clock DODGE RAM SRT-10 2006 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1682 of 5267

6. lubricate the camshaft journal with clean engine oil

then Position the camshaft (with the sprocket dowel

on the left camshaft at 11 o’clock and the right

camshaft at 12 o’clock), then position the camshaft

bearing caps.

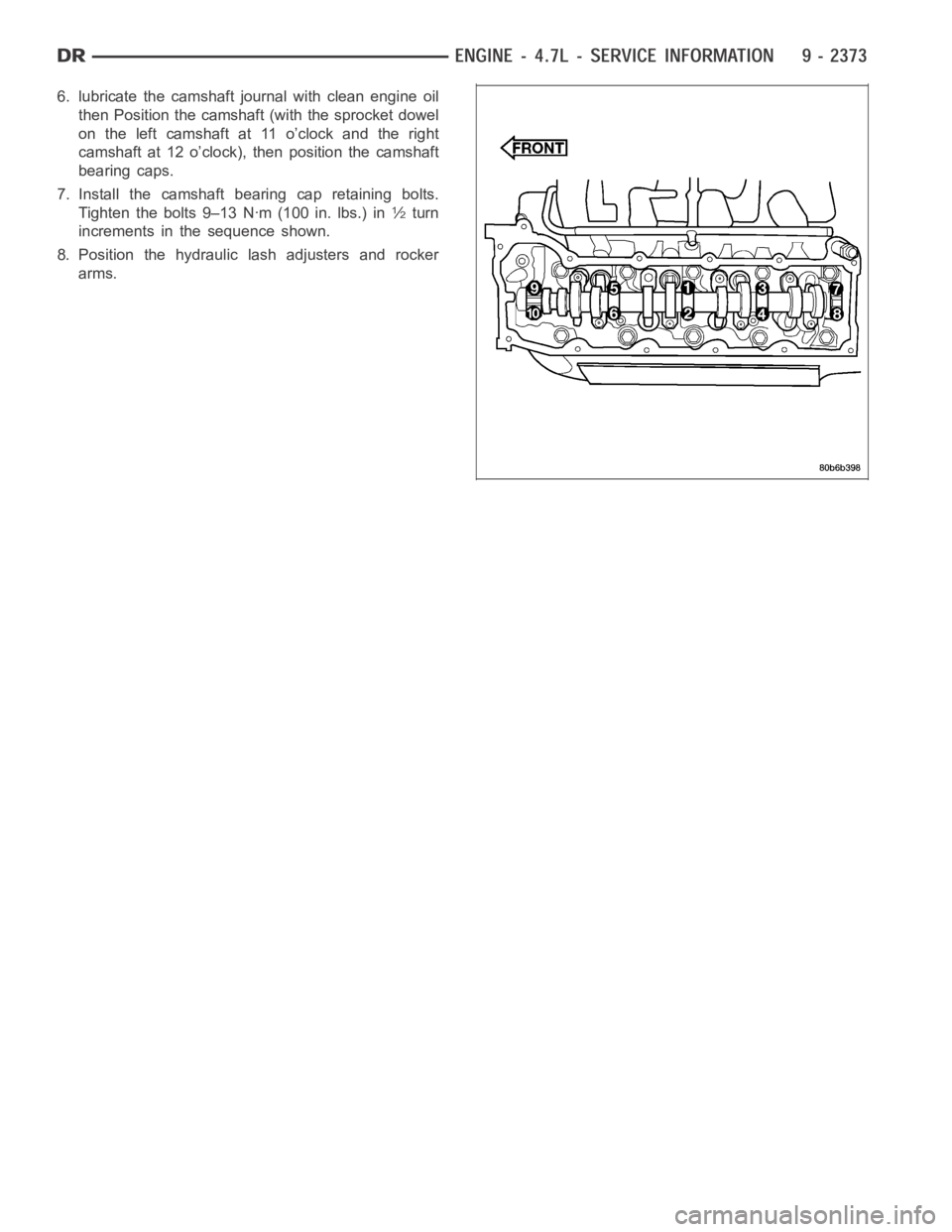

7. Install the camshaft bearing cap retaining bolts.

Tighten the bolts 9–13 Nꞏm (100 in. lbs.) in

1⁄2turn

increments in the sequence shown.

8. Position the hydraulic lash adjusters and rocker

arms.

Page 1725 of 5267

FILTER - ENGINE OIL

REMOVAL

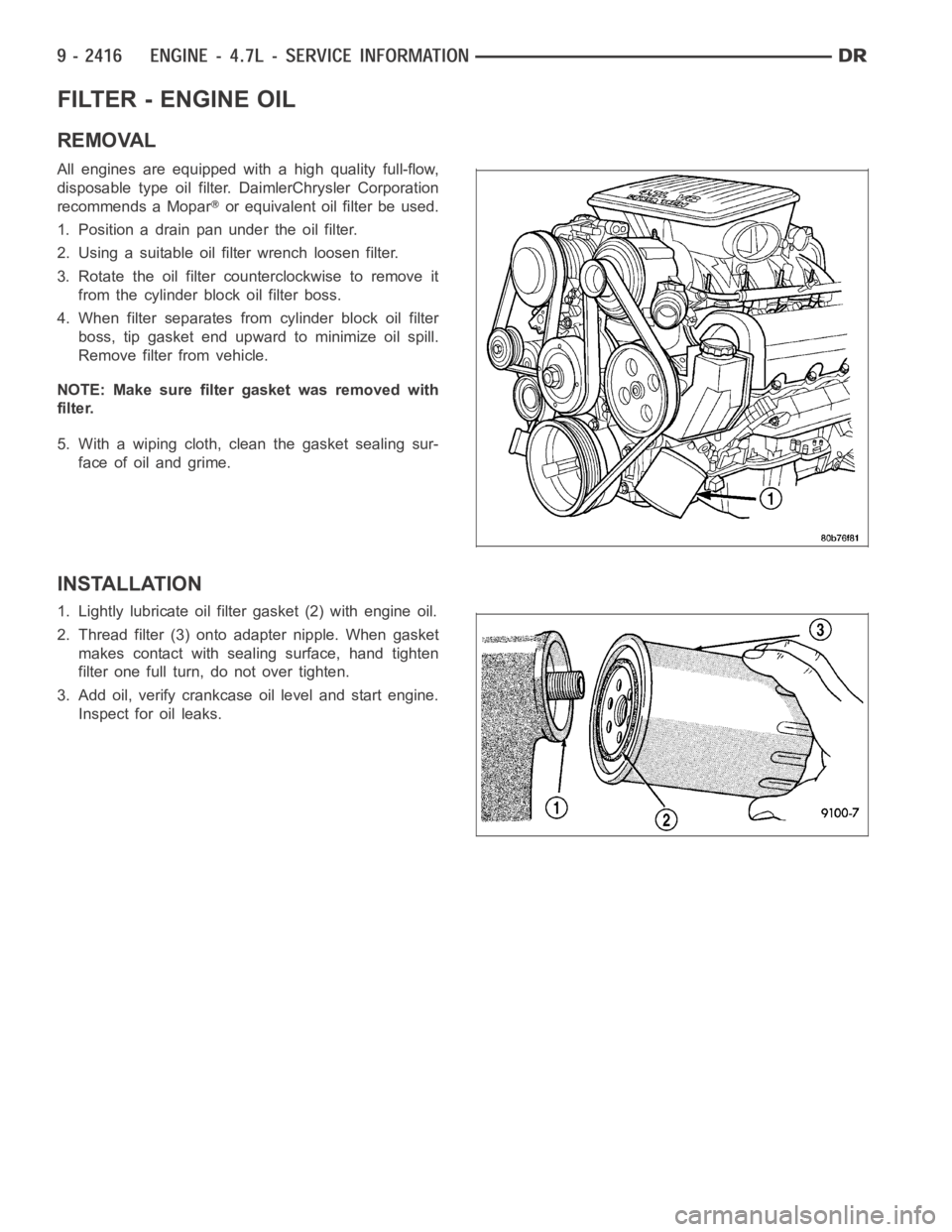

All engines are equipped with a high quality full-flow,

disposable type oil filter. DaimlerChrysler Corporation

recommends a Mopar

or equivalent oil filter be used.

1. Position a drain pan under the oil filter.

2. Using a suitable oil filter wrench loosen filter.

3. Rotate the oil filter counterclockwise to remove it

from the cylinder block oil filter boss.

4. When filter separates from cylinder block oil filter

boss, tip gasket end upward to minimize oil spill.

Remove filter from vehicle.

NOTE: Make sure filter gasket was removed with

filter.

5. With a wiping cloth, clean the gasket sealing sur-

face of oil and grime.

INSTALLATION

1. Lightly lubricate oil filter gasket (2) with engine oil.

2. Thread filter (3) onto adapter nipple. When gasket

makes contact with sealing surface, hand tighten

filter one full turn, do not over tighten.

3. Add oil, verify crankcase oil level and start engine.

Inspect for oil leaks.

Page 1740 of 5267

STANDARD PROCEDURE

STANDARD PROCEDURE - MEASURING TIMING CHAIN WEAR

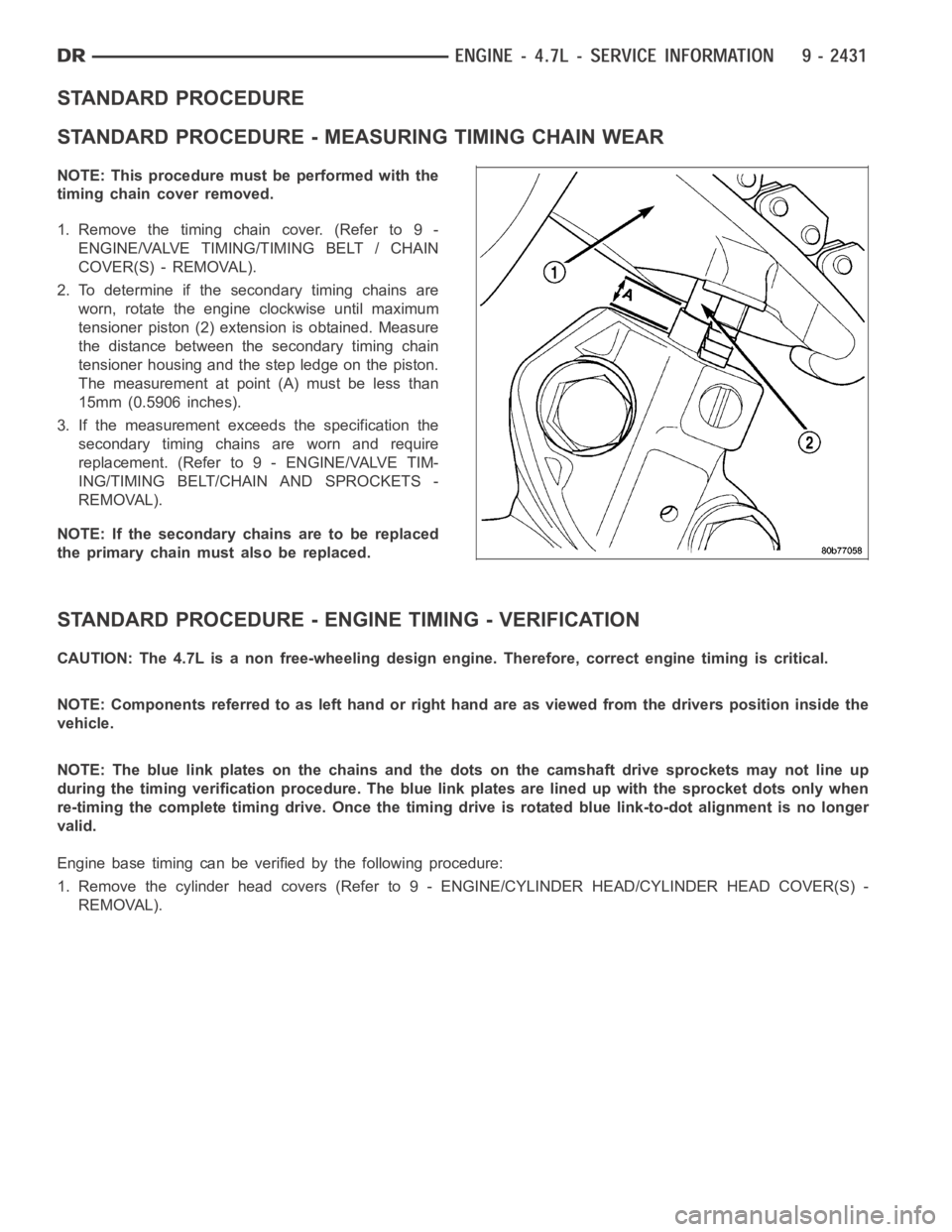

NOTE: This procedure must be performed with the

timing chain cover removed.

1.Removethetimingchaincover.(Referto9-

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

2. To determine if the secondary timing chains are

worn, rotate the engine clockwise until maximum

tensioner piston (2) extension is obtained. Measure

the distance between the secondary timing chain

tensioner housing and the step ledge on the piston.

The measurement at point (A) must be less than

15mm (0.5906 inches).

3. If the measurement exceeds the specification the

secondary timing chains are worn and require

replacement. (Refer to 9 - ENGINE/VALVE TIM-

ING/TIMING BELT/CHAIN AND SPROCKETS -

REMOVAL).

NOTE: If the secondary chains are to be replaced

the primary chain must also be replaced.

STANDARD PROCEDURE - ENGINE TIMING - VERIFICATION

CAUTION: The 4.7L is a non free-wheeling design engine. Therefore, correct engine timing is critical.

NOTE: Components referred to as left hand or right hand are as viewed from thedriverspositioninsidethe

vehicle.

NOTE: The blue link plates on the chains and the dots on the camshaft drive sprockets may not line up

during the timing verification procedure. The blue link plates are lined up with the sprocket dots only when

re-timing the complete timing drive.Once the timing drive is rotated bluelink-to-dot alignment is no longer

valid.

Engine base timing can be verified by the following procedure:

1. Remove the cylinder head covers (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDERHEADCOVER(S)-

REMOVAL).

Page 1741 of 5267

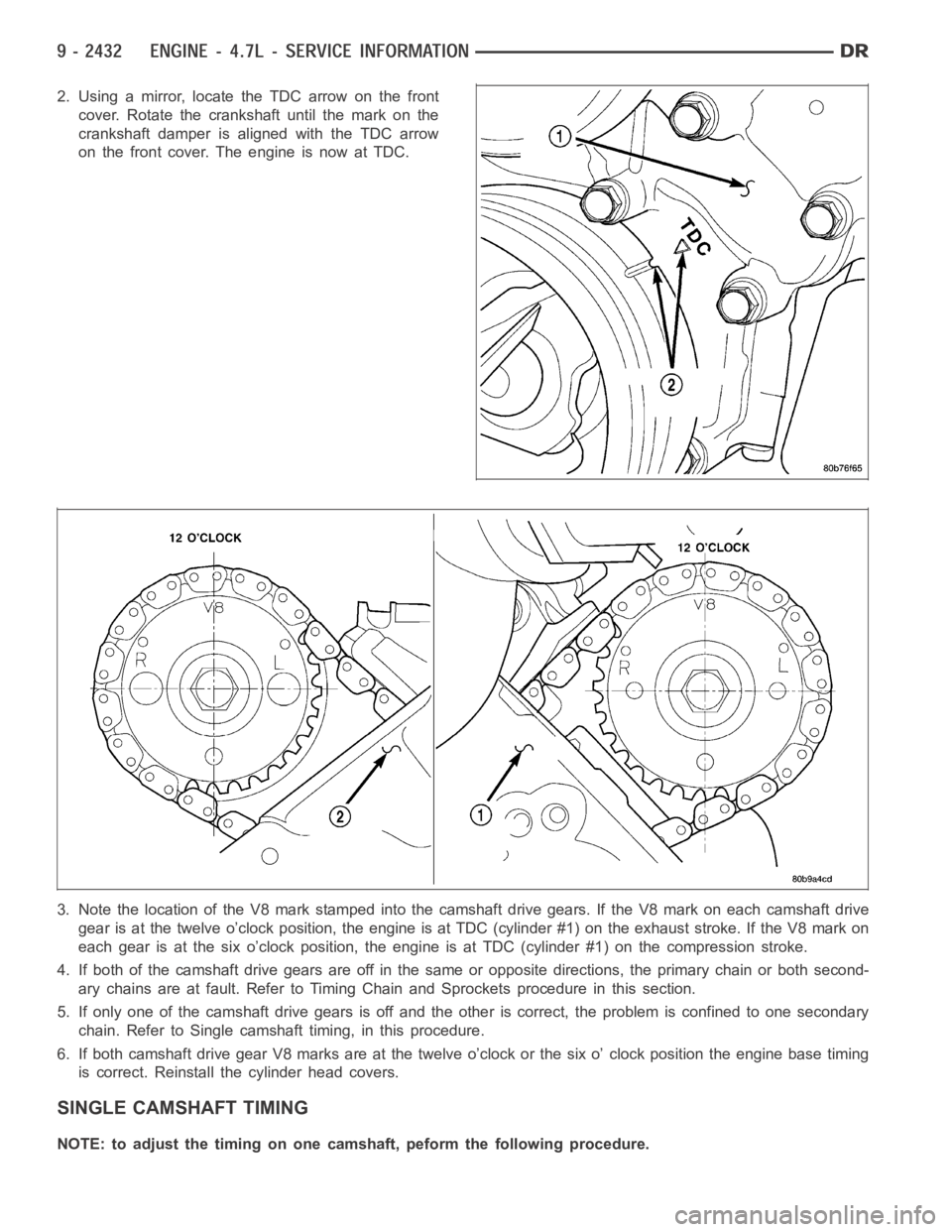

2. Using a mirror, locate the TDC arrow on the front

cover. Rotate the crankshaft until the mark on the

crankshaft damper is aligned with the TDC arrow

on the front cover. The engine is now at TDC.

3. Note the location of the V8 mark stamped into the camshaft drive gears. IftheV8markoneachcamshaftdrive

gear is at the twelve o’clock position, the engine is at TDC (cylinder #1) onthe exhaust stroke. If the V8 mark on

each gear is at the six o’clock position, the engine is at TDC (cylinder #1) on the compression stroke.

4. If both of the camshaft drive gears are off in the same or opposite directions, the primary chain or both second-

ary chains are at fault. Refer to Timing Chain and Sprockets procedure in this section.

5. If only one of the camshaft drive gears is off and the other is correct, theproblem is confined to one secondary

chain. Refer to Single camshaft timing, in this procedure.

6. If both camshaft drive gear V8 marks are at the twelve o’clock or the six o’clock position the engine base timing

is correct. Reinstall the cylinder head covers.

SINGLE CAMSHAFT TIMING

NOTE: to adjust the timing on one camshaft, peform the following procedure.

Page 1747 of 5267

TIMING CHAIN & SPROCKETS

REMOVAL

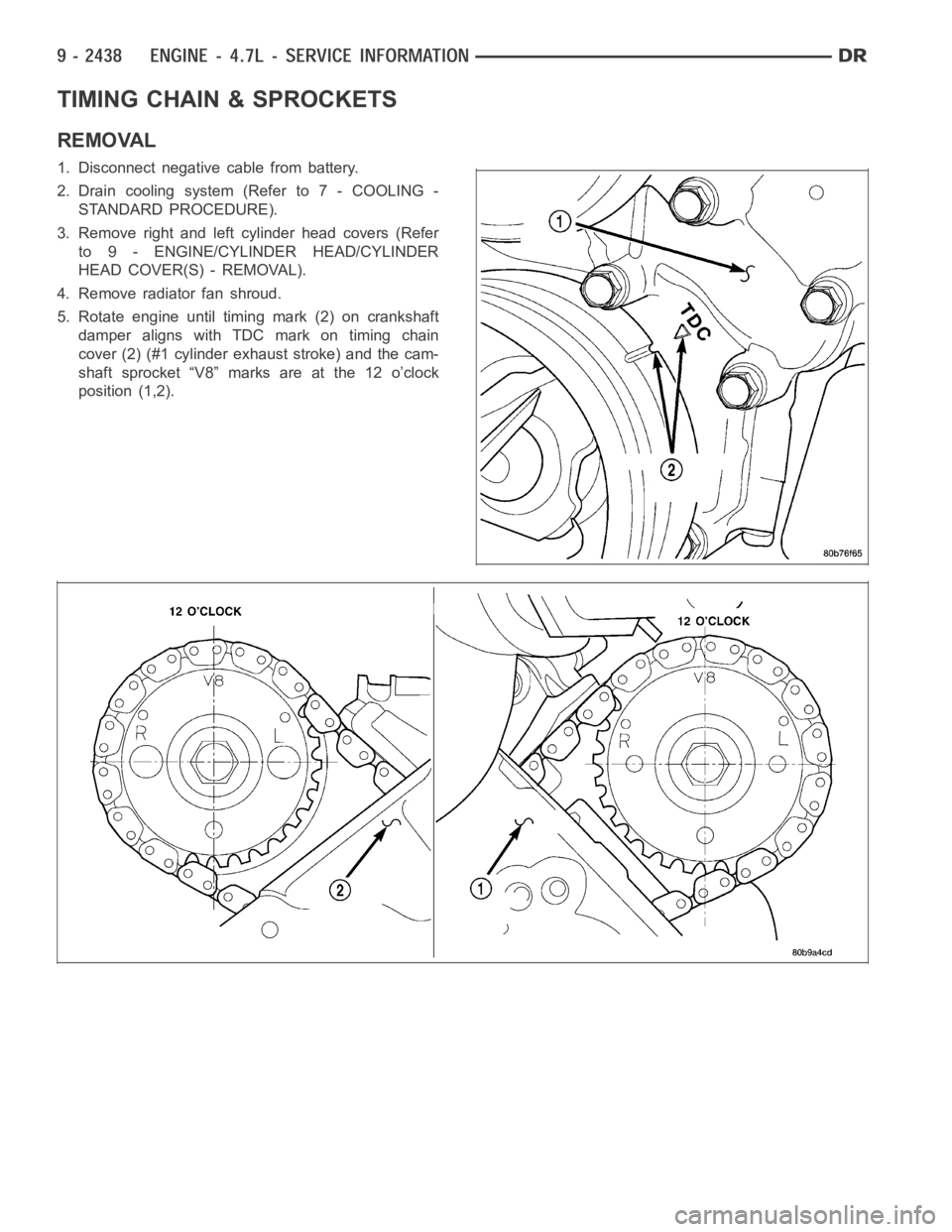

1. Disconnect negative cable from battery.

2. Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

3. Remove right and left cylinder head covers (Refer

to 9 - ENGINE/CYLINDER HEAD/CYLINDER

HEAD COVER(S) - REMOVAL).

4. Remove radiator fan shroud.

5. Rotate engine until timing mark (2) on crankshaft

damper aligns with TDC mark on timing chain

cover (2) (#1 cylinder exhaust stroke) and the cam-

shaft sprocket “V8” marks are at the 12 o’clock

position (1,2).

Page 1749 of 5267

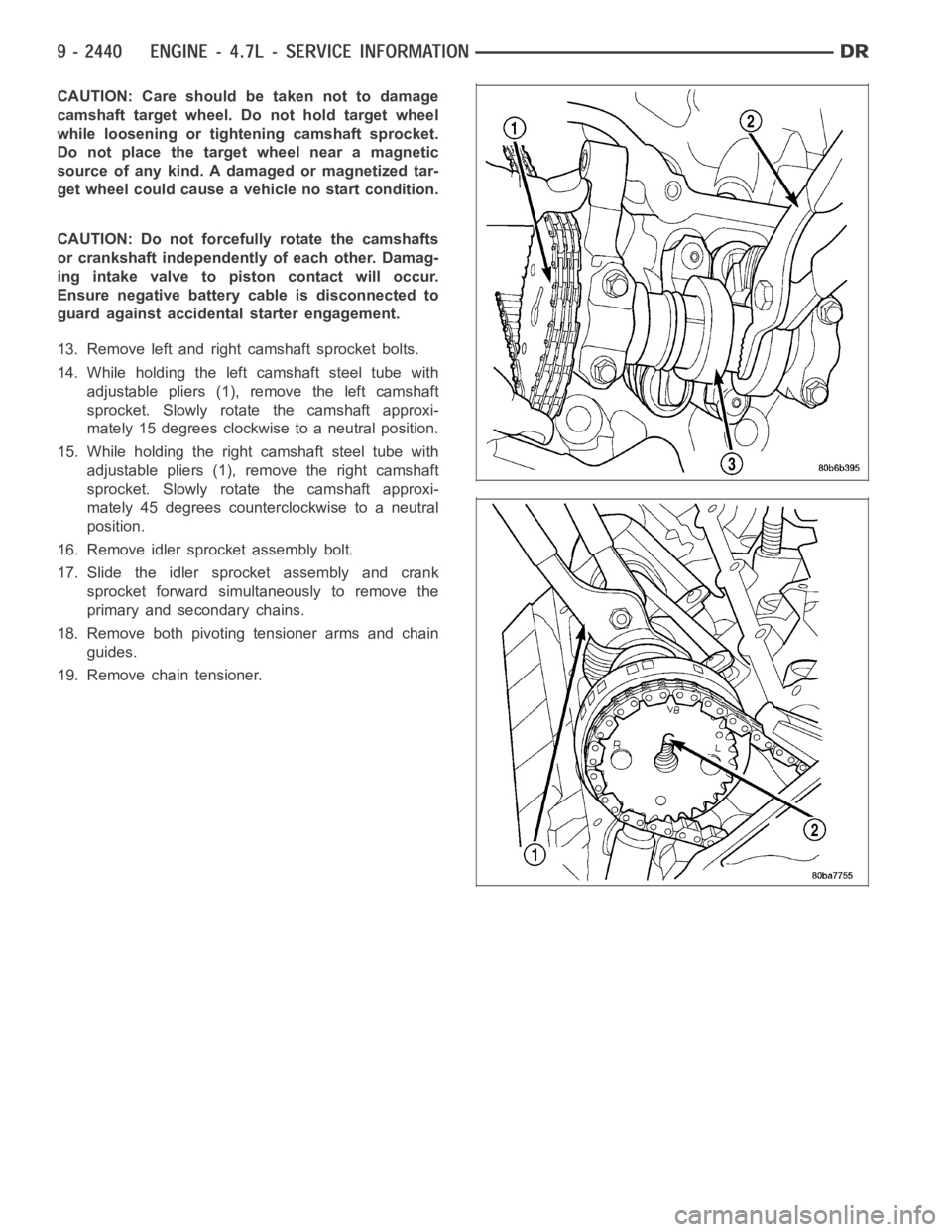

CAUTION: Care should be taken not to damage

camshaft target wheel. Do not hold target wheel

while loosening or tightening camshaft sprocket.

Do not place the target wheel near a magnetic

source of any kind. A damaged or magnetized tar-

get wheel could cause a vehicle no start condition.

CAUTION: Do not forcefully rotate the camshafts

or crankshaft independently of each other. Damag-

ing intake valve to piston contact will occur.

Ensure negative battery cable is disconnected to

guard against accidental starter engagement.

13. Remove left and right camshaft sprocket bolts.

14. While holding the left camshaft steel tube with

adjustable pliers (1), remove the left camshaft

sprocket. Slowly rotate the camshaft approxi-

mately 15 degrees clockwise to a neutral position.

15. While holding the right camshaft steel tube with

adjustable pliers (1), remove the right camshaft

sprocket. Slowly rotate the camshaft approxi-

mately 45 degrees counterclockwise to a neutral

position.

16. Remove idler sprocket assembly bolt.

17. Slide the idler sprocket assembly and crank

sprocket forward simultaneously to remove the

primary and secondary chains.

18. Remove both pivoting tensioner arms and chain

guides.

19. Remove chain tensioner.

Page 1752 of 5267

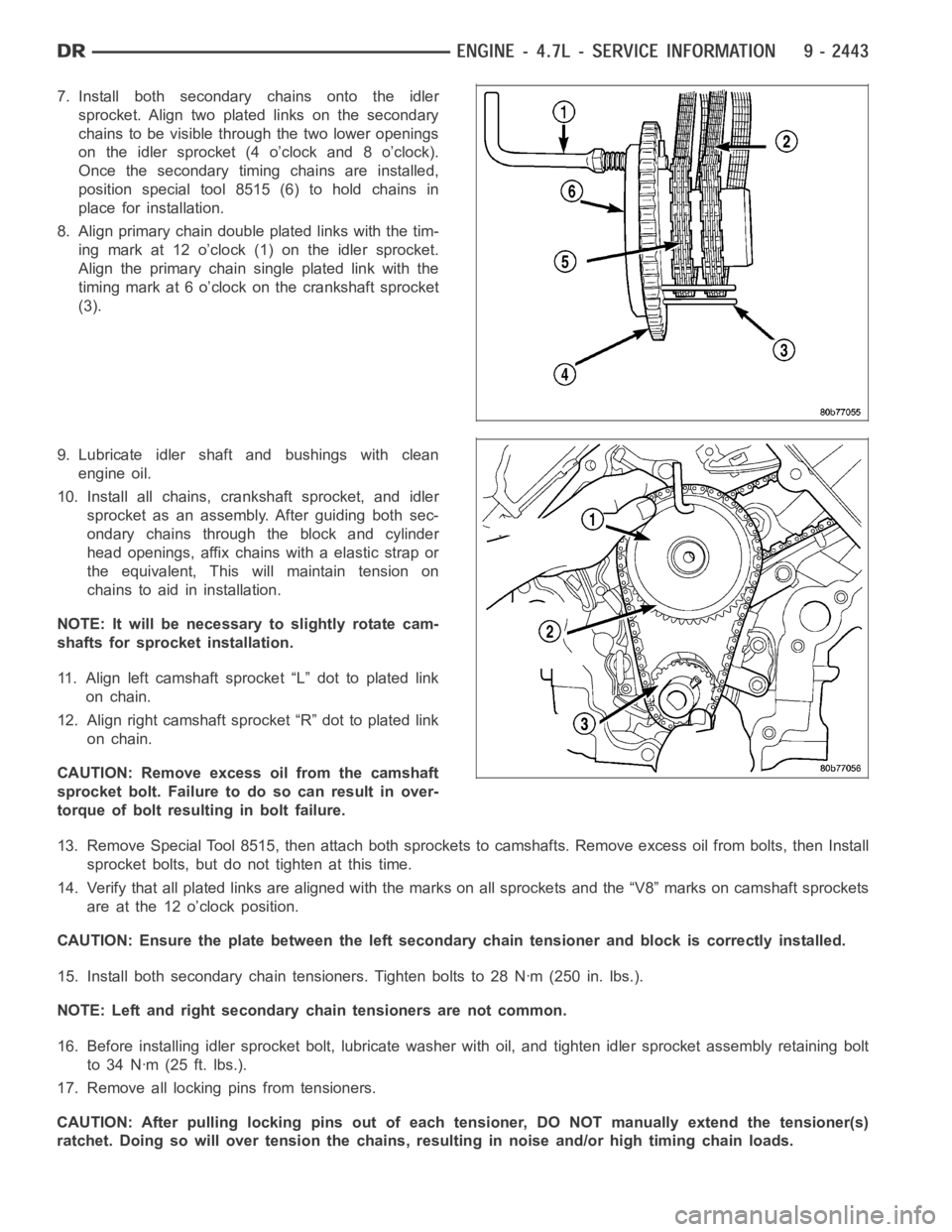

7. Install both secondary chains onto the idler

sprocket. Align two plated links on the secondary

chains to be visible through the two lower openings

on the idler sprocket (4 o’clock and 8 o’clock).

Once the secondary timing chains are installed,

position special tool 8515 (6) to hold chains in

place for installation.

8. Align primary chain double plated links with the tim-

ingmarkat12o’clock(1)ontheidlersprocket.

Align the primary chain single plated link with the

timing mark at 6 o’clock on the crankshaft sprocket

(3).

9. Lubricate idler shaft and bushings with clean

engine oil.

10. Install all chains, crankshaft sprocket, and idler

sprocket as an assembly. After guiding both sec-

ondary chains through the block and cylinder

head openings, affix chains with a elastic strap or

the equivalent, This will maintain tension on

chains to aid in installation.

NOTE: It will be necessary to slightly rotate cam-

shafts for sprocket installation.

11. Align left camshaft sprocket “L” dot to plated link

on chain.

12. Align right camshaft sprocket “R” dot to plated link

on chain.

CAUTION: Remove excess oil from the camshaft

sprocket bolt. Failure to do so can result in over-

torque of bolt resulting in bolt failure.

13. Remove Special Tool 8515, then attach both sprockets to camshafts. Remove excess oil from bolts, then Install

sprocket bolts, but do not tighten at this time.

14. Verify that all plated links are aligned with the marks on all sprocketsand the “V8” marks on camshaft sprockets

are at the 12 o’clock position.

CAUTION: Ensure the plate between the left secondary chain tensioner and block is correctly installed.

15. Install both secondary chain tensioners. Tighten bolts to 28 Nꞏm (250 in. lbs.).

NOTE: Left and right secondary chain tensioners are not common.

16. Before installing idler sprocketbolt, lubricate washer with oil, andtighten idler sprocket assembly retaining bolt

to 34 Nꞏm (25 ft. lbs.).

17. Remove all locking pins from tensioners.

CAUTION: After pulling locking pins out of each tensioner, DO NOT manuallyextend the tensioner(s)

ratchet. Doing so will over tension thechains, resulting in noise and/or high timing chain loads.

Page 1753 of 5267

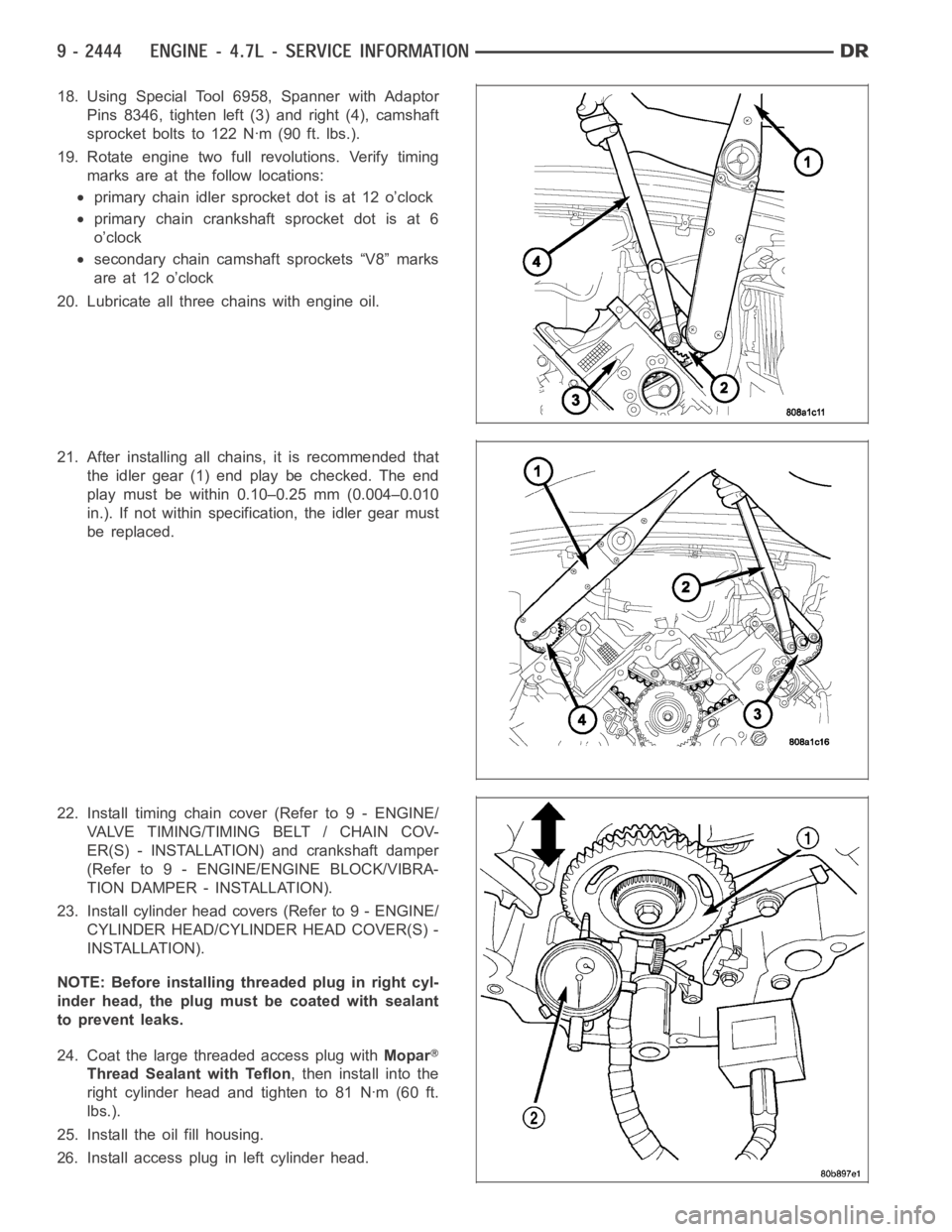

18. Using Special Tool 6958, Spanner with Adaptor

Pins 8346, tighten left (3) and right (4), camshaft

sprocket bolts to 122 Nꞏm (90 ft. lbs.).

19. Rotate engine two full revolutions. Verify timing

marks are at the follow locations:

primary chain idler sprocket dot is at 12 o’clock

primary chain crankshaft sprocket dot is at 6

o’clock

secondary chain camshaft sprockets “V8” marks

are at 12 o’clock

20. Lubricate all three chains with engine oil.

21. After installing all chains, it is recommended that

the idler gear (1) end play be checked. The end

play must be within 0.10–0.25 mm (0.004–0.010

in.). If not within specification, the idler gear must

be replaced.

22. Install timing chain cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT / CHAIN COV-

ER(S) - INSTALLATION) and crankshaft damper

(Refer to 9 - ENGINE/ENGINE BLOCK/VIBRA-

TION DAMPER - INSTALLATION).

23. Install cylinder head covers (Refer to 9 - ENGINE/

CYLINDER HEAD/CYLINDER HEAD COVER(S) -

INSTALLATION).

NOTE: Before installing threaded plug in right cyl-

inder head, the plug mustbecoatedwithsealant

to prevent leaks.

24. Coat the large threaded access plug withMopar

Thread Sealant with Teflon, then install into the

right cylinder head and tighten to 81 Nꞏm (60 ft.

lbs.).

25. Install the oil fill housing.

26. Install access plug in left cylinder head.

Page 1878 of 5267

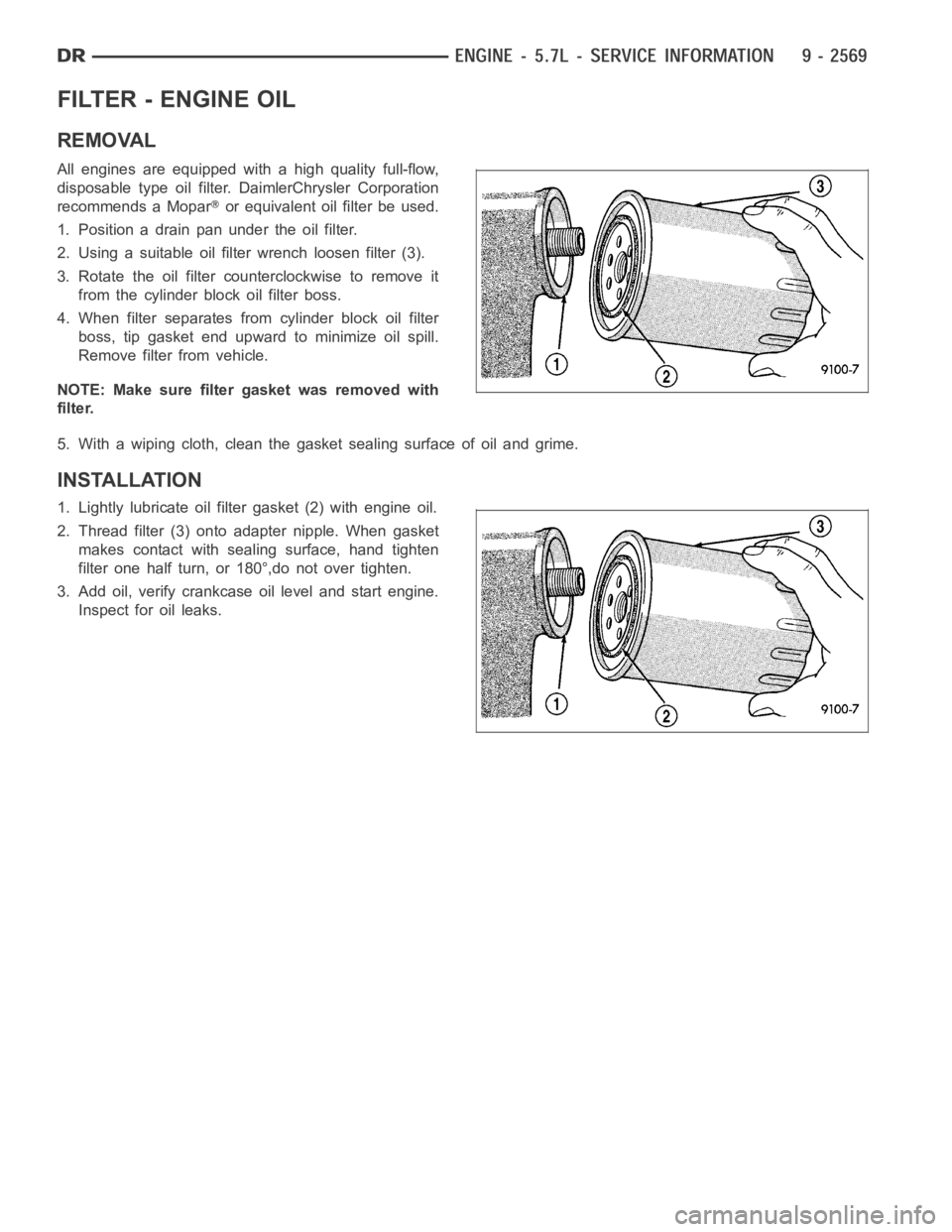

FILTER - ENGINE OIL

REMOVAL

All engines are equipped with a high quality full-flow,

disposable type oil filter. DaimlerChrysler Corporation

recommends a Mopar

or equivalent oil filter be used.

1. Position a drain pan under the oil filter.

2. Using a suitable oil filter wrench loosen filter (3).

3. Rotate the oil filter counterclockwise to remove it

from the cylinder block oil filter boss.

4. When filter separates from cylinder block oil filter

boss, tip gasket end upward to minimize oil spill.

Remove filter from vehicle.

NOTE: Make sure filter gasket was removed with

filter.

5. With a wiping cloth, clean the gasket sealing surface of oil and grime.

INSTALLATION

1. Lightly lubricate oil filter gasket (2) with engine oil.

2. Thread filter (3) onto adapter nipple. When gasket

makes contact with sealing surface, hand tighten

filter one half turn, or 180°,do not over tighten.

3. Add oil, verify crankcase oil level and start engine.

Inspect for oil leaks.

Page 1896 of 5267

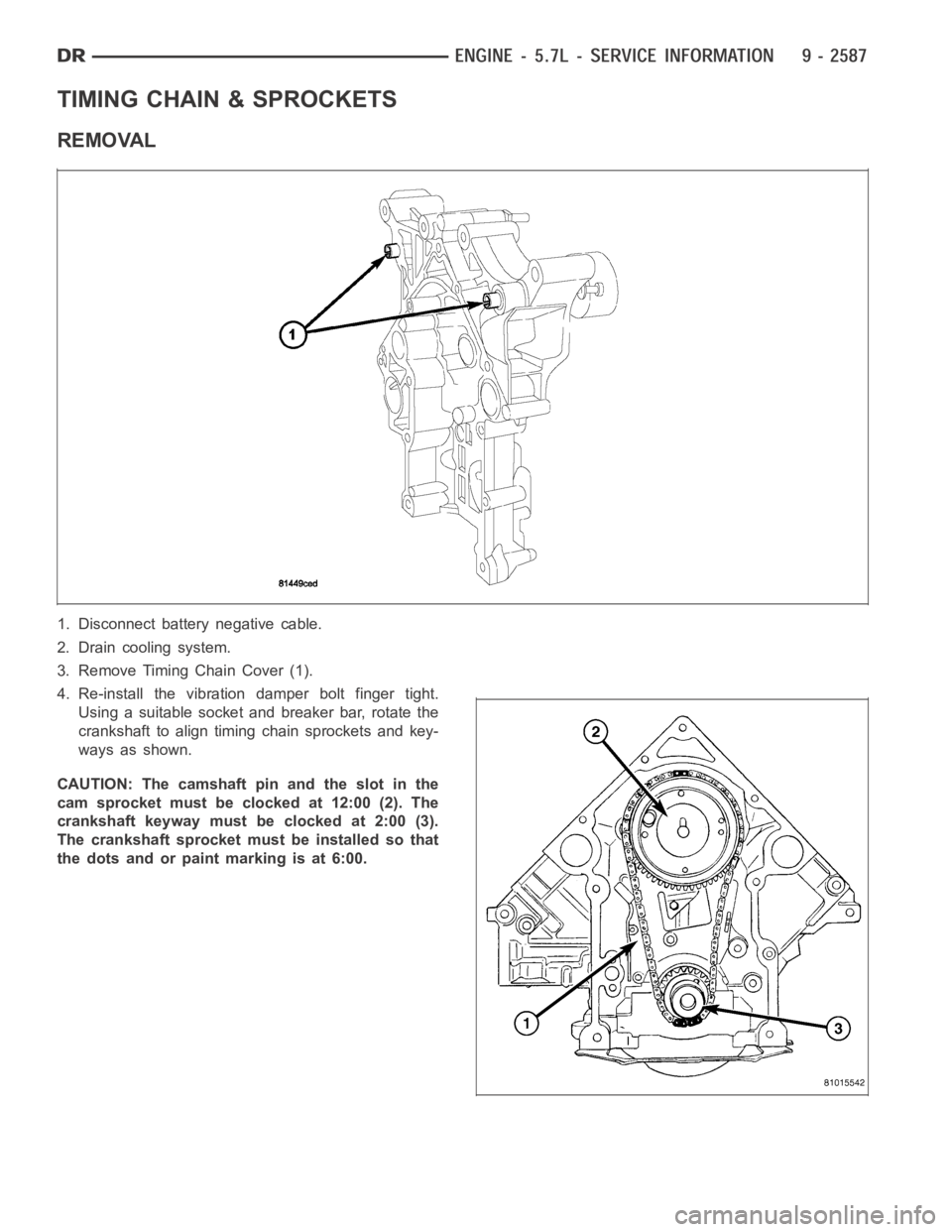

TIMING CHAIN & SPROCKETS

REMOVAL

1. Disconnect battery negative cable.

2. Drain cooling system.

3. Remove Timing Chain Cover (1).

4. Re-install the vibration damper bolt finger tight.

Using a suitable socket and breaker bar, rotate the

crankshaft to align timing chain sprockets and key-

ways as shown.

CAUTION: The camshaft pin and the slot in the

cam sprocket must be clocked at 12:00 (2). The

crankshaft keyway must be clocked at 2:00 (3).

The crankshaft sprocket must be installed so that

the dots and or paint marking is at 6:00.