DODGE RAM SRT-10 2006 Service Repair Manual

RAM SRT-10 2006

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56917/w960_56917-0.png

DODGE RAM SRT-10 2006 Service Repair Manual

Trending: coolant capacity, radiator cap, engine, oil level, checking oil, 8.3l engine removal tools, automatic transmission

Page 2661 of 5267

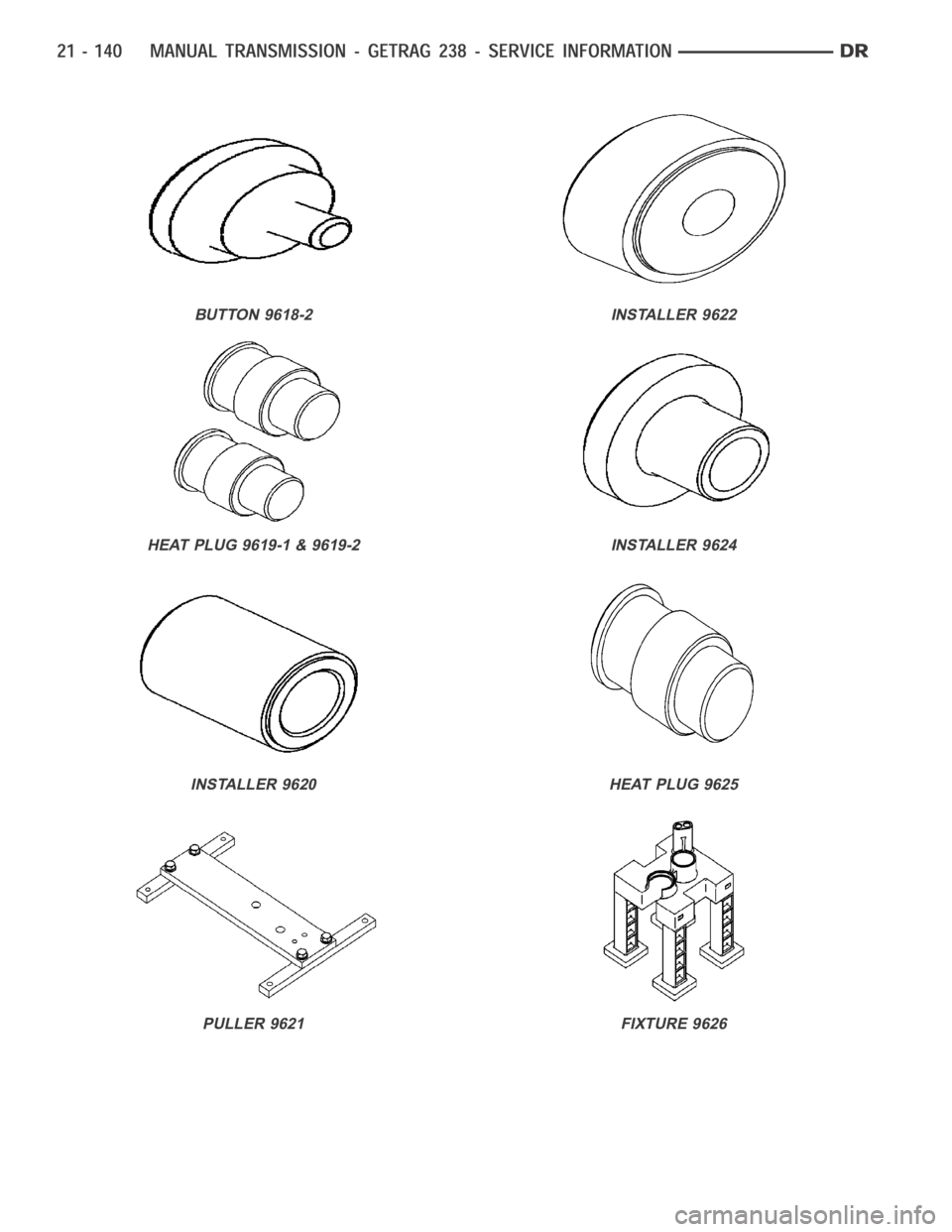

BUTTON 9618-2

HEAT PLUG 9619-1 & 9619-2

INSTALLER 9620

PULLER 9621

INSTALLER 9622

INSTALLER 9624

HEAT PLUG 9625

FIXTURE 9626

Page 2662 of 5267

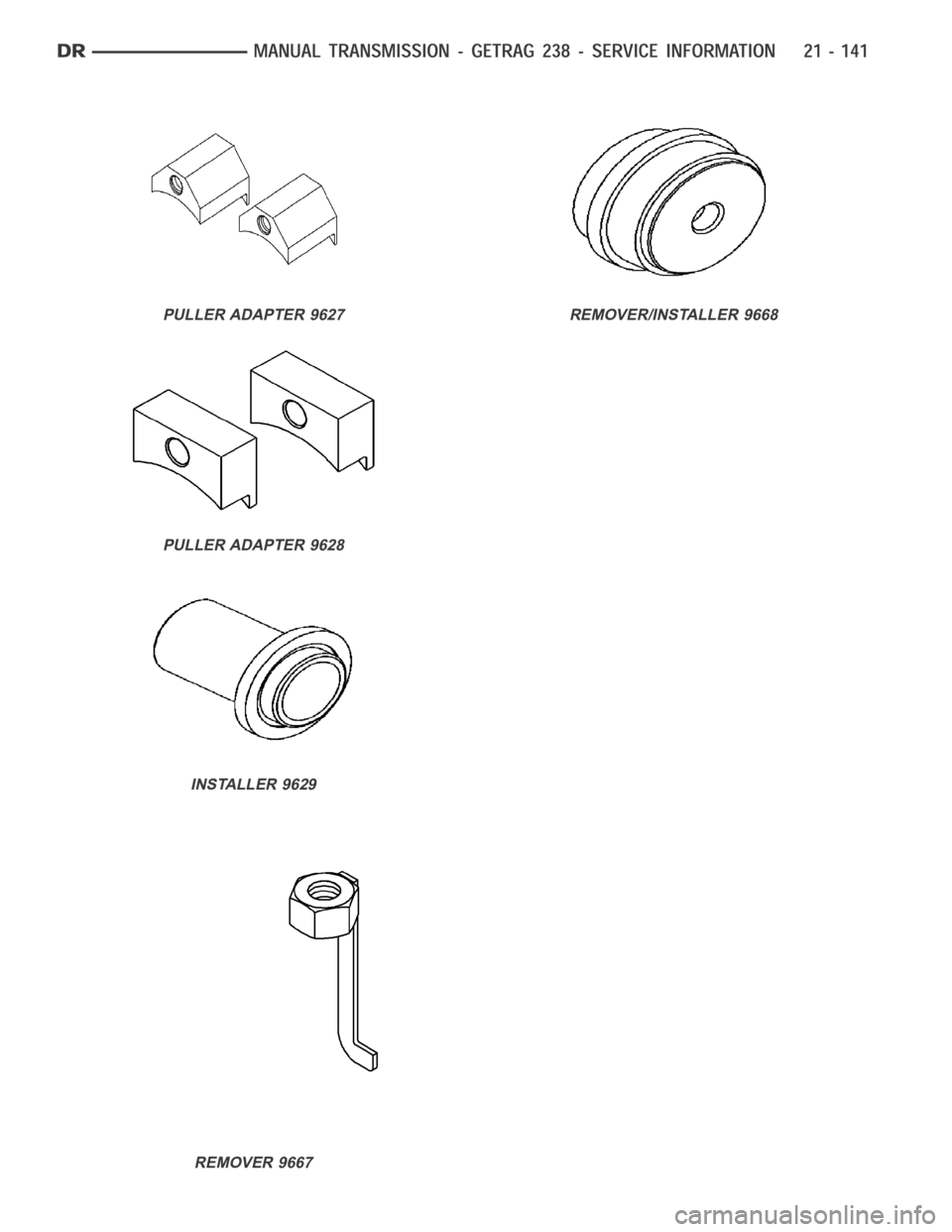

PULLER ADAPTER 9627

PULLER ADAPTER 9628

INSTALLER 9629

REMOVER 9667

REMOVER/INSTALLER 9668

Page 2663 of 5267

page page

MANUAL TRANSMISSION-T56 - SERVICE

INFORMATION

DIAGNOSIS AND TESTING

MANUAL TRANSMISSION - T56 ............. 143

STANDARD PROCEDURE - DRAIN AND FILL . . 143

REMOVAL ................................... 144

DISASSEMBLY .............................. 146

CLEANING .................................. 168

INSPECTION ................................ 168

ASSEMBLY .................................. 169

INSTALLATION .............................. 189

ADJUSTMENTS

ADUSTMENTS ............................ 191

SPECIFICATIONS

MANUAL TRANSMISSION - T56 ............. 192SPECIAL TOOLS ............................ 194

SEAL-EXTENSION HOUSING

REMOVAL ................................... 198

INSTALLATION .............................. 198

SHAFT-INPUT

REMOVAL ................................... 199

INSTALLATION .............................. 200

SOLENOID-REVERSE LOCKOUT

DESCRIPTION ............................... 201

OPERATION ................................. 201

SOLENOID-REVERSE LOCK-OUT

DESCRIPTION ............................... 202

OPERATION ................................. 202

Page 2664 of 5267

MANUAL TRANSMISSION-T56 - SERVICE INFORMATION

DIAGNOSIS AND TESTING

MANUAL TRANSMISSION - T56

LOW LUBRICANT LEVEL

A low transmission lubricant level is generally the result of a leak, inadequate lubricant fill or incorrect lubricant level

check.

Rear transmission leakswill be from the oil seals or component mating surfaces.

Front transmission leakswill be from the front bearing retainer or retainer seal. Lubricant may dripfromtheclutch

housing after extended operation. If leak is severe, it may contaminate the clutch disc.

Lubricant level checkcan only be made when the vehicle is level and allowing the lubricant to settle for a minute

before checking. This will ensure an accurate check and avoid an underfillor overfill condition.

HARD SHIFTING

Hard shifting is usually caused by low lubricant level, improper or contaminated lubricants. This will cause noise,

excessive wear, internal bind, and hard shifting. Substantial lubricantleaks can result in gear, shift rail, synchro, and

bearing damage. The first indications of component damage is usually hardshifting and noise.

Shift component damage, clutch adjustment, worn pressure plate or disc are also causes of increased shift effort. If

clutch problem is advanced, gear clash during shifts can result. Worn or damaged synchro rings can cause gear

clash when shifting into any forward gear. In some new or rebuilt transmissions, new synchro rings may tend to stick

slightly causing hard or noisy shifts. In most cases, this condition will decline as the rings wear-in.

TRANSMISSION NOISE

Most manual transmissions make some noise during normal operation. Rotating gears generate a mild whine that is

audible, but generally only at extreme speeds.

Severe, highly audible transmission noise is generally the initial indicator of a lubricant problem. Insufficient,

improper or contaminated lubricant will promote rapid wear of gears, synchros, shift rails, forks and bearings. The

overheating caused by a lubricant problem, can also lead to gear and bearing damage.

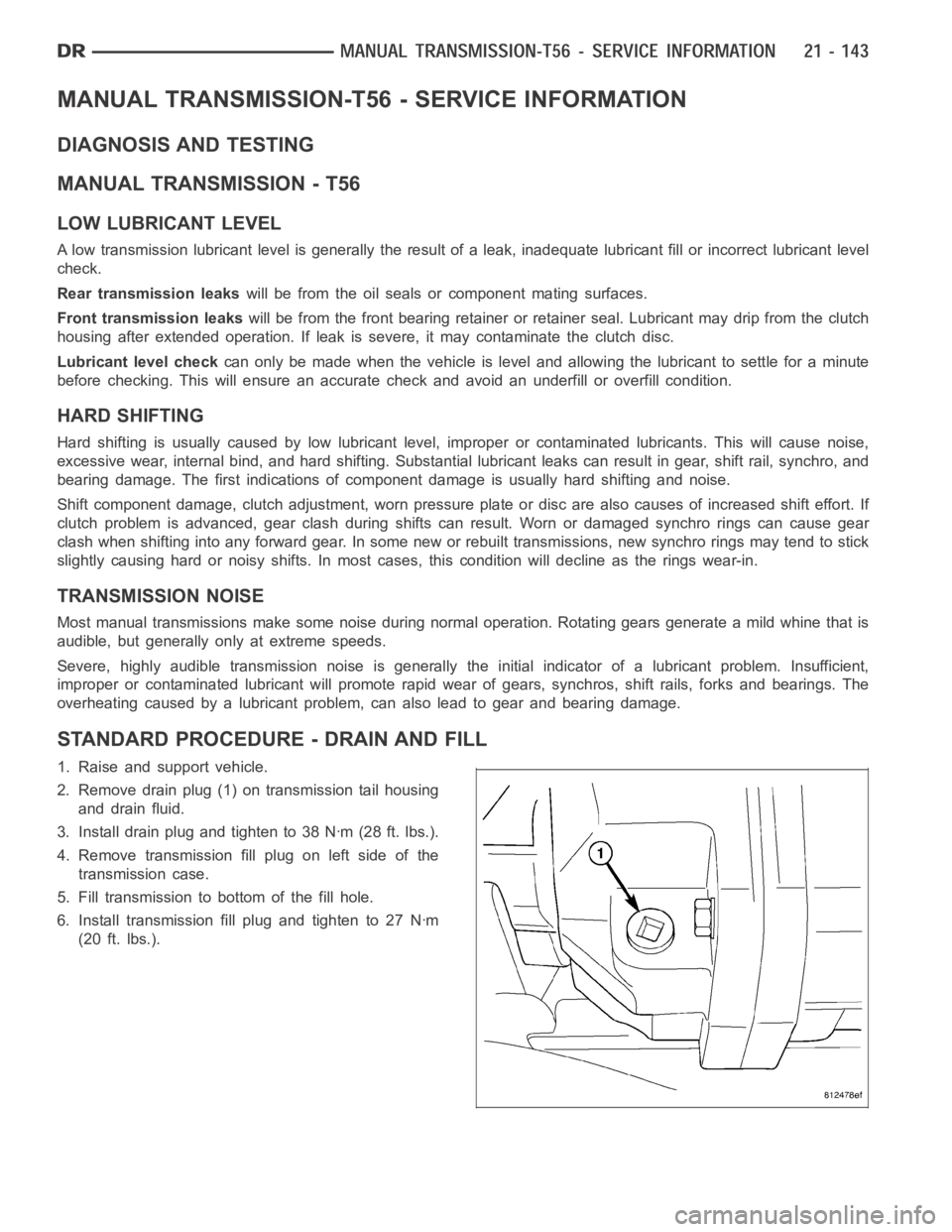

STANDARD PROCEDURE - DRAIN AND FILL

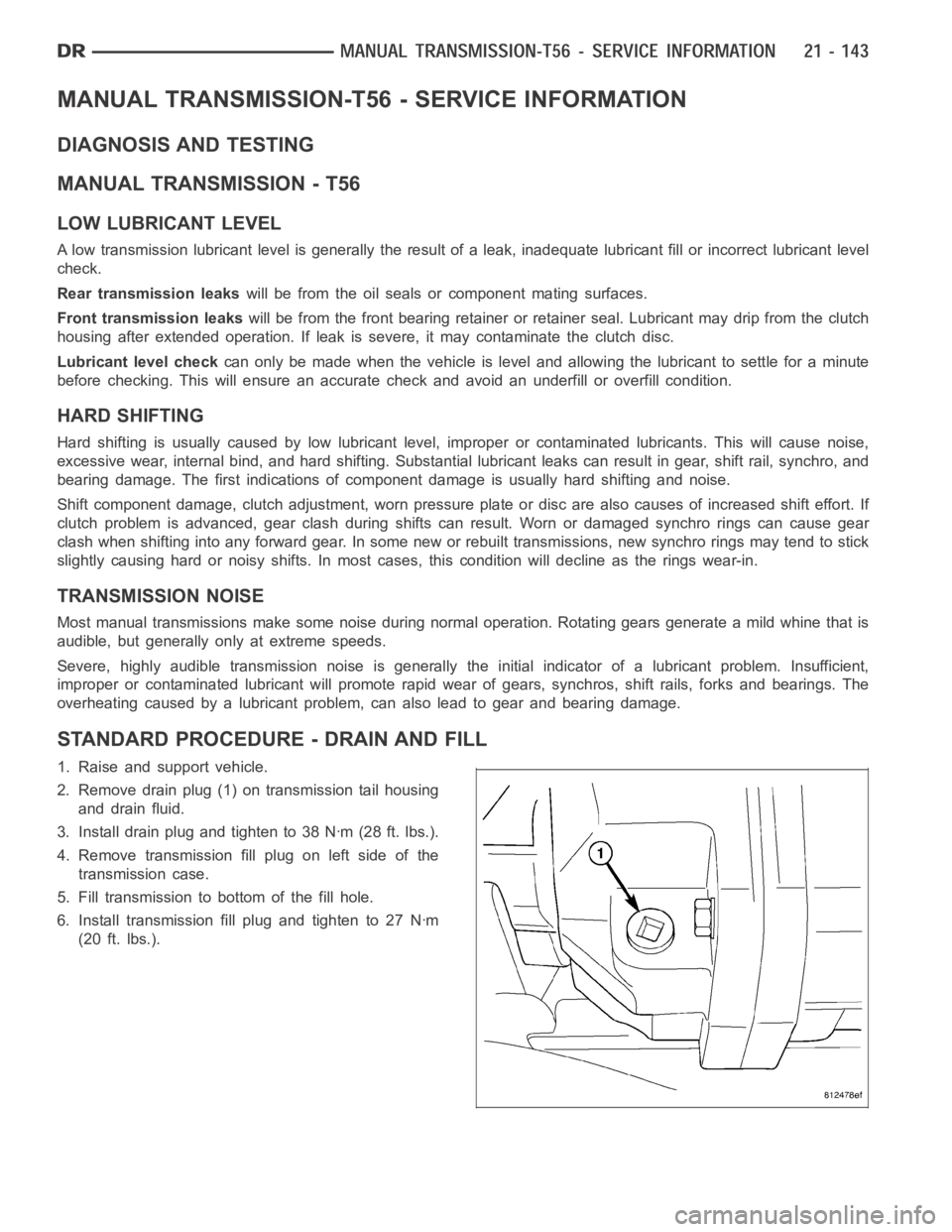

1. Raise and support vehicle.

2. Remove drain plug (1) on transmission tail housing

and drain fluid.

3. Install drain plug and tighten to 38 Nꞏm (28 ft. lbs.).

4. Remove transmission fill plug on left side of the

transmission case.

5. Fill transmission to bottom of the fill hole.

6. Install transmission fill plug and tighten to 27 Nꞏm

(20 ft. lbs.).

Page 2665 of 5267

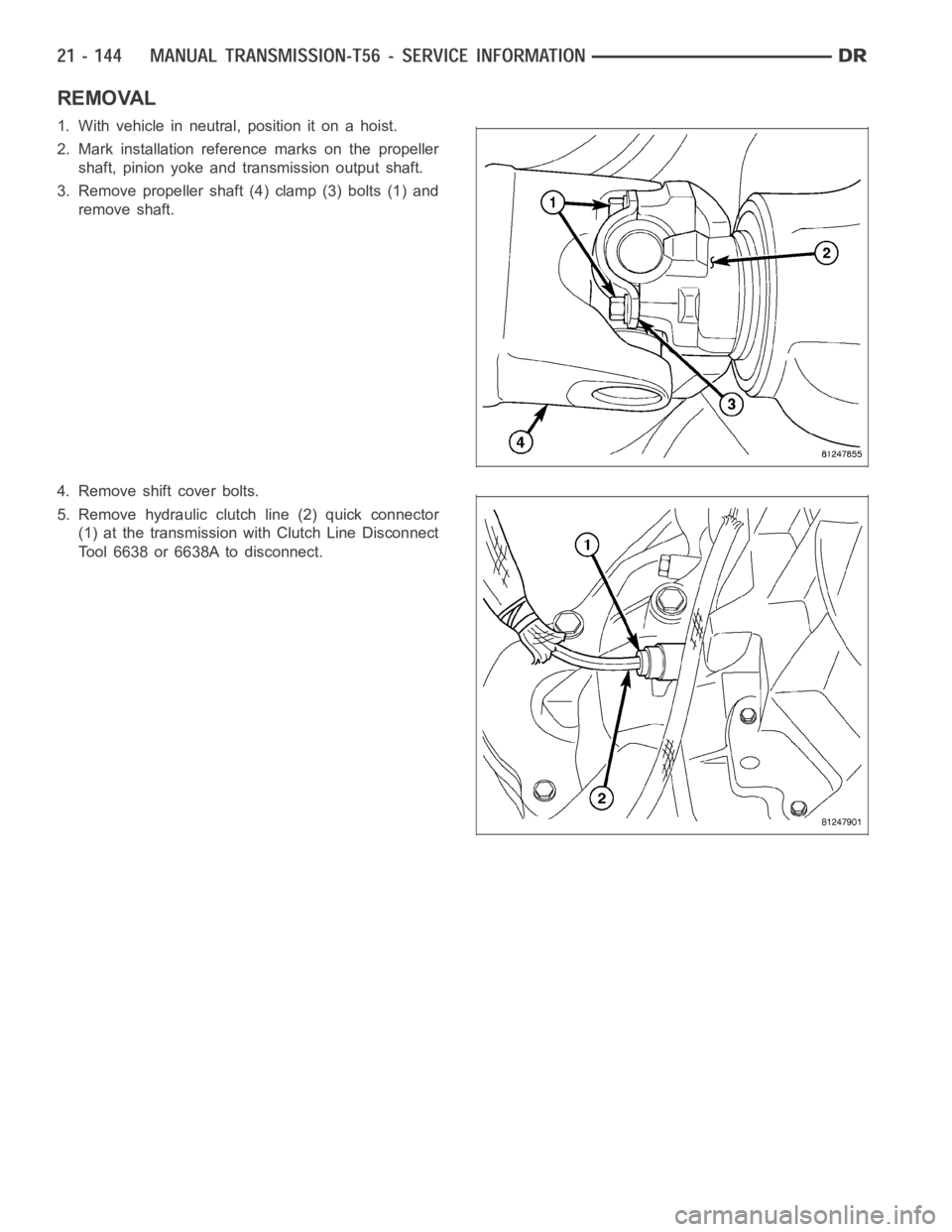

REMOVAL

1. With vehicle in neutral, position it on a hoist.

2. Mark installation reference marks on the propeller

shaft, pinion yoke and transmission output shaft.

3. Remove propeller shaft (4) clamp (3) bolts (1) and

remove shaft.

4. Remove shift cover bolts.

5. Remove hydraulic clutch line (2) quick connector

(1) at the transmission with Clutch Line Disconnect

Tool 6638 or 6638A to disconnect.

Page 2666 of 5267

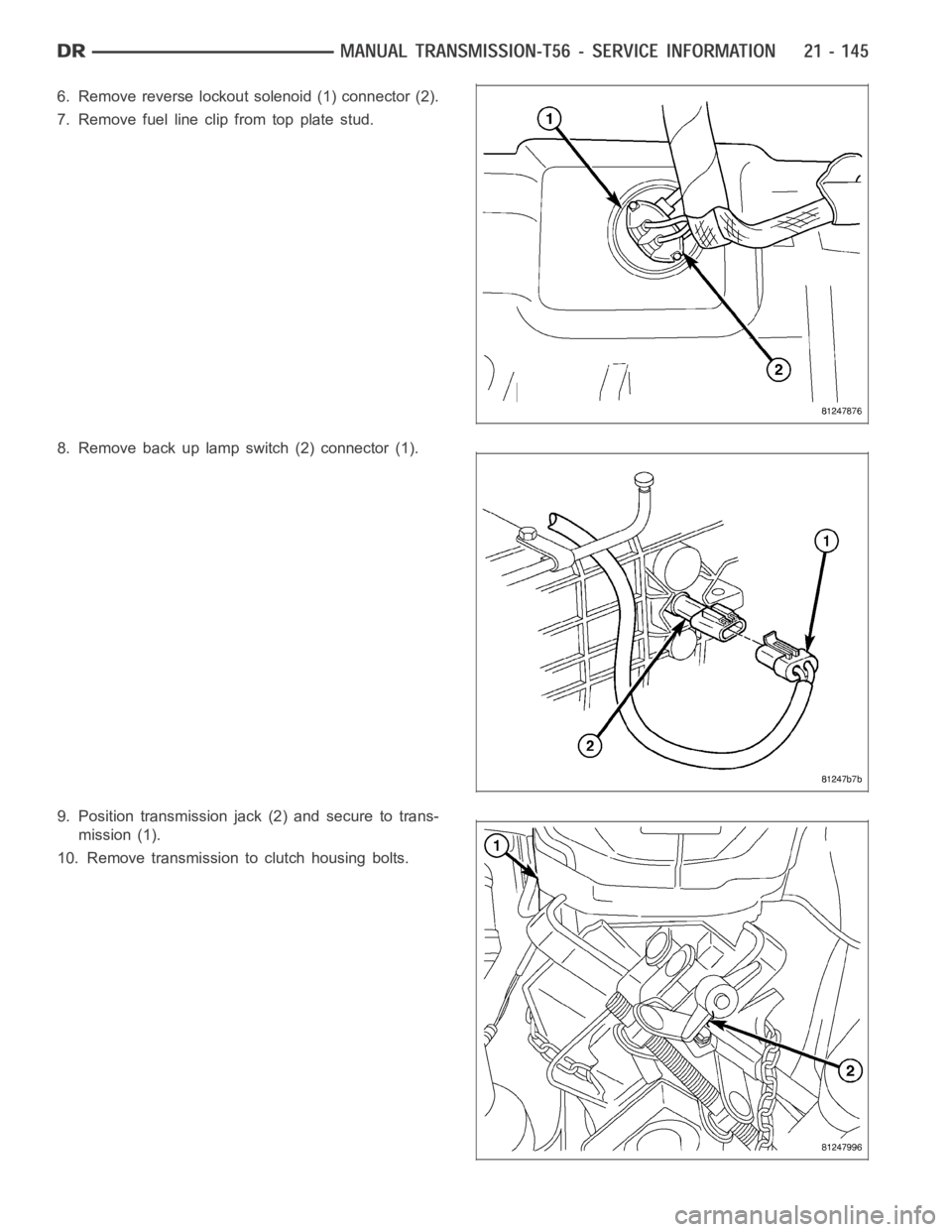

6. Remove reverse lockout solenoid (1) connector (2).

7. Remove fuel line clipfrom top plate stud.

8. Remove back up lamp switch (2) connector (1).

9. Position transmission jack (2) and secure to trans-

mission (1).

10. Remove transmission to clutch housing bolts.

Page 2667 of 5267

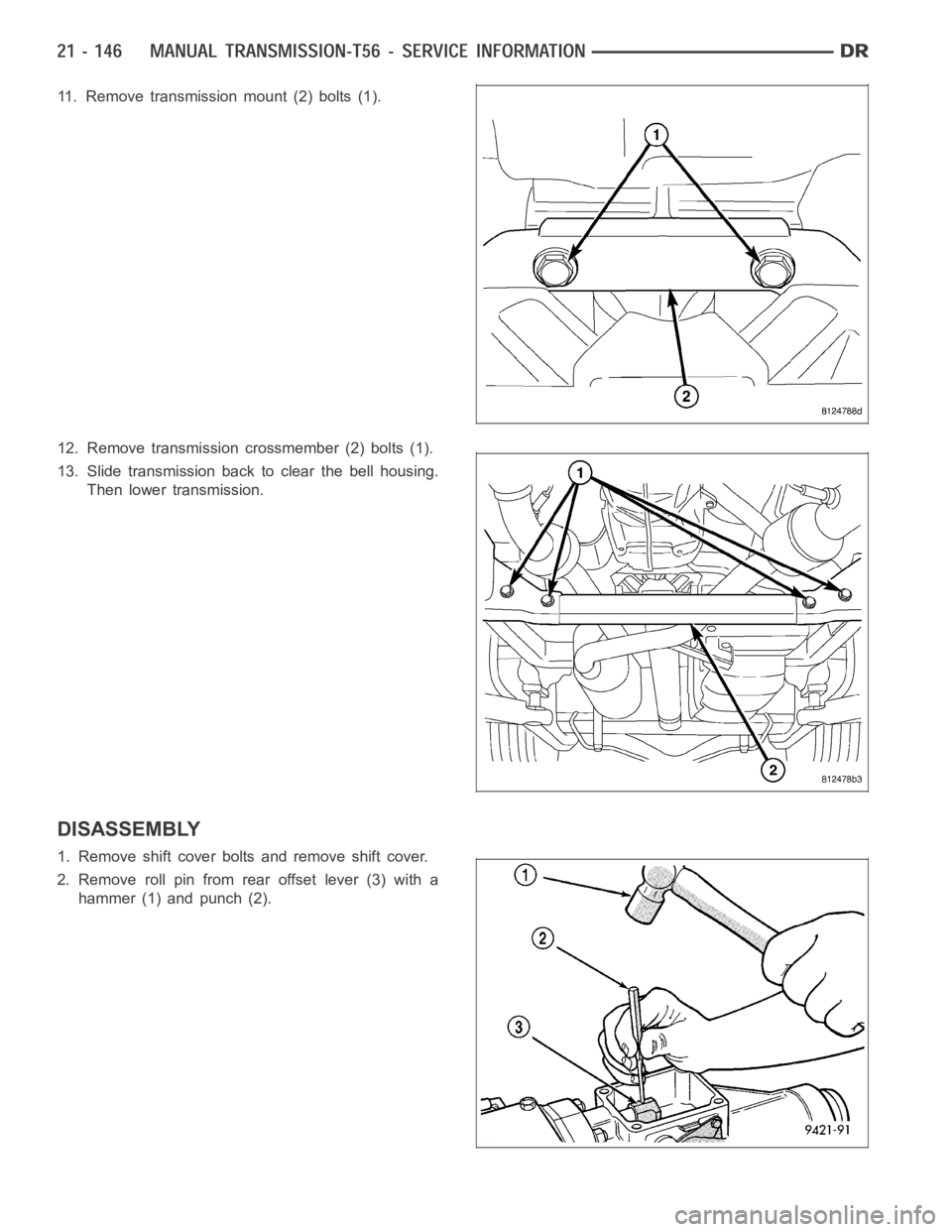

11. Remove transmission mount (2) bolts (1).

12. Remove transmission crossmember (2) bolts (1).

13. Slide transmission back to clear the bell housing.

Then lower transmission.

DISASSEMBLY

1. Remove shift cover bolts and remove shift cover.

2. Remove roll pin from rear offset lever (3) with a

hammer (1) and punch (2).

Page 2668 of 5267

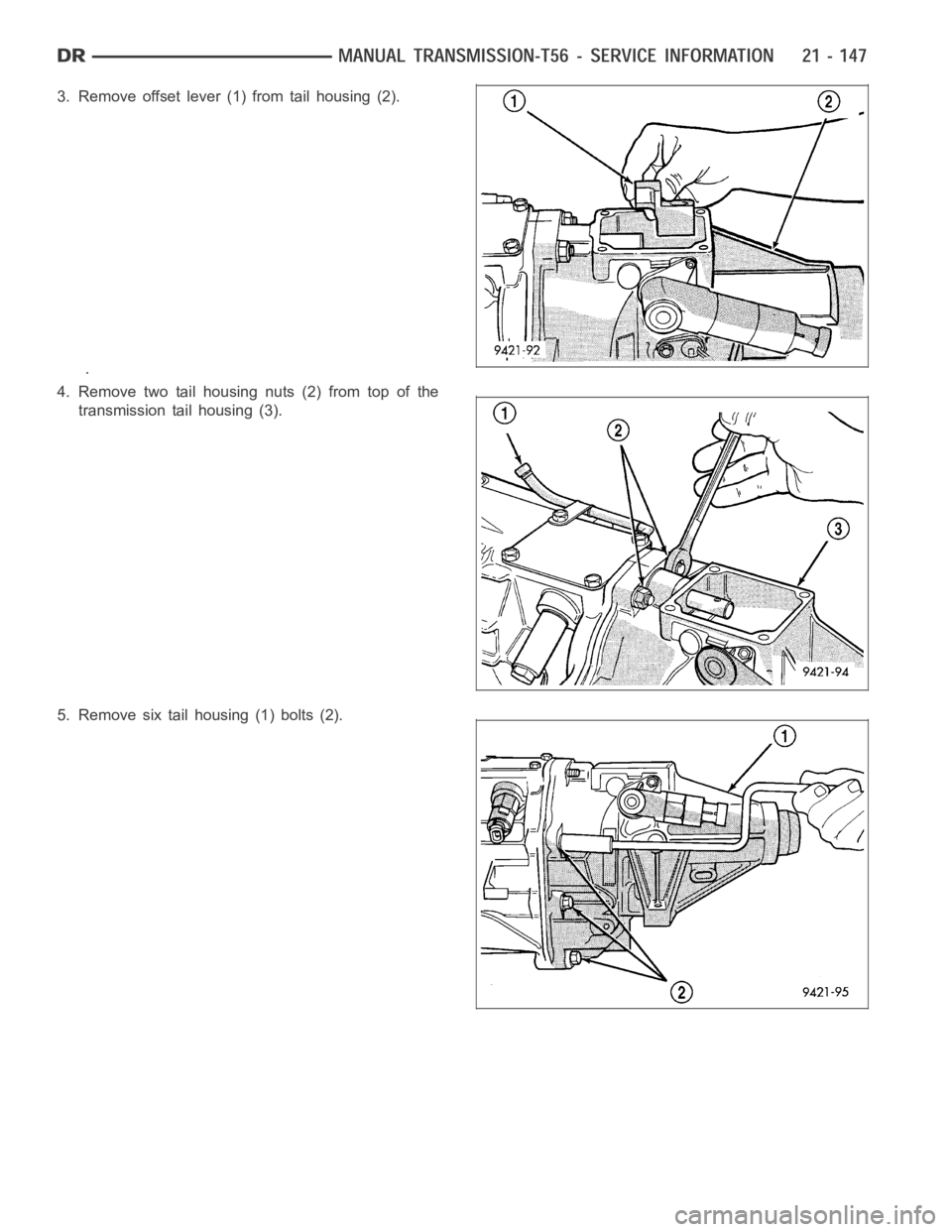

3. Remove offset lever (1) from tail housing (2).

.

4. Remove two tail housing nuts (2) from top of the

transmission tail housing (3).

5. Remove six tail housing (1) bolts (2).

Page 2669 of 5267

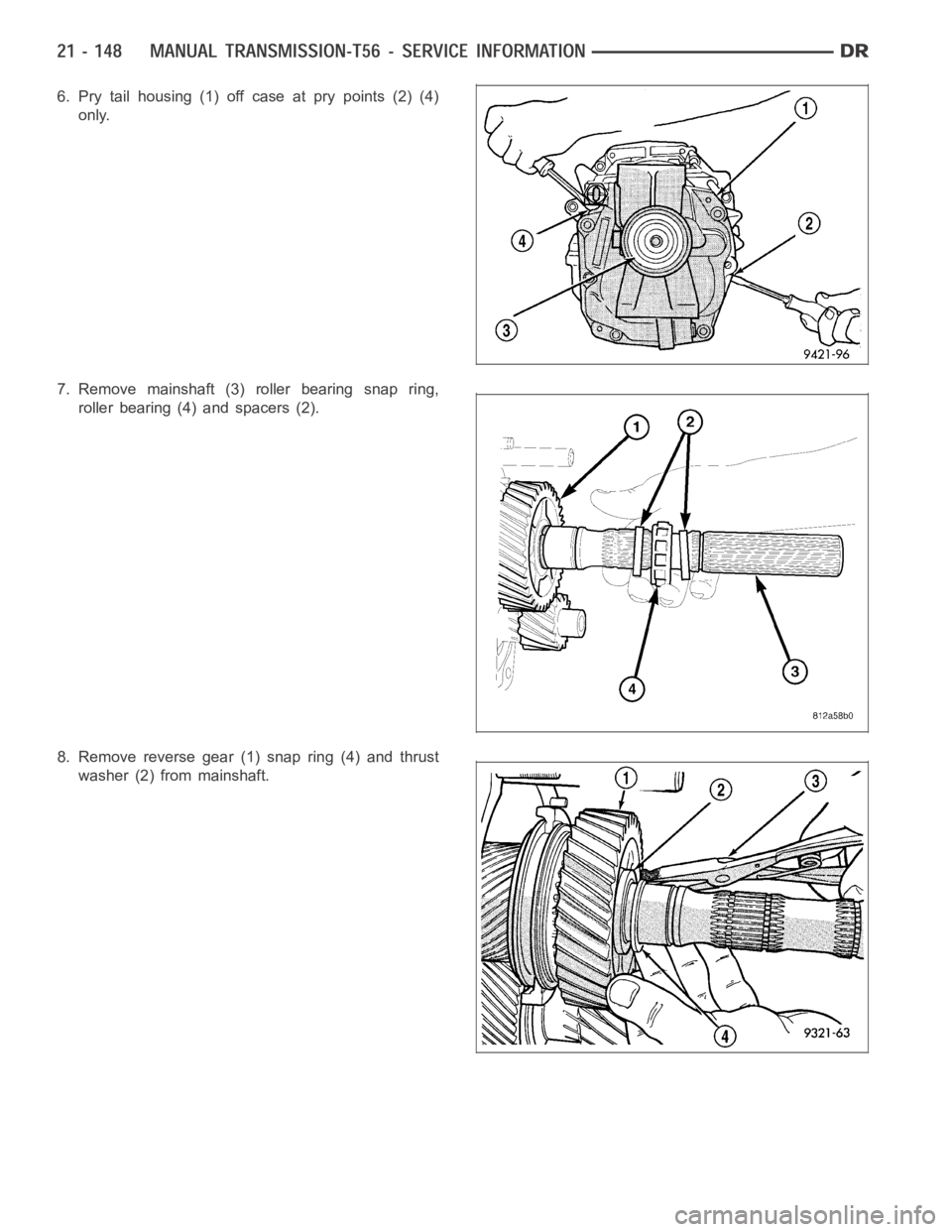

6. Pry tail housing (1) off case at pry points (2) (4)

only.

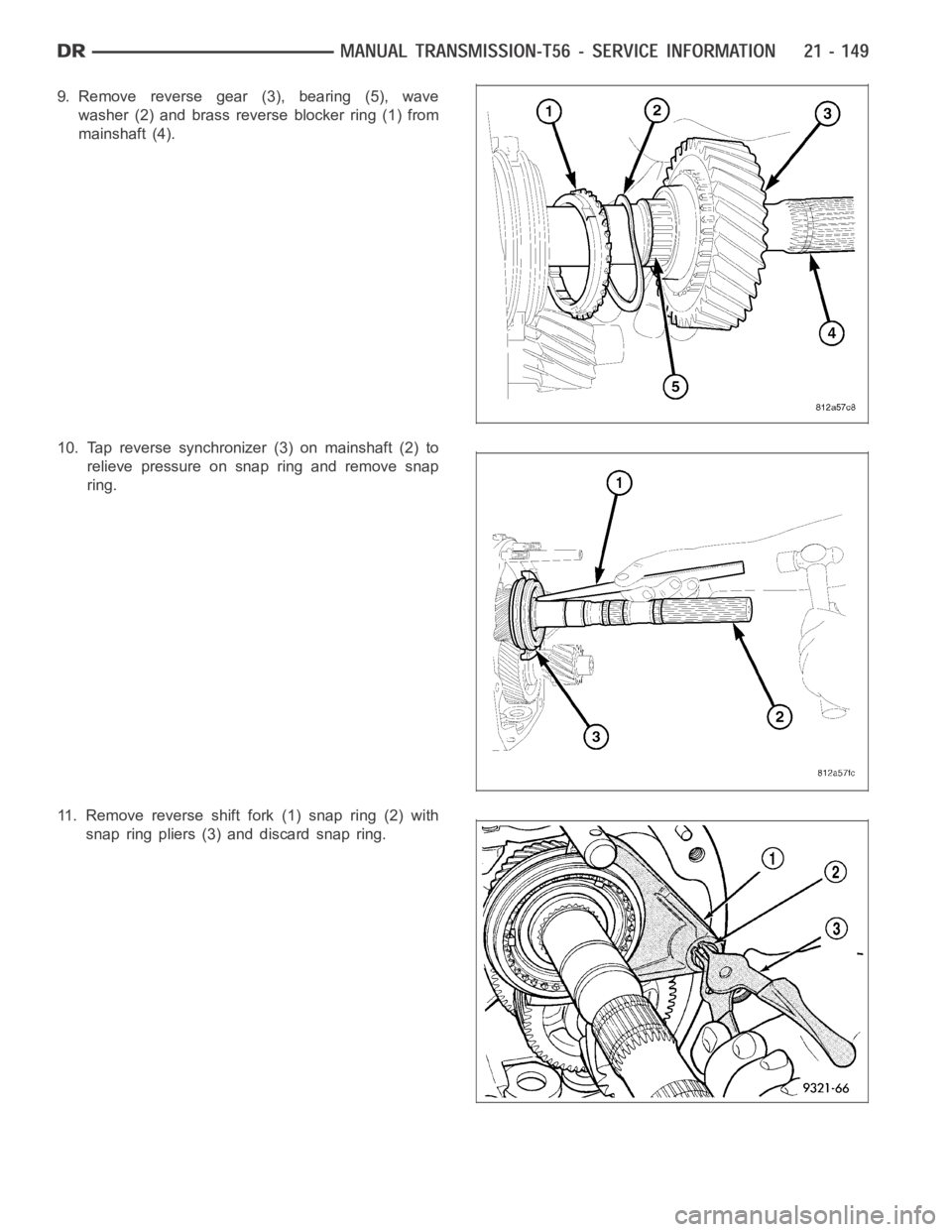

7. Remove mainshaft (3) roller bearing snap ring,

roller bearing (4) and spacers (2).

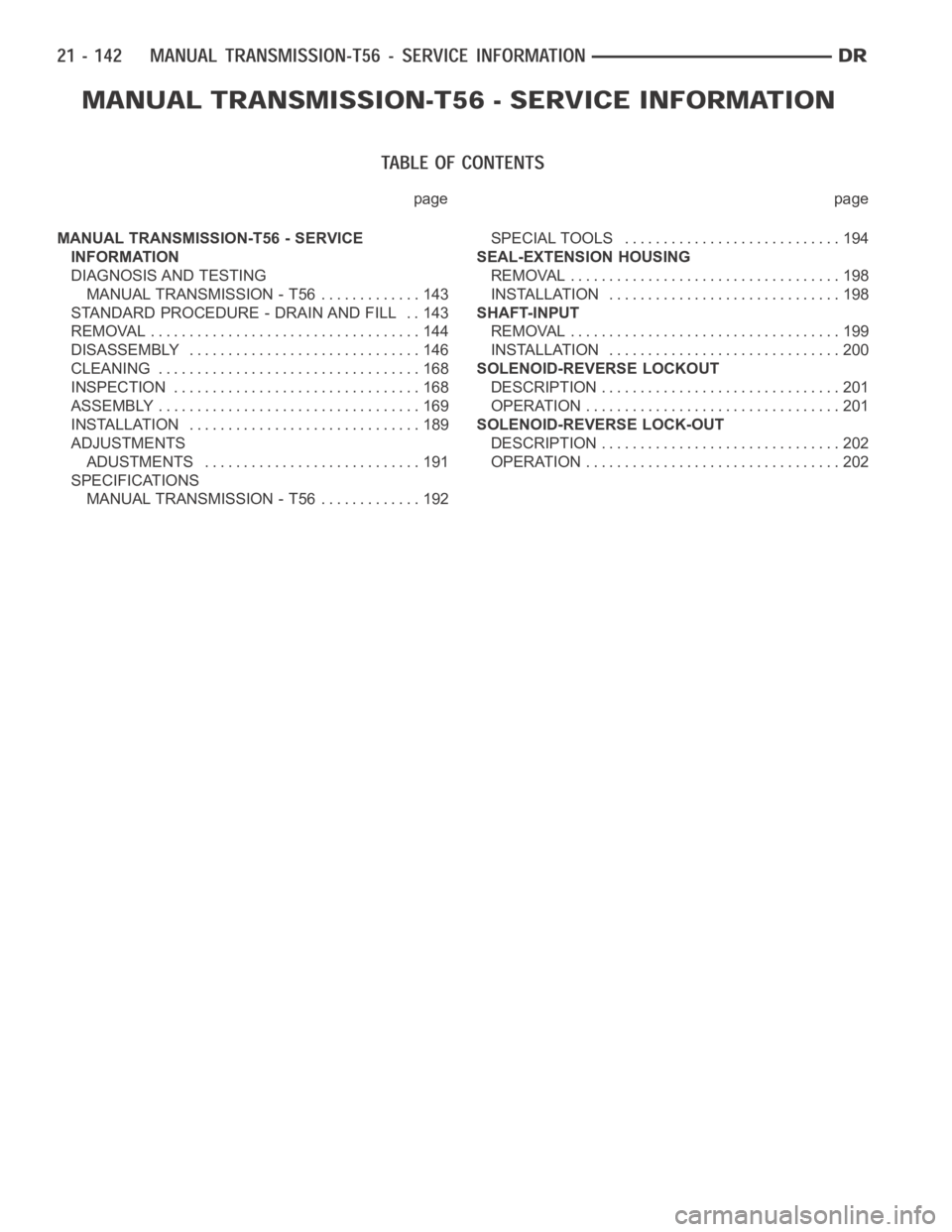

8. Remove reverse gear (1) snap ring (4) and thrust

washer (2) from mainshaft.

Page 2670 of 5267

9. Remove reverse gear (3), bearing (5), wave

washer (2) and brass reverse blocker ring (1) from

mainshaft (4).

10. Tap reverse synchronizer (3) on mainshaft (2) to

relieve pressure on snap ring and remove snap

ring.

11. Remove reverse shift fork (1) snap ring (2) with

snap ring pliers (3) and discard snap ring.

Trending: fuel filter location, tire size, climate control, oil reset, drain bolt, airbag disable, seats