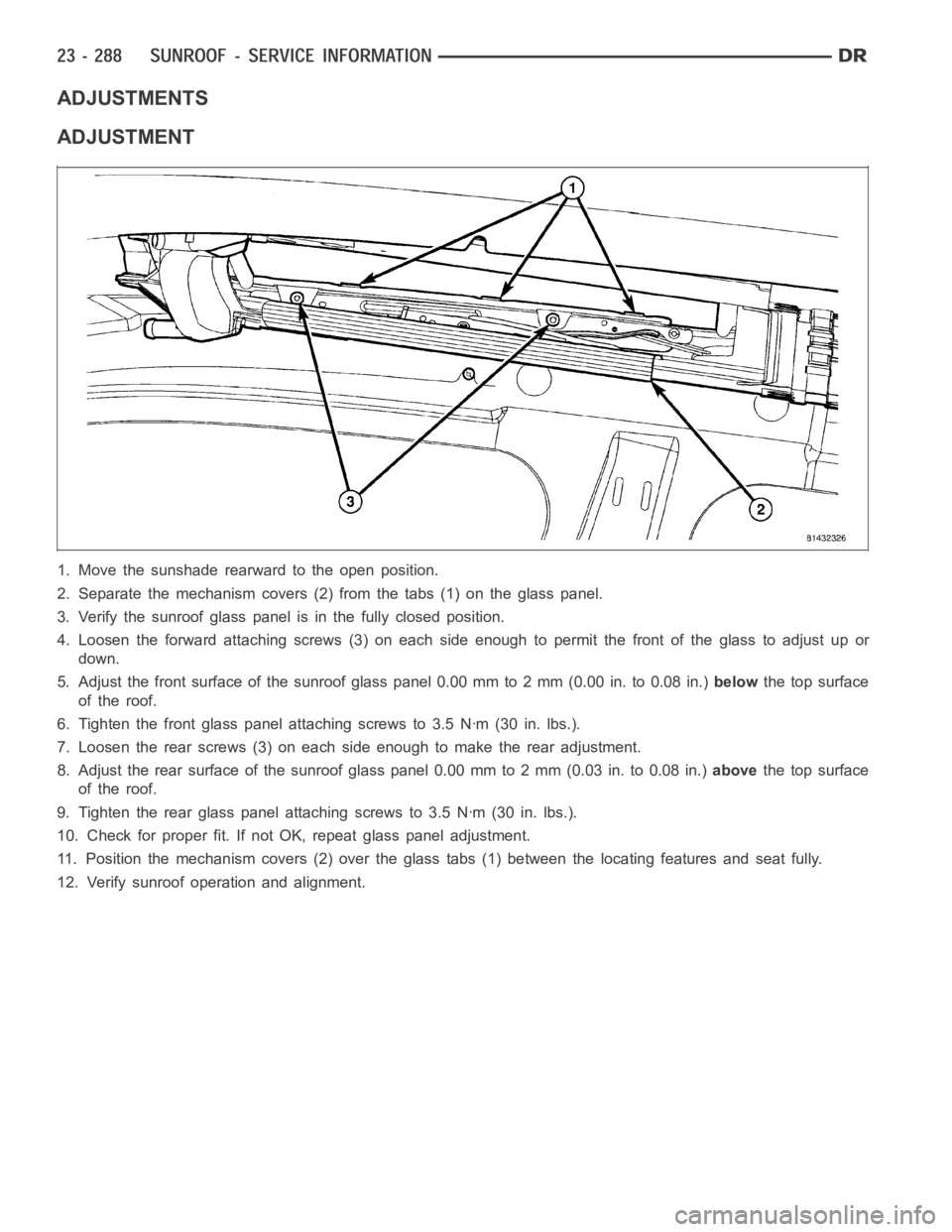

ADJUSTMENTS

ADJUSTMENT

1. Move the sunshade rearward to the open position.

2. Separate the mechanism covers (2) from the tabs (1) on the glass panel.

3. Verify the sunroof glass panel is in the fully closed position.

4. Loosen the forward attaching screws (3) on each side enough to permit thefront of the glass to adjust up or

down.

5. Adjust the front surface of the sunroof glass panel 0.00 mm to 2 mm (0.00 in.to0.08in.)belowthe top surface

of the roof.

6. Tighten the front glass panel attaching screws to 3.5 Nꞏm (30 in. lbs.).

7. Loosen the rear screws (3) on each side enough to make the rear adjustment.

8. Adjust the rear surface of the sunroof glass panel 0.00 mm to 2 mm (0.03 in.to 0.08 in.)abovethe top surface

of the roof.

9. Tighten the rear glass panel attaching screws to 3.5 Nꞏm (30 in. lbs.).

10. Check for proper fit. If not OK, repeat glass panel adjustment.

11. Position the mechanism covers (2) over the glass tabs (1) between the locating features and seat fully.

12. Verify sunroof operation and alignment.

Page 5053 of 5267

ACTUATOR DTC DETECTION TEST — DUAL-ZONE

The Actuator DTC Detection Test:

is actuated with a scan tool.

clears all actuator related DTCs when the test is actuated.

supplements the continuous diagnostics on the actuator drive system.

monitors for shorted actuator circuits allowing service to easily diagnose and troubleshoot up to three simul-

taneous shorts. Shorted actuator circuit faults (XXX Control Circuit High or XXX Control Circuit Low) will only

display after running the Actuator DTC Detection Test.

After repairing each DTC, cycle the ignition switch, and then run the Actuator DTC Detection Test again to ensure

that no new DTCs exist. If multiple DTCs are present, beginning with the passenger blend door, diagnose and repair

all short high faults and then short low faults. When the test returns passed, clear all faults and run the Actuator

Calibration function as a final check of system health.

ACTUATOR DTC DETECTION TEST — SINGLE-ZONE

The Actuator DTC Detection Test:

is actuated with a scan tool.

clears all actuator related DTCs when the test is actuated.

supplements the continuous diagnostics on the actuator drive system.

monitors for shorted actuator circuits allowing service to easily diagnose and troubleshoot up to three simul-

taneous shorts. Shorted actuator circuit faults (XXX Control Circuit High or XXX Control Circuit Low) will only

display after running the Actuator DTC Detection Test.

After repairing each DTC, cycle the ignition switch, and then run the Actuator DTC Detection Test again to ensure

that no new DTCs exist. If multiple DTCs are present, beginning with the common circuit, diagnose and repair all

short high faults and then short low faults. When the test returns passed, clear all faults and run the Actuator Cal-

ibration function as a final check of system health.

A/C PERFORMANCE

The A/C system is designed to provide the passenger compartment with low temperature and low humidity air. The

A/C evaporator, located in the HVAC housing is cooled to temperatures nearthe freezing point. As warm damp air

passes over the fins of the A/C evaporator, the air transfers its heat to therefrigerant in the evaporator coils and the

moisture in the air condenses on the evaporator fins. During periods of high heat and humidity, an A/C system will

be more effective in the Recirculation mode (max-A/C). With the system in the Recirculation mode, only air from the

passenger compartment passes through the A/C evaporator. As the passenger compartment air dehumidifies, the

A/C system performance levels rise.

Humidity has an important bearing on the temperature of the air delivered to the interior of the vehicle. It is impor-

tant to understand the effect that humidity has on the performance of the A/C system. When humidity is high, the

A/C evaporator has to perform a double duty. It must lower the air temperature, and it must lower the temperature

of the moisture in the air that condenses on the evaporator fins. Condensing the moisture in the air transfers heat

energy into the evaporator fins and coils. This reduces the amount of heat the A/C evaporator can absorb from the

air. High humidity greatly reduces the ability of the A/C evaporator to lower the temperature of the air.

However, evaporator capacity used to reduce the amount of moisture in the air is not wasted. Wringing some of the

moisture out of the air entering the vehicle adds to the comfort of the passengers. Although, an owner may expect

too much from their A/C system on humid days. A performance test is the best way to determine whether the sys-

tem is performing up to design standards. This test also provides valuableclues as to the possible cause of trouble

with the A/C system. The ambient air temperature in the location where the vehicle will be tested must be a mini-

mum of 21° C (70° F) for this test.

A/C PERFORMANCE TEST

WARNING: Refer to the applicable warnings and cautions for this system before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS). Failure to follow the warnings and cautions could result

in possible personal injury or death.

Page 5061 of 5267

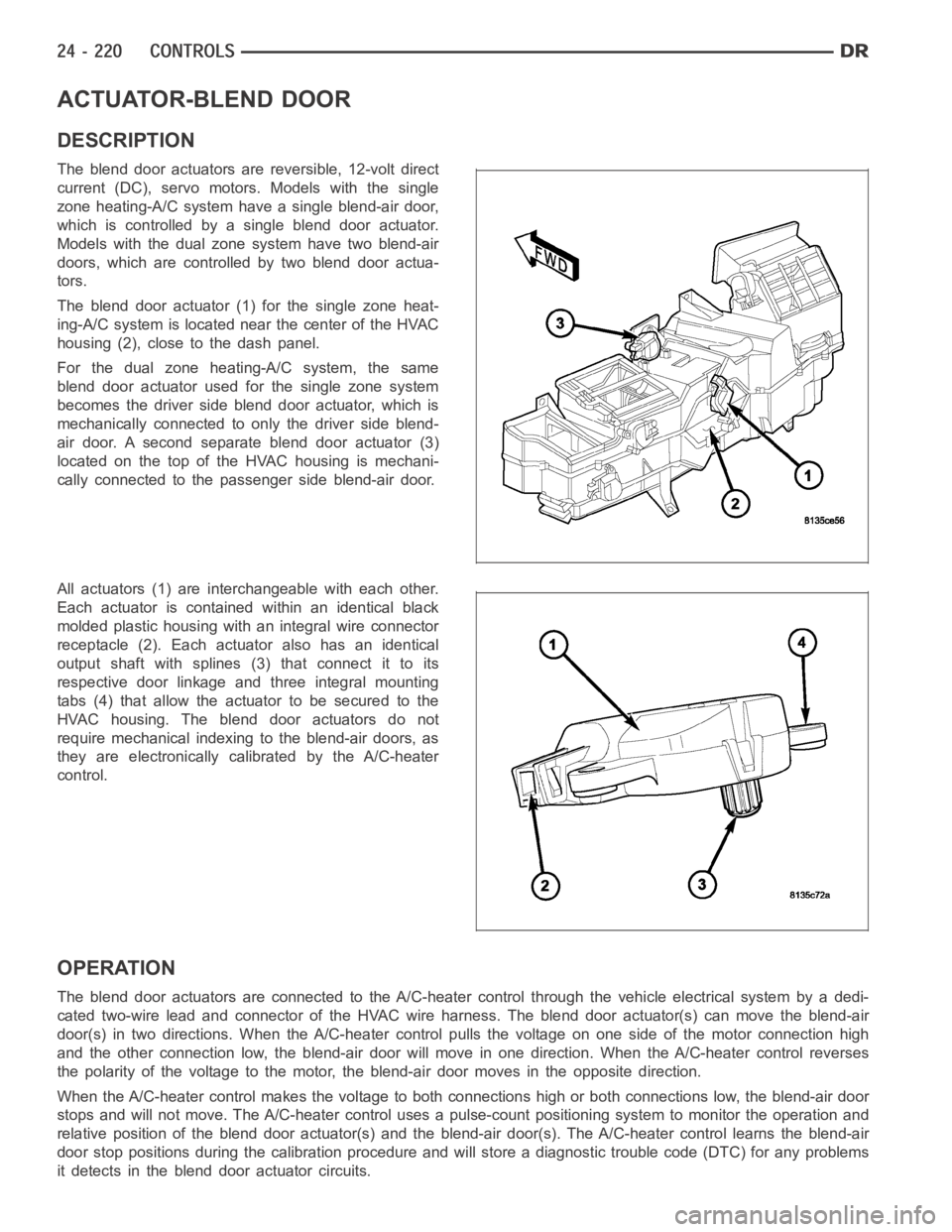

ACTUATOR-BLEND DOOR

DESCRIPTION

The blend door actuators are reversible, 12-volt direct

current (DC), servo motors. Models with the single

zone heating-A/C system have a single blend-air door,

which is controlled by a single blend door actuator.

Models with the dual zone system have two blend-air

doors, which are controlled by two blend door actua-

tors.

The blend door actuator (1) for the single zone heat-

ing-A/C system is located near the center of the HVAC

housing (2), close to the dash panel.

For the dual zone heating-A/C system, the same

blend door actuator used for the single zone system

becomes the driver side blend door actuator, which is

mechanically connected to only the driver side blend-

air door. A second separate blend door actuator (3)

located on the top of the HVAC housing is mechani-

cally connected to the passenger side blend-air door.

All actuators (1) are interchangeable with each other.

Each actuator is contained within an identical black

molded plastic housing with an integral wire connector

receptacle (2). Each actuator also has an identical

output shaft with splines (3) that connect it to its

respective door linkage and three integral mounting

tabs (4) that allow the actuator to be secured to the

HVAC housing. The blend door actuators do not

require mechanical indexing to the blend-air doors, as

they are electronically calibrated by the A/C-heater

control.

OPERATION

The blend door actuators are connected to the A/C-heater control through the vehicle electrical system by a dedi-

cated two-wire lead and connector of the HVAC wire harness. The blend door actuator(s) can move the blend-air

door(s) in two directions. When the A/C-heater control pulls the voltage on one side of the motor connection high

and the other connection low, the blend-air door will move in one direction. When the A/C-heater control reverses

the polarity of the voltage to the motor, the blend-air door moves in the opposite direction.

When the A/C-heater control makes the voltage to both connections high or both connections low, the blend-air door

stops and will not move. The A/C-heater control uses a pulse-count positioning system to monitor the operation and

relative position of the blend door actuator(s) and the blend-air door(s). The A/C-heater control learns the blend-air

door stop positions during the calibration procedure and will store a diagnostic trouble code (DTC) for any problems

it detects in the blend door actuator circuits.

Page 5066 of 5267

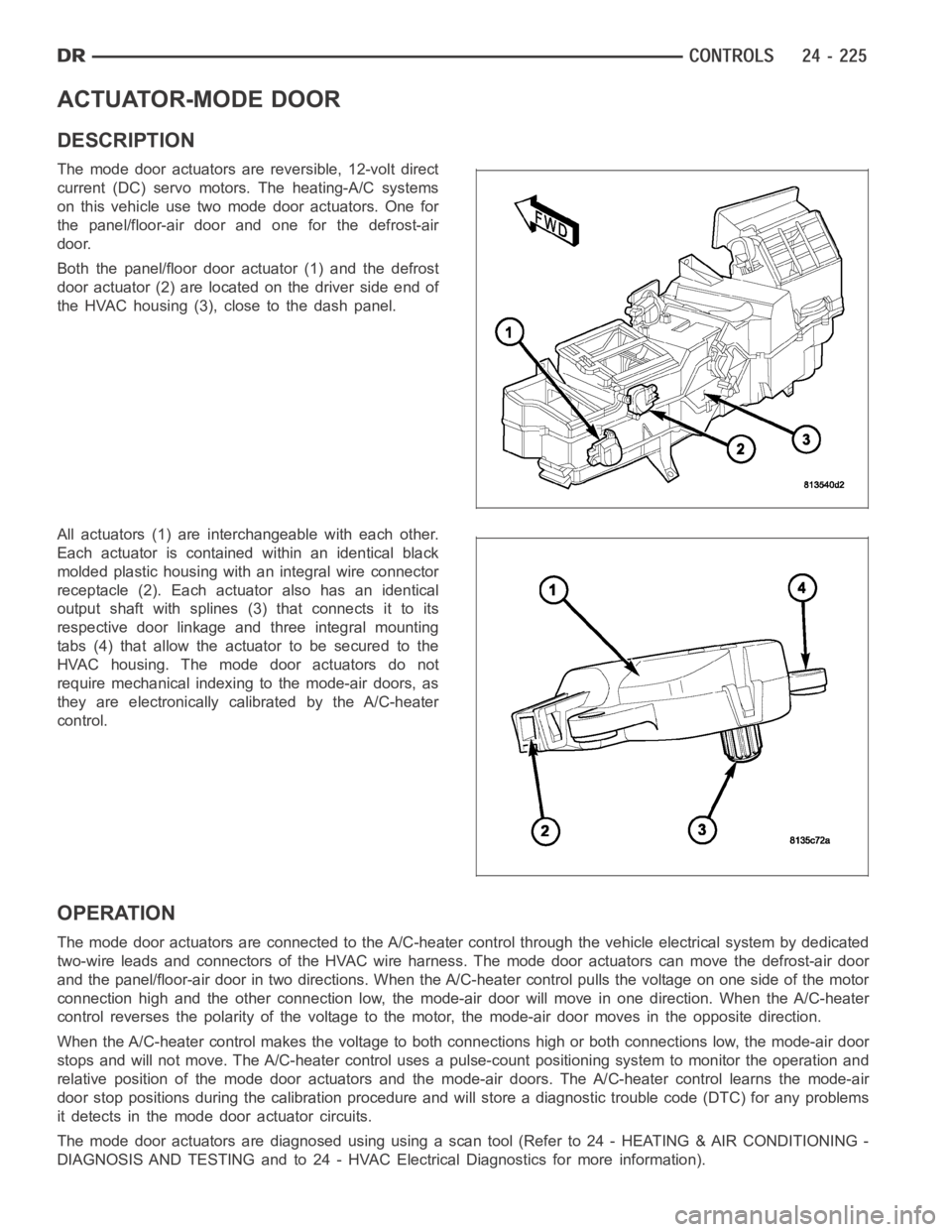

ACTUATOR-MODE DOOR

DESCRIPTION

The mode door actuators are reversible, 12-volt direct

current (DC) servo motors.The heating-A/C systems

on this vehicle use two mode door actuators. One for

the panel/floor-air door and one for the defrost-air

door.

Both the panel/floor door actuator (1) and the defrost

door actuator (2) are located on the driver side end of

the HVAC housing (3), close to the dash panel.

All actuators (1) are interchangeable with each other.

Each actuator is contained within an identical black

molded plastic housing with an integral wire connector

receptacle (2). Each actuator also has an identical

output shaft with splines (3) that connects it to its

respective door linkage and three integral mounting

tabs (4) that allow the actuator to be secured to the

HVAC housing. The mode door actuators do not

require mechanical indexing to the mode-air doors, as

they are electronically calibrated by the A/C-heater

control.

OPERATION

The mode door actuators are connectedto the A/C-heater control through the vehicle electrical system by dedicated

two-wire leads and connectors of the HVAC wire harness. The mode door actuators can move the defrost-air door

and the panel/floor-air door in two directions. When the A/C-heater control pulls the voltage on one side of the motor

connection high and the other connection low, the mode-air door will move in one direction. When the A/C-heater

control reverses the polarity of the voltage to the motor, the mode-air door moves in the opposite direction.

When the A/C-heater control makes the voltage to both connections high or both connections low, the mode-air door

stops and will not move. The A/C-heater control uses a pulse-count positioning system to monitor the operation and

relative position of the mode door actuators and the mode-air doors. The A/C-heater control learns the mode-air

door stop positions during the calibration procedure and will store a diagnostic trouble code (DTC) for any problems

it detects in the mode door actuator circuits.

The mode door actuators are diagnosed using using a scan tool (Refer to 24 - HEATING & AIR CONDITIONING -

DIAGNOSIS AND TESTING and to 24 - HVAC Electrical Diagnostics for more information).

Page 5070 of 5267

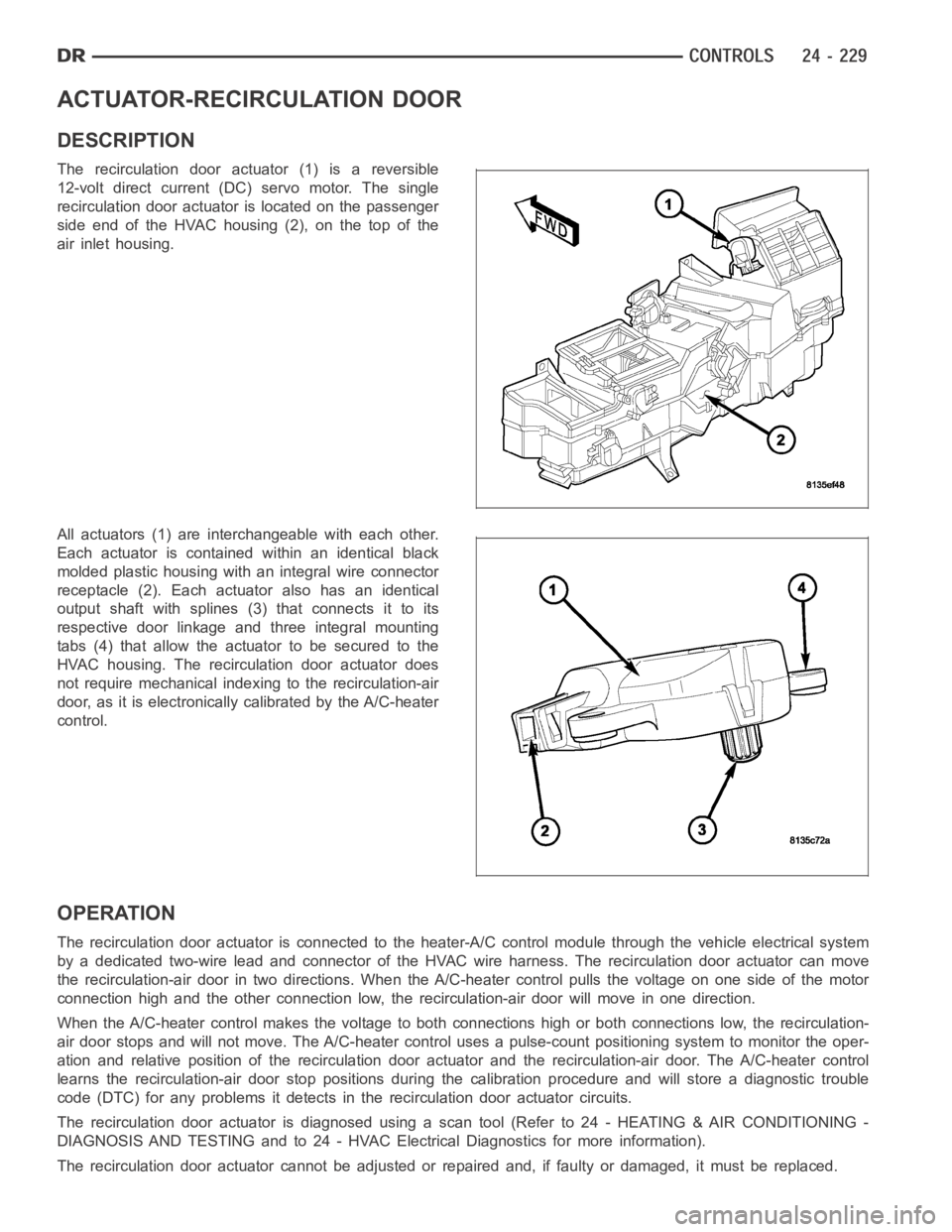

ACTUATOR-RECIRCULATION DOOR

DESCRIPTION

The recirculation door actuator (1) is a reversible

12-volt direct current (DC)servo motor. The single

recirculation door actuator is located on the passenger

side end of the HVAC housing (2), on the top of the

air inlet housing.

All actuators (1) are interchangeable with each other.

Each actuator is contained within an identical black

molded plastic housing with an integral wire connector

receptacle (2). Each actuator also has an identical

output shaft with splines (3) that connects it to its

respective door linkage and three integral mounting

tabs (4) that allow the actuator to be secured to the

HVAC housing. The recirculation door actuator does

not require mechanical indexing to the recirculation-air

door, as it is electronically calibrated by the A/C-heater

control.

OPERATION

The recirculation door actuator is connected to the heater-A/C control module through the vehicle electrical system

by a dedicated two-wire lead and connector of the HVAC wire harness. The recirculation door actuator can move

the recirculation-air door in two directions. When the A/C-heater control pulls the voltage on one side of the motor

connection high and the other connection low, the recirculation-air doorwill move in one direction.

When the A/C-heater control makes the voltage to both connections high or both connections low, the recirculation-

air door stops and will not move. The A/C-heater control uses a pulse-countpositioning system to monitor the oper-

ation and relative position of the recirculation door actuator and the recirculation-air door. The A/C-heater control

learns the recirculation-air door stop positions during the calibrationprocedure and will store a diagnostic trouble

code (DTC) for any problems it detects in the recirculation door actuator circuits.

The recirculation door actuator is diagnosed using a scan tool (Refer to 24- HEATING & AIR CONDITIONING -

DIAGNOSIS AND TESTING and to 24 - HVAC Electrical Diagnostics for more information).

The recirculation door actuator cannot be adjusted or repaired and, if faulty or damaged, it must be replaced.

Page 5081 of 5267

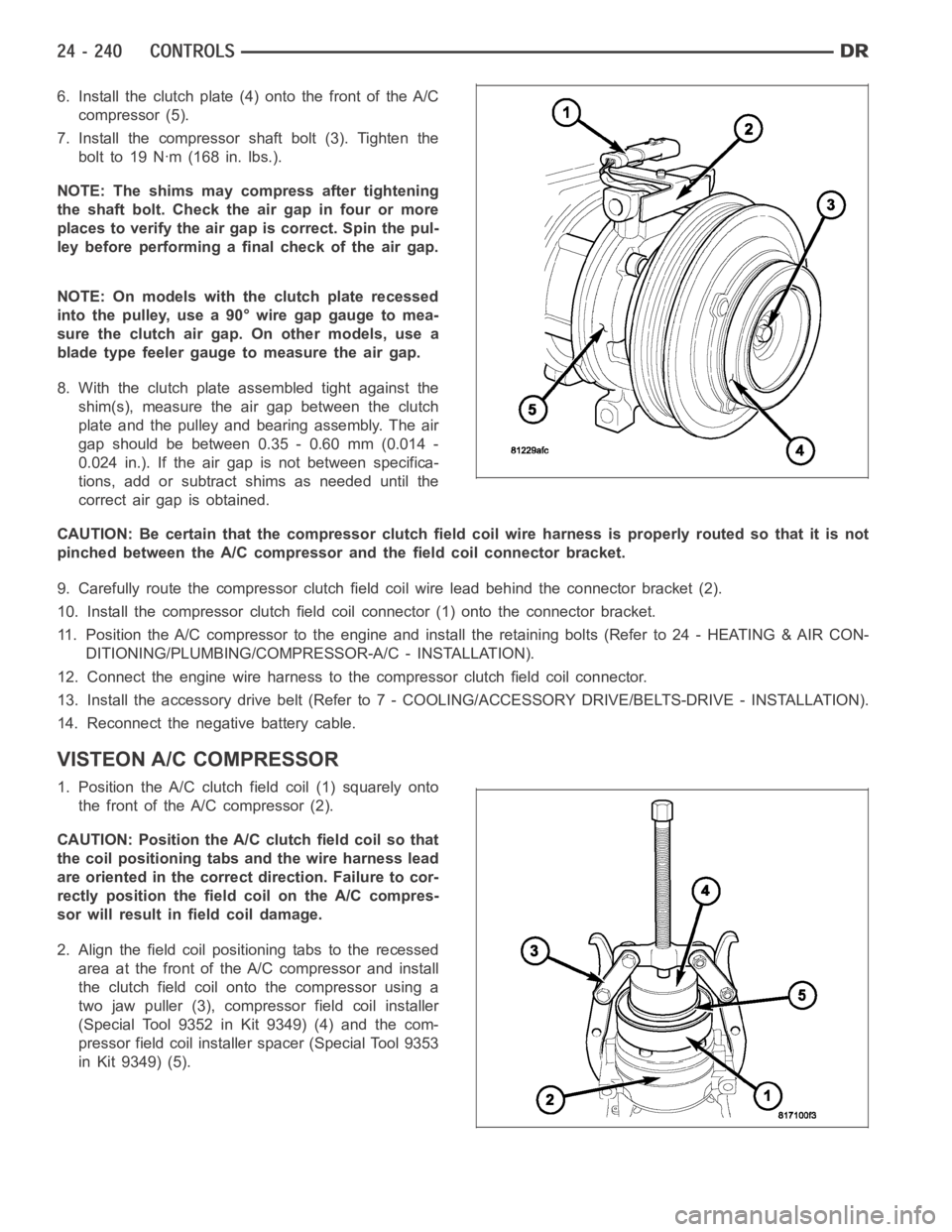

6. Install the clutch plate (4) onto the front of the A/C

compressor (5).

7. Install the compressor shaft bolt (3). Tighten the

bolt to 19 Nꞏm (168 in. lbs.).

NOTE: The shims may compress after tightening

the shaft bolt. Check the air gap in four or more

places to verify the air gap is correct. Spin the pul-

ley before performing a final check of the air gap.

NOTE: On models with the clutch plate recessed

intothepulley,usea90°wiregapgaugetomea-

sure the clutch air gap. On other models, use a

blade type feeler gauge to measure the air gap.

8. With the clutch plate assembled tight against the

shim(s), measure the air gap between the clutch

plate and the pulley and bearing assembly. The air

gap should be between 0.35 - 0.60 mm (0.014 -

0.024 in.). If the air gap is not between specifica-

tions, add or subtract shims as needed until the

correct air gap is obtained.

CAUTION: Be certain that the compressor clutch field coil wire harness is properly routed so that it is not

pinched between the A/C compressor and the field coil connector bracket.

9. Carefully route the compressor clutch field coil wire lead behind the connector bracket (2).

10. Install the compressor clutch fieldcoil connector (1) onto the connector bracket.

11. Position the A/C compressor to the engine and install the retaining bolts (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING/COMPRESSOR-A/C - INSTALLATION).

12. Connect the engine wire harness to the compressor clutch field coil connector.

13. Install the accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/BELTS-DRIVE - INSTALLATION).

14. Reconnect the negative battery cable.

VISTEON A/C COMPRESSOR

1. Position the A/C clutch field coil (1) squarely onto

the front of the A/C compressor (2).

CAUTION: Position the A/C clutch field coil so that

the coil positioning tabs and the wire harness lead

are oriented in the correct direction. Failure to cor-

rectly position the fieldcoil on the A/C compres-

sor will result in field coil damage.

2. Align the field coil positioning tabs to the recessed

area at the front of the A/C compressor and install

the clutch field coil onto the compressor using a

two jaw puller (3), compressor field coil installer

(Special Tool 9352 in Kit 9349) (4) and the com-

pressor field coil installer spacer (Special Tool 9353

in Kit 9349) (5).

Page 5107 of 5267

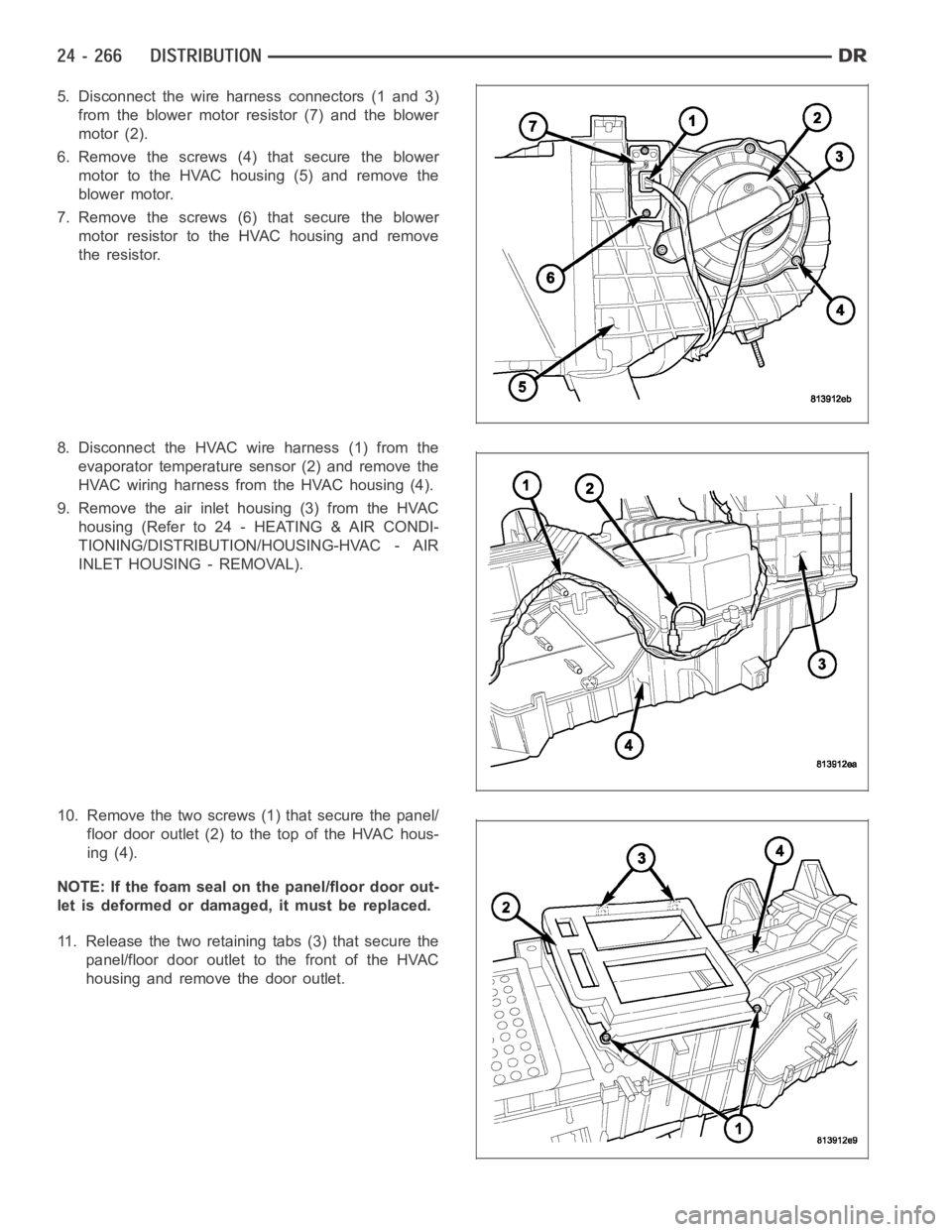

5. Disconnect the wire harness connectors (1 and 3)

from the blower motor resistor (7) and the blower

motor (2).

6. Remove the screws (4)that secure the blower

motor to the HVAC housing (5) and remove the

blower motor.

7. Remove the screws (6)that secure the blower

motor resistor to the HVAC housing and remove

the resistor.

8. Disconnect the HVAC wire harness (1) from the

evaporator temperature sensor (2) and remove the

HVAC wiring harness from the HVAC housing (4).

9. Remove the air inlet housing (3) from the HVAC

housing (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION/HOUSING-HVAC - AIR

INLET HOUSING - REMOVAL).

10. Remove the two screws (1) that secure the panel/

floor door outlet (2) to the top of the HVAC hous-

ing (4).

NOTE: If the foam seal on the panel/floor door out-

let is deformed or damaged, it must be replaced.

11. Release the two retaining tabs (3) that secure the

panel/floor door outlet to the front of the HVAC

housing and remove the door outlet.

Page 5108 of 5267

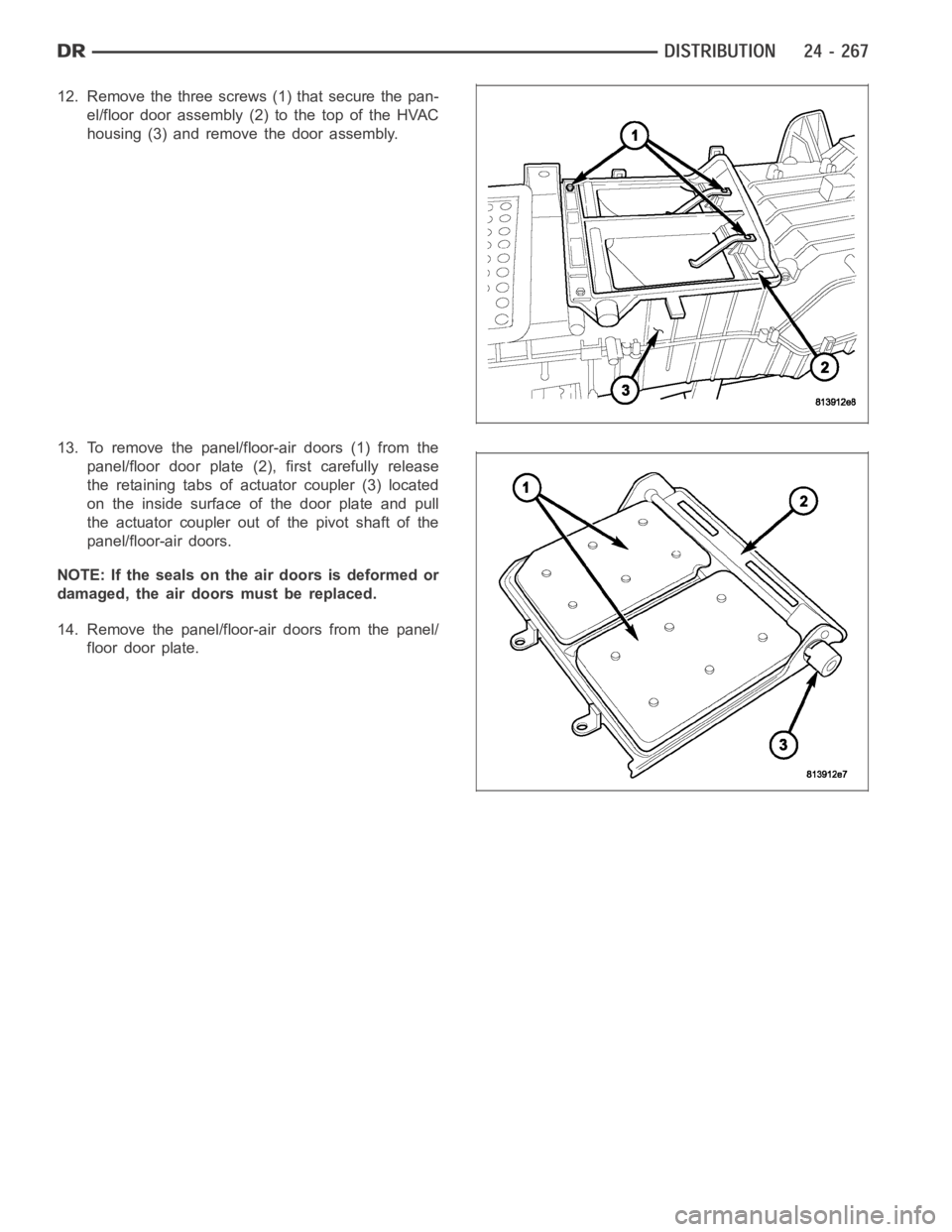

12. Remove the three screws (1) that secure the pan-

el/floor door assembly (2) to the top of the HVAC

housing (3) and remove the door assembly.

13. To remove the panel/floor-air doors (1) from the

panel/floor door plate (2), first carefully release

the retaining tabs of actuator coupler (3) located

on the inside surface of the door plate and pull

the actuator coupler out of the pivot shaft of the

panel/floor-air doors.

NOTE: If the seals on the air doors is deformed or

damaged, the air doors must be replaced.

14. Remove the panel/floor-air doors from the panel/

floor door plate.

Page 5110 of 5267

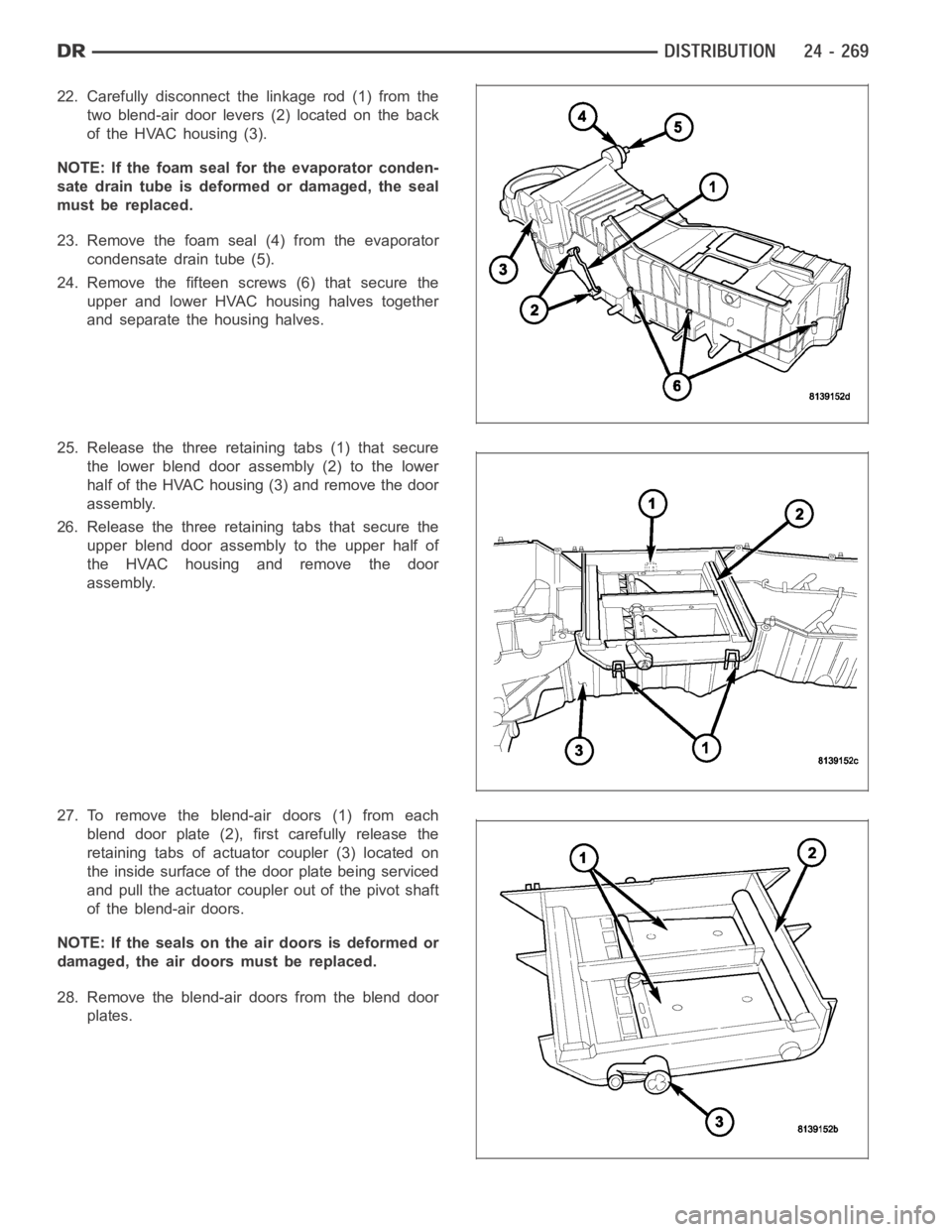

22. Carefully disconnect the linkage rod (1) from the

two blend-air door levers (2) located on the back

of the HVAC housing (3).

NOTE: If the foam seal for the evaporator conden-

sate drain tube is deformed or damaged, the seal

must be replaced.

23. Remove the foam seal (4) from the evaporator

condensate drain tube (5).

24. Remove the fifteen screws (6) that secure the

upper and lower HVAC housing halves together

and separate the housing halves.

25. Release the three retaining tabs (1) that secure

the lower blend door assembly (2) to the lower

half of the HVAC housing (3) and remove the door

assembly.

26. Release the three retaining tabs that secure the

upper blend door assembly to the upper half of

the HVAC housing and remove the door

assembly.

27. To remove the blend-air doors (1) from each

blend door plate (2), first carefully release the

retaining tabs of actuator coupler (3) located on

the inside surface of the door plate being serviced

and pull the actuator coupler out of the pivot shaft

of the blend-air doors.

NOTE: If the seals on the air doors is deformed or

damaged, the air doors must be replaced.

28. Remove the blend-air doors from the blend door

plates.

Page 5111 of 5267

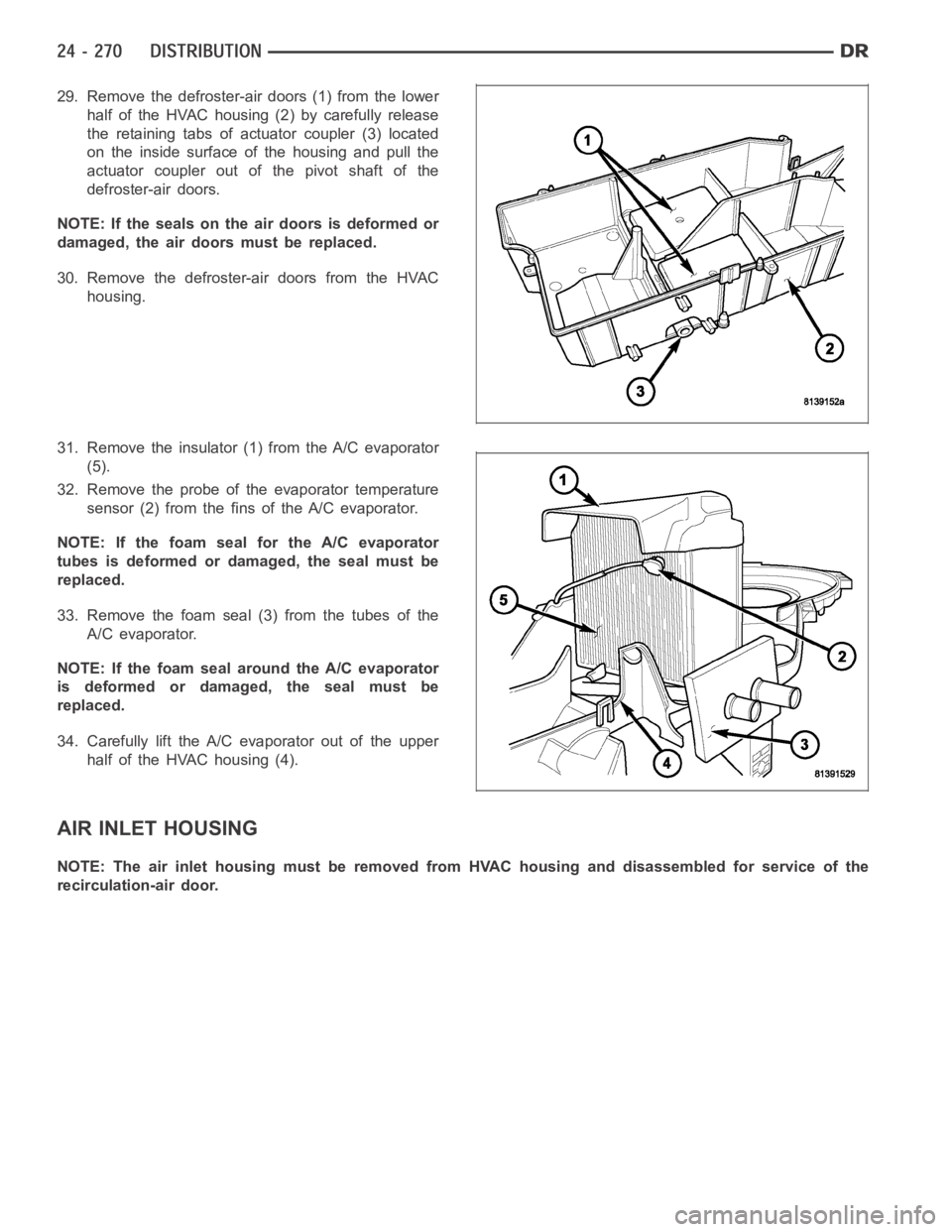

29. Remove the defroster-air doors (1) from the lower

half of the HVAC housing (2) by carefully release

the retaining tabs of actuator coupler (3) located

on the inside surface of the housing and pull the

actuator coupler out of the pivot shaft of the

defroster-air doors.

NOTE: If the seals on the air doors is deformed or

damaged, the air doors must be replaced.

30. Remove the defroster-air doors from the HVAC

housing.

31. Remove the insulator (1) from the A/C evaporator

(5).

32. Remove the probe of the evaporator temperature

sensor (2) from the fins of the A/C evaporator.

NOTE: If the foam seal for the A/C evaporator

tubes is deformed or damaged, the seal must be

replaced.

33. Remove the foam seal (3) from the tubes of the

A/C evaporator.

NOTE: If the foam seal around the A/C evaporator

is deformed or damaged, the seal must be

replaced.

34. Carefully lift the A/C evaporator out of the upper

half of the HVAC housing (4).

AIR INLET HOUSING

NOTE: The air inlet housing must be removed from HVAC housing and disassembled for service of the

recirculation-air door.