check engine DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 955 of 5267

5.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 959 of 5267

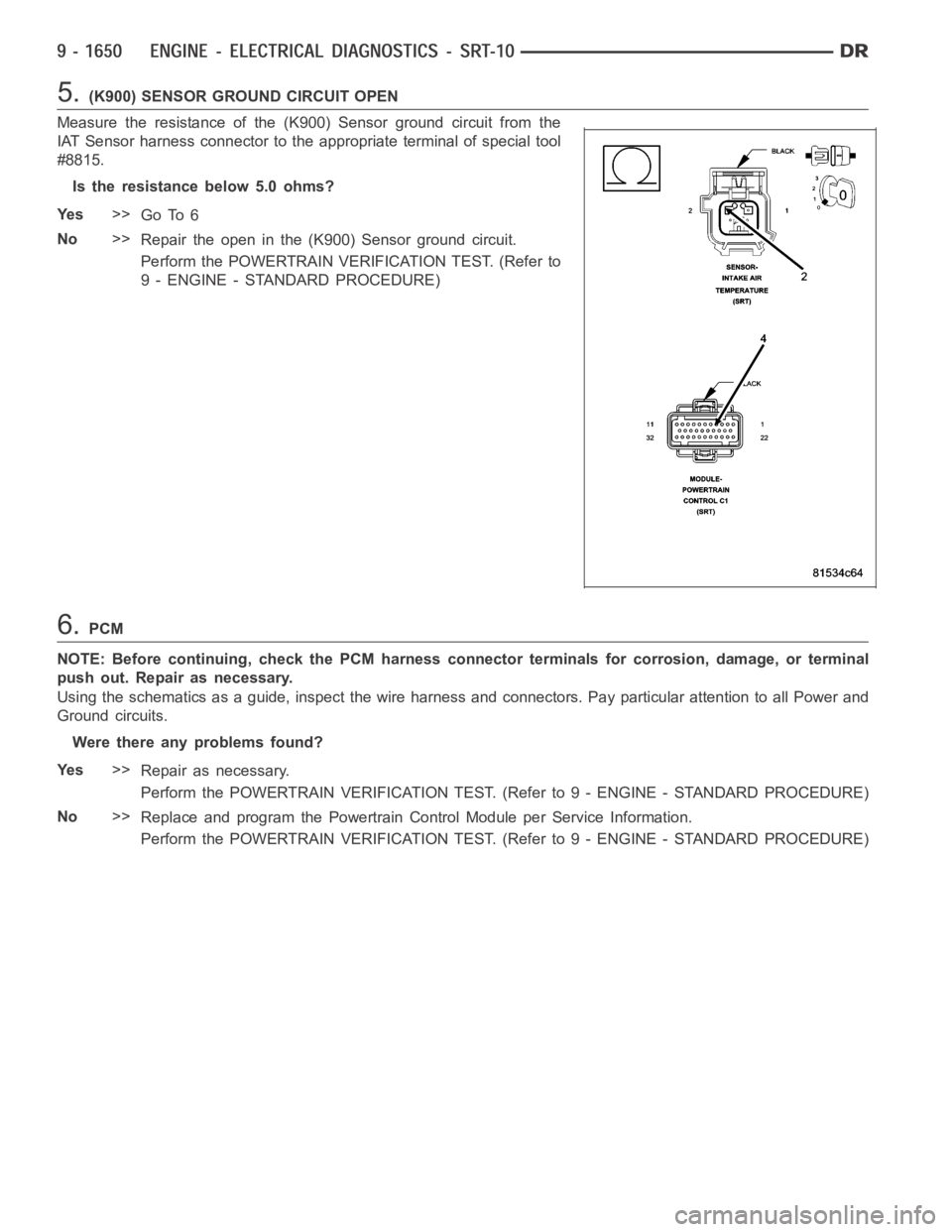

5.(K900) SENSOR GROUND CIRCUIT OPEN

Measure the resistance of the (K900) Sensor ground circuit from the

IAT Sensor harness connector to the appropriate terminal of special tool

#8815.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 6

No>>

Repair the open in the (K900) Sensor ground circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

6.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 963 of 5267

5.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 967 of 5267

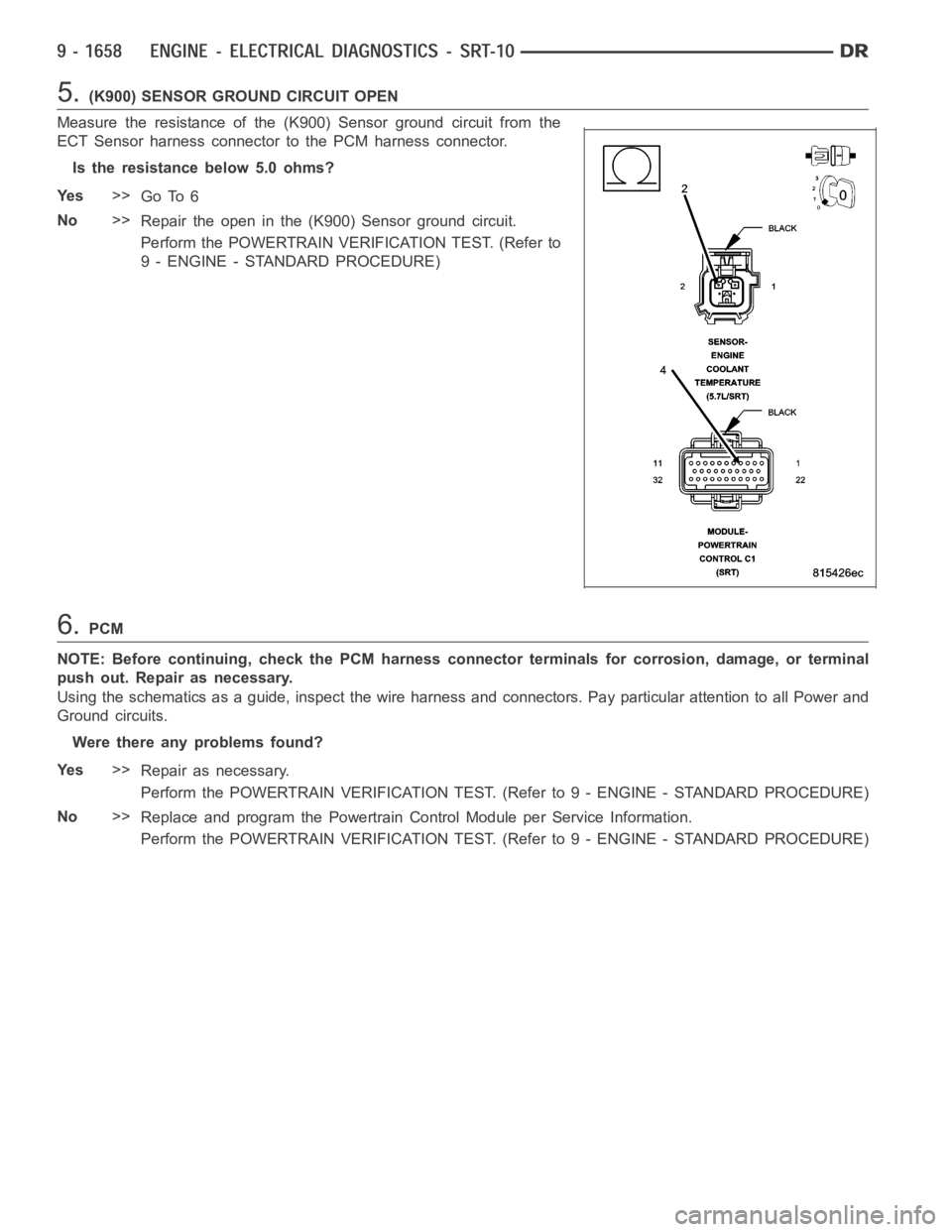

5.(K900) SENSOR GROUND CIRCUIT OPEN

Measure the resistance of the (K900) Sensor ground circuit from the

ECT Sensor harness connector to the PCM harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 6

No>>

Repair the open in the (K900) Sensor ground circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

6.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 975 of 5267

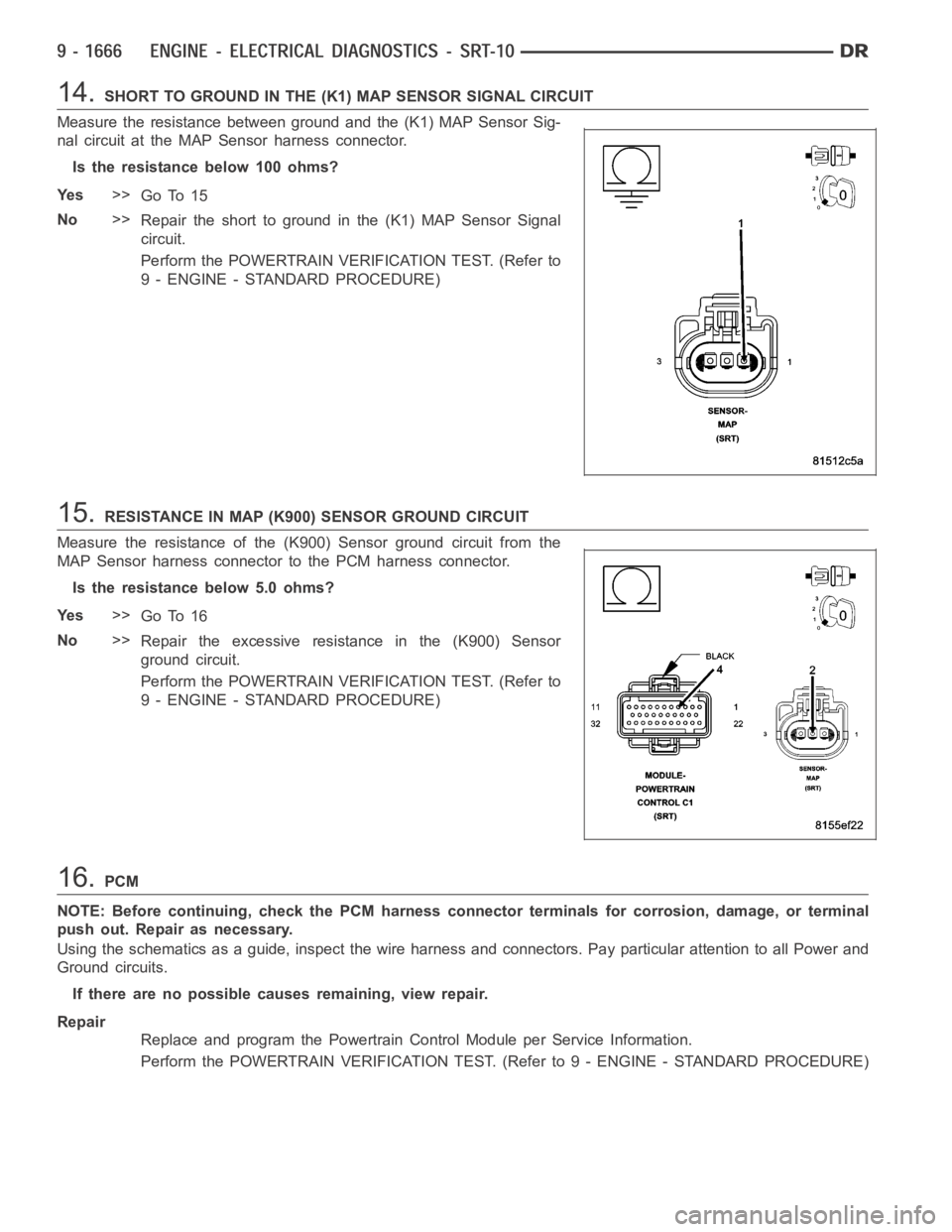

14.SHORT TO GROUND IN THE (K1) MAP SENSOR SIGNAL CIRCUIT

Measure the resistance between ground and the (K1) MAP Sensor Sig-

nal circuit at the MAP Sensor harness connector.

Istheresistancebelow100ohms?

Ye s>>

Go To 15

No>>

Repair the short to ground in the (K1) MAP Sensor Signal

circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

15.RESISTANCE IN MAP (K900) SENSOR GROUND CIRCUIT

Measure the resistance of the (K900) Sensor ground circuit from the

MAP Sensor harness connector to the PCM harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 16

No>>

Repair the excessive resistance in the (K900) Sensor

ground circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

16.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

If there are no possible causes remaining, view repair.

Repair

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 979 of 5267

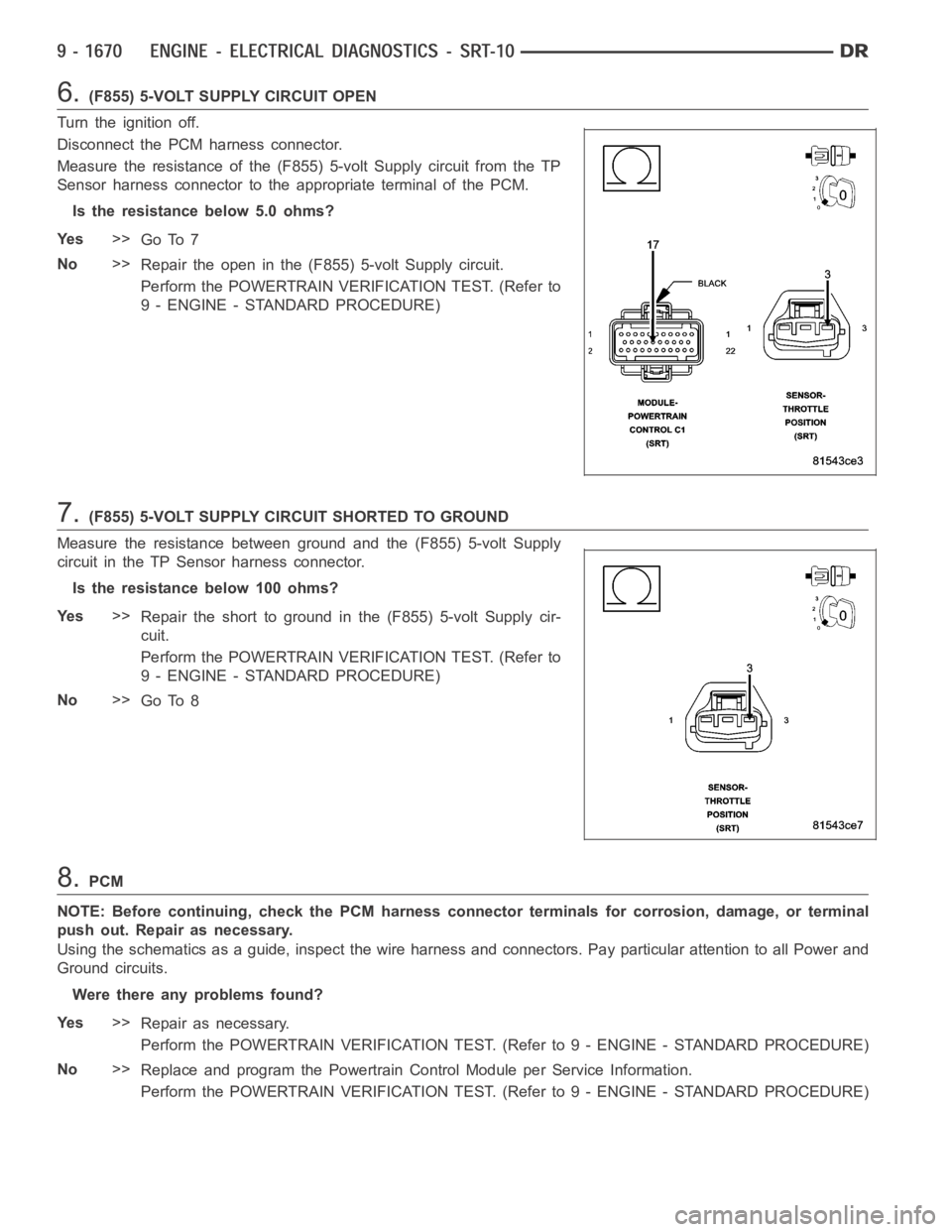

6.(F855) 5-VOLT SUPPLY CIRCUIT OPEN

Turn the ignition off.

Disconnect the PCM harness connector.

Measure the resistance of the (F855) 5-volt Supply circuit from the TP

Sensor harness connector to the appropriate terminal of the PCM.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 7

No>>

Repair the open in the (F855) 5-volt Supply circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

7.(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

Measure the resistance between ground and the (F855) 5-volt Supply

circuit in the TP Sensor harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (F855) 5-volt Supply cir-

cuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 8

8.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 984 of 5267

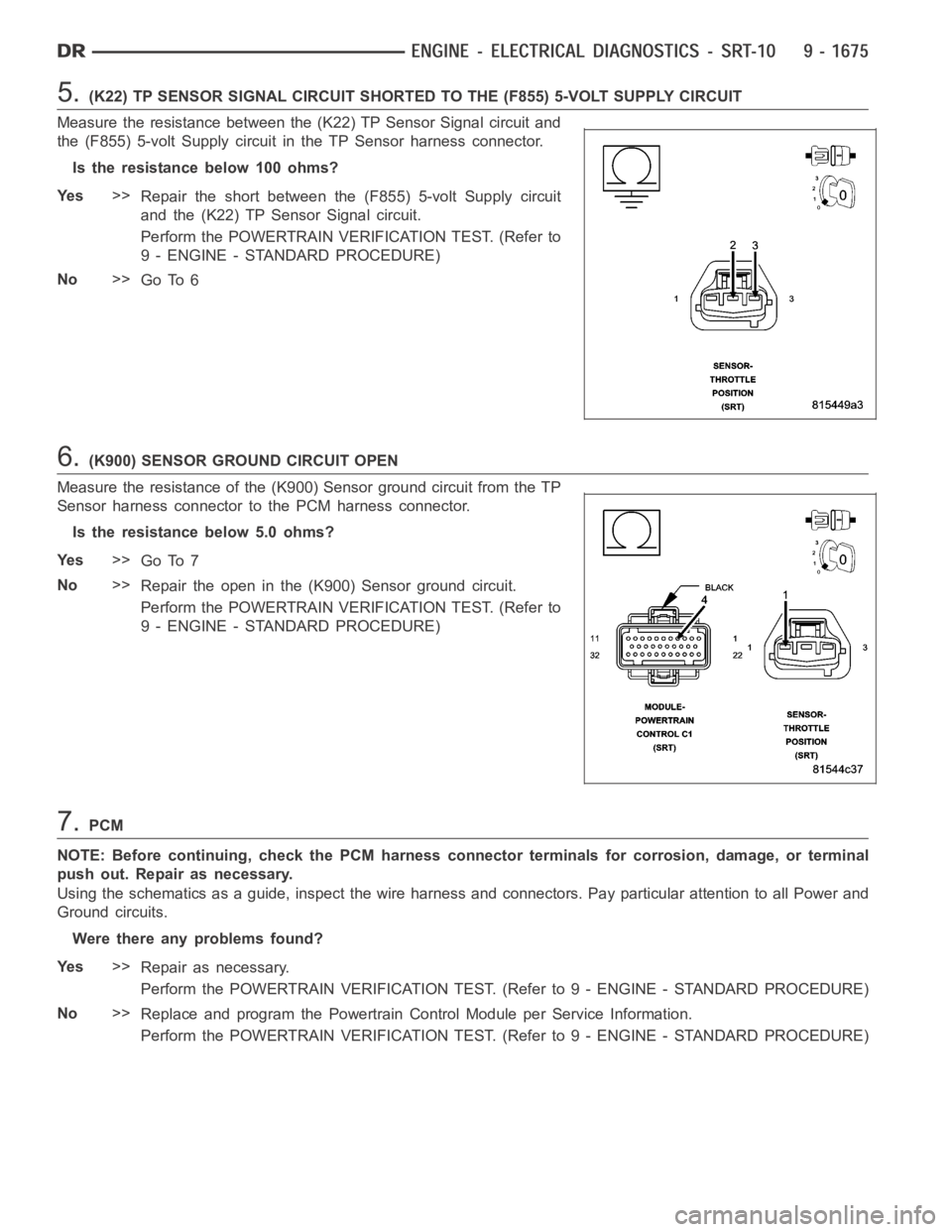

5.(K22) TP SENSOR SIGNAL CIRCUIT SHORTED TO THE (F855) 5-VOLT SUPPLY CIRCUIT

Measure the resistance between the (K22) TP Sensor Signal circuit and

the (F855) 5-volt Supply circuit in the TP Sensor harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short between the (F855) 5-volt Supply circuit

and the (K22) TP Sensor Signal circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 6

6.(K900) SENSOR GROUND CIRCUIT OPEN

Measure the resistance of the (K900) Sensor ground circuit from the TP

Sensor harness connector to the PCM harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 7

No>>

Repair the open in the (K900) Sensor ground circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

7.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 987 of 5267

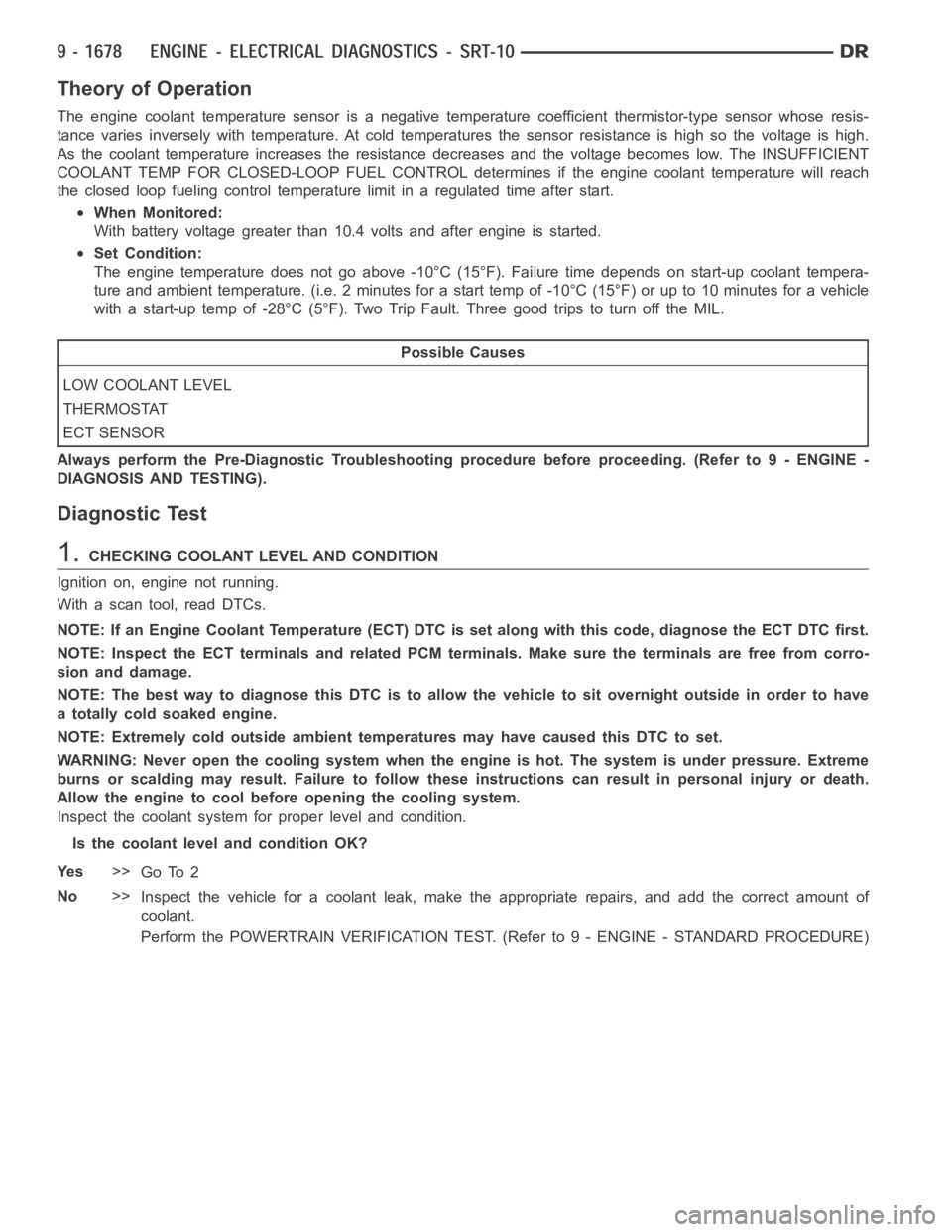

Theory of Operation

The engine coolant temperature sensor is a negative temperature coefficient thermistor-type sensor whose resis-

tance varies inversely with temperature. At cold temperatures the sensorresistance is high so the voltage is high.

As the coolant temperature increases the resistance decreases and the voltage becomes low. The INSUFFICIENT

COOLANT TEMP FOR CLOSED-LOOP FUEL CONTROL determines if the engine coolant temperature will reach

theclosedloopfuelingcontroltemperaturelimitinaregulatedtimeafterstart.

When Monitored:

With battery voltage greater than 10.4 volts and after engine is started.

Set Condition:

The engine temperature does not go above -10°C (15°F). Failure time depends on start-up coolant tempera-

ture and ambient temperature. (i.e. 2 minutes for a start temp of -10°C (15°F) or up to 10 minutes for a vehicle

with a start-up temp of -28°C (5°F). Two Trip Fault. Three good trips to turnoff the MIL.

Possible Causes

LOW COOLANT LEVEL

THERMOSTAT

ECT SENSOR

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.CHECKING COOLANT LEVEL AND CONDITION

Ignition on, engine not running.

With a scan tool, read DTCs.

NOTE: If an Engine Coolant Temperature (ECT) DTC is set along with this code, diagnose the ECT DTC first.

NOTE: Inspect the ECT terminals and related PCM terminals. Make sure the terminals are free from corro-

sion and damage.

NOTE: The best way to diagnose this DTC is to allow the vehicle to sit overnight outside in order to have

a totally cold soaked engine.

NOTE: Extremely cold outside ambient temperatures may have caused this DTCtoset.

WARNING: Never open the cooling system when the engine is hot. The system isunder pressure. Extreme

burns or scalding may result. Failure to follow these instructions can result in personal injury or death.

Allow the engine to cool before opening the cooling system.

Inspect the coolant system for proper level and condition.

Is the coolant level and condition OK?

Ye s>>

Go To 2

No>>

Inspect the vehicle for a coolant leak, make the appropriate repairs, and add the correct amount of

coolant.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 991 of 5267

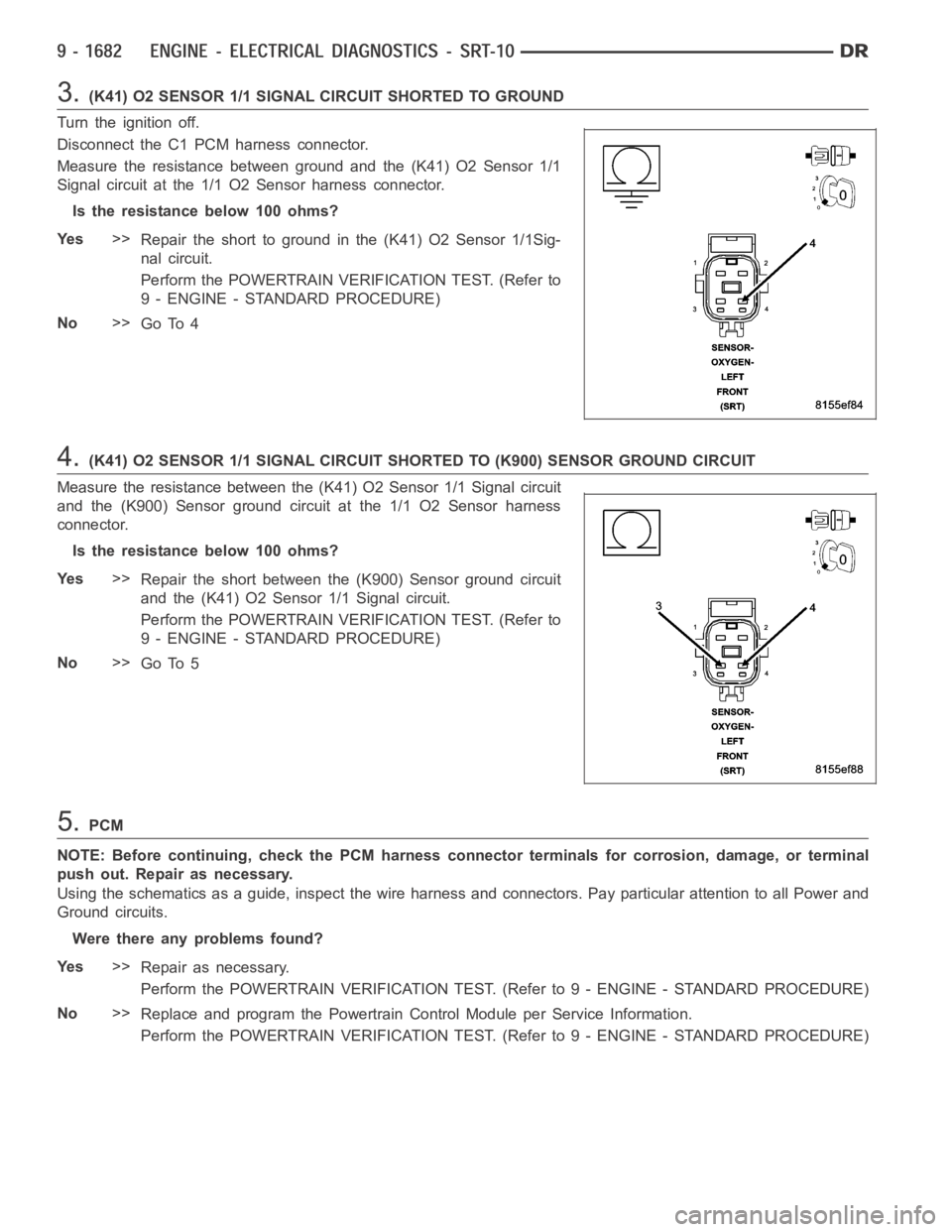

3.(K41) O2 SENSOR 1/1 SIGNAL CIRCUIT SHORTED TO GROUND

Turn the ignition off.

Disconnect the C1 PCM harness connector.

Measure the resistance between ground and the (K41) O2 Sensor 1/1

Signal circuit at the 1/1 O2 Sensor harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (K41) O2 Sensor 1/1Sig-

nal circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

4.(K41) O2 SENSOR 1/1 SIGNAL CIRCUIT SHORTED TO (K900) SENSOR GROUND CIRCUIT

Measure the resistance between the (K41) O2 Sensor 1/1 Signal circuit

and the (K900) Sensor ground circuit at the 1/1 O2 Sensor harness

connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short between the (K900) Sensor ground circuit

and the (K41) O2 Sensor 1/1 Signal circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

5.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 996 of 5267

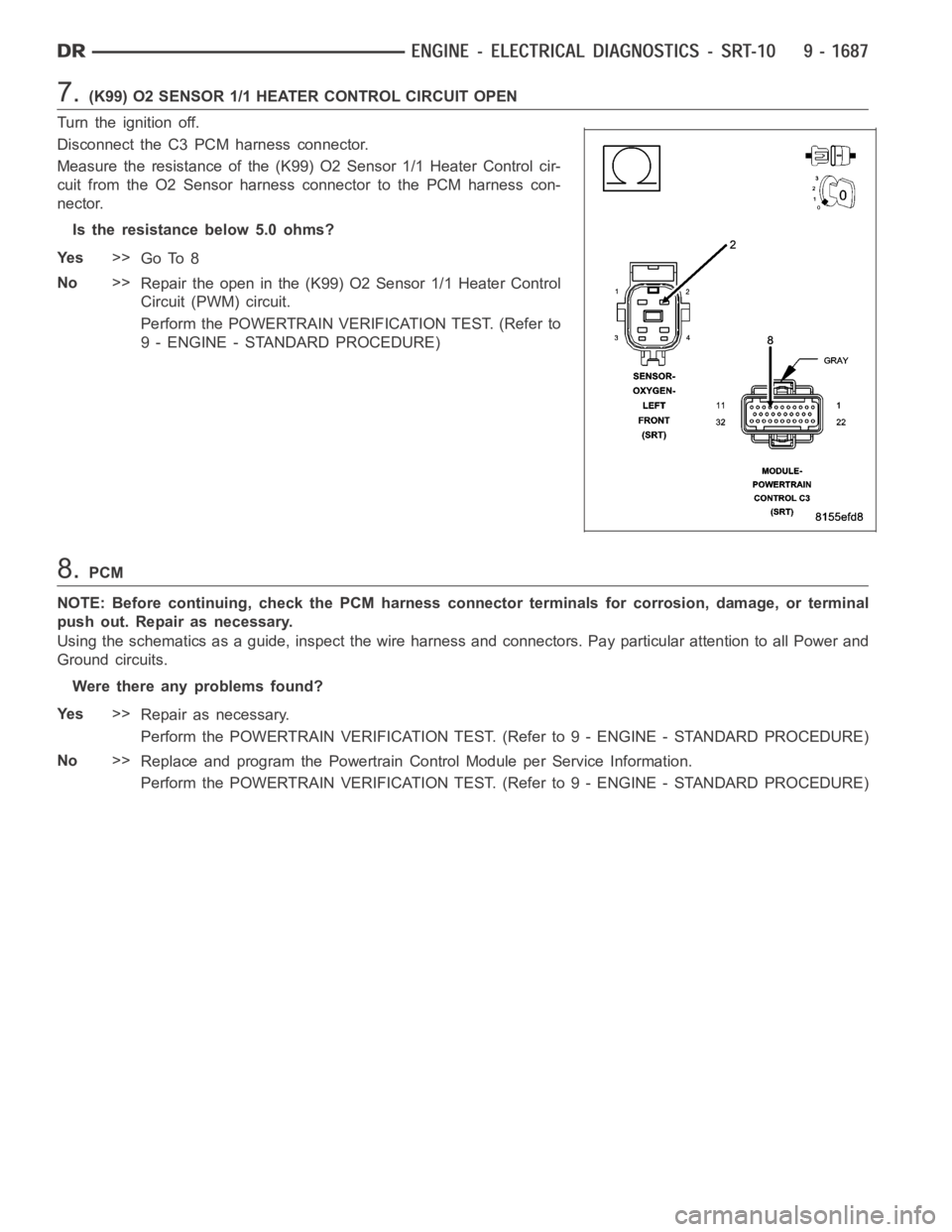

7.(K99) O2 SENSOR 1/1 HEATER CONTROL CIRCUIT OPEN

Turn the ignition off.

Disconnect the C3 PCM harness connector.

Measure the resistance of the (K99) O2 Sensor 1/1 Heater Control cir-

cuit from the O2 Sensor harness connector to the PCM harness con-

nector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 8

No>>

Repair the open in the (K99) O2 Sensor 1/1 Heater Control

Circuit (PWM) circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

8.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)