engine DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 5073 of 5267

CLUTCH-A/C COMPRESSOR

DESCRIPTION

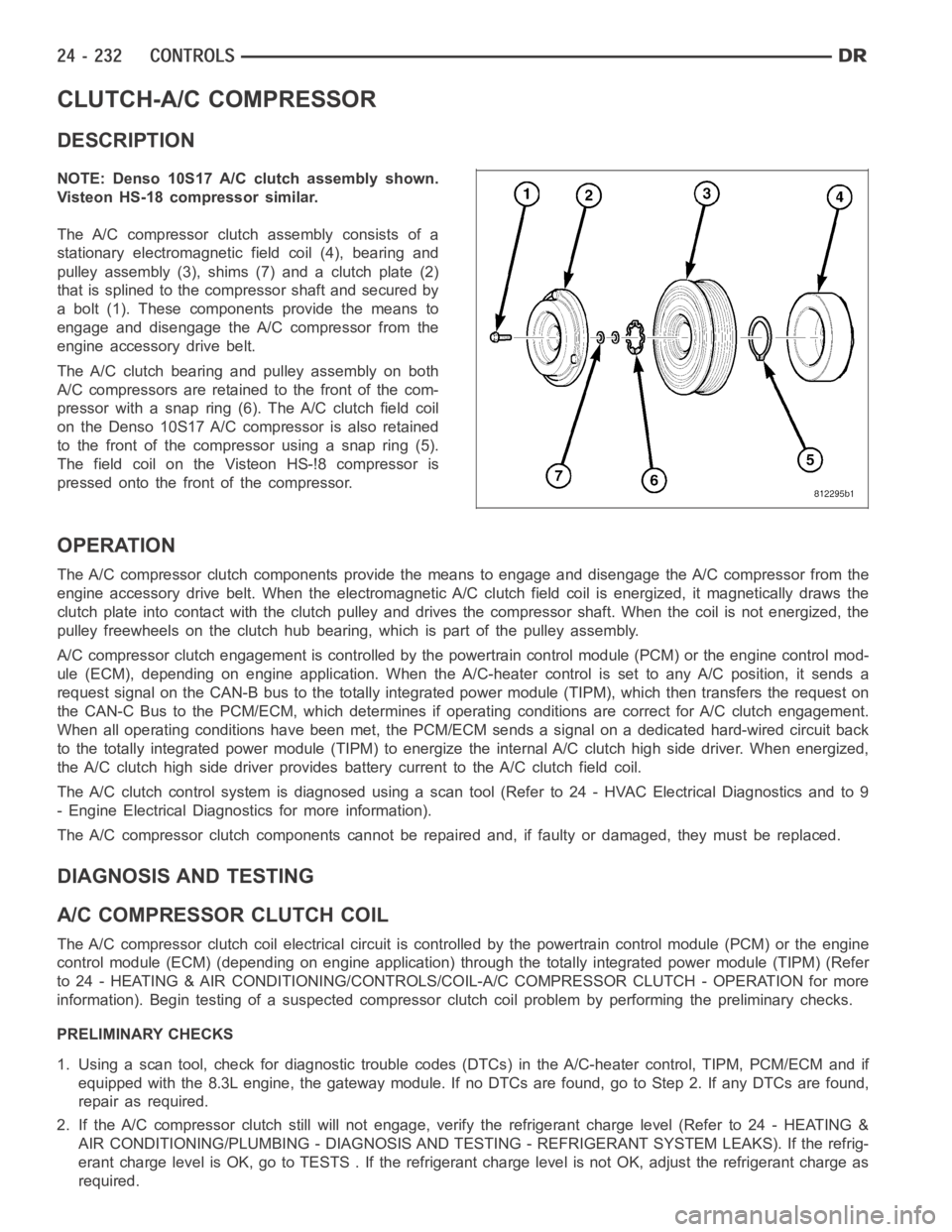

NOTE: Denso 10S17 A/C clutch assembly shown.

Visteon HS-18 compressor similar.

The A/C compressor clutch assembly consists of a

stationary electromagnetic field coil (4), bearing and

pulley assembly (3), shims (7) and a clutch plate (2)

that is splined to the compressor shaft and secured by

a bolt (1). These components provide the means to

engage and disengage the A/C compressor from the

engine accessory drive belt.

The A/C clutch bearing and pulley assembly on both

A/C compressors are retained to the front of the com-

pressor with a snap ring (6). The A/C clutch field coil

on the Denso 10S17 A/C compressor is also retained

to the front of the compressor using a snap ring (5).

The field coil on the Visteon HS-!8 compressor is

pressed onto the front of the compressor.

OPERATION

The A/C compressor clutch components provide the means to engage and disengage the A/C compressor from the

engine accessory drive belt. When the electromagnetic A/C clutch field coil is energized, it magnetically draws the

clutch plate into contact with the clutch pulley and drives the compressorshaft. When the coil is not energized, the

pulley freewheels on the clutch hub bearing, which is part of the pulley assembly.

A/C compressor clutch engagement is controlled by the powertrain controlmodule (PCM) or the engine control mod-

ule (ECM), depending on engine application. When the A/C-heater control is set to any A/C position, it sends a

request signal on the CAN-B bus to the totally integrated power module (TIPM), which then transfers the request on

the CAN-C Bus to the PCM/ECM, which determines if operating conditions arecorrect for A/C clutch engagement.

When all operating conditions have been met, the PCM/ECM sends a signal on adedicated hard-wired circuit back

to the totally integrated power module (TIPM) to energize the internal A/Cclutch high side driver. When energized,

the A/C clutch high side driver provides battery current to the A/C clutch field coil.

The A/C clutch control system is diagnosed using a scan tool (Refer to 24 - HVAC Electrical Diagnostics and to 9

- Engine Electrical Diagnostics for more information).

The A/C compressor clutch components cannot be repaired and, if faulty or damaged, they must be replaced.

DIAGNOSIS AND TESTING

A/CCOMPRESSORCLUTCHCOIL

The A/C compressor clutch coil electrical circuit is controlled by the powertrain control module (PCM) or the engine

control module (ECM) (depending on engine application) through the totally integrated power module (TIPM) (Refer

to 24 - HEATING & AIR CONDITIONING/CONTROLS/COIL-A/C COMPRESSOR CLUTCH -OPERATION for more

information). Begin testing of a suspected compressor clutch coil problem by performing the preliminary checks.

PRELIMINARY CHECKS

1. Using a scan tool, check for diagnostic trouble codes (DTCs) in the A/C-heater control, TIPM, PCM/ECM and if

equipped with the 8.3L engine, the gateway module. If no DTCs are found, go to Step 2. If any DTCs are found,

repair as required.

2. If the A/C compressor clutch still will not engage, verify the refrigerant charge level (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - DIAGNOSIS AND TESTING - REFRIGERANT SYSTEM LEAKS). If the refrig-

erant charge level is OK, go to TESTS . If the refrigerant charge level is notOK, adjust the refrigerant charge as

required.

Page 5074 of 5267

TESTS

1. Verify the battery state of charge (Refer to 8 - ELECTRICAL/BATTERY SYSTEM/BATTERY - DIAGNOSIS AND

TESTING).

2. Connect an ammeter (0 to 10 ampere scale selected) in series with the clutch coil feed terminal. Connect a

voltmeter (0 to 20 volt scale selected) to measure voltage across the battery and the clutch coil.

3. With the A/C-heater control in the A/C mode and the blower motor at low speed, start the engine and allow it to

run at a normal idle speed.

4. The A/C compressor clutch should engage immediately, and the clutch coil supply voltage should be within two

volts of the battery voltage. If the coil supply voltage is OK, go to Step 5. If the coil supply voltage is not within

two volts of battery voltage, test the clutch coil feed circuit for excessive voltage drop and repair as necessary.

5. For the acceptable A/C clutch coil current draw specifications refer to24 - HEATING & AIR CONDITIONING -

SPECIFICATIONS. Specifications apply for a work area temperature of 21° C(70° F). If voltage is more than

12.5 volts, add electrical loads by turning on electrical accessories until voltage reads below 12.5 volts.

STANDARD PROCEDURE

A/C CLUTCH PLATE INSPECTION

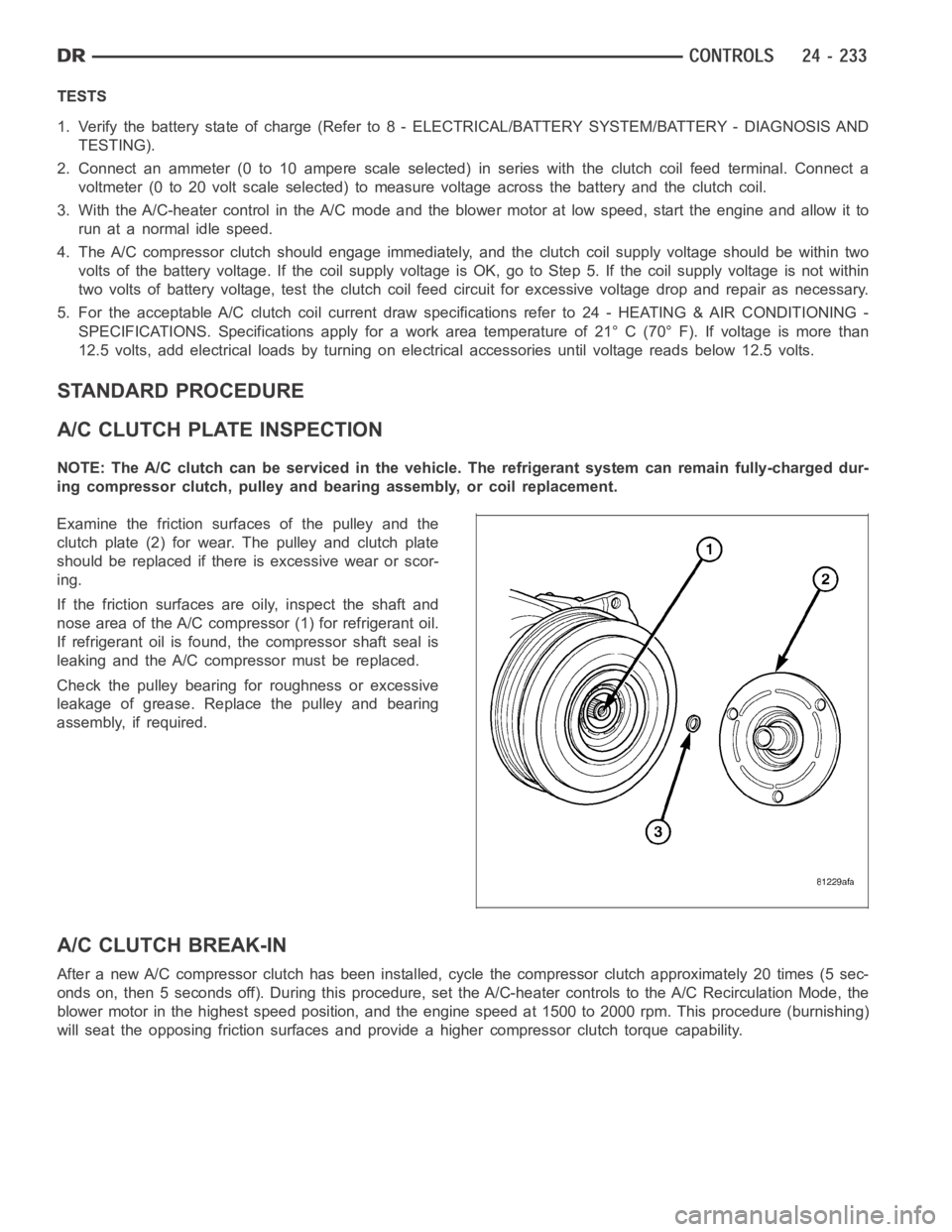

NOTE: The A/C clutch can be serviced inthe vehicle. The refrigerant systemcan remain fully-charged dur-

ing compressor clutch, pulley and bearing assembly, or coil replacement.

Examine the friction surfaces of the pulley and the

clutch plate (2) for wear. The pulley and clutch plate

should be replaced if there is excessive wear or scor-

ing.

If the friction surfaces are oily, inspect the shaft and

nose area of the A/C compressor (1) for refrigerant oil.

If refrigerant oil is found, the compressor shaft seal is

leaking and the A/C compressor must be replaced.

Check the pulley bearing for roughness or excessive

leakage of grease. Replace the pulley and bearing

assembly, if required.

A/C CLUTCH BREAK-IN

After a new A/C compressor clutch hasbeen installed, cycle the compressorclutch approximately 20 times (5 sec-

onds on, then 5 seconds off). During this procedure, set the A/C-heater controls to the A/C Recirculation Mode, the

blower motor in the highest speed position, and the engine speed at 1500 to 2000 rpm. This procedure (burnishing)

will seat the opposing friction surfaces and provide a higher compressor clutch torque capability.

Page 5075 of 5267

REMOVAL

DENSO A/C COMPRESSOR

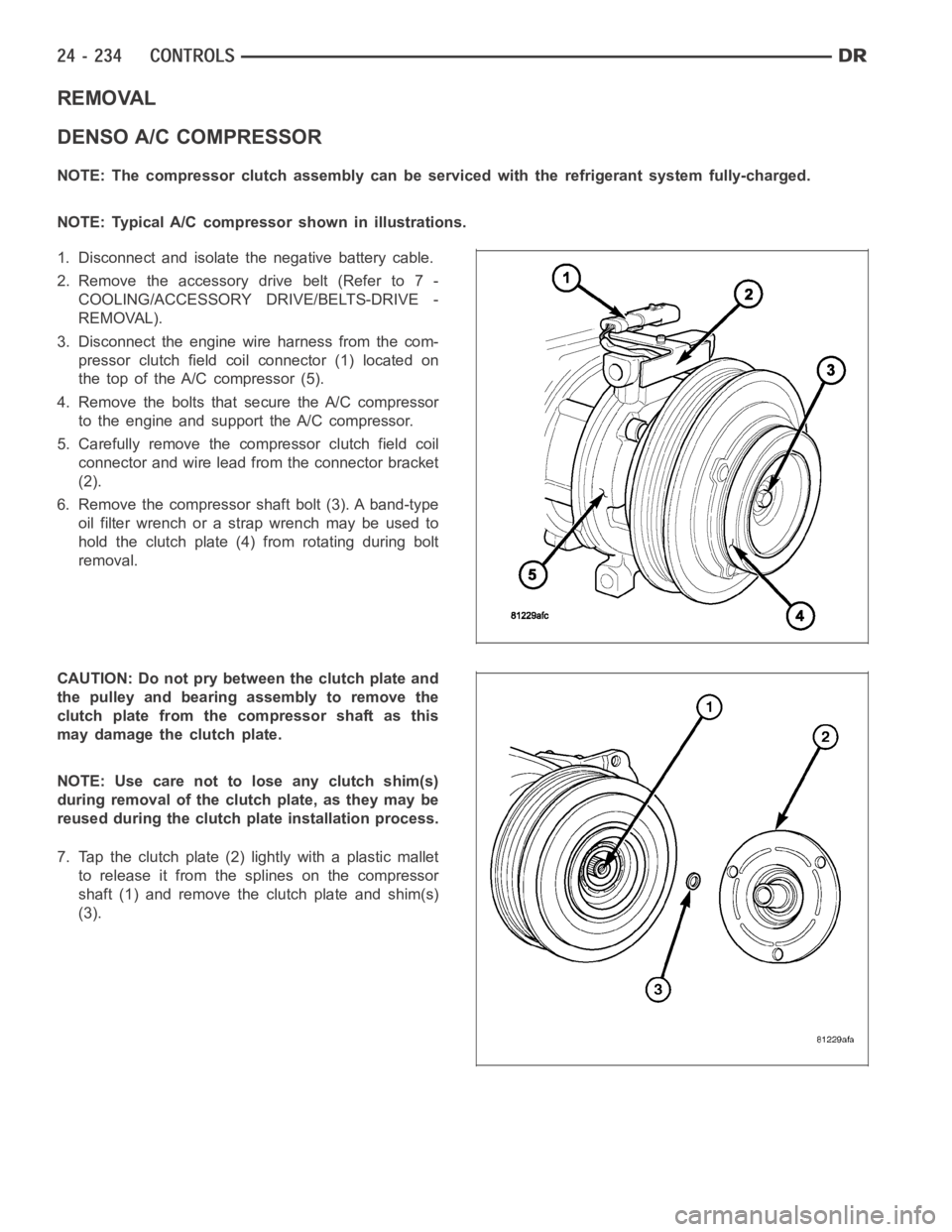

NOTE: The compressor clutch assembly can be serviced with the refrigerantsystem fully-charged.

NOTE: Typical A/C compressor shown in illustrations.

1. Disconnect and isolate the negative battery cable.

2. Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/BELTS-DRIVE -

REMOVAL).

3. Disconnect the engine wire harness from the com-

pressor clutch field coilconnector (1) located on

the top of the A/C compressor (5).

4. Remove the bolts that secure the A/C compressor

to the engine and support the A/C compressor.

5. Carefully remove the compressor clutch field coil

connector and wire lead from the connector bracket

(2).

6. Remove the compressor shaft bolt (3). A band-type

oil filter wrench or a strap wrench may be used to

hold the clutch plate (4) from rotating during bolt

removal.

CAUTION: Do not pry between the clutch plate and

the pulley and bearing assembly to remove the

clutch plate from the compressor shaft as this

may damage the clutch plate.

NOTE: Use care not to lose any clutch shim(s)

during removal of the clutch plate, as they may be

reused during the clutch plate installation process.

7. Tap the clutch plate (2) lightly with a plastic mallet

to release it from the splines on the compressor

shaft (1) and remove the clutch plate and shim(s)

(3).

Page 5077 of 5267

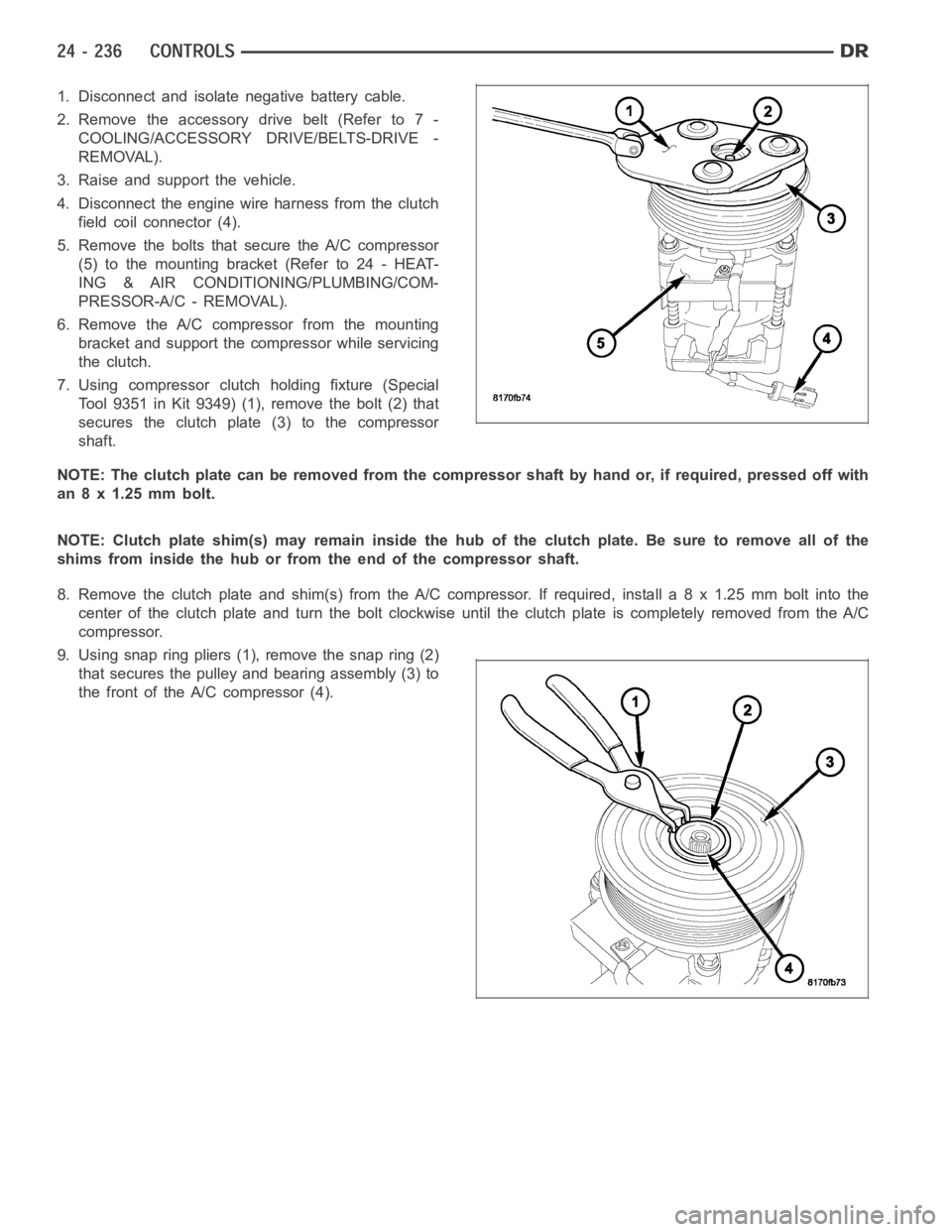

1. Disconnect and isolate negative battery cable.

2. Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/BELTS-DRIVE -

REMOVAL).

3. Raise and support the vehicle.

4. Disconnect the engine wire harness from the clutch

field coil connector (4).

5. Remove the bolts that secure the A/C compressor

(5)tothemountingbracket(Referto24-HEAT-

ING & AIR CONDITIONING/PLUMBING/COM-

PRESSOR-A/C - REMOVAL).

6. Remove the A/C compressor from the mounting

bracket and support the compressor while servicing

the clutch.

7. Using compressor clutch holding fixture (Special

Tool 9351 in Kit 9349) (1), remove the bolt (2) that

secures the clutch plate (3) to the compressor

shaft.

NOTE: The clutch plate can be removed from the compressor shaft by hand or, if required, pressed off with

an 8 x 1.25 mm bolt.

NOTE: Clutch plate shim(s) may remain inside the hub of the clutch plate. Besure to remove all of the

shims from inside the hub or from the end of the compressor shaft.

8. Remove the clutch plate and shim(s) from the A/C compressor. If required, install a 8 x 1.25 mm bolt into the

centeroftheclutchplateandturntheboltclockwiseuntiltheclutchplate is completely removed from the A/C

compressor.

9. Using snap ring pliers (1), remove the snap ring (2)

that secures the pulley and bearing assembly (3) to

the front of the A/C compressor (4).

Page 5081 of 5267

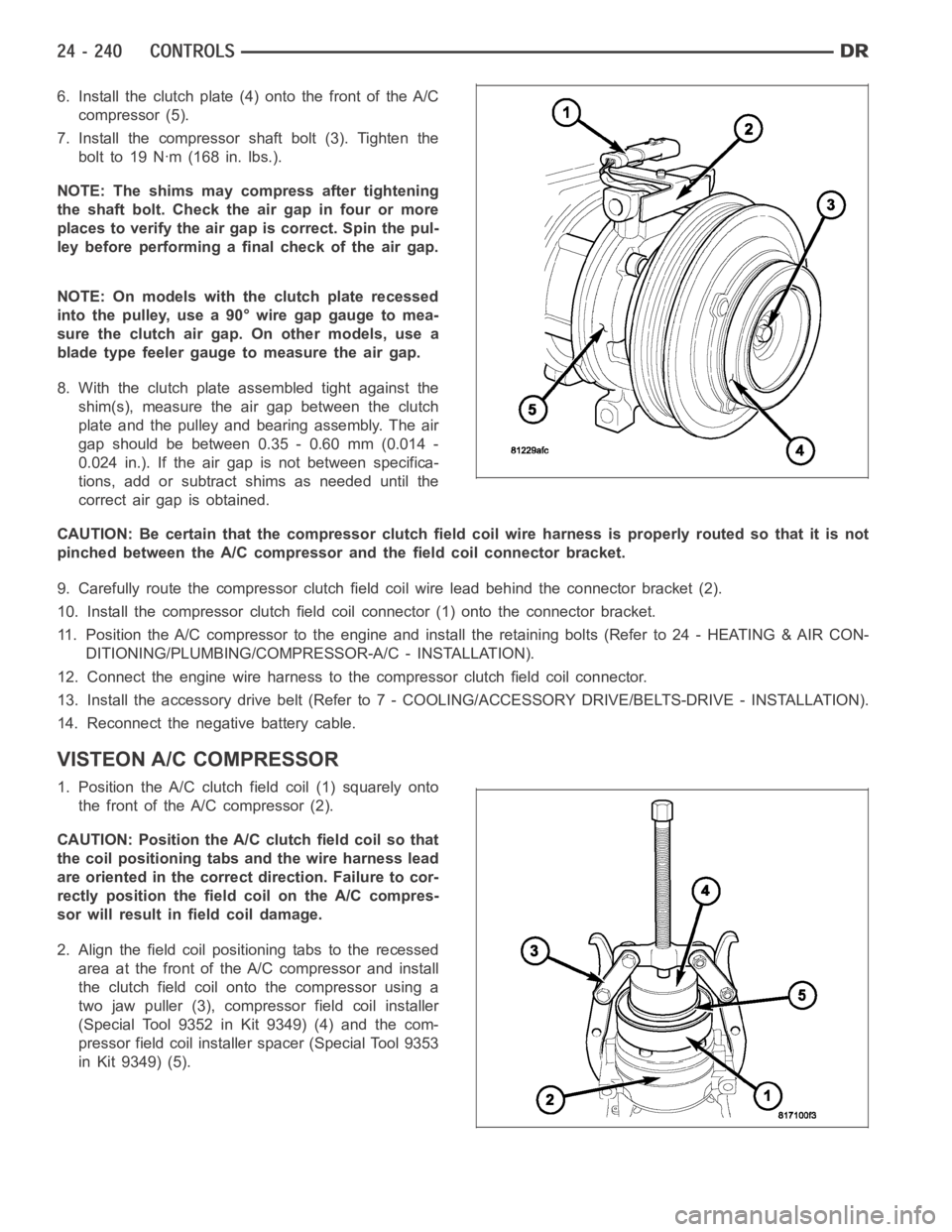

6. Install the clutch plate (4) onto the front of the A/C

compressor (5).

7. Install the compressor shaft bolt (3). Tighten the

bolt to 19 Nꞏm (168 in. lbs.).

NOTE: The shims may compress after tightening

the shaft bolt. Check the air gap in four or more

places to verify the air gap is correct. Spin the pul-

ley before performing a final check of the air gap.

NOTE: On models with the clutch plate recessed

intothepulley,usea90°wiregapgaugetomea-

sure the clutch air gap. On other models, use a

blade type feeler gauge to measure the air gap.

8. With the clutch plate assembled tight against the

shim(s), measure the air gap between the clutch

plate and the pulley and bearing assembly. The air

gap should be between 0.35 - 0.60 mm (0.014 -

0.024 in.). If the air gap is not between specifica-

tions, add or subtract shims as needed until the

correct air gap is obtained.

CAUTION: Be certain that the compressor clutch field coil wire harness is properly routed so that it is not

pinched between the A/C compressor and the field coil connector bracket.

9. Carefully route the compressor clutch field coil wire lead behind the connector bracket (2).

10. Install the compressor clutch fieldcoil connector (1) onto the connector bracket.

11. Position the A/C compressor to the engine and install the retaining bolts (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING/COMPRESSOR-A/C - INSTALLATION).

12. Connect the engine wire harness to the compressor clutch field coil connector.

13. Install the accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/BELTS-DRIVE - INSTALLATION).

14. Reconnect the negative battery cable.

VISTEON A/C COMPRESSOR

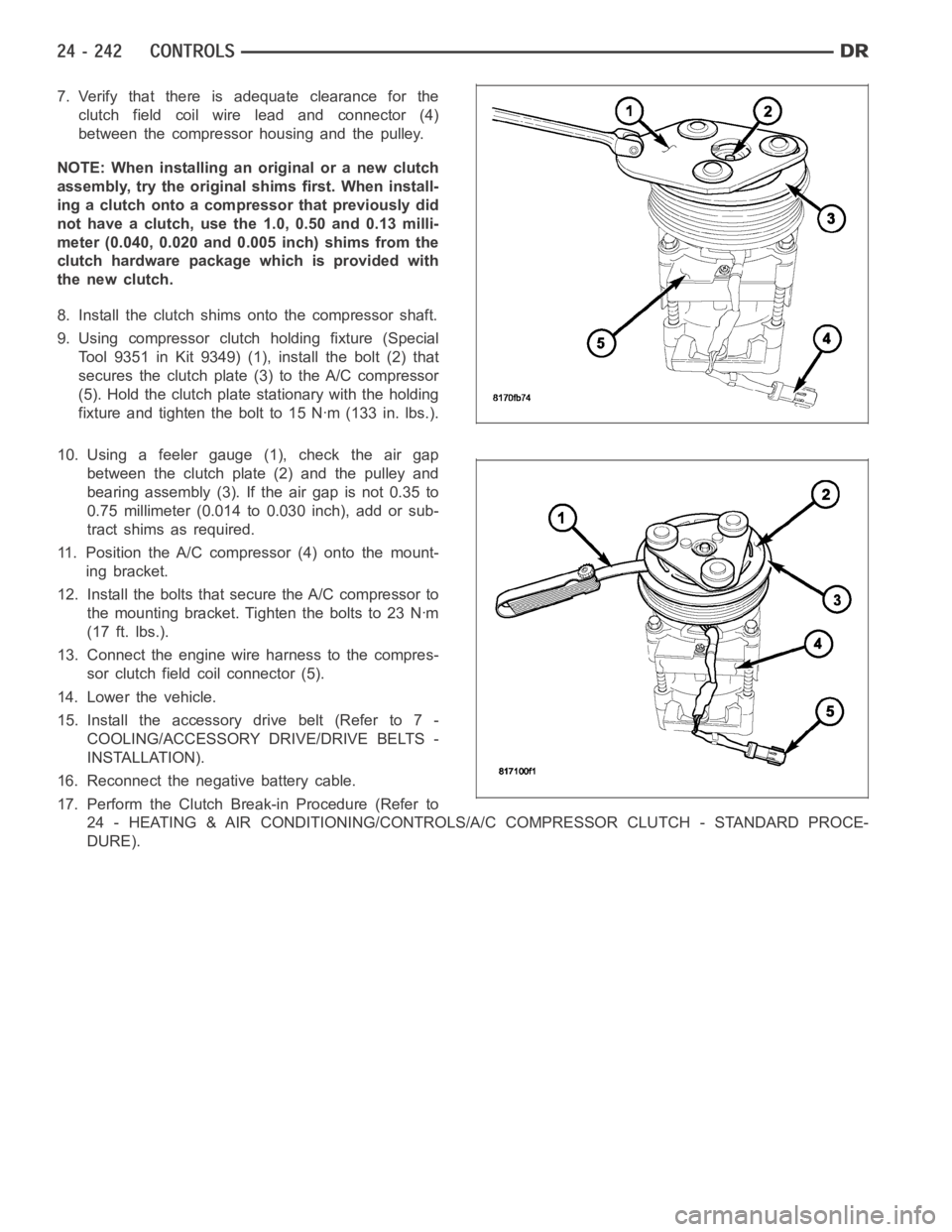

1. Position the A/C clutch field coil (1) squarely onto

the front of the A/C compressor (2).

CAUTION: Position the A/C clutch field coil so that

the coil positioning tabs and the wire harness lead

are oriented in the correct direction. Failure to cor-

rectly position the fieldcoil on the A/C compres-

sor will result in field coil damage.

2. Align the field coil positioning tabs to the recessed

area at the front of the A/C compressor and install

the clutch field coil onto the compressor using a

two jaw puller (3), compressor field coil installer

(Special Tool 9352 in Kit 9349) (4) and the com-

pressor field coil installer spacer (Special Tool 9353

in Kit 9349) (5).

Page 5083 of 5267

7. Verify that there is adequate clearance for the

clutch field coil wire lead and connector (4)

between the compressor housing and the pulley.

NOTE: When installing an original or a new clutch

assembly, try the original shims first. When install-

ing a clutch onto a compressor that previously did

not have a clutch, use the 1.0, 0.50 and 0.13 milli-

meter (0.040, 0.020 and 0.005 inch) shims from the

clutch hardware package which is provided with

the new clutch.

8. Install the clutch shims onto the compressor shaft.

9. Using compressor clutch holding fixture (Special

Tool 9351 in Kit 9349) (1), install the bolt (2) that

secures the clutch plate (3) to the A/C compressor

(5). Hold the clutch plate stationary with the holding

fixture and tighten the bolt to 15 Nꞏm (133 in. lbs.).

10. Using a feeler gauge (1), check the air gap

between the clutch plate (2) and the pulley and

bearing assembly (3). If the air gap is not 0.35 to

0.75 millimeter (0.014 to 0.030 inch), add or sub-

tract shims as required.

11. Position the A/C compressor (4) onto the mount-

ing bracket.

12. Install the bolts that secure the A/C compressor to

themountingbracket.Tightentheboltsto23Nꞏm

(17 ft. lbs.).

13. Connect the engine wire harness to the compres-

sor clutch field coil connector (5).

14. Lower the vehicle.

15. Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

16. Reconnect the negative battery cable.

17. Perform the Clutch Break-in Procedure (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS/A/C COMPRESSOR CLUTCH - STANDARD PROCE-

DURE).

Page 5089 of 5267

SENSOR-EVAPORATOR TEMPERATURE

DESCRIPTION

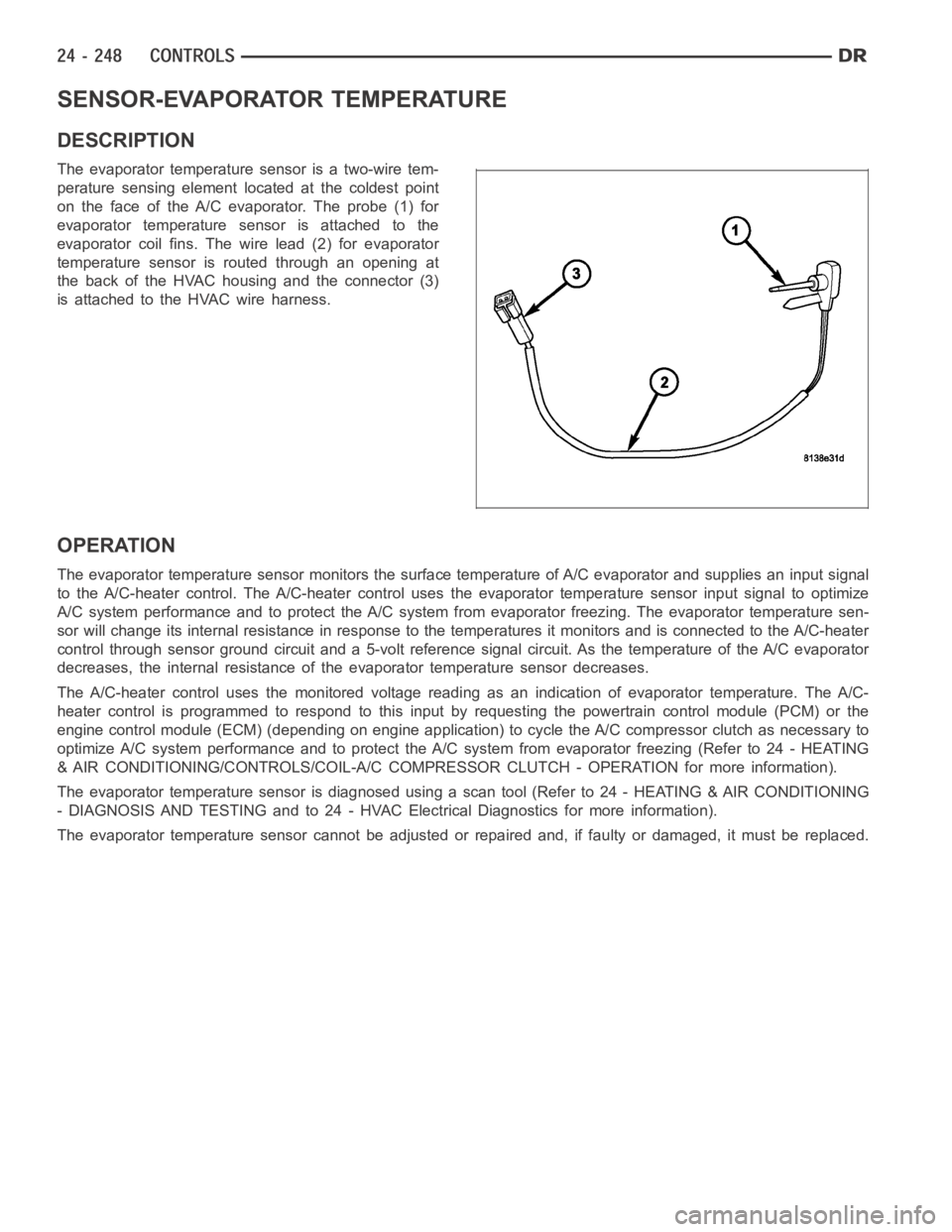

The evaporator temperature sensor is a two-wire tem-

perature sensing element located at the coldest point

on the face of the A/C evaporator. The probe (1) for

evaporator temperature sensor is attached to the

evaporator coil fins. The wire lead (2) for evaporator

temperature sensor is routed through an opening at

the back of the HVAC housing and the connector (3)

is attached to the HVAC wire harness.

OPERATION

The evaporator temperature sensor monitors the surface temperature of A/C evaporator and supplies an input signal

to the A/C-heater control. The A/C-heater control uses the evaporator temperature sensor input signal to optimize

A/C system performance and to protect the A/C system from evaporator freezing. The evaporator temperature sen-

sor will change its internal resistance in response to the temperatures itmonitors and is connected to the A/C-heater

control through sensor ground circuit and a 5-volt reference signal circuit. As the temperature of the A/C evaporator

decreases, the internal resistance of the evaporator temperature sensordecreases.

The A/C-heater control uses the monitored voltage reading as an indication of evaporator temperature. The A/C-

heater control is programmed to respond to this input by requesting the powertrain control module (PCM) or the

engine control module (ECM) (depending on engine application) to cycle the A/C compressor clutch as necessary to

optimize A/C system performance and to protect the A/C system from evaporatorfreezing(Referto24-HEATING

& AIR CONDITIONING/CONTROLS/COIL-A/C COMPRESSOR CLUTCH - OPERATION formore information).

The evaporator temperature sensor is diagnosed using a scan tool (Refer to24 - HEATING & AIR CONDITIONING

- DIAGNOSIS AND TESTING and to 24 - HVAC Electrical Diagnostics for more information).

The evaporator temperature sensor cannot be adjusted or repaired and, if faulty or damaged, it must be replaced.

Page 5092 of 5267

TRANSDUCER-A/C PRESSURE

DESCRIPTION

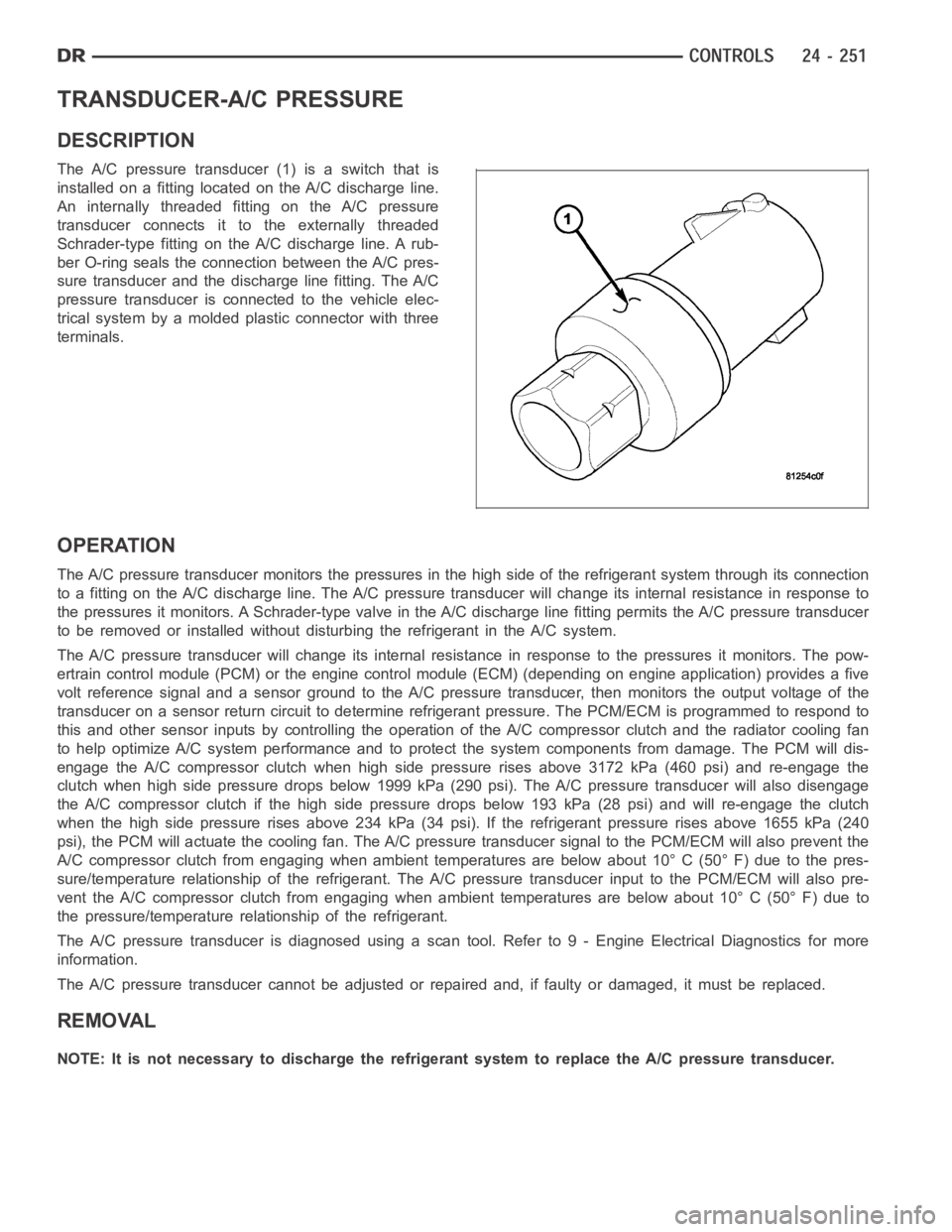

The A/C pressure transducer (1) is a switch that is

installed on a fitting located on the A/C discharge line.

An internally threaded fitting on the A/C pressure

transducer connects it to the externally threaded

Schrader-type fitting on the A/C discharge line. A rub-

ber O-ring seals the connection between the A/C pres-

sure transducer and the discharge line fitting. The A/C

pressure transducer is connected to the vehicle elec-

trical system by a molded plastic connector with three

terminals.

OPERATION

The A/C pressure transducer monitors the pressures in the high side of the refrigerant system through its connection

to a fitting on the A/C discharge line. The A/C pressure transducer will change its internal resistance in response to

the pressures it monitors. A Schrader-type valve in the A/C discharge linefitting permits the A/C pressure transducer

to be removed or installed without disturbing the refrigerant in the A/C system.

The A/C pressure transducer will change its internal resistance in response to the pressures it monitors. The pow-

ertrain control module (PCM) or the engine control module (ECM) (depending on engine application) provides a five

volt reference signal and a sensor ground to the A/C pressure transducer, then monitors the output voltage of the

transducer on a sensor return circuit to determine refrigerant pressure.The PCM/ECM is programmed to respond to

this and other sensor inputs by controlling the operation of the A/C compressor clutch and the radiator cooling fan

to help optimize A/C system performance and to protect the system components from damage. The PCM will dis-

engagetheA/Ccompressorclutchwhenhighsidepressurerisesabove3172kPa (460 psi) and re-engage the

clutch when high side pressure drops below 1999 kPa (290 psi). The A/C pressure transducer will also disengage

the A/C compressor clutch if the high side pressure drops below 193 kPa (28 psi) and will re-engage the clutch

when the high side pressure rises above 234 kPa (34 psi). If the refrigerantpressure rises above 1655 kPa (240

psi), the PCM will actuate the cooling fan. The A/C pressure transducer signal to the PCM/ECM will also prevent the

A/C compressor clutch from engaging when ambient temperatures are below about 10° C (50° F) due to the pres-

sure/temperature relationship of the refrigerant. The A/C pressure transducer input to the PCM/ECM will also pre-

vent the A/C compressor clutch from engaging when ambient temperatures are below about 10° C (50° F) due to

the pressure/temperature relationship of the refrigerant.

The A/C pressure transducer is diagnosed using a scan tool. Refer to 9 - Engine Electrical Diagnostics for more

information.

The A/C pressure transducer cannot be adjusted or repaired and, if faulty or damaged, it must be replaced.

REMOVAL

NOTE: It is not necessary to discharge the refrigerant system to replace the A/C pressure transducer.

Page 5104 of 5267

REMOVAL

HVAC HOUSING ASSEMBLY

WARNING: Refer to the applicable warnings and cautions for this system before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS). Failure to follow the warnings and cautions could result

in possible personal injury or death.

WARNING: On vehicles equipped with airbags, disable the airbag system before attempting any steering

wheel, steering column, or instrument panel component diagnosis or service. Disconnect and isolate the

negative battery (ground) cable, then wait two minutes for the airbag system capacitor to discharge before

performing further diagnosis or service. This is the only sure way to disable the airbag system. Failure to

take the proper precautions could result in accidental airbag deploymentand possible personal injury or

death.

NOTE: The HVAC housing must be removedfrom the vehicle and disassembled for service of the A/C evap-

orator, evaporator temperature sensor, mode-air and blend-air doors.

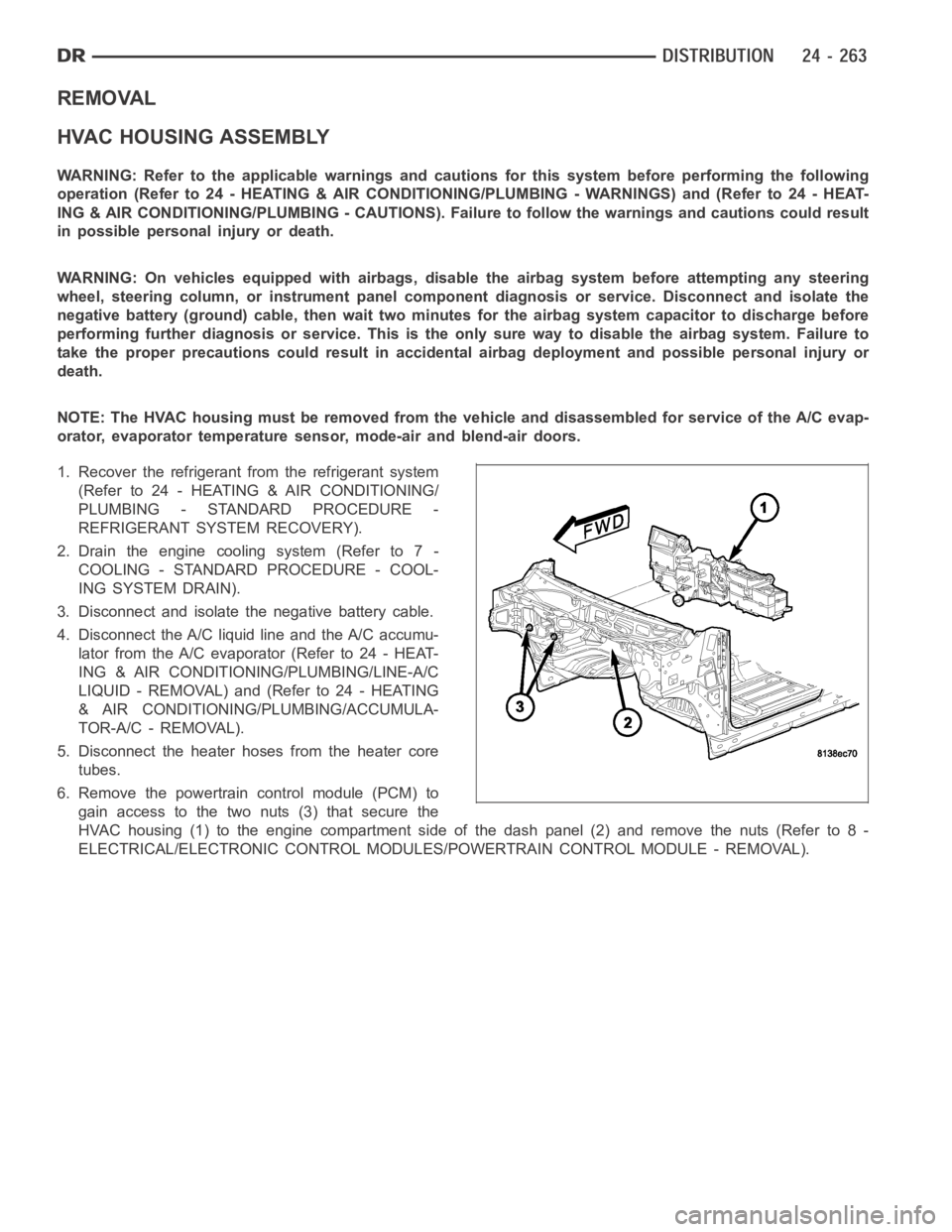

1. Recover the refrigerant from the refrigerant system

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE -

REFRIGERANT SYSTEM RECOVERY).

2. Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOL-

ING SYSTEM DRAIN).

3. Disconnect and isolate the negative battery cable.

4. Disconnect the A/C liquid line and the A/C accumu-

lator from the A/C evaporator (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/LINE-A/C

LIQUID - REMOVAL) and (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/ACCUMULA-

TOR-A/C - REMOVAL).

5. Disconnect the heater hoses from the heater core

tubes.

6. Remove the powertrain control module (PCM) to

gain access to the two nuts (3) that secure the

HVAC housing (1) to the engine compartment side of the dash panel (2) and remove the nuts (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MODULES/POWERTRAIN CONTROL MODULE - REMOVAL).

Page 5119 of 5267

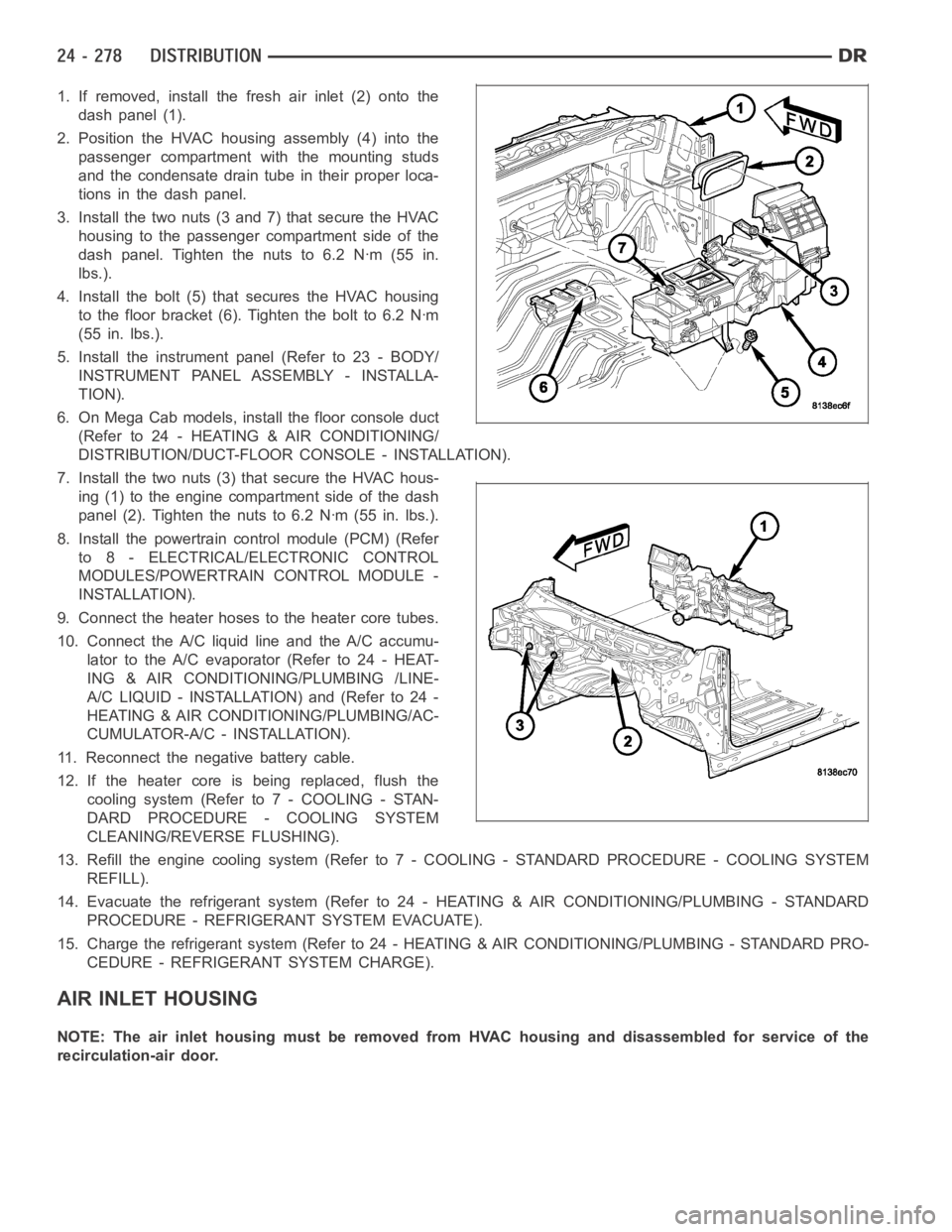

1. If removed, install the fresh air inlet (2) onto the

dash panel (1).

2. Position the HVAC housing assembly (4) into the

passenger compartment with the mounting studs

and the condensate drain tube in their proper loca-

tions in the dash panel.

3. Install the two nuts (3 and 7) that secure the HVAC

housing to the passenger compartment side of the

dash panel. Tighten the nuts to 6.2 Nꞏm (55 in.

lbs.).

4. Install the bolt (5) that secures the HVAC housing

to the floor bracket (6). Tighten the bolt to 6.2 Nꞏm

(55 in. lbs.).

5. Install the instrument panel (Refer to 23 - BODY/

INSTRUMENT PANEL ASSEMBLY - INSTALLA-

TION).

6. On Mega Cab models, install the floor console duct

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/DUCT-FLOOR CONSOLE - INSTALLATION).

7. Install the two nuts (3) that secure the HVAC hous-

ing (1) to the engine compartment side of the dash

panel (2). Tighten the nuts to 6.2 Nꞏm (55 in. lbs.).

8. Install the powertrain control module (PCM) (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/POWERTRAIN CONTROL MODULE -

INSTALLATION).

9. Connect the heater hoses to the heater core tubes.

10. Connect the A/C liquid line and the A/C accumu-

lator to the A/C evaporator (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING /LINE-

A/C LIQUID - INSTALLATION) and (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/AC-

CUMULATOR-A/C - INSTALLATION).

11. Reconnect the negative battery cable.

12. If the heater core is being replaced, flush the

coolingsystem(Referto7-COOLING-STAN-

DARD PROCEDURE - COOLING SYSTEM

CLEANING/REVERSE FLUSHING).

13. Refill the engine cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE - COOLING SYSTEM

REFILL).

14. Evacuate the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE - REFRIGERANT SYSTEM EVACUATE).

15. Charge the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE).

AIR INLET HOUSING

NOTE: The air inlet housing must be removed from HVAC housing and disassembled for service of the

recirculation-air door.