clock DODGE RAM SRT-10 2006 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2430 of 5267

TILT LEVER KNOB RELEASE

REMOVAL

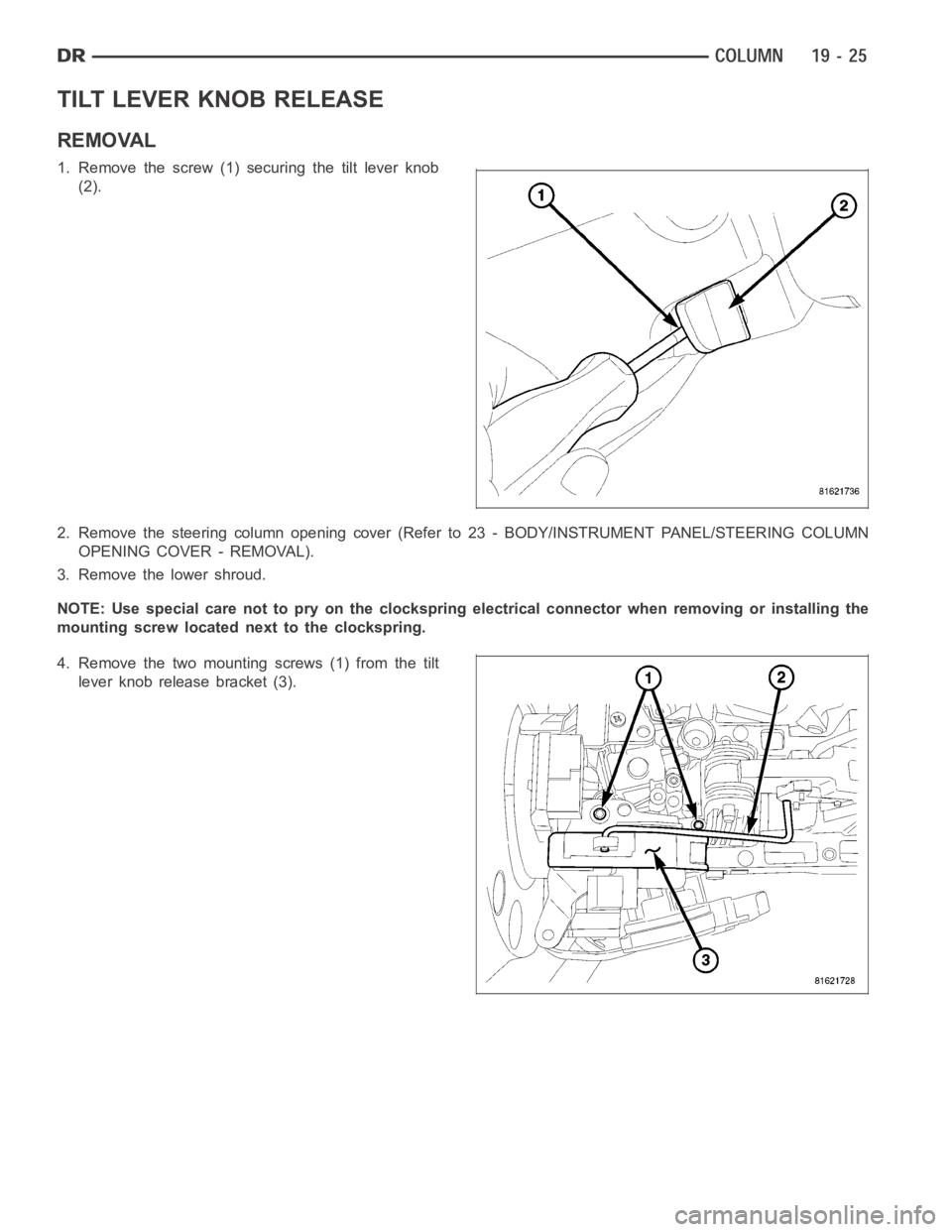

1. Remove the screw (1) securing the tilt lever knob

(2).

2. Remove the steering column opening cover (Refer to 23 - BODY/INSTRUMENTPANEL/STEERING COLUMN

OPENING COVER - REMOVAL).

3. Remove the lower shroud.

NOTE: Use special care not to pry on the clockspring electrical connector whenremovingorinstallingthe

mounting screw located next to the clockspring.

4. Remove the two mounting screws (1) from the tilt

lever knob release bracket (3).

Page 2452 of 5267

ADJUSTMENTS

ADJUSTMENT

CAUTION: Steering gear must be adjusted in the proper order. If adjustments are not performed in order,

gear damage and improper steering response may result.

NOTE: Adjusting the steering gear in the vehicle is not recommended. Remove gear from the vehicle and

drain the fluid. Then mount gear in a vise to perform adjustments.

1. Remove the steering gear from the vehicle(Referto19-STEERING/GEAR-REMOVAL).

2. Mount the gear carefully into a soft-jawed vise.

CAUTION: Do not overtighten the vise on the gear case. This may affect the adjustment

3. Hold the steering gear upside down over a drain pan and rotate the input shaft back and forth several times

lock-to-lock to discharge the fluid from the steering gear

4. Rotate the input shaft to the left stop and then back-off approximately 45 degrees. Using an inch-pound torque

wrench on the input shaft, record the peak torque required to slowly and evenly rotate the input shaft clockwise

1⁄2turn (180 degrees) starting from the 45 degree position. This peak torque reading is the preload torque. The

preload torque must be within 2 - 10 in-lbs.

5. Rotate the input shaft to its center of travel (approximately 1.5 turns from either stop). Place the torque wrench

on the input shaft with the handle in the vertical position. Rotate the torque wrench slowly and evenly

1⁄4turn (90

degrees) each side of center and record the peak torque measure on or near center. This total on-center torque

reading must be 5 - 9 in-lbs higher than the previously measured preload torque without exceeding a total of 17

in-lbs. The value of the total on-center minus the preload torque is defined as the meshload torque

6. If required, adjust the on-center torque by loosening the adjuster screw lock nut and turning the adjuster screw

until the total on-center and meshload torque readings fall within the specified values. Turn the adjuster screw

clockwise to increase and counterclockwise to decrease the torque reading. While holding the adjuster screw in

place, tighten the lock nut to 34 Nꞏm (25 ft. lbs.).

7. Re-check the preload and on-center torque readings.

8. Install pitman arm on the steering gear (Refer to 19 - STEERING/LINKAGE/PITMAN ARM - INSTALLATION).

9. Reinstall steering gear to the vehicle (Refer to 19 - STEERING/GEAR - INSTALLATION).

SPECIFICATIONS

POWER STEERING GEAR

SPECIFICATIONS

DESCRIPTION SPECIFICATION

Steering Gear

Ty peRecirculating Ball

Gear Code & Ratio 12.5:1

TORQUE

DESCRIPTION Nꞏm Ft. Lbs. In. Lbs.

Preload

To r q u e0.23-1.13 — 2-10

Meshload Torque 0.56-1.02 — 5-9

+ Preload (17 Max)

Page 2600 of 5267

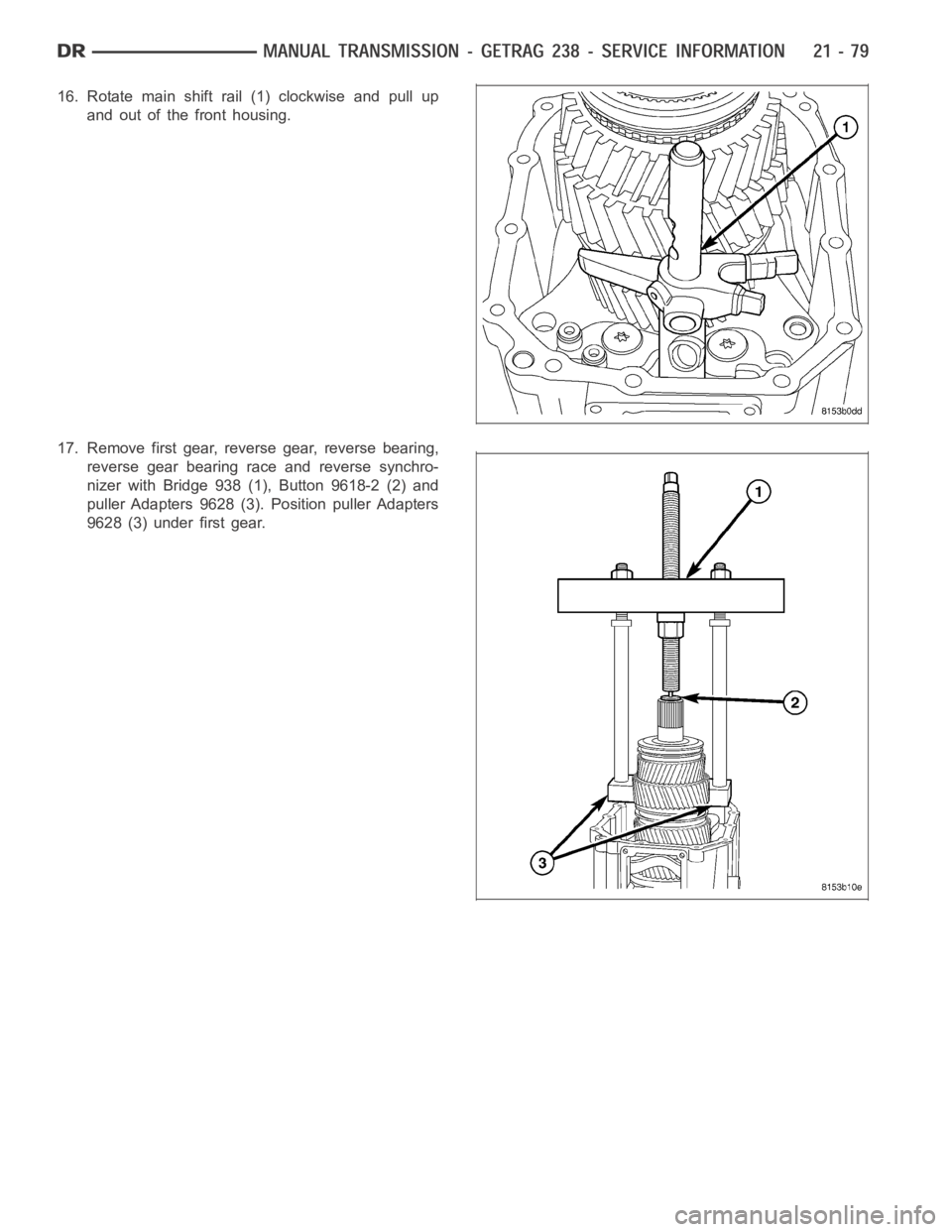

16. Rotate main shift rail (1) clockwise and pull up

and out of the front housing.

17. Remove first gear, reverse gear, reverse bearing,

reverse gear bearing race and reverse synchro-

nizer with Bridge 938 (1), Button 9618-2 (2) and

puller Adapters 9628 (3). Position puller Adapters

9628 (3) under first gear.

Page 2649 of 5267

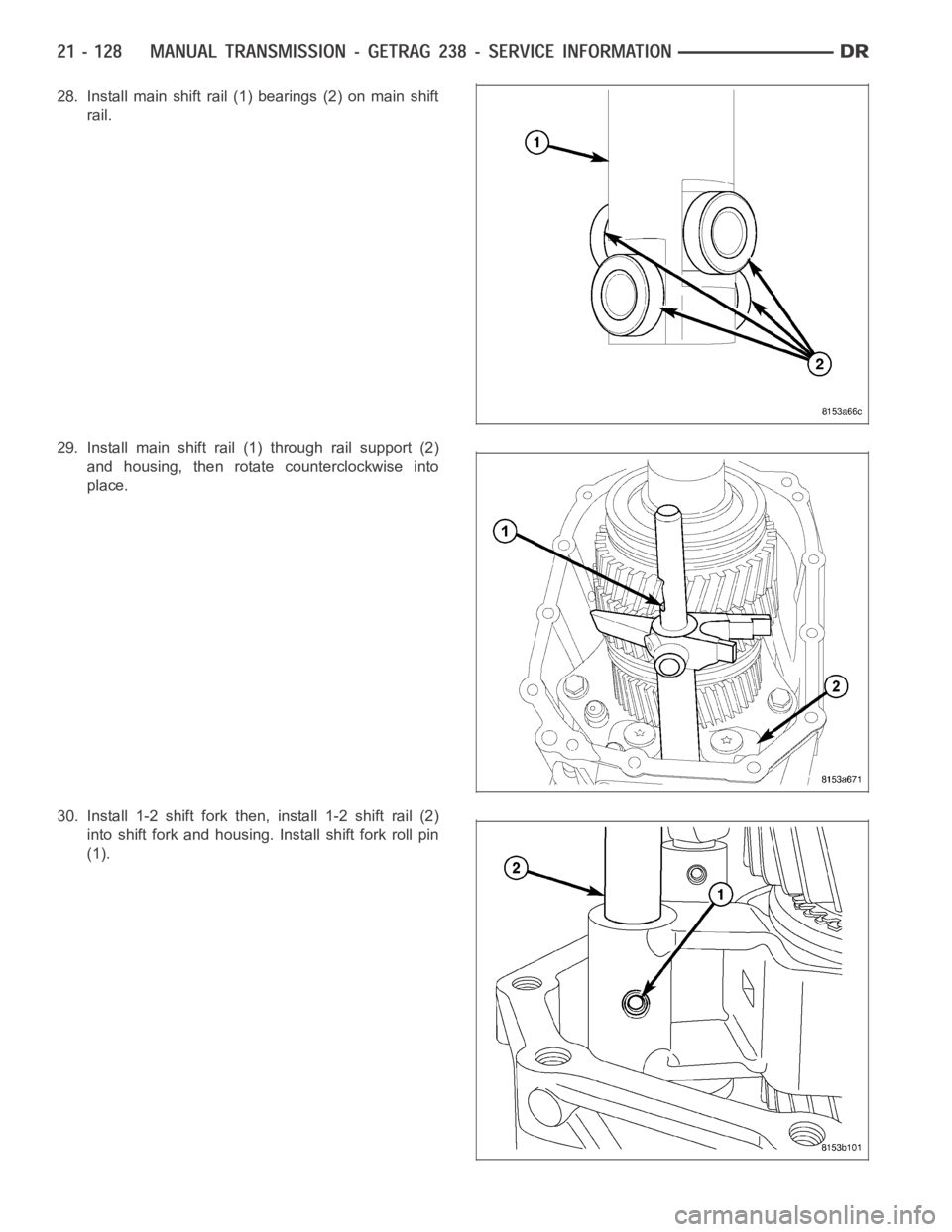

28. Install main shift rail (1) bearings (2) on main shift

rail.

29. Install main shift rail (1) through rail support (2)

and housing, then rotate counterclockwise into

place.

30. Install 1-2 shift fork then, install 1-2 shift rail (2)

into shift fork and housing. Install shift fork roll pin

(1).

Page 2927 of 5267

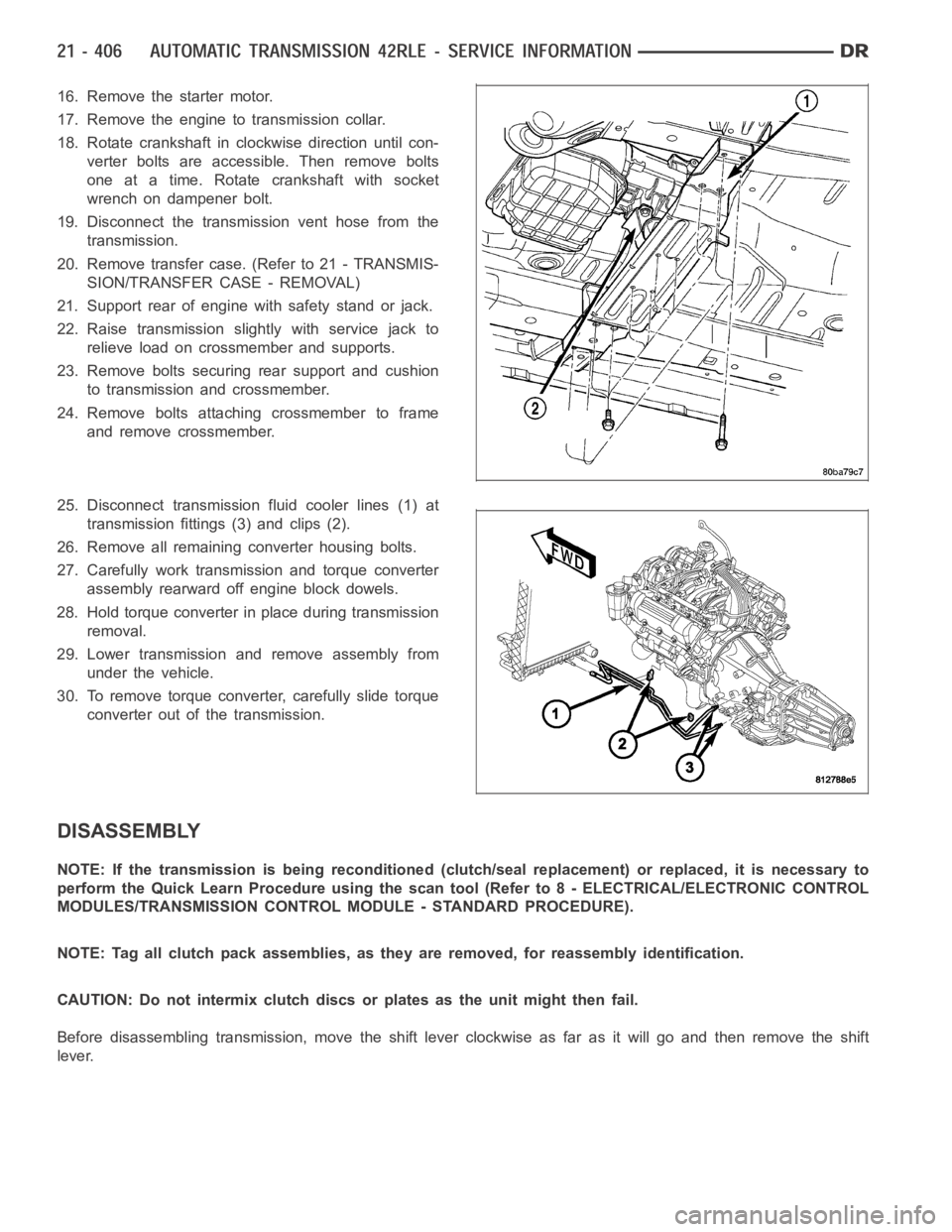

16. Remove the starter motor.

17. Remove the engine to transmission collar.

18. Rotate crankshaft in clockwise direction until con-

verter bolts are accessible. Then remove bolts

one at a time. Rotate crankshaft with socket

wrench on dampener bolt.

19. Disconnect the transmission vent hose from the

transmission.

20. Remove transfer case. (Refer to 21 - TRANSMIS-

SION/TRANSFER CASE - REMOVAL)

21. Support rear of engine with safety stand or jack.

22. Raise transmission slightly with service jack to

relieve load on crossmember and supports.

23. Remove bolts securing rear support and cushion

to transmission and crossmember.

24. Remove bolts attaching crossmember to frame

and remove crossmember.

25. Disconnect transmission fluid cooler lines (1) at

transmission fittings (3) and clips (2).

26. Remove all remaining converter housing bolts.

27. Carefully work transmission and torque converter

assembly rearward off engine block dowels.

28. Hold torque converter in place during transmission

removal.

29. Lower transmission and remove assembly from

under the vehicle.

30. To remove torque converter, carefully slide torque

converter out of the transmission.

DISASSEMBLY

NOTE: If the transmission is being reconditioned (clutch/seal replacement) or replaced, it is necessary to

perform the Quick Learn Procedure using the scan tool (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/TRANSMISSION CONTROL MODULE - STANDARD PROCEDURE).

NOTE: Tag all clutch pack assemblies, as they are removed, for reassembly identification.

CAUTION: Do not intermix clutch discs or plates as the unit might then fail.

Before disassembling transmission, move the shift lever clockwise as faras it will go and then remove the shift

lever.

Page 3066 of 5267

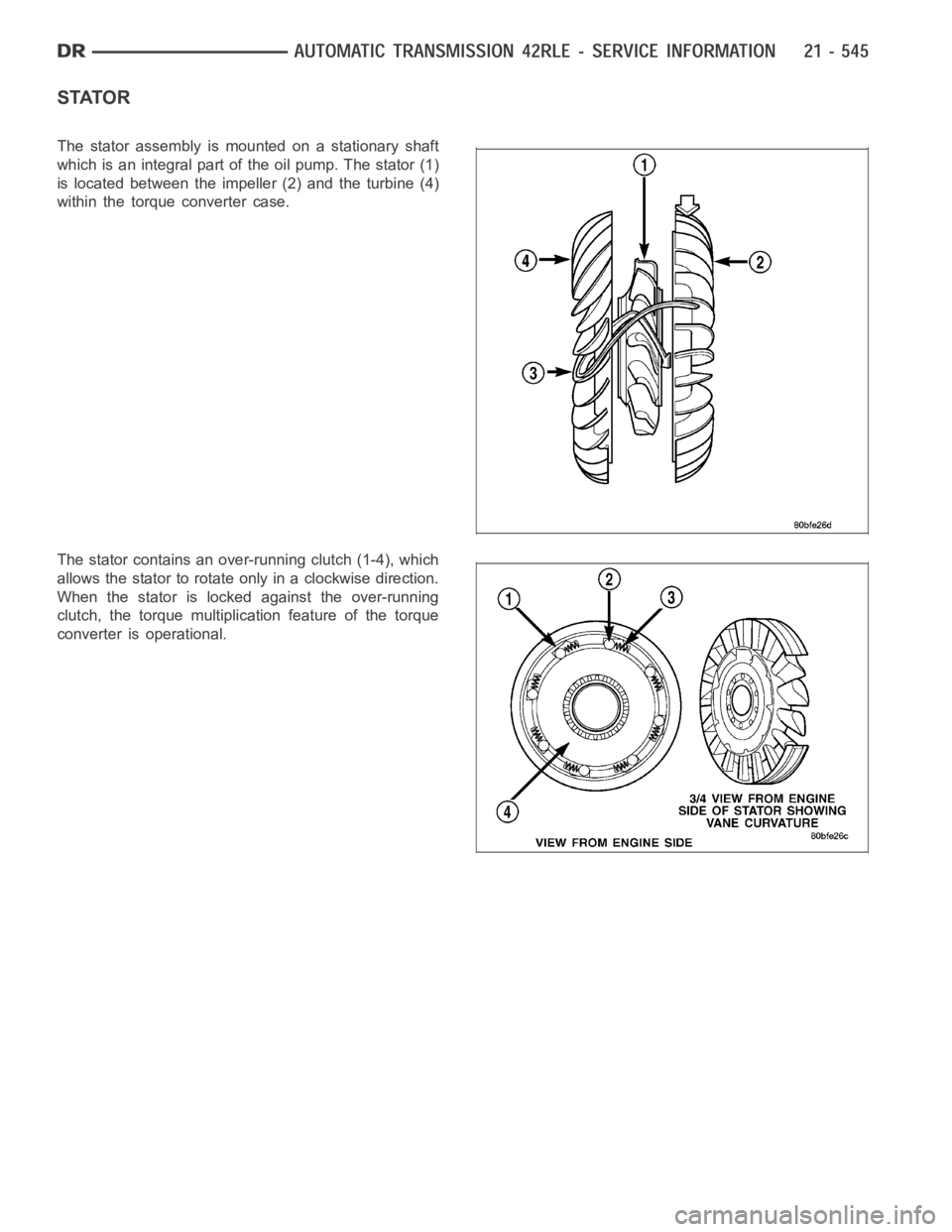

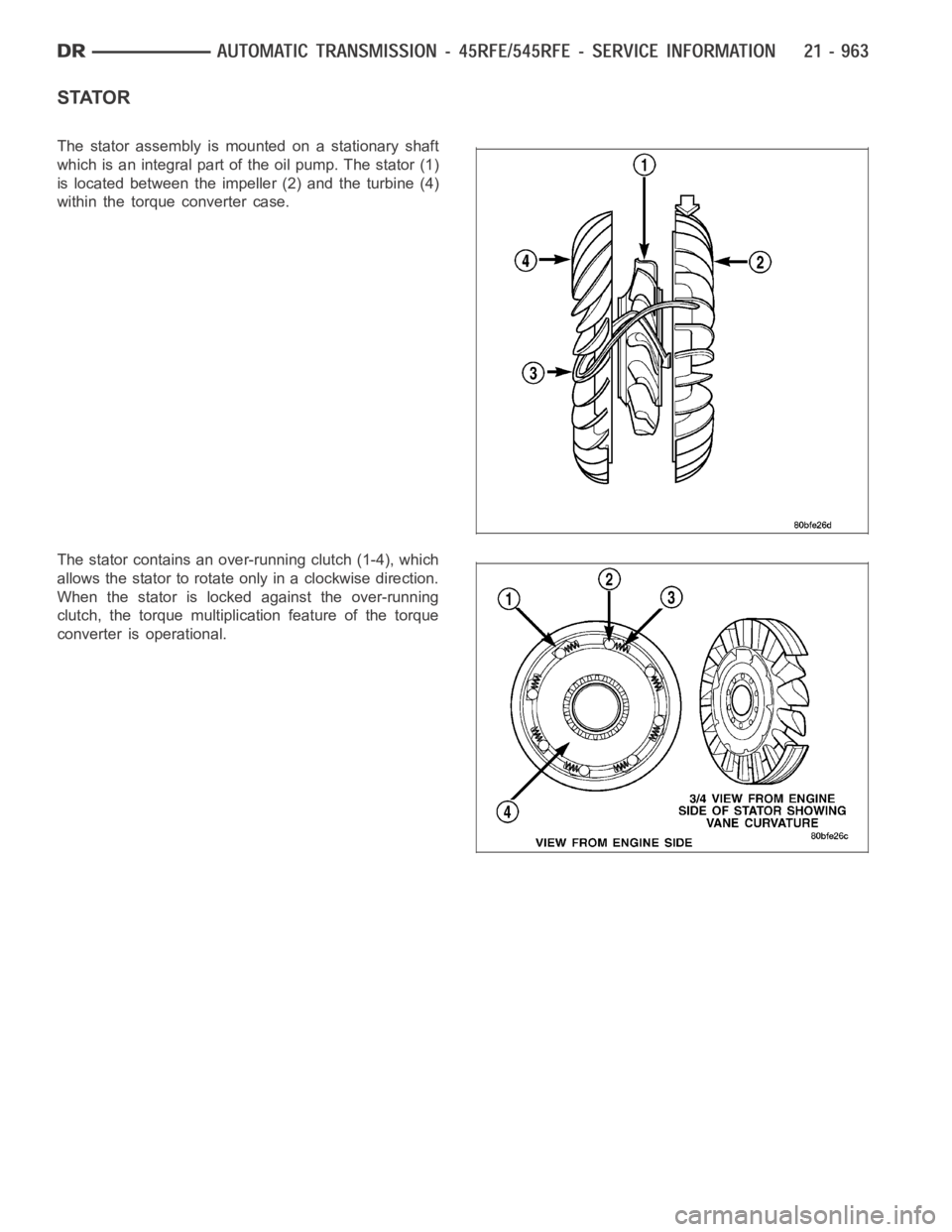

STATOR

The stator assembly is mounted on a stationary shaft

which is an integral part of the oil pump. The stator (1)

islocatedbetweentheimpeller (2) and the turbine (4)

within the torque converter case.

The stator contains an over-running clutch (1-4), which

allows the stator to rotate only in a clockwise direction.

When the stator is locked against the over-running

clutch, the torque multiplication feature of the torque

converter is operational.

Page 3068 of 5267

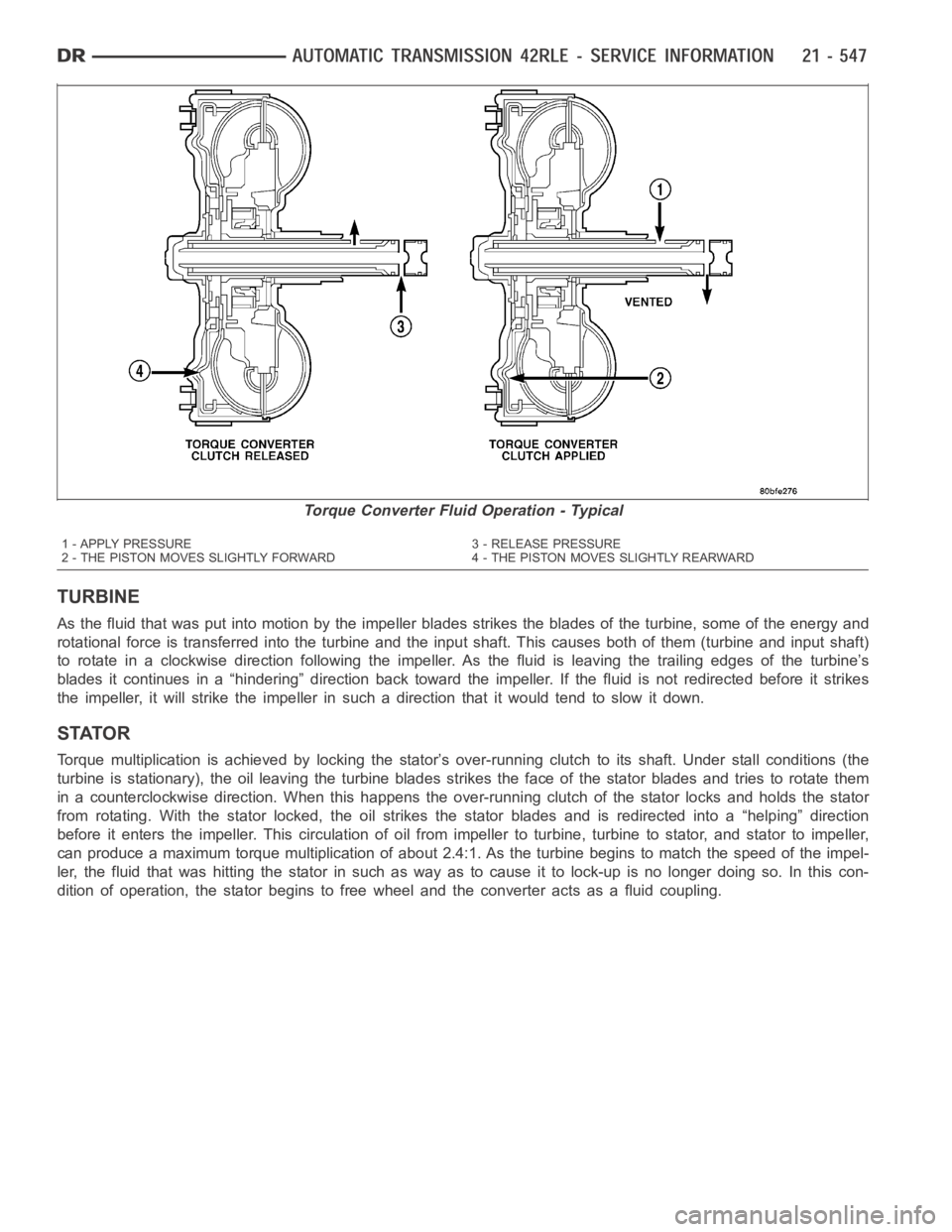

TURBINE

As the fluid that was put into motion bythe impeller blades strikes the blades of the turbine, some of the energy and

rotational force is transferred into the turbine and the input shaft. Thiscauses both of them (turbine and input shaft)

to rotate in a clockwise direction following the impeller. As the fluid is leaving the trailing edges of the turbine’s

blades it continues in a “hindering” direction back toward the impeller. If the fluid is not redirected before it strikes

the impeller, it will strike the impeller in such a direction that it would tend to slow it down.

STATOR

Torque multiplication is achieved by locking the stator’s over-running clutch to its shaft. Under stall conditions (the

turbine is stationary), the oil leaving the turbine blades strikes the face of the stator blades and tries to rotate them

in a counterclockwise direction. When this happens the over-running clutch of the stator locks and holds the stator

from rotating. With the stator locked, the oil strikes the stator blades and is redirected into a “helping” direction

before it enters the impeller. This circulation of oil from impeller to turbine, turbine to stator, and stator to impeller,

can produce a maximum torque multiplicationofabout2.4:1.Astheturbinebegins to match the speed of the impel-

ler, the fluid that was hitting the stator in such as way as to cause it to lock-up is no longer doing so. In this con-

dition of operation, the stator begins to free wheel and the converter actsas a fluid coupling.

Torque Converter Fluid Operation - Typical

1 - APPLY PRESSURE 3 - RELEASE PRESSURE

2 - THE PISTON MOVES SLIGHTLY FORWARD 4 - THE PISTON MOVES SLIGHTLY REARWARD

Page 3084 of 5267

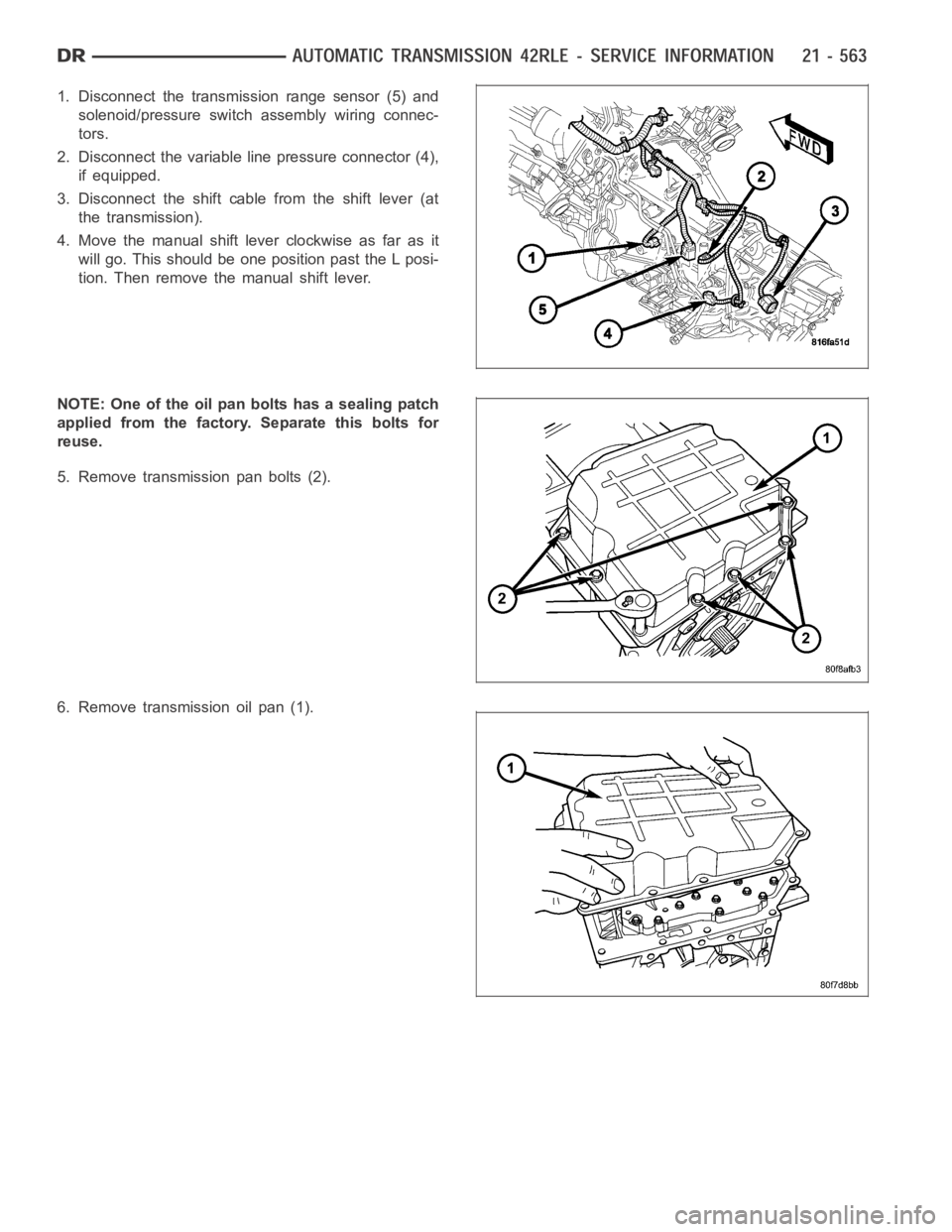

1. Disconnect the transmission range sensor (5) and

solenoid/pressure switchassembly wiring connec-

tors.

2. Disconnect the variable line pressure connector (4),

if equipped.

3. Disconnect the shift cable from the shift lever (at

the transmission).

4. Move the manual shift lever clockwise as far as it

will go. This should be one position past the L posi-

tion. Then remove the manual shift lever.

NOTE: One of the oil pan bolts has a sealing patch

applied from the factory. Separate this bolts for

reuse.

5. Remove transmission pan bolts (2).

6. Remove transmission oil pan (1).

Page 3373 of 5267

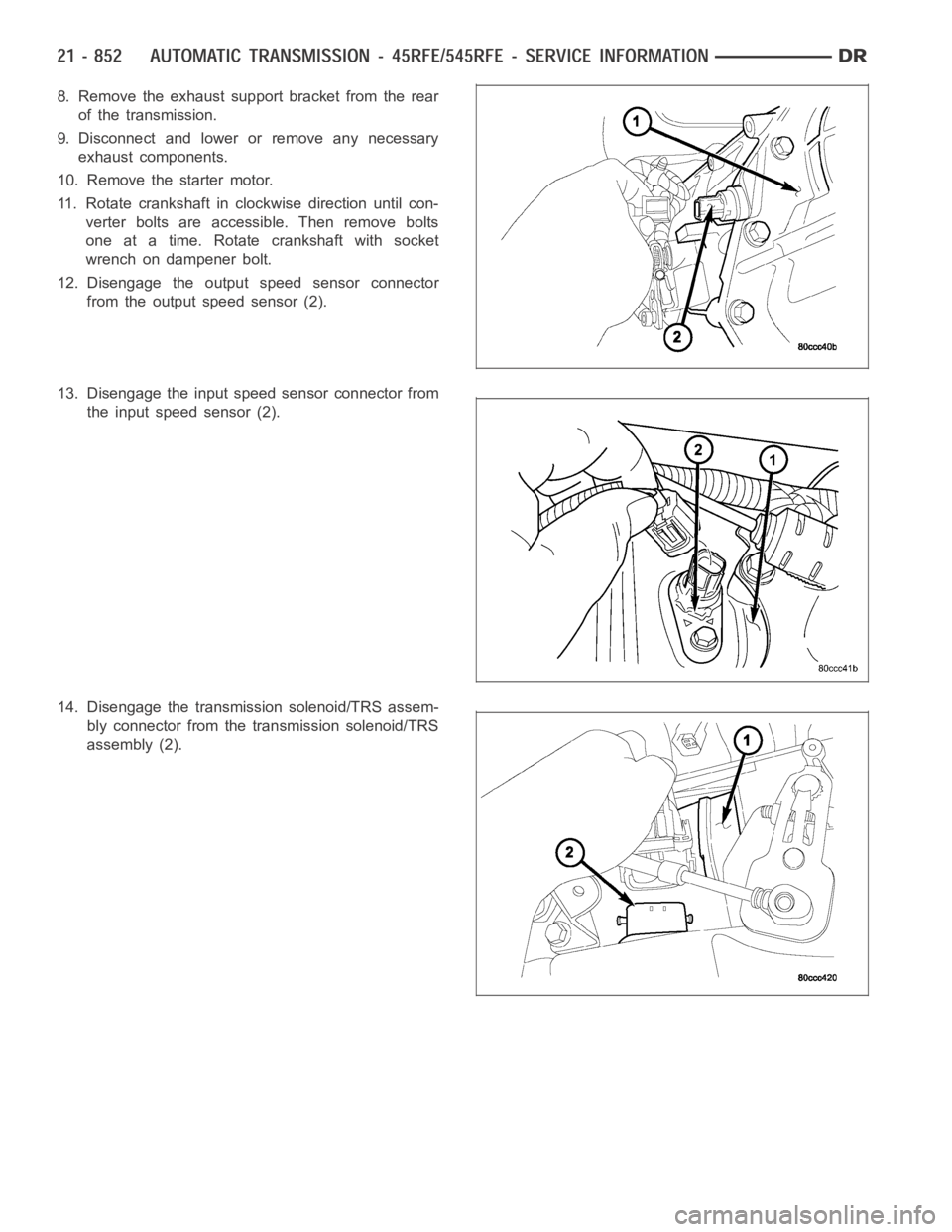

8. Remove the exhaust support bracket from the rear

of the transmission.

9. Disconnect and lower or remove any necessary

exhaust components.

10. Remove the starter motor.

11. Rotate crankshaft in clockwise direction until con-

verter bolts are accessible. Then remove bolts

one at a time. Rotate crankshaft with socket

wrench on dampener bolt.

12. Disengage the output speed sensor connector

from the output speed sensor (2).

13. Disengage the input speed sensor connector from

the input speed sensor (2).

14. Disengage the transmission solenoid/TRS assem-

bly connector from the transmission solenoid/TRS

assembly (2).

Page 3484 of 5267

STATOR

The stator assembly is mounted on a stationary shaft

which is an integral part of the oil pump. The stator (1)

islocatedbetweentheimpeller (2) and the turbine (4)

within the torque converter case.

The stator contains an over-running clutch (1-4), which

allows the stator to rotate only in a clockwise direction.

When the stator is locked against the over-running

clutch, the torque multiplication feature of the torque

converter is operational.