DODGE RAM SRT-10 2006 Service Repair Manual

RAM SRT-10 2006

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56917/w960_56917-0.png

DODGE RAM SRT-10 2006 Service Repair Manual

Trending: park assist, trailer, radiator, air condition, oil, air filter, rims

Page 1891 of 5267

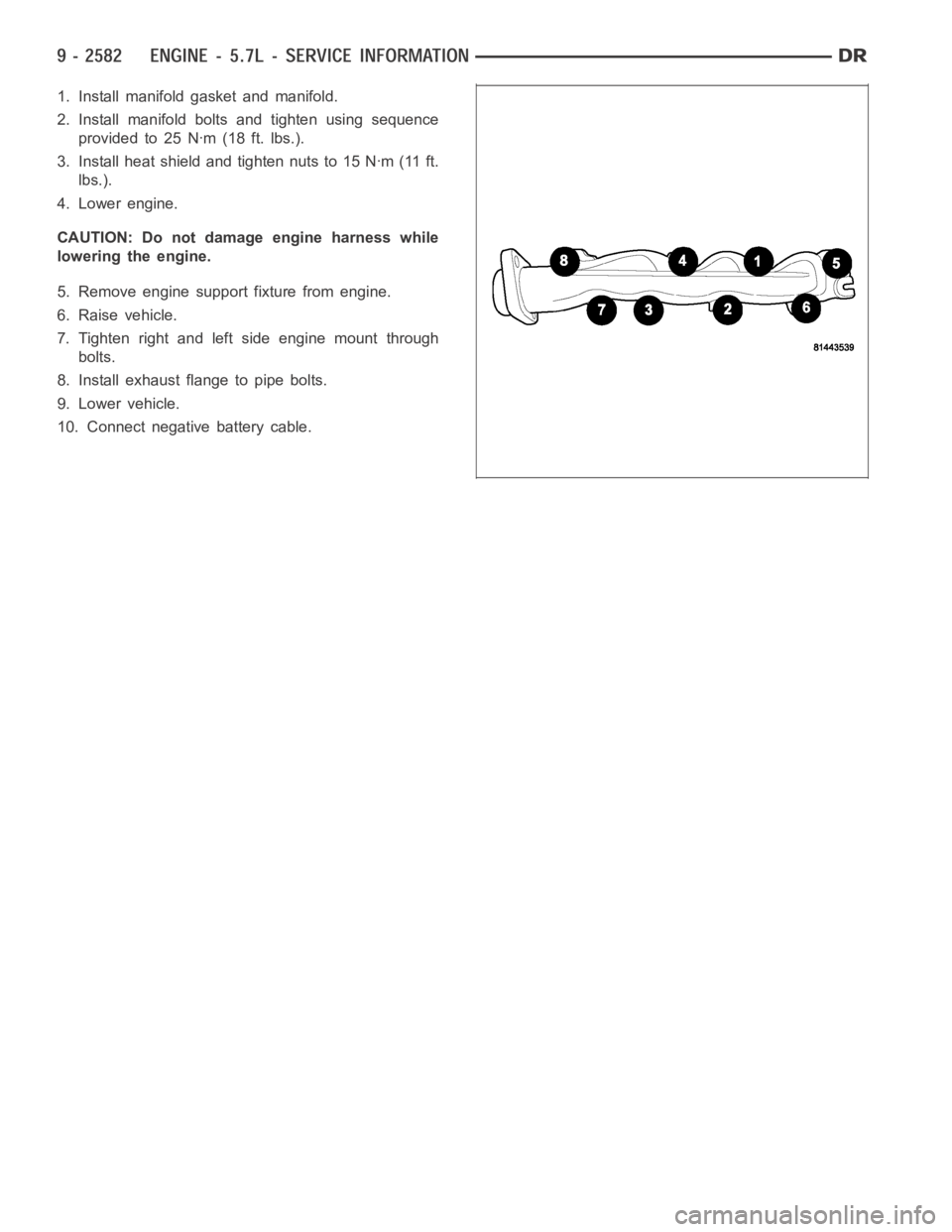

1. Install manifold gasket and manifold.

2. Install manifold bolts and tighten using sequence

provided to 25 Nꞏm (18 ft. lbs.).

3. Install heat shield and tighten nuts to 15 Nꞏm (11 ft.

lbs.).

4. Lower engine.

CAUTION: Do not damage engine harness while

lowering the engine.

5. Remove engine support fixture from engine.

6. Raise vehicle.

7. Tighten right and left side engine mount through

bolts.

8. Install exhaust flange to pipe bolts.

9. Lower vehicle.

10. Connect negative battery cable.

Page 1892 of 5267

COVER - TIMING

REMOVAL

1. Disconnect the battery negative cable.

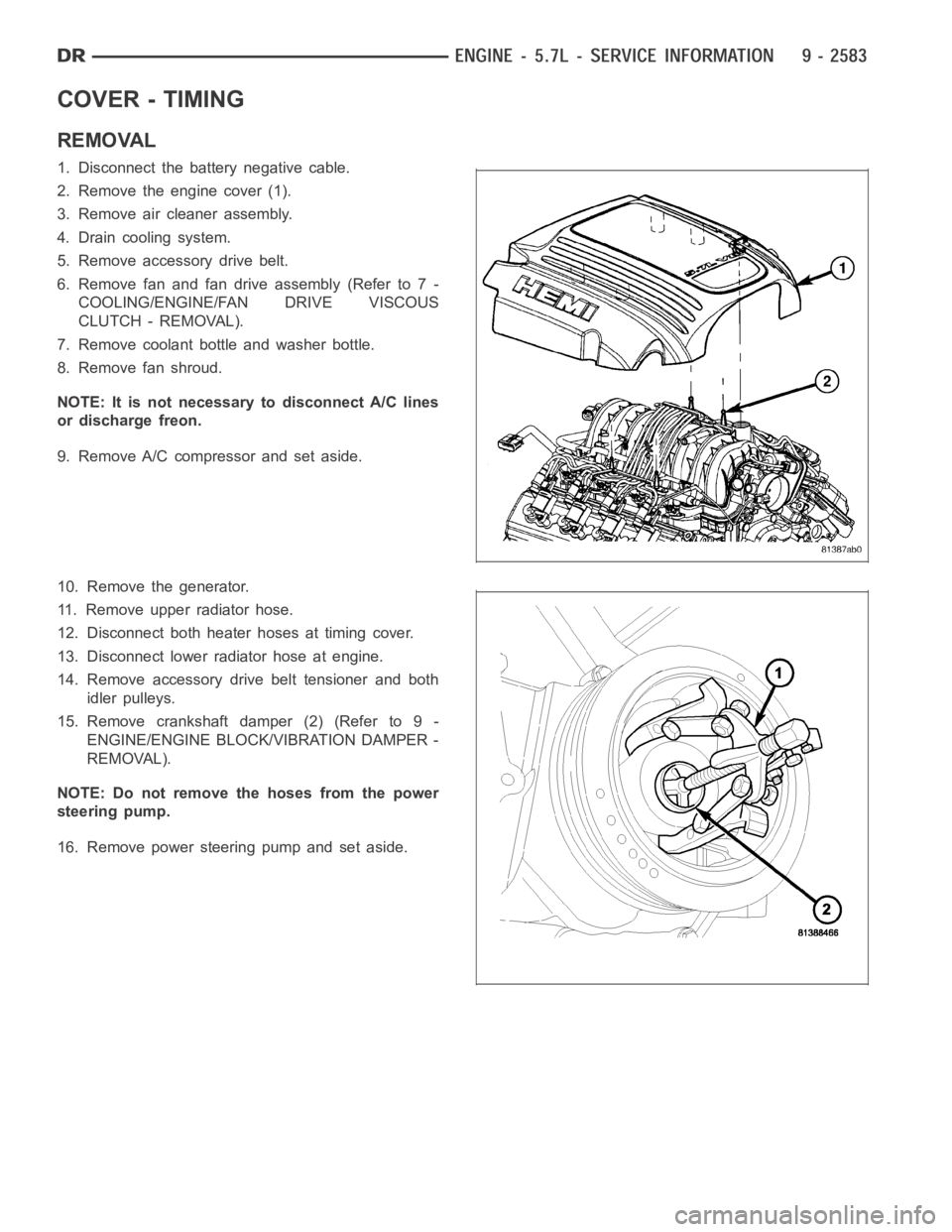

2. Remove the engine cover (1).

3. Remove air cleaner assembly.

4. Drain cooling system.

5. Remove accessory drive belt.

6. Remove fan and fan drive assembly (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL).

7. Remove coolant bottle and washer bottle.

8. Remove fan shroud.

NOTE: It is not necessary to disconnect A/C lines

or discharge freon.

9. Remove A/C compressor and set aside.

10. Remove the generator.

11. Remove upper radiator hose.

12. Disconnect both heater hoses at timing cover.

13. Disconnect lower radiator hose at engine.

14. Remove accessory drive belt tensioner and both

idler pulleys.

15. Remove crankshaft damper (2) (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

NOTE: Do not remove the hoses from the power

steering pump.

16. Remove power steering pump and set aside.

Page 1893 of 5267

17. Remove the dipstick support bolt.

18. Drain the engine oil.

19. Remove the oil pan and pick up tube (Refer to 9 - ENGINE/LUBRICATION/OILPA N - R E M O VA L ) .

NOTE: It is not necessary to remove water pump for timing cover removal.

20. Remove timing cover bolts and remove cover.

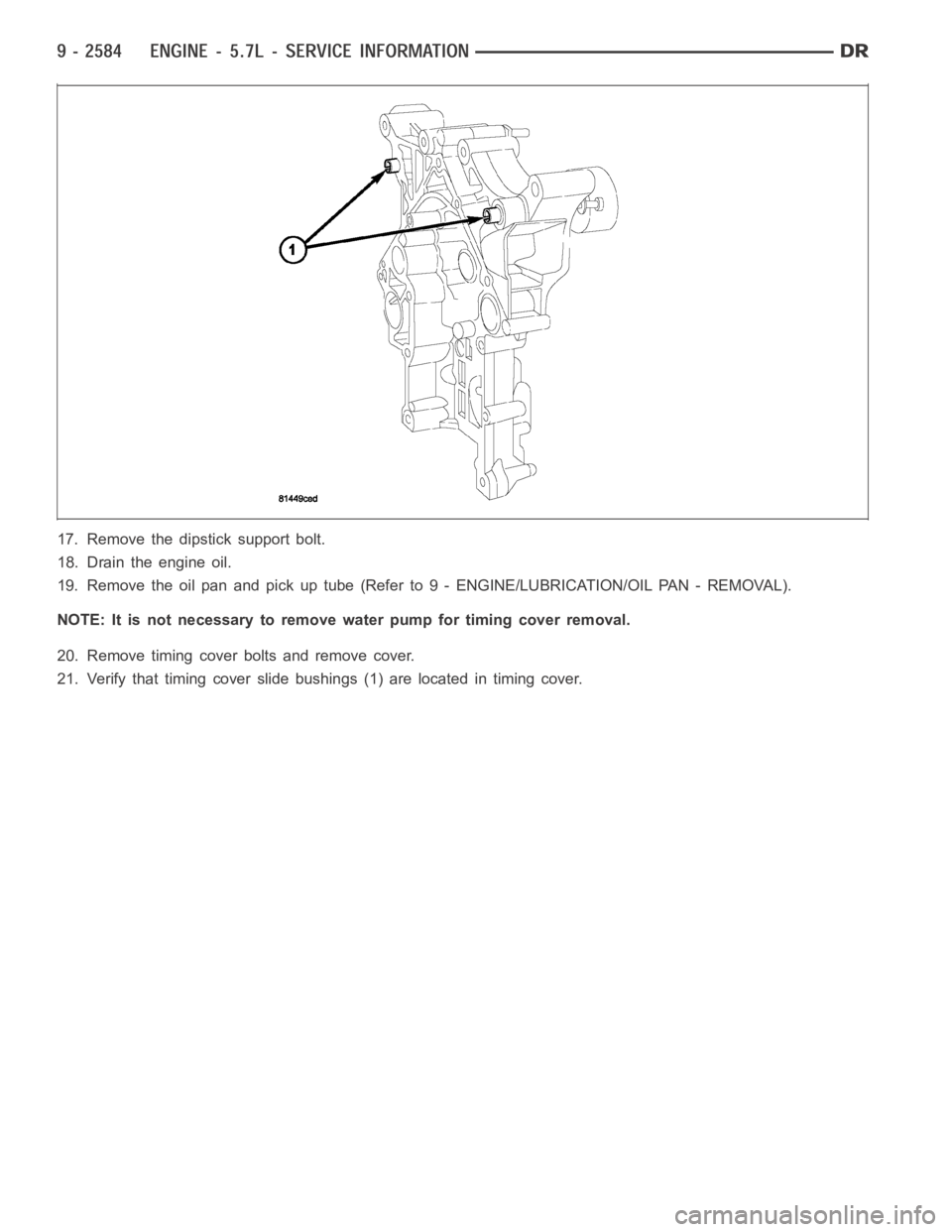

21. Verify that timing cover slide bushings (1) are located in timing cover.

Page 1894 of 5267

INSTALLATION

1. Clean timing chain cover and block surface.

NOTE: Always install a new gasket on timing cover.

2. Verify that the slide bushings (1) are installed in timing cover.

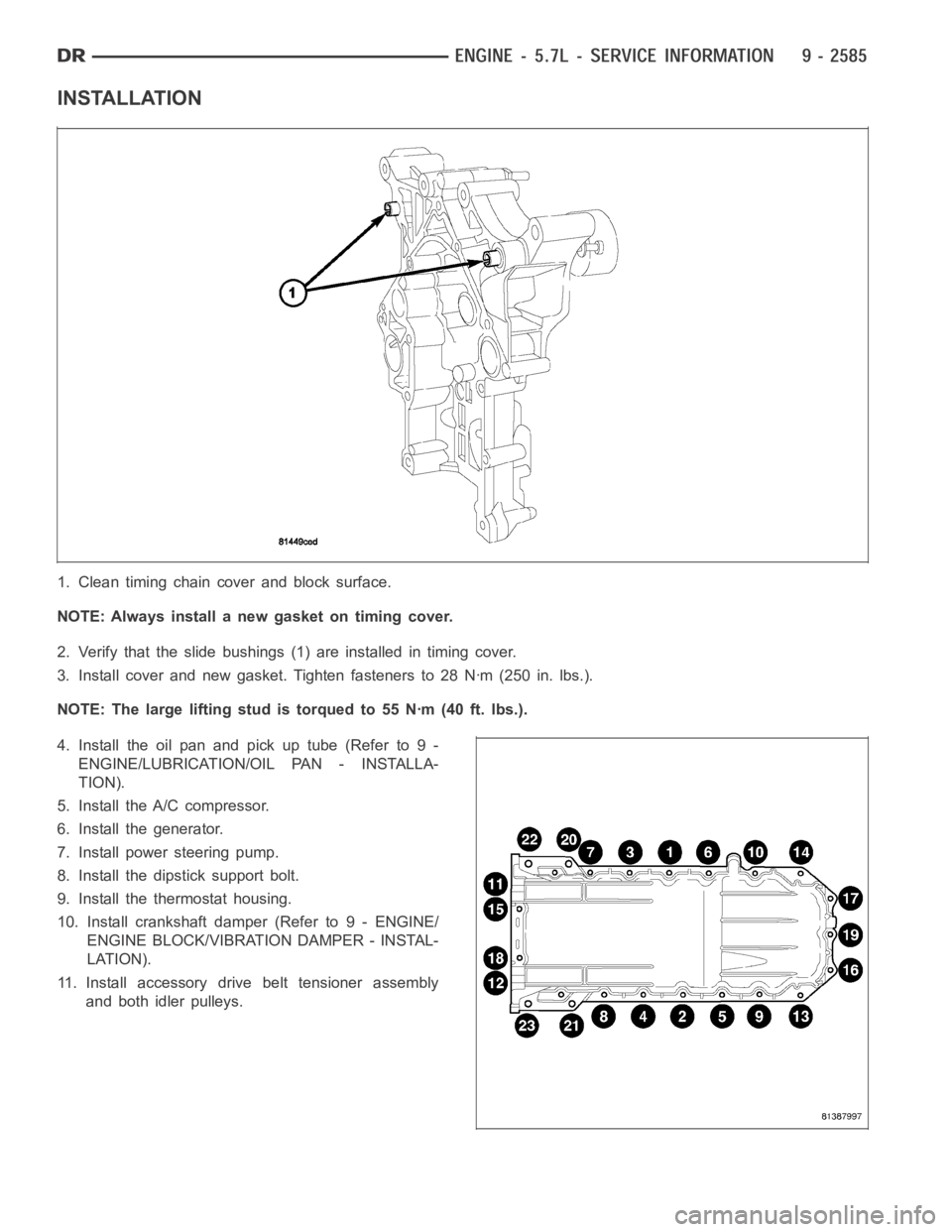

3. Install cover and new gasket. Tighten fasteners to 28 Nꞏm (250 in. lbs.).

NOTE: The large lifting stud is torqued to 55 Nꞏm (40 ft. lbs.).

4. Install the oil pan and pick up tube (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

5. Install the A/C compressor.

6. Install the generator.

7. Install power steering pump.

8. Install the dipstick support bolt.

9. Install the thermostat housing.

10. Install crankshaft damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

11. Install accessory drive belt tensioner assembly

and both idler pulleys.

Page 1895 of 5267

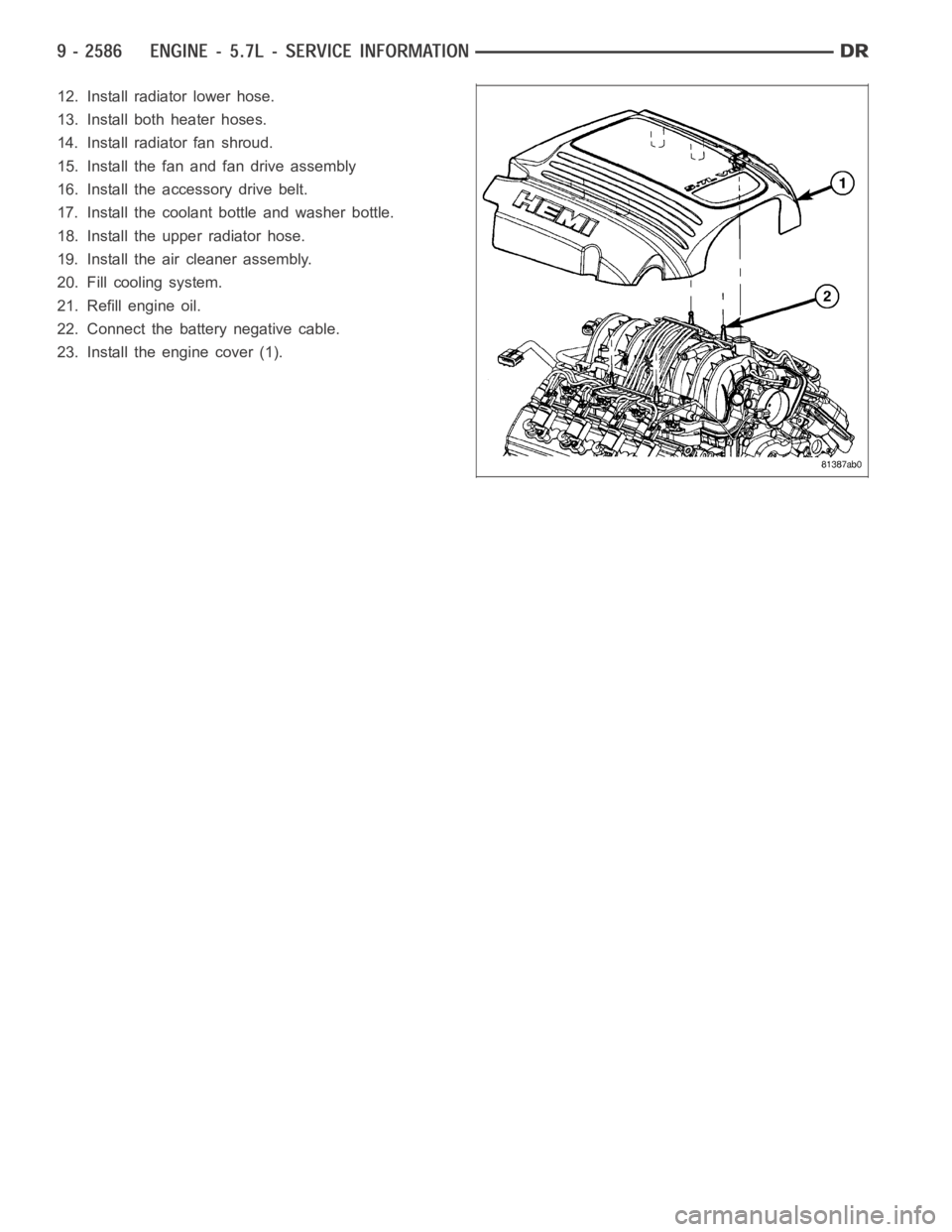

12. Install radiator lower hose.

13. Install both heater hoses.

14. Install radiator fan shroud.

15. Install the fan and fan drive assembly

16. Install the accessory drive belt.

17. Install the coolant bottle and washer bottle.

18. Install the upper radiator hose.

19. Install the air cleaner assembly.

20. Fill cooling system.

21. Refill engine oil.

22. Connect the battery negative cable.

23. Install the engine cover (1).

Page 1896 of 5267

TIMING CHAIN & SPROCKETS

REMOVAL

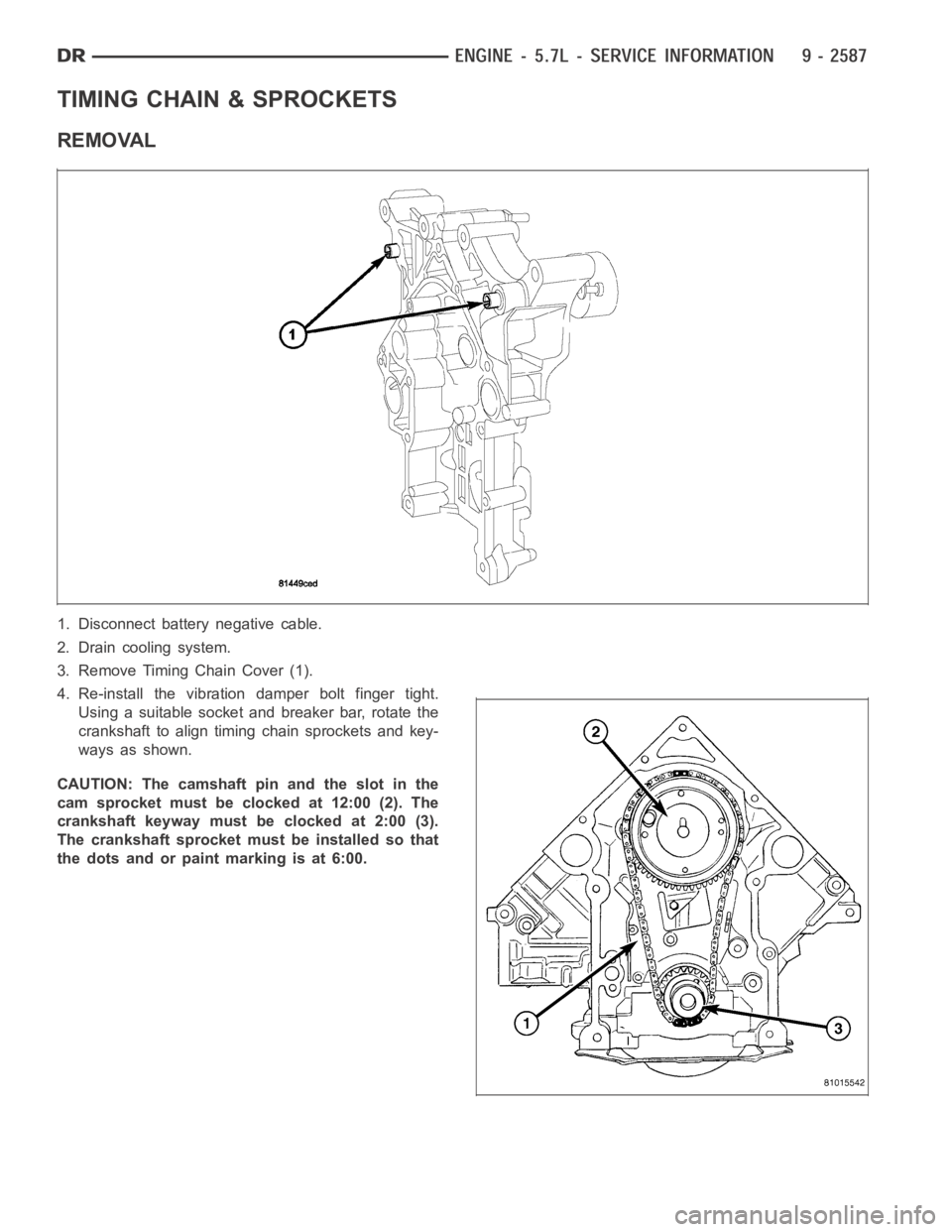

1. Disconnect battery negative cable.

2. Drain cooling system.

3. Remove Timing Chain Cover (1).

4. Re-install the vibration damper bolt finger tight.

Using a suitable socket and breaker bar, rotate the

crankshaft to align timing chain sprockets and key-

ways as shown.

CAUTION: The camshaft pin and the slot in the

cam sprocket must be clocked at 12:00 (2). The

crankshaft keyway must be clocked at 2:00 (3).

The crankshaft sprocket must be installed so that

the dots and or paint marking is at 6:00.

Page 1897 of 5267

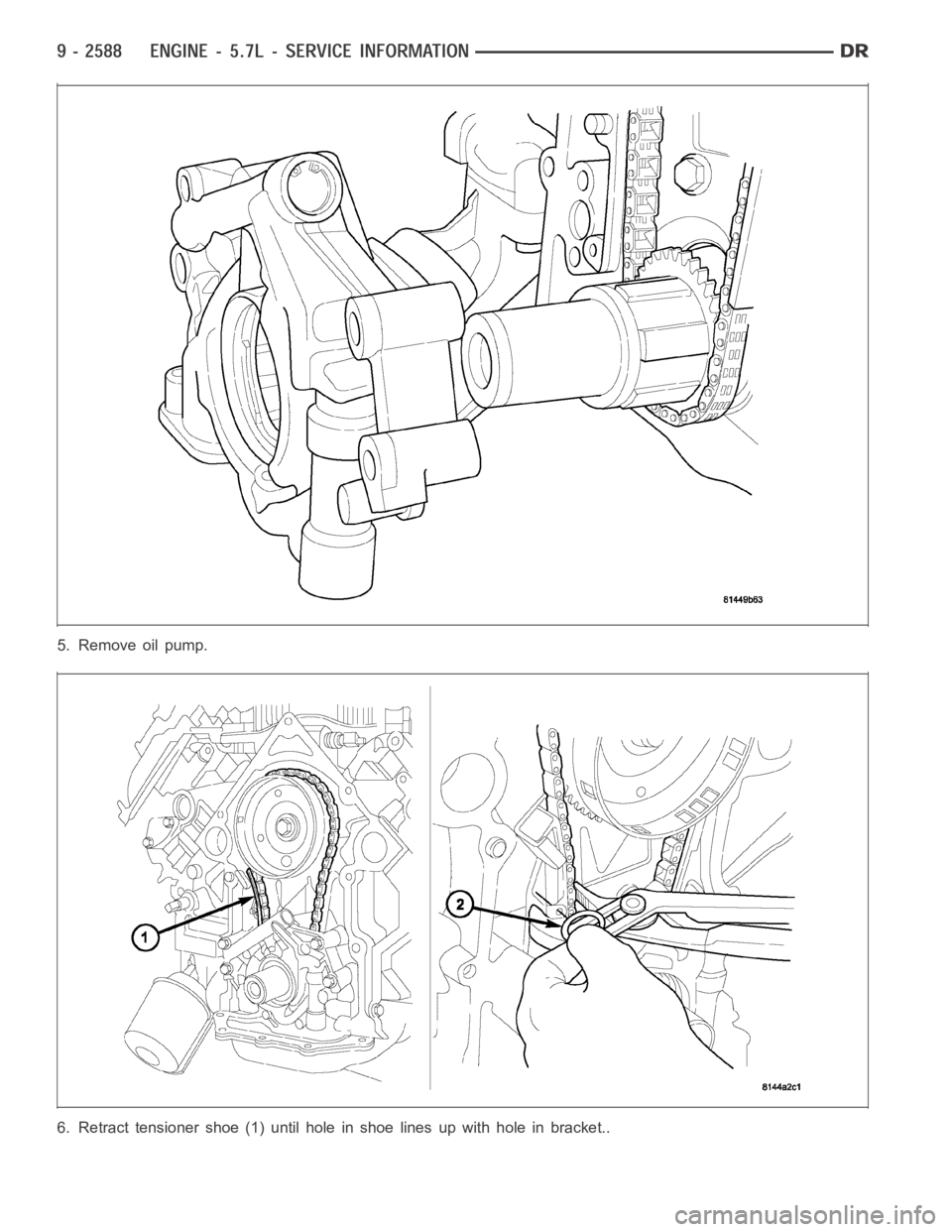

5. Remove oil pump.

6. Retract tensioner shoe (1) until hole in shoe lines up with hole in bracket..

Page 1898 of 5267

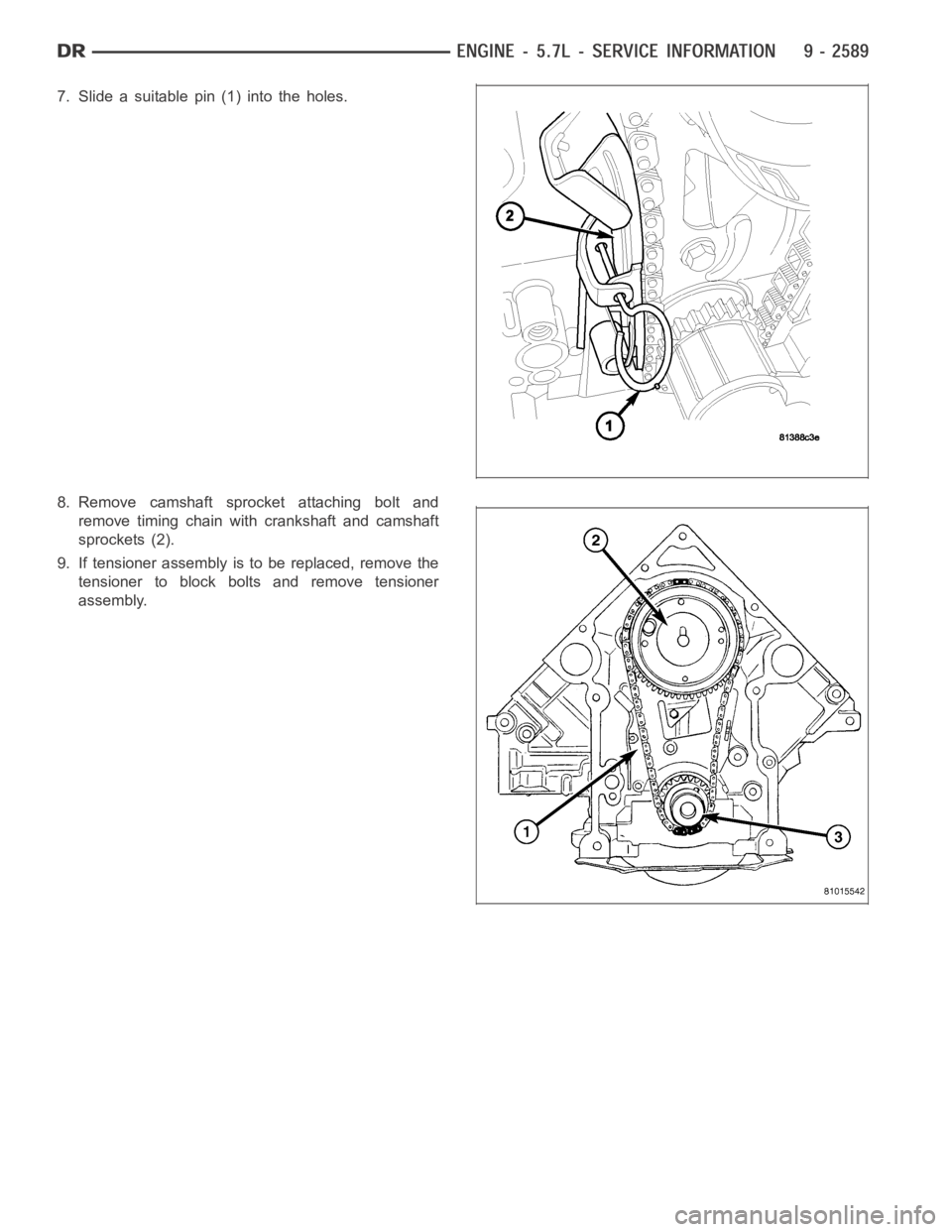

7. Slide a suitable pin (1) into the holes.

8. Remove camshaft sprocket attaching bolt and

remove timing chain with crankshaft and camshaft

sprockets (2).

9. If tensioner assembly is to be replaced, remove the

tensioner to block bolts and remove tensioner

assembly.

Page 1899 of 5267

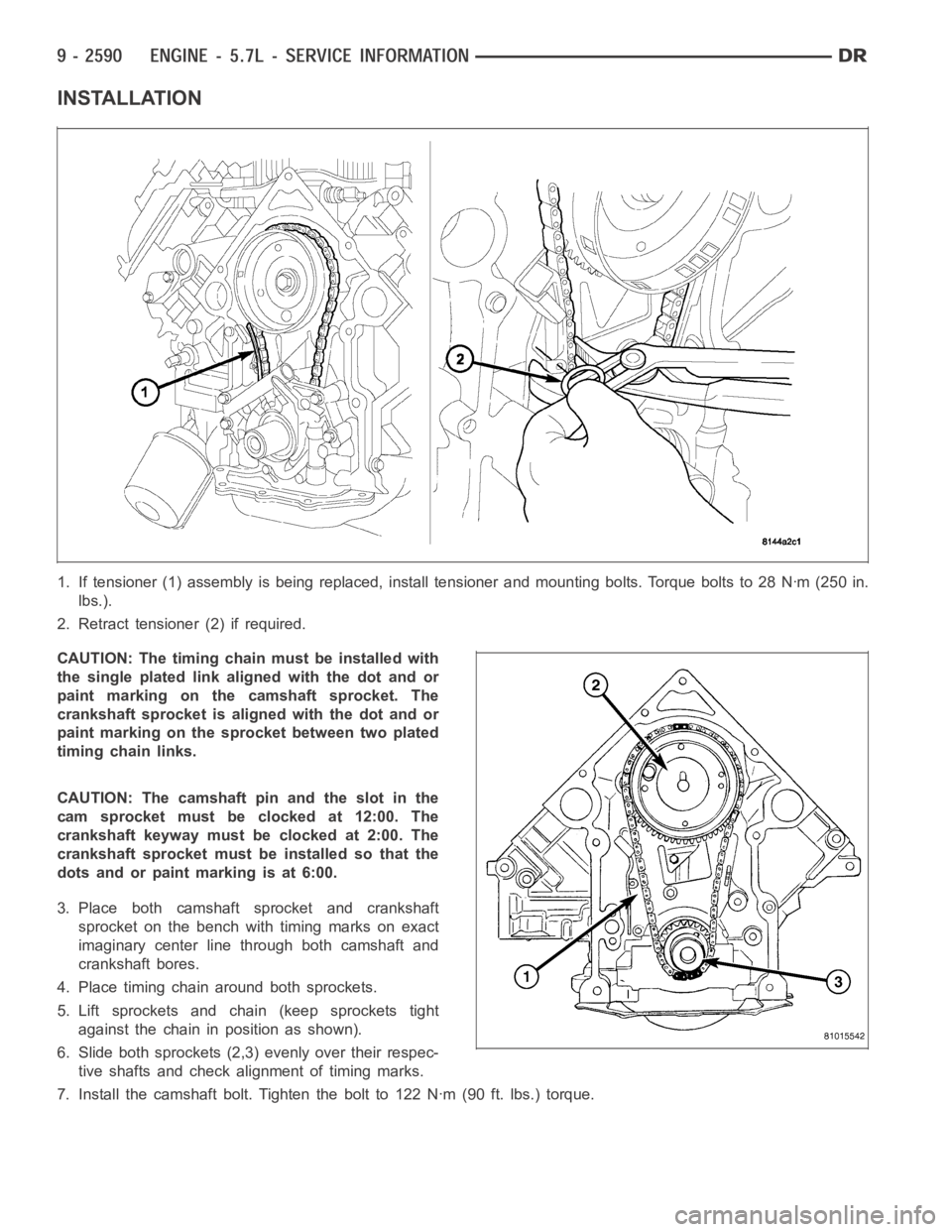

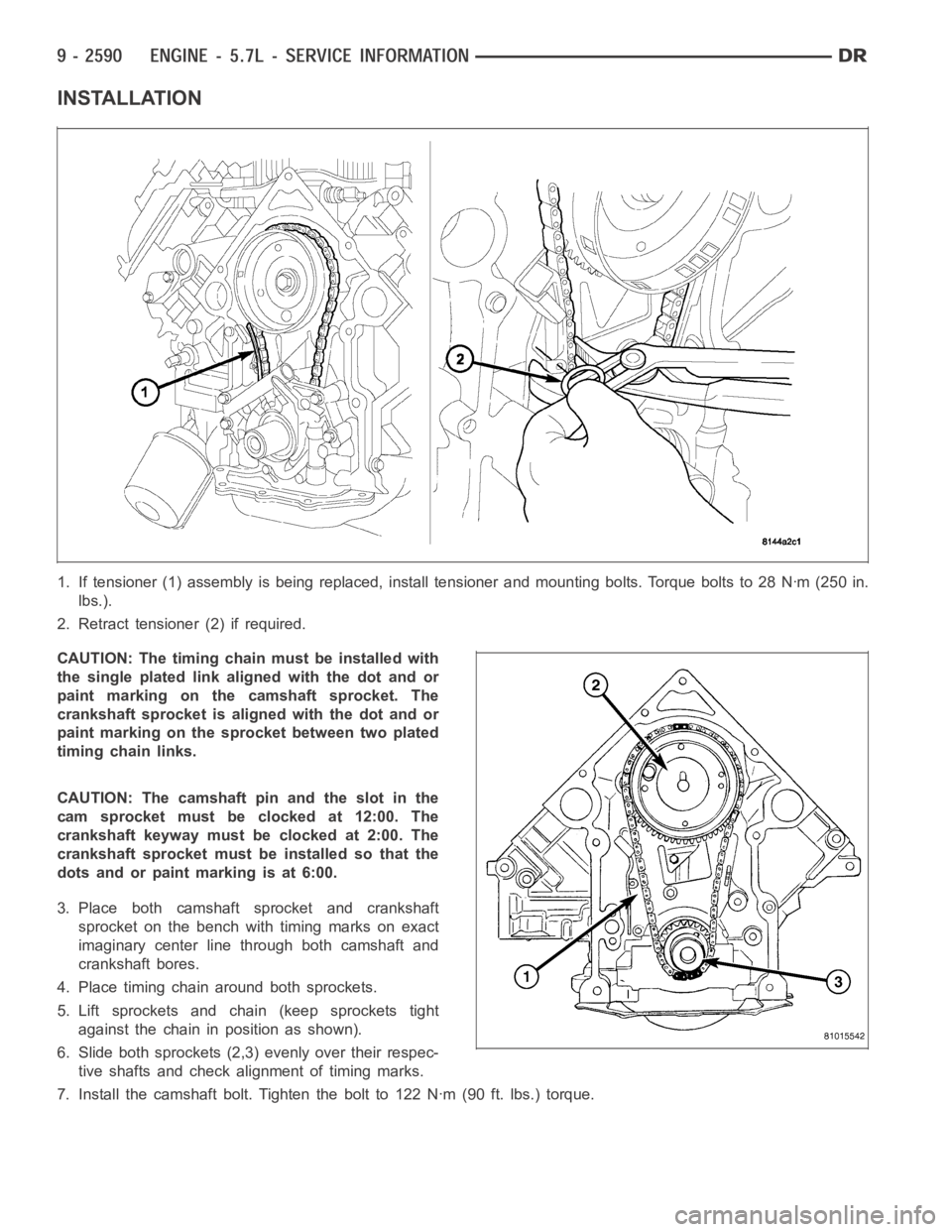

INSTALLATION

1. If tensioner (1) assembly is being replaced, install tensioner and mounting bolts. Torque bolts to 28 Nꞏm (250 in.

lbs.).

2. Retract tensioner (2) if required.

CAUTION: The timing chainmust be installed with

the single plated link aligned with the dot and or

paint marking on the camshaft sprocket. The

crankshaft sprocket is aligned with the dot and or

paint marking on the sprocket between two plated

timing chain links.

CAUTION: The camshaft pin and the slot in the

cam sprocket must be clocked at 12:00. The

crankshaft keyway must be clocked at 2:00. The

crankshaft sprocket must be installed so that the

dots and or paint marking is at 6:00.

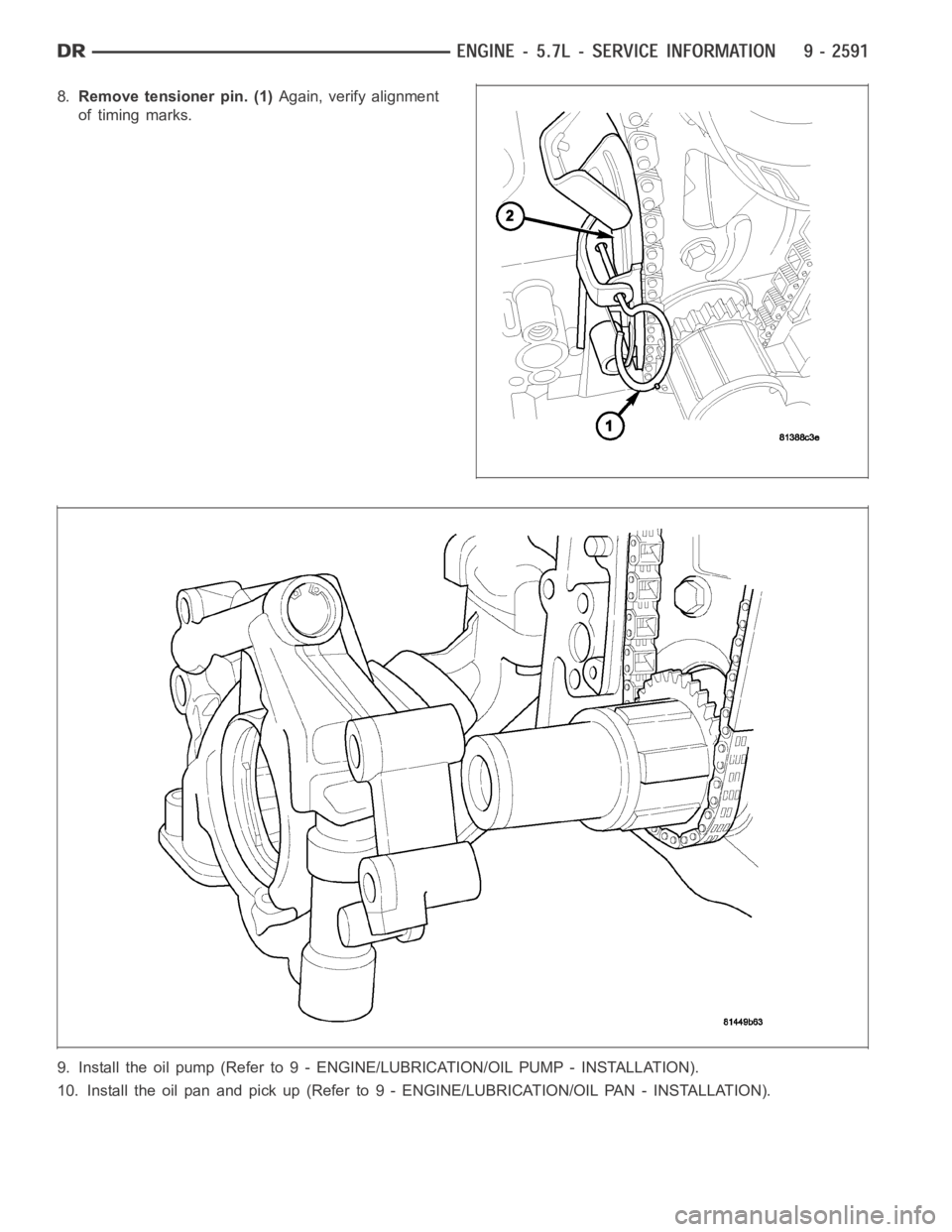

3. Place both camshaft sprocket and crankshaft

sprocket on the bench with timing marks on exact

imaginary center line through both camshaft and

crankshaft bores.

4. Place timing chain around both sprockets.

5. Lift sprockets and chain (keep sprockets tight

against the chain in position as shown).

6. Slide both sprockets (2,3) evenly over their respec-

tive shafts and check alignment of timing marks.

7. Install the camshaft bolt. Tighten the bolt to 122 Nꞏm (90 ft. lbs.) torque.

Page 1900 of 5267

8.Remove tensioner pin. (1)Again, verify alignment

of timing marks.

9. Install the oil pump (Refer to 9 - ENGINE/LUBRICATION/OIL PUMP - INSTALLAT I O N ) .

10. Install the oil pan and pick up (Refer to 9 - ENGINE/LUBRICATION/OIL PAN- INSTALLATION).

Trending: automatic transmission fluid, technical specifications, tailgate, transmission oil, lock, service interval, tow