DODGE RAM SRT-10 2006 Service Repair Manual

RAM SRT-10 2006

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56917/w960_56917-0.png

DODGE RAM SRT-10 2006 Service Repair Manual

Trending: suspension, tire size, reset, wheelbase, headlamp, fuel filter, seat memory

Page 2651 of 5267

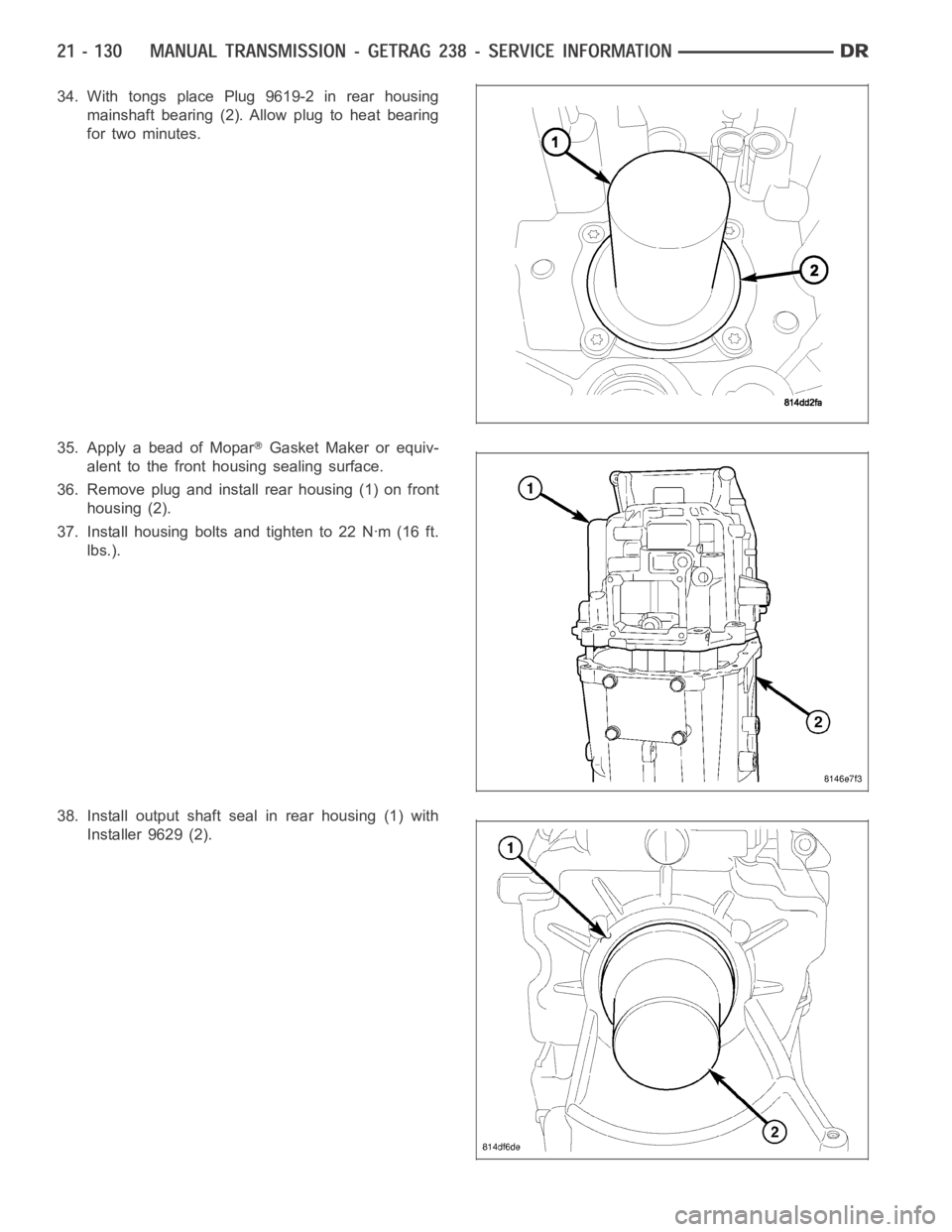

34. With tongs place Plug 9619-2 in rear housing

mainshaft bearing (2). Allow plug to heat bearing

for two minutes.

35. Apply a bead of Mopar

Gasket Maker or equiv-

alent to the front housing sealing surface.

36. Remove plug and install rear housing (1) on front

housing (2).

37. Install housing bolts and tighten to 22 Nꞏm (16 ft.

lbs.).

38. Install output shaft seal in rear housing (1) with

Installer 9629 (2).

Page 2652 of 5267

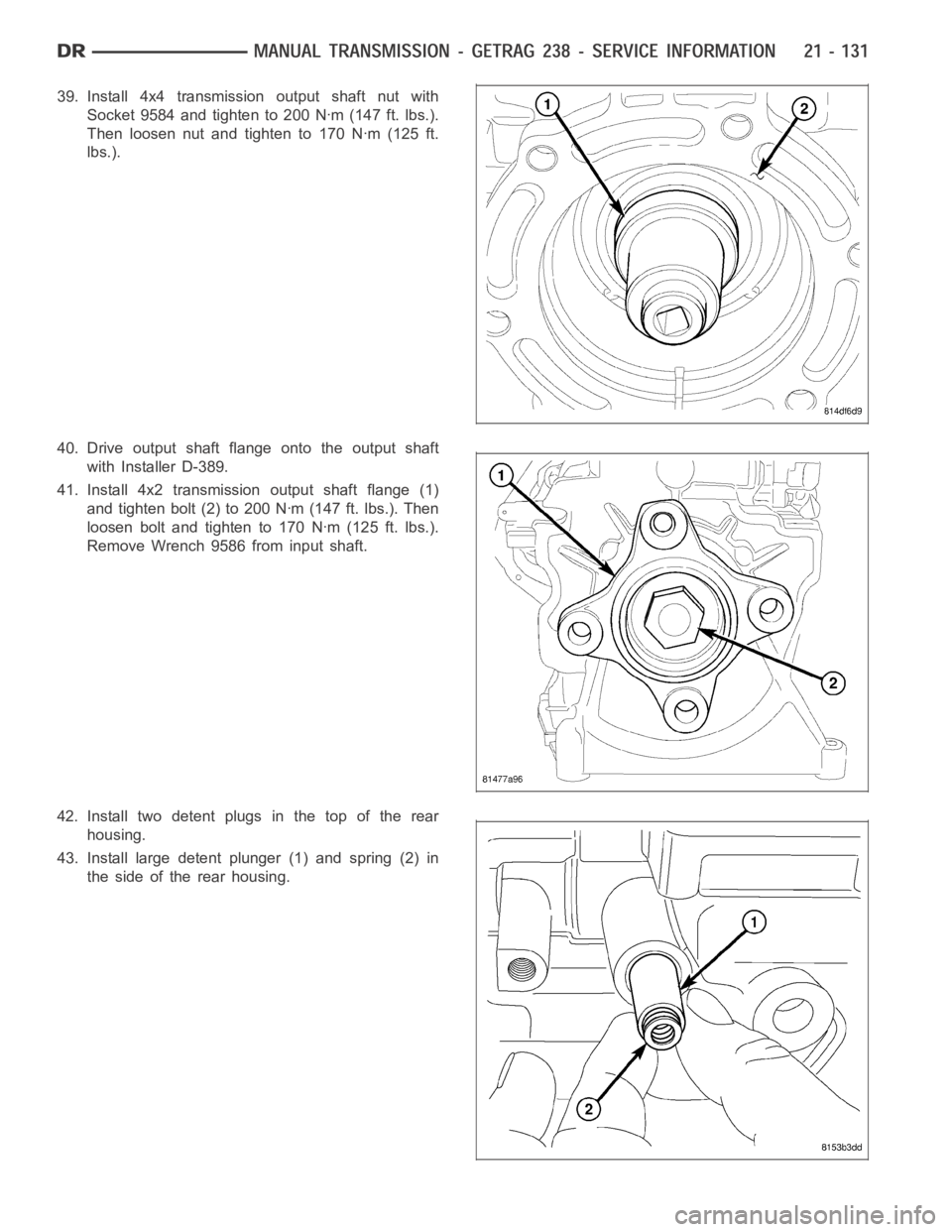

39. Install 4x4 transmission output shaft nut with

Socket 9584 and tighten to 200 Nꞏm (147 ft. lbs.).

Then loosen nut and tighten to 170 Nꞏm (125 ft.

lbs.).

40. Drive output shaft flange onto the output shaft

with Installer D-389.

41. Install 4x2 transmission output shaft flange (1)

and tighten bolt (2) to 200 Nꞏm (147 ft. lbs.). Then

loosen bolt and tighten to 170 Nꞏm (125 ft. lbs.).

Remove Wrench 9586 from input shaft.

42. Install two detent plugs in the top of the rear

housing.

43. Install large detent plunger (1) and spring (2) in

the side of the rear housing.

Page 2653 of 5267

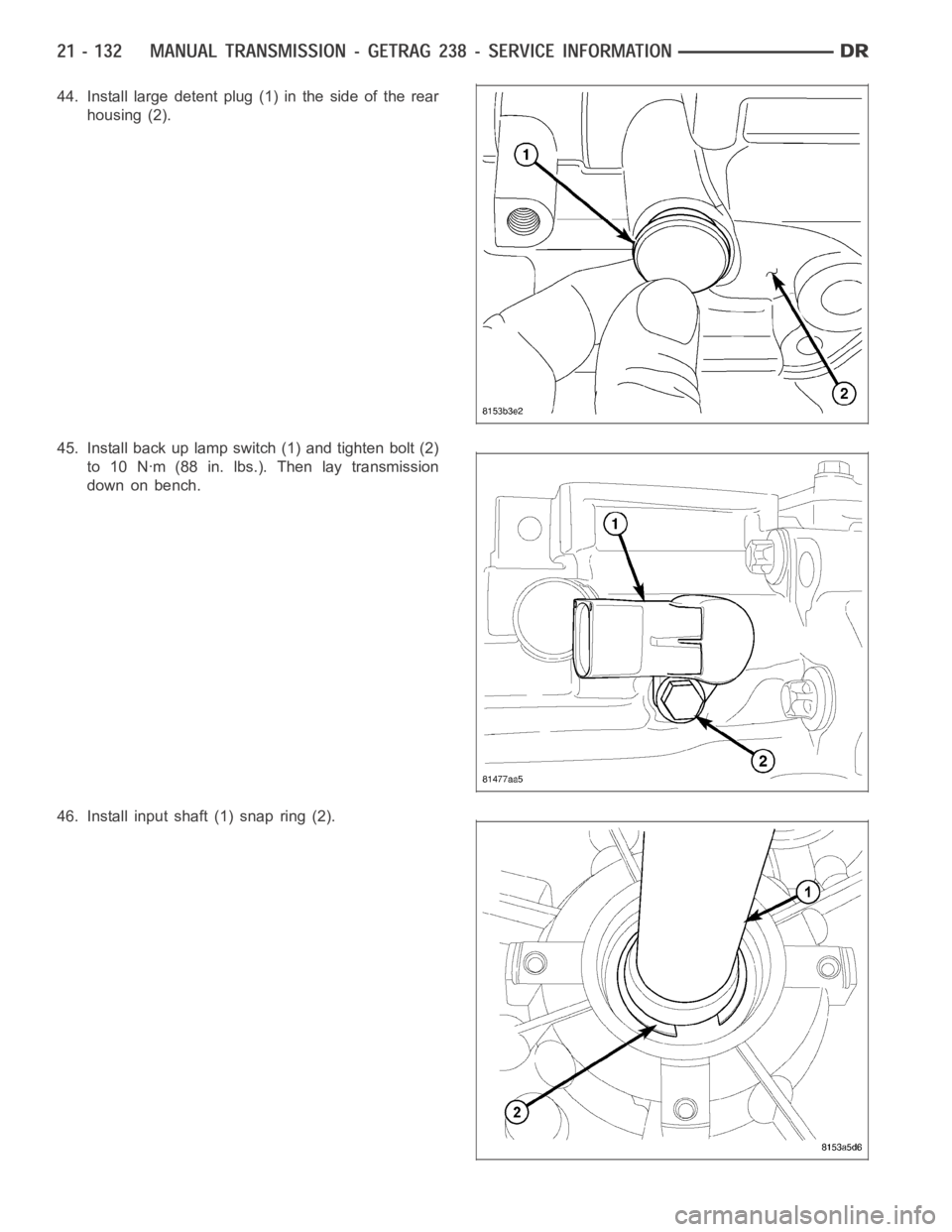

44. Install large detent plug (1) in the side of the rear

housing (2).

45. Install back up lamp switch (1) and tighten bolt (2)

to 10 Nꞏm (88 in. lbs.). Then lay transmission

down on bench.

46. Install input shaft (1) snap ring (2).

Page 2654 of 5267

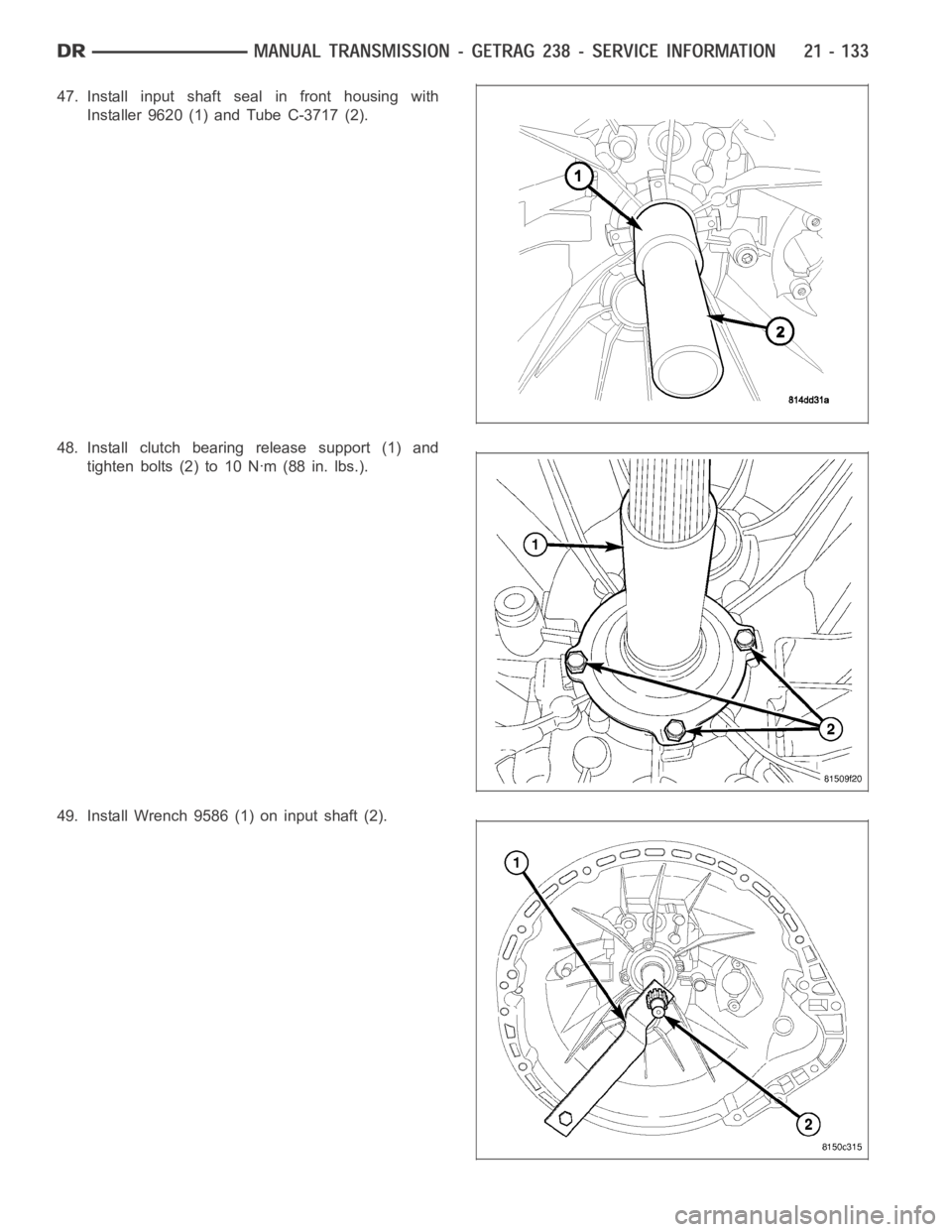

47. Install input shaft seal in front housing with

Installer 9620 (1) and Tube C-3717 (2).

48. Install clutch bearing release support (1) and

tighten bolts (2) to 10 Nꞏm (88 in. lbs.).

49. Install Wrench 9586 (1) on input shaft (2).

Page 2655 of 5267

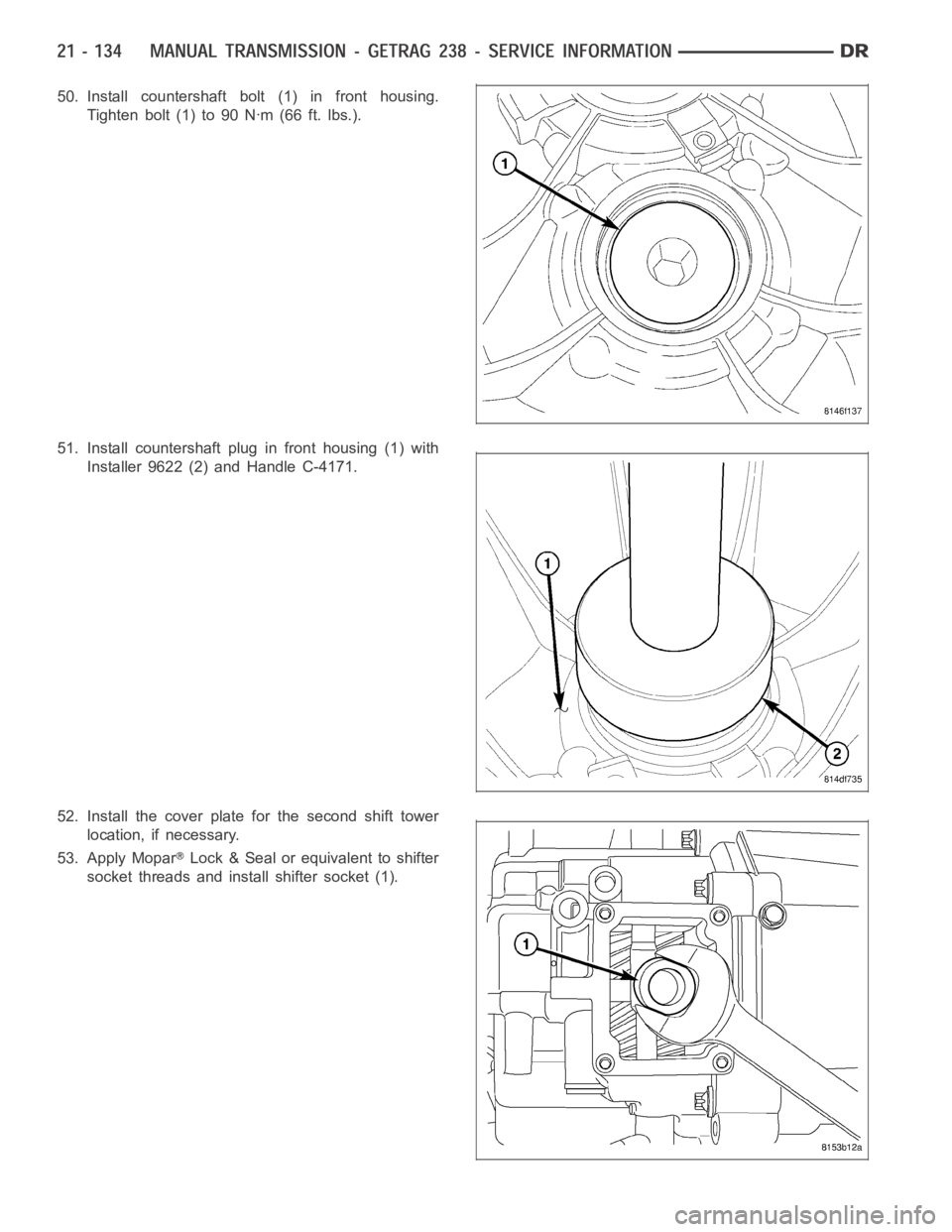

50. Install countershaft bolt (1) in front housing.

Tighten bolt (1) to 90 Nꞏm (66 ft. lbs.).

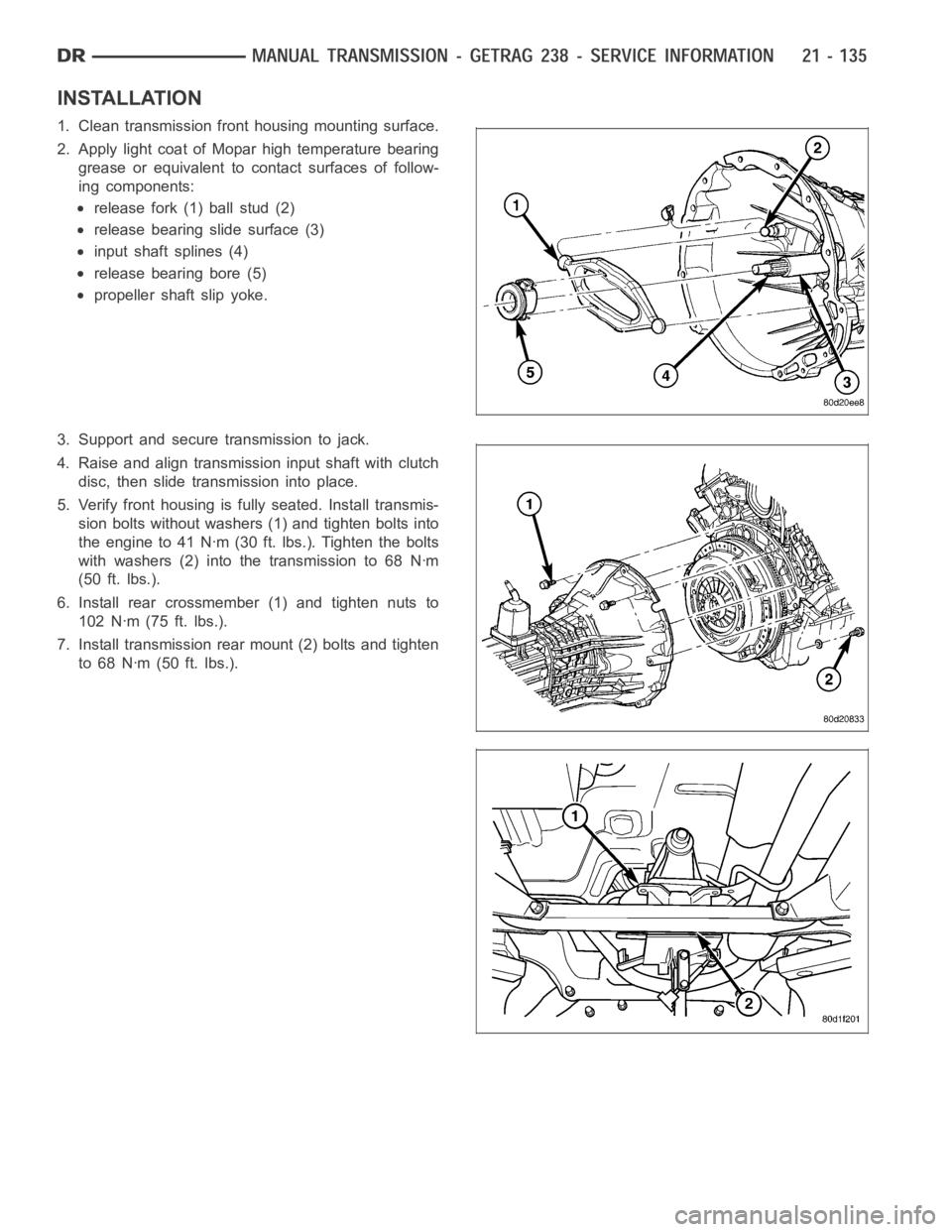

51. Install countershaft plug in front housing (1) with

Installer 9622 (2) and Handle C-4171.

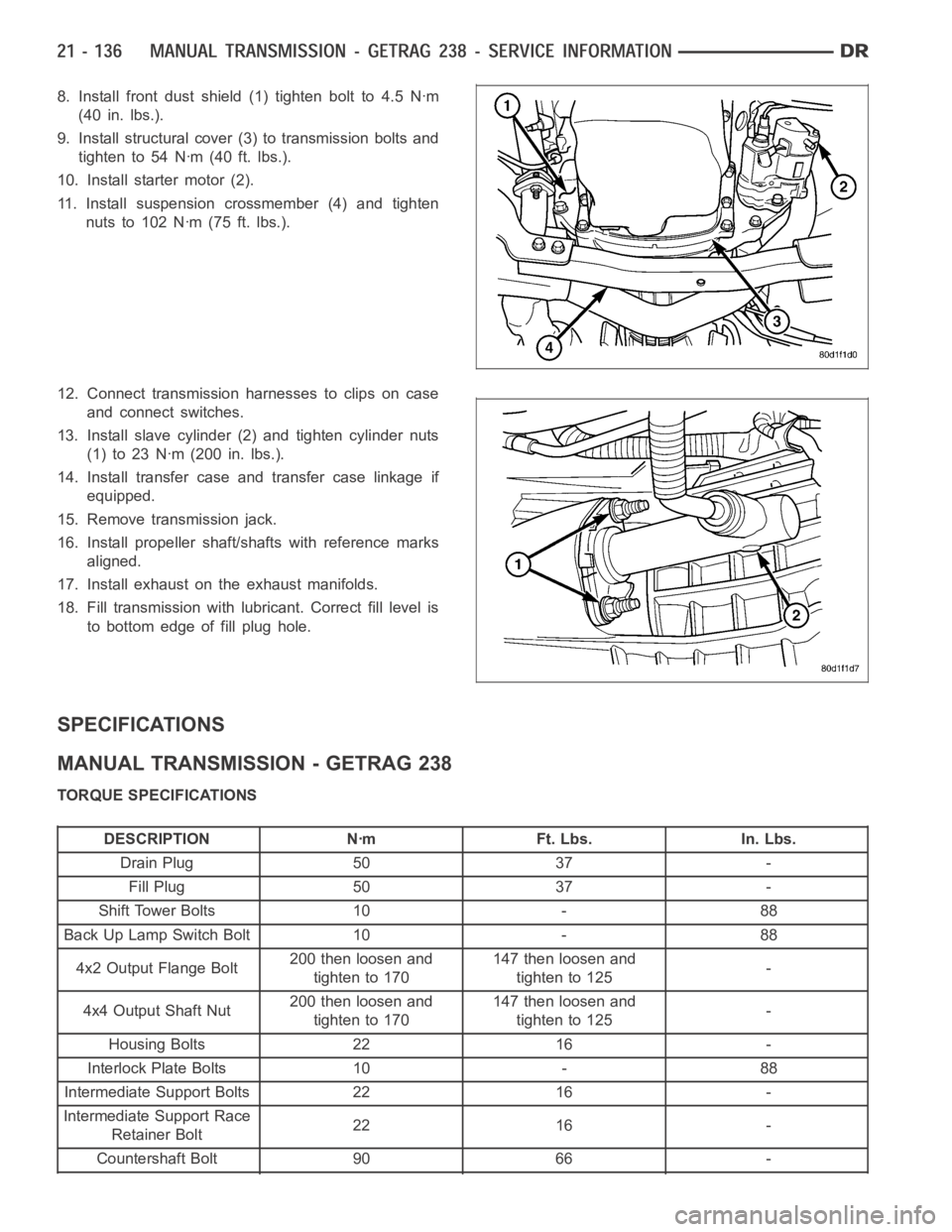

52. Install the cover plate for the second shift tower

location, if necessary.

53. Apply Mopar

Lock & Seal or equivalent to shifter

socket threads and install shifter socket (1).

Page 2656 of 5267

INSTALLATION

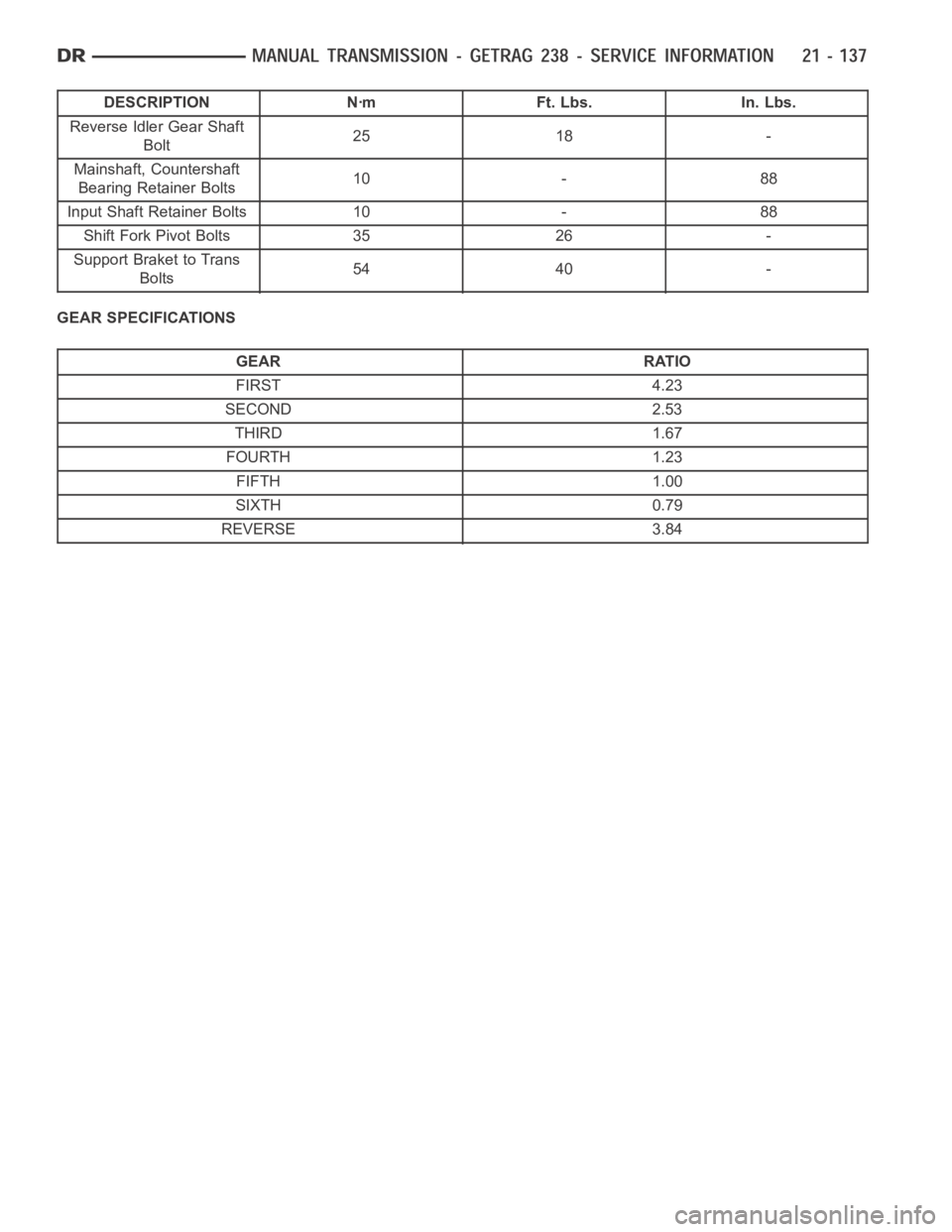

1. Clean transmission front housing mounting surface.

2. Apply light coat of Mopar high temperature bearing

grease or equivalent to contact surfaces of follow-

ing components:

release fork (1) ball stud (2)

release bearing slide surface (3)

input shaft splines (4)

release bearing bore (5)

propeller shaft slip yoke.

3. Support and secure transmission to jack.

4. Raise and align transmission input shaft with clutch

disc, then slide transmission into place.

5. Verify front housing is fully seated. Install transmis-

sion bolts without washers (1) and tighten bolts into

the engine to 41 Nꞏm (30 ft. lbs.). Tighten the bolts

with washers (2) into the transmission to 68 Nꞏm

(50 ft. lbs.).

6. Install rear crossmember (1) and tighten nuts to

102 Nꞏm (75 ft. lbs.).

7. Install transmission rear mount (2) bolts and tighten

to 68 Nꞏm (50 ft. lbs.).

Page 2657 of 5267

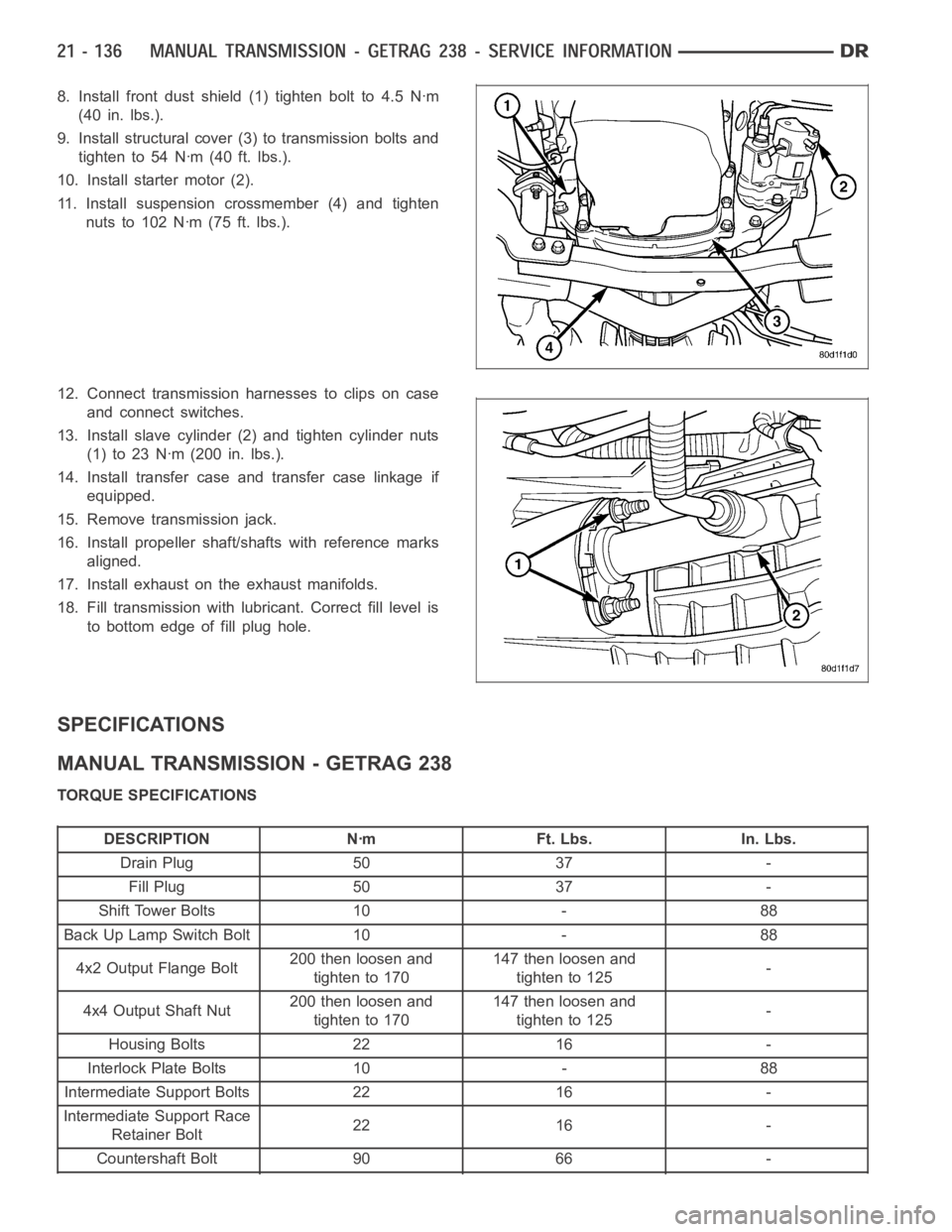

8. Install front dust shield (1) tighten bolt to 4.5 Nꞏm

(40 in. lbs.).

9. Install structural cover (3) to transmission bolts and

tighten to 54 Nꞏm (40 ft. lbs.).

10. Install starter motor (2).

11. Install suspension crossmember (4) and tighten

nuts to 102 Nꞏm (75 ft. lbs.).

12. Connect transmission harnesses to clips on case

and connect switches.

13. Install slave cylinder (2) and tighten cylinder nuts

(1)to23Nꞏm(200in.lbs.).

14. Install transfer case and transfer case linkage if

equipped.

15. Remove transmission jack.

16. Install propeller shaft/shafts with reference marks

aligned.

17. Install exhaust on the exhaust manifolds.

18. Fill transmission with lubricant. Correct fill level is

to bottom edge of fill plug hole.

SPECIFICATIONS

MANUAL TRANSMISSION - GETRAG 238

TORQUE SPECIFICATIONS

DESCRIPTION Nꞏm Ft. Lbs. In. Lbs.

Drain Plug 50 37 -

Fill Plug 50 37 -

Shift Tower Bolts 10 - 88

Back Up Lamp Switch Bolt 10 - 88

4x2 Output Flange Bolt200 then loosen and

tighten to 170147 then loosen and

tighten to 125-

4x4 Output Shaft Nut200 then loosen and

tighten to 170147 then loosen and

tighten to 125-

Housing Bolts 22 16 -

Interlock Plate Bolts 10 - 88

Intermediate Support Bolts 22 16 -

Intermediate Support Race

Retainer Bolt22 16 -

Countershaft Bolt 90 66 -

Page 2658 of 5267

DESCRIPTION Nꞏm Ft. Lbs. In. Lbs.

Reverse Idler Gear Shaft

Bolt25 18 -

Mainshaft, Countershaft

Bearing Retainer Bolts10 - 88

Input Shaft Retainer Bolts 10 - 88

Shift Fork Pivot Bolts 35 26 -

Support Braket to Trans

Bolts54 40 -

GEAR SPECIFICATIONS

GEAR RATIO

FIRST 4.23

SECOND 2.53

THIRD 1.67

FOURTH 1.23

FIFTH 1.00

SIXTH 0.79

REVERSE 3.84

Page 2659 of 5267

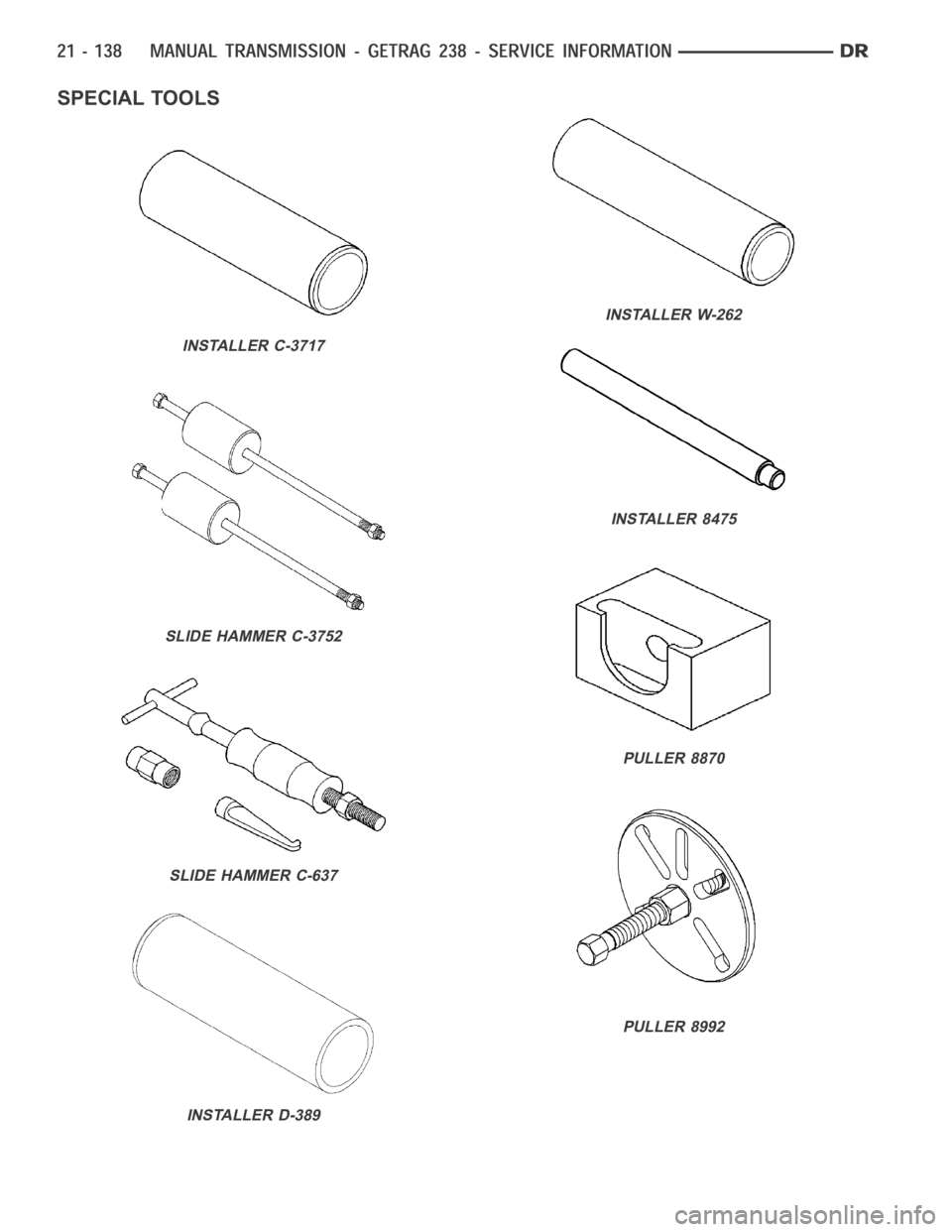

SPECIAL TOOLS

INSTALLER C-3717

SLIDE HAMMER C-3752

SLIDE HAMMER C-637

INSTALLER D-389

INSTALLER W-262

INSTALLER 8475

PULLER 8870

PULLER 8992

Page 2660 of 5267

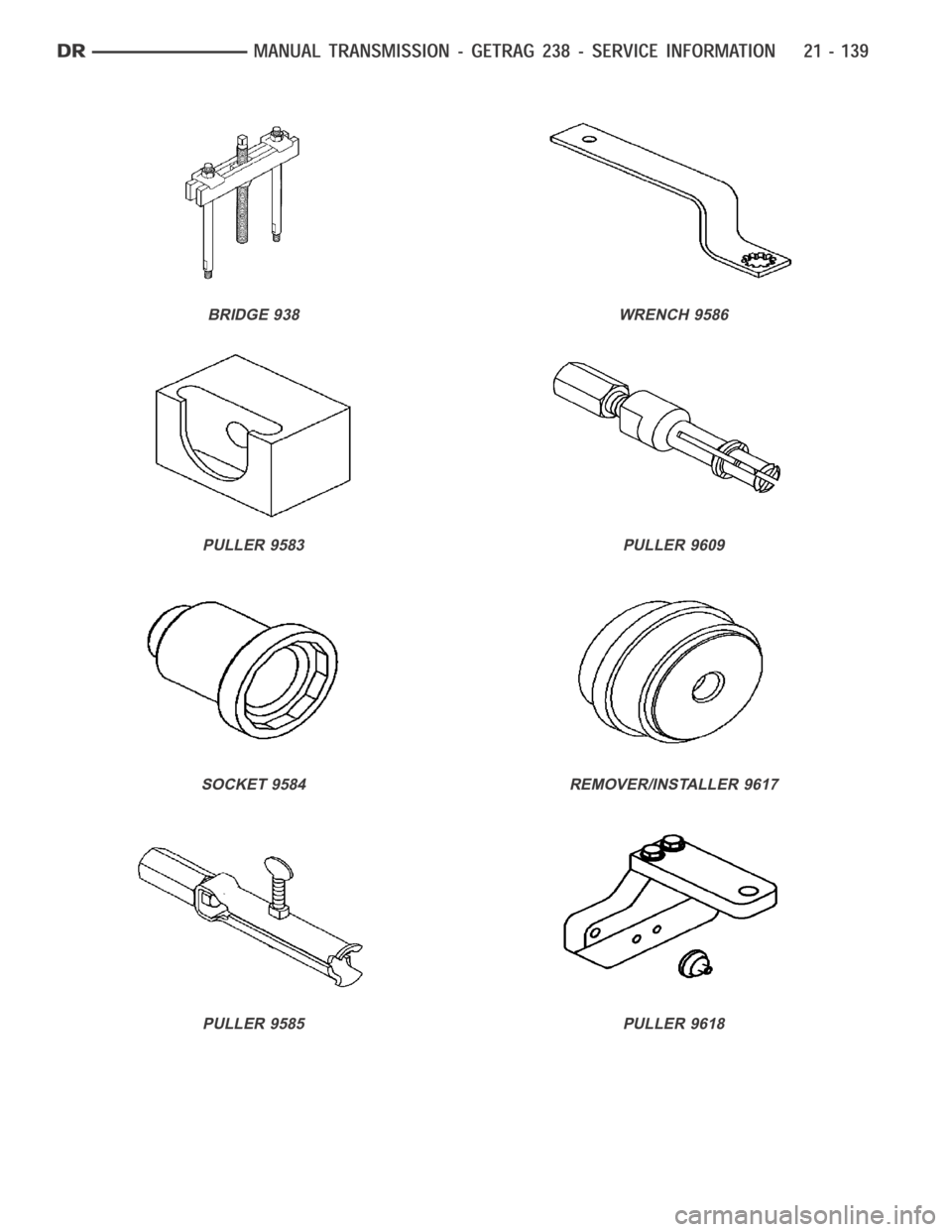

BRIDGE 938

PULLER 9583

SOCKET 9584

PULLER 9585

WRENCH 9586

PULLER 9609

REMOVER/INSTALLER 9617

PULLER 9618

Trending: length, dead battery, bolt pattern, tow, wheelbase, fuel filter, fuel tank capacity