DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1861 of 5267

Ring Position Ring/Groove Maximum

Ring Position Ring Gap Wear Limit

Upper Ring 0.23-0.38mm 0.43mm

(0.0090-0.0149 in.) (0.017 in.)

Intermediate Ring 0.35-0.60mm 0.74mm

(0.0137-0.0236 in.) (0.029 in.)

Oil Control Ring 0.015-0.66mm 0.76mm

(Steel Rail) (0.0059- 0.0259 in.) (0.030 in.)

7. The No. 1 and No. 2 piston rings have a different cross section. Ensure No.2 ring is installed with manufacturers

I.D. mark (Dot) facing up, towards top of the piston.

NOTE: Piston rings are installed in the following order:

Oil ring expander.

Lower oil ring side rail.

Upper oil ring side rail.

No. 2 Intermediate piston ring.

No. 1 Upper piston ring.

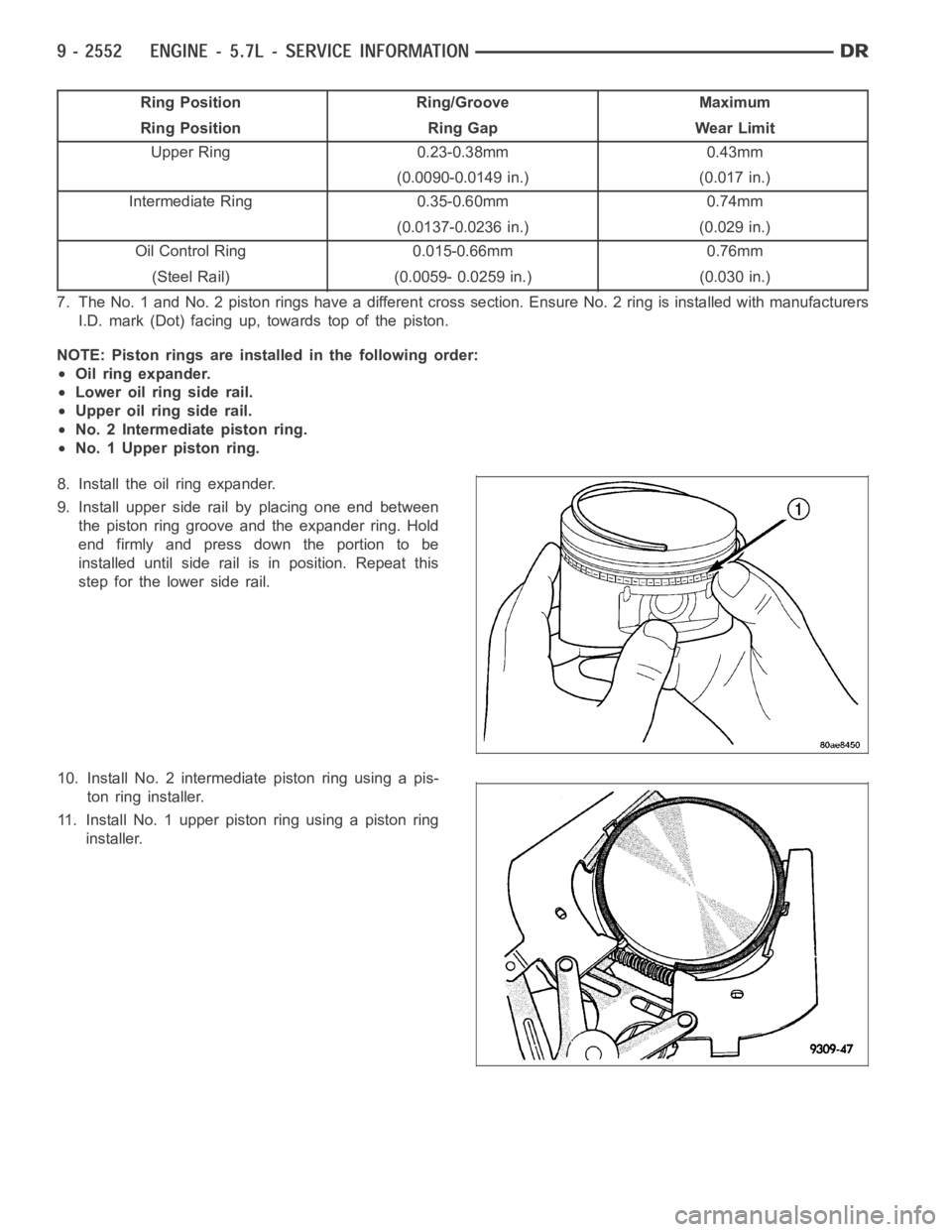

8. Install the oil ring expander.

9. Install upper side rail by placing one end between

the piston ring groove and the expander ring. Hold

end firmly and press down the portion to be

installed until side rail is in position. Repeat this

step for the lower side rail.

10. Install No. 2 intermediate piston ring using a pis-

ton ring installer.

11. Install No. 1 upper piston ring using a piston ring

installer.

Page 1862 of 5267

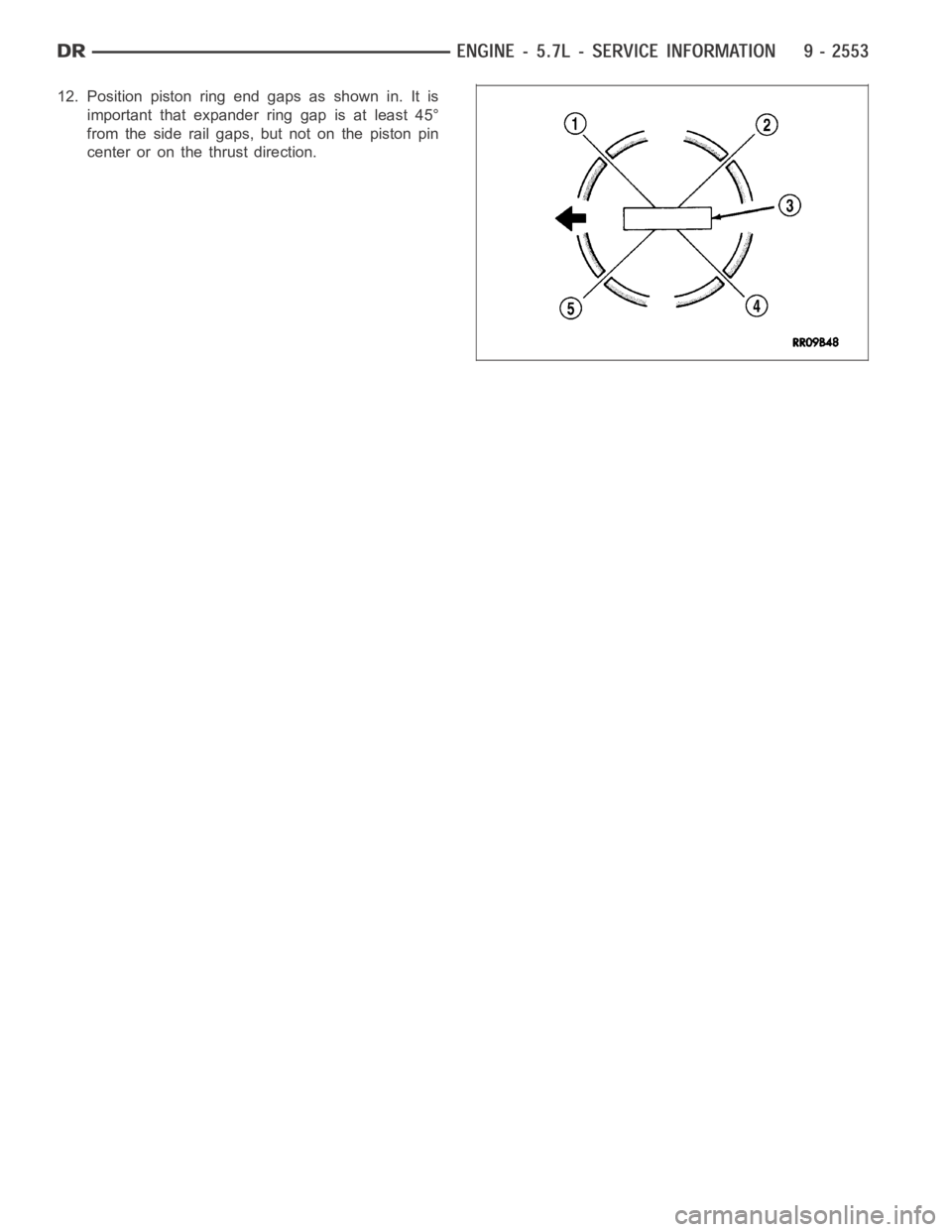

12. Position piston ring end gaps as shown in. It is

important that expander ring gap is at least 45°

from the side rail gaps, but not on the piston pin

center or on the thrust direction.

Page 1863 of 5267

DAMPER - CRANKSHAFT

REMOVAL

1. Disconnect negative cable from battery.

2. Remove accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - REMOVAL).

3. Drain cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE).

4. Remove radiator upper hose.

5. Removefanshroud(Referto7-COOLING/ENGINE/RADIATOR FAN - REMOVAL).

6. Remove crankshaft damper bolt.

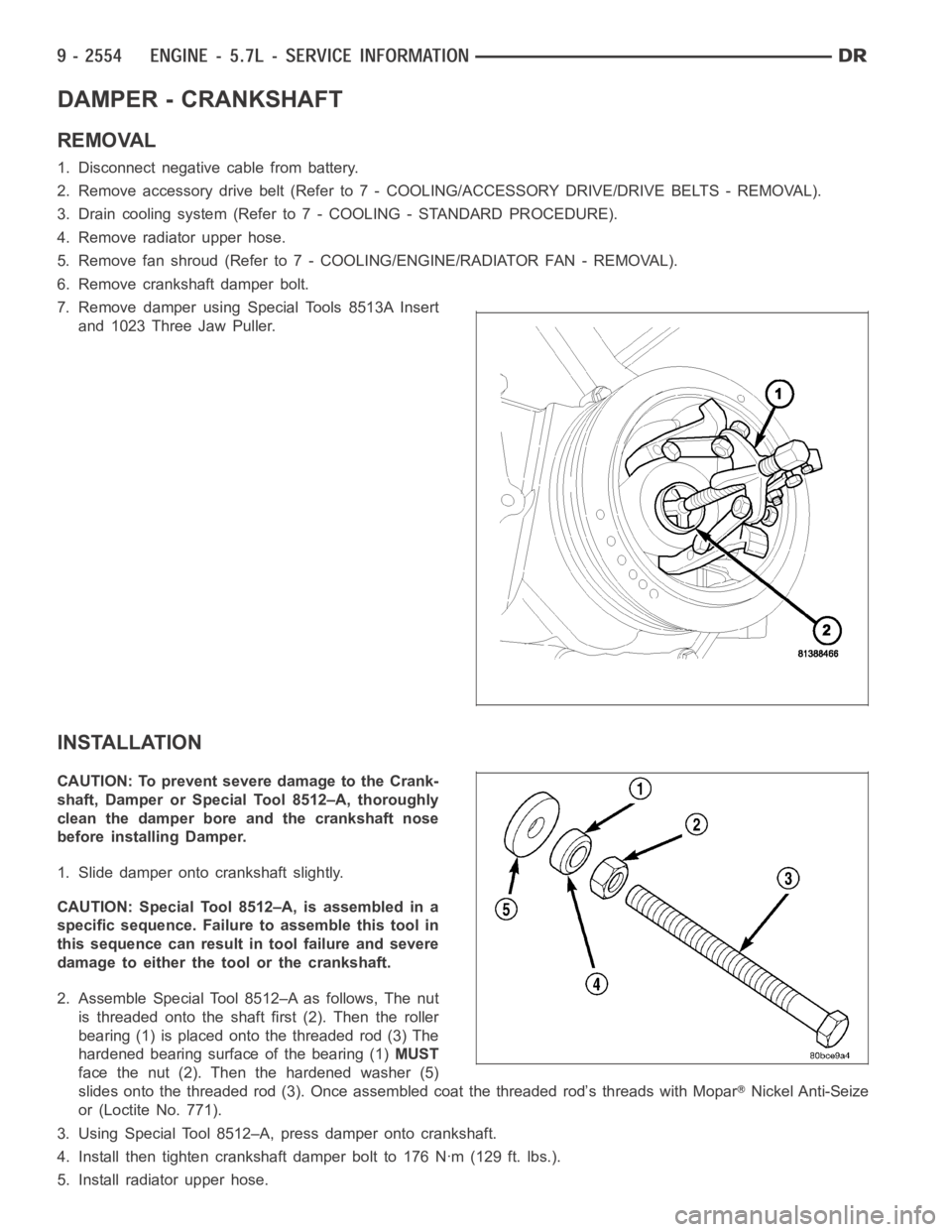

7. Remove damper using Special Tools 8513A Insert

and 1023 Three Jaw Puller.

INSTALLATION

CAUTION: To prevent severe damage to the Crank-

shaft, Damper or Special Tool 8512–A, thoroughly

clean the damper bore and the crankshaft nose

before installing Damper.

1. Slide damper onto crankshaft slightly.

CAUTION: Special Tool 8512–A, is assembled in a

specific sequence. Failure to assemble this tool in

this sequence can result in tool failure and severe

damage to either the tool or the crankshaft.

2. Assemble Special Tool 8512–A as follows, The nut

is threaded onto the shaft first (2). Then the roller

bearing (1) is placed onto the threaded rod (3) The

hardened bearing surface of the bearing (1)MUST

face the nut (2). Then the hardened washer (5)

slides onto the threaded rod (3). Once assembled coat the threaded rod’s threads with Mopar

Nickel Anti-Seize

or (Loctite No. 771).

3. Using Special Tool 8512–A, press damper onto crankshaft.

4. Install then tighten crankshaft damper bolt to 176 Nꞏm (129 ft. lbs.).

5. Install radiator upper hose.

Page 1864 of 5267

6. Install accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

7. Refill cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE).

8. Connect negative cable to battery.

Page 1865 of 5267

COVER - STRUCTURAL

DESCRIPTION

The structural dust cover is made of die cast aluminum and joins the lower half of the transmission bell housing to

the engine.

OPERATION

The structural cover provides additional powertrain stiffness and reduces noise and vibration.

REMOVAL

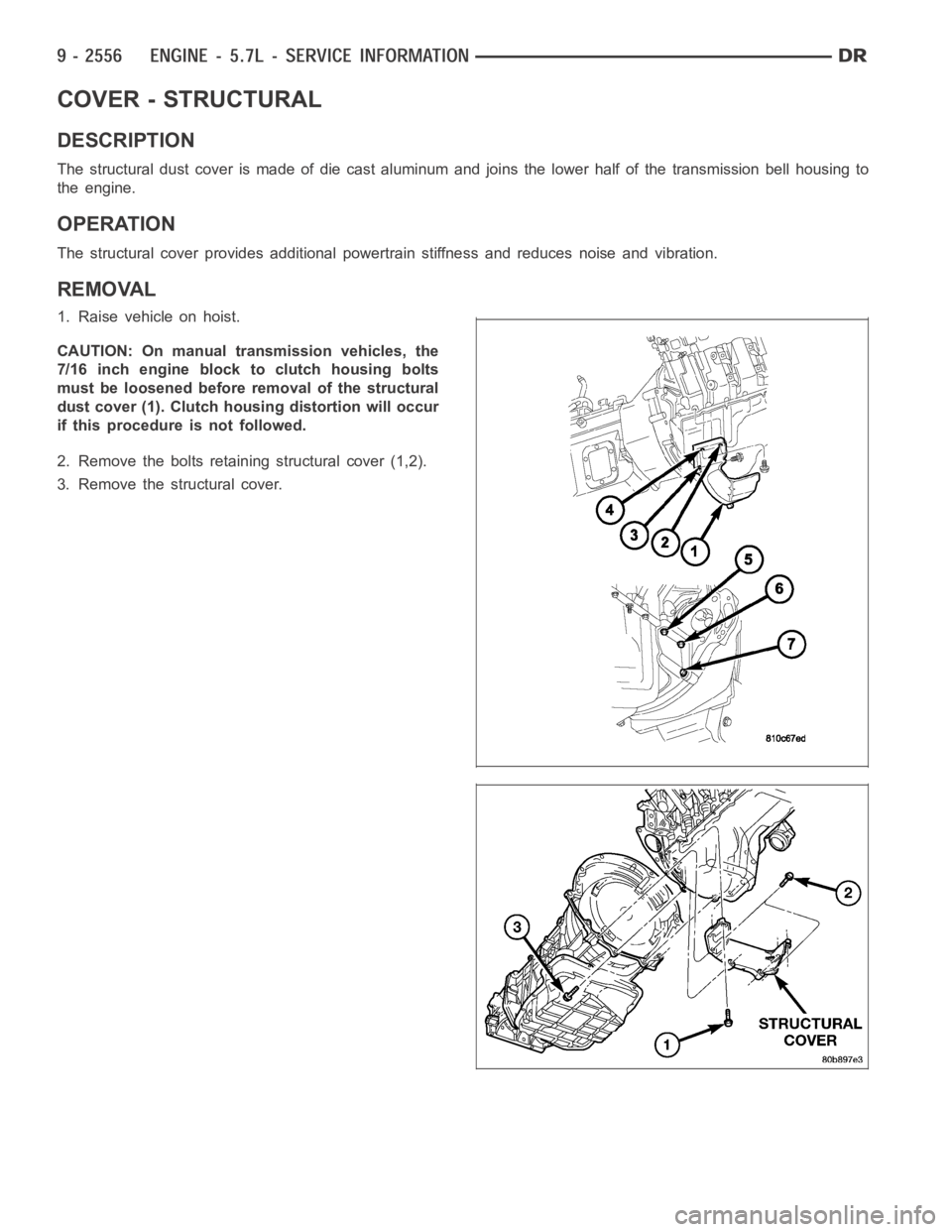

1. Raise vehicle on hoist.

CAUTION: On manual transmission vehicles, the

7/16 inch engine block to clutch housing bolts

must be loosened before removal of the structural

dust cover (1). Clutch housing distortion will occur

if this procedure is not followed.

2. Remove the bolts retaining structural cover (1,2).

3. Remove the structural cover.

Page 1866 of 5267

INSTALLATION

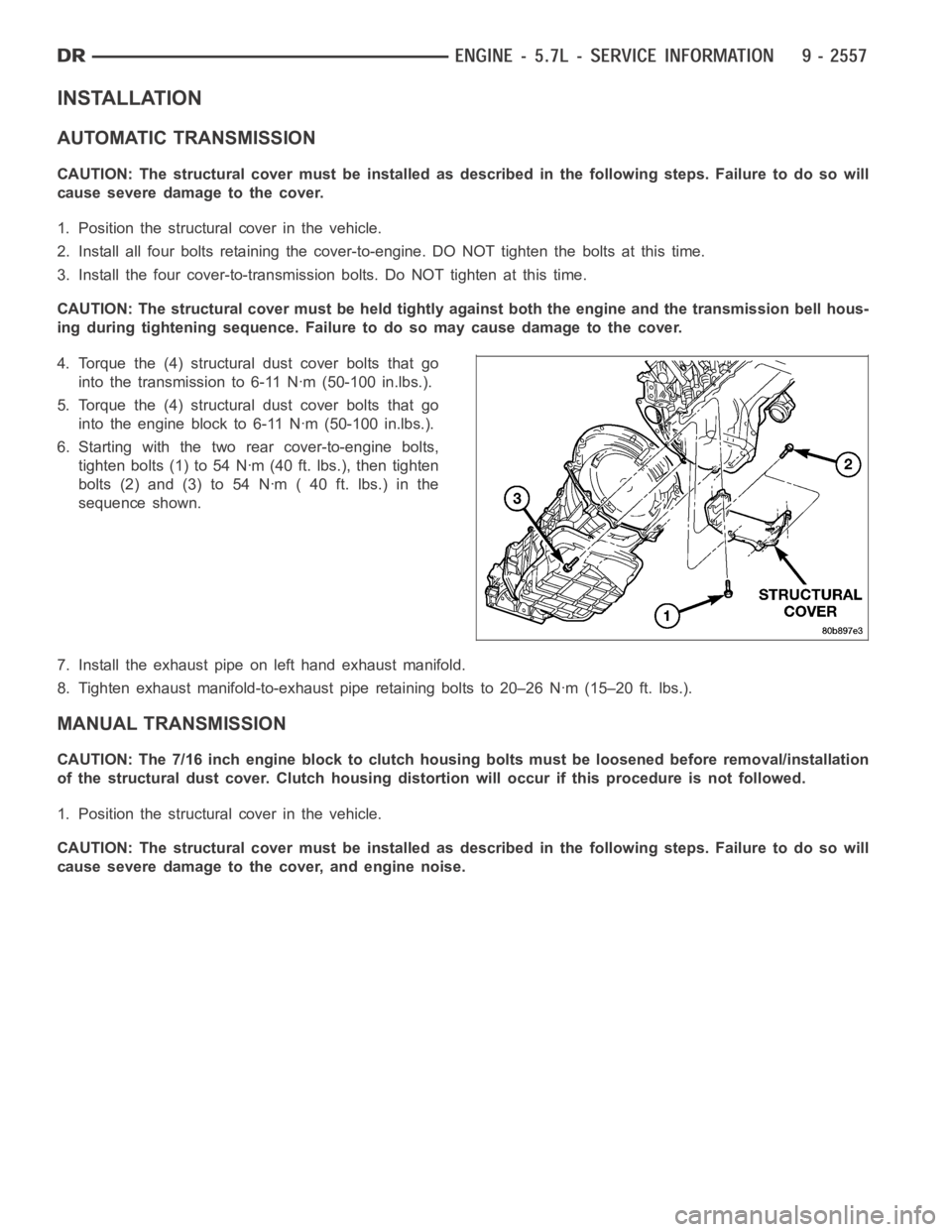

AUTOMATIC TRANSMISSION

CAUTION: The structural cover must be installed as described in the following steps. Failure to do so will

cause severe damage to the cover.

1. Position the structural cover in the vehicle.

2. Install all four bolts retaining the cover-to-engine. DO NOT tighten the bolts at this time.

3. Install the four cover-to-transmission bolts. Do NOT tighten at this time.

CAUTION: The structural cover must be held tightly against both the engineand the transmission bell hous-

ing during tightening sequence. Failure to do so may cause damage to the cover.

4. Torque the (4) structural dust cover bolts that go

intothetransmissionto6-11Nꞏm(50-100in.lbs.).

5. Torque the (4) structural dust cover bolts that go

into the engine block to 6-11 Nꞏm (50-100 in.lbs.).

6. Starting with the two rearcover-to-engine bolts,

tighten bolts (1) to 54 Nꞏm (40 ft. lbs.), then tighten

bolts(2)and(3)to54Nꞏm(40ft.lbs.)inthe

sequence shown.

7. Install the exhaust pipe on left hand exhaust manifold.

8. Tighten exhaust manifold-to-exhaust pipe retaining bolts to 20–26 Nꞏm(15–20 ft. lbs.).

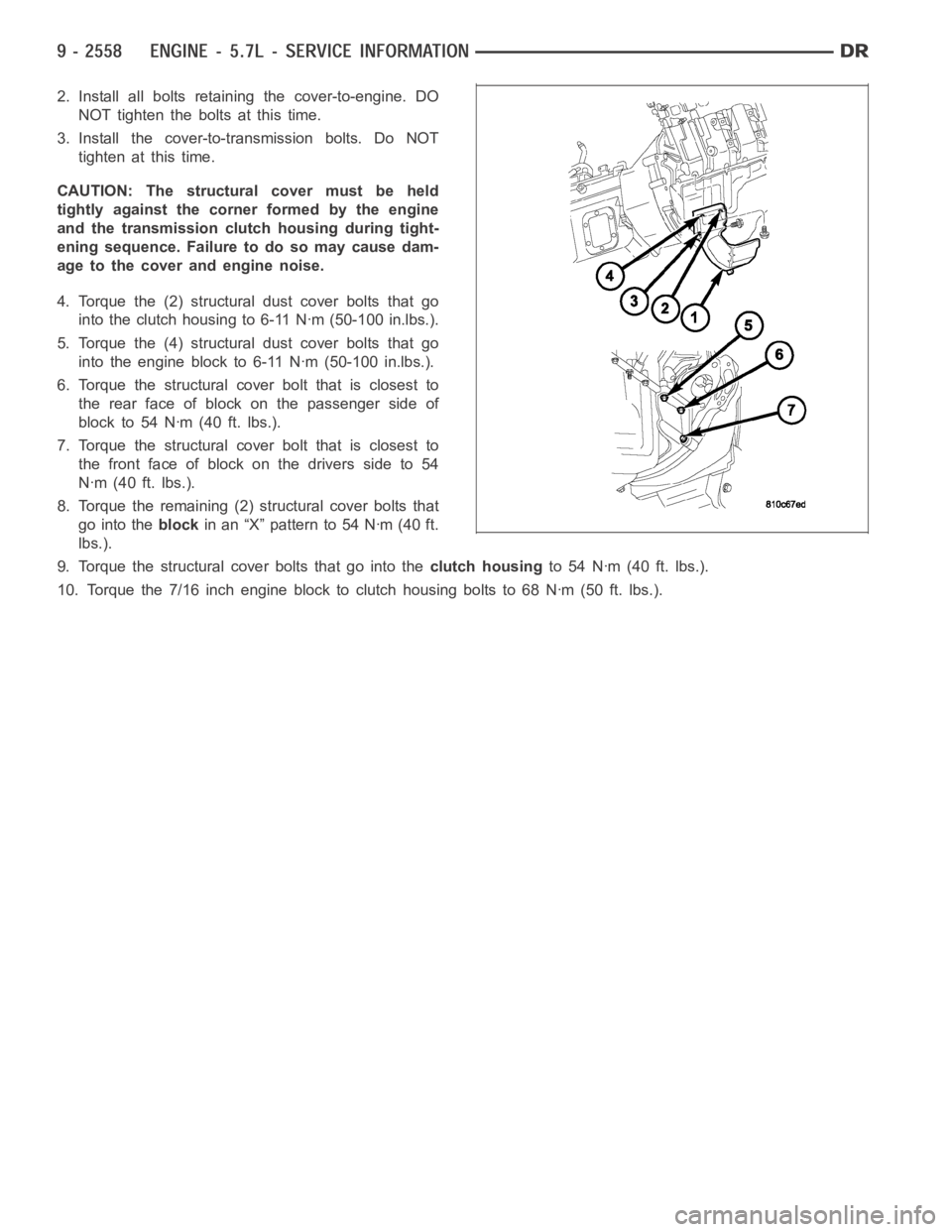

MANUAL TRANSMISSION

CAUTION: The 7/16 inch engine block to clutch housing bolts must be loosened before removal/installation

of the structural dust cover. Clutch housing distortion will occur if thisprocedure is not followed.

1. Position the structural cover in the vehicle.

CAUTION: The structural cover must be installed as described in the following steps. Failure to do so will

cause severe damage to the cover, and engine noise.

Page 1867 of 5267

2. Install all bolts retaining the cover-to-engine. DO

NOT tighten the bolts at this time.

3. Install the cover-to-transmission bolts. Do NOT

tighten at this time.

CAUTION: The structural cover must be held

tightly against the corner formed by the engine

and the transmission clutch housing during tight-

ening sequence. Failure to do so may cause dam-

age to the cover and engine noise.

4. Torque the (2) structural dust cover bolts that go

into the clutch housing to 6-11 Nꞏm (50-100 in.lbs.).

5. Torque the (4) structural dust cover bolts that go

into the engine block to 6-11 Nꞏm (50-100 in.lbs.).

6. Torque the structural cover bolt that is closest to

the rear face of block on the passenger side of

blockto54Nꞏm(40ft.lbs.).

7. Torque the structural cover bolt that is closest to

the front face of block on the drivers side to 54

Nꞏm (40 ft. lbs.).

8. Torque the remaining (2) structural cover bolts that

go into theblockin an “X” pattern to 54 Nꞏm (40 ft.

lbs.).

9. Torque the structural cover bolts that go into theclutch housingto 54 Nꞏm (40 ft. lbs.).

10. Torque the 7/16 inch engine block to clutch housing bolts to 68 Nꞏm (50 ft.lbs.).

Page 1868 of 5267

SOLENOID-MDS

DESCRIPTION

The Multi Displacement System selectively deactivates cylinders 1,4,6,and 7, to improve fuel economy. It has two

modes of operation :

8 cylinders for acceleraton and heavy loads.

4 cylinders for cruising and city traffic.

The main components of the Multi Displacement System are :

Unique MDS camshaft.

Deactivating roller tappets.

4 control valves/solenoids.

control valve/solenoid wiring harness.

oil temp sensor.

OPERATION

Cylinder Deactivation

Trap an exhaust charge from a normal combustion event

Normal combustion event

Don’t open the exhaust valve

Don’t open the intake valve

Piston is an air spring

Cylinders deactivated in firing sequence

Cylinder Reactivation

Open the exhaust valve

Empty the cylinder

Open the intake valve

Normal combustion event

Cylinders reactivated in firing sequence

DIAGNOSIS AND TESTING

The Multi Displacement System has the following detectible issues:

Solenoid circuit

Fail to deactivate a cylinder(s)

Fail to reactivate a cylinder(s)

Low oil pressure

CONDITION POSSIBLE CAUSES CORRECTION

MDS does not activate 1. Low oil pressure 1. Check for proper oil pressure

2. Bad oil temp sensor 2. Replace oil temp sensor

3. Malfunctioning MDS Solenoid 3. Replace Solenoid

4. Malfunctioning MDS Tappet 4. Replace Tappet

MDS Does Not Deactivate 1. Low oil pressure 1. Check for proper oil pressure

2. Bad oil temp sensor 2. Replace oil temp sensor

3. Malfunctioning MDS Solenoid 3. Replace Solenoid

4. Malfunctioning MDS Tappet 4. Replace Tappet

Page 1869 of 5267

REMOVAL

1. Disconnect the negative battery cable.

2. Remove the intake manifold. (Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANIFOLD - REMOVAL).

3. Remove wiring harness connectors from the MDS solenoids.

4. Remove hold down bolt from MDS solenoid.

5. Remove MDS solenoid.

INSTALLATION

1. Verify that MDS bores are free of debris, before solenoid installation.

2. Install MDS solenoid fully into block.

3. Install hold down bolt and torque to 11 Nꞏm (97 in. lbs.).

4. Reconnect the MDS wiring harness to the solenoids.

5. Install the intake manifold. (Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANIFOLD - INSTALLATION).

Page 1870 of 5267

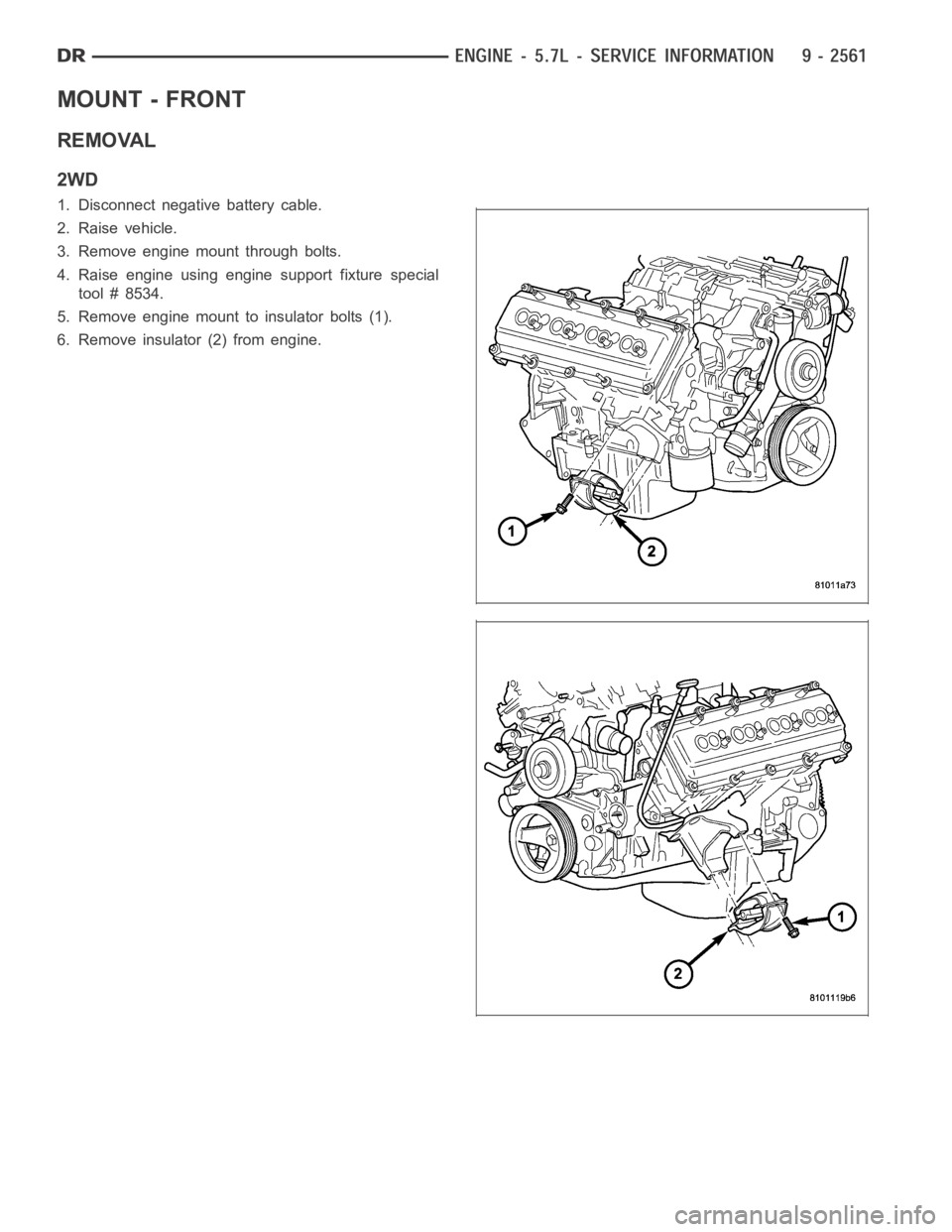

MOUNT - FRONT

REMOVAL

2WD

1. Disconnect negative battery cable.

2. Raise vehicle.

3. Remove engine mount through bolts.

4. Raise engine using engine support fixture special

tool # 8534.

5. Remove engine mount to insulator bolts (1).

6. Remove insulator (2) from engine.