clock DODGE RAM SRT-10 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1620 of 5267

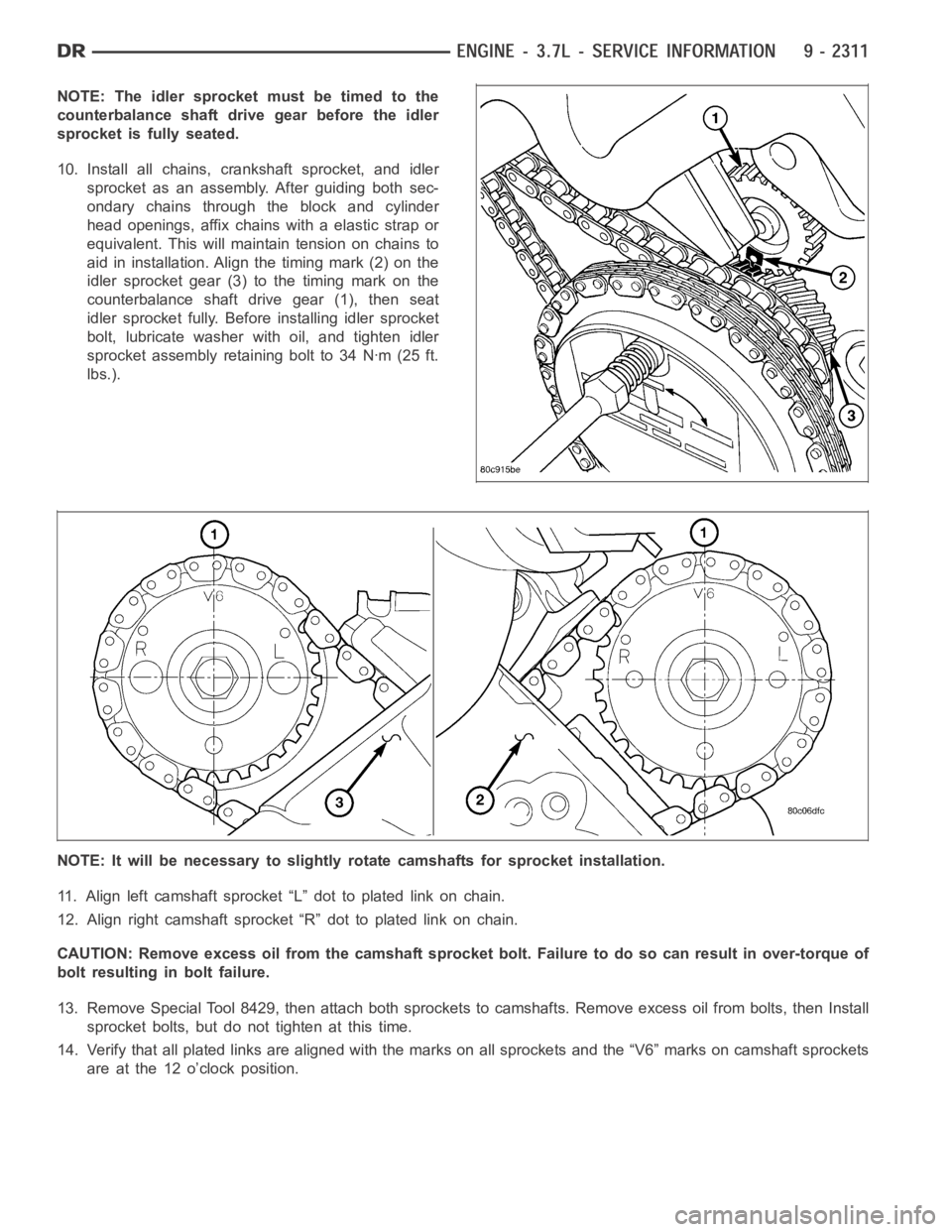

NOTE: The idler sprocket must be timed to the

counterbalance shaft drive gear before the idler

sprocket is fully seated.

10. Install all chains, crankshaft sprocket, and idler

sprocket as an assembly. After guiding both sec-

ondary chains through the block and cylinder

head openings, affix chains with a elastic strap or

equivalent. This will maintain tension on chains to

aid in installation. Align the timing mark (2) on the

idler sprocket gear (3) to the timing mark on the

counterbalance shaft drive gear (1), then seat

idler sprocket fully. Before installing idler sprocket

bolt, lubricate washer with oil, and tighten idler

sprocketassemblyretainingboltto34Nꞏm(25ft.

lbs.).

NOTE: It will be necessary to slightly rotate camshafts for sprocket installation.

11. Align left camshaft sprocket “L” dot to plated link on chain.

12. Align right camshaft sprocket “R” dot to plated link on chain.

CAUTION: Remove excess oil from the camshaft sprocket bolt. Failure to do so can result in over-torque of

bolt resulting in bolt failure.

13. Remove Special Tool 8429, then attach both sprockets to camshafts. Remove excess oil from bolts, then Install

sprocket bolts, but do not tighten at this time.

14. Verify that all plated links are aligned with the marks on all sprocketsand the “V6” marks on camshaft sprockets

are at the 12 o’clock position.

Page 1621 of 5267

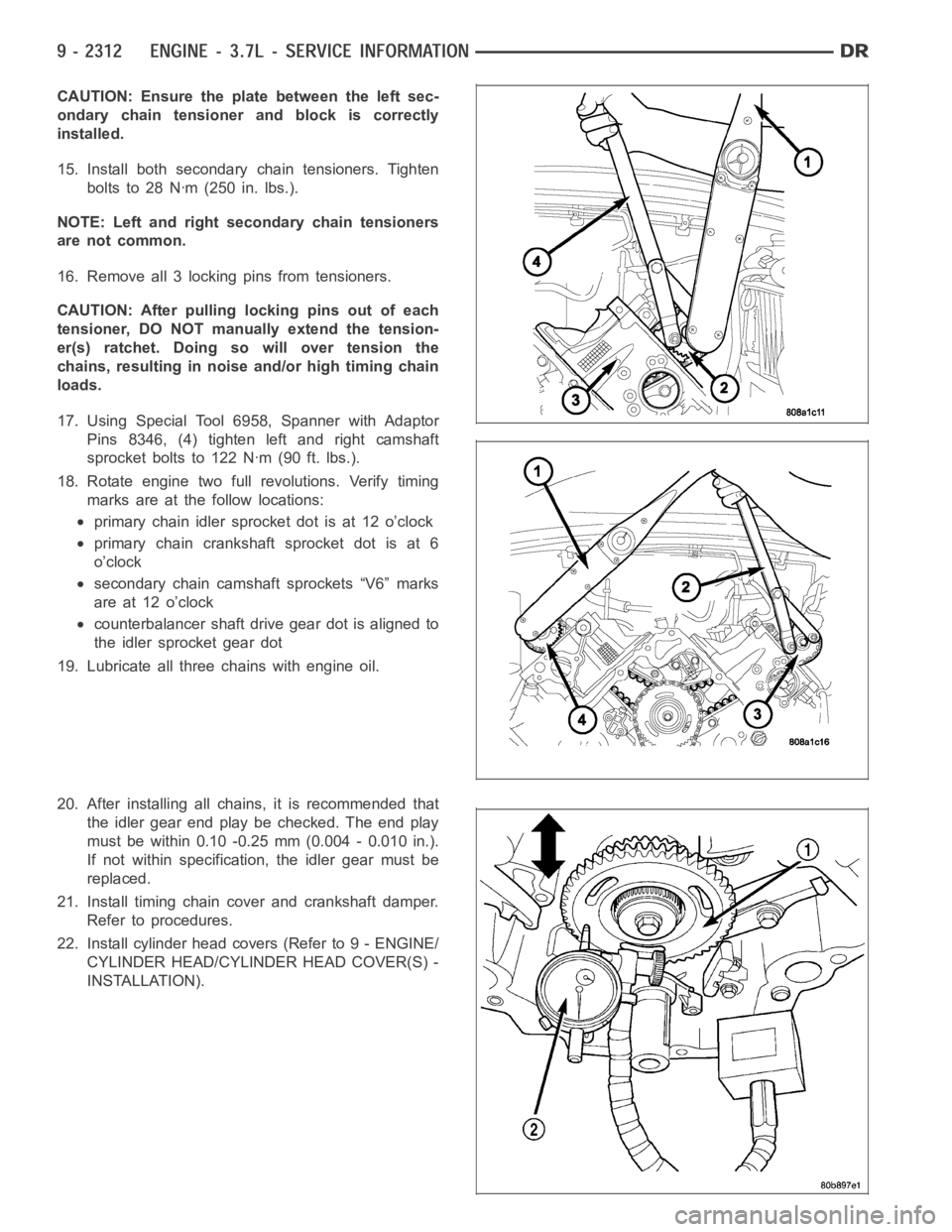

CAUTION: Ensure the plate between the left sec-

ondary chain tensioner and block is correctly

installed.

15. Install both secondary chain tensioners. Tighten

boltsto28Nꞏm(250in.lbs.).

NOTE: Left and right secondary chain tensioners

are not common.

16. Remove all 3 locking pins from tensioners.

CAUTION: After pulling locking pins out of each

tensioner, DO NOT manually extend the tension-

er(s) ratchet. Doing so will over tension the

chains, resulting in noise and/or high timing chain

loads.

17. Using Special Tool 6958, Spanner with Adaptor

Pins 8346, (4) tighten left and right camshaft

sprocket bolts to 122 Nꞏm (90 ft. lbs.).

18. Rotate engine two full revolutions. Verify timing

marks are at the follow locations:

primary chain idler sprocket dot is at 12 o’clock

primary chain crankshaft sprocket dot is at 6

o’clock

secondary chain camshaft sprockets “V6” marks

are at 12 o’clock

counterbalancer shaft drive gear dot is aligned to

the idler sprocket gear dot

19. Lubricate all three chains with engine oil.

20. After installing all chains, it is recommended that

the idler gear end play be checked. The end play

must be within 0.10 -0.25 mm (0.004 - 0.010 in.).

If not within specification, the idler gear must be

replaced.

21. Install timing chain cover and crankshaft damper.

Refer to procedures.

22. Install cylinder head covers (Refer to 9 - ENGINE/

CYLINDER HEAD/CYLINDER HEAD COVER(S) -

INSTALLATION).

Page 1655 of 5267

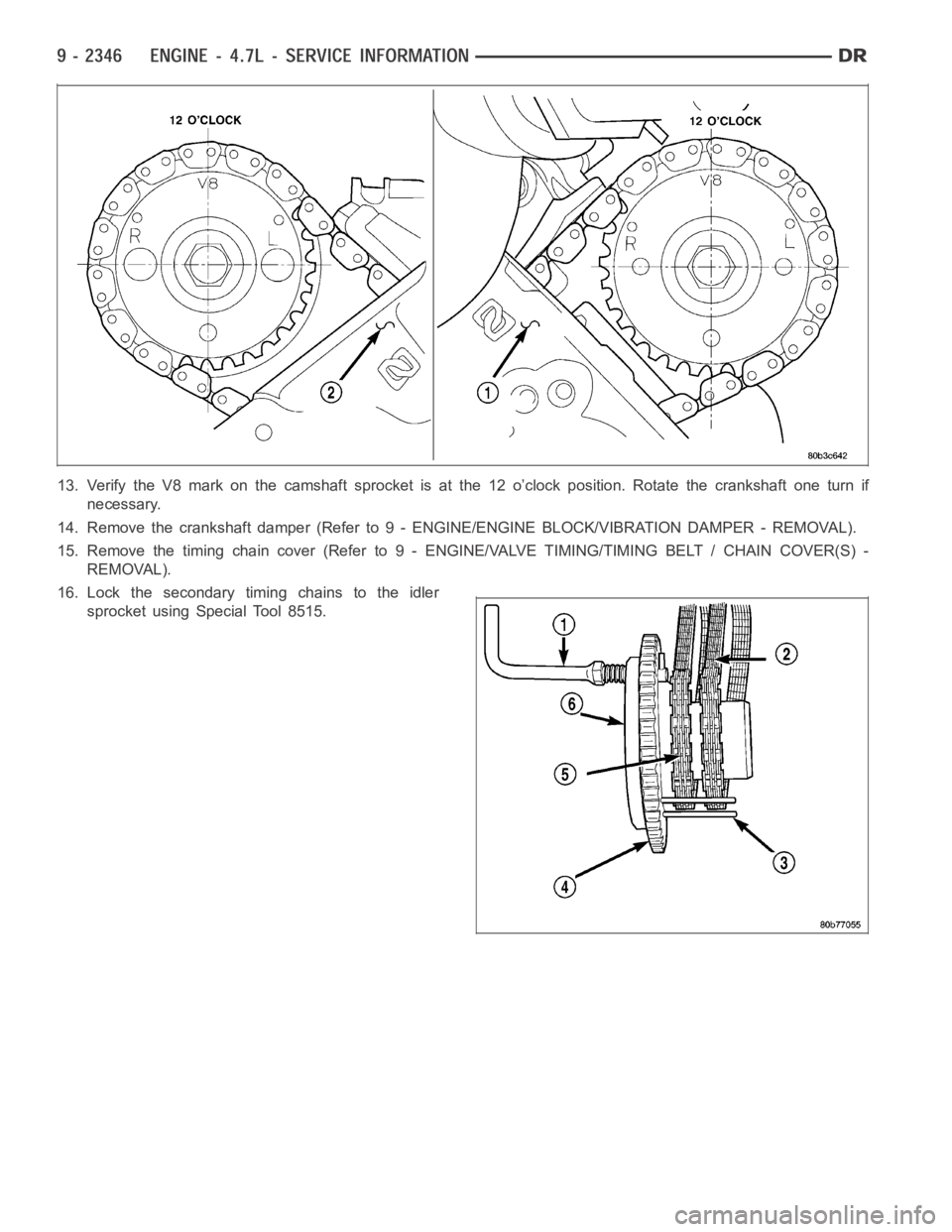

13. Verify the V8 mark on the camshaft sprocket is at the 12 o’clock position. Rotate the crankshaft one turn if

necessary.

14. Remove the crankshaft damper (Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION DAMPER - REMOVAL).

15. Remove the timing chain cover (Refer to 9 - ENGINE/VALVE TIMING/TIMINGBELT / CHAIN COVER(S) -

REMOVAL).

16. Lock the secondary timing chains to the idler

sprocket using Special Tool 8515.

Page 1658 of 5267

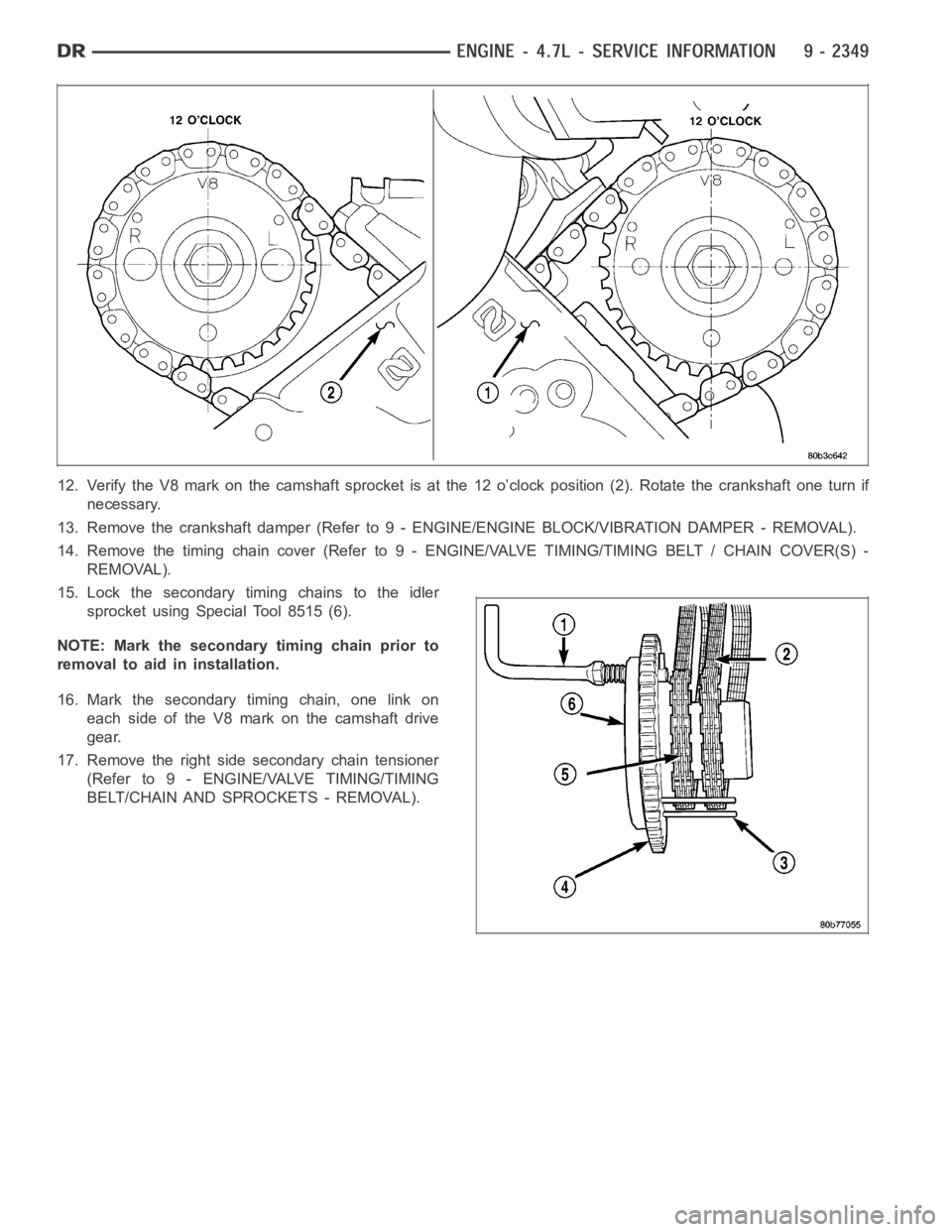

12. Verify the V8 mark on the camshaft sprocket is at the 12 o’clock position(2). Rotate the crankshaft one turn if

necessary.

13. Remove the crankshaft damper (Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION DAMPER - REMOVAL).

14. Remove the timing chain cover (Refer to 9 - ENGINE/VALVE TIMING/TIMINGBELT / CHAIN COVER(S) -

REMOVAL).

15. Lock the secondary timing chains to the idler

sprocket using Special Tool 8515 (6).

NOTE: Mark the secondary timing chain prior to

removal to aid in installation.

16. Mark the secondary timing chain, one link on

each side of the V8 mark on the camshaft drive

gear.

17. Remove the right side secondary chain tensioner

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL).

Page 1666 of 5267

CAMSHAFT - LEFT

DESCRIPTION

The camshafts consist of powdered metal steel lobes which are sinter-bonded to a steel tube. A steel post or nose

piece is friction-welded to the steel camshaft tube. Five bearing journals are machined into the camshaft, four on the

steel tube and one on the steel nose piece. Camshaft end play is controlled by two thrust walls that border the nose

piece journal. Engine oil enters the hollow camshafts at the third journaland lubricates every intake lobe rocker

throughadrilledpassageintheintakelobe.

REMOVAL

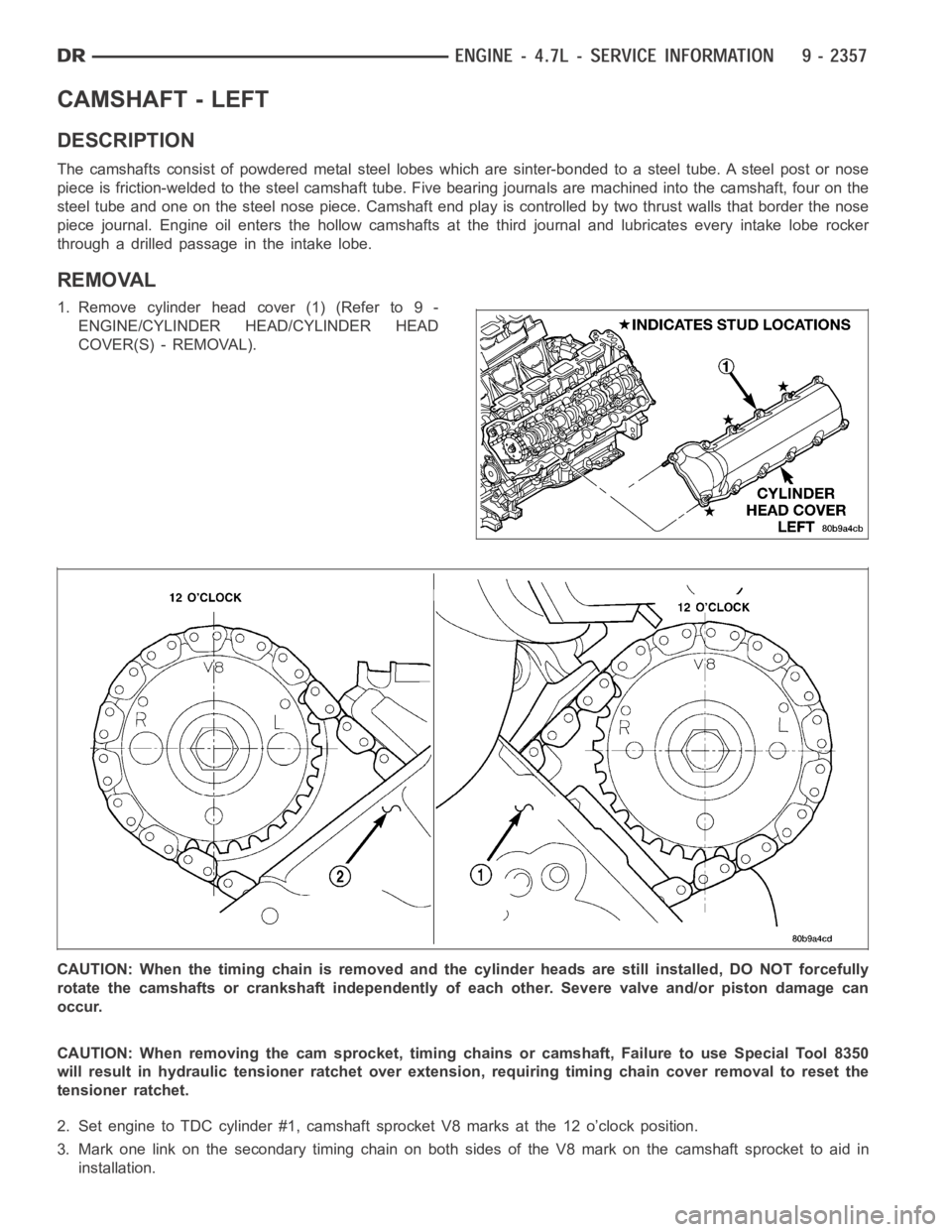

1. Remove cylinder head cover (1) (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

CAUTION: When the timing chain is removed and the cylinder heads are still installed, DO NOT forcefully

rotate the camshafts or crankshaft independently of each other. Severe valve and/or piston damage can

occur.

CAUTION: When removing the cam sprocket, timing chains or camshaft, Failure to use Special Tool 8350

will result in hydraulic tensioner ratchet over extension, requiring timing chain cover removal to reset the

tensioner ratchet.

2. Set engine to TDC cylinder #1, camshaft sprocket V8 marks at the 12 o’clock position.

3. Mark one link on the secondary timing chain on both sides of the V8 mark on the camshaft sprocket to aid in

installation.

Page 1667 of 5267

CAUTION: Do not hold or pry on the camshaft target wheel (Located on the right side camshaft sprocket)

for any reason, Severe damage will occur to the target wheel resulting in a vehicle no start condition.

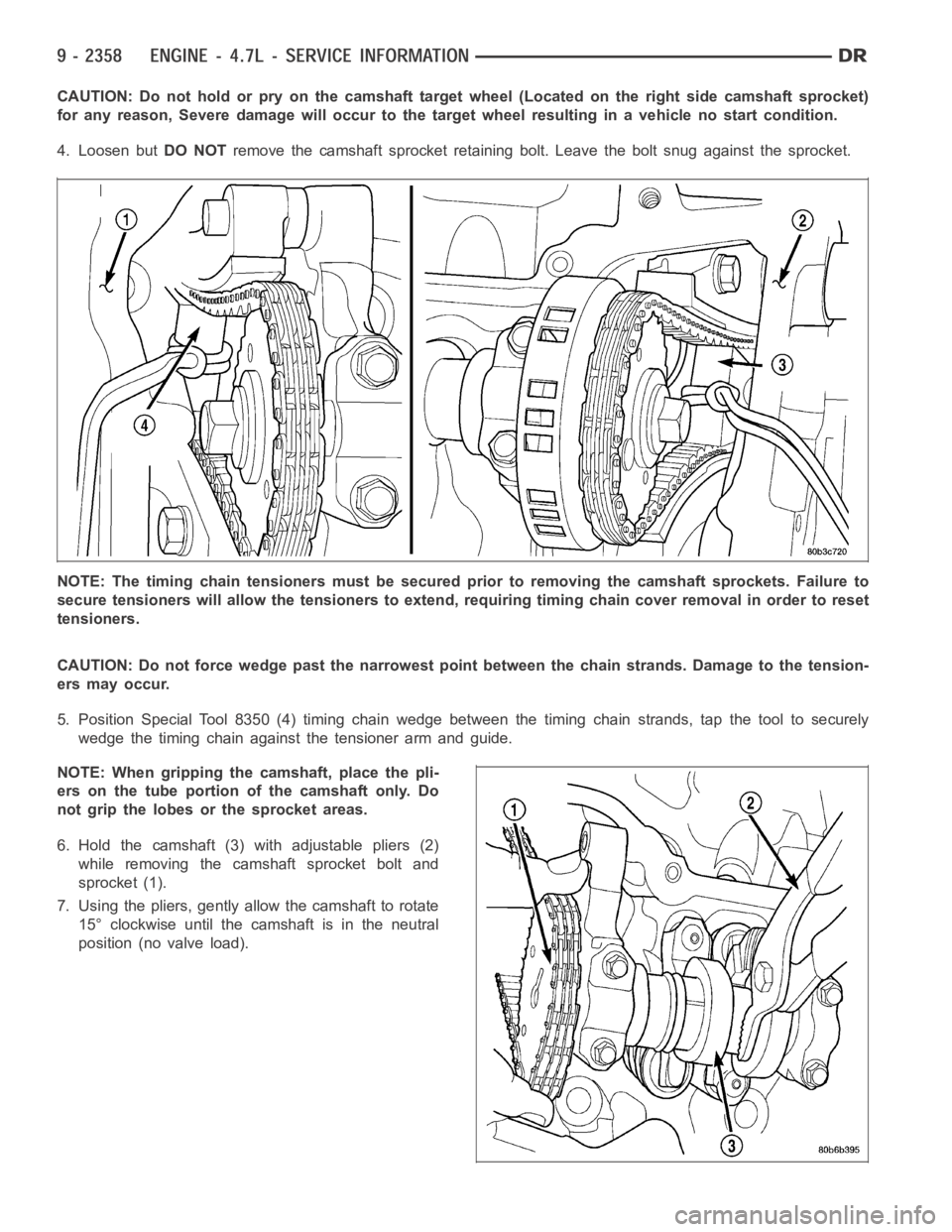

4. Loosen butDO NOTremove the camshaft sprocket retaining bolt. Leave the bolt snug against the sprocket.

NOTE: The timing chain tensioners must be secured prior to removing the camshaft sprockets. Failure to

secure tensioners will allow the tensioners to extend, requiring timing chain cover removal in order to reset

tensioners.

CAUTION: Do not force wedge past the narrowest point between the chain strands. Damage to the tension-

ers may occur.

5. Position Special Tool 8350 (4) timing chain wedge between the timing chain strands, tap the tool to securely

wedge the timing chain against the tensioner arm and guide.

NOTE: When gripping the camshaft, place the pli-

ers on the tube portion of the camshaft only. Do

not grip the lobes or the sprocket areas.

6. Hold the camshaft (3) with adjustable pliers (2)

while removing the camshaft sprocket bolt and

sprocket (1).

7. Using the pliers, gently allow the camshaft to rotate

15° clockwise until the camshaft is in the neutral

position (no valve load).

Page 1668 of 5267

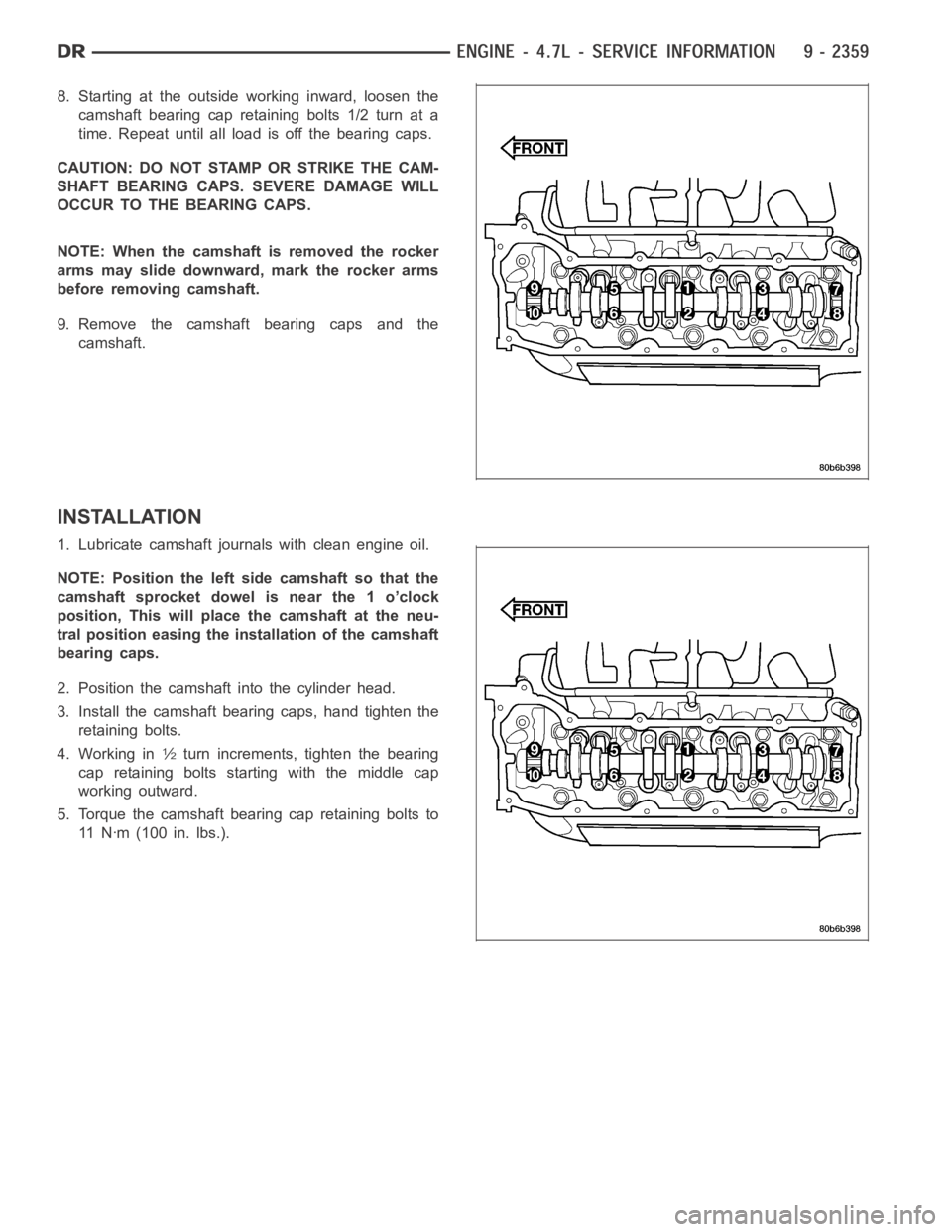

8. Starting at the outside working inward, loosen the

camshaft bearing cap retaining bolts 1/2 turn at a

time. Repeat until all load is off the bearing caps.

CAUTION: DO NOT STAMP OR STRIKE THE CAM-

SHAFT BEARING CAPS. SEVERE DAMAGE WILL

OCCUR TO THE BEARING CAPS.

NOTE: When the camshaft is removed the rocker

arms may slide downward, mark the rocker arms

before removing camshaft.

9. Remove the camshaft bearing caps and the

camshaft.

INSTALLATION

1. Lubricate camshaft journals with clean engine oil.

NOTE: Position the left side camshaft so that the

camshaft sprocket dowel is near the 1 o’clock

position, This will place the camshaft at the neu-

tral position easing the installation of the camshaft

bearing caps.

2. Position the camshaft into the cylinder head.

3. Install the camshaft bearing caps, hand tighten the

retaining bolts.

4. Working in

1⁄2turn increments, tighten the bearing

cap retaining bolts starting with the middle cap

working outward.

5. Torque the camshaft bearing cap retaining bolts to

11 N ꞏm ( 1 0 0 i n . l b s . ) .

Page 1671 of 5267

CAMSHAFT - RIGHT

DESCRIPTION

The camshafts consist of powdered metal steel lobes which are sinter-bonded to a steel tube. A steel post or nose

piece is friction-welded to the steel camshaft tube. Five bearing journals are machined into the camshaft, four on the

steel tube and one on the steel nose piece. Camshaft end play is controlled by two thrust walls that border the nose

piece journal. Engine oil enters the hollow camshafts at the third journaland lubricates every intake lobe rocker

throughadrilledpassageintheintakelobe.

REMOVAL

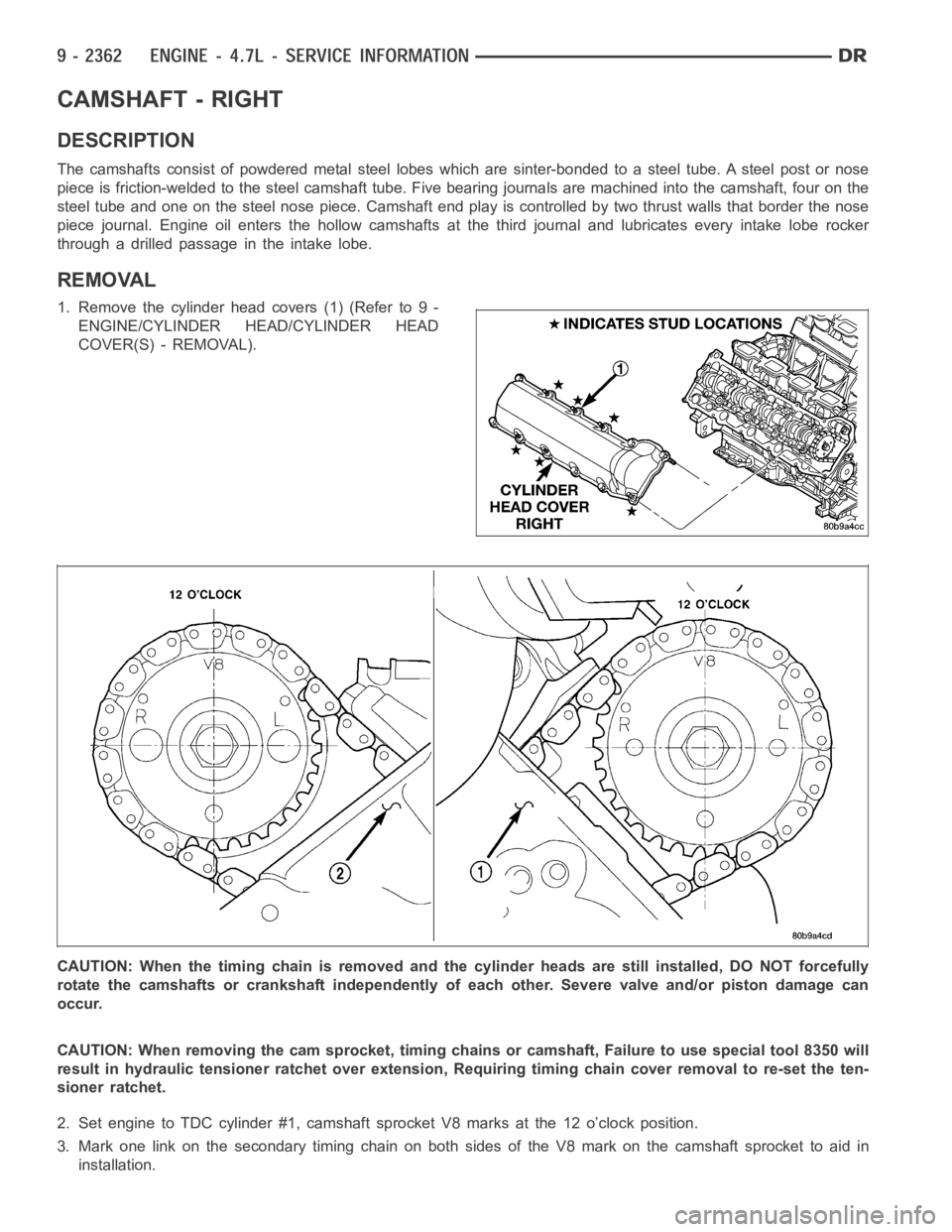

1. Remove the cylinder head covers (1) (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

CAUTION: When the timing chain is removed and the cylinder heads are still installed, DO NOT forcefully

rotate the camshafts or crankshaft independently of each other. Severe valve and/or piston damage can

occur.

CAUTION: When removing the cam sprocket, timing chains or camshaft, Failure to use special tool 8350 will

result in hydraulic tensioner ratchet over extension, Requiring timing chain cover removal to re-set the ten-

sioner ratchet.

2. Set engine to TDC cylinder #1, camshaft sprocket V8 marks at the 12 o’clock position.

3. Mark one link on the secondary timing chain on both sides of the V8 mark on the camshaft sprocket to aid in

installation.

Page 1673 of 5267

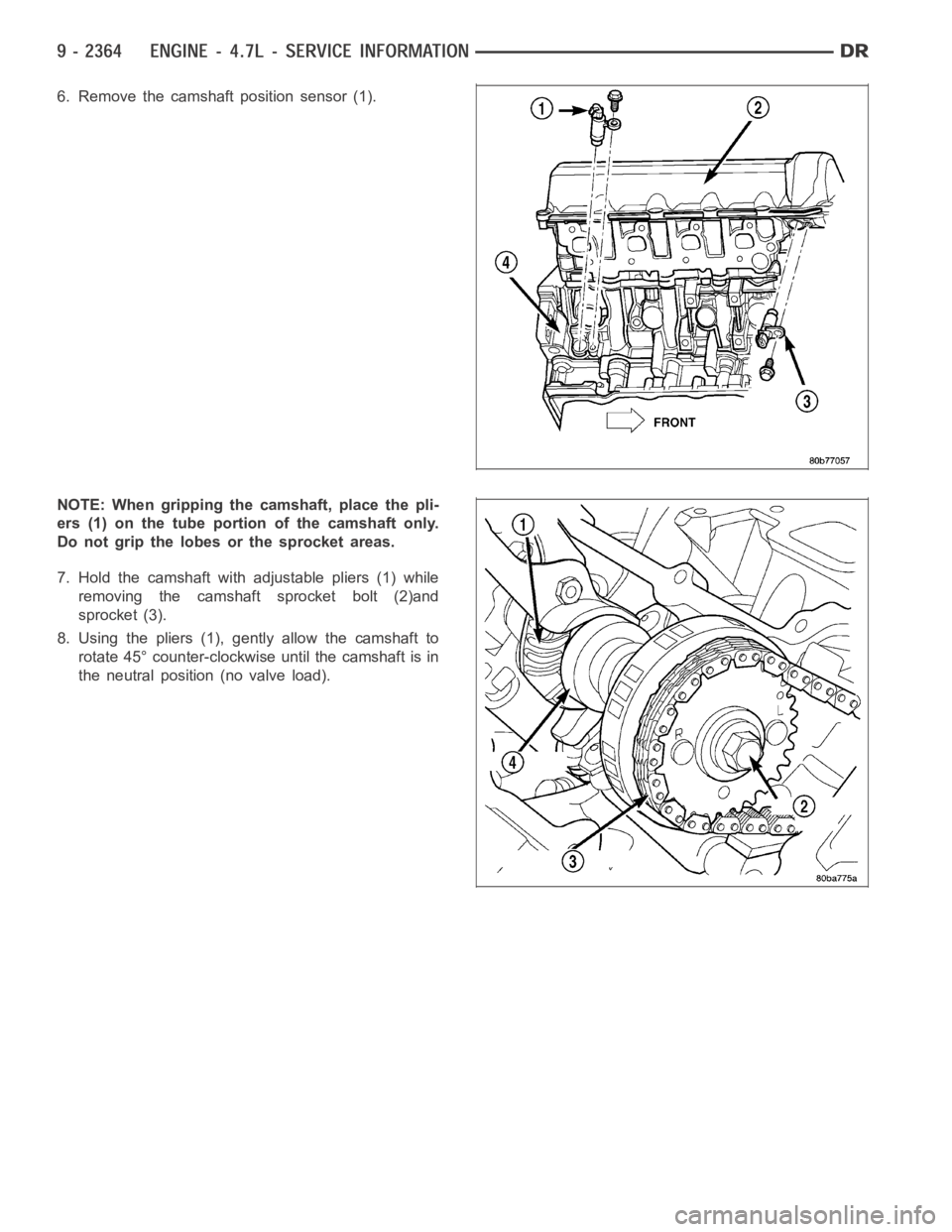

6. Remove the camshaft position sensor (1).

NOTE: When gripping the camshaft, place the pli-

ers (1) on the tube portion of the camshaft only.

Do not grip the lobes or the sprocket areas.

7. Hold the camshaft with adjustable pliers (1) while

removing the camshaft sprocket bolt (2)and

sprocket (3).

8. Using the pliers (1), gently allow the camshaft to

rotate 45° counter-clockwise until the camshaft is in

the neutral position (no valve load).

Page 1674 of 5267

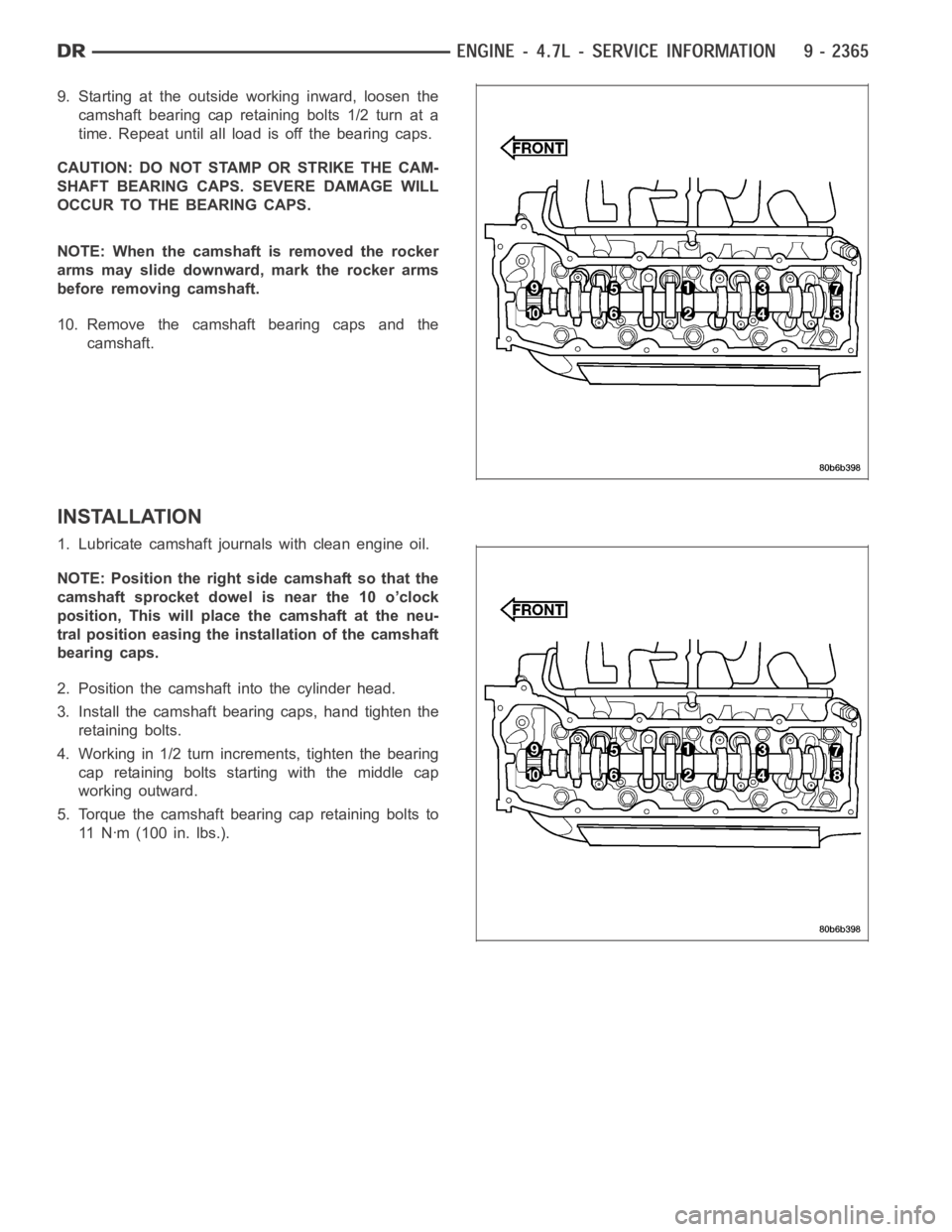

9. Starting at the outside working inward, loosen the

camshaft bearing cap retaining bolts 1/2 turn at a

time. Repeat until all load is off the bearing caps.

CAUTION: DO NOT STAMP OR STRIKE THE CAM-

SHAFT BEARING CAPS. SEVERE DAMAGE WILL

OCCUR TO THE BEARING CAPS.

NOTE: When the camshaft is removed the rocker

arms may slide downward, mark the rocker arms

before removing camshaft.

10. Remove the camshaft bearing caps and the

camshaft.

INSTALLATION

1. Lubricate camshaft journals with clean engine oil.

NOTE: Position the right side camshaft so that the

camshaft sprocket dowel is near the 10 o’clock

position, This will place the camshaft at the neu-

tral position easing the installation of the camshaft

bearing caps.

2. Position the camshaft into the cylinder head.

3. Install the camshaft bearing caps, hand tighten the

retaining bolts.

4. Working in 1/2 turn increments, tighten the bearing

cap retaining bolts starting with the middle cap

working outward.

5. Torque the camshaft bearing cap retaining bolts to

11 N ꞏm ( 1 0 0 i n . l b s . ) .