cooling DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2081 of 5267

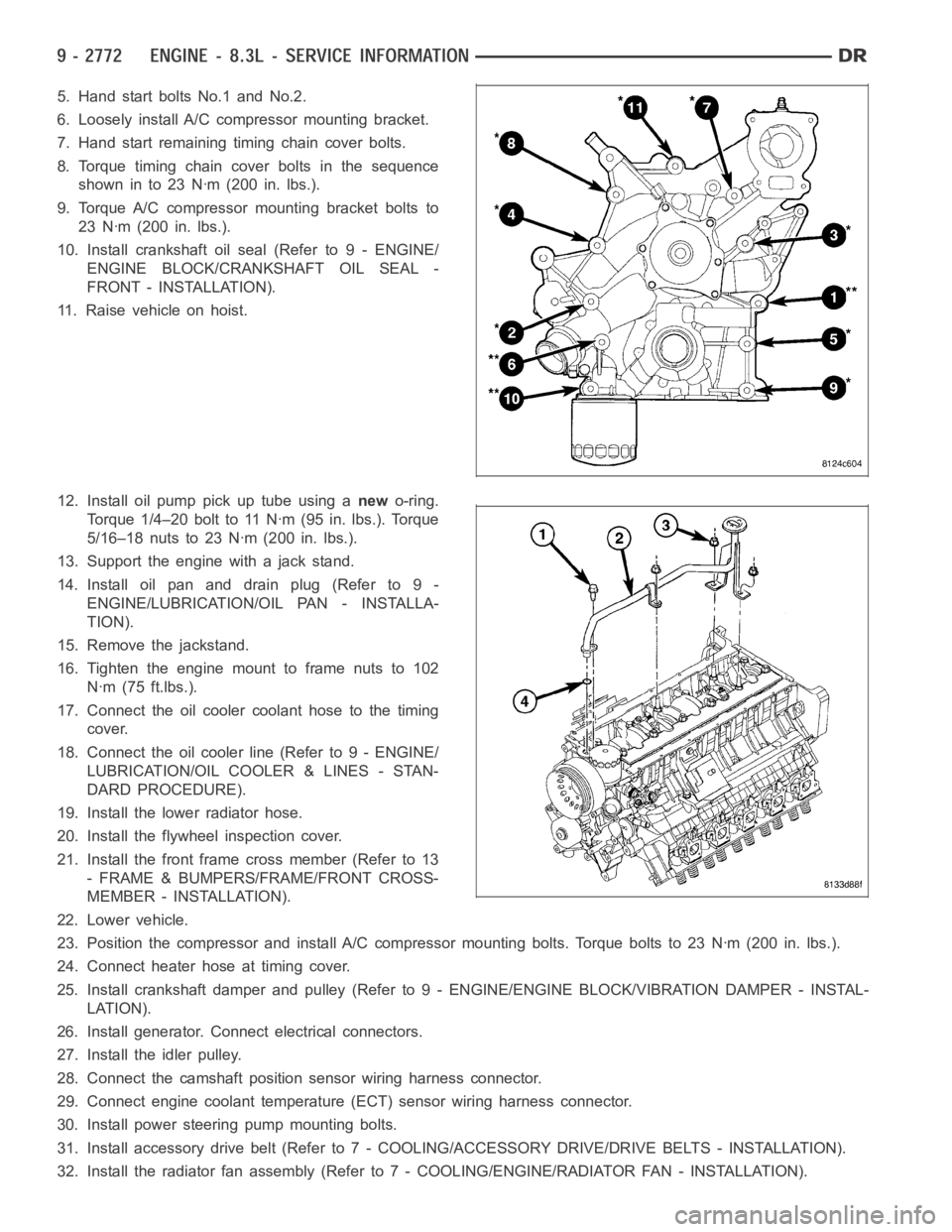

5. Hand start bolts No.1 and No.2.

6. Loosely install A/C compressor mounting bracket.

7. Hand start remaining timing chain cover bolts.

8. Torque timing chain cover bolts in the sequence

showninto23Nꞏm(200in.lbs.).

9. Torque A/C compressor mounting bracket bolts to

23 Nꞏm (200 in. lbs.).

10. Install crankshaft oil seal (Refer to 9 - ENGINE/

ENGINE BLOCK/CRANKSHAFT OIL SEAL -

FRONT - INSTALLATION).

11. Raise vehicle on hoist.

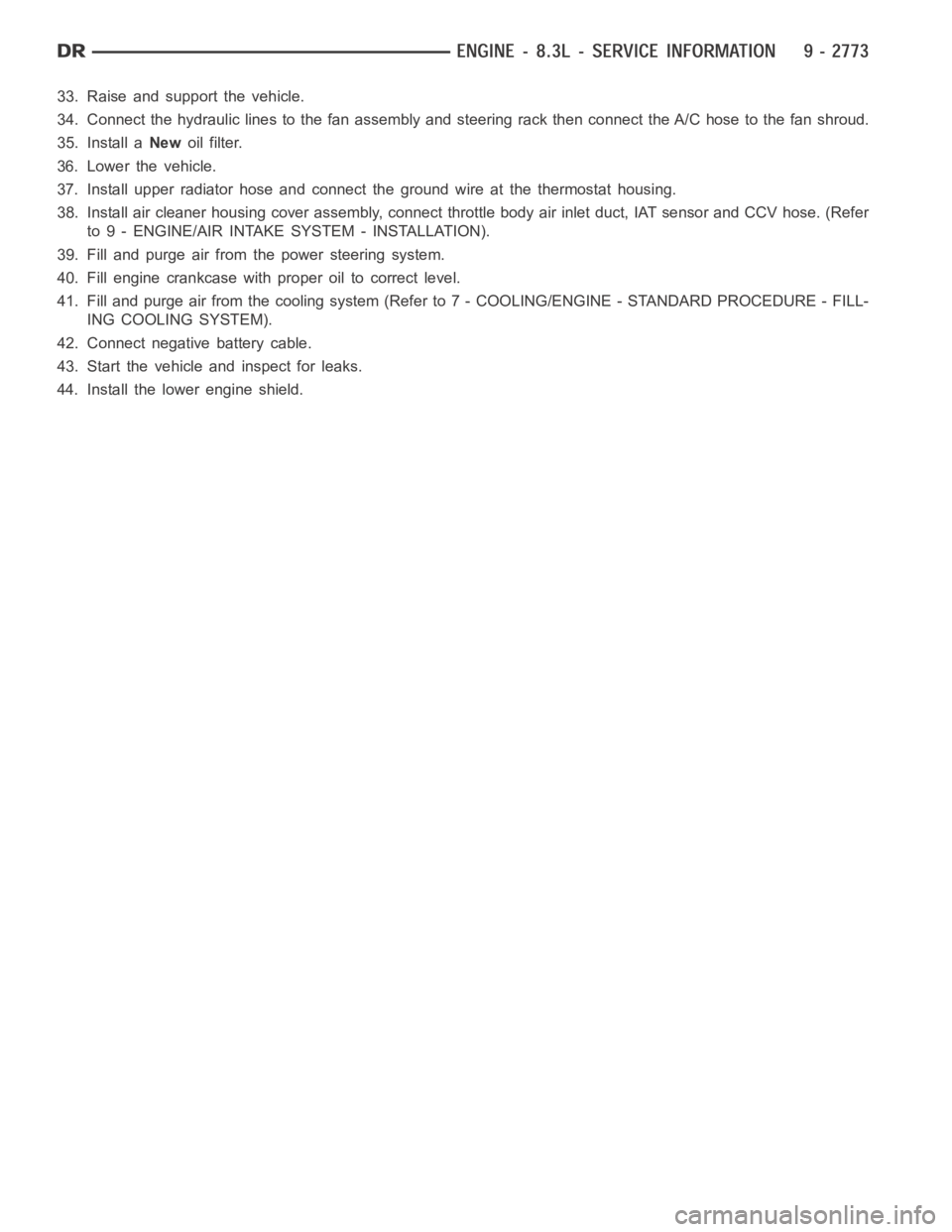

12. Install oil pump pick up tube using anewo-ring.

Torque 1/4–20 bolt to 11 Nꞏm (95 in. lbs.). Torque

5/16–18 nuts to 23 Nꞏm (200 in. lbs.).

13. Support the engine with a jack stand.

14. Install oil pan and drain plug (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

15. Remove the jackstand.

16. Tighten the engine mount to frame nuts to 102

Nꞏm (75 ft.lbs.).

17. Connect the oil cooler coolant hose to the timing

cover.

18. Connect the oil cooler line (Refer to 9 - ENGINE/

LUBRICATION/OIL COOLER & LINES - STAN-

DARD PROCEDURE).

19. Install the lower radiator hose.

20. Install the flywheel inspection cover.

21. Install the front frame cross member (Refer to 13

- FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - INSTALLATION).

22. Lower vehicle.

23. Position the compressor and install A/C compressor mounting bolts. Torque bolts to 23 Nꞏm (200 in. lbs.).

24. Connect heater hose at timing cover.

25. Install crankshaft damper and pulley (Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

26. Install generator. Connect electrical connectors.

27. Install the idler pulley.

28. Connect the camshaft position sensor wiring harness connector.

29. Connect engine coolant temperature (ECT) sensor wiring harness connector.

30. Install power steering pump mounting bolts.

31. Install accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

32. Install the radiator fan assembly (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - INSTALLATION).

Page 2082 of 5267

33. Raise and support the vehicle.

34. Connect the hydraulic lines to the fan assembly and steering rack then connect the A/C hose to the fan shroud.

35. Install aNewoil filter.

36. Lower the vehicle.

37. Install upper radiator hose and connect the ground wire at the thermostat housing.

38. Install air cleaner housing cover assembly, connect throttle body airinlet duct, IAT sensor and CCV hose. (Refer

to 9 - ENGINE/AIR INTAKE SYSTEM - INSTALLATION).

39. Fill and purge air from the power steering system.

40. Fill engine crankcase with proper oil to correct level.

41. Fill and purge air from the cooling system (Refer to 7 - COOLING/ENGINE -STANDARD PROCEDURE - FILL-

ING COOLING SYSTEM).

42. Connect negative battery cable.

43. Start the vehicle and inspect for leaks.

44. Install the lower engine shield.

Page 2091 of 5267

ASSEMBLY

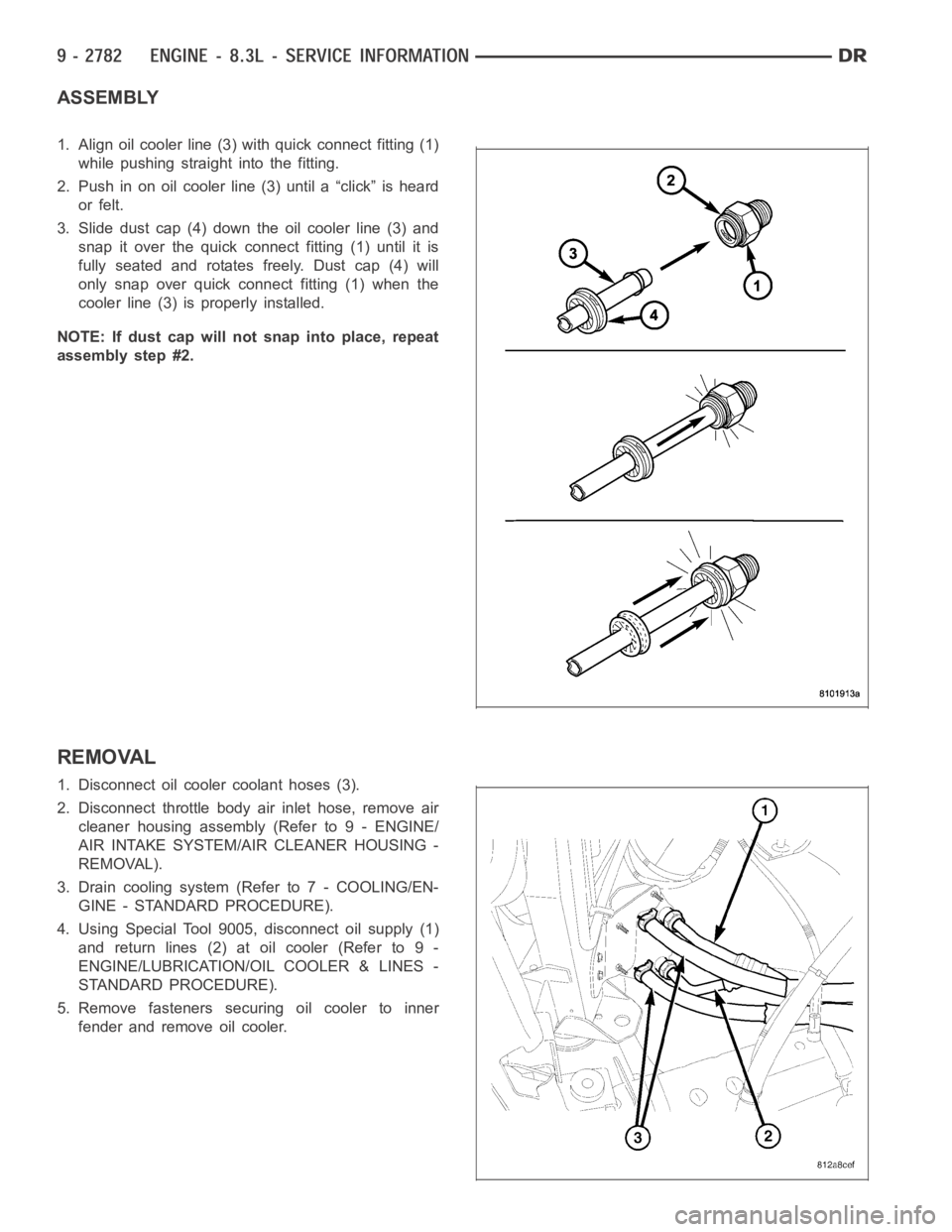

1. Align oil cooler line (3) with quick connect fitting (1)

while pushing straight into the fitting.

2. Push in on oil cooler line (3) until a “click” is heard

or felt.

3. Slide dust cap (4) down the oil cooler line (3) and

snap it over the quick connect fitting (1) until it is

fully seated and rotates freely. Dust cap (4) will

only snap over quick connect fitting (1) when the

cooler line (3) is properly installed.

NOTE: If dust cap will not snap into place, repeat

assembly step #2.

REMOVAL

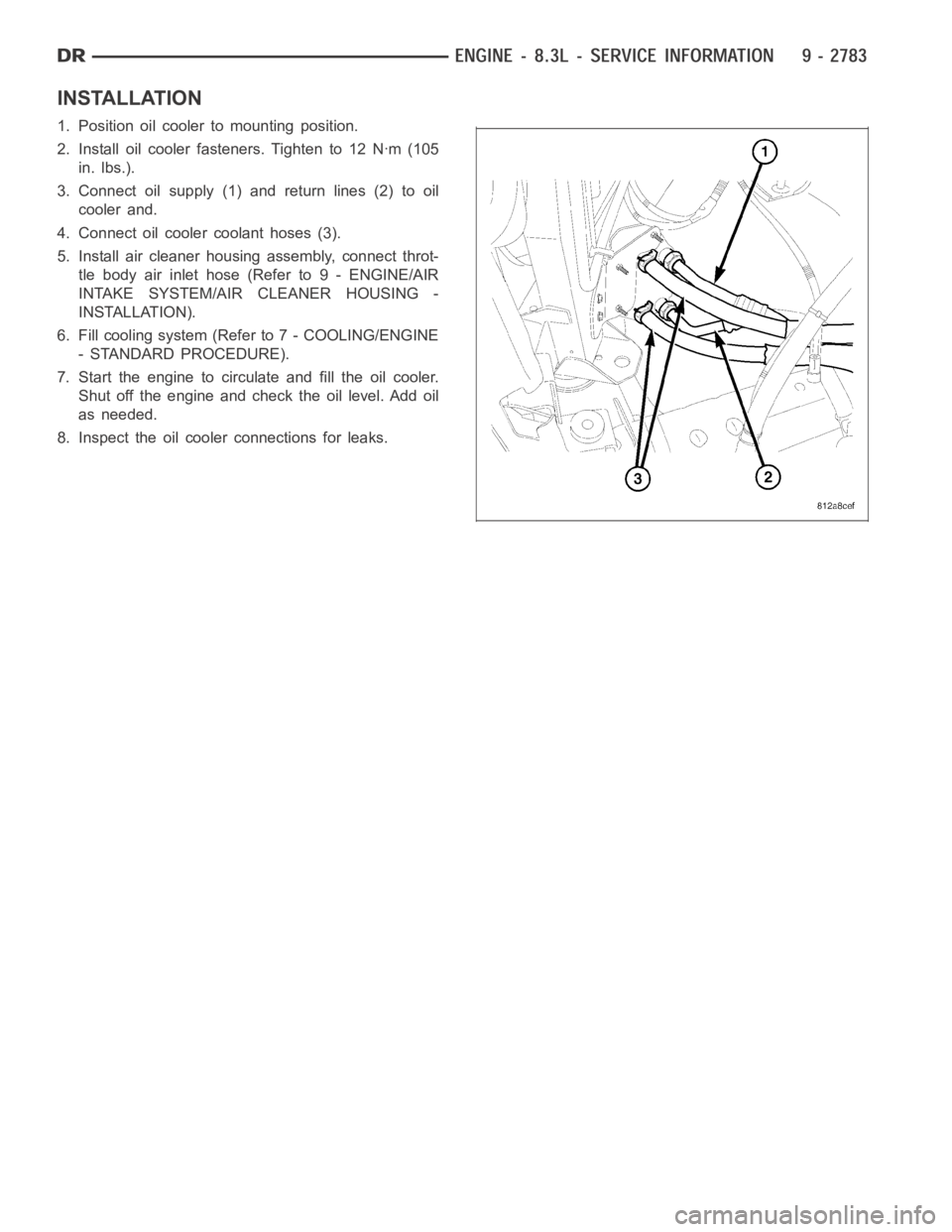

1. Disconnect oil cooler coolant hoses (3).

2. Disconnect throttle body air inlet hose, remove air

cleaner housing assembly (Refer to 9 - ENGINE/

AIR INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

3. Drain cooling system (Refer to 7 - COOLING/EN-

GINE - STANDARD PROCEDURE).

4. Using Special Tool 9005, disconnect oil supply (1)

and return lines (2) at oil cooler (Refer to 9 -

ENGINE/LUBRICATION/OIL COOLER & LINES -

STANDARD PROCEDURE).

5. Remove fasteners securing oil cooler to inner

fender and remove oil cooler.

Page 2092 of 5267

INSTALLATION

1. Position oil cooler to mounting position.

2. Install oil cooler fasteners. Tighten to 12 Nꞏm (105

in. lbs.).

3. Connect oil supply (1) and return lines (2) to oil

cooler and.

4. Connect oil cooler coolant hoses (3).

5. Install air cleaner housing assembly, connect throt-

tle body air inlet hose (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

6. Fill cooling system (Refer to 7 - COOLING/ENGINE

- STANDARD PROCEDURE).

7. Start the engine to circulate and fill the oil cooler.

Shut off the engine and check the oil level. Add oil

as needed.

8. Inspect the oil cooler connections for leaks.

Page 2108 of 5267

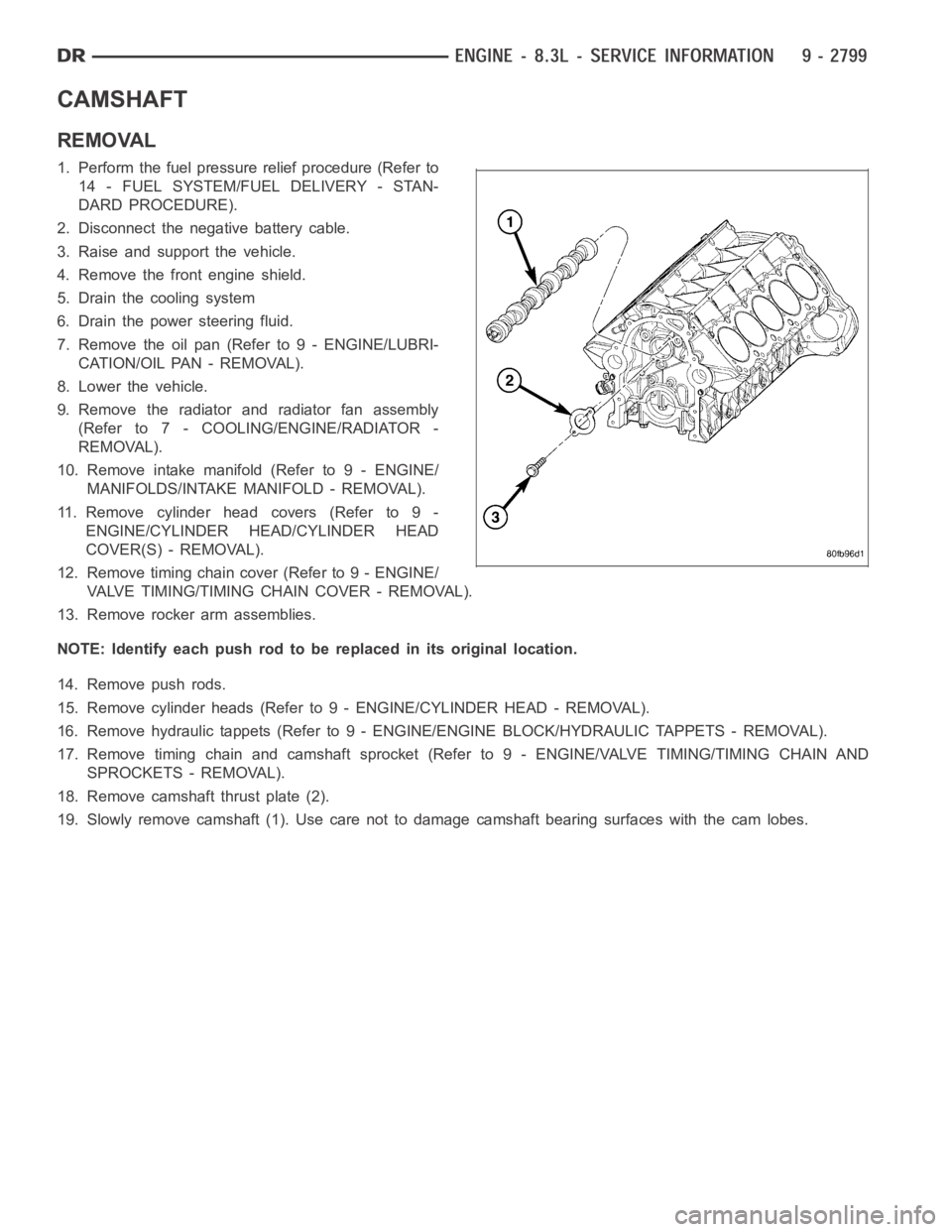

CAMSHAFT

REMOVAL

1. Perform the fuel pressure relief procedure (Refer to

14 - FUEL SYSTEM/FUEL DELIVERY - STAN-

DARD PROCEDURE).

2. Disconnect the negative battery cable.

3. Raise and support the vehicle.

4. Remove the front engine shield.

5. Drain the cooling system

6. Drain the power steering fluid.

7. Remove the oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL).

8. Lower the vehicle.

9. Remove the radiator and radiator fan assembly

(Refer to 7 - COOLING/ENGINE/RADIATOR -

REMOVAL).

10. Remove intake manifold (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - REMOVAL).

11. Remove cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

12. Remove timing chain cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMING CHAIN COVER - REMOVAL).

13. Remove rocker arm assemblies.

NOTE: Identify each push rod to be replaced in its original location.

14. Remove push rods.

15. Remove cylinder heads (Refer to 9 - ENGINE/CYLINDER HEAD - REMOVAL).

16. Remove hydraulic tappets (Refer to 9 - ENGINE/ENGINE BLOCK/HYDRAULICTAPPETS - REMOVAL).

17. Remove timing chain and camshaft sprocket (Refer to 9 - ENGINE/VALVE TIMING/TIMING CHAIN AND

SPROCKETS - REMOVAL).

18. Remove camshaft thrust plate (2).

19. Slowly remove camshaft (1). Use care not to damage camshaft bearing surfaces with the cam lobes.

Page 2109 of 5267

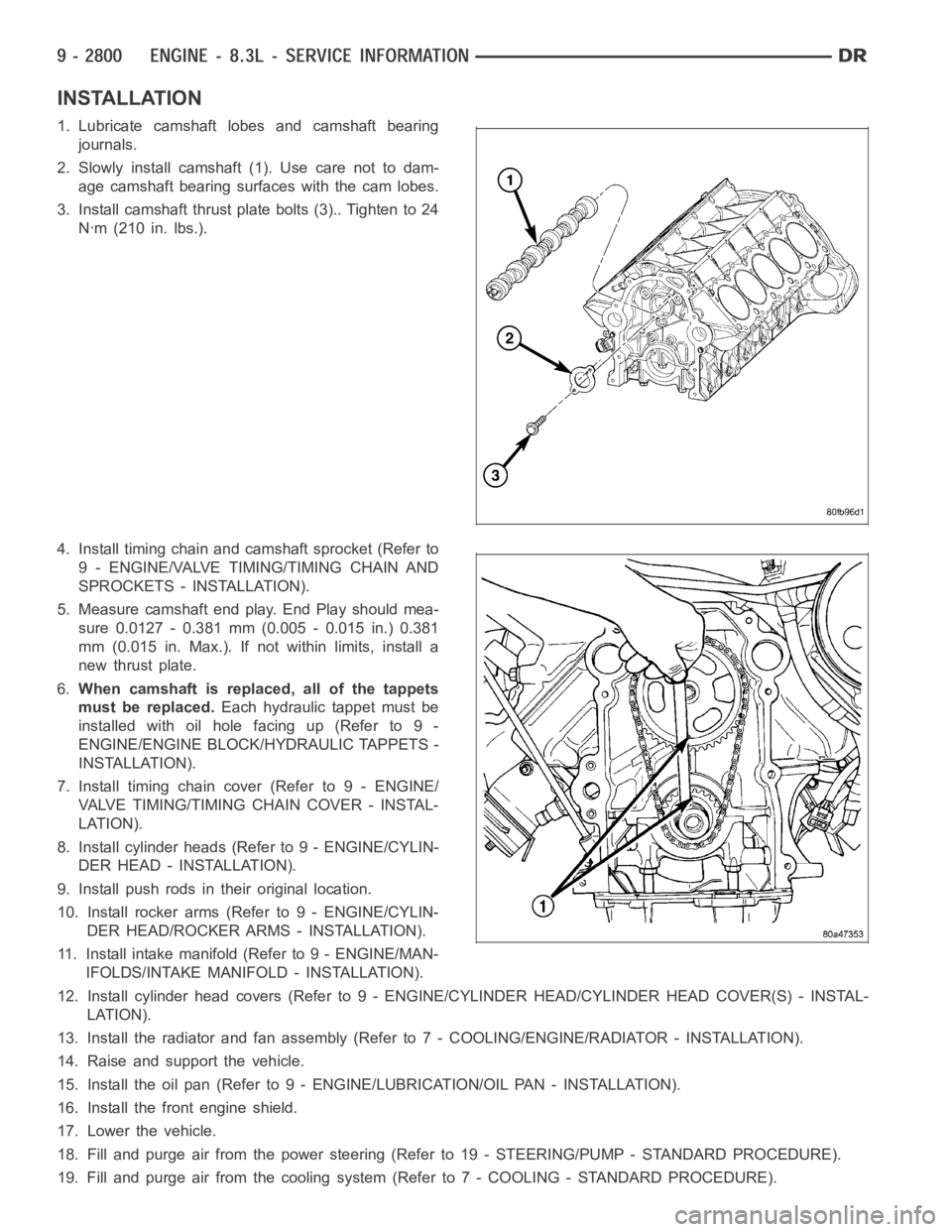

INSTALLATION

1. Lubricate camshaft lobes and camshaft bearing

journals.

2. Slowly install camshaft (1). Use care not to dam-

age camshaft bearing surfaces with the cam lobes.

3. Install camshaft thrust plate bolts (3).. Tighten to 24

Nꞏm (210 in. lbs.).

4. Install timing chain and camshaft sprocket (Refer to

9 - ENGINE/VALVE TIMING/TIMING CHAIN AND

SPROCKETS - INSTALLATION).

5. Measure camshaft end play. End Play should mea-

sure 0.0127 - 0.381 mm (0.005 - 0.015 in.) 0.381

mm (0.015 in. Max.). If not within limits, install a

new thrust plate.

6.When camshaft is replaced, all of the tappets

must be replaced.Each hydraulic tappet must be

installed with oil hole facing up (Refer to 9 -

ENGINE/ENGINE BLOCK/HYDRAULIC TAPPETS -

INSTALLATION).

7. Install timing chain cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMINGCHAIN COVER - INSTAL-

LATION).

8. Install cylinder heads (Refer to 9 - ENGINE/CYLIN-

DER HEAD - INSTALLATION).

9. Install push rods in their original location.

10. Install rocker arms (Refer to 9 - ENGINE/CYLIN-

DER HEAD/ROCKER ARMS - INSTALLATION).

11. Install intake manifold (Refer to 9 - ENGINE/MAN-

IFOLDS/INTAKE MANIFOLD - INSTALLATION).

12. Install cylinder head covers (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) - INSTAL-

LATION).

13. Install the radiator and fan assembly (Refer to 7 - COOLING/ENGINE/RADIATOR - INSTALLATION).

14. Raise and support the vehicle.

15. Install the oil pan (Refer to 9 - ENGINE/LUBRICATION/OIL PAN - INSTALLATION).

16. Install the front engine shield.

17. Lower the vehicle.

18. Fill and purge air from the power steering (Refer to 19 - STEERING/PUMP -STANDARD PROCEDURE).

19. Fill and purge air from the coolingsystem (Refer to 7 - COOLING - STANDARD PROCEDURE).

Page 2121 of 5267

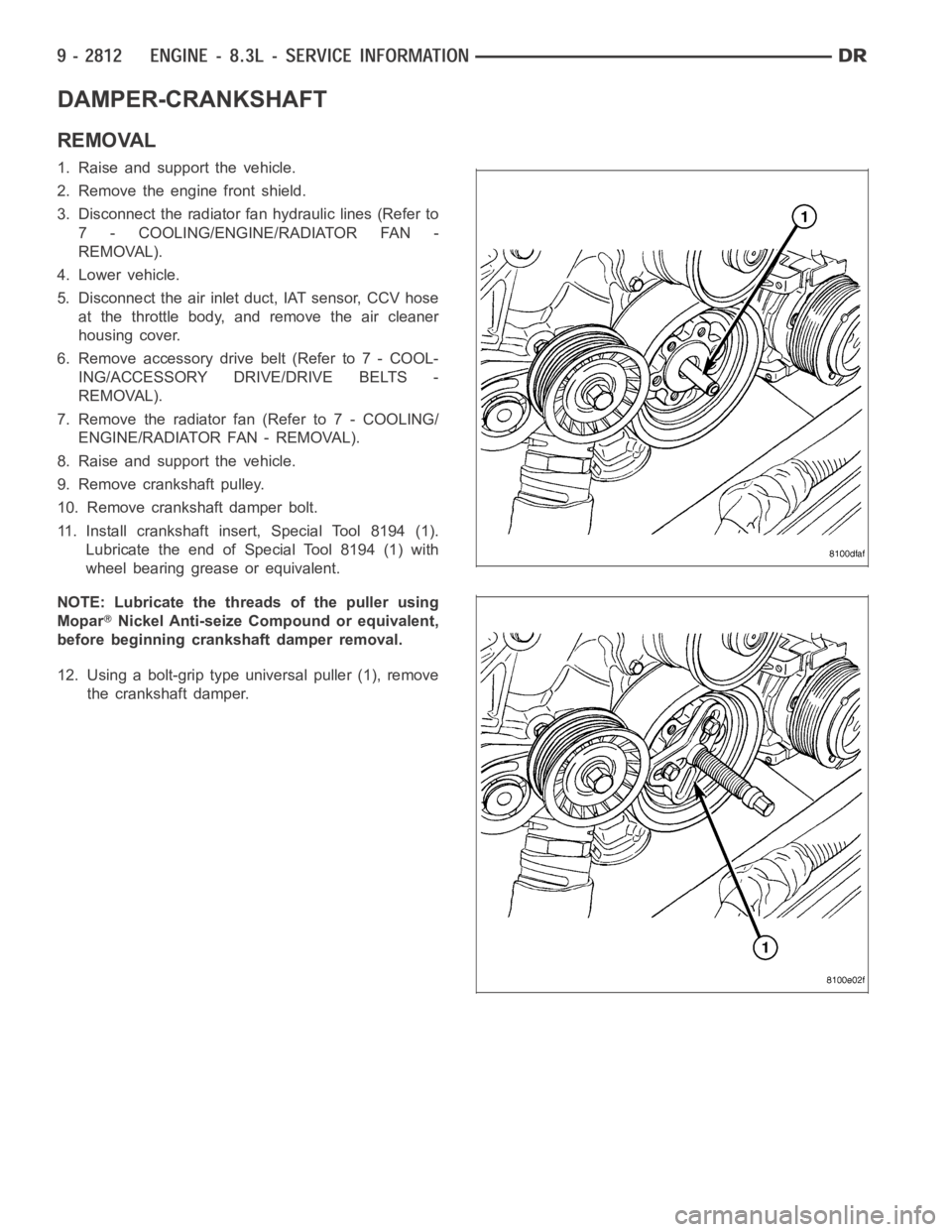

DAMPER-CRANKSHAFT

REMOVAL

1. Raise and support the vehicle.

2. Remove the engine front shield.

3. Disconnect the radiator fan hydraulic lines (Refer to

7 - COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

4. Lower vehicle.

5. Disconnect the air inlet duct, IAT sensor, CCV hose

at the throttle body, and remove the air cleaner

housing cover.

6. Remove accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

7. Remove the radiator fan (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - REMOVAL).

8. Raise and support the vehicle.

9. Remove crankshaft pulley.

10. Remove crankshaft damper bolt.

11. Install crankshaft insert, Special Tool 8194 (1).

Lubricate the end of Special Tool 8194 (1) with

wheel bearing grease or equivalent.

NOTE: Lubricate the threads of the puller using

Mopar

Nickel Anti-seize Compound or equivalent,

before beginning crankshaft damper removal.

12. Using a bolt-grip type universal puller (1), remove

the crankshaft damper.

Page 2122 of 5267

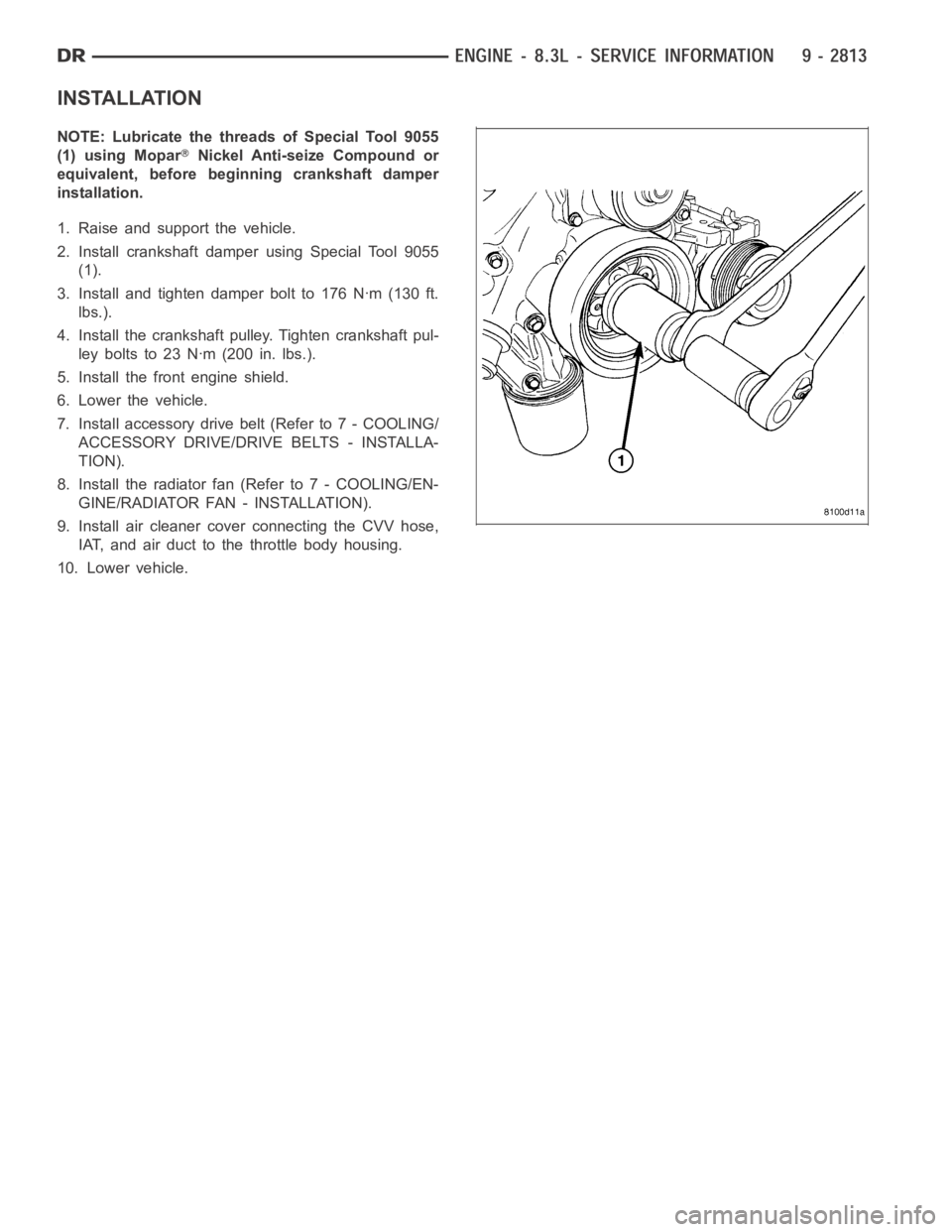

INSTALLATION

NOTE: Lubricate the threads of Special Tool 9055

(1) using Mopar

Nickel Anti-seize Compound or

equivalent, before beginning crankshaft damper

installation.

1. Raise and support the vehicle.

2. Install crankshaft damper using Special Tool 9055

(1).

3. Install and tighten damper bolt to 176 Nꞏm (130 ft.

lbs.).

4. Install the crankshaft pulley. Tighten crankshaft pul-

ley bolts to 23 Nꞏm (200 in. lbs.).

5. Install the front engine shield.

6. Lower the vehicle.

7. Install accessory drive belt (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

8. Install the radiator fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

9. Install air cleaner cover connecting the CVV hose,

IAT, and air duct to the throttle body housing.

10. Lower vehicle.

Page 2123 of 5267

SEAL-CRANKSHAFT OIL- FRONT

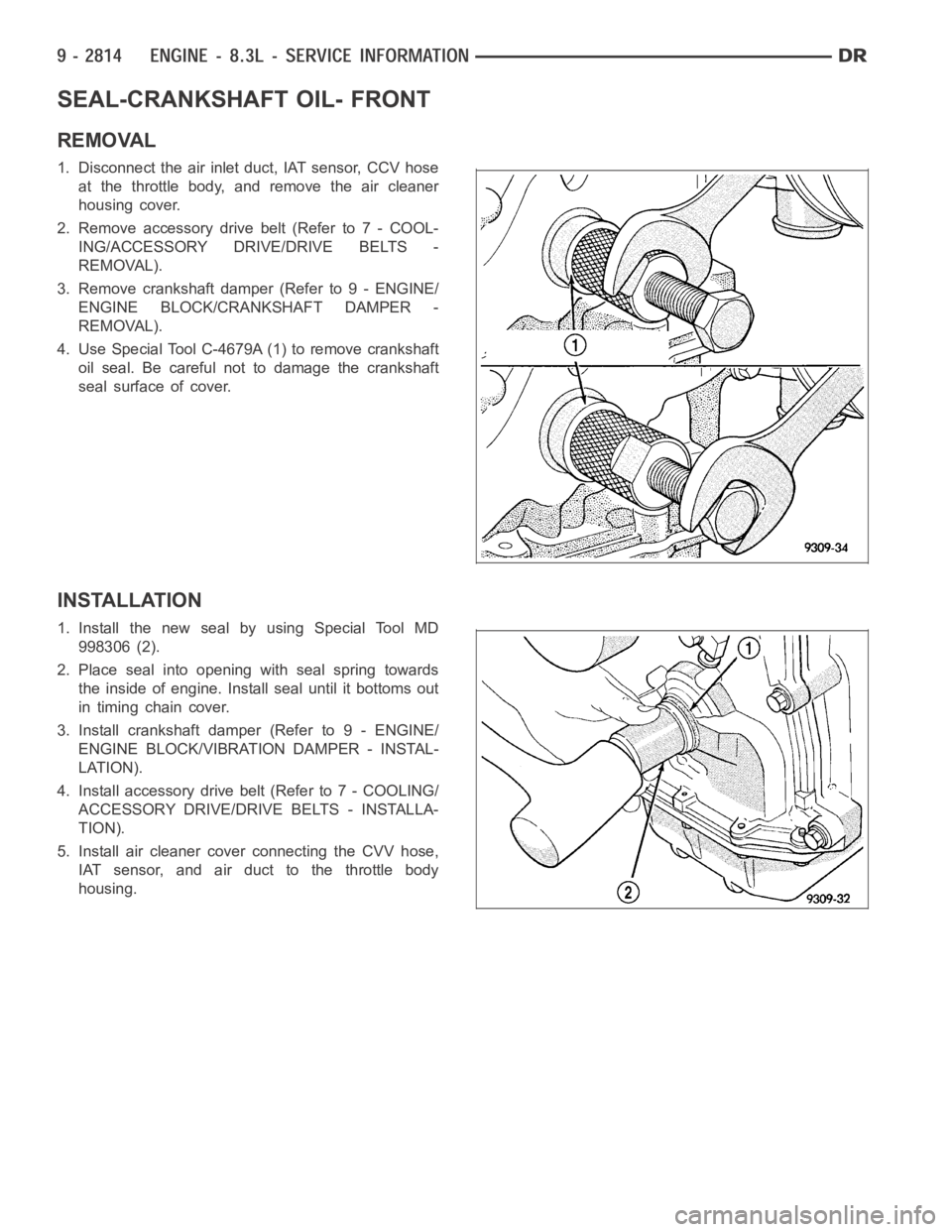

REMOVAL

1. Disconnect the air inlet duct, IAT sensor, CCV hose

at the throttle body, and remove the air cleaner

housing cover.

2. Remove accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

3. Remove crankshaft damper (Refer to 9 - ENGINE/

ENGINE BLOCK/CRANKSHAFT DAMPER -

REMOVAL).

4. Use Special Tool C-4679A (1) to remove crankshaft

oil seal. Be careful not to damage the crankshaft

seal surface of cover.

INSTALLATION

1. Install the new seal by using Special Tool MD

998306 (2).

2. Place seal into opening with seal spring towards

the inside of engine. Install seal until it bottoms out

in timing chain cover.

3. Install crankshaft damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

4. Install accessory drive belt (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

5. Install air cleaner cover connecting the CVV hose,

IAT sensor, and air duct to the throttle body

housing.

Page 2170 of 5267

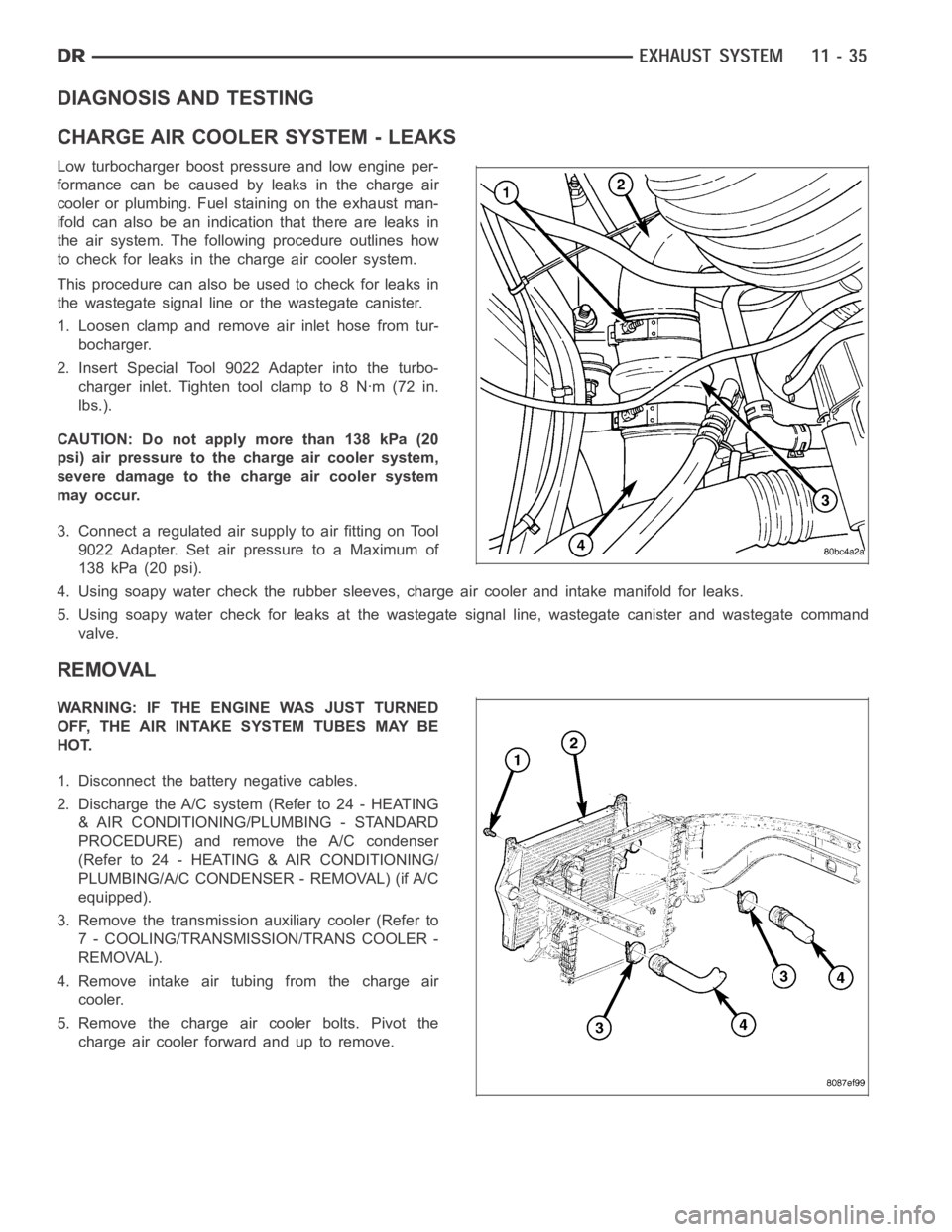

DIAGNOSIS AND TESTING

CHARGE AIR COOLER SYSTEM - LEAKS

Low turbocharger boost pressure and low engine per-

formance can be caused by leaks in the charge air

cooler or plumbing. Fuel staining on the exhaust man-

ifold can also be an indication that there are leaks in

the air system. The followingprocedure outlines how

to check for leaks in the charge air cooler system.

This procedure can also be used to check for leaks in

the wastegate signal line or the wastegate canister.

1. Loosen clamp and remove air inlet hose from tur-

bocharger.

2. Insert Special Tool 9022 Adapter into the turbo-

charger inlet. Tighten tool clamp to 8 Nꞏm (72 in.

lbs.).

CAUTION: Do not apply more than 138 kPa (20

psi) air pressure to the charge air cooler system,

severe damage to the charge air cooler system

may occur.

3. Connect a regulated air supply to air fitting on Tool

9022 Adapter. Set air pressure to a Maximum of

138 kPa (20 psi).

4. Using soapy water check the rubber sleeves, charge air cooler and intakemanifold for leaks.

5. Using soapy water check for leaks at the wastegate signal line, wastegate canister and wastegate command

valve.

REMOVAL

WARNING: IF THE ENGINE WAS JUST TURNED

OFF, THE AIR INTAKE SYSTEM TUBES MAY BE

HOT.

1. Disconnect the battery negative cables.

2. Discharge the A/C system (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE) and remove the A/C condenser

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - REMOVAL) (if A/C

equipped).

3. Remove the transmission auxiliary cooler (Refer to

7 - COOLING/TRANSMISSION/TRANS COOLER -

REMOVAL).

4. Remove intake air tubing from the charge air

cooler.

5. Remove the charge air cooler bolts. Pivot the

charge air cooler forward and up to remove.