clock DODGE RAM SRT-10 2006 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2348 of 5267

FILTER - FUEL / WATER SEPARATOR

DESCRIPTION

The fuel filter/water separator assembly is located on left side of engineabove the starter motor. The assembly also

includes the fuel heater, Water-In-Fuel (WIF) sensor and a screened banjobolt attached at the bottom of the fuel

filter canister.

OPERATION

The fuel filter/water separator protects the fuel injection pump by removing water and contaminants from the fuel.

The construction of the filter/separator allows fuel to pass through it, but helps prevent moisture (water) from doing

so. Moisture collects at the bottom of the canister.

Refer to the maintenance schedules in the owners manual for the recommended fuel filter replacement intervals.

For draining of water from canister, refer to Fuel Filter/Water SeparatorRemoval/Installation section.

There is a screened banjo bolt that is attached at the bottom of the fuel filter canister. It provides additional filtering

for the high pressure fuel system components.

A Water-In-Fuel (WIF) sensor is attached to the side of fuel filter housing. Refer to Water-In-Fuel Sensor Descrip-

tion/Operation.

The fuel heater is installed into the top of the filter/separator housing.Refer to Fuel Heater Description/Operation.

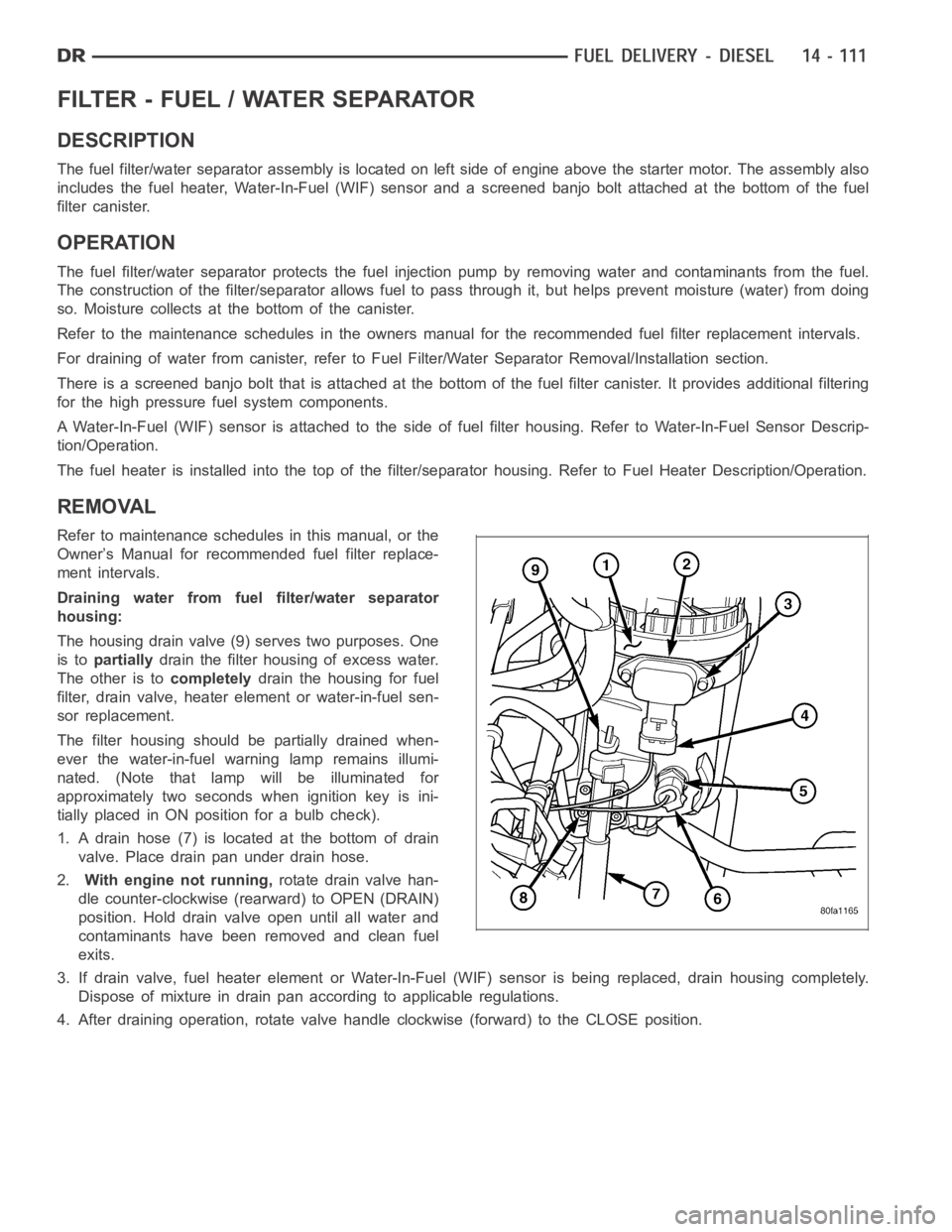

REMOVAL

Refer to maintenance schedules in this manual, or the

Owner’s Manual for recommended fuel filter replace-

ment intervals.

Draining water from fuel filter/water separator

housing:

The housing drain valve (9) serves two purposes. One

is topartiallydrain the filter housing of excess water.

The other is tocompletelydrain the housing for fuel

filter, drain valve, heater element or water-in-fuel sen-

sor replacement.

The filter housing should be partially drained when-

ever the water-in-fuel warning lamp remains illumi-

nated. (Note that lamp will be illuminated for

approximately two seconds when ignition key is ini-

tially placed in ON position for a bulb check).

1. A drain hose (7) is located at the bottom of drain

valve. Place drain pan under drain hose.

2.With engine not running,rotate drain valve han-

dle counter-clockwise (rearward) to OPEN (DRAIN)

position. Hold drain valve open until all water and

contaminants have been removed and clean fuel

exits.

3. If drain valve, fuel heater element or Water-In-Fuel (WIF) sensor is being replaced, drain housing completely.

Dispose of mixture in drain pan according to applicable regulations.

4. After draining operation, rotate valve handle clockwise (forward) to the CLOSE position.

Page 2349 of 5267

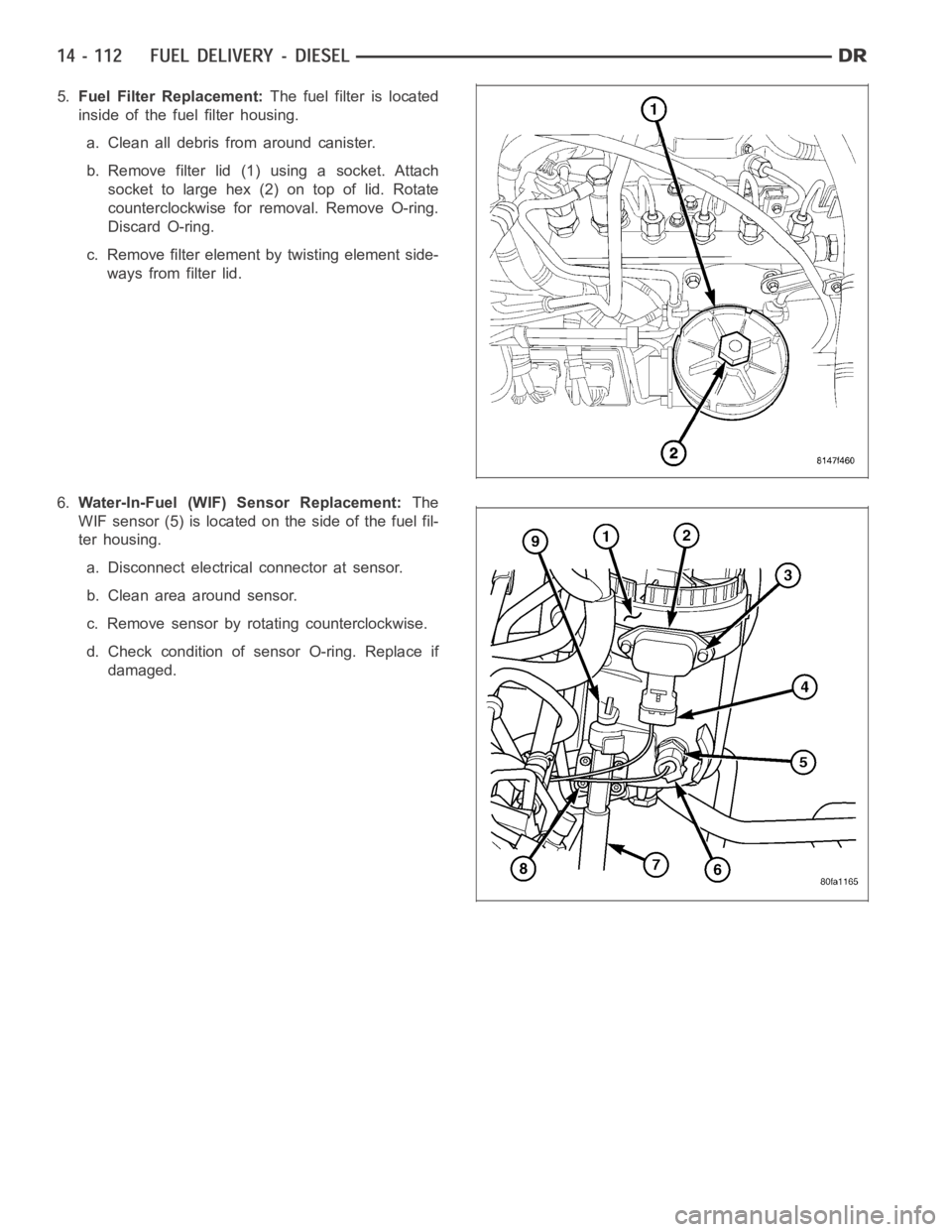

5.Fuel Filter Replacement:The fuel filter is located

inside of the fuel filter housing.

a. Clean all debris from around canister.

b. Remove filter lid (1) using a socket. Attach

socket to large hex (2) on top of lid. Rotate

counterclockwise for removal. Remove O-ring.

Discard O-ring.

c. Remove filter element by twisting element side-

ways from filter lid.

6.Water-In-Fuel (WIF) Sensor Replacement:The

WIF sensor (5) is located on the side of the fuel fil-

ter housing.

a. Disconnect electrical connector at sensor.

b. Clean area around sensor.

c. Remove sensor by rotating counterclockwise.

d. Check condition of sensor O-ring. Replace if

damaged.

Page 2350 of 5267

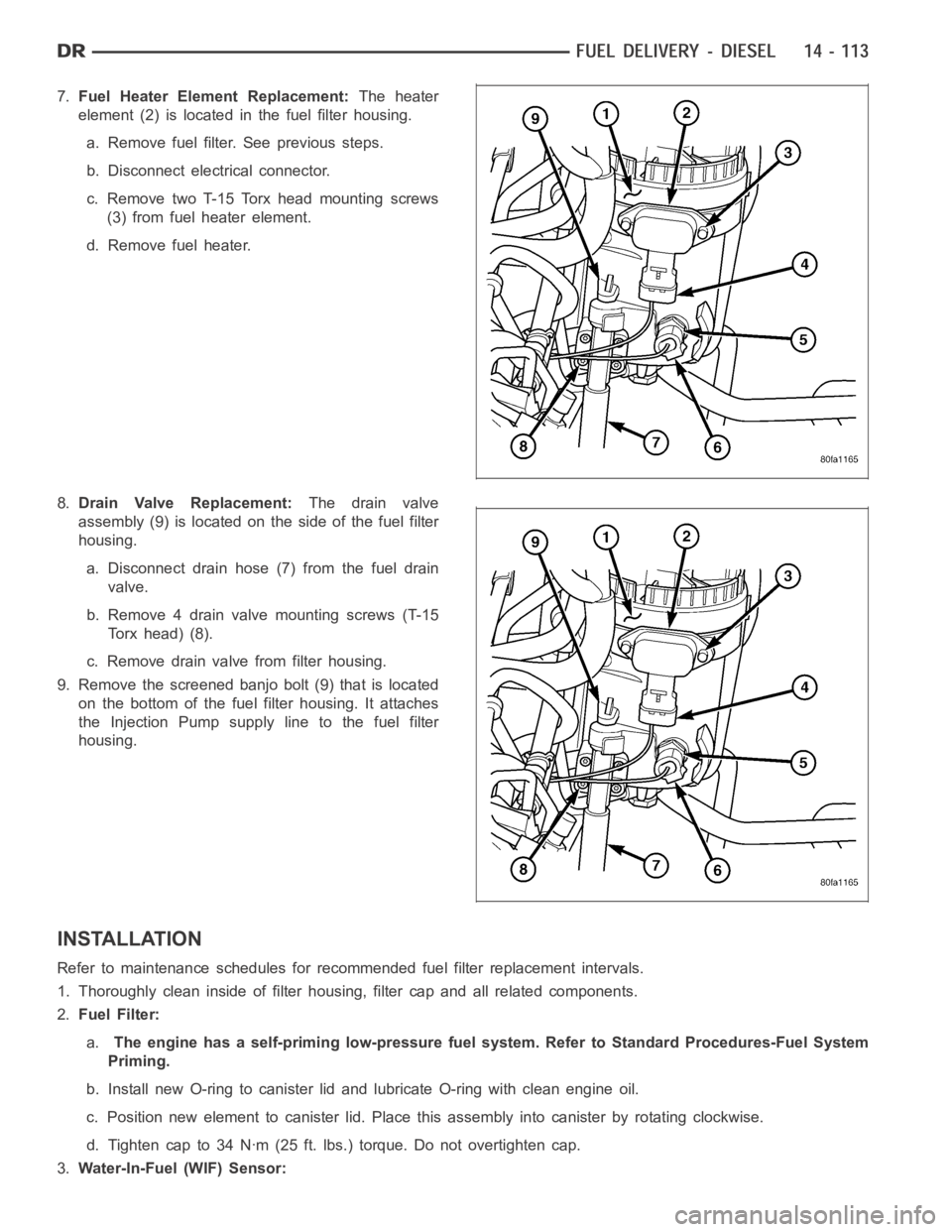

7.Fuel Heater Element Replacement:The heater

element (2) is located in the fuel filter housing.

a. Remove fuel filter. See previous steps.

b. Disconnect electrical connector.

c. Remove two T-15 Torx head mounting screws

(3) from fuel heater element.

d. Remove fuel heater.

8.Drain Valve Replacement:The drain valve

assembly (9) is located on the side of the fuel filter

housing.

a. Disconnect drain hose (7) from the fuel drain

valve.

b. Remove 4 drain valve mounting screws (T-15

Torx head) (8).

c. Remove drain valve from filter housing.

9. Remove the screened banjo bolt (9) that is located

on the bottom of the fuel filter housing. It attaches

the Injection Pump supply line to the fuel filter

housing.

INSTALLATION

Refer to maintenance schedules for recommended fuel filter replacement intervals.

1. Thoroughly clean inside of filter housing, filter cap and all related components.

2.Fuel Filter:

a.The engine has a self-priming low-pressure fuel system. Refer to StandardProcedures-Fuel System

Priming.

b. Install new O-ring to canister lid and lubricate O-ring with clean engine oil.

c. Position new element to canister lid. Place this assembly into canisterby rotating clockwise.

d. Tighten cap to 34 Nꞏm (25 ft. lbs.) torque. Do not overtighten cap.

3.Water-In-Fuel (WIF) Sensor:

Page 2371 of 5267

MODULE - FUEL TANK

DESCRIPTION

.

The fuel tank module is installed in the top of the fuel tank. The fuel tank module contains the following compo-

nents:

An electric fuel transfer (lift) pump

Fuel reservoir

A separate in-tank fuel filter

Fuel gauge sending unit (fuel level sensor)

Fuel supply line connection

A special lockring to retain module to fuel tank

Fuel return line connection

OPERATION

Refer to Fuel Gauge Sending Unit.

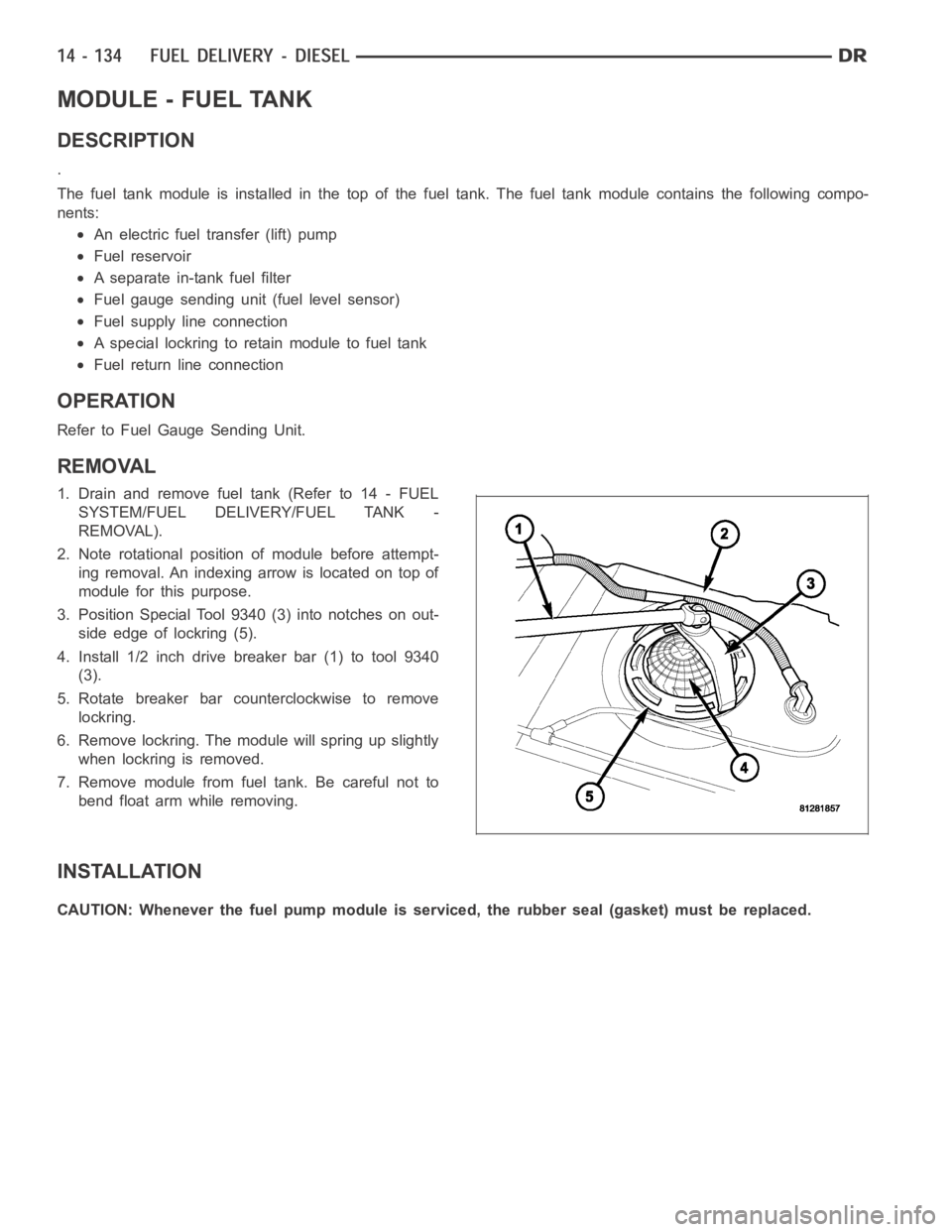

REMOVAL

1. Drain and remove fuel tank (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/FUEL TANK -

REMOVAL).

2. Note rotational position of module before attempt-

ing removal. An indexing arrow is located on top of

module for this purpose.

3. Position Special Tool 9340 (3) into notches on out-

side edge of lockring (5).

4. Install 1/2 inch drive breaker bar (1) to tool 9340

(3).

5. Rotate breaker bar counterclockwise to remove

lockring.

6. Remove lockring. The module will spring up slightly

when lockring is removed.

7. Remove module from fuel tank. Be careful not to

bend float arm while removing.

INSTALLATION

CAUTION: Whenever the fuel pump module is serviced, the rubber seal (gasket) must be replaced.

Page 2372 of 5267

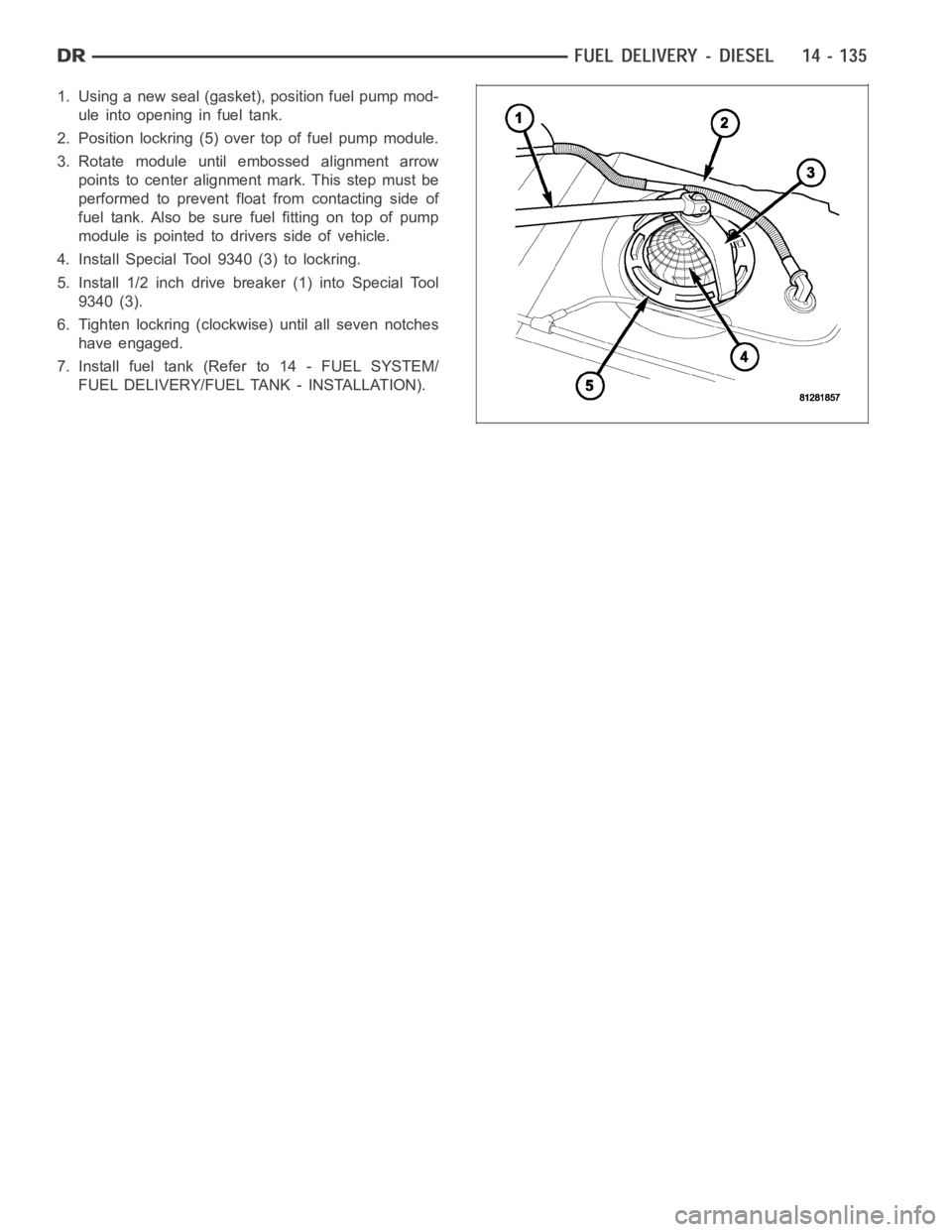

1. Using a new seal (gasket), position fuel pump mod-

uleintoopeninginfueltank.

2. Position lockring (5) over top of fuel pump module.

3. Rotate module until embossed alignment arrow

points to center alignment mark. This step must be

performed to prevent float from contacting side of

fuel tank. Also be sure fuel fitting on top of pump

module is pointed to drivers side of vehicle.

4. Install Special Tool 9340 (3) to lockring.

5. Install 1/2 inch drive breaker (1) into Special Tool

9340 (3).

6. Tighten lockring (clockwise) until all seven notches

have engaged.

7. Install fuel tank (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/FUEL TANK - INSTALLATION).

Page 2384 of 5267

ACTUATOR - FUEL CONTROL

DESCRIPTION

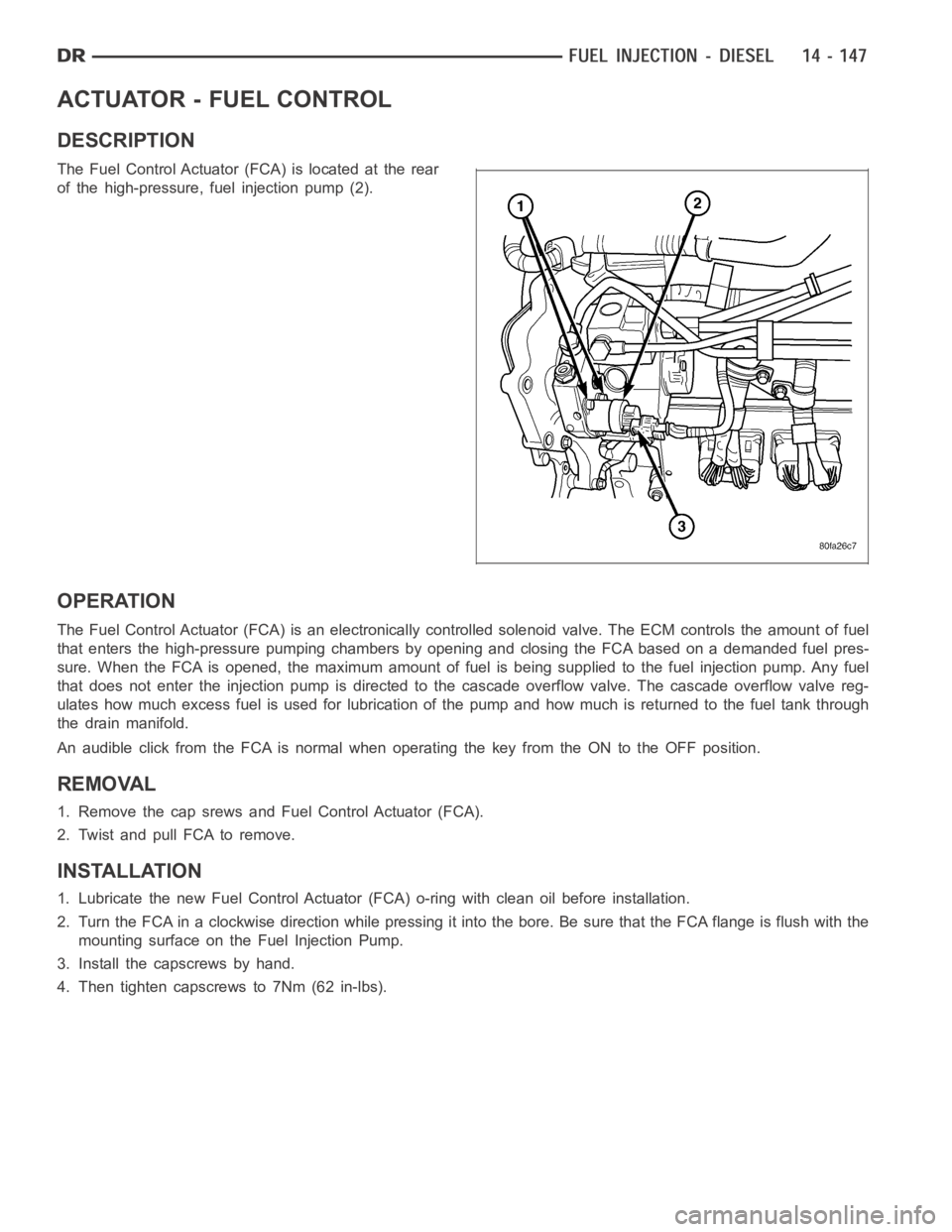

The Fuel Control Actuator (FCA) is located at the rear

of the high-pressure, fuel injection pump (2).

OPERATION

The Fuel Control Actuator (FCA) is an electronically controlled solenoidvalve. The ECM controls the amount of fuel

that enters the high-pressure pumping chambers by opening and closing theFCA based on a demanded fuel pres-

sure. When the FCA is opened, the maximum amount of fuel is being supplied tothe fuel injection pump. Any fuel

that does not enter the injection pump is directed to the cascade overflow valve. The cascade overflow valve reg-

ulates how much excess fuel is used for lubrication of the pump and how much is returned to the fuel tank through

the drain manifold.

An audible click from the FCA is normal when operating the key from the ON to the OFF position.

REMOVAL

1. Remove the cap srews and Fuel Control Actuator (FCA).

2. Twist and pull FCA to remove.

INSTALLATION

1. Lubricate the new Fuel Control Actuator (FCA) o-ring with clean oil before installation.

2. Turn the FCA in a clockwise direction while pressing it into the bore. Be sure that the FCA flange is flush with the

mounting surface on the Fuel Injection Pump.

3. Install the capscrews by hand.

4. Then tighten capscrews to 7Nm (62 in-lbs).

Page 2414 of 5267

DESCRIPTION - SRT10

The SRT-10 column has noSTARTposition on the key cylinder. The push starter button switch is mounted on the

Instrument panel center stack. All SRT-10 columns are Tilt columns, Standard cab trucks come with manual trans-

missions, Quad cab trucks come equipped with automatic transmissions.

DIAGNOSIS AND TESTING

STEERING COLUMN

If the vehicle is involved in a front end collision/the air bag has deployedthe column must be inspected. This

inspection will determine if the Column has collapsed. Inspect the columnmounting capsules visually and manually

push and pull them to check for separation or fractures. If capsules are fractured or have moved the column MUST

be replaced.

REMOVAL

WARNING: Before servicing the steering column the airbag system must be disarmed. Refer to electrical

restraint system for service procedures. Failure to do so may result in accidental deployment of the airbag

and possible personal injury.

CAUTION: All fasteners must be torqued to specification to ensure proper operation of the steering column.

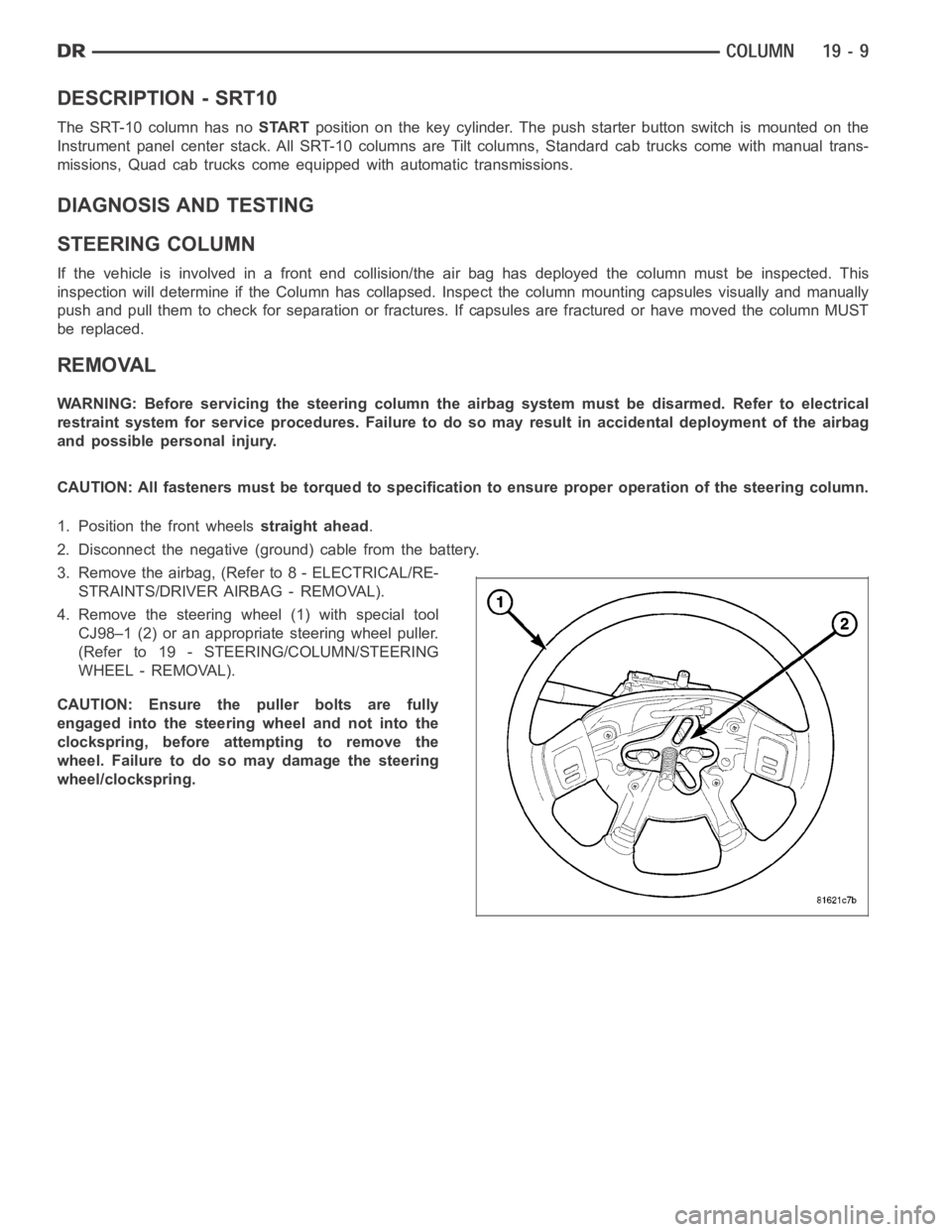

1. Position the front wheelsstraight ahead.

2. Disconnect the negative (ground) cable from the battery.

3. Remove the airbag, (Refer to 8 - ELECTRICAL/RE-

STRAINTS/DRIVER AIRBAG - REMOVAL).

4. Remove the steering wheel (1) with special tool

CJ98–1 (2) or an appropriate steering wheel puller.

(Refer to 19 - STEERING/COLUMN/STEERING

WHEEL - REMOVAL).

CAUTION: Ensure the puller bolts are fully

engaged into the steering wheel and not into the

clockspring, before attempting to remove the

wheel. Failure to do so may damage the steering

wheel/clockspring.

Page 2416 of 5267

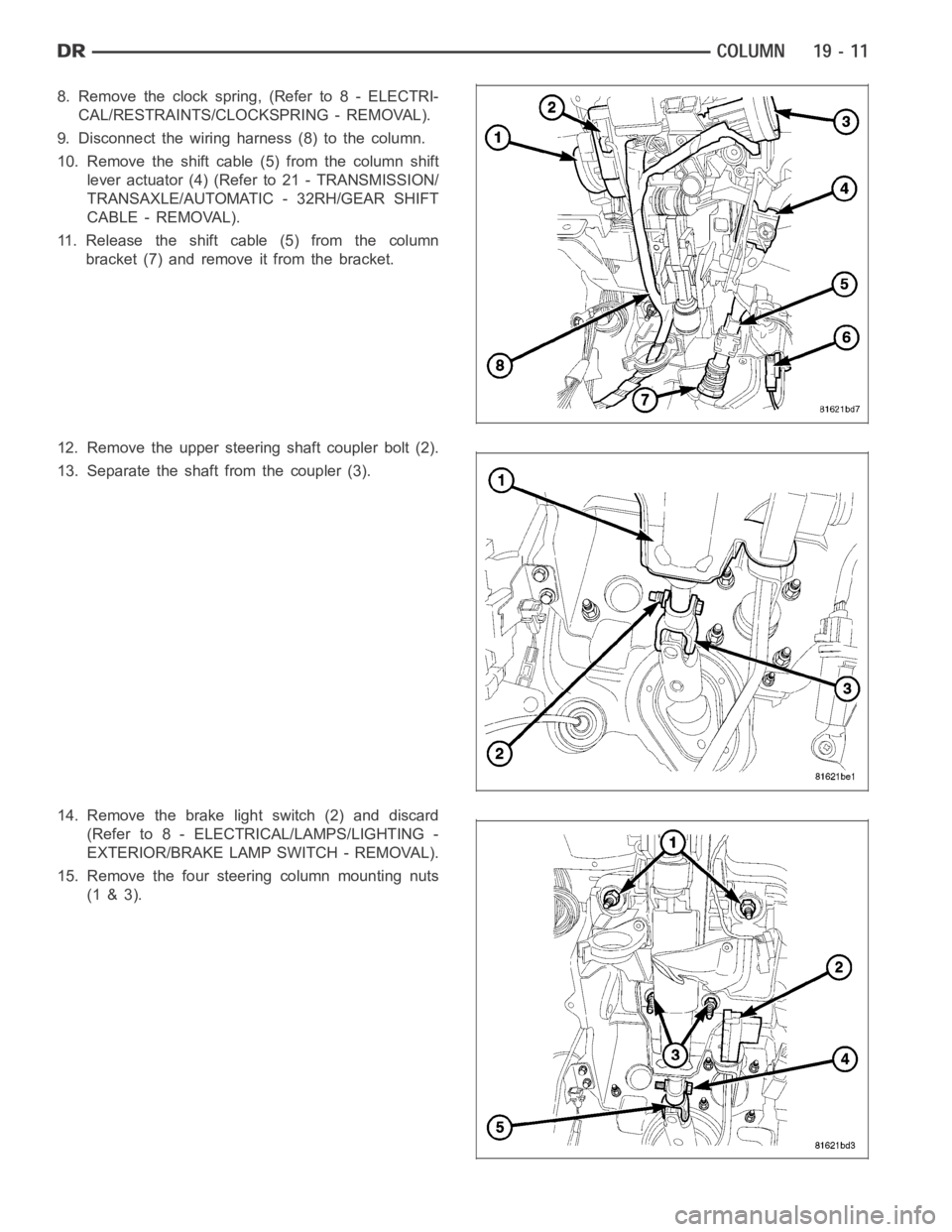

8. Remove the clock spring, (Refer to 8 - ELECTRI-

CAL/RESTRAINTS/CLOCKSPRING - REMOVAL).

9. Disconnect the wiring harness (8) to the column.

10. Remove the shift cable (5) from the column shift

lever actuator (4) (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 32RH/GEAR SHIFT

CABLE - REMOVAL).

11. Release the shift cable (5) from the column

bracket (7) and remove it from the bracket.

12. Remove the upper steering shaft coupler bolt (2).

13. Separate the shaft from the coupler (3).

14. Remove the brake light switch (2) and discard

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/BRAKE LAMP SWITCH - REMOVAL).

15. Remove the four steering column mounting nuts

(1 & 3).

Page 2418 of 5267

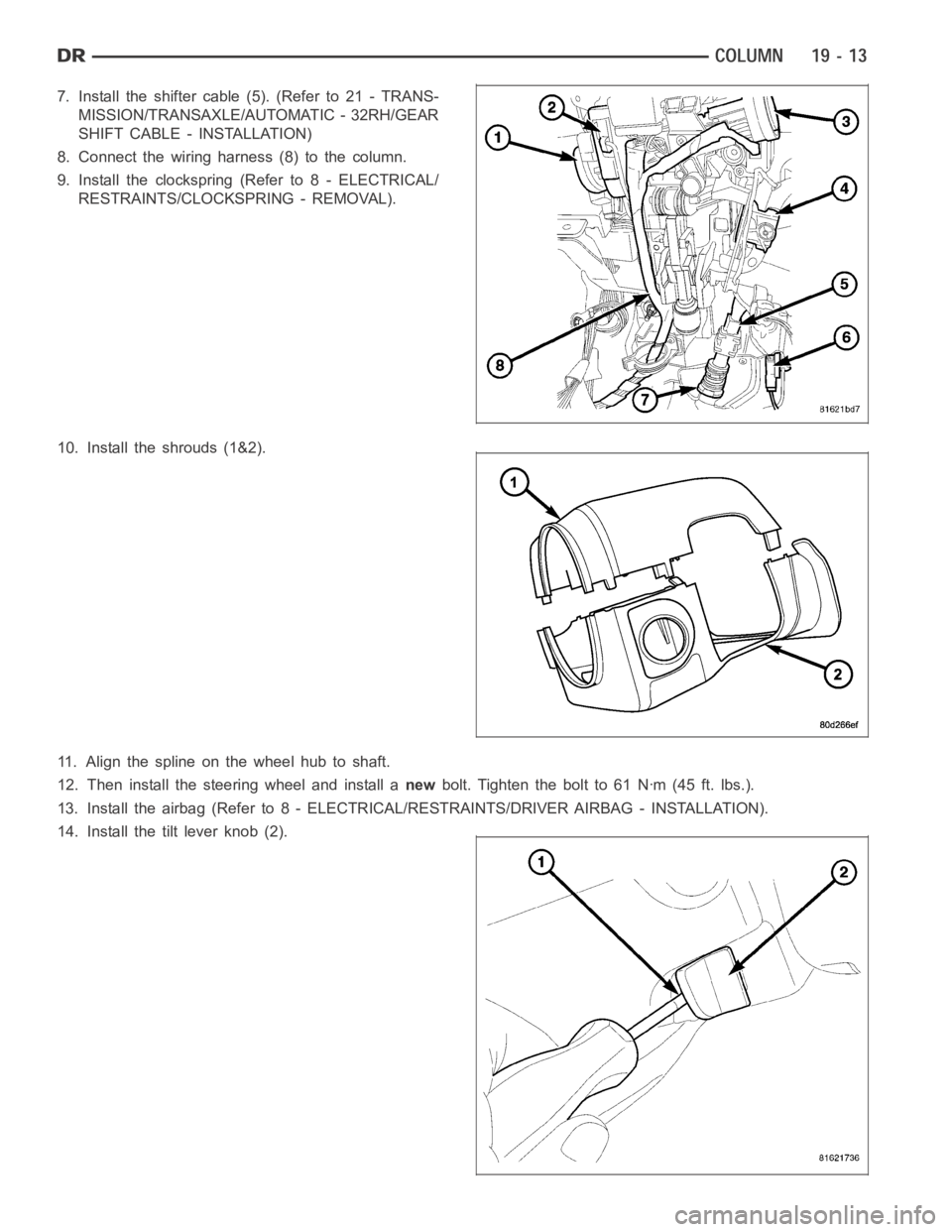

7. Install the shifter cable (5). (Refer to 21 - TRANS-

MISSION/TRANSAXLE/AUTOMATIC - 32RH/GEAR

SHIFT CABLE - INSTALLATION)

8. Connect the wiring harness (8) to the column.

9. Install the clockspring (Refer to 8 - ELECTRICAL/

RESTRAINTS/CLOCKSPRING - REMOVAL).

10. Install the shrouds (1&2).

11. Align the spline on the wheel hub to shaft.

12. Then install the steering wheel and install anewbolt. Tighten the bolt to 61 Nꞏm (45 ft. lbs.).

13. Install the airbag (Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER AIRBAG- INSTALLATION).

14. Install the tilt lever knob (2).

Page 2429 of 5267

STEERING WHEEL

REMOVAL

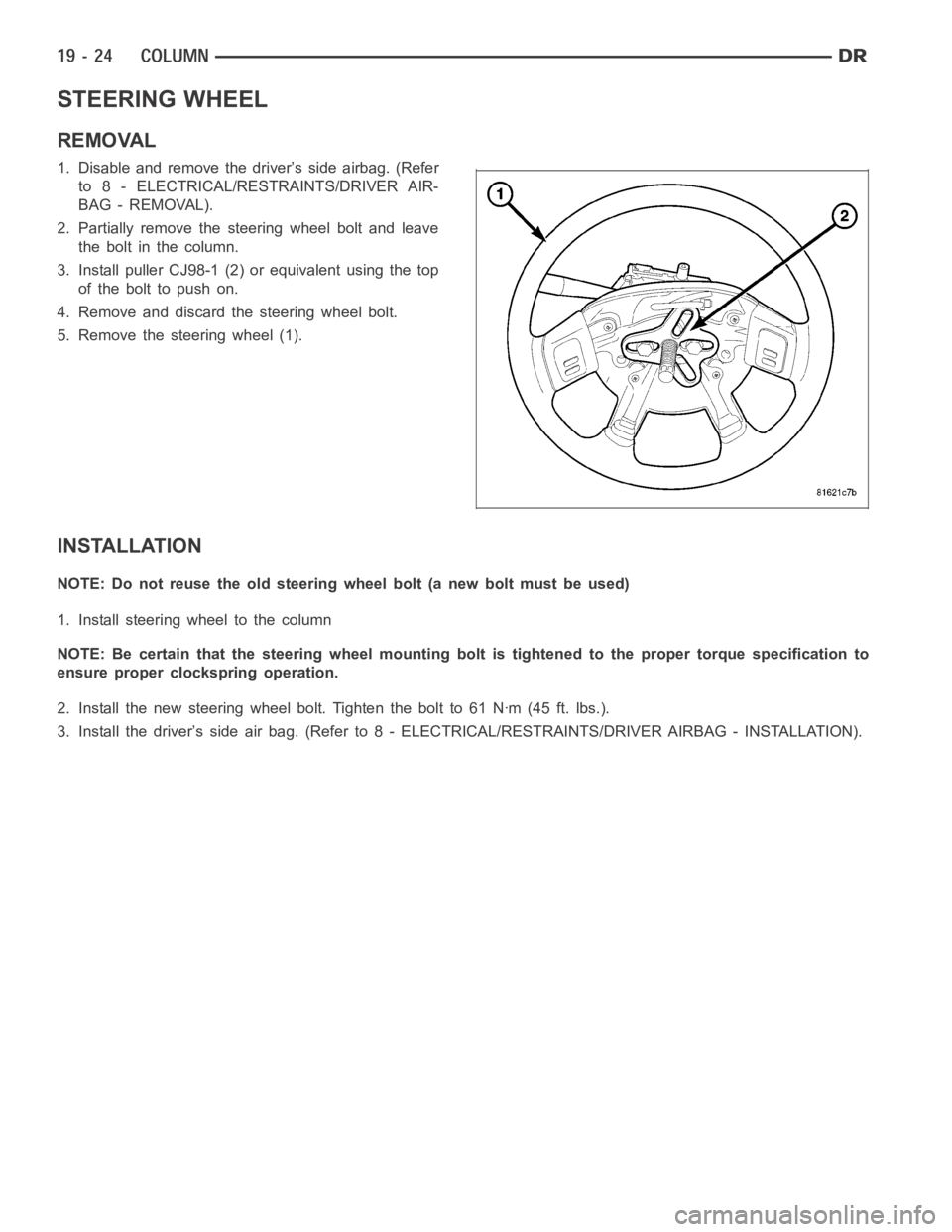

1. Disable and remove the driver’s side airbag. (Refer

to 8 - ELECTRICAL/RESTRAINTS/DRIVER AIR-

BAG - REMOVAL).

2. Partially remove the steering wheel bolt and leave

theboltinthecolumn.

3. Install puller CJ98-1 (2) or equivalent using the top

ofthebolttopushon.

4. Remove and discard the steering wheel bolt.

5. Remove the steering wheel (1).

INSTALLATION

NOTE: Do not reuse the old steering wheel bolt (a new bolt must be used)

1. Install steering wheel to the column

NOTE: Be certain that the steering wheel mounting bolt is tightened to the proper torque specification to

ensure proper clockspring operation.

2. Install the new steering wheel bolt. Tighten the bolt to 61 Nꞏm (45 ft. lbs.).

3. Install the driver’s side air bag. (Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER AIRBAG - INSTALLATION).