check engine DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 826 of 5267

When Monitored:

While the key is on and during engine operation.

Set Condition:

The APPS signal circuit voltage at the ECM goes above 4.24 volts for more than 2 seconds.

Possible Causes

(K167) APPS NO. 1 RETURN CIRCUIT OPEN

(K23) APPS NO. 1 SIGNAL CIRCUIT SHORTED TO (K852) APPS NO. 1 5-VOLT SUPPLY

(K23) APPS SIGNAL CIRCUIT SHORTED TO ANOTHER CIRCUIT

ECM

APPS

INTERMITTENT CONDITION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

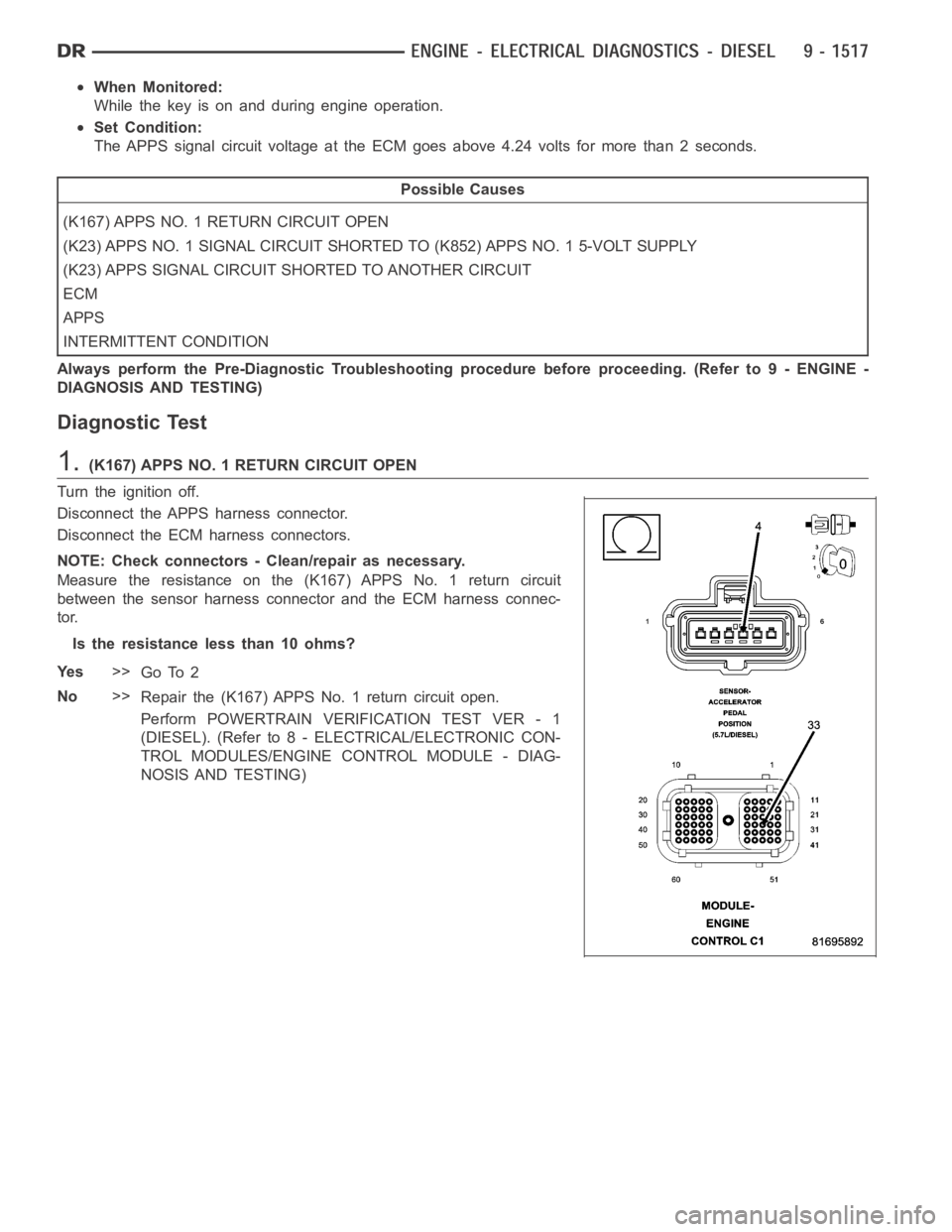

1.(K167) APPS NO. 1 RETURN CIRCUIT OPEN

Turn the ignition off.

Disconnect the APPS harness connector.

Disconnect the ECM harness connectors.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance on the (K167) APPS No. 1 return circuit

between the sensor harness connector and the ECM harness connec-

tor.

Is the resistance less than 10 ohms?

Ye s>>

Go To 2

No>>

Repair the (K167) APPS No. 1 return circuit open.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 830 of 5267

When Monitored:

While the key is on and during engine operation.

Set Condition:

The APPS circuit voltage at the ECM goes below 0.13 volt for more than 2 seconds.

Possible Causes

APPS

ECM

(K29) APPS NO. 2 SIGNAL CIRCUIT OPEN

(F856) APPS NO. 2 5-VOLT SUPPLY OPEN

(K29) APPS NO. 2 SIGNAL CIRCUIT SHORTED TO GROUND

(K29) APPS NO. 2 SIGNAL CIRCUIT SHORTED TO OTHER CIRCUITS

(F856) APPS NO. 2 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

(F856) APPS NO. 2 5-VOLT SUPPLY CIRCUIT SHORTED TO OTHER CIRCUITS

INTERMITTENT CONDITION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

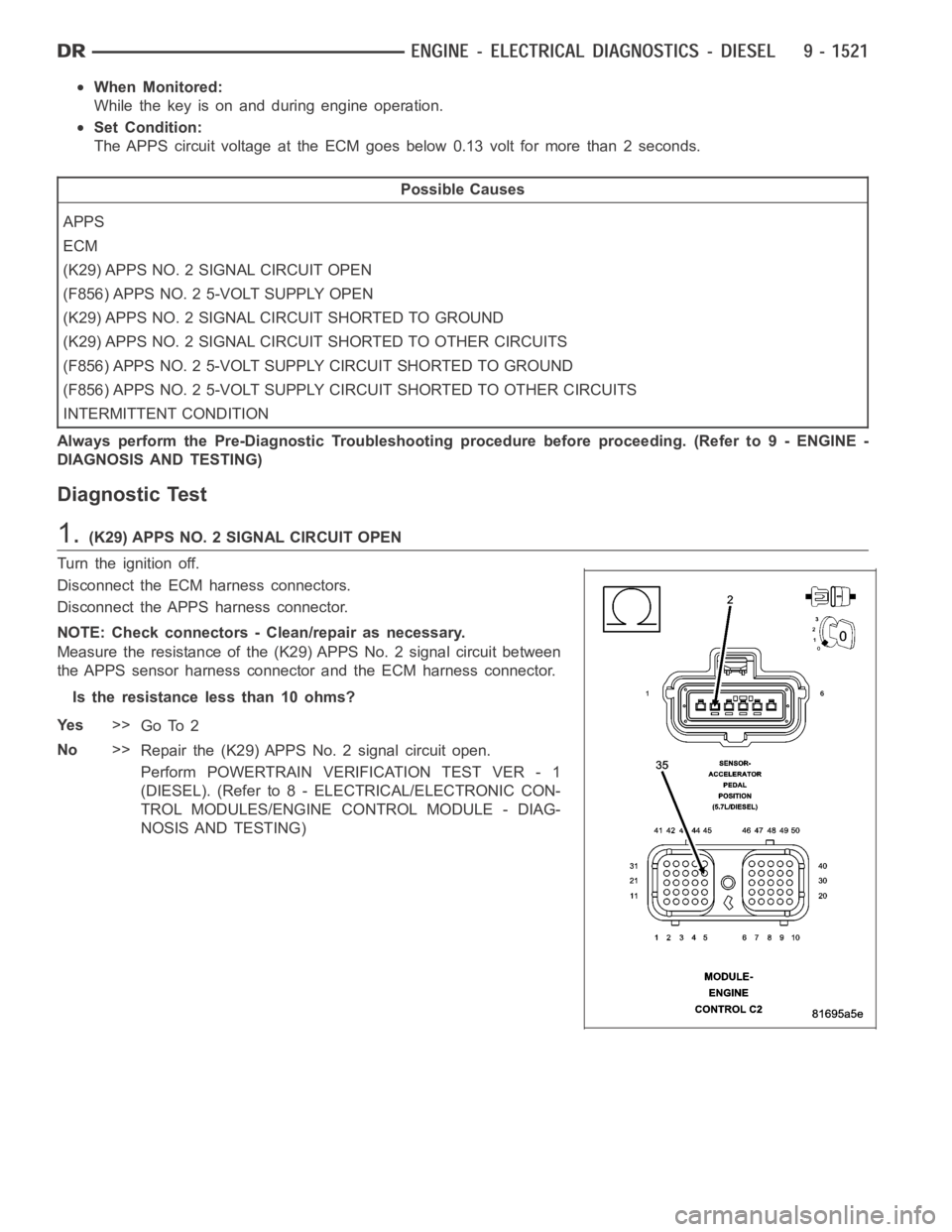

1.(K29) APPS NO. 2 SIGNAL CIRCUIT OPEN

Turn the ignition off.

Disconnect the ECM harness connectors.

Disconnect the APPS harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance of the (K29) APPS No. 2 signal circuit between

the APPS sensor harness connector and the ECMharness connector.

Is the resistance less than 10 ohms?

Ye s>>

Go To 2

No>>

Repair the (K29) APPS No. 2 signal circuit open.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 835 of 5267

When Monitored:

While the key is on and during engine operation.

Set Condition:

The APPS signal circuit voltage at the ECM goes above 4.24 volts for more than 2 seconds.

Possible Causes

(K400) APPS NO. 1 RETURN CIRCUIT OPEN

(K29) APPS NO. 2 SIGNAL CIRCUIT SHORTED TO (K854) APPS NO. 2 5-VOLT SUPPLY

(K29) APPS SIGNAL CIRCUIT SHORTED TO ANOTHER CIRCUIT

ECM

APPS

INTERMITTENT CONDITION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

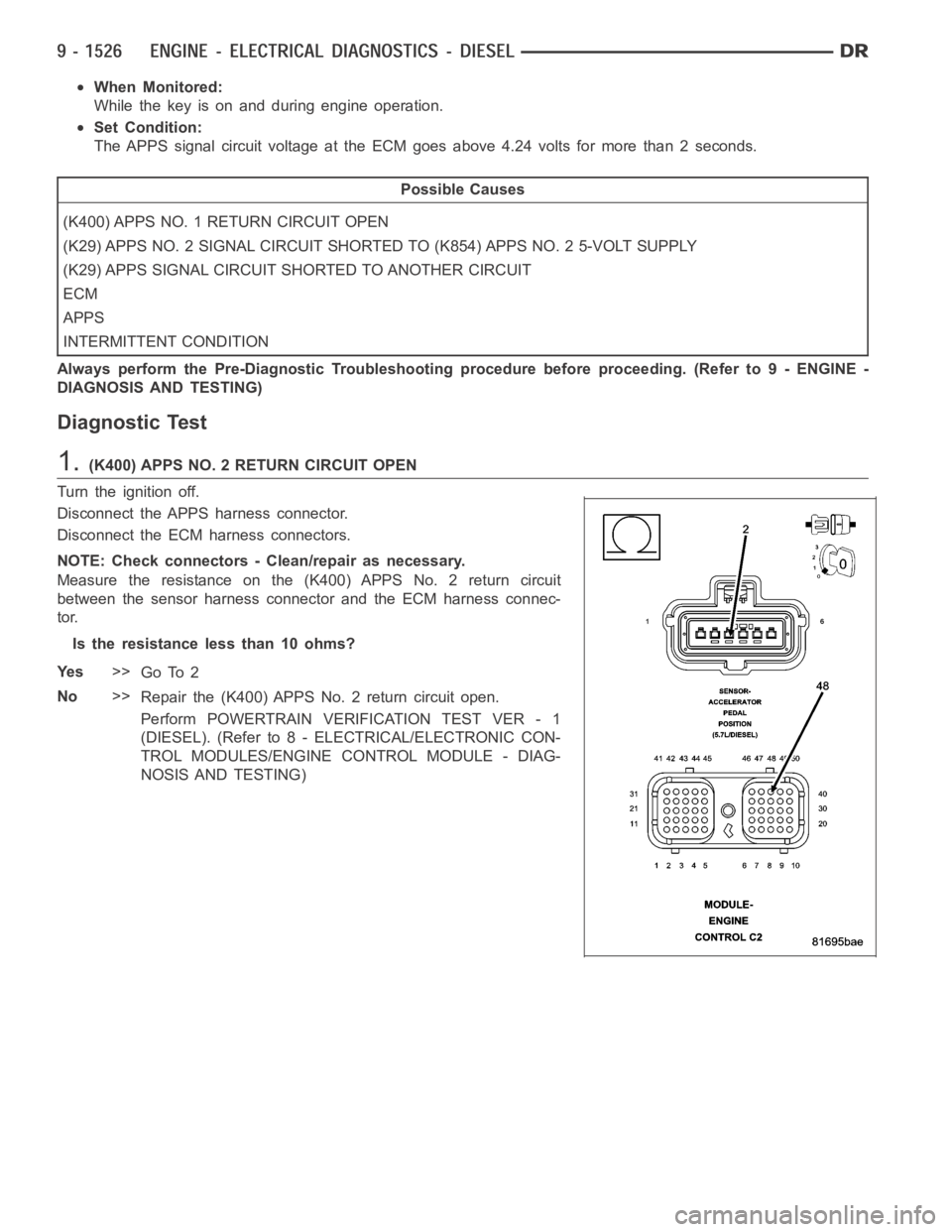

1.(K400) APPS NO. 2 RETURN CIRCUIT OPEN

Turn the ignition off.

Disconnect the APPS harness connector.

Disconnect the ECM harness connectors.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance on the (K400) APPS No. 2 return circuit

between the sensor harness connector and the ECM harness connec-

tor.

Is the resistance less than 10 ohms?

Ye s>>

Go To 2

No>>

Repair the (K400) APPS No. 2 return circuit open.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 839 of 5267

When Monitored:

While the engine is running.

Set Condition:

A circuit failure detected at cylinders 1,2, or 3 or any combination of cylinders 1,2, or 3.

Possible Causes

OTHER DTC’S

HIGH SIDE DRIVER CIRCUIT OPEN

LOW SIDE DRIVER CIRCUIT OPEN

HIGH SIDE DRIVER SHORTED TO LOW SIDE DRIVER

HIGH SIDE DRIVERS SHORTED LOW

LOW SIDE DRIVER CIRCUIT SHORTED OTHER LOW SIDE DRIVER CIRCUIT

LOW SIDE DRIVERS SHORTED LOW

HIGH SIDE DRIVER SHORTED TO VOLTAGE

LOW SIDE DRIVER SHORTED TO VOLTAGE

LOW SIDE DRIVER CIRCUIT SHORTED IN INJECTOR HARNESS

INJECTOR

INJECTOR HARNESS

INTERMITTENT CONDITION

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.OTHER DTC’S

With the scan tool, read DTCs.

Do you have any combination of DTC’s P0201, P0202, or P0203?

Ye s>>

Repair other DTC’s first.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 2

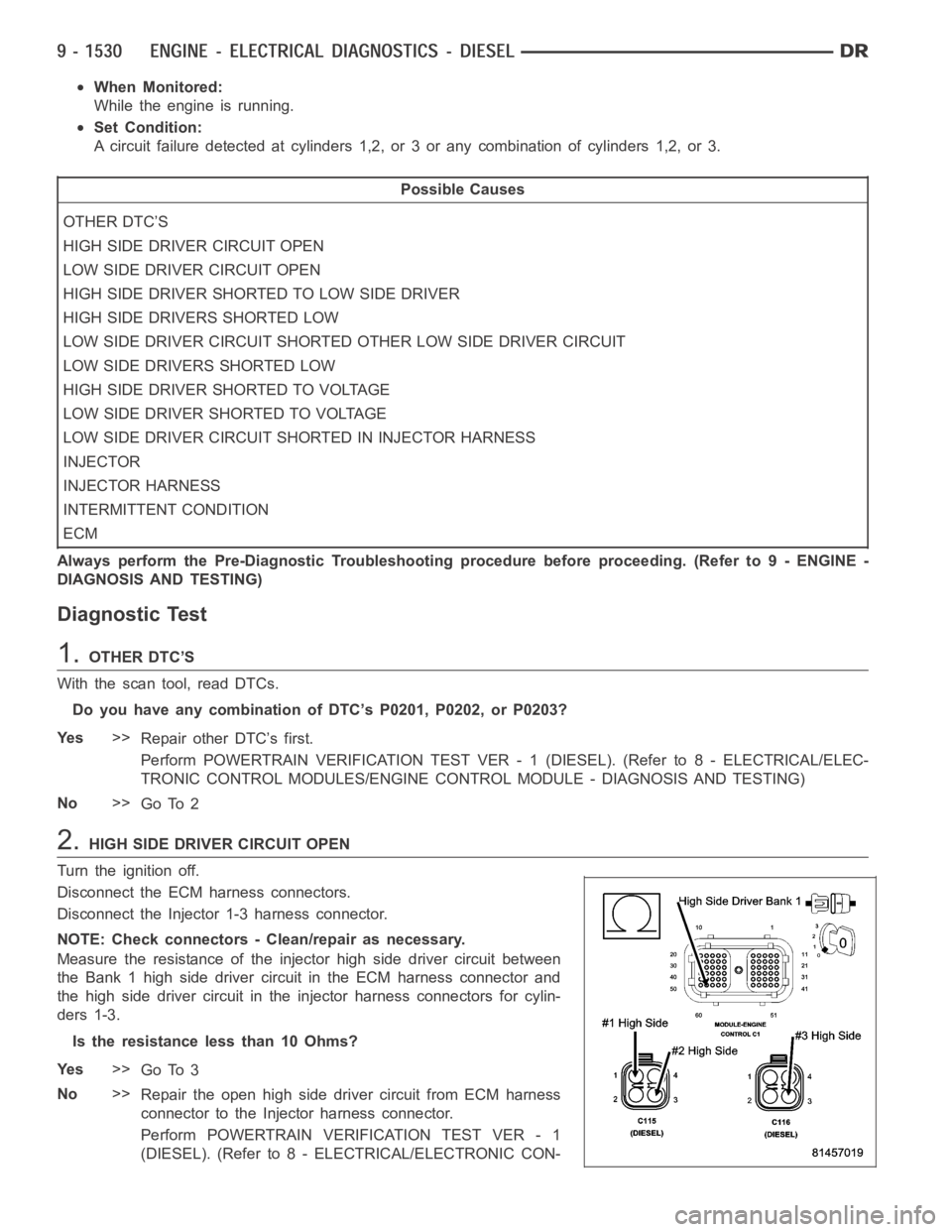

2.HIGH SIDE DRIVER CIRCUIT OPEN

Turn the ignition off.

Disconnect the ECM harness connectors.

Disconnect the Injector 1-3 harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance of the injector high side driver circuit between

the Bank 1 high side driver circuit in the ECM harness connector and

the high side driver circuit in the injector harness connectors for cylin-

ders 1-3.

Is the resistance less than 10 Ohms?

Ye s>>

Go To 3

No>>

Repair the open high side driver circuit from ECM harness

connector to the Injector harness connector.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

Page 844 of 5267

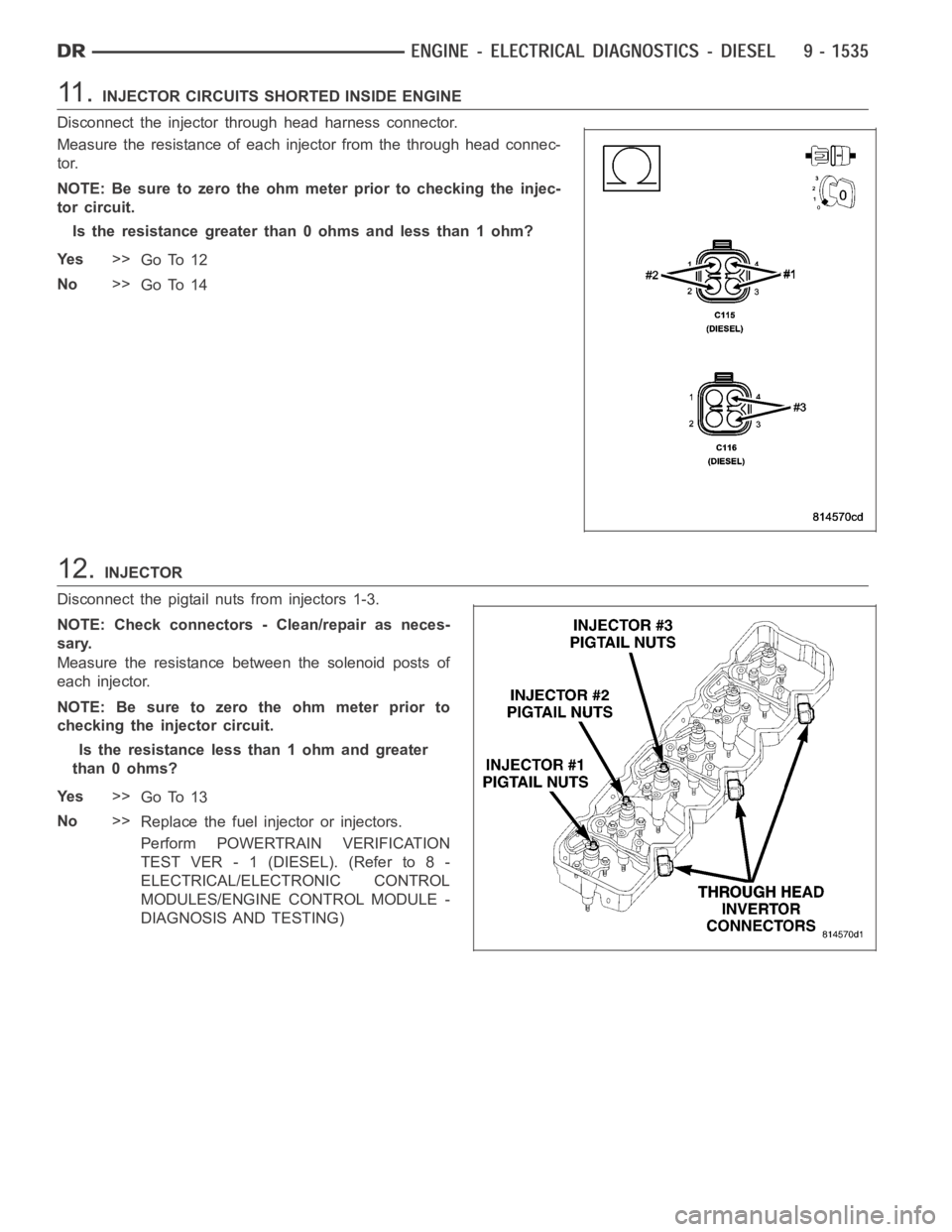

11 .INJECTOR CIRCUITS SHORTED INSIDE ENGINE

Disconnect the injector through head harness connector.

Measure the resistance of each injector from the through head connec-

tor.

NOTE: Be sure to zero the ohm meter prior to checking the injec-

tor circuit.

Is the resistance greater than 0 ohms and less than 1 ohm?

Ye s>>

Go To 12

No>>

Go To 14

12.INJECTOR

Disconnect the pigtail nuts from injectors 1-3.

NOTE: Check connectors - Clean/repair as neces-

sary.

Measure the resistance between the solenoid posts of

each injector.

NOTE: Be sure to zero the ohm meter prior to

checking the injector circuit.

Is the resistance less than 1 ohm and greater

than 0 ohms?

Ye s>>

Go To 13

No>>

Replace the fuel injector or injectors.

Perform POWERTRAIN VERIFICATION

TEST VER - 1 (DIESEL). (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL

MODULES/ENGINE CONTROL MODULE -

DIAGNOSIS AND TESTING)

Page 847 of 5267

When Monitored:

While the engine is running.

Set Condition:

A misfire detected at cylinders 4,5, or 6 or any combination of cylinders 4,5, or 6.

Possible Causes

OTHER DTC’S

HIGH SIDE DRIVER CIRCUIT OPEN

LOW SIDE DRIVER CIRCUIT OPEN

HIGH SIDE DRIVER SHORTED TO LOW SIDE DRIVER

HIGH SIDE DRIVERS SHORTED LOW

LOW SIDE DRIVER CIRCUIT SHORTED OTHER LOW SIDE DRIVER CIRCUIT

LOW SIDE DRIVERS SHORTED LOW

HIGH SIDE DRIVER SHORTED TO VOLTAGE

LOW SIDE DRIVER SHORTED TO VOLTAGE

LOW SIDE DRIVER CIRCUIT SHORTED IN INJECTOR HARNESS

INJECTOR

INJECTOR HARNESS

ECM

INTERMITTENT CONDITION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.OTHER DTC’S

With the scan tool, read DTCs.

Do you have any combination of DTC’s P0204, P0205, or P0206?

Ye s>>

Repair other DTC’s first.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 2

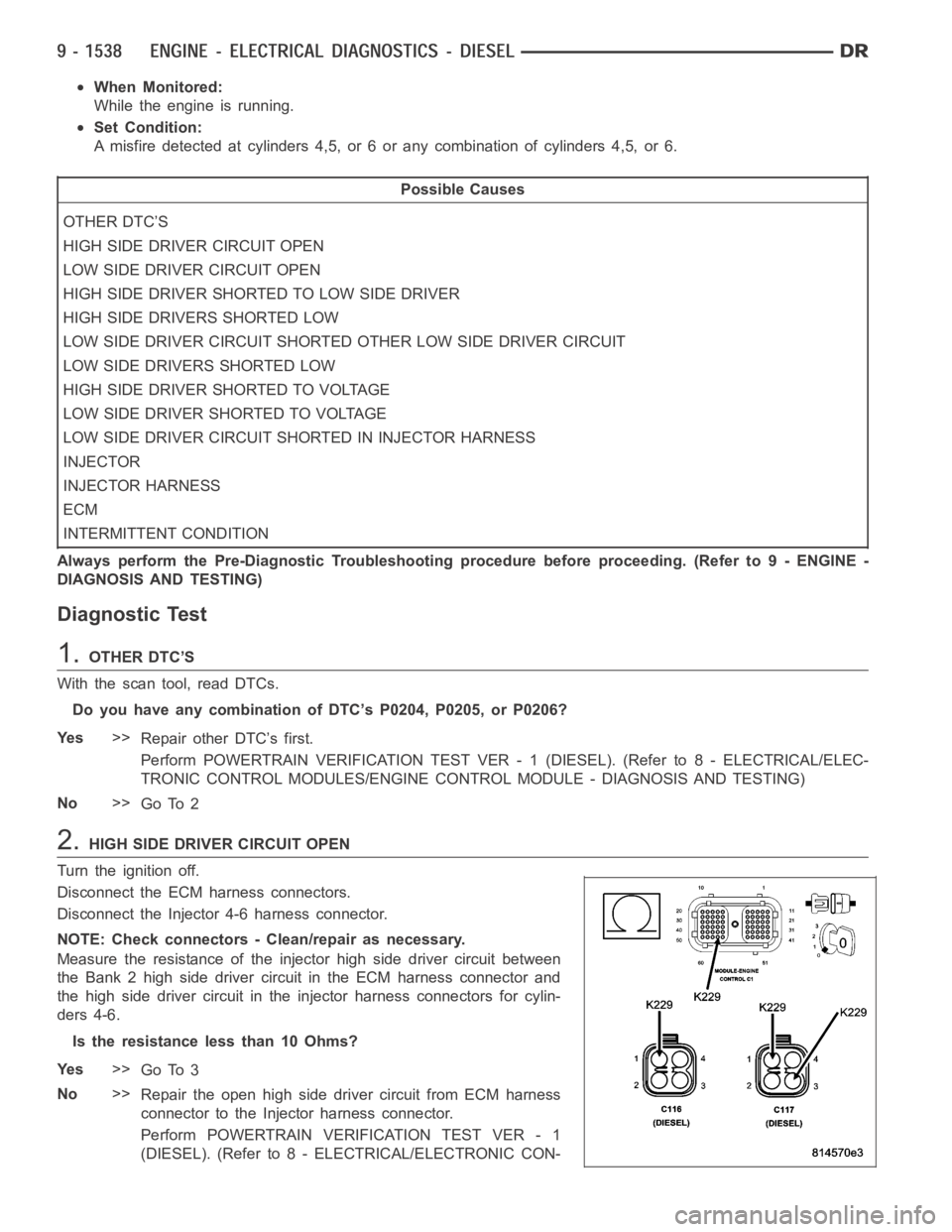

2.HIGH SIDE DRIVER CIRCUIT OPEN

Turn the ignition off.

Disconnect the ECM harness connectors.

Disconnect the Injector 4-6 harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance of the injector high side driver circuit between

the Bank 2 high side driver circuit in the ECM harness connector and

the high side driver circuit in the injector harness connectors for cylin-

ders 4-6.

Is the resistance less than 10 Ohms?

Ye s>>

Go To 3

No>>

Repair the open high side driver circuit from ECM harness

connector to the Injector harness connector.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

Page 851 of 5267

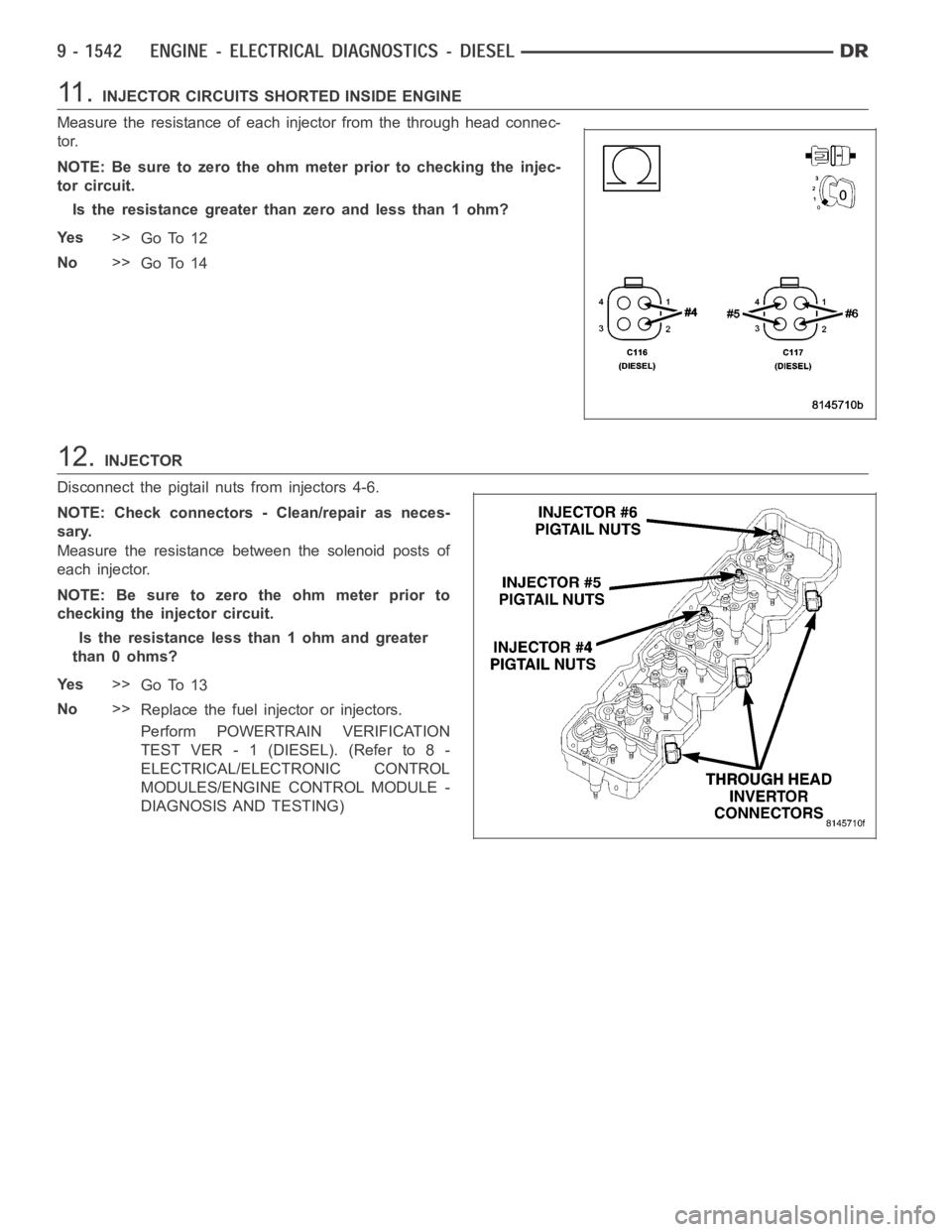

11 .INJECTOR CIRCUITS SHORTED INSIDE ENGINE

Measure the resistance of each injector from the through head connec-

tor.

NOTE: Be sure to zero the ohm meter prior to checking the injec-

tor circuit.

Is the resistance greater than zero and less than 1 ohm?

Ye s>>

Go To 12

No>>

Go To 14

12.INJECTOR

Disconnect the pigtail nuts from injectors 4-6.

NOTE: Check connectors - Clean/repair as neces-

sary.

Measure the resistance between the solenoid posts of

each injector.

NOTE: Be sure to zero the ohm meter prior to

checking the injector circuit.

Is the resistance less than 1 ohm and greater

than 0 ohms?

Ye s>>

Go To 13

No>>

Replace the fuel injector or injectors.

Perform POWERTRAIN VERIFICATION

TEST VER - 1 (DIESEL). (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL

MODULES/ENGINE CONTROL MODULE -

DIAGNOSIS AND TESTING)

Page 854 of 5267

When Monitored:

Ignition on.

Set Condition:

Low voltage detected at the WIF signal circuit at the ECM.

Possible Causes

WATER IN FUEL SENSOR

ECM

(G123) WATER IN FUEL SENSOR SIGNAL CIRCUIT SHORTED TO (K914) RETURN CIRCUIT

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

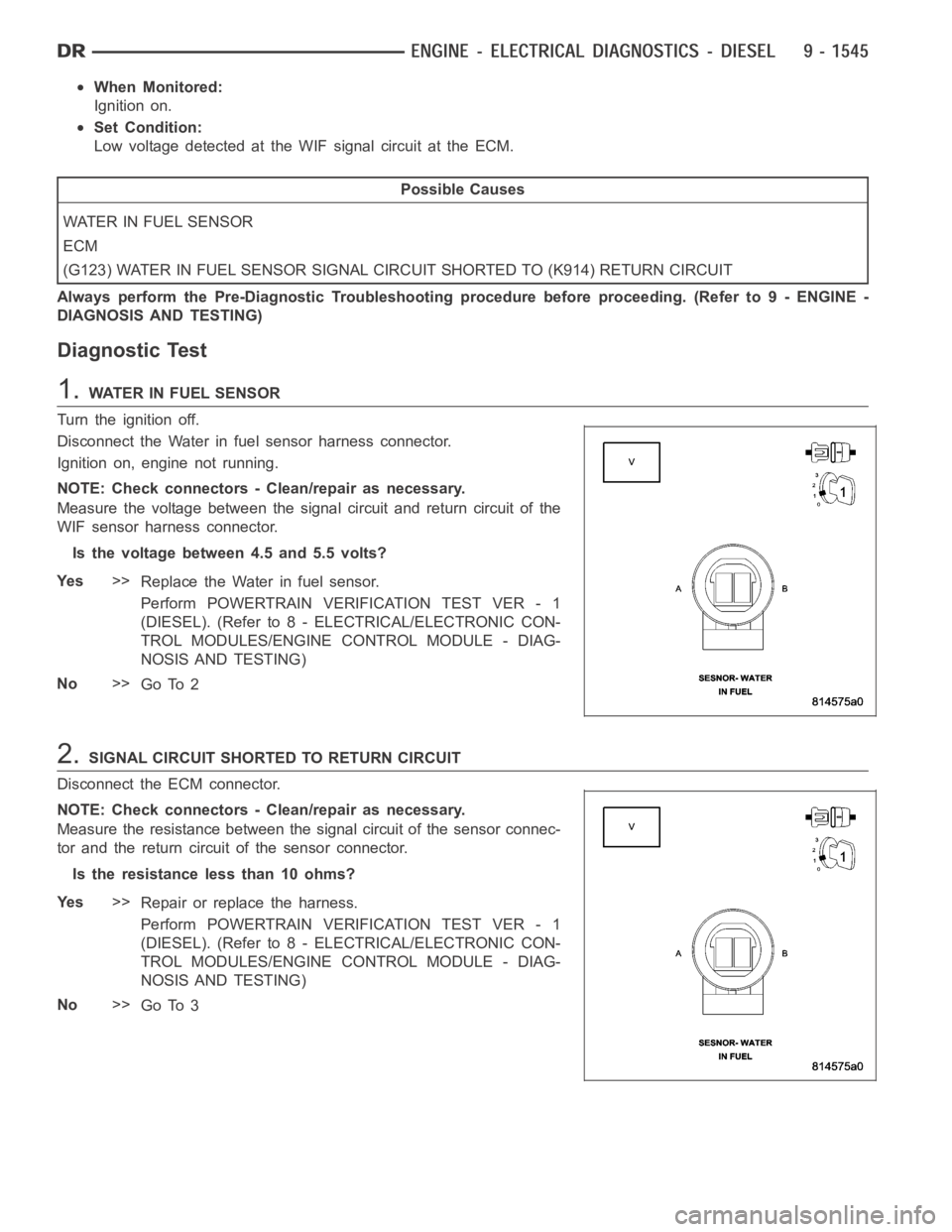

1.WATER IN FUEL SENSOR

Turn the ignition off.

Disconnect the Water in fuel sensor harness connector.

Ignition on, engine not running.

NOTE: Check connectors - Clean/repair as necessary.

Measure the voltage between the signal circuit and return circuit of the

WIF sensor harness connector.

Is the voltage between 4.5 and 5.5 volts?

Ye s>>

Replace the Water in fuel sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

No>>

Go To 2

2.SIGNAL CIRCUIT SHORTED TO RETURN CIRCUIT

Disconnect the ECM connector.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance between the signal circuit of the sensor connec-

tor and the return circuit of the sensor connector.

Is the resistance less than 10 ohms?

Ye s>>

Repair or replace the harness.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

No>>

Go To 3

Page 857 of 5267

When Monitored:

Ignition on.

Set Condition:

Low voltage detected at the WIF signal circuit at the ECM.

Possible Causes

OTHER DTC’S PRESENT

WATER IN FUEL

ECM

INTERMITTENT CONDITION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.OTHER DTC’S PRESENT

With the scan tool, read DTCs.

Do you have any additional water in fuel DTC’s?

Ye s>>

Repair other Water in fuel sensor DTC’s first.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 2

2.WAT E R I N F U E L

Using the service publications as a guide, drain the water in fuel separator.

Did the DTC become inactive after draining the water in fuel separator?

Ye s>>

Clear DTC, repair complete.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 3

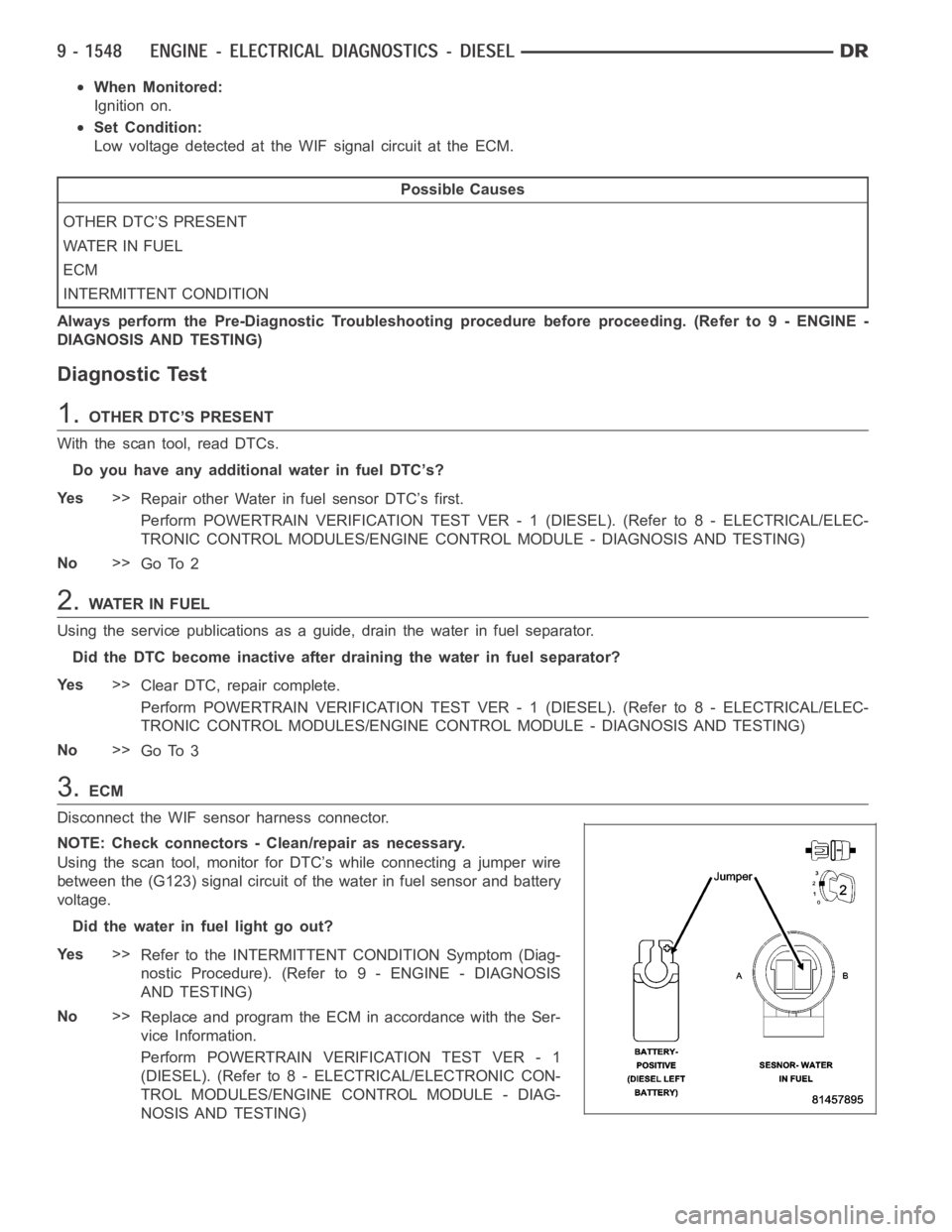

3.ECM

Disconnect the WIF sensor harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Using the scan tool, monitor for DTC’s while connecting a jumper wire

between the (G123) signal circuit of the water in fuel sensor and battery

voltage.

Did the water in fuel light go out?

Ye s>>

Refer to the INTERMITTENT CONDITION Symptom (Diag-

nostic Procedure). (Refer to 9 - ENGINE - DIAGNOSIS

AND TESTING)

No>>

Replace and program the ECM in accordance with the Ser-

vice Information.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 860 of 5267

4.HIGH RESISTANCE IN THE GROUND CIRCUIT

Measure the voltage between the generator case and the B- post of the battery.

Is the voltage above .1 volts?

Ye s>>

Repair the high resistance in the ground circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 5

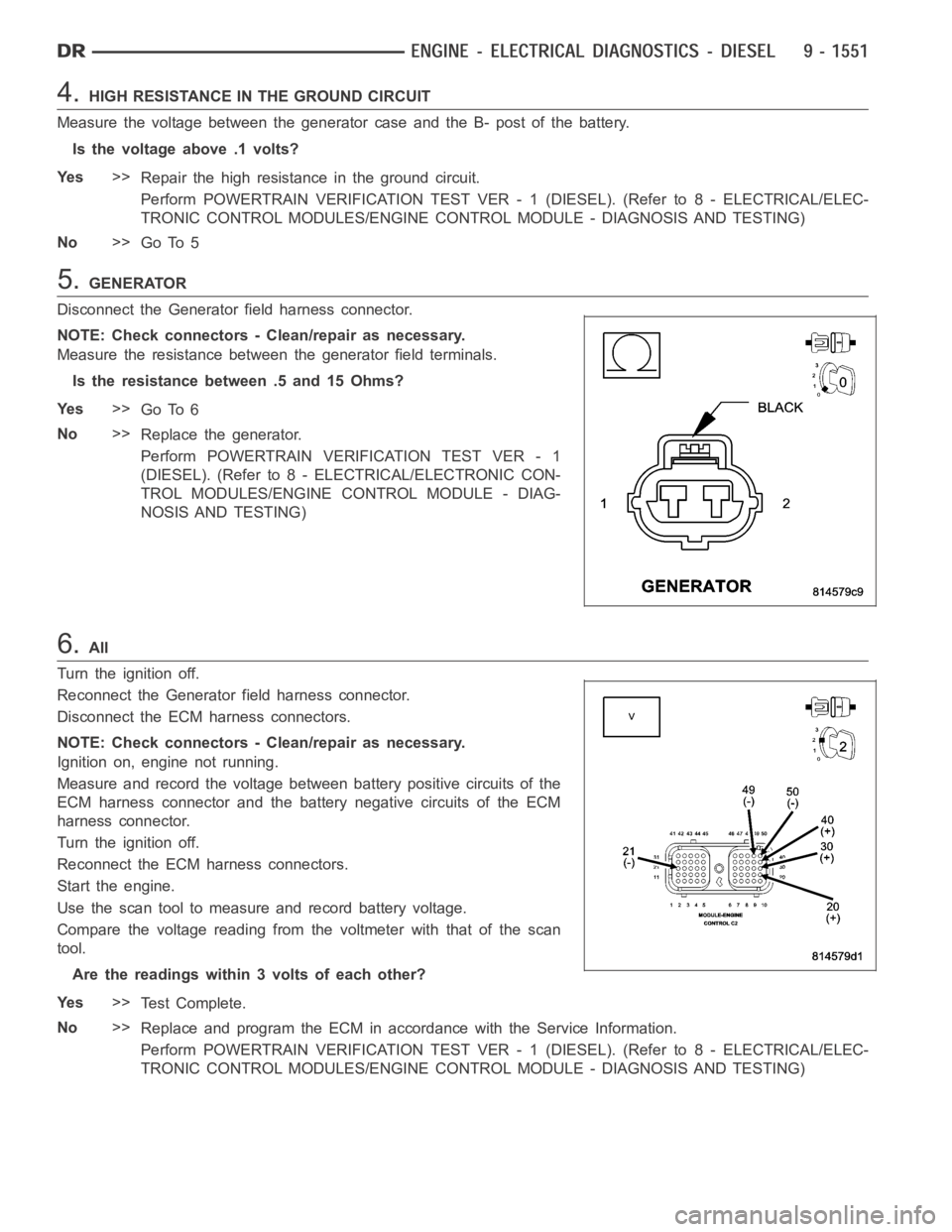

5.GENERATOR

Disconnect the Generator field harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance between the generator field terminals.

Is the resistance between .5 and 15 Ohms?

Ye s>>

Go To 6

No>>

Replace the generator.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

6.All

Turn the ignition off.

Reconnect the Generator field harness connector.

Disconnect the ECM harness connectors.

NOTE: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Measure and record the voltage between battery positive circuits of the

ECM harness connector and the battery negative circuits of the ECM

harness connector.

Turn the ignition off.

Reconnect the ECM harness connectors.

Start the engine.

Use the scan tool to measure and record battery voltage.

Compare the voltage reading from the voltmeter with that of the scan

tool.

Are the readings within 3 volts of each other?

Ye s>>

Te s t C o m p l e t e .

No>>

Replace and program the ECM in accordance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)