DODGE RAM SRT-10 2006 Service Repair Manual

RAM SRT-10 2006

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56917/w960_56917-0.png

DODGE RAM SRT-10 2006 Service Repair Manual

Trending: height adjustment, tailgate, hood open, bulb, washer fluid, fuse diagram, warning

Page 2681 of 5267

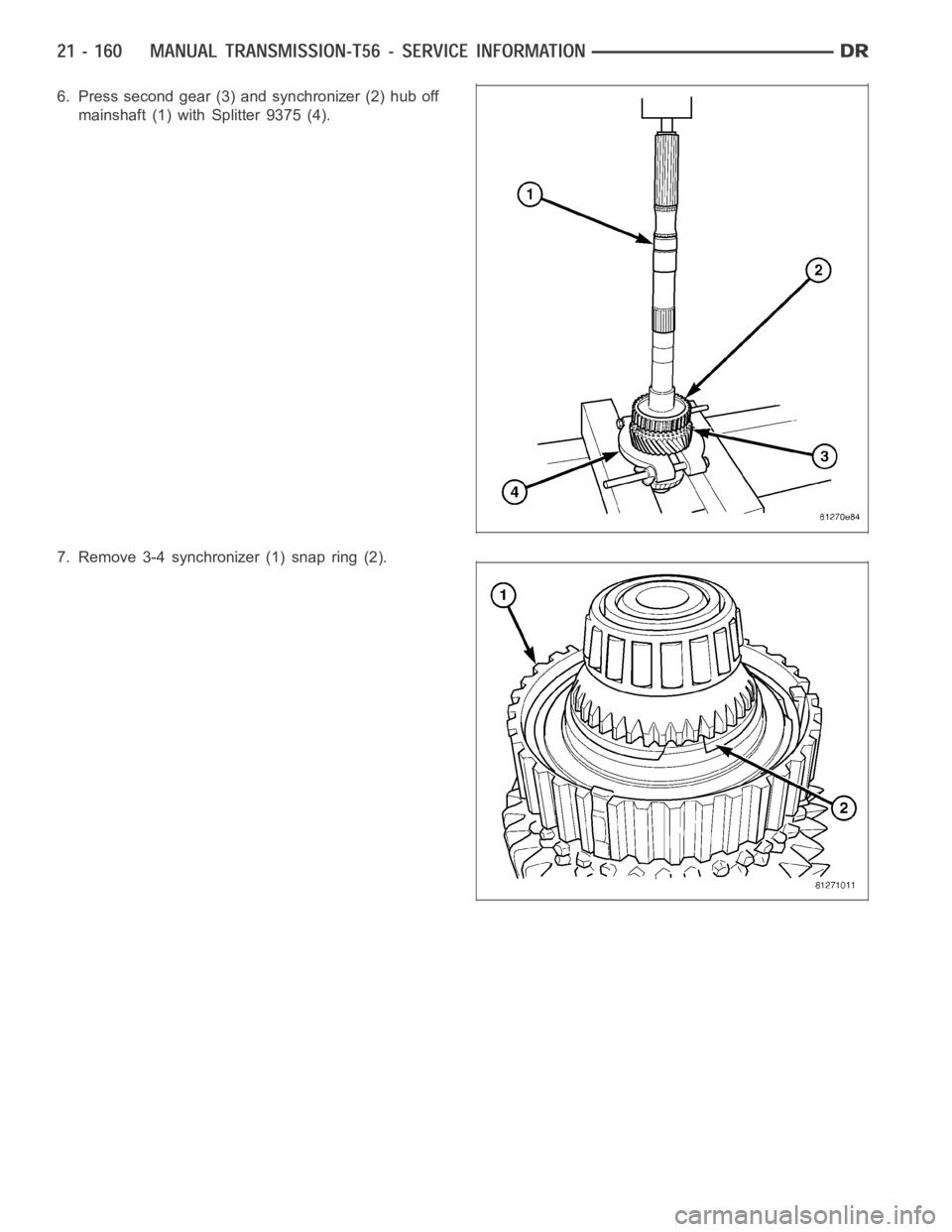

6. Press second gear (3) and synchronizer (2) hub off

mainshaft (1) with Splitter 9375 (4).

7. Remove 3-4 synchronizer (1) snap ring (2).

Page 2682 of 5267

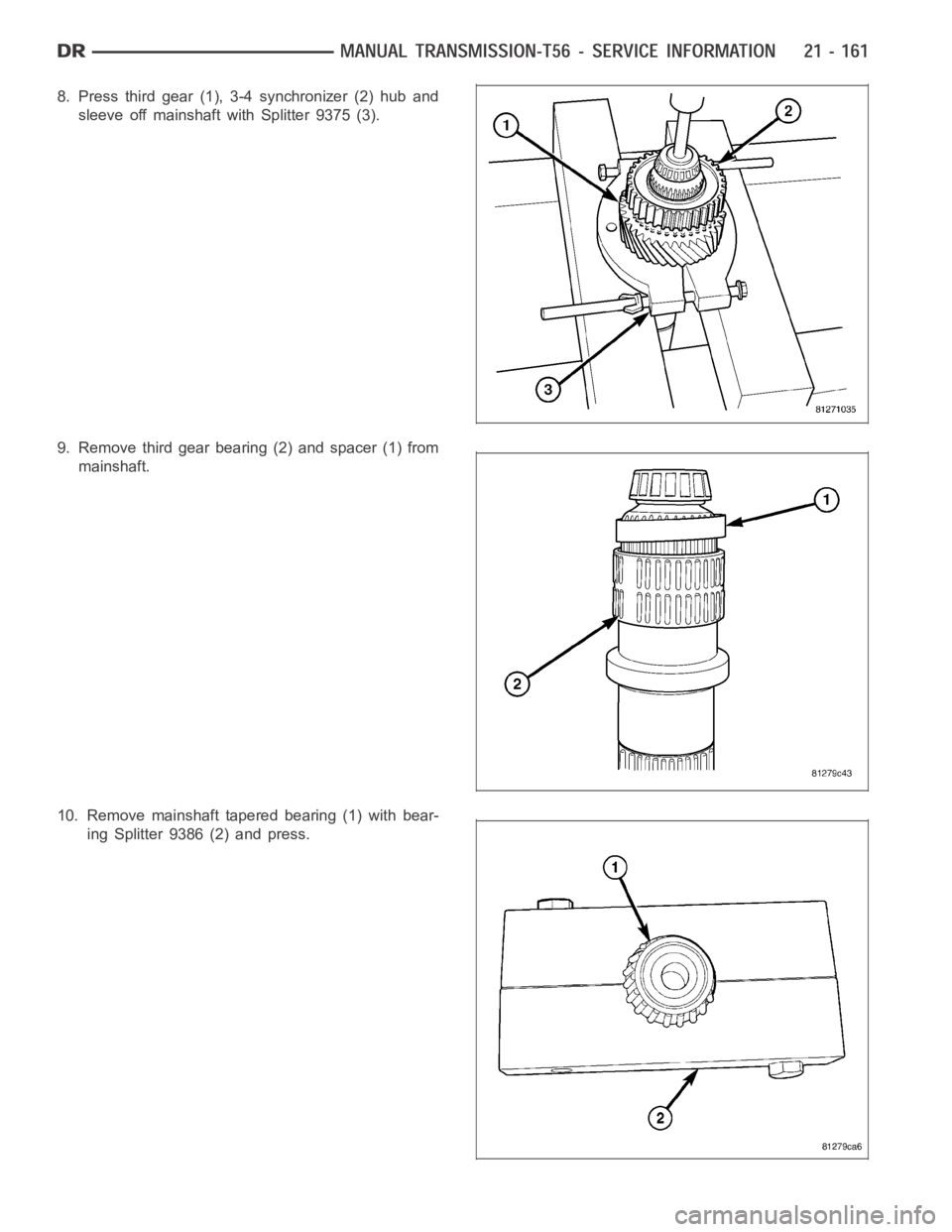

8. Press third gear (1), 3-4 synchronizer (2) hub and

sleeve off mainshaft with Splitter 9375 (3).

9. Remove third gear bearing (2) and spacer (1) from

mainshaft.

10. Remove mainshaft tapered bearing (1) with bear-

ing Splitter 9386 (2) and press.

Page 2683 of 5267

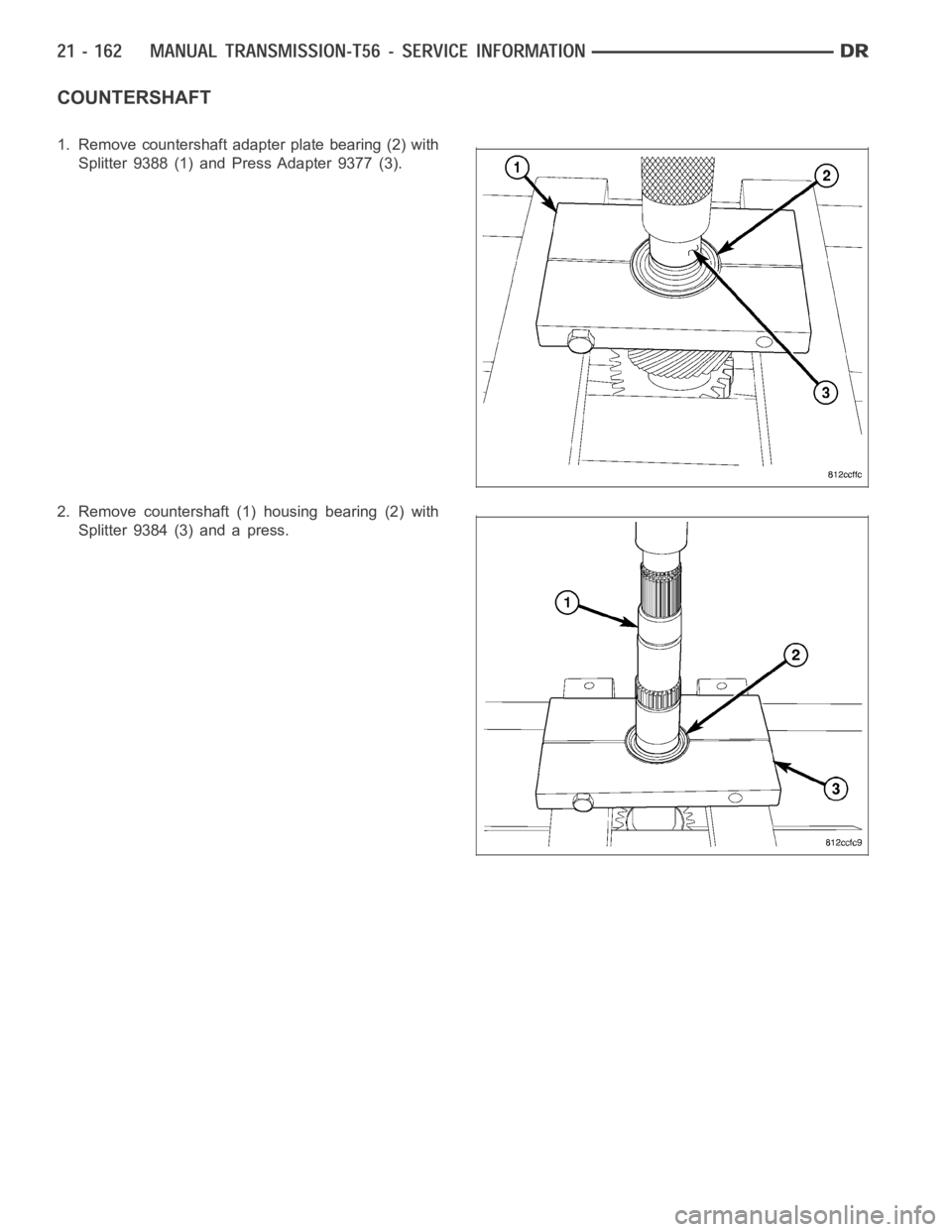

COUNTERSHAFT

1. Remove countershaft adapter plate bearing (2) with

Splitter 9388 (1) and Press Adapter 9377 (3).

2. Remove countershaft (1) housing bearing (2) with

Splitter 9384 (3) and a press.

Page 2684 of 5267

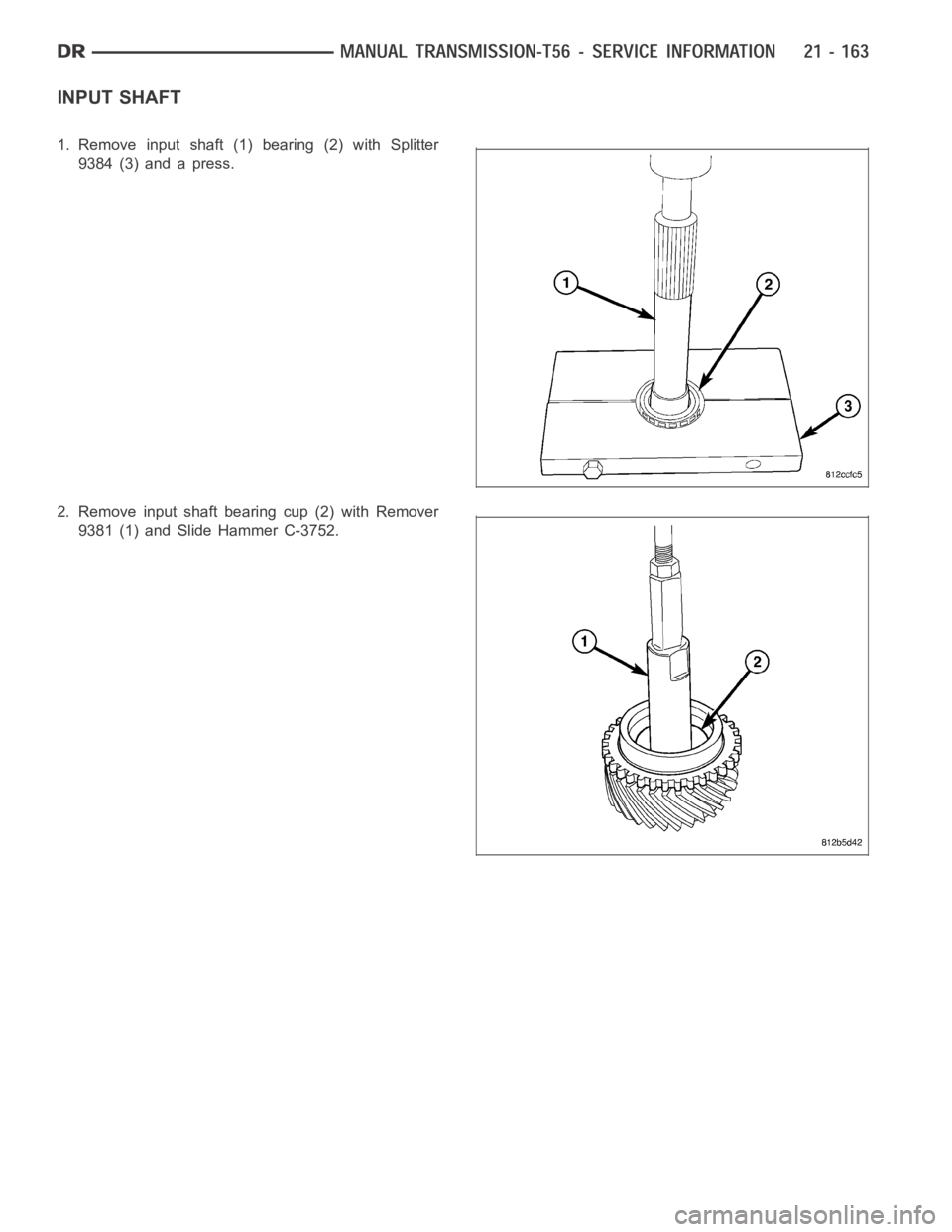

INPUT SHAFT

1. Remove input shaft (1) bearing (2) with Splitter

9384 (3) and a press.

2. Remove input shaft bearing cup (2) with Remover

9381 (1) and Slide Hammer C-3752.

Page 2685 of 5267

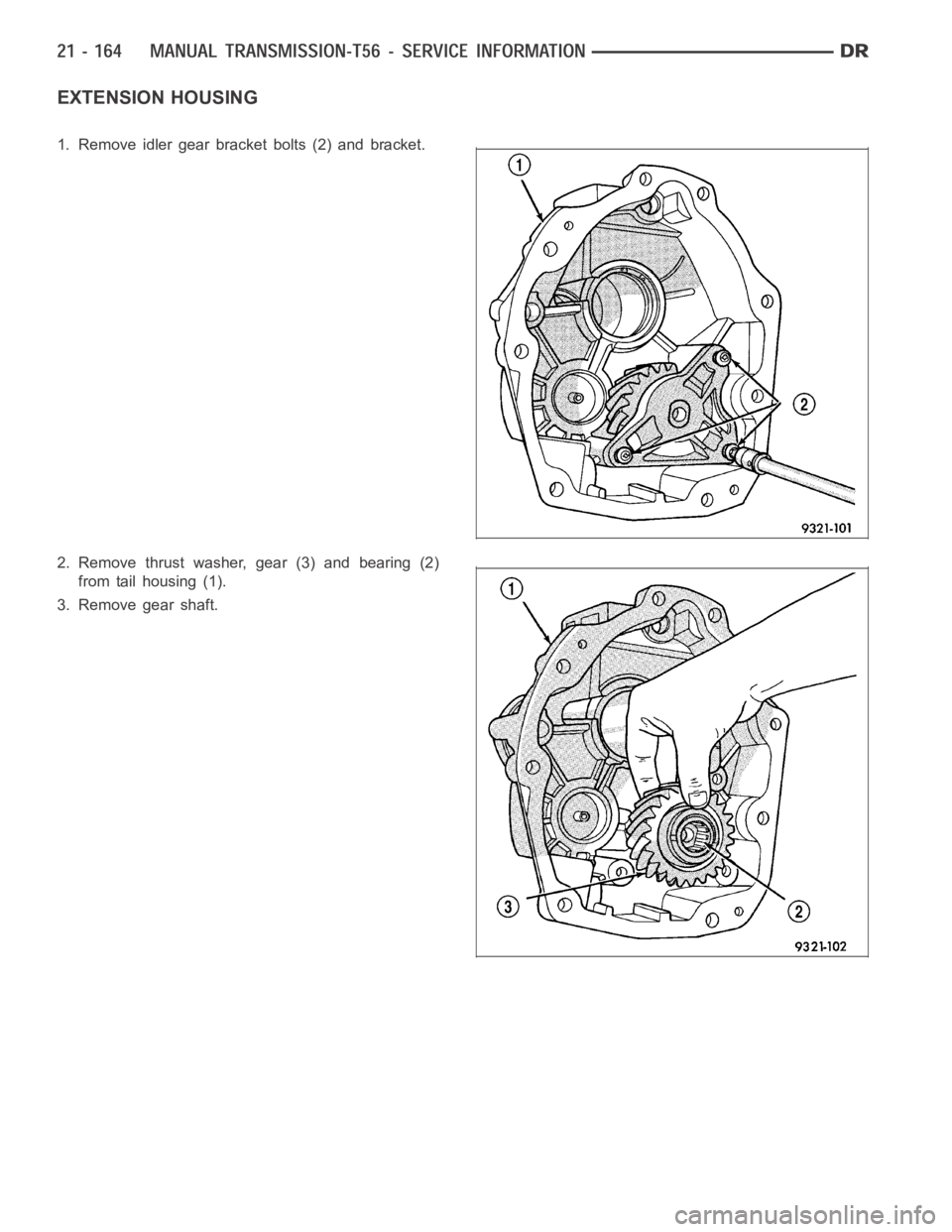

EXTENSION HOUSING

1. Remove idler gear bracket bolts (2) and bracket.

2. Remove thrust washer, gear (3) and bearing (2)

from tail housing (1).

3. Remove gear shaft.

Page 2686 of 5267

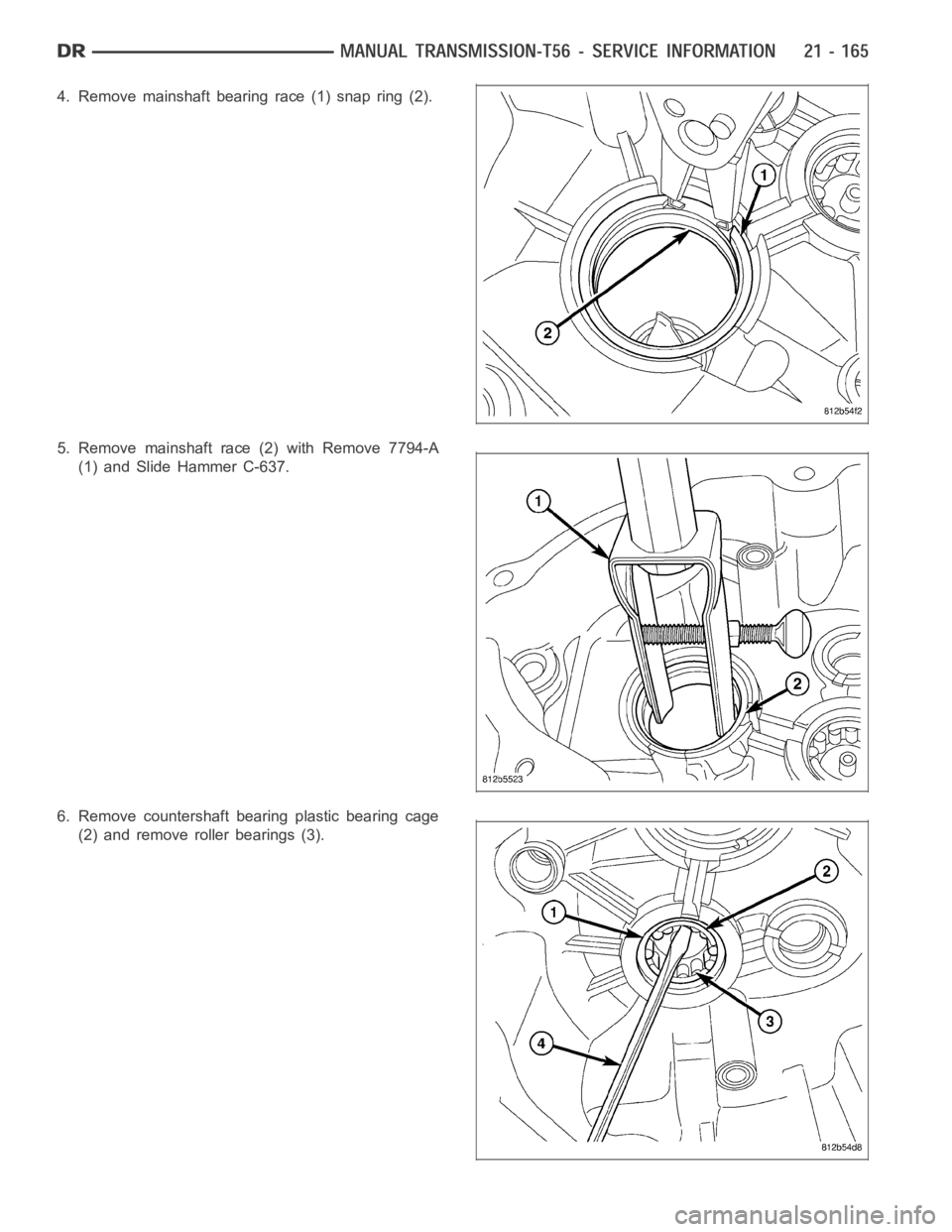

4. Remove mainshaft bearing race (1) snap ring (2).

5. Remove mainshaft race (2) with Remove 7794-A

(1) and Slide Hammer C-637.

6. Remove countershaft bearing plastic bearing cage

(2) and remove roller bearings (3).

Page 2687 of 5267

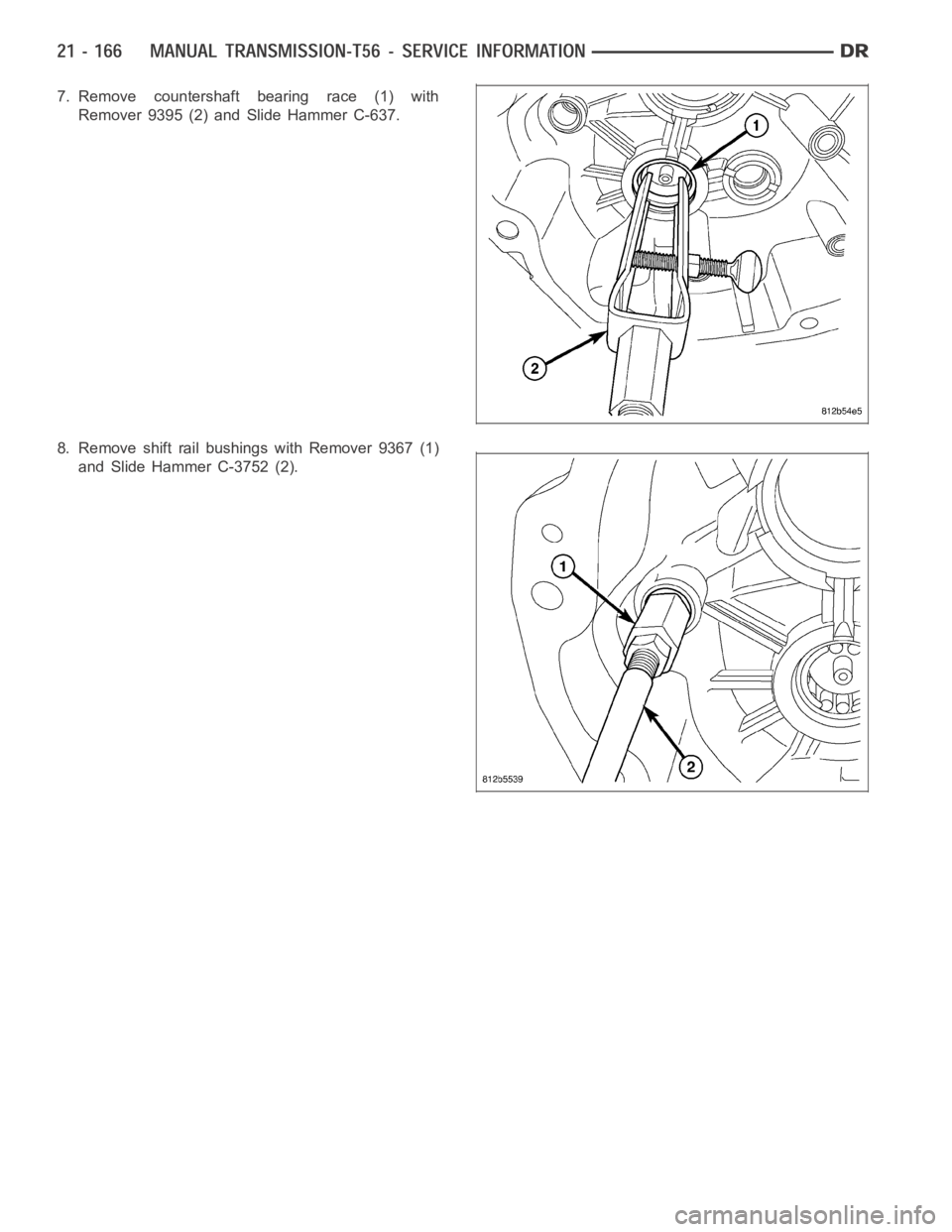

7. Remove countershaft bearing race (1) with

Remover 9395 (2) and Slide Hammer C-637.

8. Remove shift rail bushings with Remover 9367 (1)

and Slide Hammer C-3752 (2).

Page 2688 of 5267

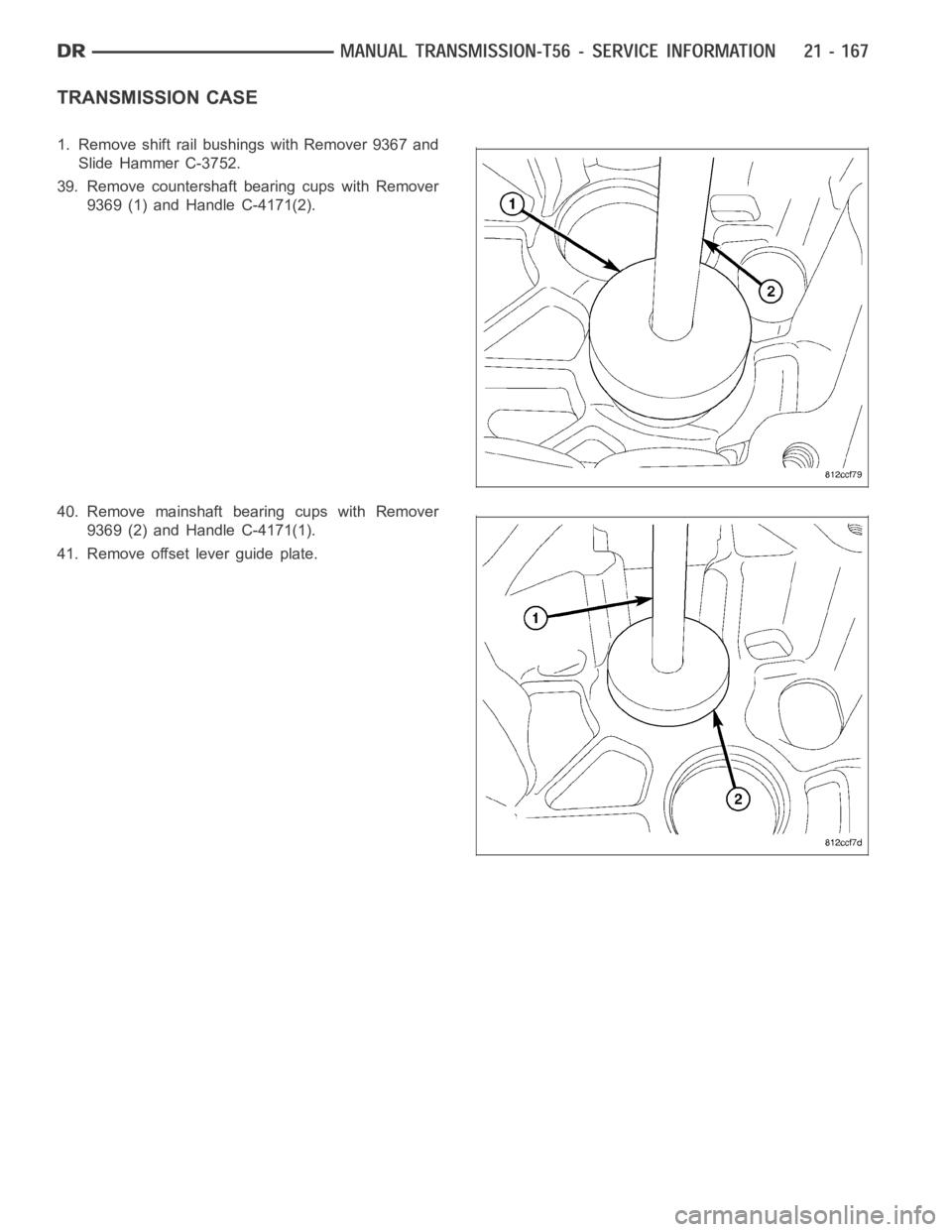

TRANSMISSION CASE

1. Remove shift rail bushings with Remover 9367 and

Slide Hammer C-3752.

39. Remove countershaft bearing cups with Remover

9369 (1) and Handle C-4171(2).

40. Remove mainshaft bearing cups with Remover

9369 (2) and Handle C-4171(1).

41. Remove offset lever guide plate.

Page 2689 of 5267

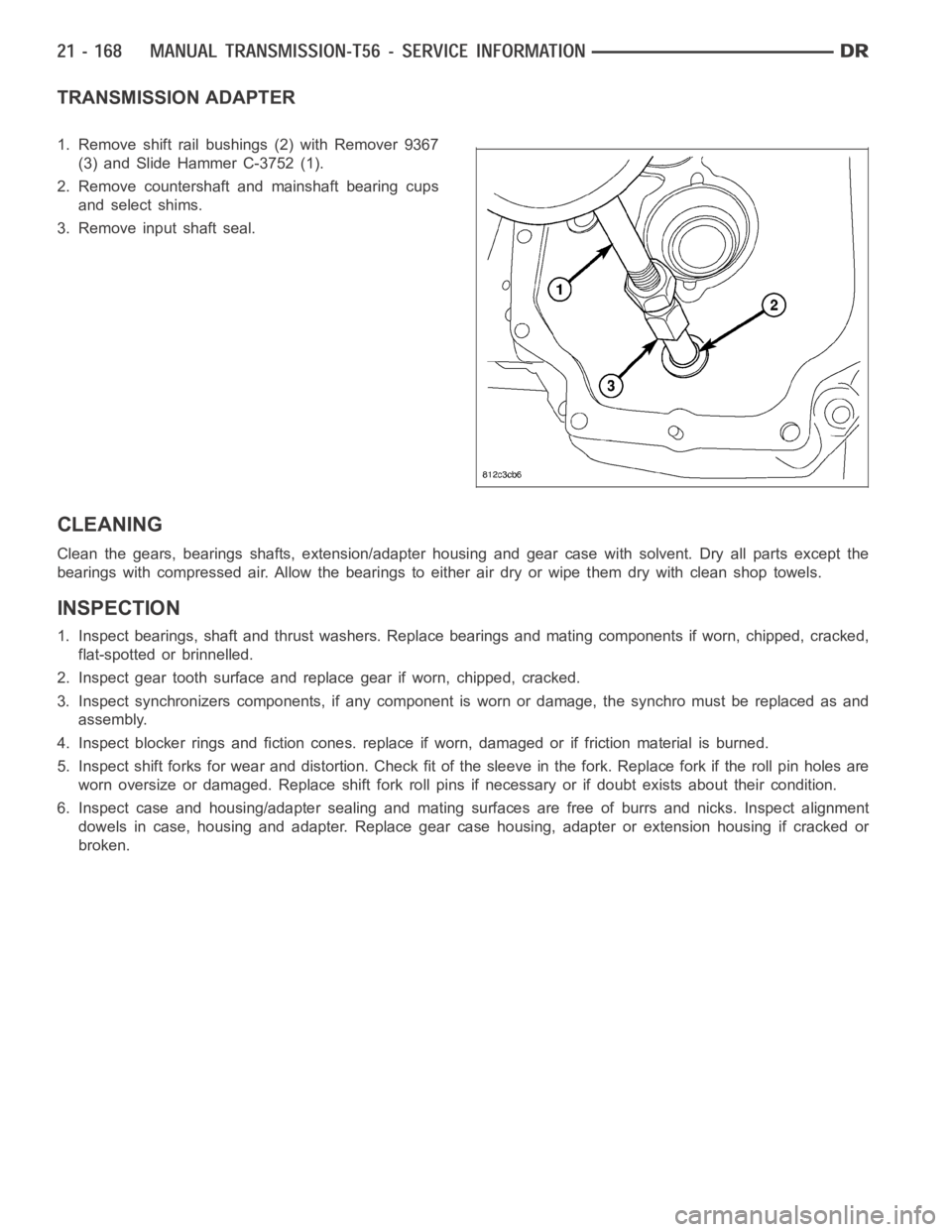

TRANSMISSION ADAPTER

1. Remove shift rail bushings (2) with Remover 9367

(3) and Slide Hammer C-3752 (1).

2. Remove countershaft and mainshaft bearing cups

and select shims.

3. Remove input shaft seal.

CLEANING

Clean the gears, bearings shafts, extension/adapter housing and gear case with solvent. Dry all parts except the

bearings with compressed air. Allow the bearings to either air dry or wipe them dry with clean shop towels.

INSPECTION

1. Inspect bearings, shaft and thrust washers. Replace bearings and mating components if worn, chipped, cracked,

flat-spotted or brinnelled.

2. Inspect gear tooth surface and replace gear if worn, chipped, cracked.

3. Inspect synchronizers components, if any component is worn or damage, the synchro must be replaced as and

assembly.

4. Inspect blocker rings and fiction cones. replace if worn, damaged or if friction material is burned.

5. Inspect shift forks for wear and distortion. Check fit of the sleeve in the fork. Replace fork if the roll pin holes are

worn oversize or damaged. Replace shift fork roll pins if necessary or if doubt exists about their condition.

6. Inspect case and housing/adapter sealing and mating surfaces are free of burrs and nicks. Inspect alignment

dowels in case, housing and adapter. Replace gear case housing, adapter orextension housing if cracked or

broken.

Page 2690 of 5267

ASSEMBLY

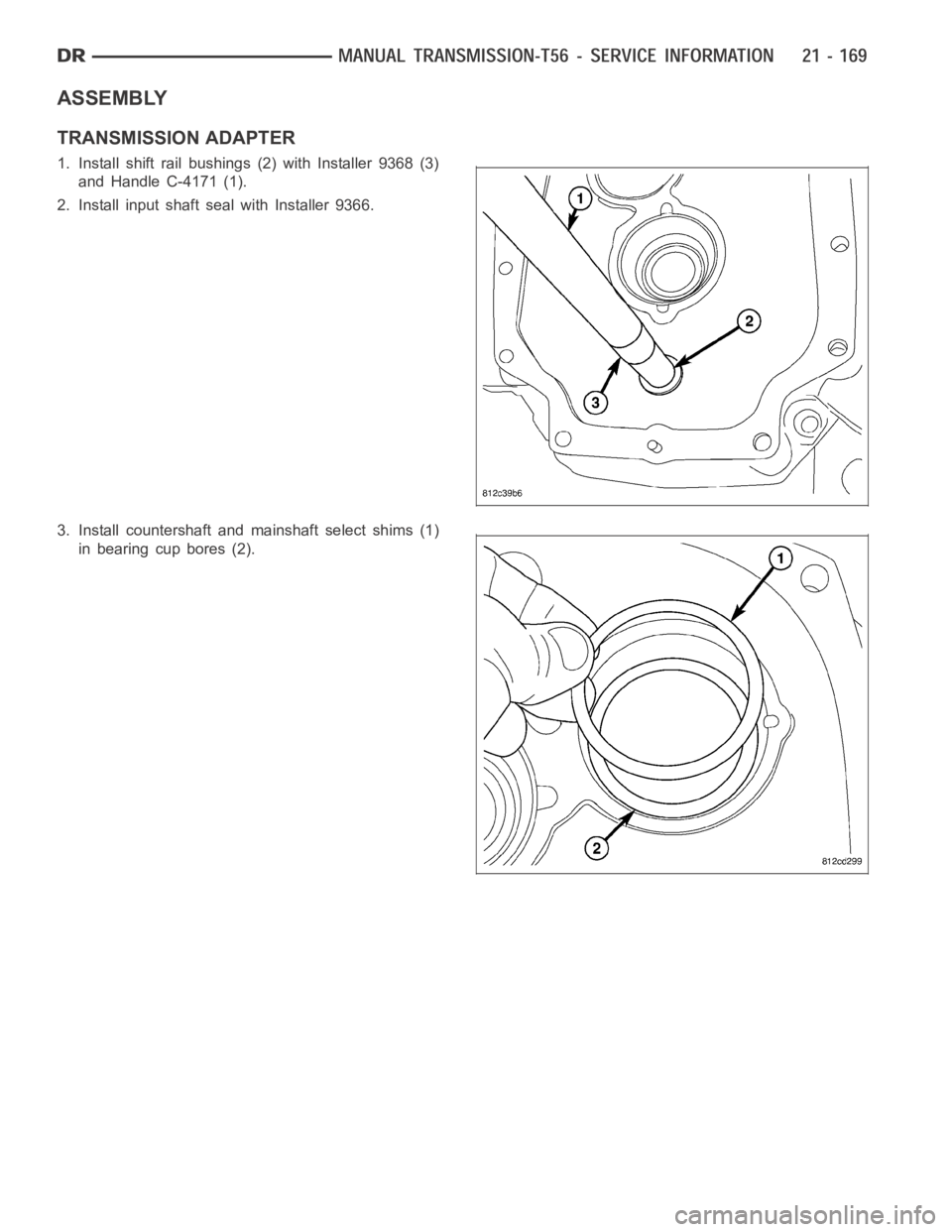

TRANSMISSION ADAPTER

1. Install shift rail bushings (2) with Installer 9368 (3)

and Handle C-4171 (1).

2. Install input shaft seal with Installer 9366.

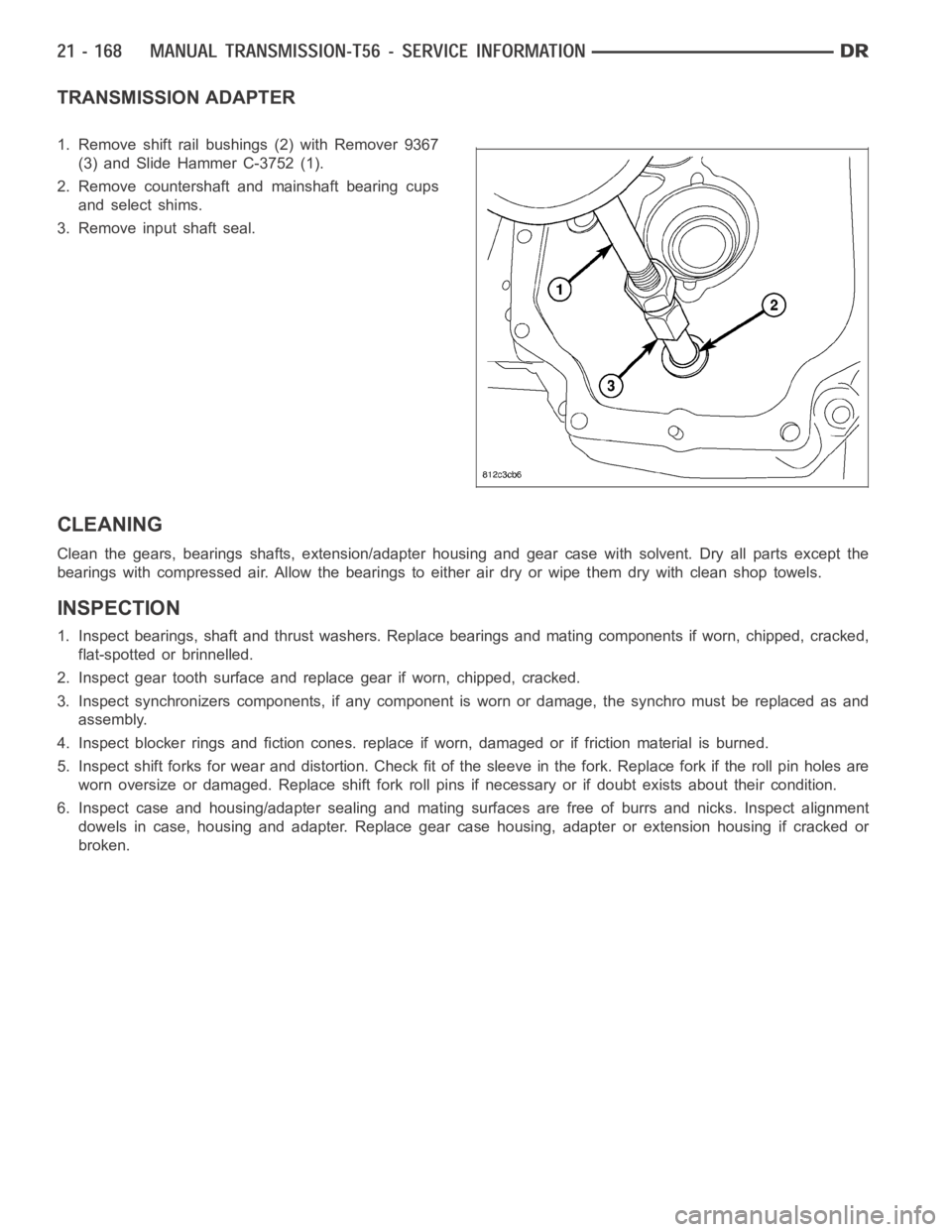

3. Install countershaft and mainshaft select shims (1)

in bearing cup bores (2).

Trending: change wheel, automatic transmission, air suspension, brake fluid, width, Crank pulley bolt, relay