DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1851 of 5267

FLEX PLATE

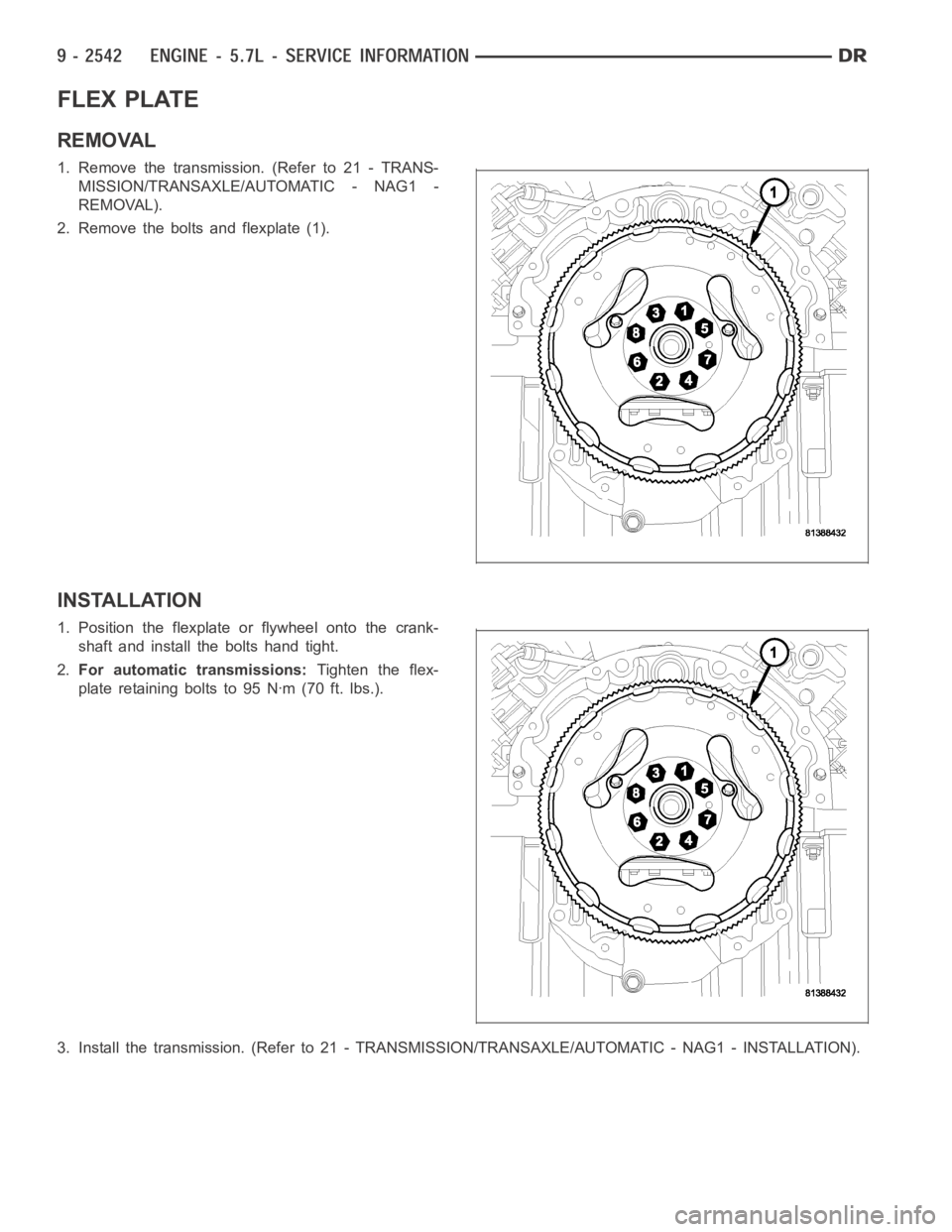

REMOVAL

1. Remove the transmission. (Refer to 21 - TRANS-

MISSION/TRANSAXLE/AUTOMATIC - NAG1 -

REMOVAL).

2. Remove the bolts and flexplate (1).

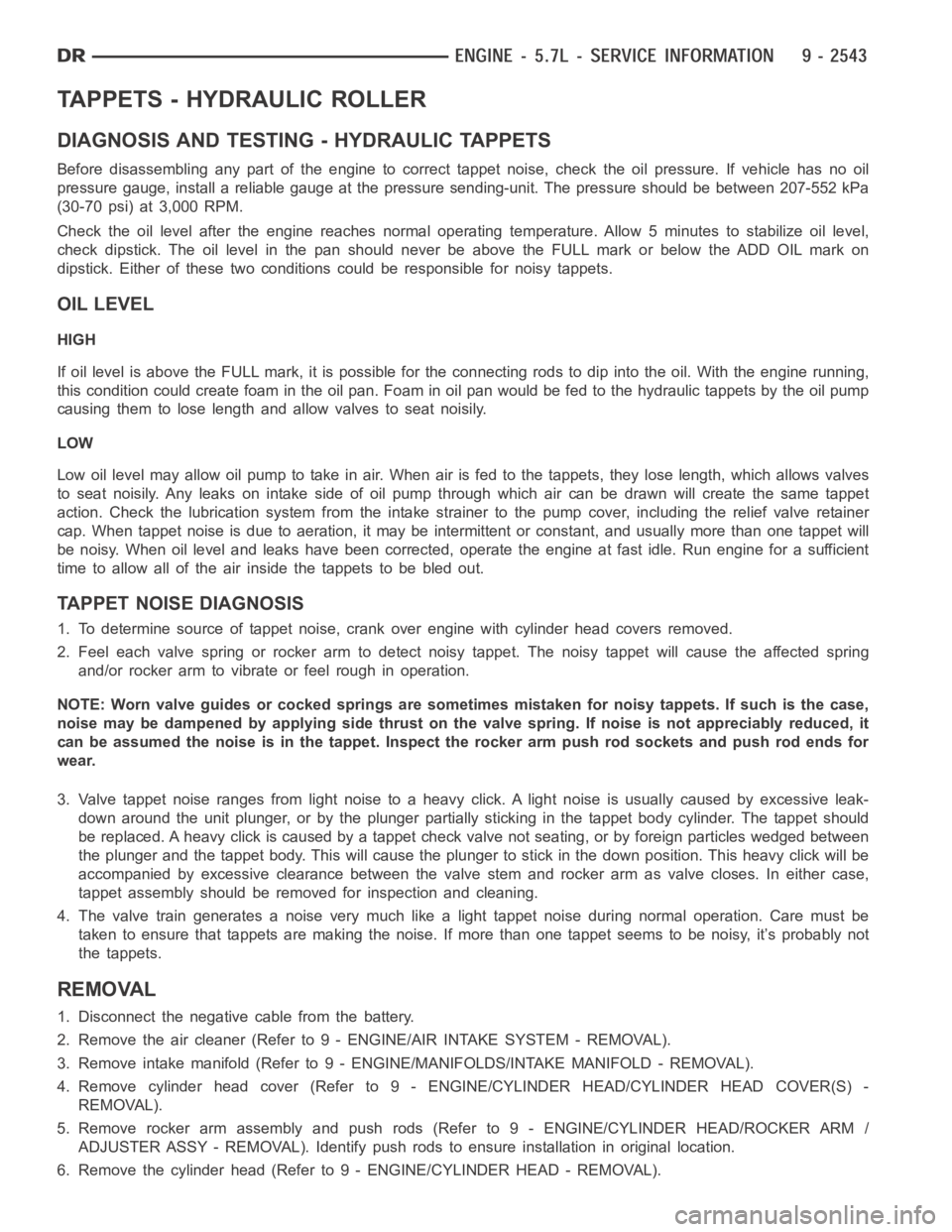

INSTALLATION

1. Position the flexplate or flywheel onto the crank-

shaft and install the bolts hand tight.

2.For automatic transmissions:Tighten the flex-

plate retaining bolts to 95 Nꞏm (70 ft. lbs.).

3. Install the transmission. (Refer to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - NAG1 - INSTALLATION).

Page 1852 of 5267

TAPPETS - HYDRAULIC ROLLER

DIAGNOSIS AND TESTING - HYDRAULIC TAPPETS

Before disassembling any part of the engine to correct tappet noise, checkthe oil pressure. If vehicle has no oil

pressure gauge, install a reliable gauge at the pressure sending-unit. The pressure should be between 207-552 kPa

(30-70 psi) at 3,000 RPM.

Check the oil level after the engine reaches normal operating temperature. Allow 5 minutes to stabilize oil level,

check dipstick. The oil level in the pan should never be above the FULL mark or below the ADD OIL mark on

dipstick. Either of these two conditions could be responsible for noisy tappets.

OIL LEVEL

HIGH

If oil level is above the FULL mark, it is possible for the connecting rods todip into the oil. With the engine running,

this condition could create foam in the oil pan. Foam in oil pan would be fed to the hydraulic tappets by the oil pump

causing them to lose length and allow valves to seat noisily.

LOW

Low oil level may allow oil pump to take in air. When air is fed to the tappets,they lose length, which allows valves

to seat noisily. Any leaks on intake side of oil pump through which air can bedrawn will create the same tappet

action. Check the lubrication system from the intake strainer to the pump cover, including the relief valve retainer

cap. When tappet noise is due to aeration, it may be intermittent or constant, and usually more than one tappet will

be noisy. When oil level and leaks have been corrected, operate the engine at fast idle. Run engine for a sufficient

time to allow all of the air inside the tappets to be bled out.

TAPPET NOISE DIAGNOSIS

1. To determine source of tappet noise, crank over engine with cylinder head covers removed.

2. Feel each valve spring or rocker arm to detect noisy tappet. The noisy tappet will cause the affected spring

and/or rocker arm to vibrate or feel rough in operation.

NOTE: Worn valve guides or cocked springs are sometimes mistaken for noisytappets. If such is the case,

noise may be dampened by applying side thrust on the valve spring. If noise is not appreciably reduced, it

can be assumed the noise is in the tappet. Inspect the rocker arm push rod sockets and push rod ends for

wear.

3. Valve tappet noise ranges from light noise to a heavy click. A light noiseis usually caused by excessive leak-

down around the unit plunger, or by the plunger partially sticking in the tappet body cylinder. The tappet should

be replaced. A heavy click is caused by a tappet check valve not seating, or by foreign particles wedged between

the plunger and the tappet body. This will cause the plunger to stick in the down position. This heavy click will be

accompanied by excessive clearance between the valve stem and rocker arm as valve closes. In either case,

tappet assembly should be removed for inspection and cleaning.

4. The valve train generates a noise very much like a light tappet noise during normal operation. Care must be

taken to ensure that tappets are making the noise. If more than one tappet seems to be noisy, it’s probably not

the tappets.

REMOVAL

1. Disconnect the negative cable from the battery.

2. Remove the air cleaner (Refer to 9 - ENGINE/AIR INTAKE SYSTEM - REMOVAL).

3. Remove intake manifold (Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANIFOLD-REMOVAL).

4. Remove cylinder head cover (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDERHEAD COVER(S) -

REMOVAL).

5. Remove rocker arm assembly and push rods (Refer to 9 - ENGINE/CYLINDER HEAD/ROCKER ARM /

ADJUSTER ASSY - REMOVAL). Identify push rods to ensure installation in original location.

6. Remove the cylinder head (Refer to 9 - ENGINE/CYLINDER HEAD - REMOVAL).

Page 1853 of 5267

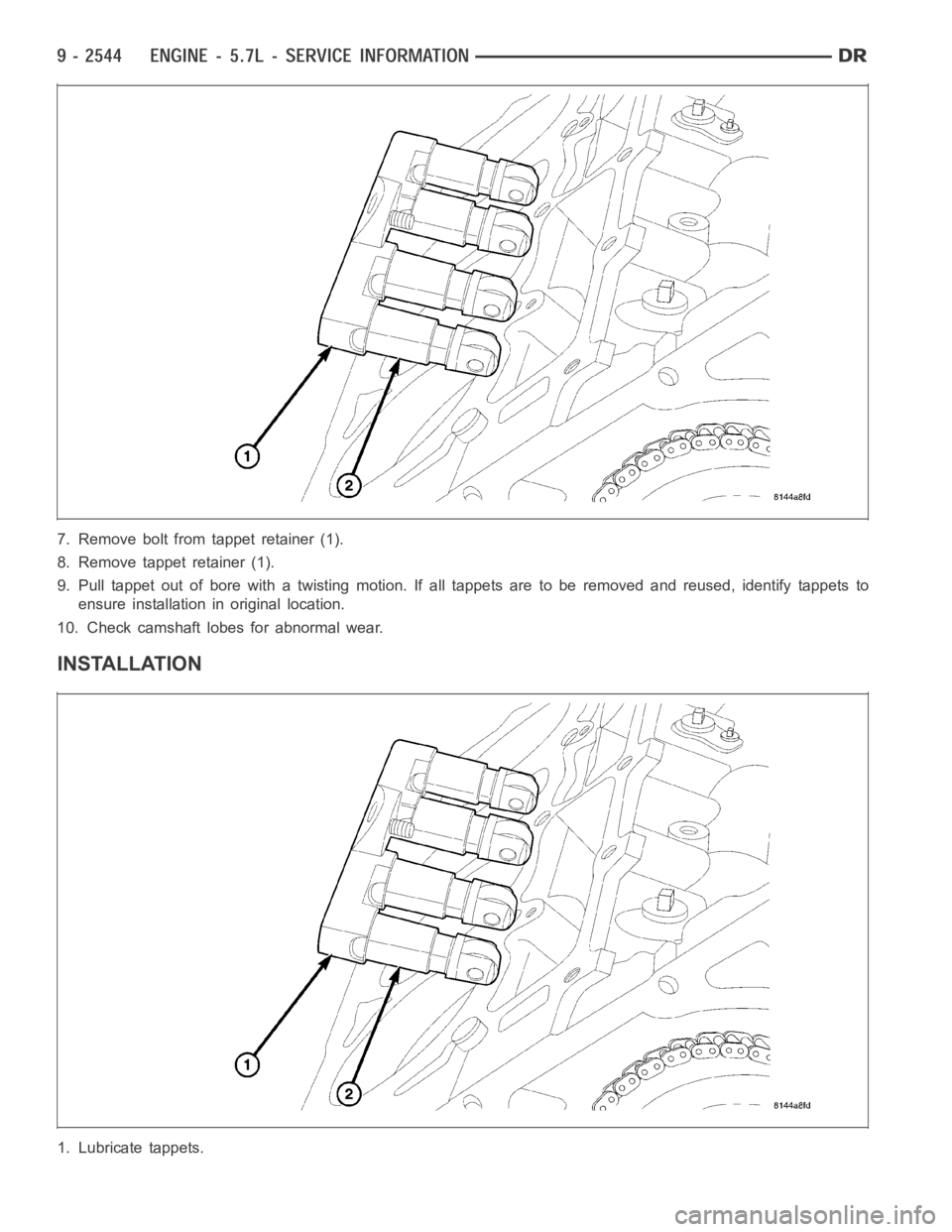

7. Remove bolt from tappet retainer (1).

8. Remove tappet retainer (1).

9. Pull tappet out of bore with a twisting motion. If all tappets are to be removed and reused, identify tappets to

ensure installation in original location.

10. Check camshaft lobes for abnormal wear.

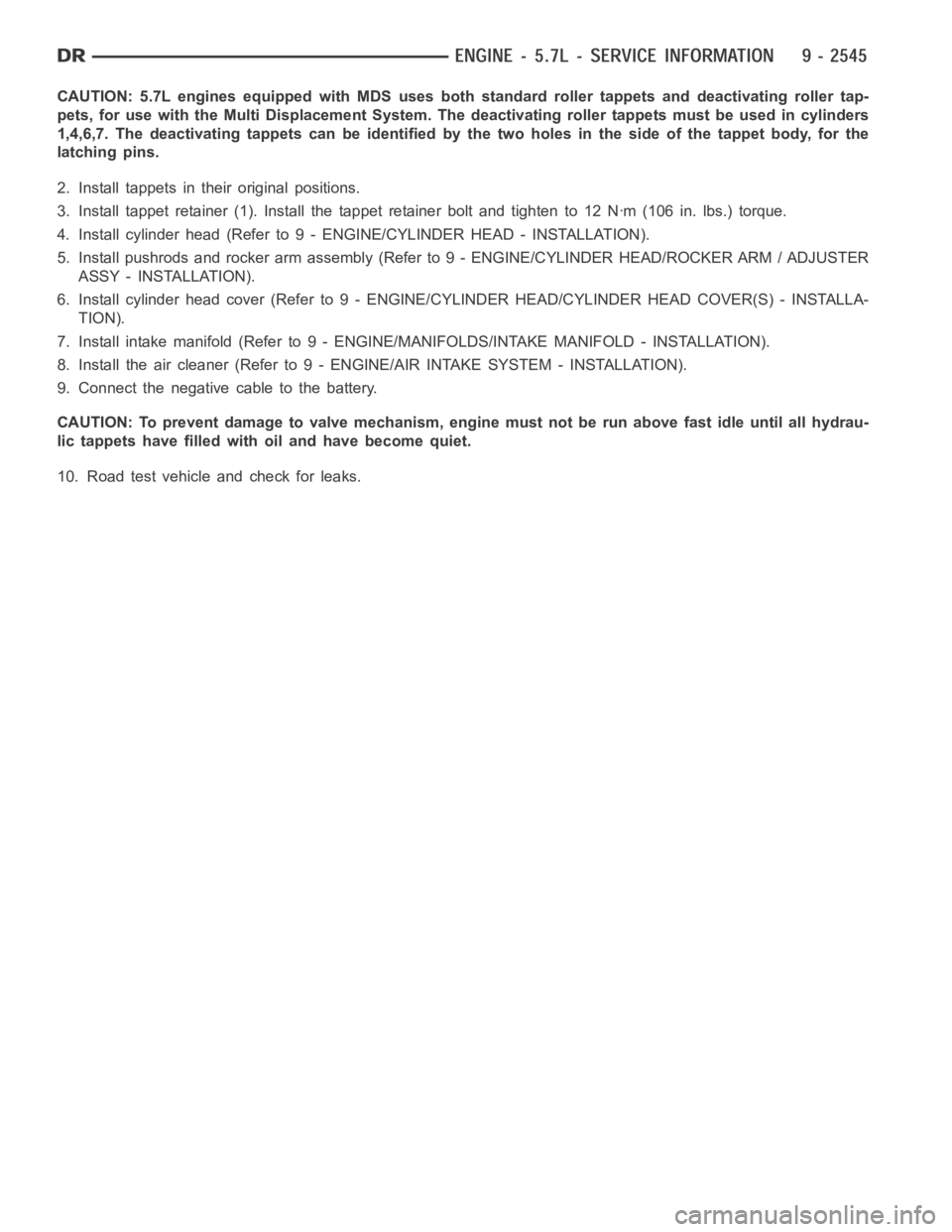

INSTALLATION

1. Lubricate tappets.

Page 1854 of 5267

CAUTION: 5.7L engines equipped with MDS uses both standard roller tappetsand deactivating roller tap-

pets, for use with the Multi Displacement System. The deactivating rollertappets must be used in cylinders

1,4,6,7. The deactivating tappets can be identified by the two holes in theside of the tappet body, for the

latching pins.

2. Install tappets in their original positions.

3. Install tappet retainer (1). Install the tappet retainer bolt and tighten to 12 Nꞏm (106 in. lbs.) torque.

4. Install cylinder head (Refer to 9 - ENGINE/CYLINDER HEAD - INSTALLATION).

5. Install pushrods and rocker arm assembly (Refer to 9 - ENGINE/CYLINDER HEAD/ROCKER ARM / ADJUSTER

ASSY - INSTALLATION).

6. Install cylinder head cover (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) - INSTALLA-

TION).

7. Install intake manifold (Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANIFOLD-INSTALLATION).

8. Install the air cleaner (Refer to 9 - ENGINE/AIR INTAKE SYSTEM - INSTALLATION).

9. Connect the negative cable to the battery.

CAUTION: To prevent damage to valve mechanism, engine must not be run abovefast idle until all hydrau-

lic tappets have filled with oil and have become quiet.

10. Road test vehicle and check for leaks.

Page 1855 of 5267

PISTON & CONNECTING ROD

DESCRIPTION

CAUTION: Do not use a metal stamp to mark connecting rods as damage may result, instead use ink or a

scratch awl.

The pistons are made of a high strength aluminum alloy. Piston skirts are coated with a solid lubricant (Molykote) to

reduce friction and provide scuff resistance. The piston top ring groove and land is anodized. The connecting rods

are made of forged powdered metal, with a “fractured cap” design. A pressedfit piston pin is used to attach the

piston and connecting rod.

STANDARD PROCEDURE - PISTON FITTING

1. To correctly select the proper size piston, a cylinder bore gauge, capable of reading in 0.003 mm ( .0001 in.)

INCREMENTS is required. If a bore gauge is not available, do not use an insidemicrometer.

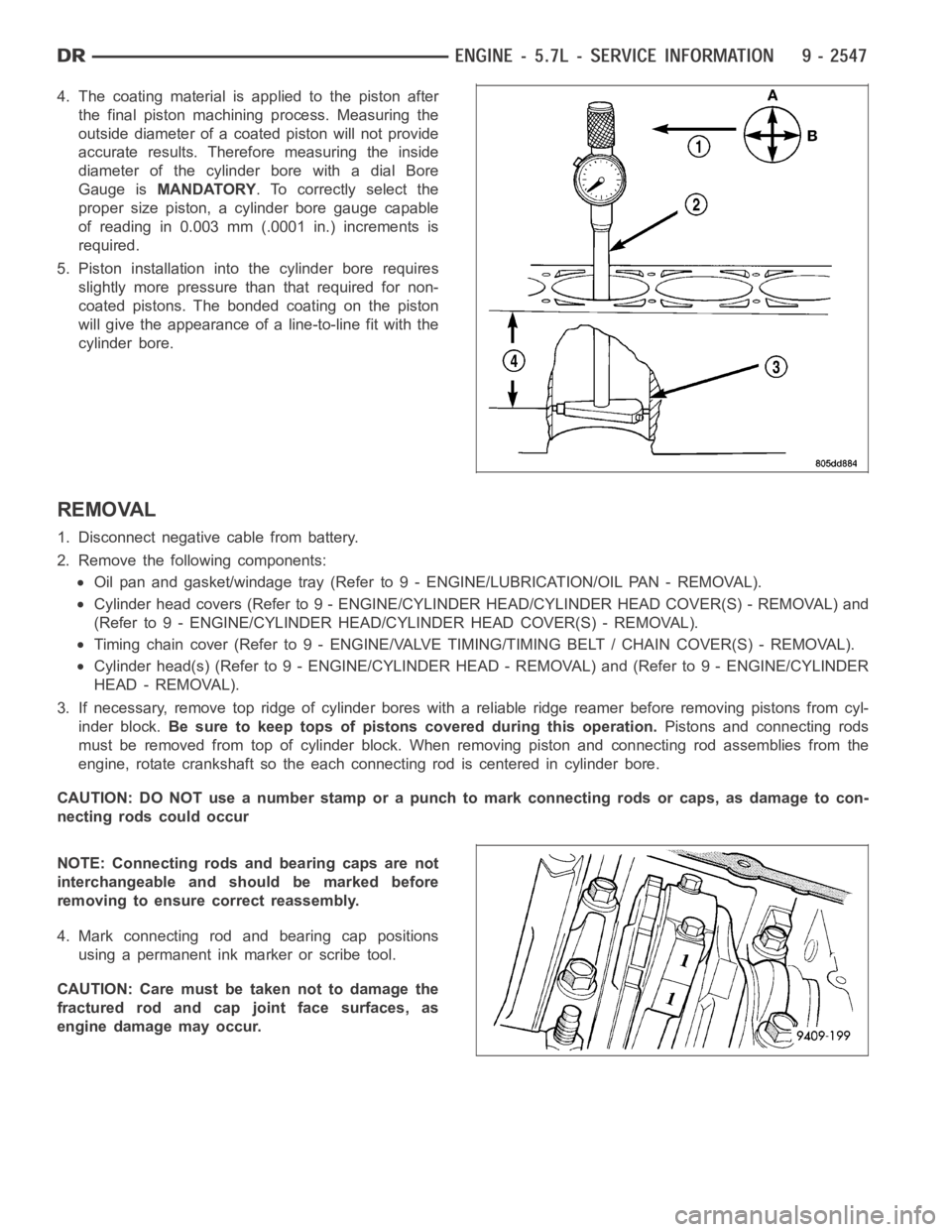

2. Measure the inside diameter of the cylinder bore at a point 38.0 mm (1.5 inches) below top of bore. Start per-

pendicular (across or at 90 degrees) to the axis of the crankshaft at point Aand then take an additional bore

reading 90 degrees to that at point B.

3. The coated pistons will be serviced with the piston pin and connecting rod pre-assembled. The piston-rod assem-

bly is specific for the left cylinder bank ( odd numbered) and the right cylinder bank ( even numbered) and must

not be interchanged.

Page 1856 of 5267

4. The coating material is applied to the piston after

the final piston machining process. Measuring the

outside diameter of a coated piston will not provide

accurate results. Therefore measuring the inside

diameter of the cylinder bore with a dial Bore

Gauge isMANDATORY. To correctly select the

proper size piston, a cylinder bore gauge capable

of reading in 0.003 mm (.0001 in.) increments is

required.

5. Piston installation intothe cylinder bore requires

slightly more pressure than that required for non-

coated pistons. The bonded coating on the piston

will give the appearance of a line-to-line fit with the

cylinder bore.

REMOVAL

1. Disconnect negative cable from battery.

2. Remove the following components:

Oil pan and gasket/windage tray (Refer to 9 - ENGINE/LUBRICATION/OIL PAN -REMOVAL).

Cylinder head covers (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) - REMOVAL) and

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) - REMOVAL).

Timing chain cover (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT / CHAIN COVER(S) - REMOVAL).

Cylinder head(s) (Refer to 9 - ENGINE/CYLINDER HEAD - REMOVAL) and (Refer to 9 - ENGINE/CYLINDER

HEAD - REMOVAL).

3. If necessary, remove top ridge of cylinder bores with a reliable ridge reamer before removing pistons from cyl-

inder block.Be sure to keep tops of pistons covered during this operation.Pistons and connecting rods

must be removed from top of cylinder block. When removing piston and connecting rod assemblies from the

engine, rotate crankshaft so the each connecting rod is centered in cylinder bore.

CAUTION: DO NOT use a number stamp or a punch to mark connecting rods or caps,as damage to con-

necting rods could occur

NOTE: Connecting rods and bearing caps are not

interchangeable and should be marked before

removing to ensure correct reassembly.

4. Mark connecting rod and bearing cap positions

using a permanent ink marker or scribe tool.

CAUTION: Care must be taken not to damage the

fractured rod and cap joint face surfaces, as

engine damage may occur.

Page 1857 of 5267

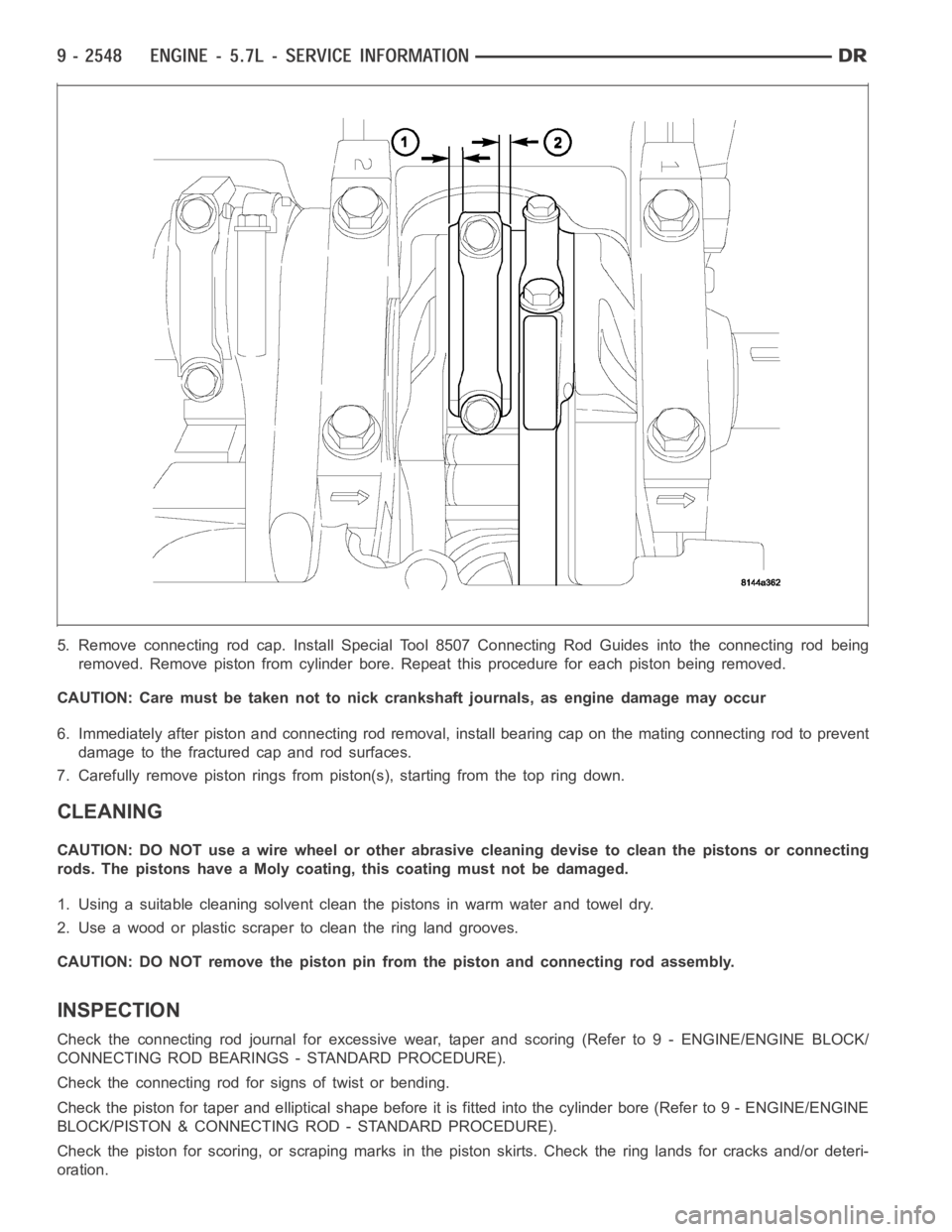

5. Remove connecting rod cap. Install Special Tool 8507 Connecting Rod Guides into the connecting rod being

removed. Remove piston from cylinder bore. Repeat this procedure for eachpiston being removed.

CAUTION: Care must be taken not to nick crankshaft journals, as engine damage may occur

6. Immediately after piston and connecting rod removal, install bearing cap on the mating connecting rod to prevent

damage to the fractured cap and rod surfaces.

7. Carefully remove piston rings from piston(s), starting from the top ring down.

CLEANING

CAUTION: DO NOT use a wire wheel or other abrasive cleaning devise to clean the pistons or connecting

rods. The pistons have a Moly coating, this coating must not be damaged.

1. Using a suitable cleaning solvent clean the pistons in warm water and towel dry.

2. Use a wood or plastic scraper to clean the ring land grooves.

CAUTION: DO NOT remove the piston pin from the piston and connecting rod assembly.

INSPECTION

Check the connecting rod journal for excessive wear, taper and scoring (Refer to 9 - ENGINE/ENGINE BLOCK/

CONNECTING ROD BEARINGS - STANDARD PROCEDURE).

Check the connecting rod for signs of twist or bending.

Check the piston for taper and elliptical shape before it is fitted into thecylinder bore (Refer to 9 - ENGINE/ENGINE

BLOCK/PISTON & CONNECTING ROD - STANDARD PROCEDURE).

Check the piston for scoring, or scraping marks in the piston skirts. Checkthe ring lands for cracks and/or deteri-

oration.

Page 1858 of 5267

INSTALLATION

1. Before installing piston and connecting rod assemblies into the bore, install the piston rings (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON RINGS - STANDARD PROCEDURE).

2. Immerse the piston head and rings in clean engine oil. Position a ring compressor over the piston and rings.

Tighten ring compressor.Ensure position of rings do not change during this operation.

3. Position bearing onto connecting rod. Lubricate bearing surface with clean engine oil.

4. Install Special Tool 8507 Connecting Rod Guides into connecting rod bolt threads.

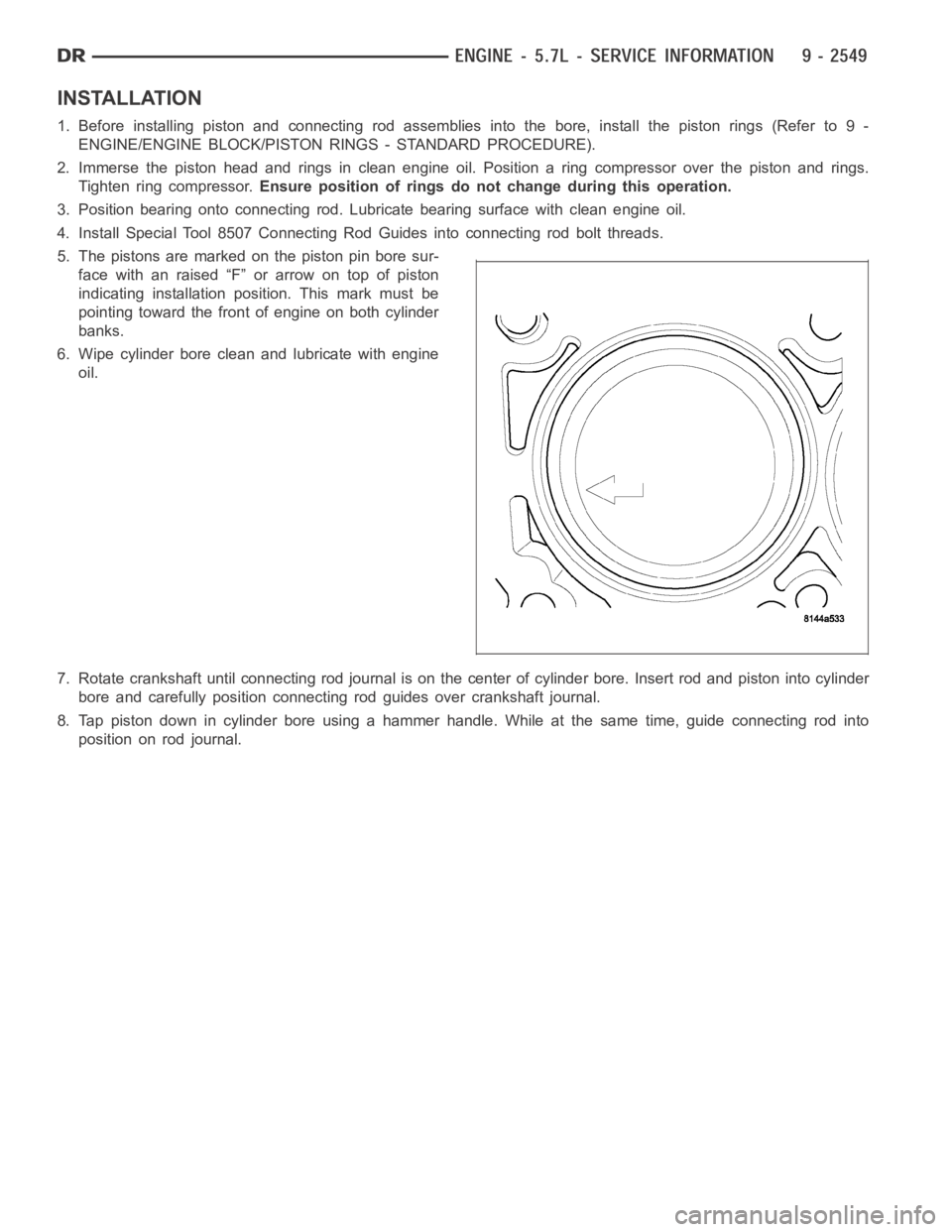

5. The pistons are marked on the piston pin bore sur-

face with an raised “F” or arrow on top of piston

indicating installation position. This mark must be

pointing toward the front of engine on both cylinder

banks.

6. Wipe cylinder bore clean and lubricate with engine

oil.

7. Rotate crankshaft until connecting rod journal is on the center of cylinder bore. Insert rod and piston into cylinder

bore and carefully position connecting rod guides over crankshaft journal.

8. Tap piston down in cylinder bore using a hammer handle. While at the same time, guide connecting rod into

position on rod journal.

Page 1859 of 5267

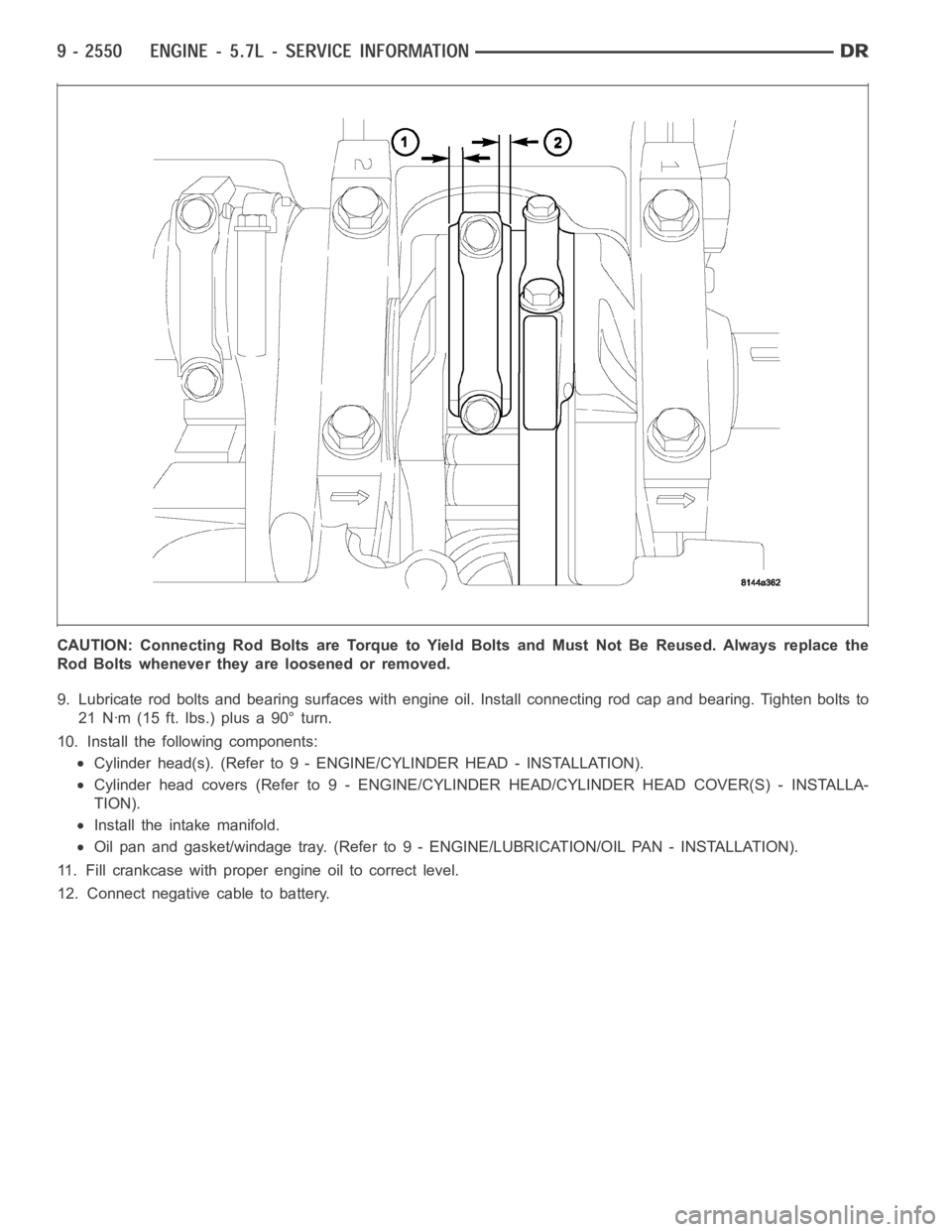

CAUTION: Connecting Rod Bolts are Torque to Yield Bolts and Must Not Be Reused. Always replace the

Rod Bolts whenever they are loosened or removed.

9. Lubricate rod bolts and bearing surfaces with engine oil. Install connecting rod cap and bearing. Tighten bolts to

21 Nꞏm (15 ft. lbs.) plus a 90° turn.

10. Install the following components:

Cylinder head(s). (Refer to 9 - ENGINE/CYLINDER HEAD - INSTALLATION).

Cylinderheadcovers(Referto9-ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) - INSTALLA-

TION).

Install the intake manifold.

Oil pan and gasket/windage tray. (Refer to 9 - ENGINE/LUBRICATION/OIL PAN- INSTALLATION).

11. Fill crankcase with proper engine oil to correct level.

12. Connect negative cable to battery.

Page 1860 of 5267

RINGS - PISTON

STANDARD PROCEDURE - PISTON RING FITTING

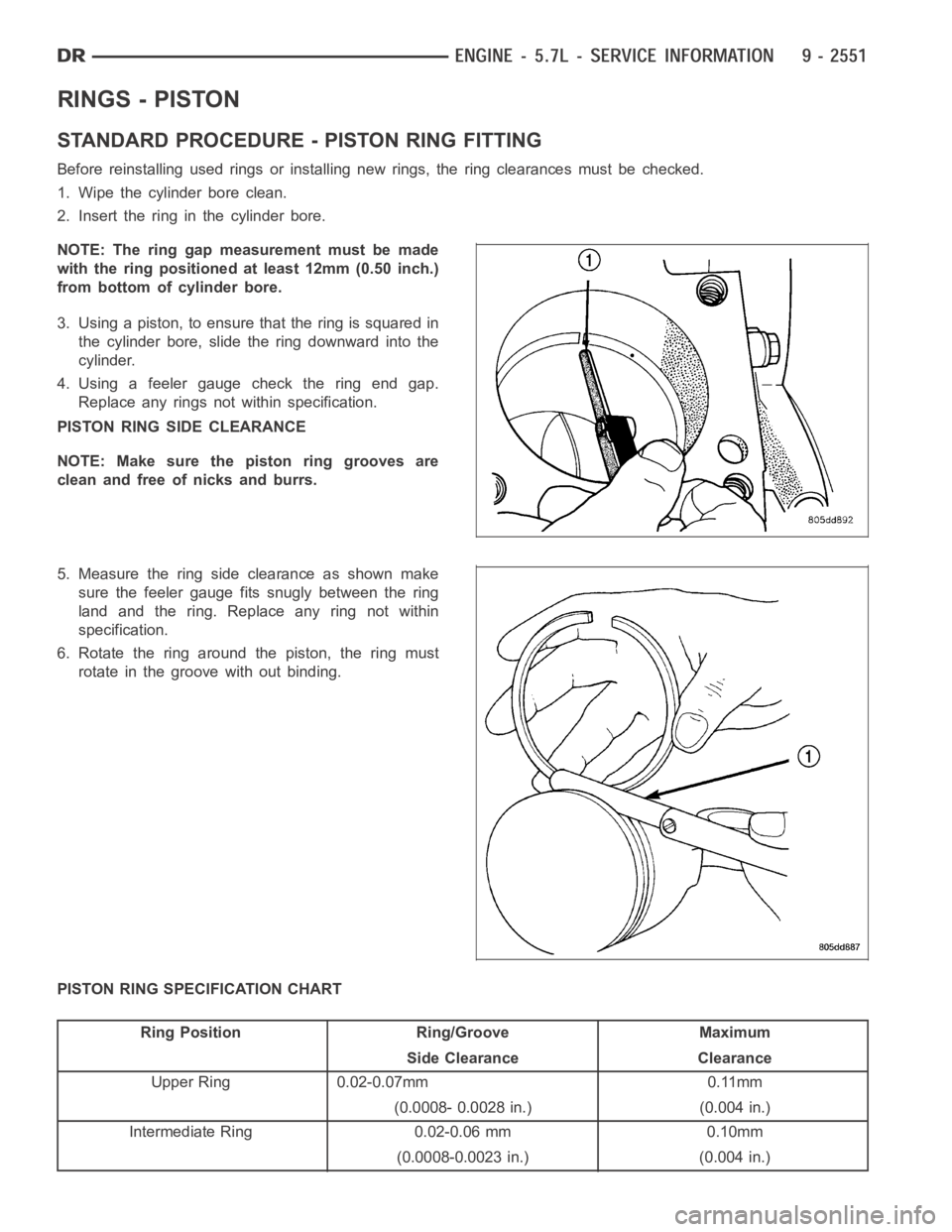

Before reinstalling used rings or installing new rings, the ring clearances must be checked.

1. Wipe the cylinder bore clean.

2. Insert the ring in the cylinder bore.

NOTE: The ring gap measurement must be made

with the ring positioned at least 12mm (0.50 inch.)

from bottom of cylinder bore.

3. Using a piston, to ensure that the ring is squared in

the cylinder bore, slide the ring downward into the

cylinder.

4. Using a feeler gauge check the ring end gap.

Replace any rings not within specification.

PISTON RING SIDE CLEARANCE

NOTE: Make sure the piston ring grooves are

clean and free of nicks and burrs.

5. Measure the ring side clearance as shown make

sure the feeler gauge fits snugly between the ring

land and the ring. Replace any ring not within

specification.

6. Rotate the ring around the piston, the ring must

rotate in the groove with out binding.

PISTON RING SPECIFICATION CHART

Ring Position Ring/Groove Maximum

Side Clearance Clearance

Upper Ring 0.02-0.07mm 0.11mm

(0.0008- 0.0028 in.) (0.004 in.)

Intermediate Ring 0.02-0.06 mm 0.10mm

(0.0008-0.0023 in.) (0.004 in.)