clock DODGE RAM SRT-10 2006 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2015 of 5267

VALVE TIMING

STANDARD PROCEDURE - TIMING VERIFICATION

1. Remove the cylinder head cover (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) -

REMOVAL).

2. Remove fuel injector from cylindernumber 1 (Refer to 14 - FUEL SYSTEM/FUEL INJECTION/FUEL INJECTOR

- REMOVAL).

3. Using Special Tool 7471B rotate the engine until the TDC mark on the damper is at 12 o’clock.

4. Using a 8 in.x 1/4 in. dowel rod inserted into cylinder number 1, rock the crankshaft back and forth to verify

piston number 1 is at TDC.

5. With cylinder number still at TDC, inspect the keyway on the crankshaft gear for proper alignment (12 o’clock

position).

6. If the keyway is not at 12 o’clock position replace the crankshaft gear assembly.

7. If the keyway is at 12 o’clock position, remove front gear cover and verify timing mark alignment between the

camshaft gear and crankshaft gear, if not aligned inspect keyway on camshaft gear.

8. Inspect keyway on camshaft gear for proper alignment with the key in the camshaft, if alignment is off replace

the camshaft/gear assembly.

9. If timing marks alignment is off and no damage is found at either the crankshaft or camshaft gear keyways,

realign timing marks as necessary.

Page 2085 of 5267

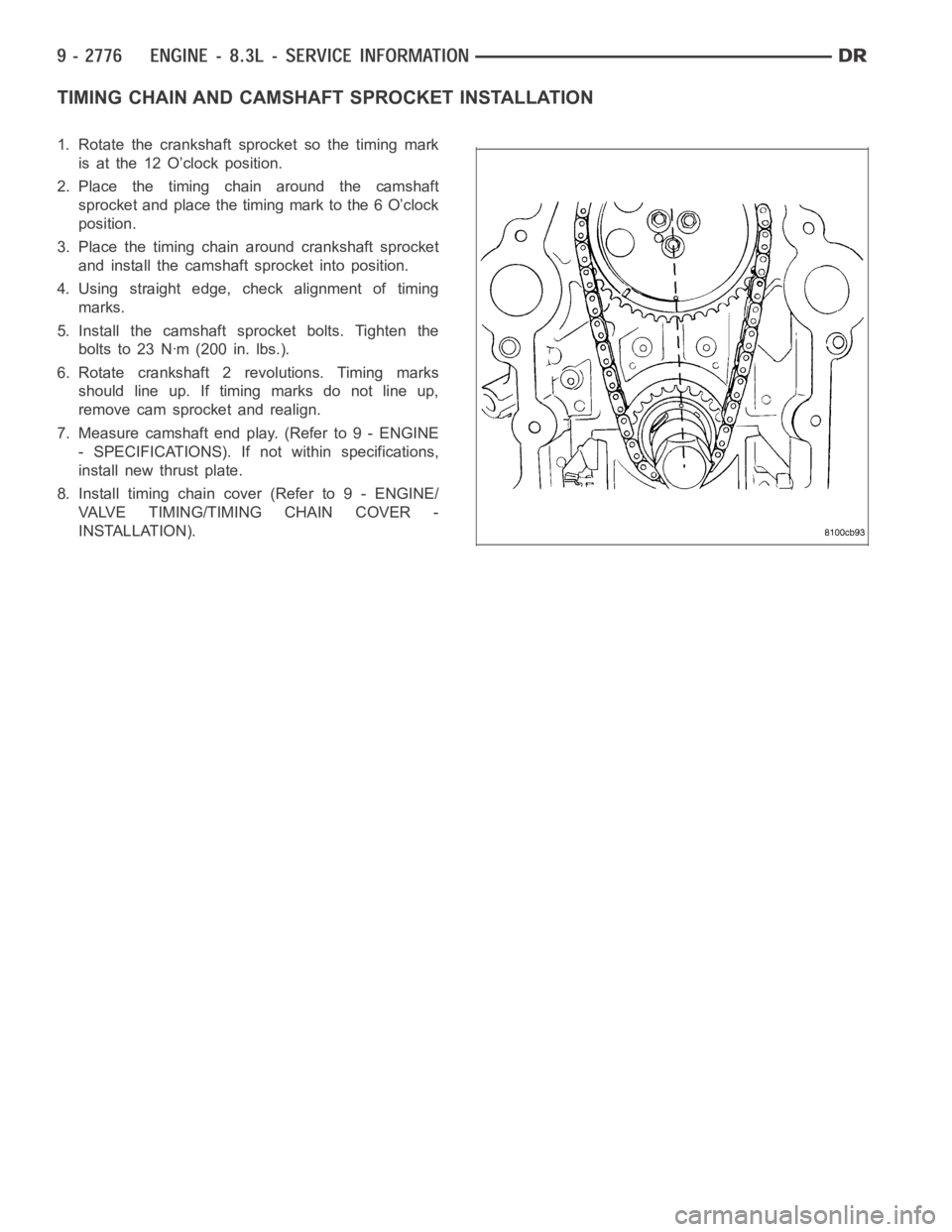

TIMING CHAIN ANDCAMSHAFT SPROCKET INSTALLATION

1. Rotate the crankshaft sprocket so the timing mark

is at the 12 O’clock position.

2. Place the timing chain around the camshaft

sprocket and place the timing mark to the 6 O’clock

position.

3. Place the timing chain around crankshaft sprocket

and install the camshaft sprocket into position.

4. Using straight edge, check alignment of timing

marks.

5. Install the camshaft sprocket bolts. Tighten the

bolts to 23 Nꞏm (200 in. lbs.).

6. Rotate crankshaft 2 revolutions. Timing marks

should line up. If timing marks do not line up,

remove cam sprocket and realign.

7. Measure camshaft end play. (Refer to 9 - ENGINE

- SPECIFICATIONS). If not within specifications,

install new thrust plate.

8. Install timing chain cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMING CHAIN COVER -

INSTALLATION).

Page 2257 of 5267

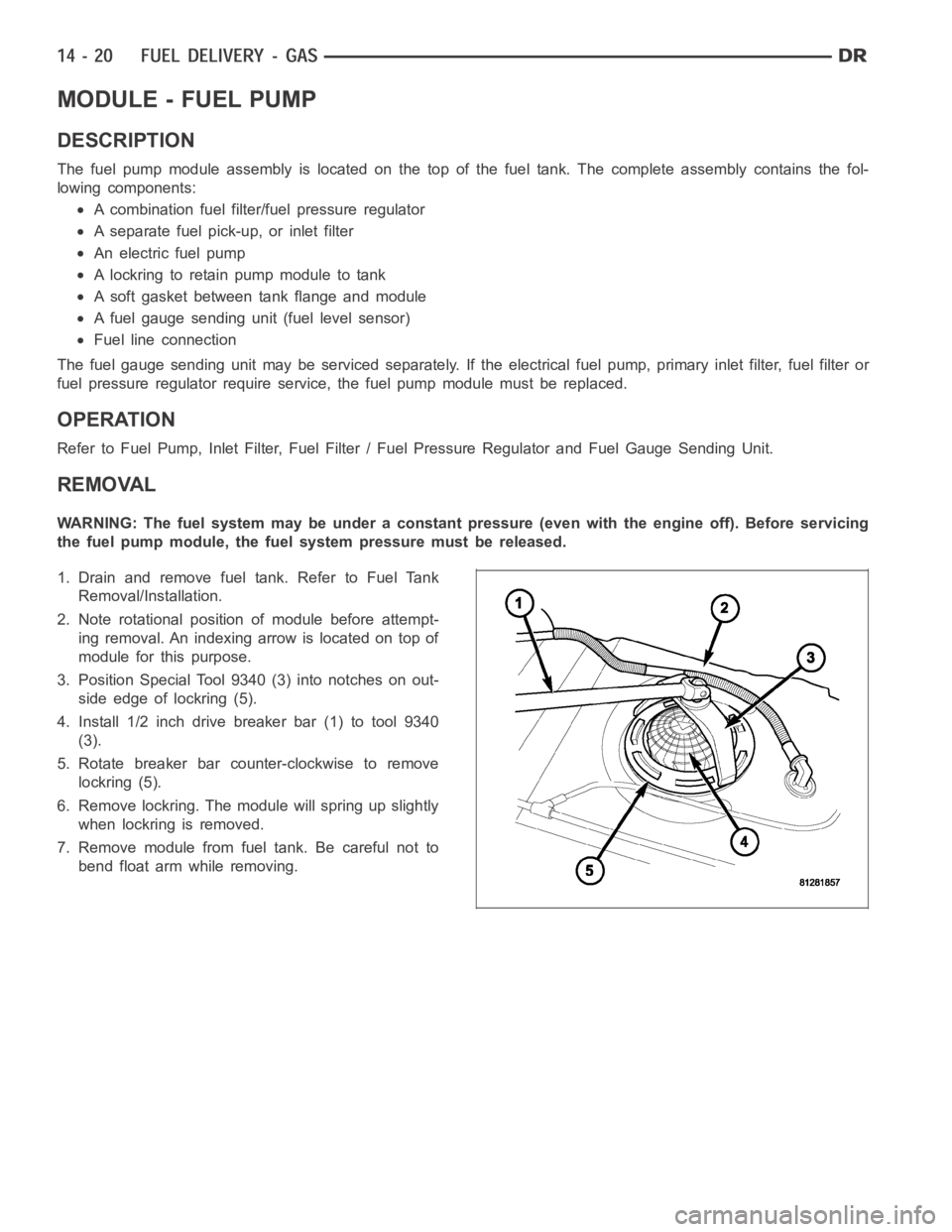

MODULE - FUEL PUMP

DESCRIPTION

The fuel pump module assembly is located on the top of the fuel tank. The complete assembly contains the fol-

lowing components:

A combination fuel filter/fuel pressure regulator

A separate fuel pick-up, or inlet filter

An electric fuel pump

Alockringtoretainpumpmoduletotank

A soft gasket between tank flange and module

A fuel gauge sending unit (fuel level sensor)

Fuel line connection

The fuel gauge sending unit may be serviced separately. If the electrical fuel pump, primary inlet filter, fuel filter or

fuel pressure regulator require service, the fuel pump module must be replaced.

OPERATION

Refer to Fuel Pump, Inlet Filter, Fuel Filter / Fuel Pressure Regulator andFuel Gauge Sending Unit.

REMOVAL

WARNING: The fuel system may be under a constant pressure (even with the engine off). Before servicing

the fuel pump module, the fuel system pressure must be released.

1. Drain and remove fuel tank. Refer to Fuel Tank

Removal/Installation.

2. Note rotational position of module before attempt-

ing removal. An indexing arrow is located on top of

module for this purpose.

3. Position Special Tool 9340 (3) into notches on out-

side edge of lockring (5).

4. Install 1/2 inch drive breaker bar (1) to tool 9340

(3).

5. Rotate breaker bar counter-clockwise to remove

lockring (5).

6. Remove lockring. The module will spring up slightly

when lockring is removed.

7. Remove module from fuel tank. Be careful not to

bend float arm while removing.

Page 2258 of 5267

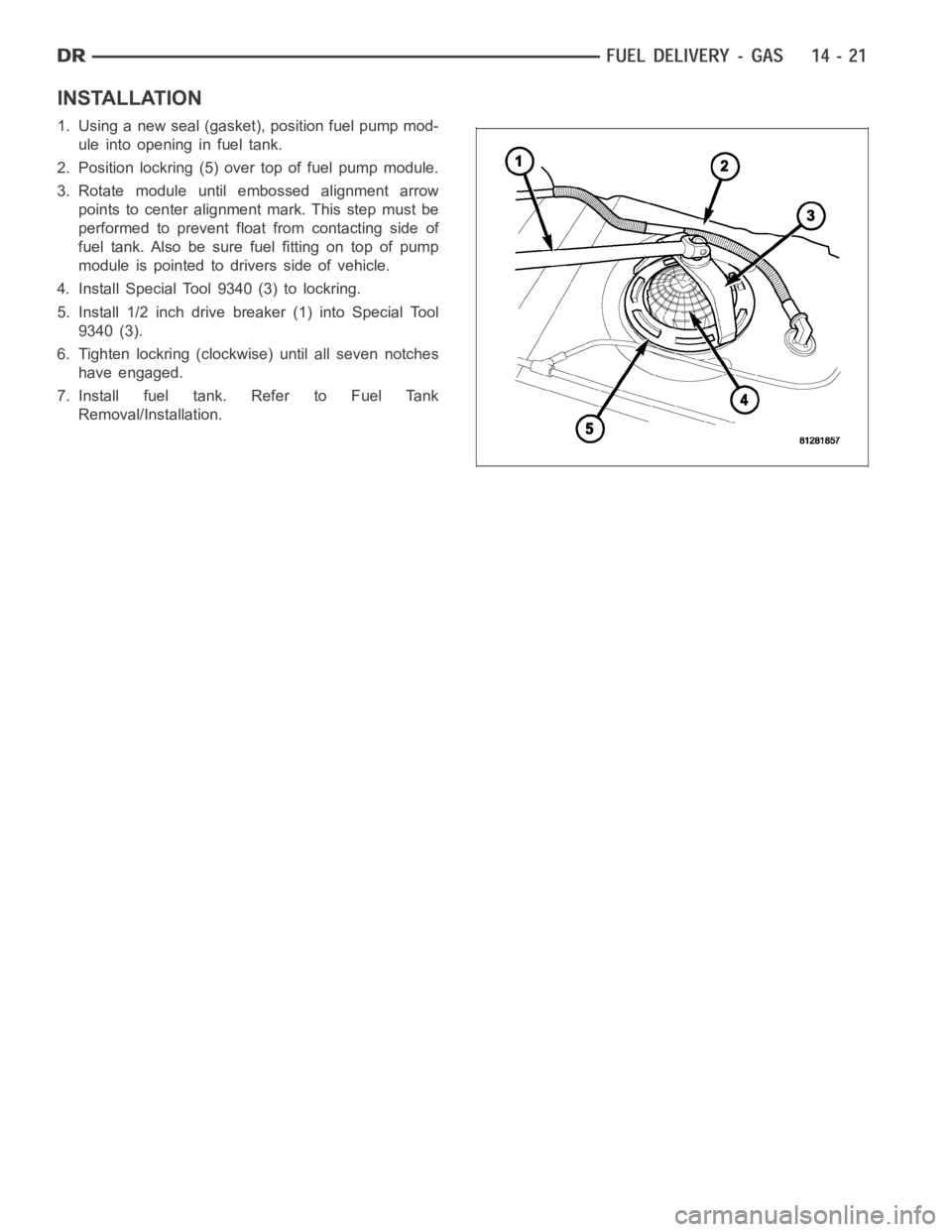

INSTALLATION

1. Using a new seal (gasket), position fuel pump mod-

uleintoopeninginfueltank.

2. Position lockring (5) over top of fuel pump module.

3. Rotate module until embossed alignment arrow

points to center alignment mark. This step must be

performed to prevent float from contacting side of

fuel tank. Also be sure fuel fitting on top of pump

module is pointed to drivers side of vehicle.

4. Install Special Tool 9340 (3) to lockring.

5. Install 1/2 inch drive breaker (1) into Special Tool

9340 (3).

6. Tighten lockring (clockwise) until all seven notches

have engaged.

7. Install fuel tank. Refer to Fuel Tank

Removal/Installation.

Page 2308 of 5267

REMOVAL

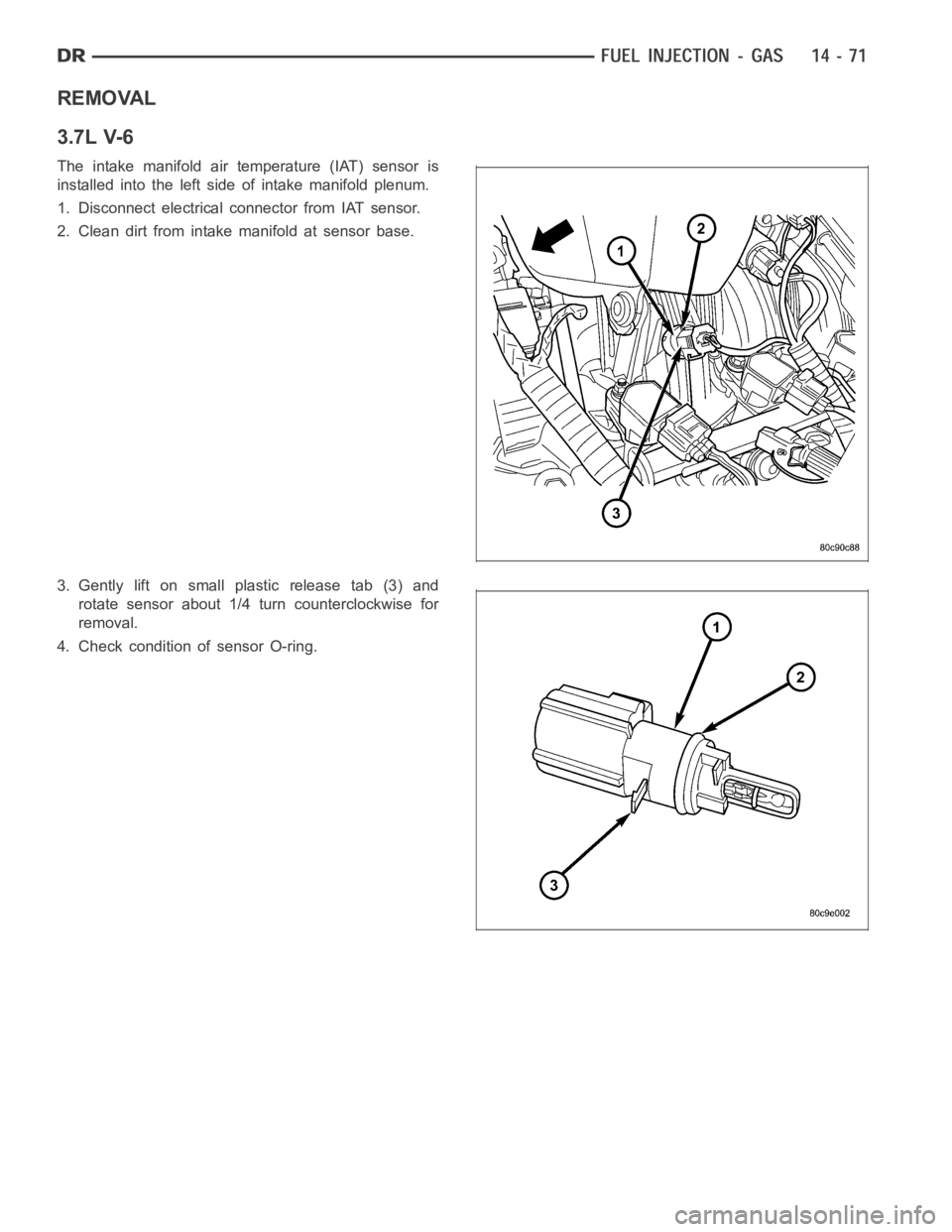

3.7L V-6

The intake manifold air temperature (IAT) sensor is

installed into the left side of intake manifold plenum.

1. Disconnect electrical connector from IAT sensor.

2. Clean dirt from intake manifold at sensor base.

3. Gently lift on small plastic release tab (3) and

rotate sensor about 1/4 turn counterclockwise for

removal.

4. Check condition of sensor O-ring.

Page 2309 of 5267

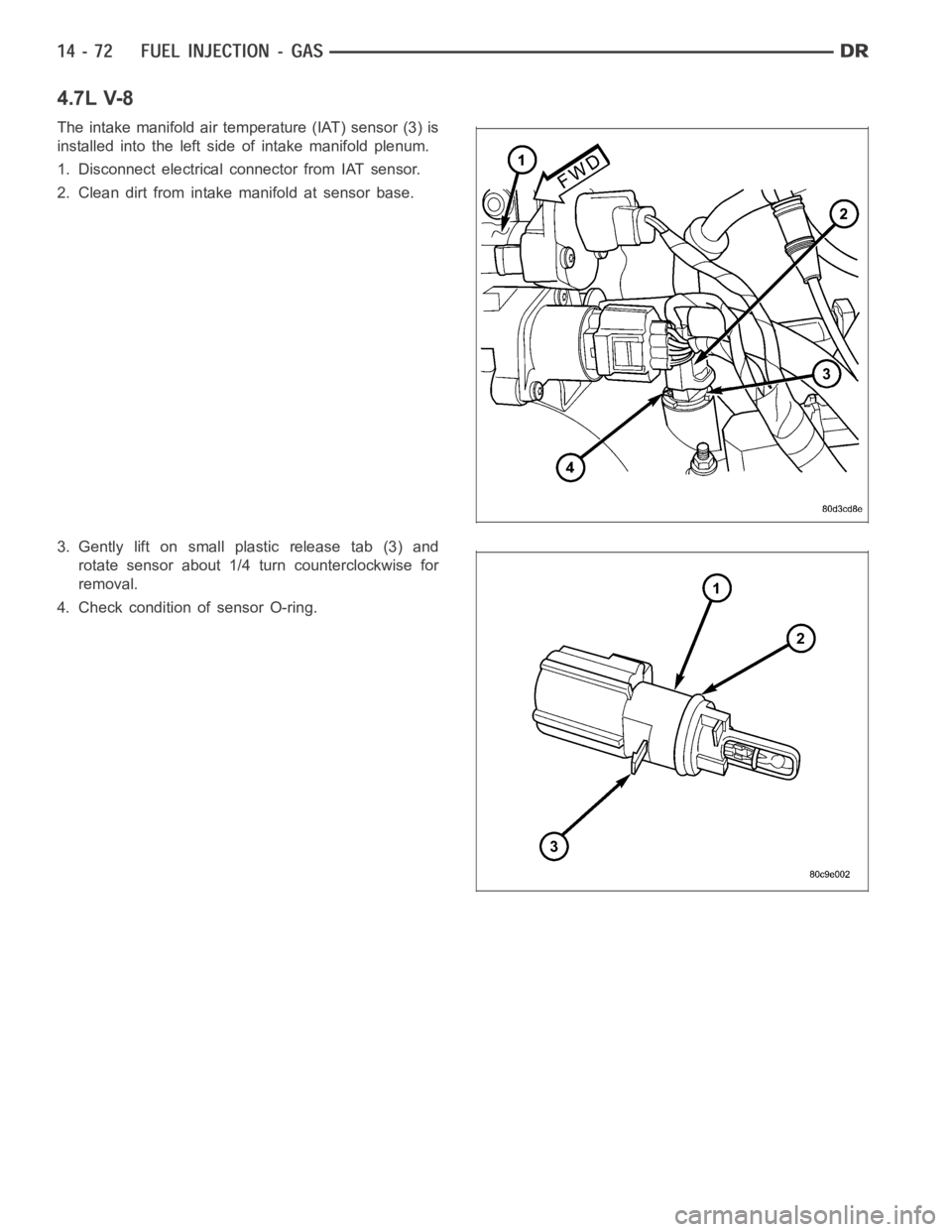

4.7L V-8

The intake manifold air temperature (IAT) sensor (3) is

installed into the left side of intake manifold plenum.

1. Disconnect electrical connector from IAT sensor.

2. Clean dirt from intake manifold at sensor base.

3. Gently lift on small plastic release tab (3) and

rotate sensor about 1/4 turn counterclockwise for

removal.

4. Check condition of sensor O-ring.

Page 2311 of 5267

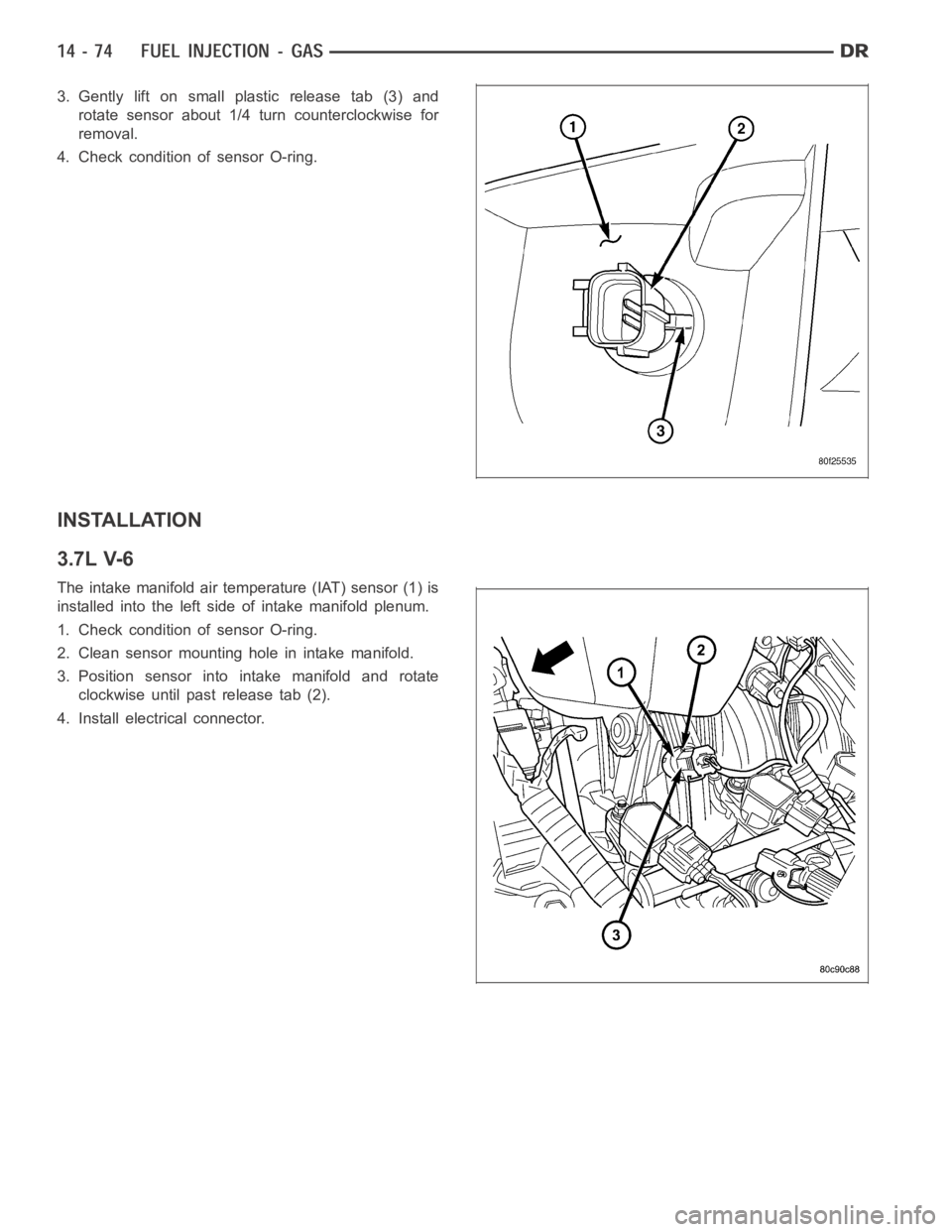

3. Gently lift on small plastic release tab (3) and

rotate sensor about 1/4 turn counterclockwise for

removal.

4. Check condition of sensor O-ring.

INSTALLATION

3.7L V-6

The intake manifold air temperature (IAT) sensor (1) is

installed into the left side of intake manifold plenum.

1. Check condition of sensor O-ring.

2. Clean sensor mounting hole in intake manifold.

3. Position sensor into intake manifold and rotate

clockwise until past release tab (2).

4. Install electrical connector.

Page 2312 of 5267

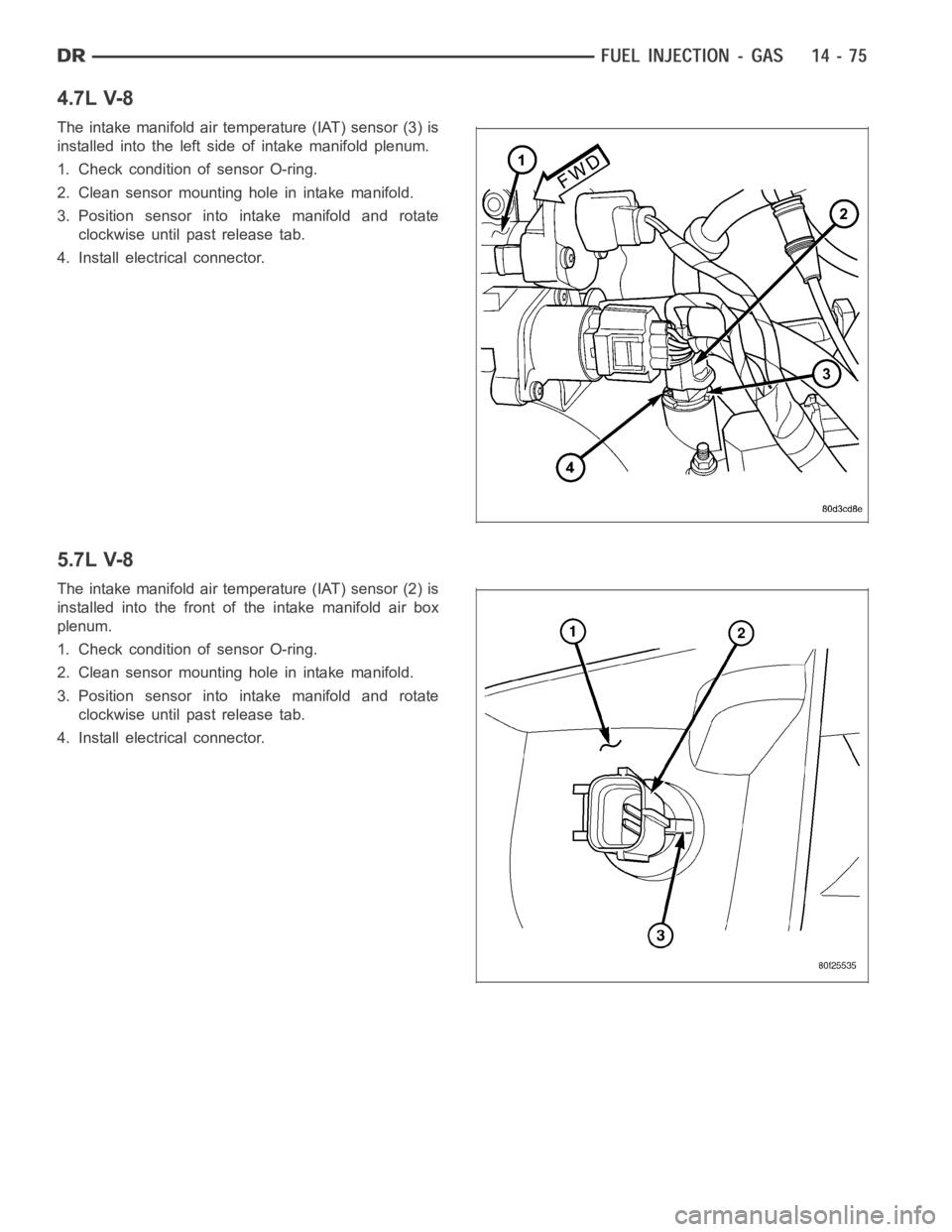

4.7L V-8

The intake manifold air temperature (IAT) sensor (3) is

installed into the left side of intake manifold plenum.

1. Check condition of sensor O-ring.

2. Clean sensor mounting hole in intake manifold.

3. Position sensor into intake manifold and rotate

clockwise until past release tab.

4. Install electrical connector.

5.7L V-8

The intake manifold air temperature (IAT) sensor (2) is

installed into the front of the intake manifold air box

plenum.

1. Check condition of sensor O-ring.

2. Clean sensor mounting hole in intake manifold.

3. Position sensor into intake manifold and rotate

clockwise until past release tab.

4. Install electrical connector.

Page 2318 of 5267

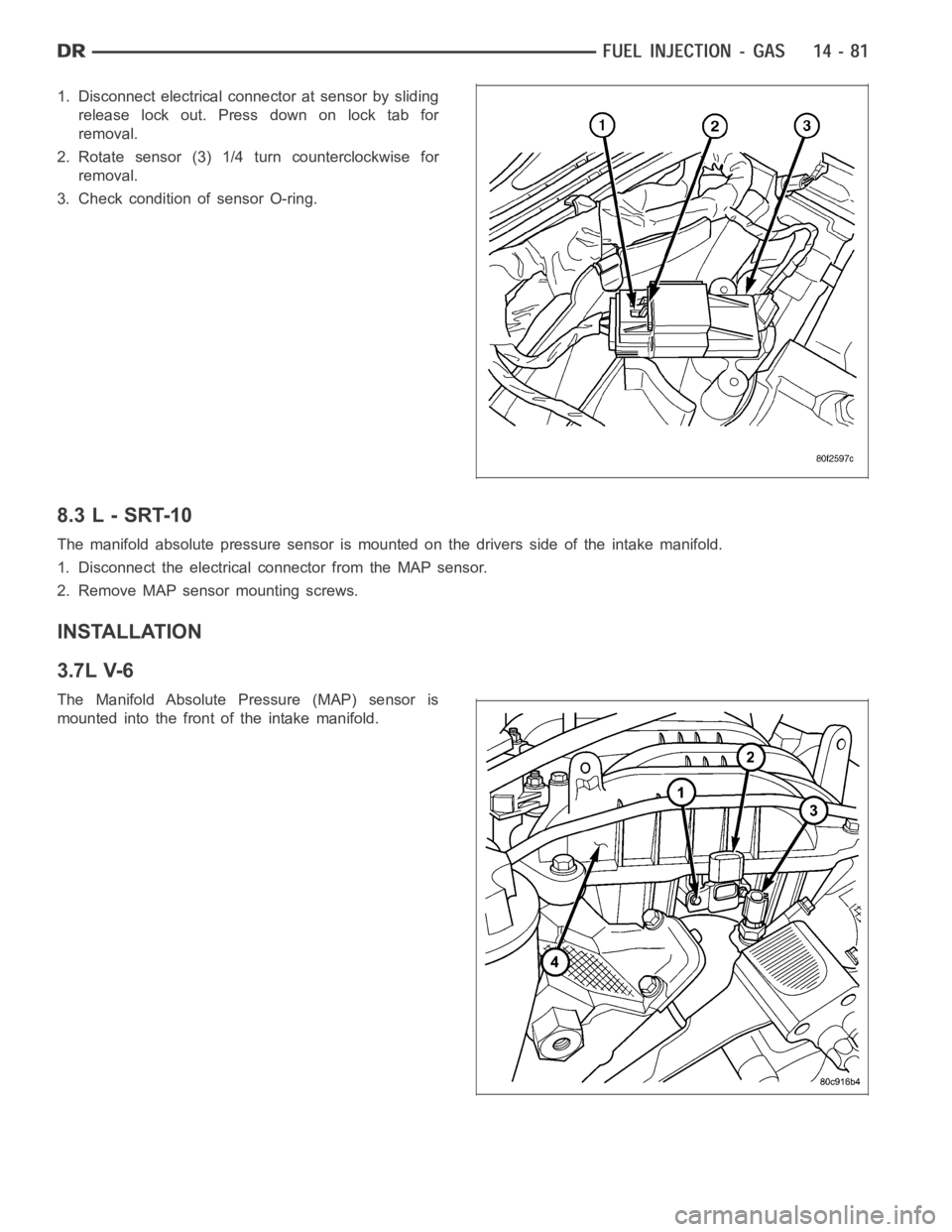

1. Disconnect electrical connector at sensor by sliding

release lock out. Press down on lock tab for

removal.

2. Rotate sensor (3) 1/4 turn counterclockwise for

removal.

3. Check condition of sensor O-ring.

8.3 L - SRT-10

The manifold absolute pressure sensor is mounted on the drivers side of theintake manifold.

1. Disconnect the electrical connector from the MAP sensor.

2. Remove MAP sensor mounting screws.

INSTALLATION

3.7L V-6

The Manifold Absolute Pressure (MAP) sensor is

mounted into the front of the intake manifold.

Page 2320 of 5267

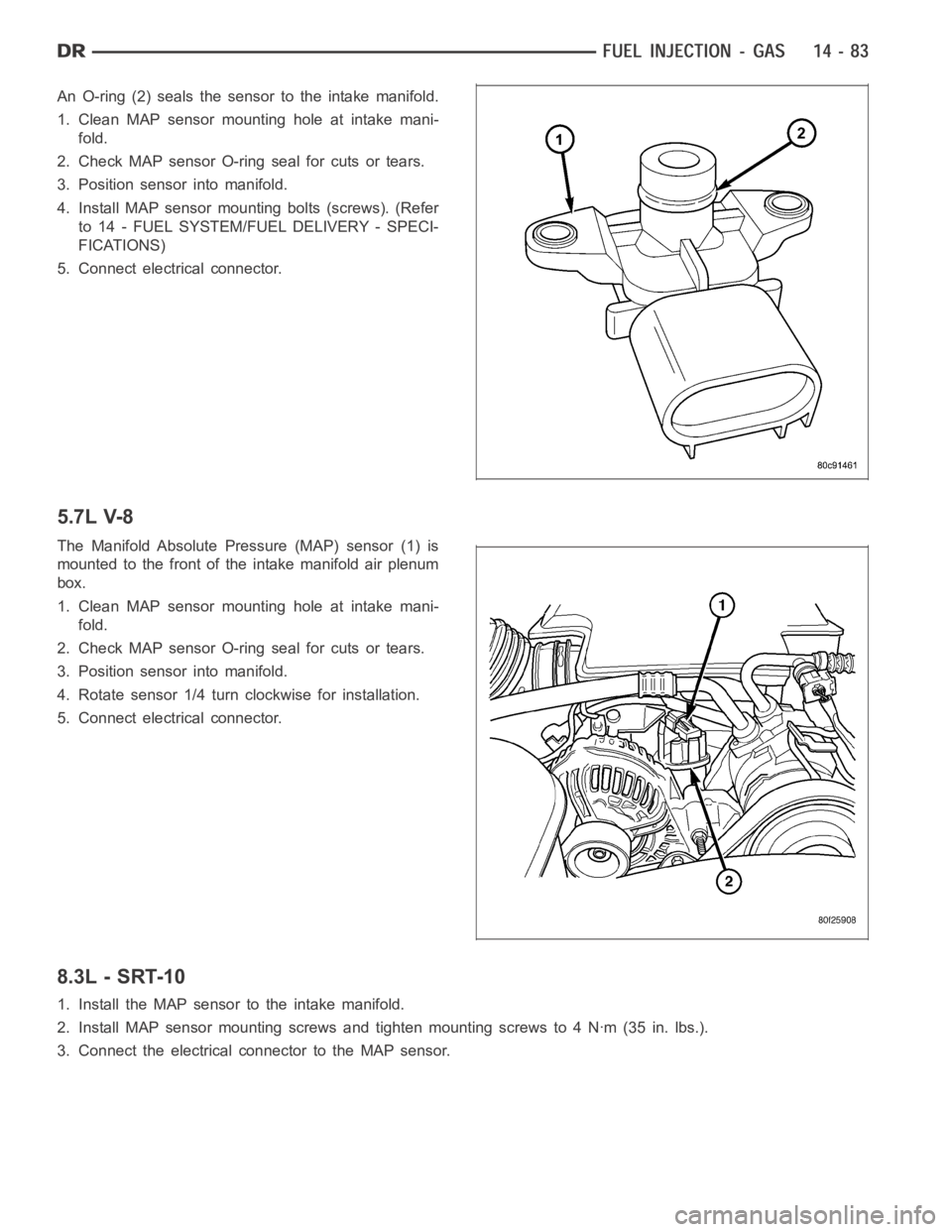

An O-ring (2) seals the sensor to the intake manifold.

1. Clean MAP sensor mounting hole at intake mani-

fold.

2. Check MAP sensor O-ring seal for cuts or tears.

3. Position sensor into manifold.

4. Install MAP sensor mounting bolts (screws). (Refer

to 14 - FUEL SYSTEM/FUEL DELIVERY - SPECI-

FICATIONS)

5. Connect electrical connector.

5.7L V-8

The Manifold Absolute Pressure (MAP) sensor (1) is

mounted to the front of the intake manifold air plenum

box.

1. Clean MAP sensor mounting hole at intake mani-

fold.

2. Check MAP sensor O-ring seal for cuts or tears.

3. Position sensor into manifold.

4. Rotate sensor 1/4 turn clockwise for installation.

5. Connect electrical connector.

8.3L - SRT-10

1. Install the MAP sensor to the intake manifold.

2. Install MAP sensor mounting screws and tighten mounting screws to 4 Nꞏm (35 in. lbs.).

3. Connect the electrical connector to the MAP sensor.