cooling DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2172 of 5267

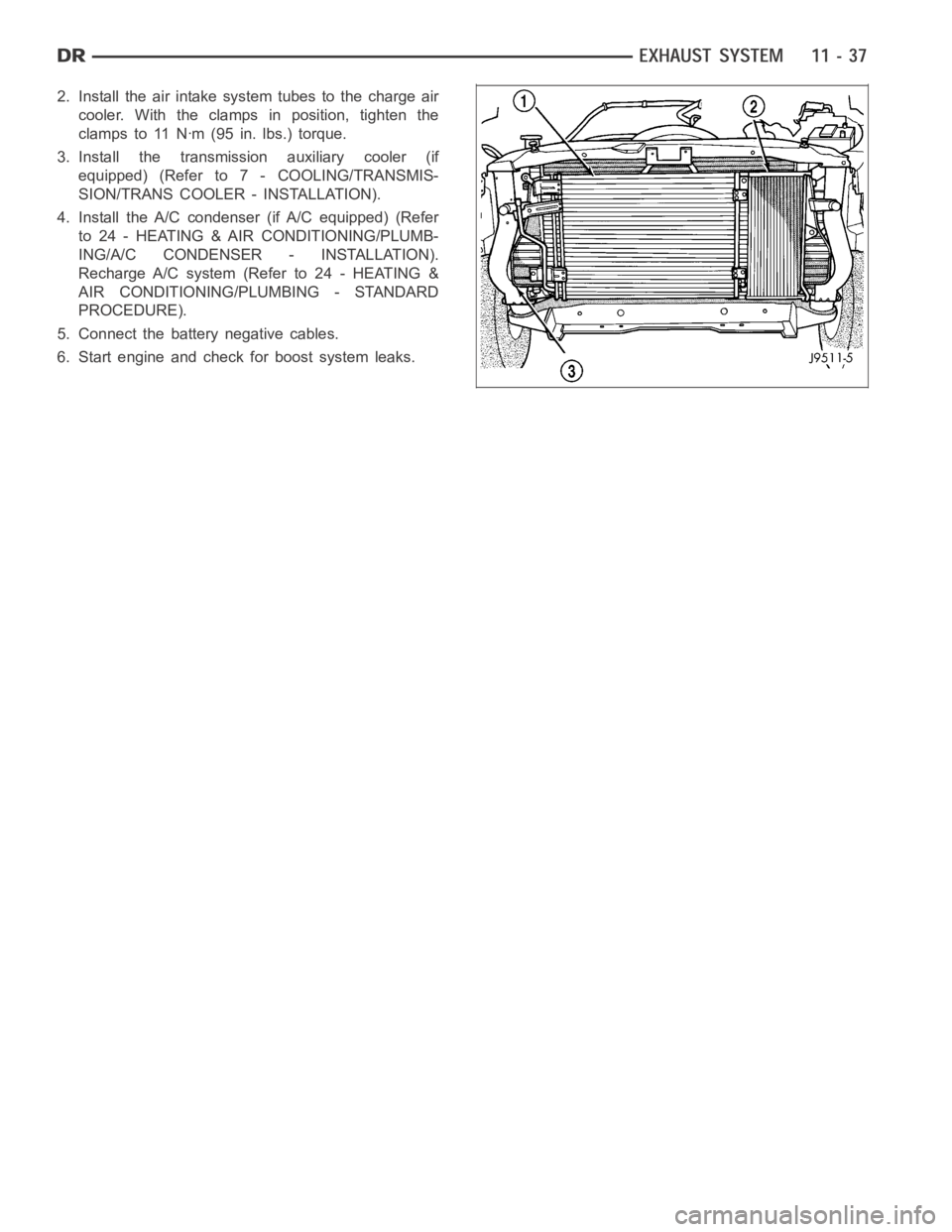

2. Install the air intake system tubes to the charge air

cooler. With the clamps in position, tighten the

clamps to 11 Nꞏm (95 in. lbs.) torque.

3. Install the transmission auxiliary cooler (if

equipped) (Refer to 7 - COOLING/TRANSMIS-

SION/TRANS COOLER - INSTALLATION).

4. Install the A/C condenser (if A/C equipped) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING/A/C CONDENSER - INSTALLATION).

Recharge A/C system (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE).

5. Connect the battery negative cables.

6. Start engine and check for boost system leaks.

Page 2192 of 5267

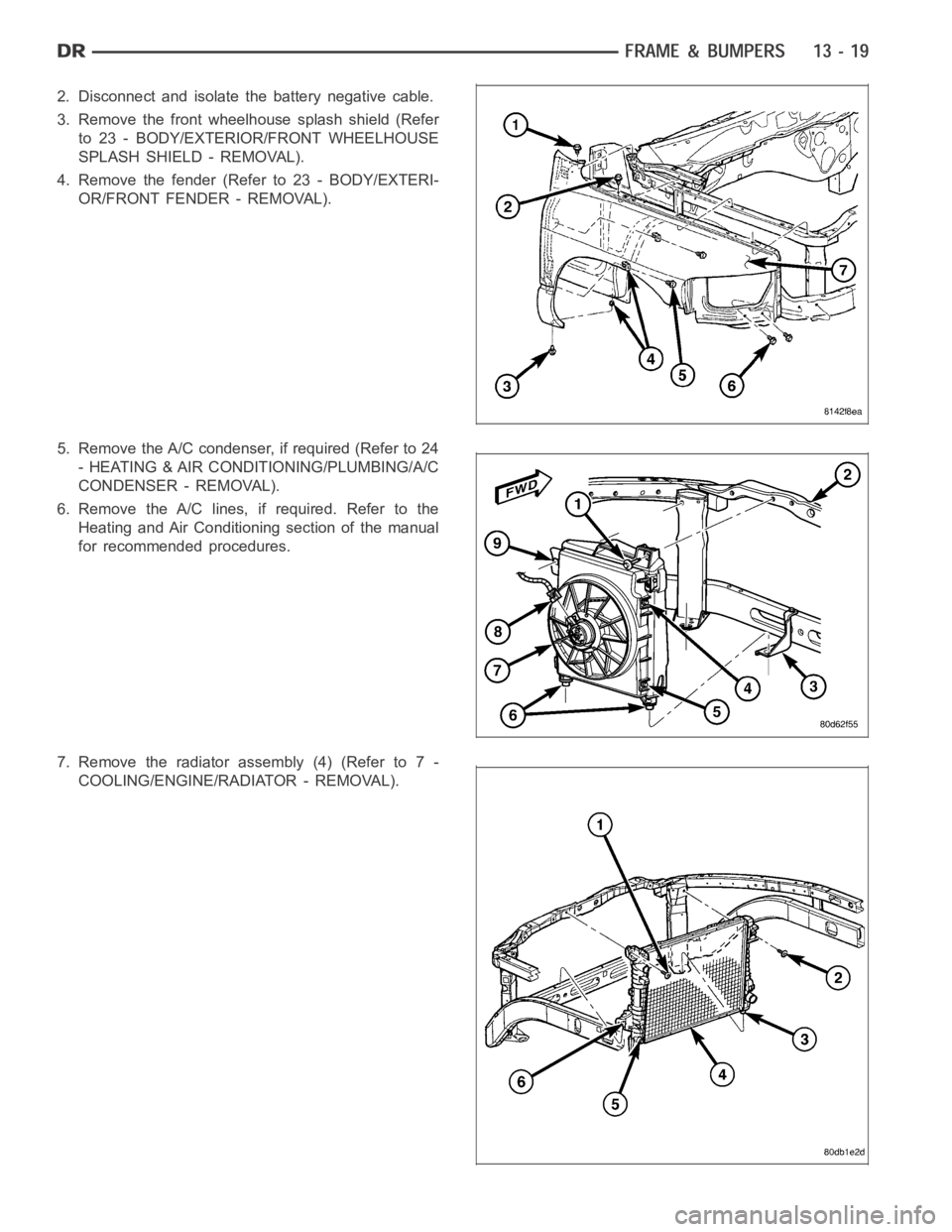

2. Disconnect and isolate the battery negative cable.

3. Remove the front wheelhouse splash shield (Refer

to 23 - BODY/EXTERIOR/FRONT WHEELHOUSE

SPLASH SHIELD - REMOVAL).

4. Remove the fender (Refer to 23 - BODY/EXTERI-

OR/FRONT FENDER - REMOVAL).

5. Remove the A/C condenser, if required (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/A/C

CONDENSER - REMOVAL).

6. Remove the A/C lines, if required. Refer to the

Heating and Air Conditioning section of the manual

for recommended procedures.

7. Remove the radiator assembly (4) (Refer to 7 -

COOLING/ENGINE/RADIATOR - REMOVAL).

Page 2199 of 5267

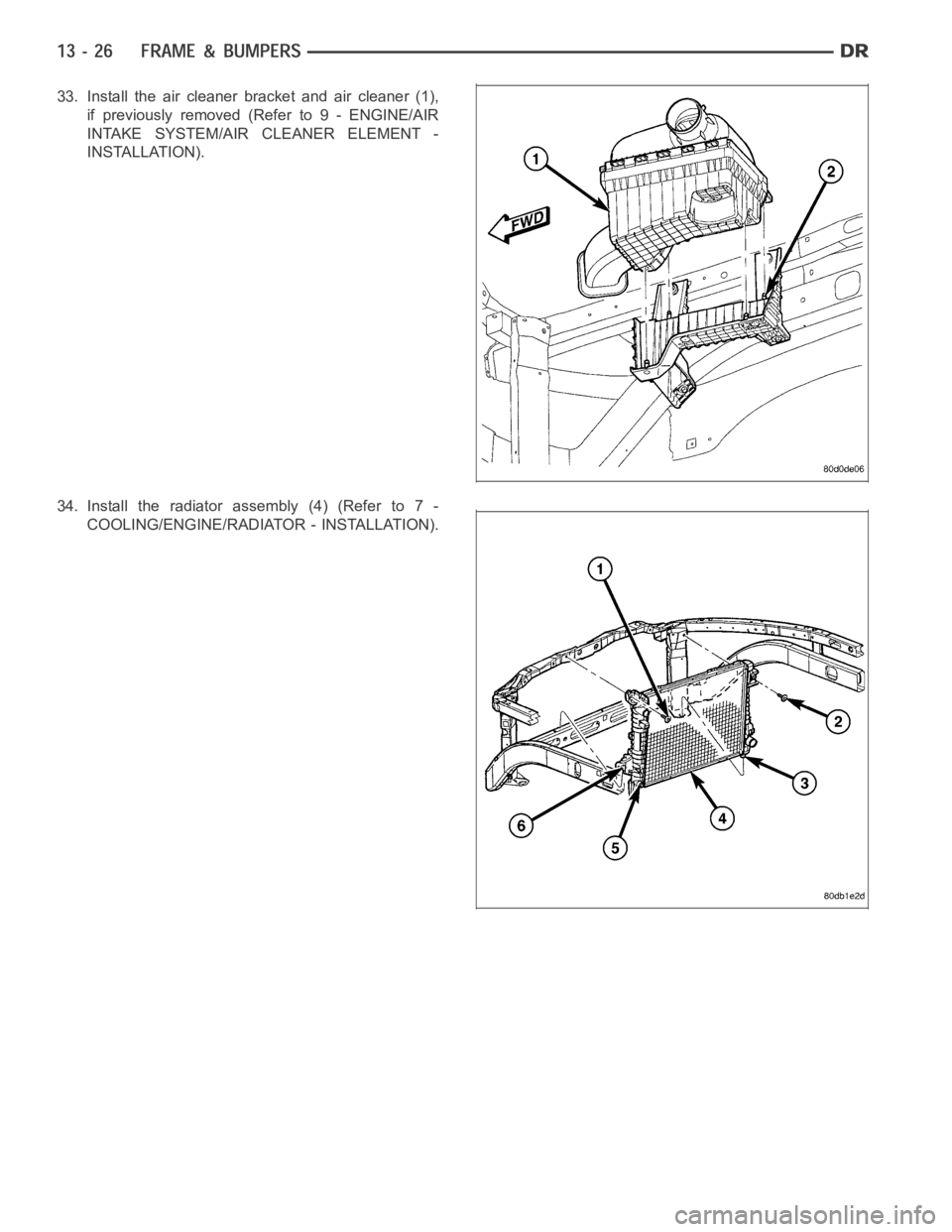

33. Install the air cleaner bracket and air cleaner (1),

if previously removed (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER ELEMENT -

INSTALLATION).

34. Install the radiator assembly (4) (Refer to 7 -

COOLING/ENGINE/RADIATOR - INSTALLATION).

Page 2485 of 5267

INSTALLATION

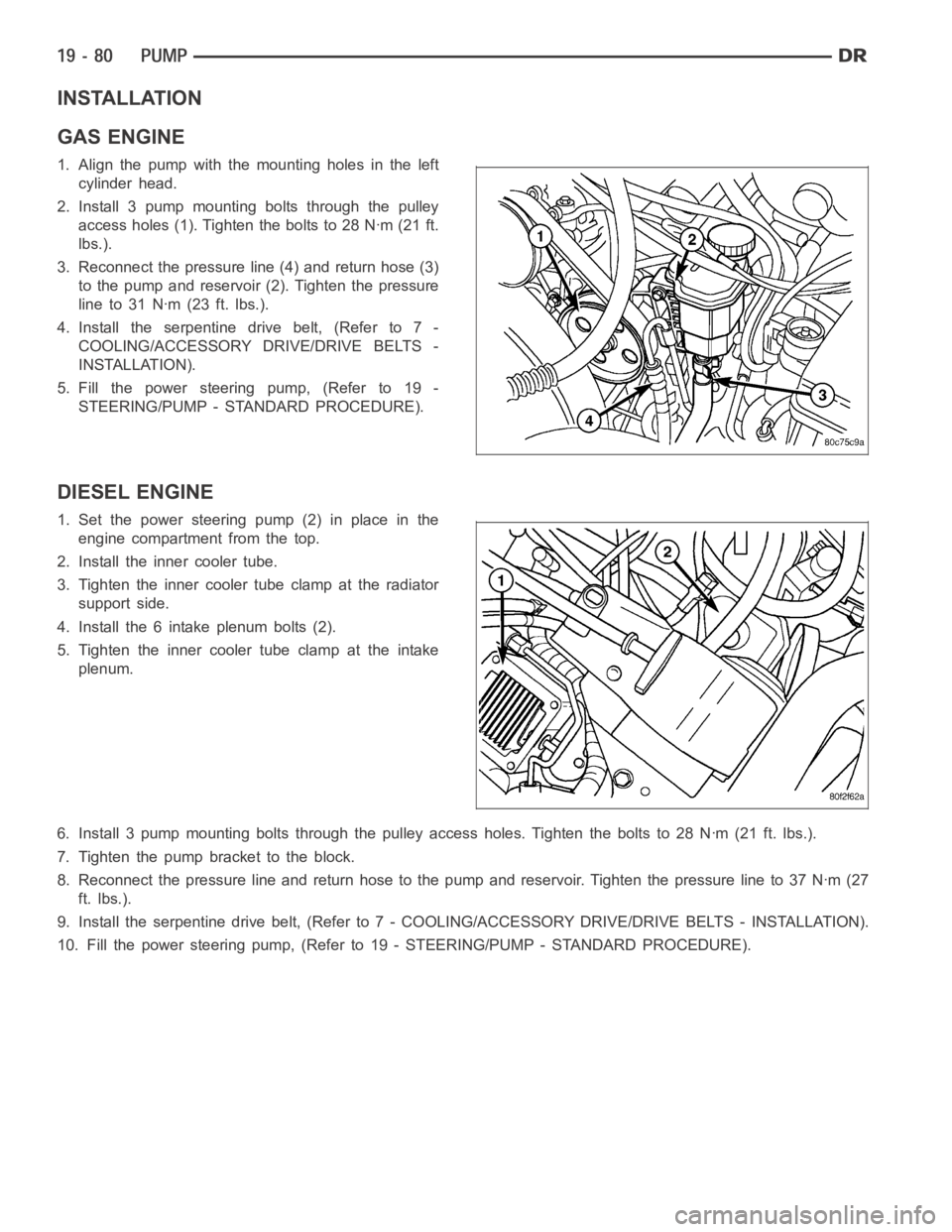

GAS ENGINE

1. Align the pump with the mounting holes in the left

cylinder head.

2. Install 3 pump mounting bolts through the pulley

access holes (1). Tighten the bolts to 28 Nꞏm (21 ft.

lbs.).

3. Reconnect the pressure line (4) and return hose (3)

to the pump and reservoir (2). Tighten the pressure

line to 31 Nꞏm (23 ft. lbs.).

4. Install the serpentine drive belt, (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

5. Fill the power steering pump, (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

DIESEL ENGINE

1. Set the power steering pump (2) in place in the

engine compartment from the top.

2. Install the inner cooler tube.

3. Tighten the inner cooler tube clamp at the radiator

support side.

4. Install the 6 intake plenum bolts (2).

5. Tighten the inner cooler tube clamp at the intake

plenum.

6. Install 3 pump mounting bolts through the pulley access holes. Tighten theboltsto28Nꞏm(21ft.lbs.).

7. Tighten the pump bracket to the block.

8. Reconnect the pressure line and return hose to the pump and reservoir. Tightenthepressurelineto37Nꞏm(27

ft. lbs.).

9. Install the serpentine drive belt, (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

10. Fill the power steering pump, (Refer to 19 - STEERING/PUMP - STANDARD PROCEDURE).

Page 2496 of 5267

RESERVOIR

REMOVAL

1. Drain and siphon the power steering fluid from the reservoir.

2. Remove the serpentine belt.

3. Remove the power steering pump (Refer to 19 - STEERING/PUMP - REMOVAL).

4. Remove the reservoir mounting bolts.

5. Remove the reservoir.

6. Remove the rear bracket to the pump mounting bolts.

INSTALLATION

1. Install the reservoir bracket to the pump housing.Do not reuse the o-rings (install new o-rings).Tighten bolts

to7Nꞏm(62in.lbs.).

NOTE: Ensure the reservoir is fully seated onto the pump.

2. Install the reservoir to the bracket/pump body.

3. Install the reservoir mounting bolts. Tighten bolts to 13 Nꞏm (120 in. lbs.).

4. Install the power steering pump (Refer to 19 - STEERING/PUMP - INSTALLATION).

5. Install the serpentine drive belt, (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

6. Fill the power steering pump, (Refer to 19 - STEERING/PUMP - STANDARD PROCEDURE).

Page 2502 of 5267

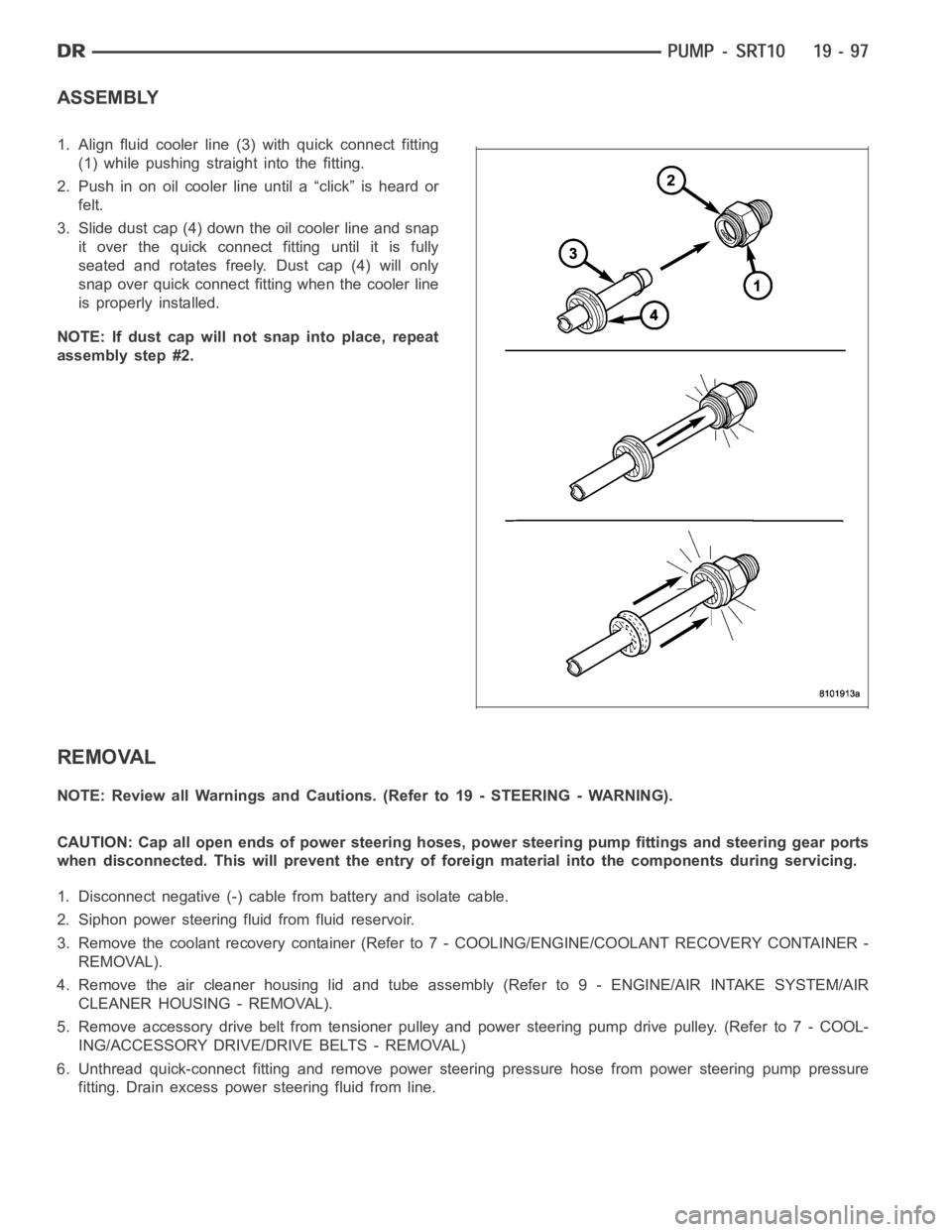

ASSEMBLY

1. Align fluid cooler line (3) with quick connect fitting

(1) while pushing straight into the fitting.

2. Push in on oil cooler line until a “click” is heard or

felt.

3. Slide dust cap (4) down the oil cooler line and snap

it over the quick connect fitting until it is fully

seated and rotates freely. Dust cap (4) will only

snap over quick connect fitting when the cooler line

is properly installed.

NOTE: If dust cap will not snap into place, repeat

assembly step #2.

REMOVAL

NOTE: Review all Warnings and Cautions. (Refer to 19 - STEERING - WARNING).

CAUTION: Cap all open ends of power steering hoses, power steering pump fittings and steering gear ports

when disconnected. This will prevent the entry of foreign material into the components during servicing.

1. Disconnect negative (-) cable from battery and isolate cable.

2. Siphon power steering fluid from fluid reservoir.

3. Remove the coolant recovery container (Refer to 7 - COOLING/ENGINE/COOLANT RECOVERY CONTAINER -

REMOVAL).

4. Remove the air cleaner housing lid and tube assembly (Refer to 9 - ENGINE/AIR INTAKE SYSTEM/AIR

CLEANER HOUSING - REMOVAL).

5. Remove accessory drive belt from tensioner pulley and power steering pump drive pulley. (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - REMOVAL)

6. Unthread quick-connect fitting and remove power steering pressure hose from power steering pump pressure

fitting. Drain excess power steering fluid from line.

Page 2504 of 5267

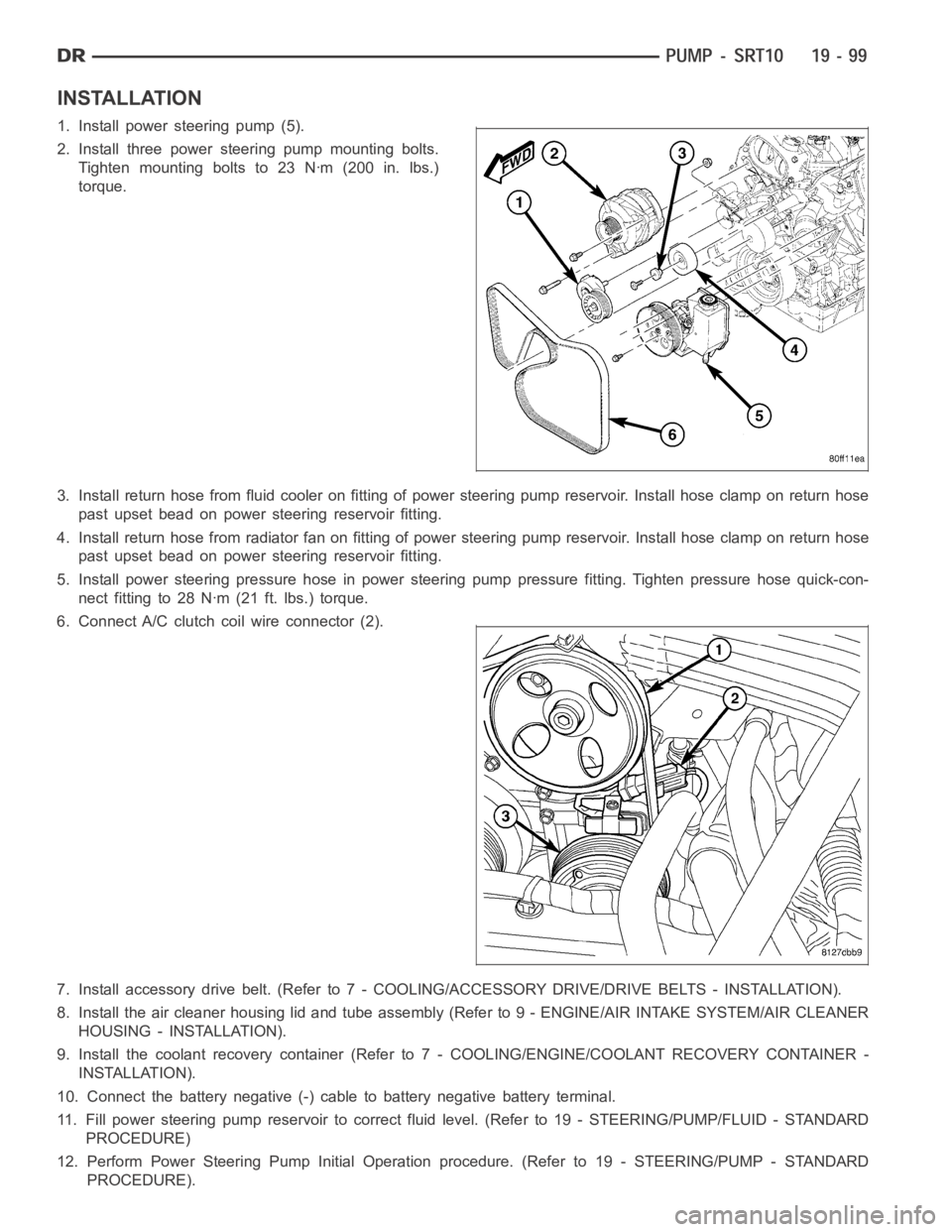

INSTALLATION

1. Install power steering pump (5).

2. Install three power steering pump mounting bolts.

Tighten mounting bolts to 23 Nꞏm (200 in. lbs.)

torque.

3. Install return hose from fluid cooler on fitting of power steering pump reservoir. Install hose clamp on return hose

past upset bead on power steering reservoir fitting.

4. Install return hose from radiator fan on fitting of power steering pump reservoir. Install hose clamp on return hose

past upset bead on power steering reservoir fitting.

5. Install power steering pressure hose in power steering pump pressure fitting. Tighten pressure hose quick-con-

nect fitting to 28 Nꞏm (21 ft. lbs.) torque.

6. Connect A/C clutch coil wire connector (2).

7. Install accessory drive belt. (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

8. Install the air cleaner housing lid and tube assembly (Refer to 9 - ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - INSTALLATION).

9. Install the coolant recovery container (Refer to 7 - COOLING/ENGINE/COOLANT RECOVERY CONTAINER -

INSTALLATION).

10. Connect the battery negative (-) cable to battery negative battery terminal.

11. Fill power steering pump reservoir to correct fluid level. (Refer to 19- STEERING/PUMP/FLUID - STANDARD

PROCEDURE)

12. Perform Power Steering Pump Initial Operation procedure. (Refer to 19- STEERING/PUMP - STANDARD

PROCEDURE).

Page 2507 of 5267

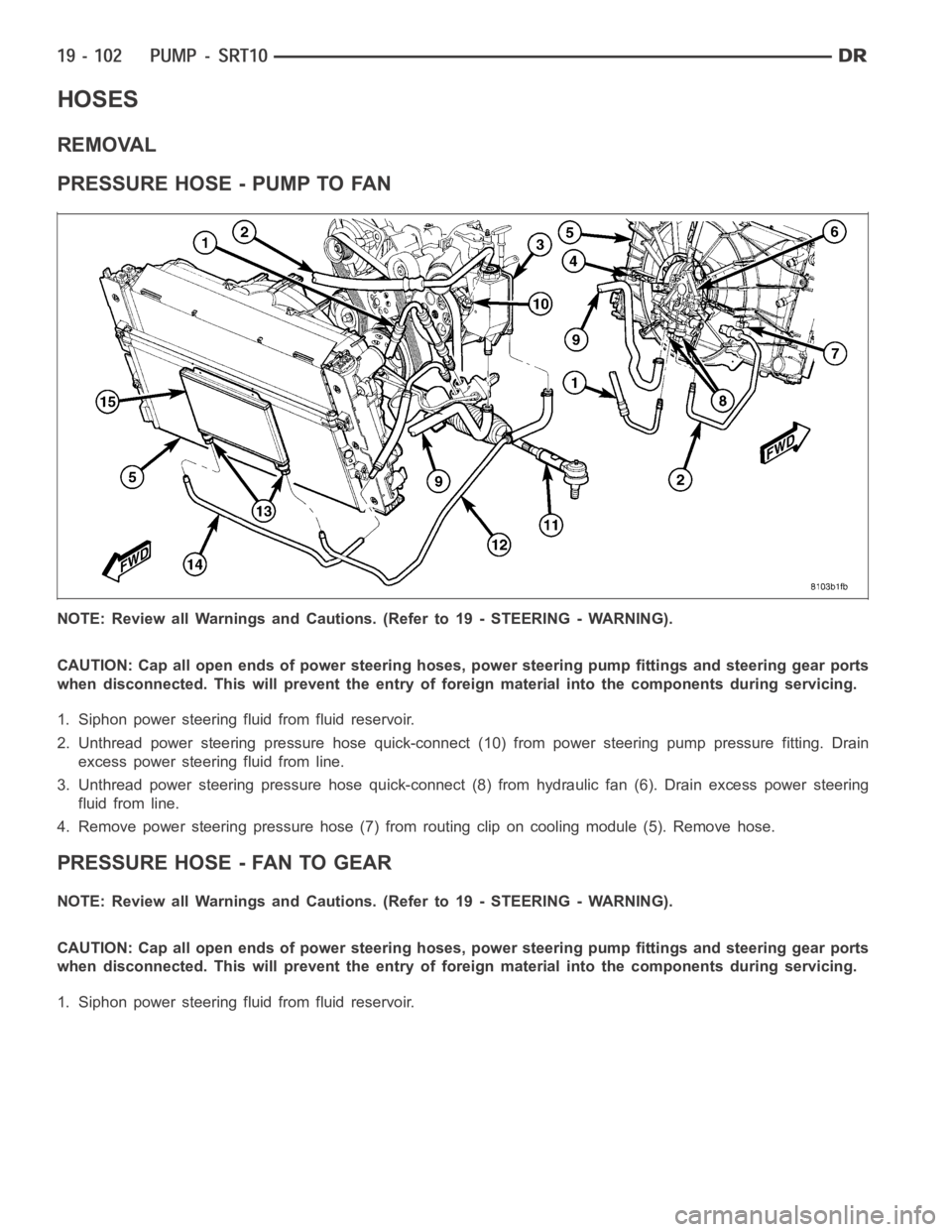

HOSES

REMOVAL

PRESSURE HOSE - PUMP TO FAN

NOTE: Review all Warnings and Cautions. (Refer to 19 - STEERING - WARNING).

CAUTION: Cap all open ends of power steering hoses, power steering pump fittings and steering gear ports

when disconnected. This will prevent the entry of foreign material into the components during servicing.

1. Siphon power steering fluid from fluid reservoir.

2. Unthread power steering pressure hose quick-connect (10) from power steering pump pressure fitting. Drain

excess power steering fluid from line.

3. Unthread power steering pressure hose quick-connect (8) from hydraulic fan (6). Drain excess power steering

fluid from line.

4. Remove power steering pressure hose (7) from routing clip on cooling module (5). Remove hose.

PRESSURE HOSE - FAN TO GEAR

NOTE: Review all Warnings and Cautions. (Refer to 19 - STEERING - WARNING).

CAUTION: Cap all open ends of power steering hoses, power steering pump fittings and steering gear ports

when disconnected. This will prevent the entry of foreign material into the components during servicing.

1. Siphon power steering fluid from fluid reservoir.

Page 2510 of 5267

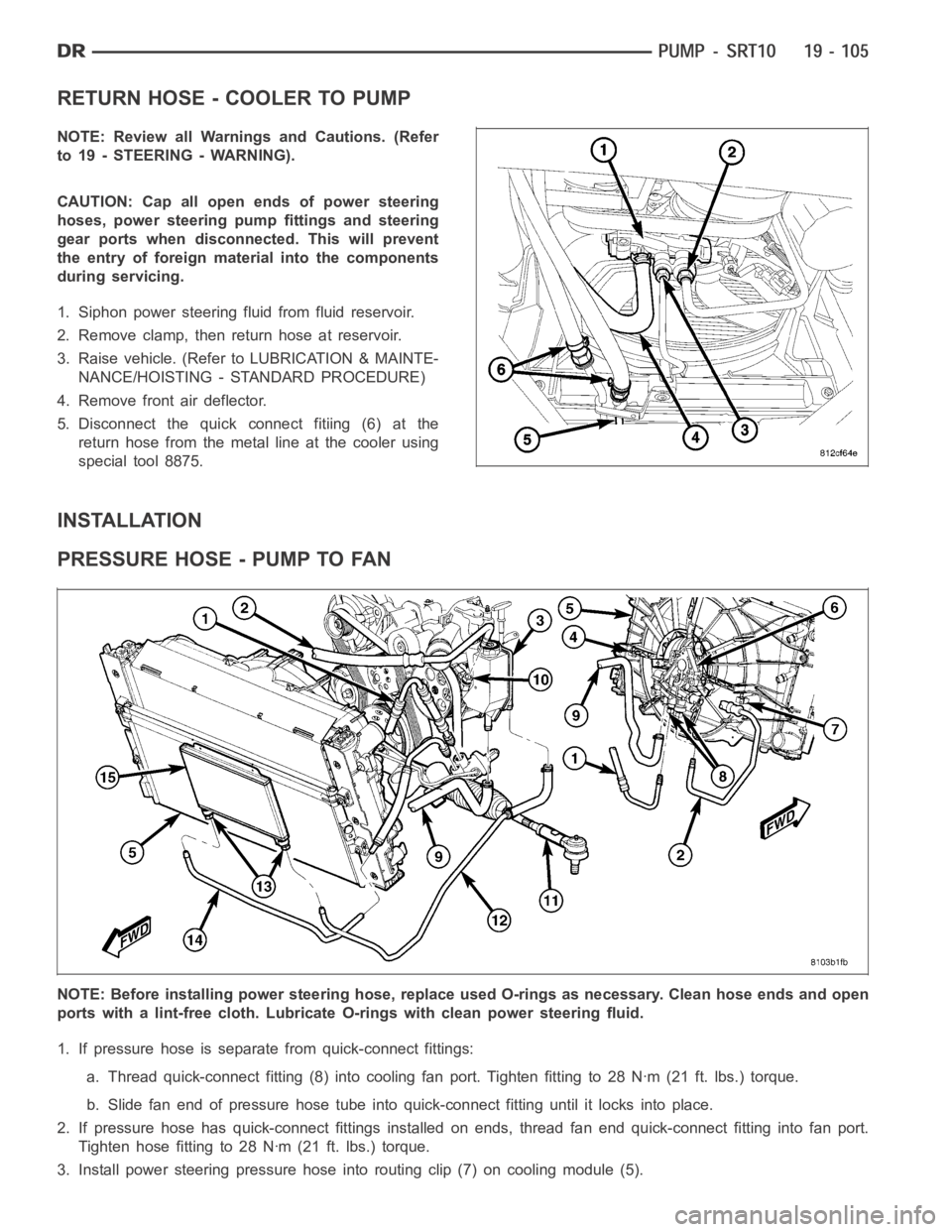

RETURN HOSE - COOLER TO PUMP

NOTE: Review all Warnings and Cautions. (Refer

to 19 - STEERING - WARNING).

CAUTION: Cap all open ends of power steering

hoses, power steering pump fittings and steering

gear ports when disconnected. This will prevent

the entry of foreign material into the components

during servicing.

1. Siphon power steering fluid from fluid reservoir.

2. Remove clamp, then return hose at reservoir.

3. Raise vehicle. (Refer to LUBRICATION & MAINTE-

NANCE/HOISTING - STANDARD PROCEDURE)

4. Remove front air deflector.

5. Disconnect the quick connect fitiing (6) at the

return hose from the metal line at the cooler using

special tool 8875.

INSTALLATION

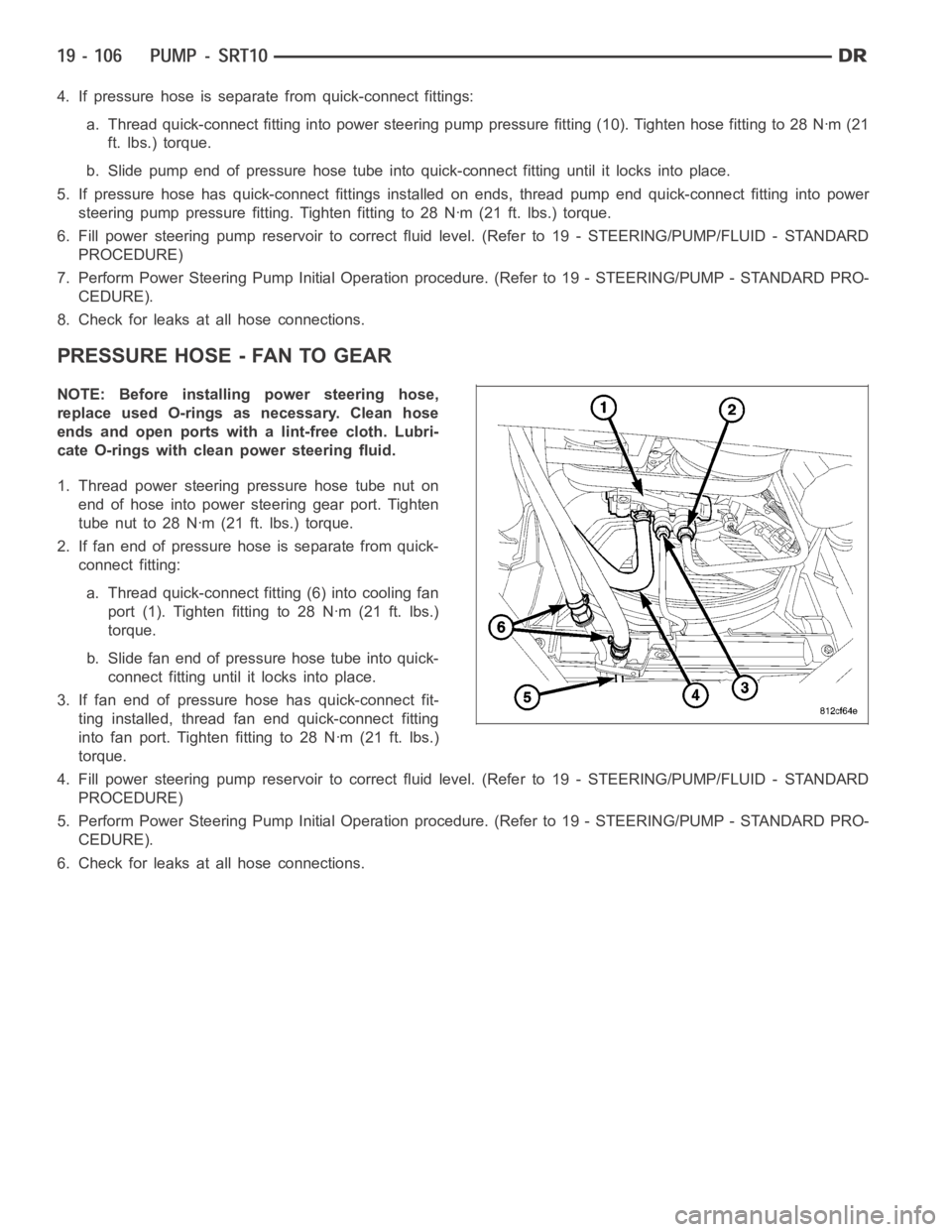

PRESSURE HOSE - PUMP TO FAN

NOTE: Before installing power steering hose, replace used O-rings as necessary. Clean hose ends and open

ports with a lint-free cloth. Lubricate O-rings with clean power steeringfluid.

1. If pressure hose is separate from quick-connect fittings:

a. Thread quick-connect fitting (8) into cooling fan port. Tighten fittingto28Nꞏm(21ft.lbs.)torque.

b. Slide fan end of pressure hose tube into quick-connect fitting until it locks into place.

2. If pressure hose has quick-connect fittings installed on ends, thread fan end quick-connect fitting into fan port.

Tighten hose fitting to 28 Nꞏm (21 ft. lbs.) torque.

3. Install power steering pressure hose into routing clip (7) on cooling module (5).

Page 2511 of 5267

4. If pressure hose is separate from quick-connect fittings:

a. Thread quick-connect fitting into power steering pump pressure fitting (10). Tighten hose fitting to 28 Nꞏm (21

ft. lbs.) torque.

b. Slide pump end of pressure hose tube into quick-connect fitting until itlocks into place.

5. If pressure hose has quick-connect fittings installed on ends, thread pump end quick-connect fitting into power

steering pump pressure fitting. Tighten fitting to 28 Nꞏm (21 ft. lbs.) torque.

6. Fill power steering pump reservoir to correct fluid level. (Refer to 19 -STEERING/PUMP/FLUID - STANDARD

PROCEDURE)

7. Perform Power Steering Pump Initial Operation procedure. (Refer to 19 -STEERING/PUMP - STANDARD PRO-

CEDURE).

8. Check for leaks at all hose connections.

PRESSURE HOSE - FAN TO GEAR

NOTE: Before installing power steering hose,

replace used O-rings as necessary. Clean hose

ends and open ports with a lint-free cloth. Lubri-

cate O-rings with clean power steering fluid.

1. Thread power steering pressure hose tube nut on

end of hose into power steering gear port. Tighten

tube nut to 28 Nꞏm (21 ft. lbs.) torque.

2. If fan end of pressure hose is separate from quick-

connect fitting:

a. Thread quick-connect fitting (6) into cooling fan

port (1). Tighten fitting to 28 Nꞏm (21 ft. lbs.)

torque.

b. Slide fan end of pressure hose tube into quick-

connect fitting until it locks into place.

3. If fan end of pressure hose has quick-connect fit-

ting installed, thread fan end quick-connect fitting

into fan port. Tighten fitting to 28 Nꞏm (21 ft. lbs.)

torque.

4. Fill power steering pump reservoir to correct fluid level. (Refer to 19 -STEERING/PUMP/FLUID - STANDARD

PROCEDURE)

5. Perform Power Steering Pump Initial Operation procedure. (Refer to 19 -STEERING/PUMP - STANDARD PRO-

CEDURE).

6. Check for leaks at all hose connections.