cooling DODGE RAM SRT-10 2006 Service Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1961 of 5267

6. Use a drill, a fine grit Flex-hone and a mixture of

equal parts of mineral spirits and SAE 30W engine

oil to de-glaze the bores.

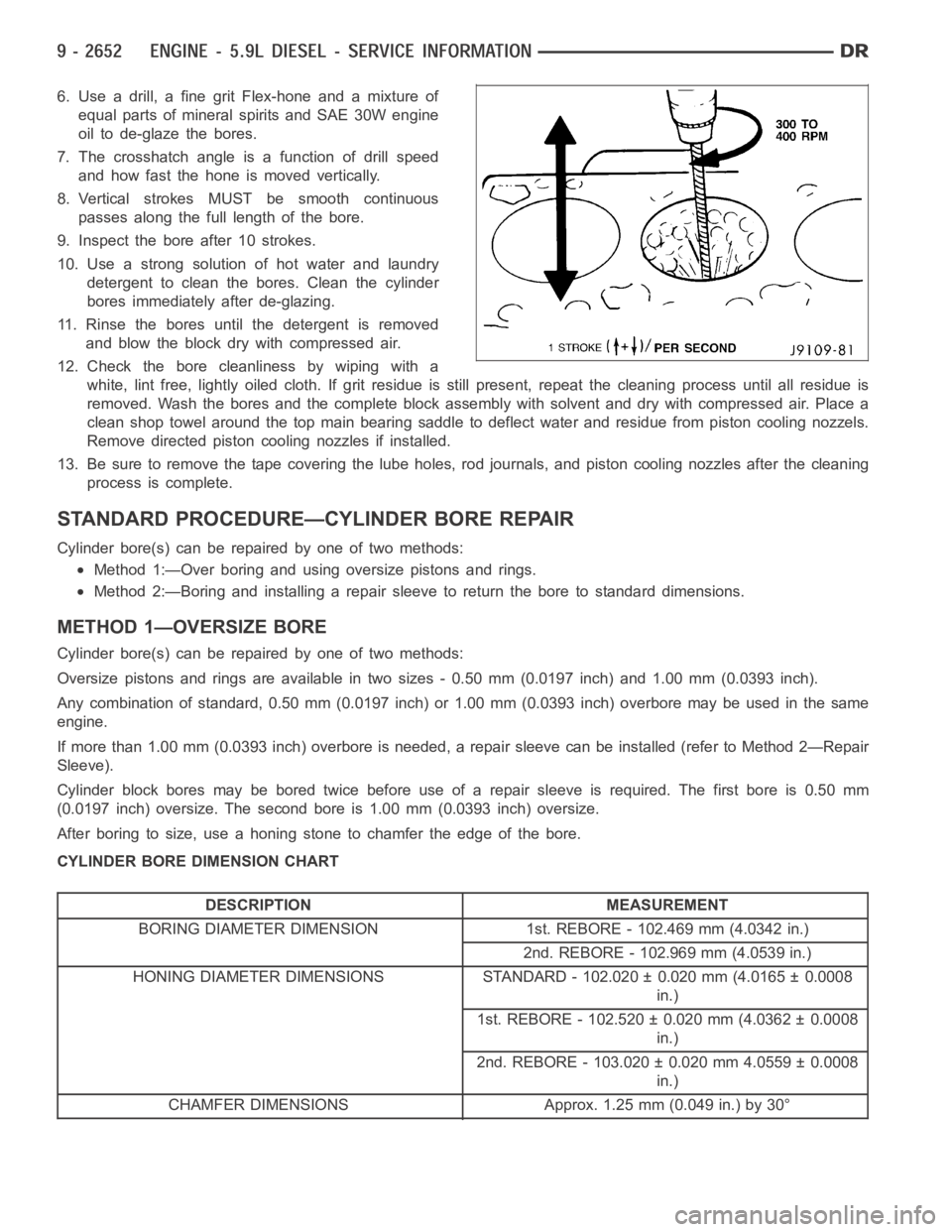

7. The crosshatch angle is a function of drill speed

and how fast the hone is moved vertically.

8. Vertical strokes MUST be smooth continuous

passes along the full length of the bore.

9. Inspect the bore after 10 strokes.

10. Use a strong solution of hot water and laundry

detergent to clean the bores. Clean the cylinder

bores immediately after de-glazing.

11. Rinse the bores until the detergent is removed

and blow the block dry with compressed air.

12. Check the bore cleanliness by wiping with a

white, lint free, lightly oiled cloth. If grit residue is still present, repeat the cleaning process until all residue is

removed. Wash the bores and the complete block assembly with solvent and dry with compressed air. Place a

clean shop towel around the top main bearing saddle to deflect water and residue from piston cooling nozzels.

Remove directed piston cooling nozzles if installed.

13. Be sure to remove the tape covering the lube holes, rod journals, and piston cooling nozzles after the cleaning

process is complete.

STANDARD PROCEDURE—CYLINDER BORE REPAIR

Cylinder bore(s) can be repaired by one of two methods:

Method 1:—Over boring and using oversize pistons and rings.

Method 2:—Boring and installing a repair sleeve to return the bore to standard dimensions.

METHOD 1—OVERSIZE BORE

Cylinder bore(s) can be repaired by one of two methods:

Oversize pistons and rings are available in two sizes - 0.50 mm (0.0197 inch) and 1.00 mm (0.0393 inch).

Any combination of standard, 0.50 mm (0.0197 inch) or 1.00 mm (0.0393 inch)overbore may be used in the same

engine.

If more than 1.00 mm (0.0393 inch) overbore is needed, a repair sleeve can beinstalled (refer to Method 2—Repair

Sleeve).

Cylinder block bores may be bored twice before use of a repair sleeve is required. The first bore is 0.50 mm

(0.0197 inch) oversize. The second bore is 1.00 mm (0.0393 inch) oversize.

After boring to size, use a honing stone to chamfer the edge of the bore.

CYLINDER BORE DIMENSION CHART

DESCRIPTION MEASUREMENT

BORING DIAMETER DIMENSION 1st. REBORE - 102.469 mm (4.0342 in.)

2nd. REBORE - 102.969 mm (4.0539 in.)

HONING DIAMETER DIMENSIONS STANDARD - 102.020 ± 0.020 mm (4.0165 ± 0.0008

in.)

1st. REBORE - 102.520 ± 0.020 mm (4.0362 ± 0.0008

in.)

2nd. REBORE - 103.020 ± 0.020 mm 4.0559 ± 0.0008

in.)

CHAMFER DIMENSIONS Approx. 1.25 mm (0.049 in.) by 30°

Page 1966 of 5267

CAMSHAFT & BEARINGS (IN BLOCK)

REMOVAL

CAMSHAFT BEARINGS

NOTE: Measure the diameter of each bore. If the camshaft bore for the cam bushing is worn beyond the

limit, install a new service bushing. Inspect the rest of the camshaft bores for damage or excessive wear.If

the bores without a bushing are worn beyond the limit, the engine must be removed for machining and

installation of service bushings. If badly worn, replace the cylinder block.

1. Remove the camshaft (Refer to 9 - ENGINE/ENGINE BLOCK/CAMSHAFT & BEARINGS (IN BLOCK) -

REMOVAL).

2. Remove the bushing from the No.1 bore.

3. Mark the cylinder block so you can align the oil hole in the cylinder blockwith the oil hole in the bushing.

CAMSHAFT

1. Disconnect both battery negative cables.

2. Recover A/C refrigerant (if A/C equipped) (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE).

3. Raise vehicle on hoist.

4. Drain engine coolant into container suitable for re-use (Refer to 7 - COOLING - STANDARD PROCEDURE).

5. Lower vehicle.

6. Remove radiator upper hose.

7. Remove viscous fan/drive/shroud assembly (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - REMOVAL).

8. Disconnect the coolant recovery bottle hose from the radiator filler neck.

9. Disconnect lower radiator hose from radiator outlet.

10.Automatic Transmission models:Disconnect transmission oil cooler lines from front of radiator using Special

Tool 6931 (unless equipped with finger-release disconnect).

11. Remove radiator mounting screws and lift radiator out of engine compartment.

12. Remove upper radiator support panel.

13. If A/C equipped, disconnect A/C condenser refrigerant lines.

14. Disconnect charge air cooler piping from the cooler inlet and outlet.

15. Remove the two charge air cooler mounting bolts.

16. Remove charge air cooler (and A/C condenser if equipped) from vehicle.

17. Remove accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - REMOVAL).

18. Remove accessory drive belt tensioner.

19. Remove the fan support/hub assembly.

20. Remove crankshaft damper and speed indicator ring (Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL).

21. Remove the gear cover-to-housing bolts and gently pry the cover away from the housing, taking care not to mar

the sealing surfaces. Remove dust seal with cover.

22. Using Special Tool 7471–B Crankshaft Barring Tool, rotate the crankshaft to align the timing marks on the

crankshaft and the camshaft gears.

23. Remove the cylinder head cover (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) -

REMOVAL).

Page 1971 of 5267

12. Install gear housing cover (Refer to 9 - ENGINE/VALVE TIMING/GEAR HOUSING COVER - INSTALLATION).

Install front crankshaft dust seal.

13. Install the crankshaft damper with the speed indicator ring (Refer to 9- ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - INSTALLATION).

14. Install the fan support/hub assembly Refer to (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION).

15. Install the power steering pump.

16. Install accessory drive belt tensioner. Torque bolt to 43 Nꞏm (32 ft. lbs.).

17. Install the accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

18. Install the charge air cooler (with a/c condenser and auxiliary transmission oil cooler, if equipped) and tighten

the mounting bolts to 2 Nꞏm (17 in. lbs.) torque.

19. Connect charge air cooler inlet and outlet pipes. Tighten clamps to 11 Nꞏm (95 in. lbs.) torque.

20. Install the radiator upper support panel.

21. Close radiator petcock and lower the radiator into the engine compartment. Tighten the mounting bolts to 11

Nꞏm (95 in. lbs.) torque.

22. Raise vehicle on hoist.

23. Connect radiator lower hose and install clamp.

24. Connect transmission auxiliary oil cooler lines (if equipped).

25. Lower vehicle.

26. Install the fandrive/shroud assembly. (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - INSTALLATION)

27. Install the coolant recovery and windshield washer fluid reservoirs to the fan shroud.

28. Connect the coolant recovery hose to the radiator filler neck.

29. Add engine coolant (Refer to 7 - COOLING - STANDARD PROCEDURE).

30. Charge A/C system with refrigerant (if A/C equipped) (Refer to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING - STANDARD PROCEDURE).

31. Connect the battery negative cables.

32. Start engine and check for engine oil and coolant leaks.

Page 1976 of 5267

SEAL - CRANKSHAFT OIL - FRONT

REMOVAL

1. Disconnect both battery negative cables.

2. Raise vehicle on hoist.

3. Partially drain engine coolant into container suitable for re-use (Refer to 7 - COOLING - STANDARD PROCE-

DURE).

4. Lower vehicle.

5. Remove radiator upper hose.

6. Disconnect coolant recovery bottle hose from radiator filler neck.

7. Disconnect windshield washer pump supply hose and electrical connections and lift washer bottle off of fan

shroud.

8. Remove viscous fan/drive assembly. (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - REMOVAL).

9. Remove cooling fan shroud and fan assembly from the vehicle.

10. Remove the accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - REMOVAL).

11. Remove the cooling fan support/hub from the front of the engine.

12. Raisethevehicleonhoist.

13. Remove the crankshaft damper and speed indicator ring.

14. Remove power steering pump.

15. Remove accessory drive belt tensioner.

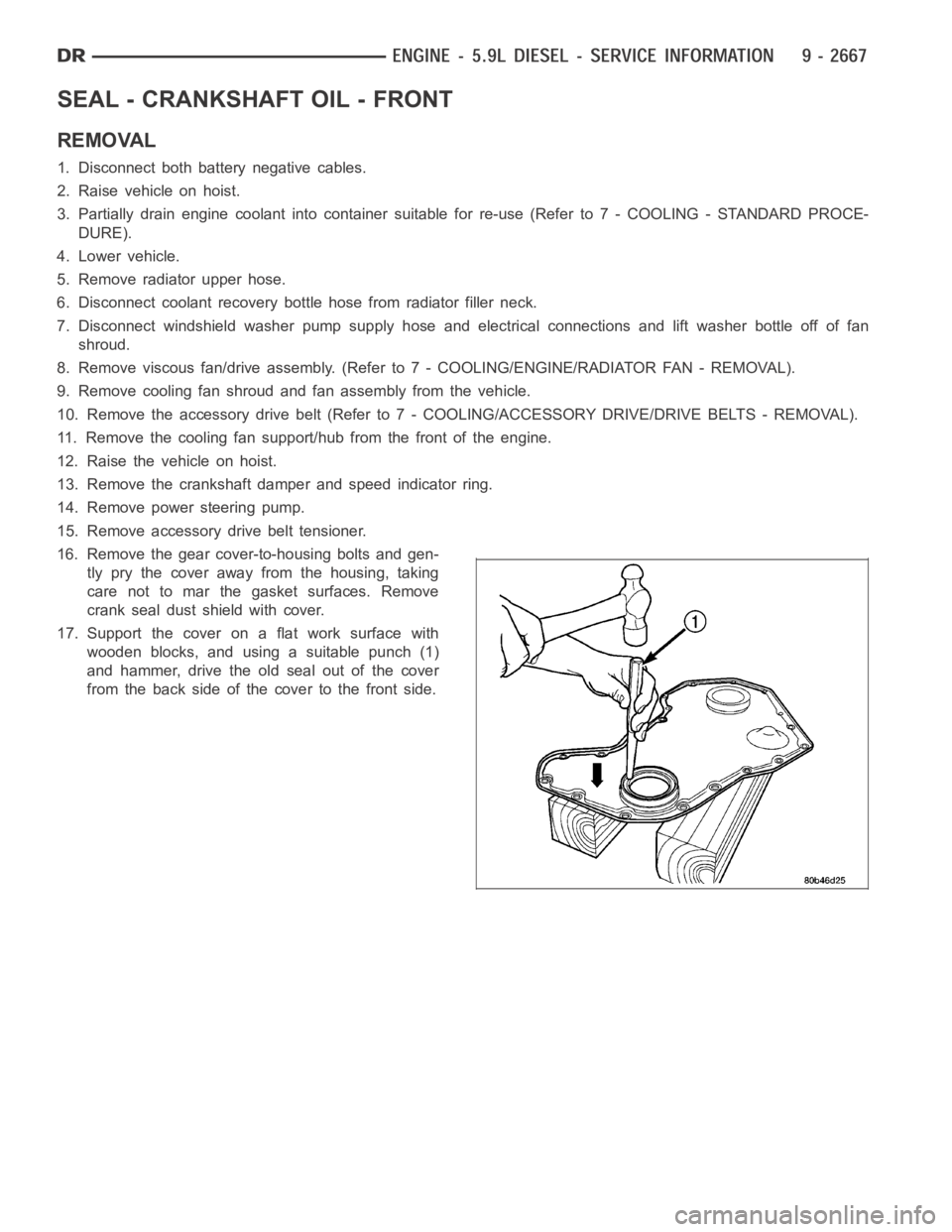

16. Remove the gear cover-to-housing bolts and gen-

tly pry the cover away from the housing, taking

care not to mar the gasket surfaces. Remove

crank seal dust shield with cover.

17. Support the cover on a flat work surface with

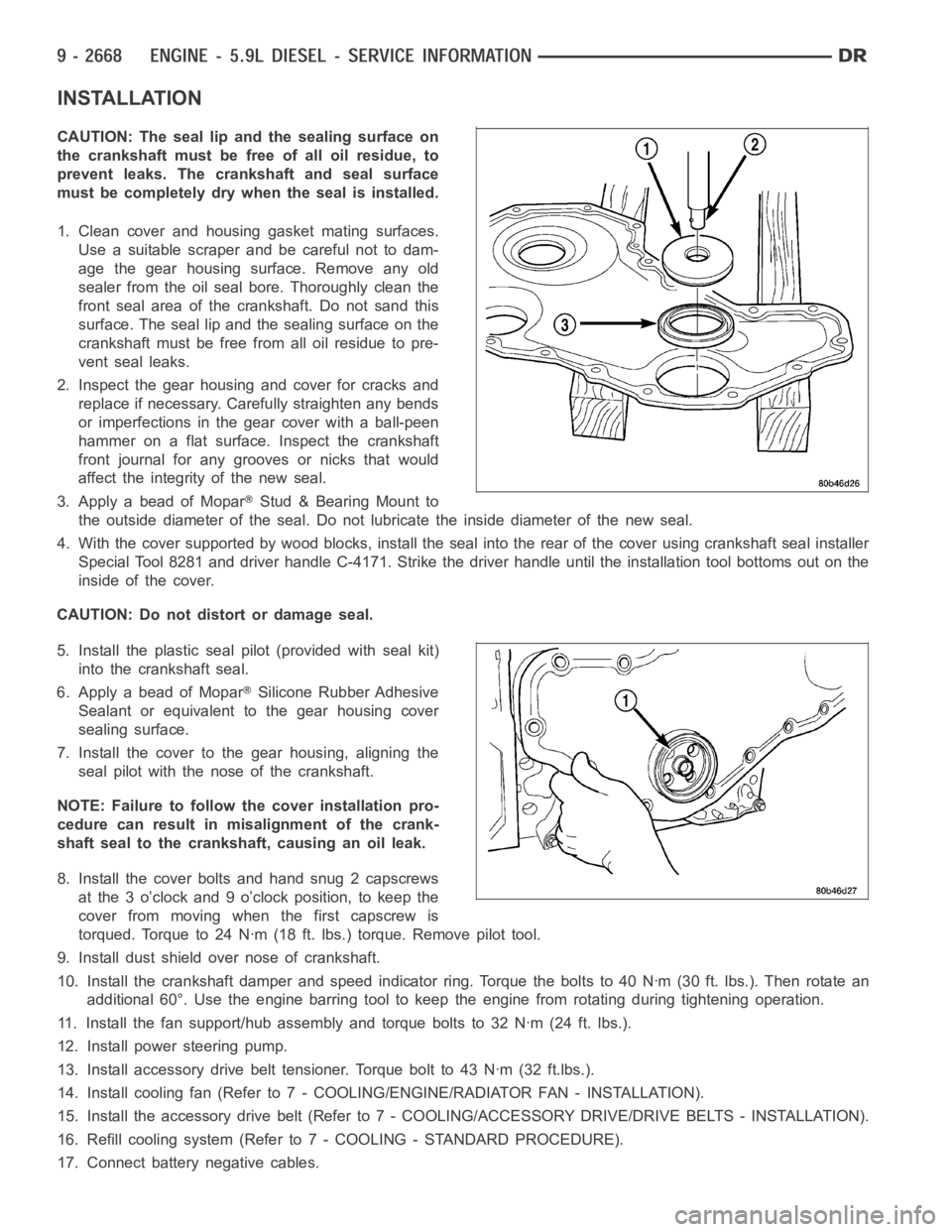

wooden blocks, and using a suitable punch (1)

and hammer, drive the old seal out of the cover

from the back side of the cover to the front side.

Page 1977 of 5267

INSTALLATION

CAUTION: The seal lip and the sealing surface on

thecrankshaftmustbefreeofalloilresidue,to

prevent leaks. The crankshaft and seal surface

must be completely dry when the seal is installed.

1. Clean cover and housing gasket mating surfaces.

Use a suitable scraper and be careful not to dam-

age the gear housing surface. Remove any old

sealer from the oil seal bore. Thoroughly clean the

front seal area of the crankshaft. Do not sand this

surface. The seal lip and the sealing surface on the

crankshaft must be free from all oil residue to pre-

vent seal leaks.

2. Inspect the gear housing and cover for cracks and

replace if necessary. Carefully straighten any bends

or imperfections in the gear cover with a ball-peen

hammer on a flat surface. Inspect the crankshaft

front journal for any grooves or nicks that would

affect the integrity of the new seal.

3. Apply a bead of Mopar

Stud & Bearing Mount to

the outside diameter of the seal. Do not lubricate the inside diameter of thenewseal.

4. With the cover supported by wood blocks, install the seal into the rear ofthe cover using crankshaft seal installer

Special Tool 8281 and driver handle C-4171. Strike the driver handle untilthe installation tool bottoms out on the

inside of the cover.

CAUTION: Do not distort or damage seal.

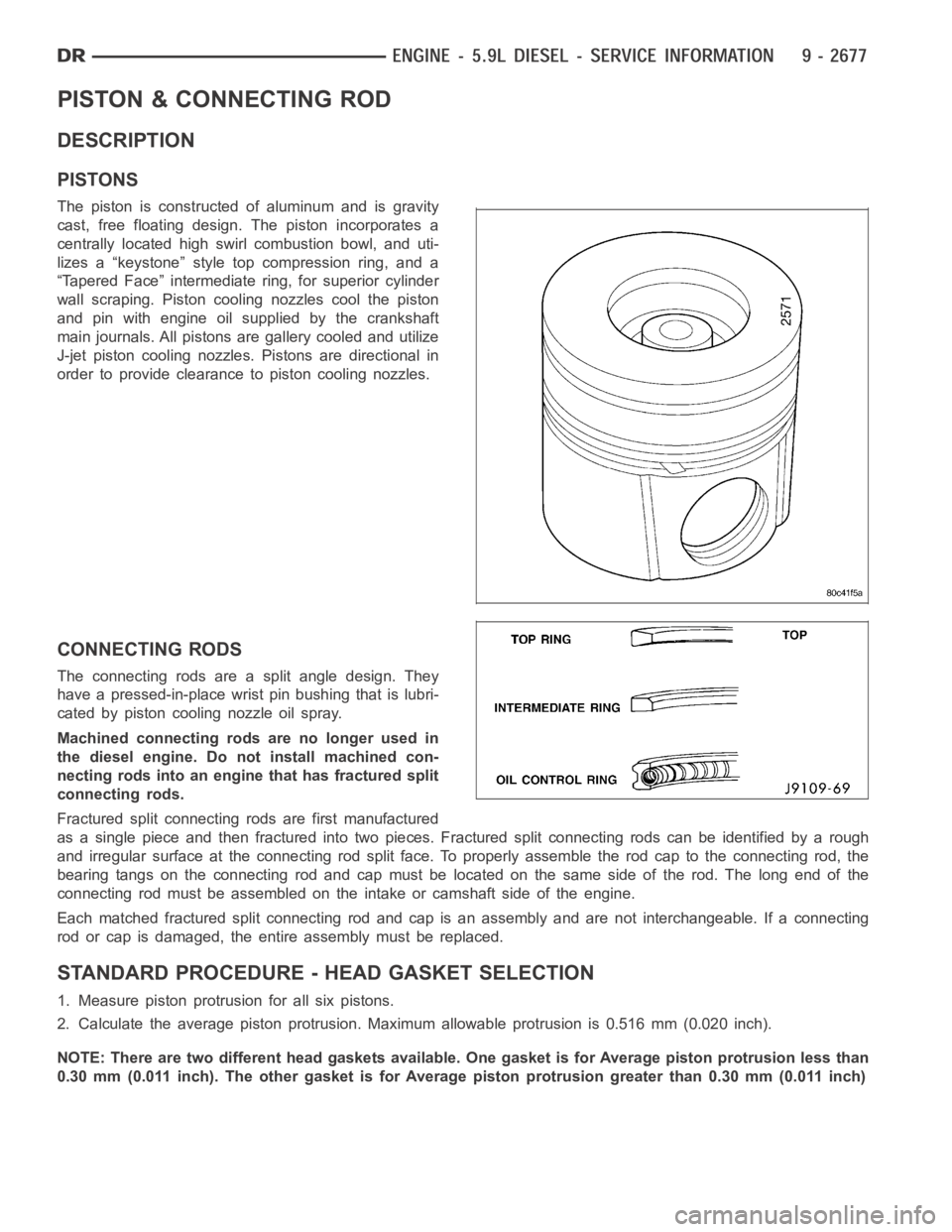

5. Install the plastic seal pilot (provided with seal kit)

into the crankshaft seal.

6. Apply a bead of Mopar

Silicone Rubber Adhesive

Sealant or equivalent to the gear housing cover

sealing surface.

7. Install the cover to the gear housing, aligning the

seal pilot with the nose of the crankshaft.

NOTE: Failure to follow the cover installation pro-

cedure can result in misalignment of the crank-

shaft seal to the crankshaft, causing an oil leak.

8. Install the cover bolts and hand snug 2 capscrews

at the 3 o’clock and 9 o’clock position, to keep the

cover from moving when the first capscrew is

torqued. Torque to 24 Nꞏm (18 ft. lbs.) torque. Remove pilot tool.

9. Install dust shield over nose of crankshaft.

10. Install the crankshaft damper and speed indicator ring. Torque the bolts to 40 Nꞏm (30 ft. lbs.). Then rotate an

additional 60°. Use the engine barring tool to keep the engine from rotating during tightening operation.

11. Install the fan support/hub assembly and torque bolts to 32 Nꞏm (24 ft. lbs.).

12. Install power steering pump.

13. Install accessory drive belt tensioner. Torque bolt to 43 Nꞏm (32 ft.lbs.).

14. Install cooling fan (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - INSTALLATION).

15. Install the accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

16. Refill cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE).

17. Connect battery negative cables.

Page 1986 of 5267

PISTON & CONNECTING ROD

DESCRIPTION

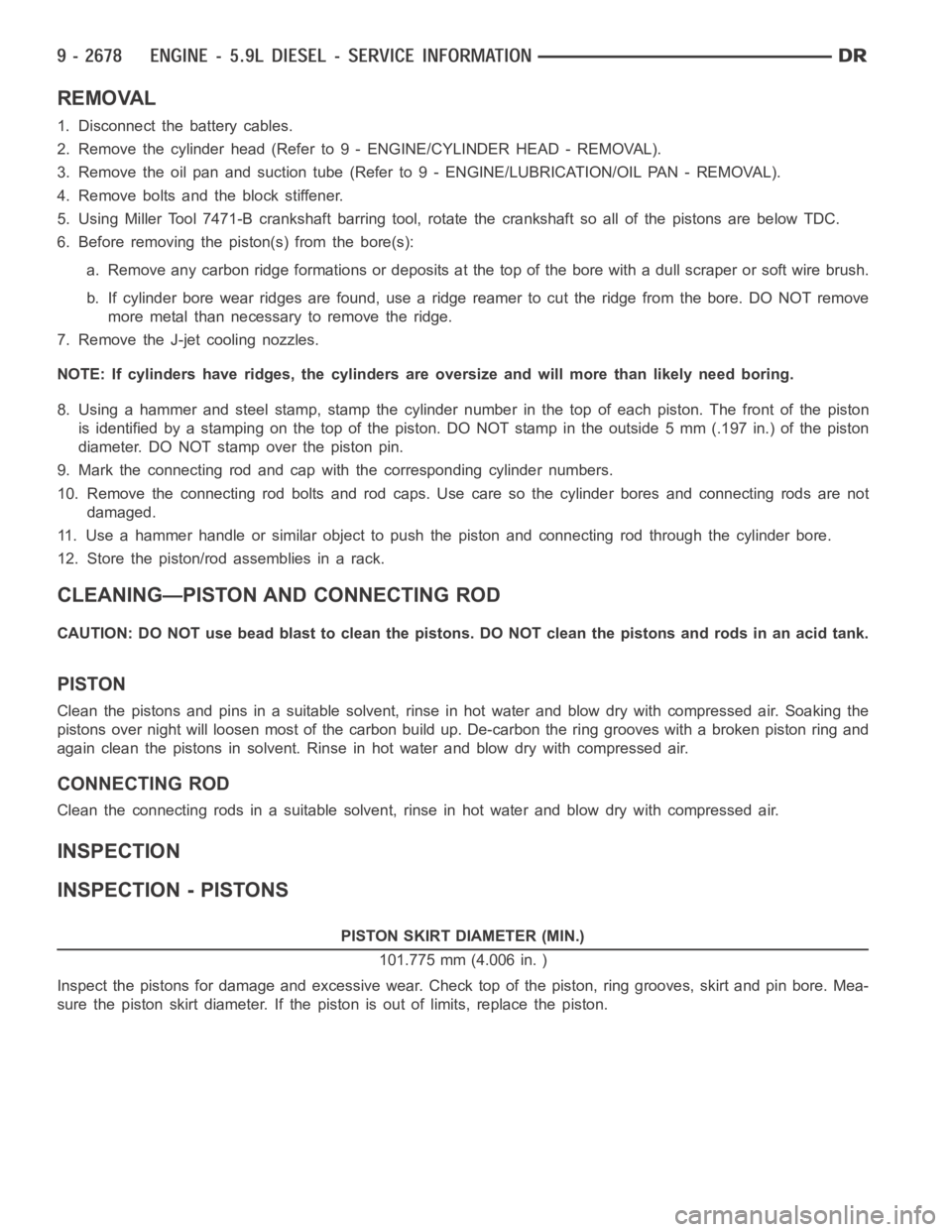

PISTONS

The piston is constructed of aluminum and is gravity

cast, free floating design. The piston incorporates a

centrally located high swirl combustion bowl, and uti-

lizes a “keystone” style top compression ring, and a

“Tapered Face” intermediate ring, for superior cylinder

wall scraping. Piston cooling nozzles cool the piston

and pin with engine oil supplied by the crankshaft

main journals. All pistons are gallery cooled and utilize

J-jet piston cooling nozzles. Pistons are directional in

order to provide clearance to piston cooling nozzles.

CONNECTING RODS

The connecting rods are a split angle design. They

have a pressed-in-place wrist pin bushing that is lubri-

cated by piston cooling nozzle oil spray.

Machined connecting rods are no longer used in

the diesel engine. Do not install machined con-

necting rods into an engine that has fractured split

connecting rods.

Fractured split connecting rods are first manufactured

asasinglepieceandthenfracturedintotwopieces.Fracturedsplitconnecting rods can be identified by a rough

and irregular surface at the connecting rod split face. To properly assemble the rod cap to the connecting rod, the

bearing tangs on the connecting rod and cap must be located on the same side of the rod. The long end of the

connecting rod must be assembled on theintake or camshaft side of the engine.

Each matched fractured split connecting rod and cap is an assembly and are not interchangeable. If a connecting

rod or cap is damaged, the entire assembly must be replaced.

STANDARD PROCEDURE - HEAD GASKET SELECTION

1. Measure piston protrusion for all six pistons.

2. Calculate the average piston protrusion. Maximum allowable protrusion is 0.516 mm (0.020 inch).

NOTE: There are two different head gaskets available. One gasket is for Average piston protrusion less than

0.30 mm (0.011 inch). The other gasket is for Average piston protrusion greater than 0.30 mm (0.011 inch)

Page 1987 of 5267

REMOVAL

1. Disconnect the battery cables.

2. Remove the cylinder head (Refer to 9 - ENGINE/CYLINDER HEAD - REMOVAL).

3. Remove the oil pan and suction tube (Refer to 9 - ENGINE/LUBRICATION/OILPA N - R E M O VA L ) .

4. Remove bolts and the block stiffener.

5. Using Miller Tool 7471-B crankshaft barring tool, rotate the crankshaft so all of the pistons are below TDC.

6. Before removing the piston(s) from the bore(s):

a. Remove any carbon ridge formations or deposits at the top of the bore witha dull scraper or soft wire brush.

b. If cylinder bore wear ridges are found, use a ridge reamer to cut the ridgefrom the bore. DO NOT remove

more metal than necessaryto remove the ridge.

7. Remove the J-jet cooling nozzles.

NOTE: If cylinders have ridges, the cylinders are oversize and will more than likely need boring.

8. Using a hammer and steel stamp, stamp the cylinder number in the top of eachpiston.Thefrontofthepiston

is identified by a stamping on the top of the piston. DO NOT stamp in the outside 5 mm (.197 in.) of the piston

diameter. DO NOT stamp over the piston pin.

9. Mark the connecting rod and cap with the corresponding cylinder numbers.

10. Remove the connecting rod bolts and rod caps. Use care so the cylinder bores and connecting rods are not

damaged.

11. Use a hammer handle or similar object to push the piston and connecting rod through the cylinder bore.

12. Store the piston/rod assemblies in a rack.

CLEANING—PISTON AND CONNECTING ROD

CAUTION: DO NOT use bead blast to clean the pistons. DO NOT clean the pistonsandrodsinanacidtank.

PISTON

Clean the pistons and pins in a suitable solvent, rinse in hot water and blowdry with compressed air. Soaking the

pistons over night will loosen most of the carbon build up. De-carbon the ringgrooveswithabrokenpistonringand

again clean the pistons in solvent. Rinse in hot water and blow dry with compressed air.

CONNECTING ROD

Clean the connecting rods in a suitable solvent, rinse in hot water and blowdry with compressed air.

INSPECTION

INSPECTION - PISTONS

PISTON SKIRT DIAMETER (MIN.)

101.775 mm (4.006 in. )

Inspect the pistons for damage and excessive wear. Check top of the piston,ring grooves, skirt and pin bore. Mea-

sure the piston skirt diameter. If the piston is out of limits, replace the piston.

Page 1990 of 5267

a. The connecting rod split/face mustface toward the same side as the piston notch feature on the skirt. The

split face will face toward the exhaust side of the engine if properly installed.

11. Install the rod cap and bolts to the connecting rod. Tighten the connecting rod bolts evenly in 3 steps.

Tighten the bolts to 30 Nꞏm (22 ft. lbs.) torque.

Tighten the bolts to 60 Nꞏm (44 ft. lbs.) torque.

Rotate 60° clockwise.

12. The crankshaft must rotate freely. Check for freedom of rotation as thecaps are installed. If the crankshaft does

not rotate freely, check the installation of the rod bearing and the bearingsize.

13. Measure the side clearance between the connecting rod and the crankshaft. DO NOT measure the clearance

between the cap and crankshaft.

14. Install J-jet piston cooling nozzles.

15. Install block stiffener. Torque to 43 Nꞏm (32 ft. lbs.).

16. Install the suction tube and oil pan (Refer to 9 - ENGINE/LUBRICATION/OIL PAN - INSTALLATION).

17. Install the cylinder head onto the engine (Refer to 9 - ENGINE/CYLINDERHEAD - INSTALLATION).

18. Install a new filter and fill the crankcase with new engine oil.Prefill the filter with clean oil.

19. Connect the battery negative cables and start engine.

Page 1993 of 5267

DAMPER - CRANKSHAFT

REMOVAL

1. Remove the accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - REMOVAL).

2. Remove the four (4) damper to crankshaft bolts and remove damper and speed indicator ring.

INSPECTION

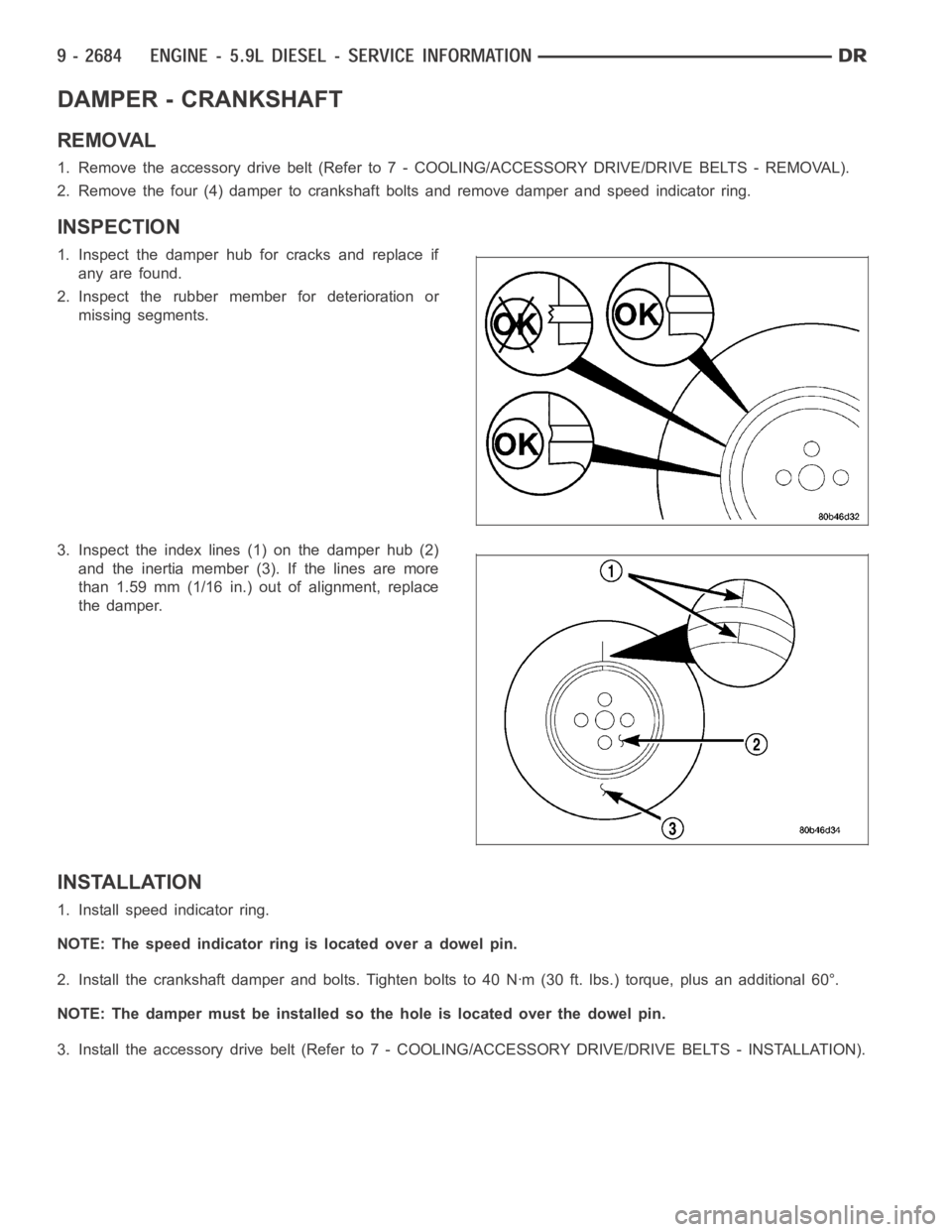

1. Inspect the damper hub for cracks and replace if

any are found.

2. Inspect the rubber member for deterioration or

missing segments.

3. Inspect the index lines (1) on the damper hub (2)

and the inertia member (3). If the lines are more

than 1.59 mm (1/16 in.) out of alignment, replace

the damper.

INSTALLATION

1. Install speed indicator ring.

NOTE: The speed indicator ring is located over a dowel pin.

2. Install the crankshaft damper and bolts. Tighten bolts to 40 Nꞏm (30 ft. lbs.) torque, plus an additional 60°.

NOTE: The damper must be installed so the hole is located over the dowel pin.

3. Install the accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

Page 1994 of 5267

MOUNT - FRONT

REMOVAL

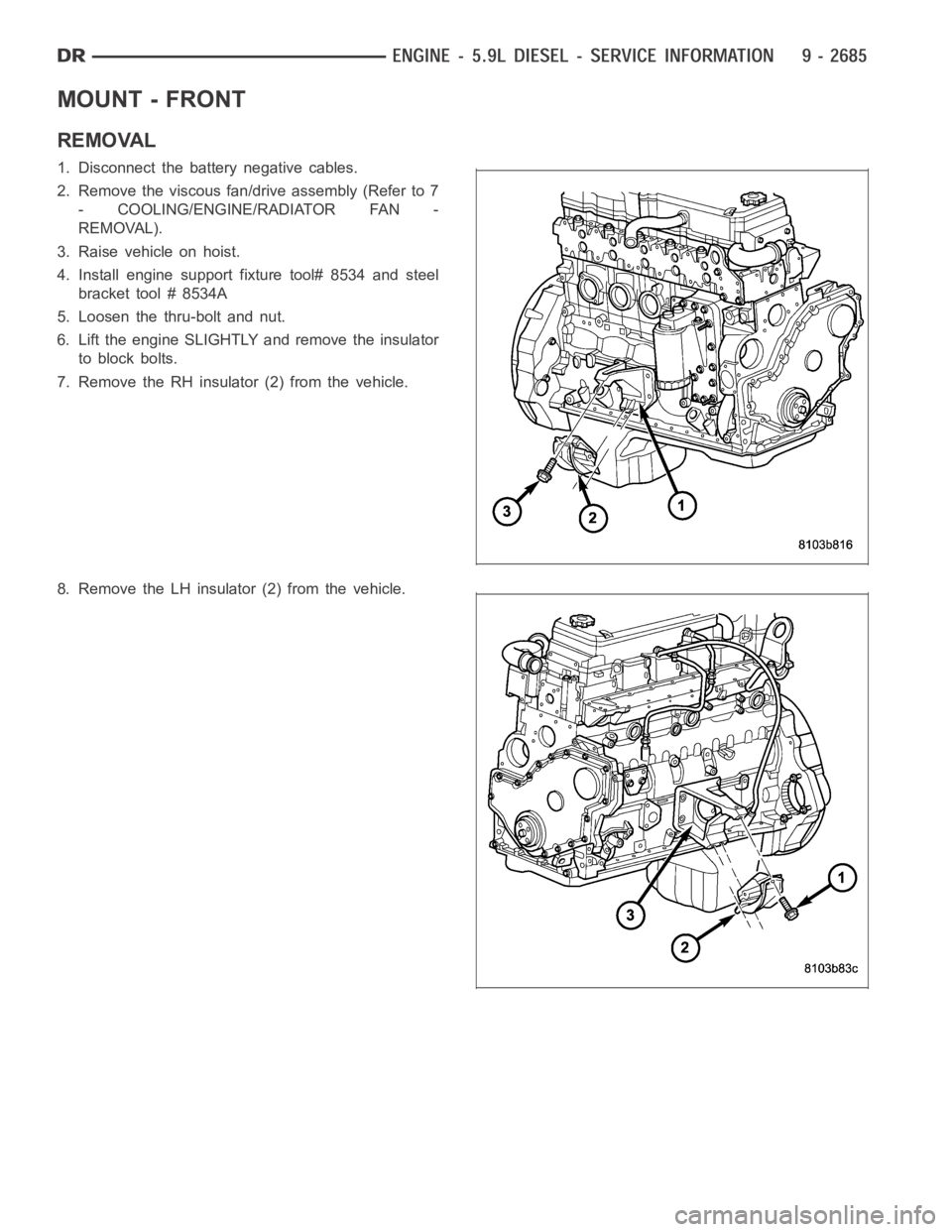

1. Disconnect the battery negative cables.

2. Remove the viscous fan/drive assembly (Refer to 7

- COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

3. Raise vehicle on hoist.

4. Install engine support fixture tool# 8534 and steel

bracket tool # 8534A

5. Loosen the thru-bolt and nut.

6. Lift the engine SLIGHTLY and remove the insulator

to block bolts.

7. Remove the RH insulator (2) from the vehicle.

8. Remove the LH insulator (2) from the vehicle.