light DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3915 of 5267

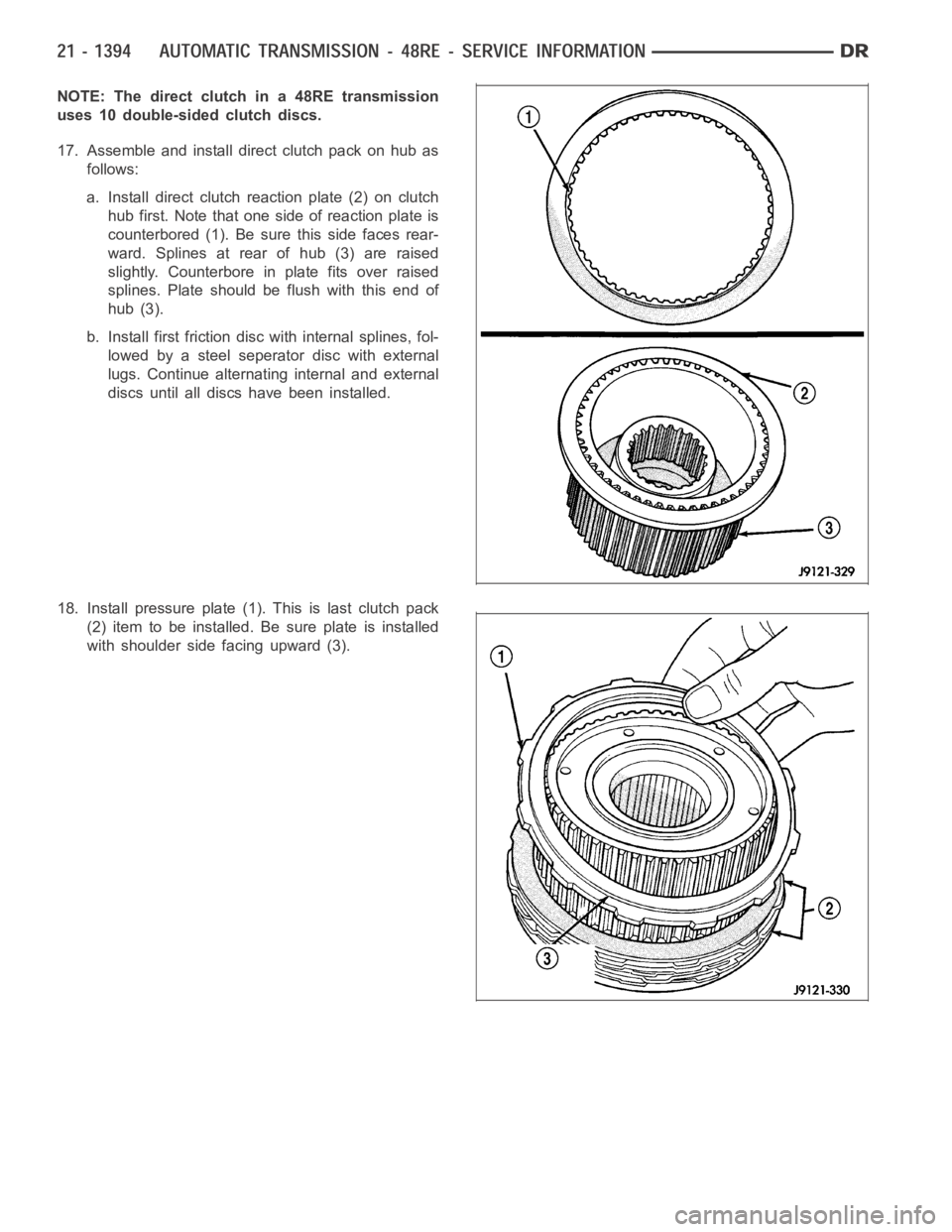

NOTE: The direct clutch in a 48RE transmission

uses 10 double-sided clutch discs.

17. Assemble and install direct clutch pack on hub as

follows:

a. Install direct clutch reaction plate (2) on clutch

hub first. Note that one side of reaction plate is

counterbored (1). Be sure this side faces rear-

ward. Splines at rear of hub (3) are raised

slightly. Counterbore in plate fits over raised

splines. Plate should be flush with this end of

hub (3).

b. Install first friction disc with internal splines, fol-

lowed by a steel seperator disc with external

lugs. Continue alternating internal and external

discs until all discs have been installed.

18. Install pressure plate (1). This is last clutch pack

(2) item to be installed. Be sure plate is installed

with shoulder side facing upward (3).

Page 3938 of 5267

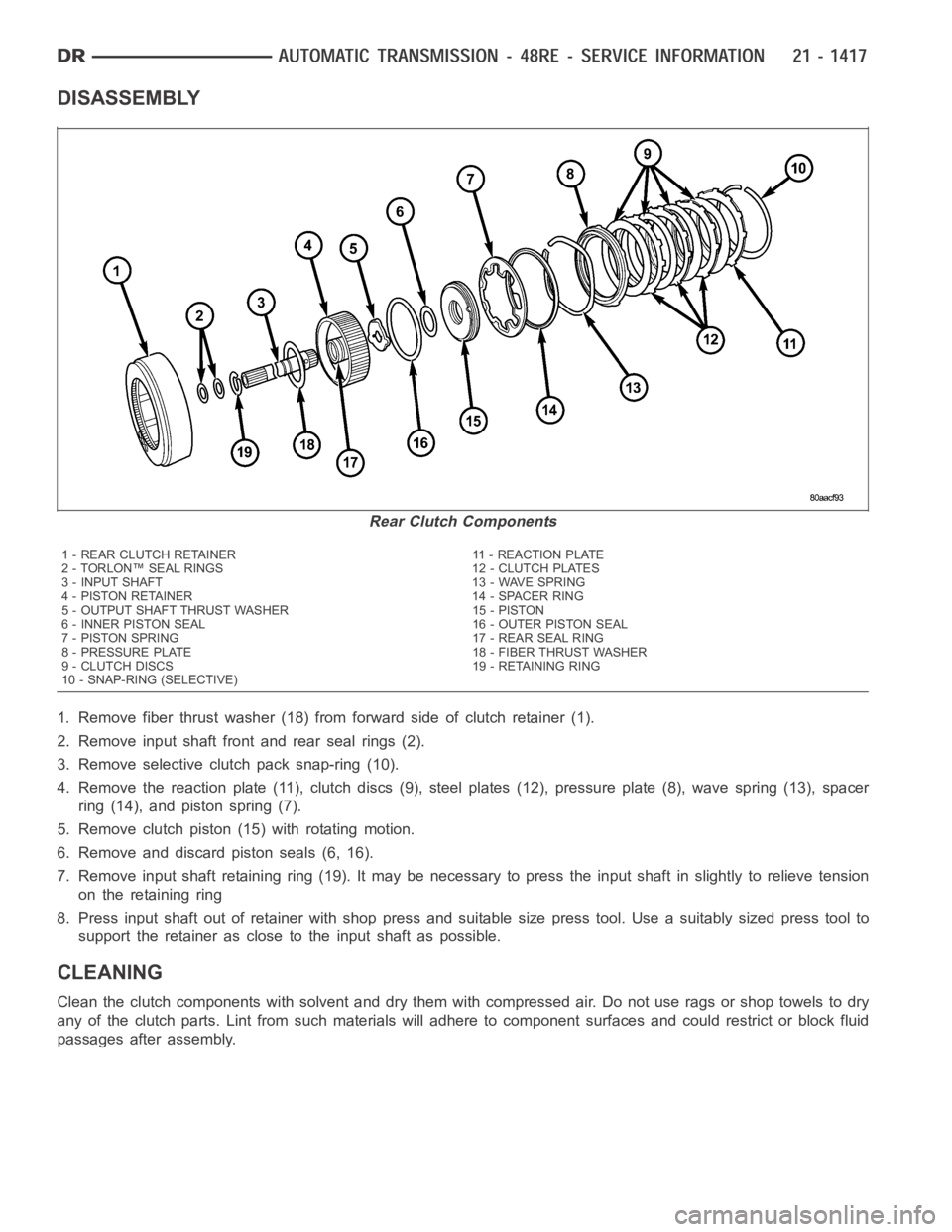

DISASSEMBLY

1. Remove fiber thrust washer (18) from forward side of clutch retainer (1).

2. Remove input shaft front and rear seal rings (2).

3. Remove selective clutch pack snap-ring (10).

4. Remove the reaction plate (11), clutch discs (9), steel plates (12), pressure plate (8), wave spring (13), spacer

ring (14), and piston spring (7).

5. Remove clutch piston (15) with rotating motion.

6. Remove and discard piston seals (6, 16).

7. Remove input shaft retaining ring (19). It may be necessary to press the input shaft in slightly to relieve tension

on the retaining ring

8. Press input shaft out of retainer with shop press and suitable size presstool. Use a suitably sized press tool to

support the retainer as close to the input shaft as possible.

CLEANING

Clean the clutch components with solvent and dry them with compressed air.Do not use rags or shop towels to dry

any of the clutch parts. Lint from such materials will adhere to component surfaces and could restrict or block fluid

passages after assembly.

Rear Clutch Components

1 - REAR CLUTCH RETAINER 11 - REACTION PLATE

2 - TORLON™ SEAL RINGS 12 - CLUTCH PLATES

3 - INPUT SHAFT 13 - WAVE SPRING

4 - PISTON RETAINER 14 - SPACER RING

5 - OUTPUT SHAFT THRUST WASHER 15 - PISTON

6 - INNER PISTON SEAL 16 - OUTER PISTON SEAL

7 - PISTON SPRING 17 - REAR SEAL RING

8 - PRESSURE PLATE 18 - FIBER THRUST WASHER

9 - CLUTCH DISCS 19 - RETAINING RING

10 - SNAP-RING (SELECTIVE)

Page 3940 of 5267

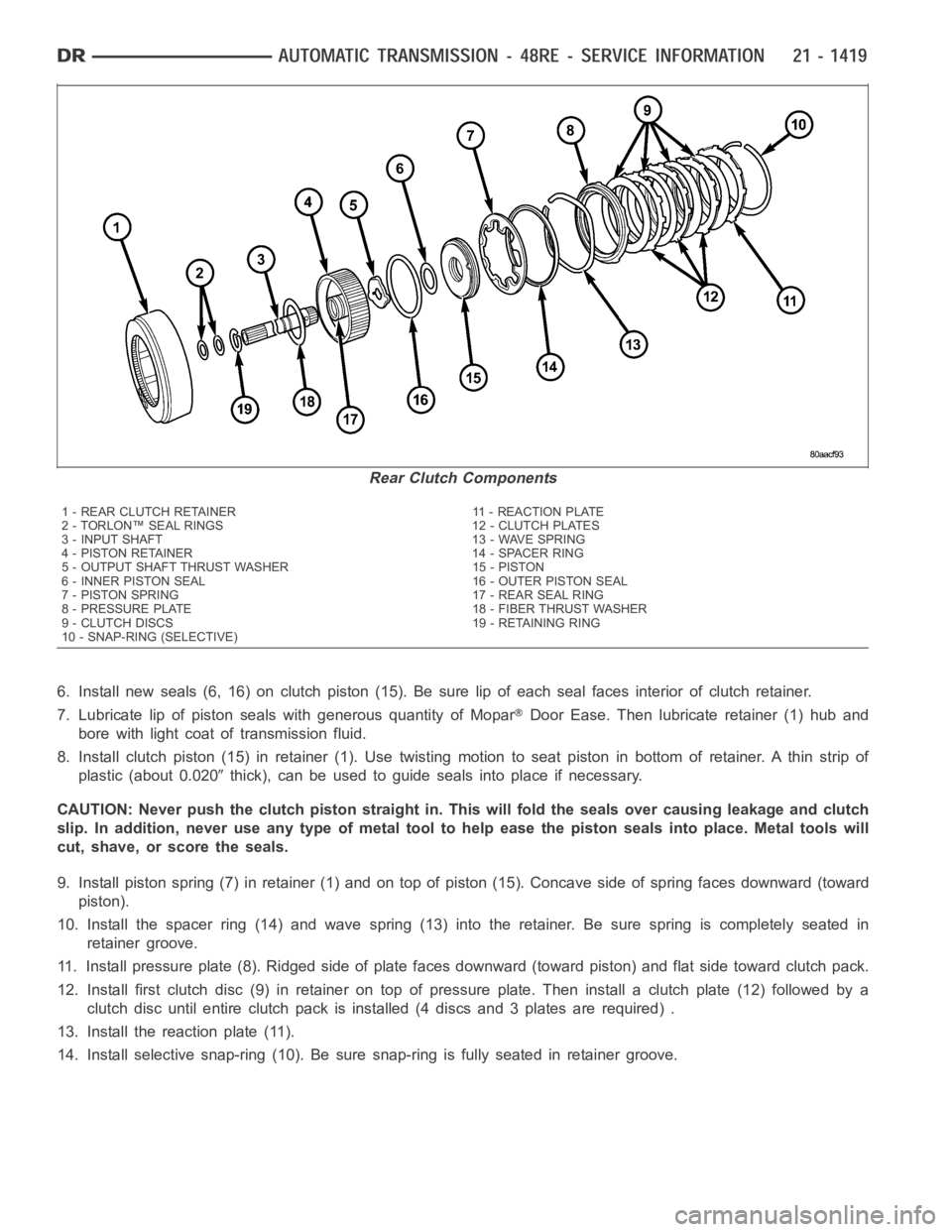

6. Install new seals (6, 16) on clutch piston (15). Be sure lip of each seal faces interior of clutch retainer.

7. Lubricate lip of piston seals with generous quantity of Mopar

Door Ease. Then lubricate retainer (1) hub and

bore with light coat of transmission fluid.

8. Install clutch piston (15) in retainer (1). Use twisting motion to seat piston in bottom of retainer. A thin strip of

plastic (about 0.020

thick), can be used to guide seals into place if necessary.

CAUTION: Never push the clutch piston straight in. This will fold the sealsover causing leakage and clutch

slip. In addition, never use any type of metal tool to help ease the piston seals into place. Metal tools will

cut, shave, or score the seals.

9. Install piston spring (7) in retainer (1) and on top of piston (15). Concave side of spring faces downward (toward

piston).

10. Install the spacer ring (14) and wave spring (13) into the retainer. Be sure spring is completely seated in

retainer groove.

11. Install pressure plate (8). Ridged side of plate faces downward (toward piston) and flat side toward clutch pack.

12. Install first clutch disc (9) in retainer on top of pressure plate. Theninstall a clutch plate (12) followed by a

clutch disc until entire clutch pack is installed (4 discs and 3 plates are required) .

13. Install the reaction plate (11).

14. Install selective snap-ring (10). Be sure snap-ring is fully seated inretainer groove.

Rear Clutch Components

1 - REAR CLUTCH RETAINER 11 - REACTION PLATE

2 - TORLON™ SEAL RINGS 12 - CLUTCH PLATES

3 - INPUT SHAFT 13 - WAVE SPRING

4 - PISTON RETAINER 14 - SPACER RING

5 - OUTPUT SHAFT THRUST WASHER 15 - PISTON

6 - INNER PISTON SEAL 16 - OUTER PISTON SEAL

7 - PISTON SPRING 17 - REAR SEAL RING

8 - PRESSURE PLATE 18 - FIBER THRUST WASHER

9 - CLUTCH DISCS 19 - RETAINING RING

10 - SNAP-RING (SELECTIVE)

Page 3950 of 5267

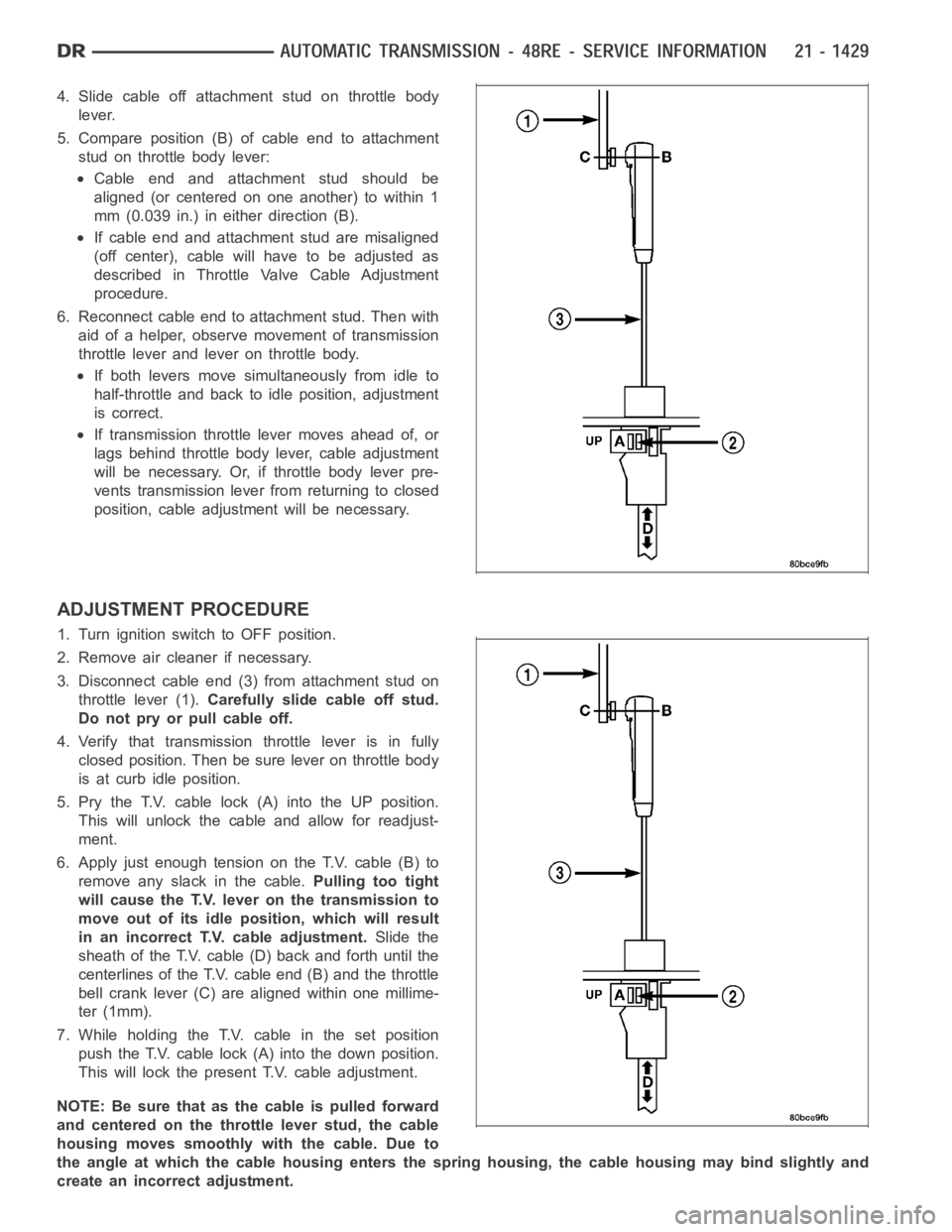

4. Slide cable off attachment stud on throttle body

lever.

5. Compare position (B) of cable end to attachment

stud on throttle body lever:

Cable end and attachment stud should be

aligned (or centered on one another) to within 1

mm (0.039 in.) in either direction (B).

If cable end and attachment stud are misaligned

(off center), cable will have to be adjusted as

described in Throttle Valve Cable Adjustment

procedure.

6. Reconnect cable end to attachment stud. Then with

aid of a helper, observe movement of transmission

throttle lever and lever on throttle body.

If both levers move simultaneously from idle to

half-throttle and back to idle position, adjustment

is correct.

If transmission throttle lever moves ahead of, or

lags behind throttle body lever, cable adjustment

will be necessary. Or, if throttle body lever pre-

vents transmission lever from returning to closed

position, cable adjustment will be necessary.

ADJUSTMENT PROCEDURE

1. Turn ignition switch to OFF position.

2. Remove air cleaner if necessary.

3. Disconnect cable end (3) from attachment stud on

throttle lever (1).Carefully slide cable off stud.

Do not pry or pull cable off.

4. Verify that transmission throttle lever is in fully

closed position. Then be sure lever on throttle body

is at curb idle position.

5. Pry the T.V. cable lock (A) into the UP position.

This will unlock the cable and allow for readjust-

ment.

6. Apply just enough tension on the T.V. cable (B) to

remove any slack in the cable.Pulling too tight

will cause the T.V. lever on the transmission to

move out of its idle position, which will result

in an incorrect T.V. cable adjustment.Slide the

sheath of the T.V. cable (D) back and forth until the

centerlines of the T.V. cable end (B) and the throttle

bell crank lever (C) are aligned within one millime-

ter (1mm).

7. While holding the T.V. cable in the set position

push the T.V. cable lock (A) into the down position.

This will lock the present T.V. cable adjustment.

NOTE:Besurethatasthecableispulledforward

and centered on the throttle lever stud, the cable

housing moves smoothly with the cable. Due to

the angle at which the cable housing enters the spring housing, the cable housing may bind slightly and

create an incorrect adjustment.

Page 3956 of 5267

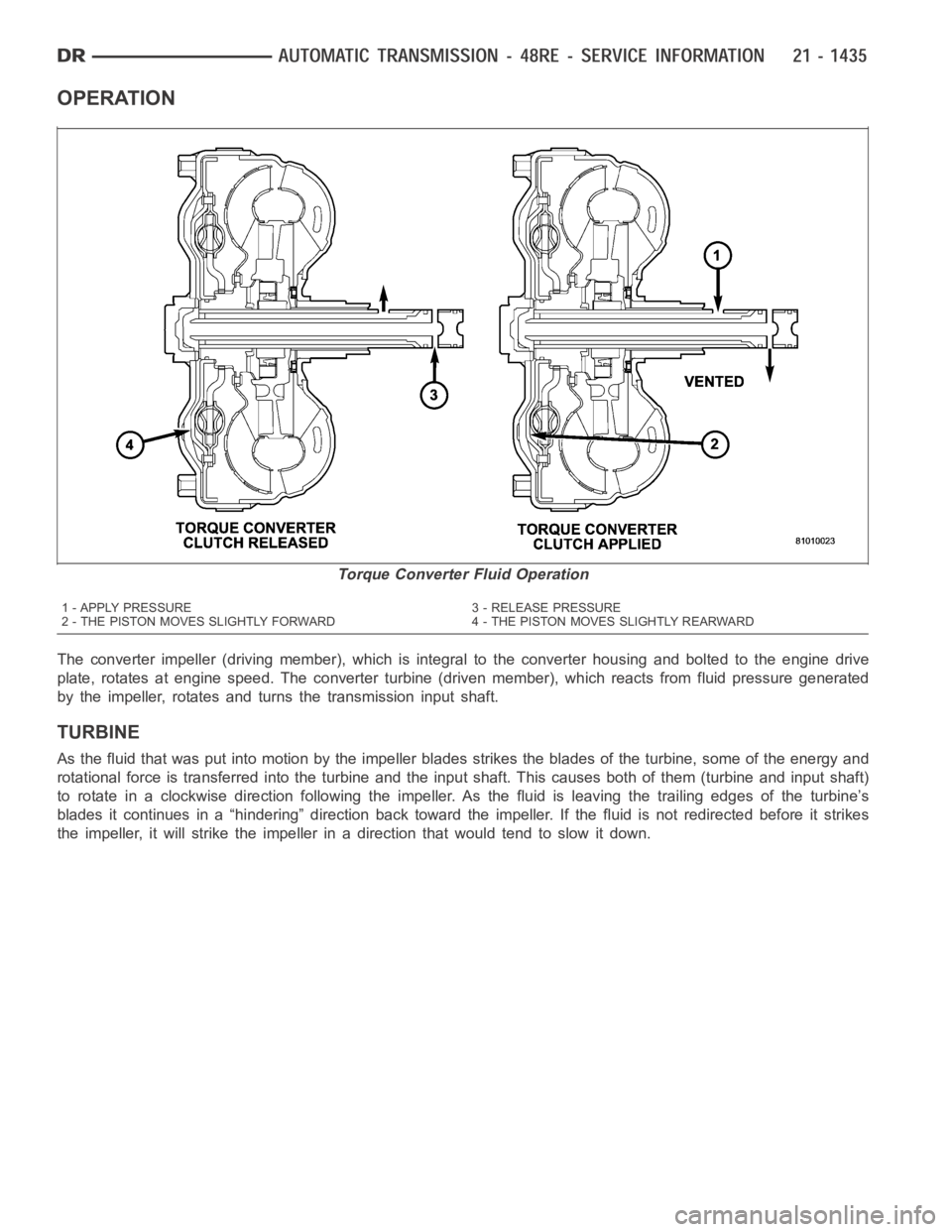

OPERATION

The converter impeller (driving member), which is integral to the converter housing and bolted to the engine drive

plate, rotates at engine speed. The converter turbine (driven member), which reacts from fluid pressure generated

by the impeller, rotates and turns the transmission input shaft.

TURBINE

As the fluid that was put into motion bythe impeller blades strikes the blades of the turbine, some of the energy and

rotational force is transferred into the turbine and the input shaft. Thiscauses both of them (turbine and input shaft)

to rotate in a clockwise direction following the impeller. As the fluid is leaving the trailing edges of the turbine’s

blades it continues in a “hindering” direction back toward the impeller. If the fluid is not redirected before it strikes

the impeller, it will strike the impeller in a direction that would tend to slow it down.

Torque Converter Fluid Operation

1 - APPLY PRESSURE 3 - RELEASE PRESSURE

2 - THE PISTON MOVES SLIGHTLY FORWARD 4 - THE PISTON MOVES SLIGHTLY REARWARD

Page 3961 of 5267

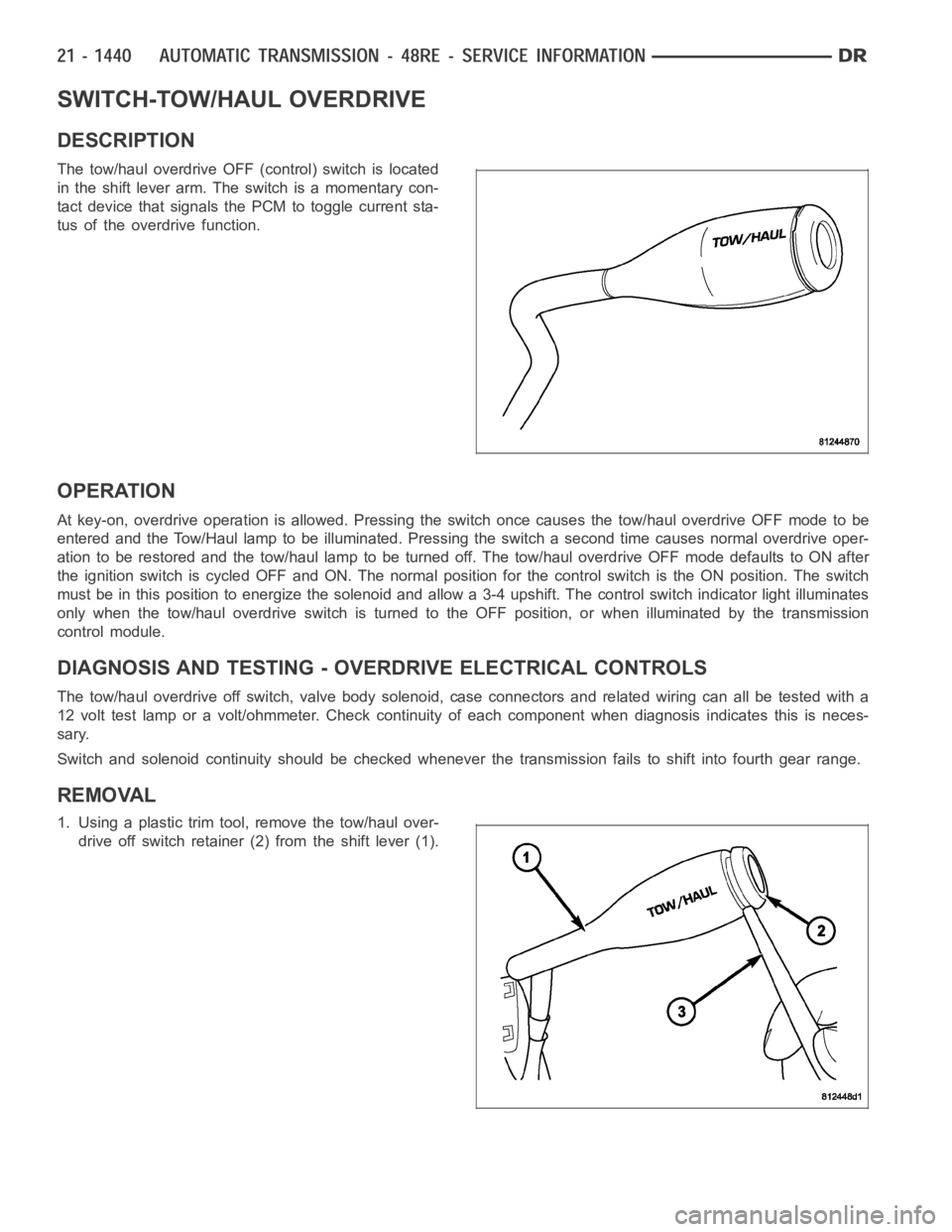

SWITCH-TOW/HAUL OVERDRIVE

DESCRIPTION

The tow/haul overdrive OFF (control) switch is located

in the shift lever arm. The switch is a momentary con-

tact device that signals the PCM to toggle current sta-

tus of the overdrive function.

OPERATION

At key-on, overdrive operation is allowed. Pressing the switch once causes the tow/haul overdrive OFF mode to be

entered and the Tow/Haul lamp to be illuminated. Pressing the switch a second time causes normal overdrive oper-

ationtoberestoredandthetow/haullamptobeturnedoff.Thetow/hauloverdrive OFF mode defaults to ON after

the ignition switch is cycled OFF and ON. The normal position for the control switch is the ON position. The switch

must be in this position to energize the solenoid and allow a 3-4 upshift. The control switch indicator light illuminates

only when the tow/haul overdrive switch is turned to the OFF position, or when illuminated by the transmission

control module.

DIAGNOSIS AND TESTING - OVERDRIVE ELECTRICAL CONTROLS

The tow/haul overdrive off switch, valve body solenoid, case connectors and related wiring can all be tested with a

12 volt test lamp or a volt/ohmmeter. Check continuity of each component when diagnosis indicates this is neces-

sary.

Switch and solenoid continuity shouldbe checked whenever the transmission fails to shift into fourth gear range.

REMOVAL

1. Using a plastic trim tool, remove the tow/haul over-

drive off switch retainer (2) from the shift lever (1).

Page 4006 of 5267

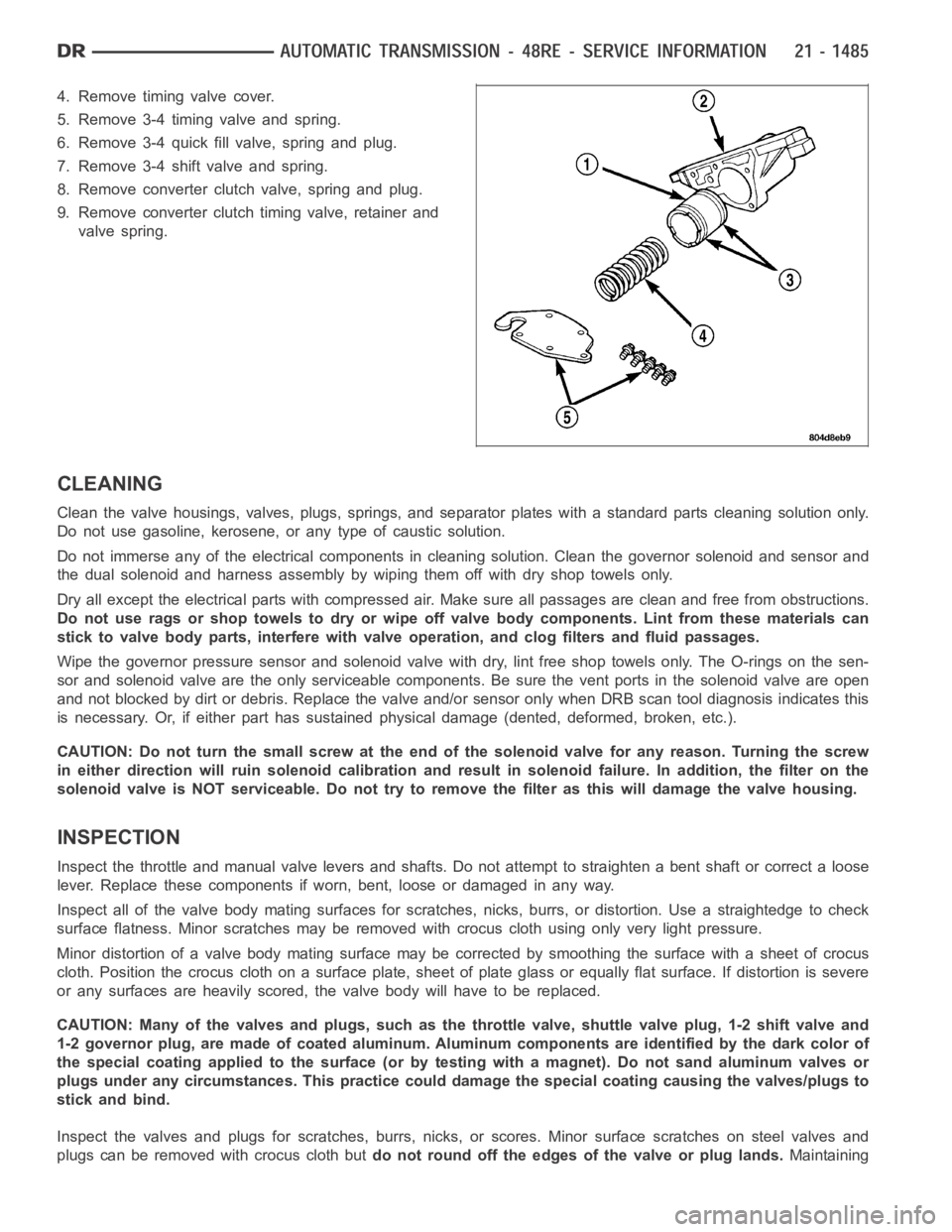

4. Remove timing valve cover.

5. Remove 3-4 timing valve and spring.

6. Remove 3-4 quick fill valve, spring and plug.

7. Remove 3-4 shift valve and spring.

8. Remove converter clutch valve, spring and plug.

9. Remove converter clutch timing valve, retainer and

valve spring.

CLEANING

Clean the valve housings, valves, plugs, springs, and separator plates with a standard parts cleaning solution only.

Do not use gasoline, kerosene, or any type of caustic solution.

Do not immerse any of the electrical components in cleaning solution. Clean the governor solenoid and sensor and

the dual solenoid and harness assembly by wiping them off with dry shop towels only.

Dry all except the electrical parts with compressed air. Make sure all passages are clean and free from obstructions.

Do not use rags or shop towels to dry or wipe off valve body components. Lint from these materials can

stick to valve body parts, interfere with valve operation, and clog filters and fluid passages.

Wipe the governor pressure sensor and solenoid valve with dry, lint free shop towels only. The O-rings on the sen-

sor and solenoid valve are the only serviceable components. Be sure the vent ports in the solenoid valve are open

and not blocked by dirt or debris. Replace the valve and/or sensor only whenDRB scan tool diagnosis indicates this

is necessary. Or, if either part has sustained physical damage (dented, deformed, broken, etc.).

CAUTION: Do not turn the small screw at the end of the solenoid valve for any reason. Turning the screw

in either direction will ruin solenoid calibration and result in solenoidfailure. In addition, the filter on the

solenoid valve is NOT serviceable. Do not try to remove the filter as this will damage the valve housing.

INSPECTION

Inspect the throttle and manual valve levers and shafts. Do not attempt to straighten a bent shaft or correct a loose

lever. Replace these components if worn, bent, loose or damaged in any way.

Inspect all of the valve body mating surfaces for scratches, nicks, burrs,or distortion. Use a straightedge to check

surface flatness. Minor scratches may be removed with crocus cloth using only very light pressure.

Minor distortion of a valve body mating surface may be corrected by smoothing the surface with a sheet of crocus

cloth. Position the crocus cloth on a surface plate, sheet of plate glass orequally flat surface. If distortion is severe

or any surfaces are heavily scored, the valve body will have to be replaced.

CAUTION: Many of the valves and plugs, such as the throttle valve, shuttle valve plug, 1-2 shift valve and

1-2 governor plug, are made of coated aluminum. Aluminum components are identified by the dark color of

thespecialcoatingappliedtothesurface(orbytestingwithamagnet).Donot sand aluminum valves or

plugs under any circumstances. This practice could damage the special coating causing the valves/plugs to

stick and bind.

Inspect the valves and plugs for scratches, burrs, nicks, or scores. Minorsurface scratches on steel valves and

plugs can be removed with crocus cloth butdo not round off the edges of the valve or plug lands.Maintaining

Page 4007 of 5267

sharpness of these edges is vitally important. The edges prevent foreign matter from lodging between the valves

and plugs and the bore.

Inspect all the valve and plug bores in the valve body. Use a penlight to viewthe bore interiors. Replace the valve

body if any bores are distorted or scored. Inspect all of the valve body springs. The springs must be free of dis-

tortion, warpage or broken coils.

Check the two separator plates for distortion or damage of any kind. Inspect the upper housing, lower housing, 3-4

accumulator housing, and transfer plate carefully. Be sure all fluid passages are clean and clear. Check condition of

the upper housing and transfer plate check balls as well. The check balls and ball seats must not be worn or dam-

aged.

Trial fit each valve and plug in its bore to check freedom of operation. Whenclean and dry, the valves and plugs

shoulddropfreelyintothebores.

Valve body bores do not change dimensionally with use. If the valve body functioned correctly when new, it will

continue to operate properly after cleaning and inspection. It should notbe necessary to replace a valve body

assembly unless it is damaged in handling.

The only serviceable valve body components are listed below. The remaining valve body components are serviced

only as part of a complete valve body assembly. Serviceable parts are:

dual solenoid and harness assembly

solenoid gasket

solenoid case connector O-rings and shoulder bolt

switch valve and spring

pressure adjusting screw and bracket assembly

throttle lever

manual lever and shaft seal

throttle lever shaft seal, washer, and E-clip

fluid filter and screws

detent ball and spring

valve body screws

governor pressure solenoid

governor pressure sensor and retaining clip

park lock rod and E-clip

ASSEMBLY

CAUTION: Do not force valves or plugs into place during reassembly. If the valve body bores, valves and

plugs are free of distortion or burrs, the valve body components should allslide into place easily. In addi-

tion, do not overtighten the transfer plate and valve body screws during reassembly. Overtightening can

distort the housings resulting in valve sticking, cross leakage and unsatisfactory operation. Tighten valve

body screws to recommended torque only.

Page 4017 of 5267

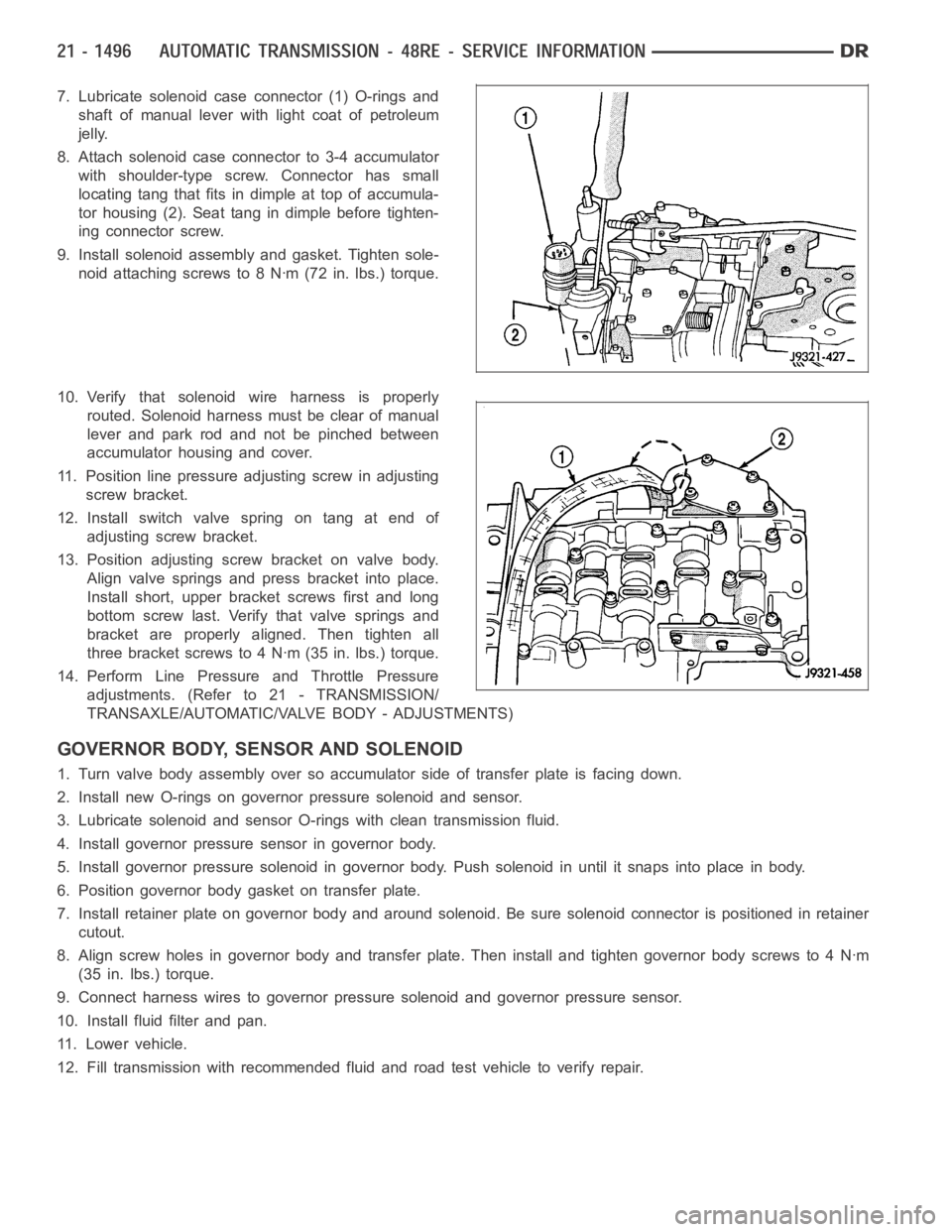

7. Lubricate solenoid case connector (1) O-rings and

shaft of manual lever with light coat of petroleum

jelly.

8. Attach solenoid case connector to 3-4 accumulator

with shoulder-type screw. Connector has small

locating tang that fits indimple at top of accumula-

tor housing (2). Seat tang in dimple before tighten-

ing connector screw.

9. Install solenoid assembly and gasket. Tighten sole-

noid attaching screws to 8 Nꞏm (72 in. lbs.) torque.

10. Verify that solenoid wire harness is properly

routed. Solenoid harness must be clear of manual

lever and park rod and not be pinched between

accumulator housing and cover.

11. Position line pressure adjusting screw in adjusting

screw bracket.

12. Install switch valve spring on tang at end of

adjusting screw bracket.

13. Position adjusting screw bracket on valve body.

Align valve springs and press bracket into place.

Install short, upper bracket screws first and long

bottom screw last. Verify that valve springs and

bracket are properly aligned. Then tighten all

three bracket screws to 4 Nꞏm (35 in. lbs.) torque.

14. Perform Line Pressure and Throttle Pressure

adjustments. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC/VALVE BODY - ADJUSTMENTS)

GOVERNOR BODY, SENSOR AND SOLENOID

1. Turn valve body assembly over so accumulator side of transfer plate is facing down.

2. Install new O-rings on governor pressure solenoid and sensor.

3. Lubricate solenoid and sensor O-rings with clean transmission fluid.

4. Install governor pressure sensor in governor body.

5. Install governor pressure solenoid in governor body. Push solenoid in until it snaps into place in body.

6. Position governor body gasket on transfer plate.

7. Install retainer plate on governor body and around solenoid. Be sure solenoid connector is positioned in retainer

cutout.

8. Align screw holes in governor body and transfer plate. Then install and tighten governor body screws to 4 Nꞏm

(35 in. lbs.) torque.

9. Connect harness wires to governor pressure solenoid and governor pressure sensor.

10. Install fluid filter and pan.

11. Lower vehicle.

12. Fill transmission with recommended fluid and road test vehicle to verify repair.

Page 4043 of 5267

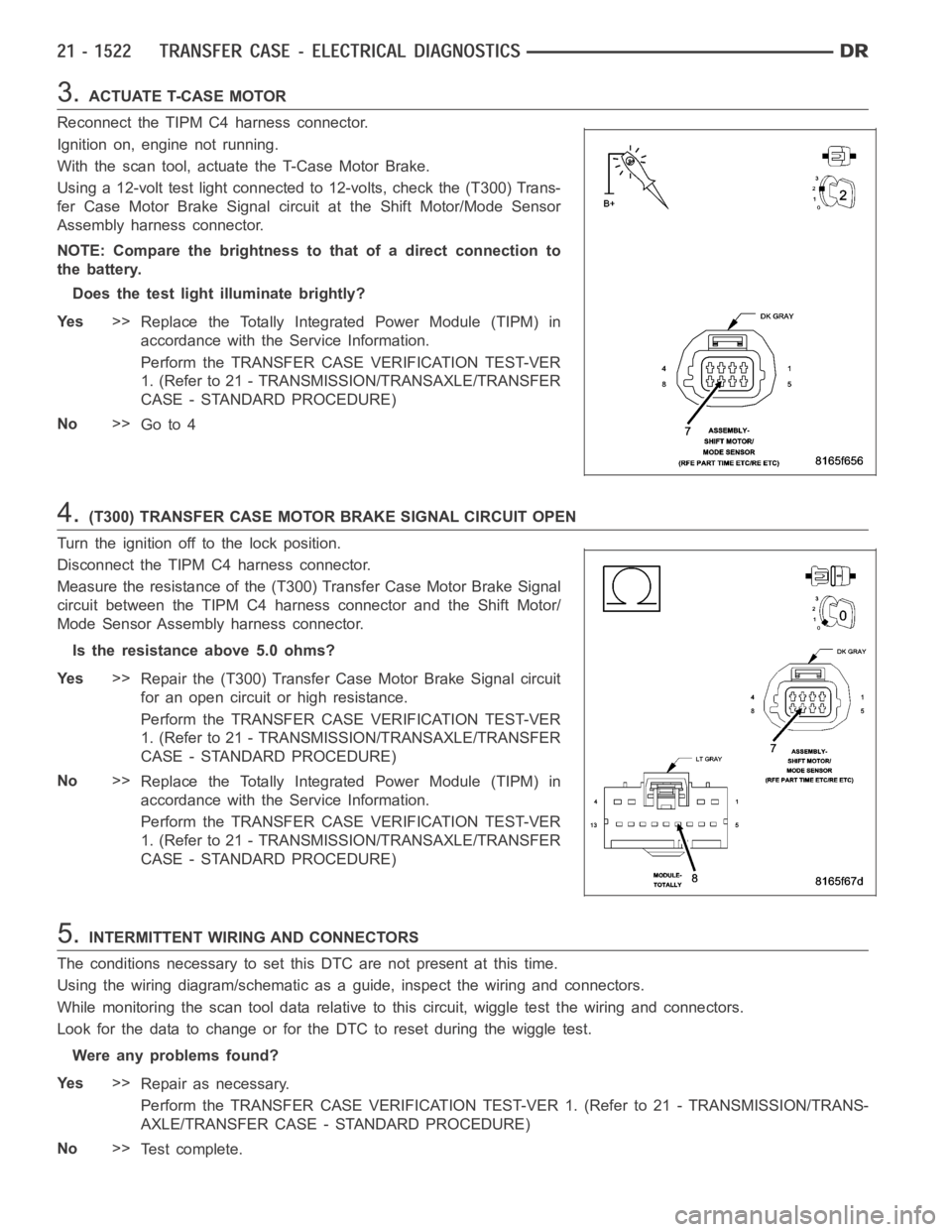

3.ACTUATE T-CASE MOTOR

Reconnect the TIPM C4 harness connector.

Ignition on, engine not running.

With the scan tool, actuate the T-Case Motor Brake.

Using a 12-volt test light connected to 12-volts, check the (T300) Trans-

fer Case Motor Brake Signal circuit at the Shift Motor/Mode Sensor

Assembly harness connector.

NOTE: Compare the brightness to that of a direct connection to

the battery.

Does the test light illuminate brightly?

Ye s>>

Replace the Totally Integrated Power Module (TIPM) in

accordance with the Service Information.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go to 4

4.(T300) TRANSFER CASE MOTOR BRAKE SIGNAL CIRCUIT OPEN

Turn the ignition off to the lock position.

Disconnect the TIPM C4 harness connector.

Measure the resistance of the (T300) Transfer Case Motor Brake Signal

circuit between the TIPM C4 harness connector and the Shift Motor/

Mode Sensor Assembly harness connector.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the (T300) Transfer Case Motor Brake Signal circuit

for an open circuit or high resistance.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module (TIPM) in

accordance with the Service Information.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

5.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the TRANSFER CASE VERIFICATION TEST-VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/TRANSFER CASE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .