light DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4340 of 5267

vehicle. If the leak occurs on left turns, hoist the left side of the vehicle. If the leak occurs on right turns, hoist

the right side of the vehicle. For hoisting recommendations (Refer to LUBRICATION & MAINTENANCE/HOIST-

ING - STANDARD PROCEDURE).

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water test and watch for water tracks or droplets forming on the inside of

the vehicle. If necessary, remove interior trim covers or panels to gain visual access to the leak area. If the hose

cannot be positioned without being held, have someone help do the water test.

Some water leaks must be tested for a considerable length of time to become apparent. When a leak appears, find

the highest point of the water track or drop. The highest point usually willshow the point of entry. After leak point

has been found, repair the leak and water test to verify that the leak has stopped.

Locating the entry point of water that is leaking into a cavity between panels can be difficult. The trapped water may

splash or run from the cavity, often at adistance from the entry point. Mostwater leaks of this type become appar-

ent after accelerating, stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use a suitable mirror to gainvisual access. A mirror can also be used

to deflect light to a limited-access area to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can be detected without water testing. Position the vehicle in a

brightly lit area. From inside the darkened luggage compartment inspect around seals and body seams. If neces-

sary, have a helper direct a drop light over the suspected leak areas aroundthe luggage compartment. If light is

visible through a normally sealed location, water could enter through theopening.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compartment cannot be detected by water testing, pressurize the passenger

compartment and soap test exterior ofthe vehicle. To pressurize the passenger compartment, close all doors and

windows, start engine, and set heater control to high blower in HEAT position. If engine can not be started, connect

a charger to the battery to ensure adequate voltage to the blower. With interior pressurized, apply dish detergent

solution to suspected leak area on the exterior of the vehicle. Apply detergent solution with spray device or soft

bristle brush. If soap bubbles occur at a body seam, joint, seal or gasket, the leak entry point could be at that

location.

WIND NOISE

Wind noise is the result of most air leaks. Air leaks can be caused by poor sealing, improper body component

alignment, body seam porosity, or missing plugs in the engine compartmentor door hinge pillar areas. All body

sealing points should be airtight in normal driving conditions. Moving sealing surfaces will not always seal airtight

under all conditions. At times, side glass or door seals will allow wind noise to be noticed in the passenger com-

partment during high cross winds. Over compensating on door or glass adjustments to stop wind noise that occurs

under severe conditions can cause premature seal wear and excessive closing or latching effort. After a repair pro-

cedure has been performed, test vehicle to verify noise has stopped beforereturning vehicle to use.

VISUAL INSPECTION BEFORE TESTS

Verify that floor and body plugs are in place and body components are aligned and sealed. If component alignment

or sealing is necessary, refer to the appropriate section of this group forproper procedures.

ROAD TESTING WIND NOISE

1. Drive the vehicle to verify the general location of the wind noise.

2. Apply 50 mm (2 in.) masking tape in 150 mm (6 in.) lengths along weatherstrips, weld seams or moldings. After

each length is applied, drive the vehicle. If noise goes away after a piece of tape is applied, remove tape, locate,

and repair defect.

Page 4344 of 5267

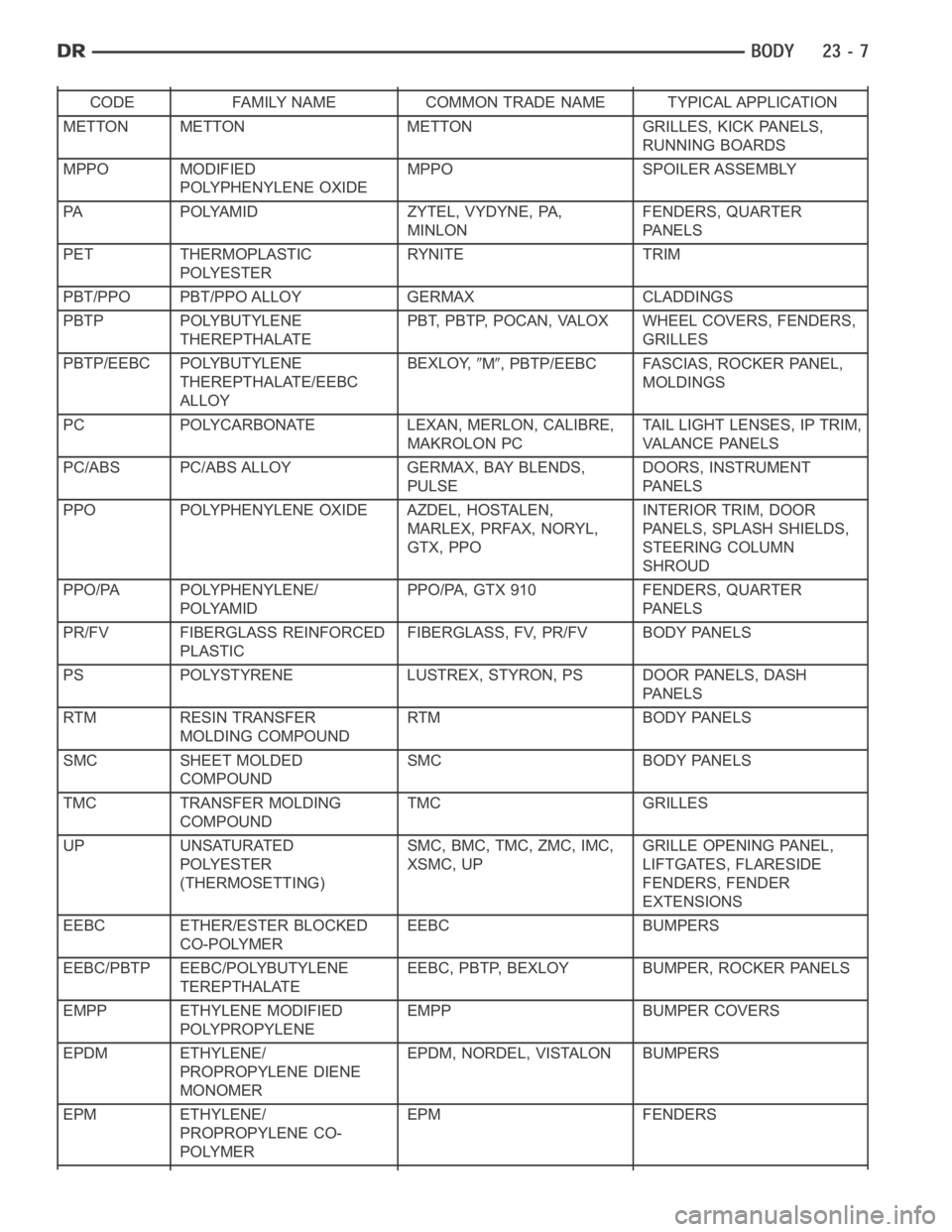

CODE FAMILY NAME COMMON TRADE NAME TYPICAL APPLICATION

METTON METTON METTON GRILLES, KICK PANELS,

RUNNING BOARDS

MPPO MODIFIED

POLYPHENYLENE OXIDEMPPO SPOILER ASSEMBLY

PA POLYAMID ZYTEL, VYDYNE, PA,

MINLONFENDERS, QUARTER

PA N E L S

PET THERMOPLASTIC

POLYESTERRYNITE TRIM

PBT/PPO PBT/PPO ALLOY GERMAX CLADDINGS

PBTP POLYBUTYLENE

THEREPTHALATEPBT, PBTP, POCAN, VALOX WHEEL COVERS, FENDERS,

GRILLES

PBTP/EEBC POLYBUTYLENE

THEREPTHALATE/EEBC

ALLOYBEXLOY,

M, PBTP/EEBC FASCIAS, ROCKER PANEL,

MOLDINGS

PC POLYCARBONATE LEXAN, MERLON, CALIBRE,

MAKROLON PCTAIL LIGHT LENSES, IP TRIM,

VA L A N C E PA N E L S

PC/ABS PC/ABS ALLOY GERMAX, BAY BLENDS,

PULSEDOORS, INSTRUMENT

PA N E L S

PPO POLYPHENYLENE OXIDE AZDEL, HOSTALEN,

MARLEX, PRFAX, NORYL,

GTX, PPOINTERIOR TRIM, DOOR

PANELS, SPLASH SHIELDS,

STEERING COLUMN

SHROUD

PPO/PA POLYPHENYLENE/

POLYAMIDPPO/PA, GTX 910 FENDERS, QUARTER

PA N E L S

PR/FV FIBERGLASS REINFORCED

PLASTICFIBERGLASS, FV, PR/FV BODY PANELS

PS POLYSTYRENE LUSTREX, STYRON, PS DOOR PANELS, DASH

PA N E L S

RTM RESIN TRANSFER

MOLDING COMPOUNDRTM BODY PANELS

SMC SHEET MOLDED

COMPOUNDSMC BODY PANELS

TMC TRANSFER MOLDING

COMPOUNDTMC GRILLES

UP UNSATURATED

POLYESTER

(THERMOSETTING)SMC, BMC, TMC, ZMC, IMC,

XSMC, UPGRILLE OPENING PANEL,

LIFTGATES, FLARESIDE

FENDERS, FENDER

EXTENSIONS

EEBC ETHER/ESTER BLOCKED

CO-POLYMEREEBC BUMPERS

EEBC/PBTP EEBC/POLYBUTYLENE

TEREPTHALATEEEBC, PBTP, BEXLOY BUMPER, ROCKER PANELS

EMPP ETHYLENE MODIFIED

POLYPROPYLENEEMPP BUMPER COVERS

EPDM ETHYLENE/

PROPROPYLENE DIENE

MONOMEREPDM, NORDEL, VISTALON BUMPERS

EPM ETHYLENE/

PROPROPYLENE CO-

POLYMEREPM FENDERS

Page 4345 of 5267

CODE FAMILY NAME COMMON TRADE NAME TYPICAL APPLICATION

MPU FOAM POLYURETHANE MPU SPOILERS

PE POLYETHYLENE ALATHON, DYLAN,

LUPOLEN, MARLEX—

PP POLYPROPYLENE

(BLENDS)NORYL, AZDEL, MARLOX,

DYLON, PRAVEXINNER FENDER, SPOILERS,

KICK PANELS

PP/EPDM PP/EPDM ALLOY PP/EPDM SPOILERS, GRILLES

PUR POLYURETHANE COLONELS, PUR, PU FASCIAS, BUMPERS

PUR/PC PUR/PC ALLOY TEXIN BUMPERS

PVC POLYVINYL CHLORIDE APEX, GEON, VINYLITE BODY MOLDINGS, WIRE

INSULATION, STEERING

WHEELS

RIM REACTION INJECTED

MOLDED POLYURETHANERIM, BAYFLEX FRONT FASCIAS, MODULAR

WINDOWS

RRIM REINFORCED REACTION

INJECTED MOLDEDPUR, RRIM FASCIAS, BODY PANELS,

BODY TRIMS

TPE THERMO POLYETHYLENE TPE, HYTREL, BEXLOY-V FASCIAS, BUMPERS,

CLADDINGS

TPO THERMOPOLYOLEFIN POLYTROPE, RENFLEX,

SANTOPRENE, VISAFLEX,

ETA, APEX, TPO, SHIELDS,

CLADDINGSBUMPERS, END CAPS,

TELCAR, RUBBER, STRIPS,

SIGHT, INTERIOR B POST

TPP THERMO-POLYPROPYLENE TPP BUMPERS

TPU THERMOPOLYURETHANE,

POLYESTERTPU, HYTREL, TEXIN,

ESTANEBUMPERS, BODY SIDE,

MOLDINGS, FENDERS,

FASCIAS

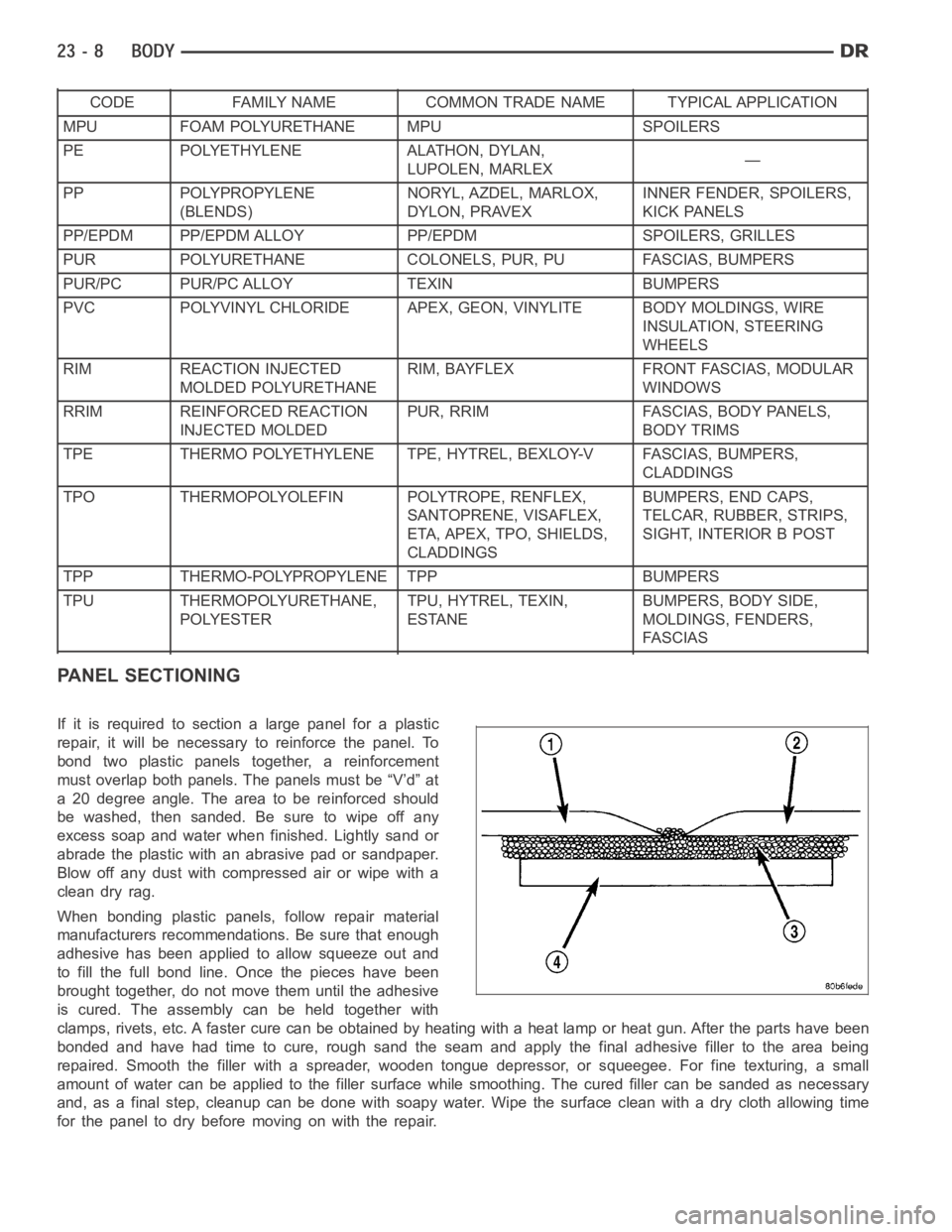

PANEL SECTIONING

If it is required to section a large panel for a plastic

repair, it will be necessary to reinforce the panel. To

bond two plastic panels together, a reinforcement

must overlap both panels. The panels must be “V’d” at

a 20 degree angle. The area to be reinforced should

be washed, then sanded. Be sure to wipe off any

excess soap and water when finished. Lightly sand or

abrade the plastic with an abrasive pad or sandpaper.

Blow off any dust with compressed air or wipe with a

clean dry rag.

When bonding plastic panels, follow repair material

manufacturers recommendations. Be sure that enough

adhesive has been applied to allow squeeze out and

to fill the full bond line. Once the pieces have been

brought together, do not move them until the adhesive

is cured. The assembly can be held together with

clamps, rivets, etc. A faster cure can be obtained by heating with a heat lamp or heat gun. After the parts have been

bonded and have had time to cure, rough sand the seam and apply the final adhesive filler to the area being

repaired. Smooth the filler with a spreader, wooden tongue depressor, or squeegee. For fine texturing, a small

amount of water can be applied to the filler surface while smoothing. The cured filler can be sanded as necessary

and, as a final step, cleanup can be done with soapy water. Wipe the surface clean with a dry cloth allowing time

for the panel to dry before moving on with the repair.

Page 4426 of 5267

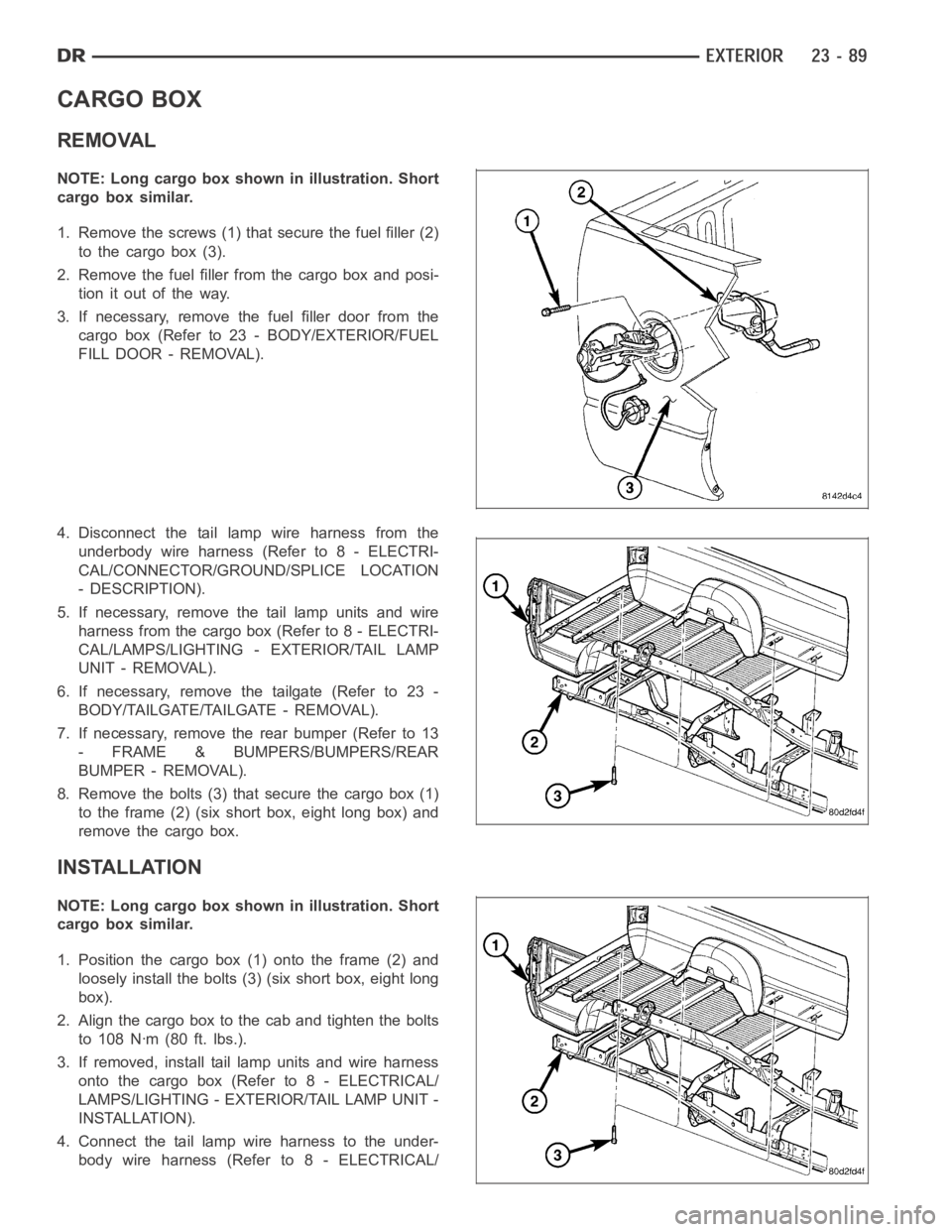

CARGO BOX

REMOVAL

NOTE: Long cargo box shown in illustration. Short

cargo box similar.

1. Remove the screws (1) that secure the fuel filler (2)

to the cargo box (3).

2. Remove the fuel filler from the cargo box and posi-

tionitoutoftheway.

3. If necessary, remove the fuel filler door from the

cargo box (Refer to 23 - BODY/EXTERIOR/FUEL

FILL DOOR - REMOVAL).

4. Disconnect the tail lamp wire harness from the

underbody wire harness (Refer to 8 - ELECTRI-

CAL/CONNECTOR/GROUND/SPLICE LOCATION

- DESCRIPTION).

5. If necessary, remove the tail lamp units and wire

harness from the cargo box (Refer to 8 - ELECTRI-

CAL/LAMPS/LIGHTING - EXTERIOR/TAIL LAMP

UNIT - REMOVAL).

6. If necessary, remove the tailgate (Refer to 23 -

BODY/TAILGATE/TAILGATE - REMOVAL).

7. If necessary, remove the rear bumper (Refer to 13

- FRAME & BUMPERS/BUMPERS/REAR

BUMPER - REMOVAL).

8. Remove the bolts (3) that secure the cargo box (1)

to the frame (2) (six short box, eight long box) and

remove the cargo box.

INSTALLATION

NOTE: Long cargo box shown in illustration. Short

cargo box similar.

1. Position the cargo box (1) onto the frame (2) and

loosely install the bolts (3) (six short box, eight long

box).

2. Align the cargo box to the cab and tighten the bolts

to 108 Nꞏm (80 ft. lbs.).

3. If removed, install tail lamp units and wire harness

onto the cargo box (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/TAIL LAMP UNIT -

INSTALLATION).

4. Connect the tail lamp wire harness to the under-

body wire harness (Refer to 8 - ELECTRICAL/

Page 4432 of 5267

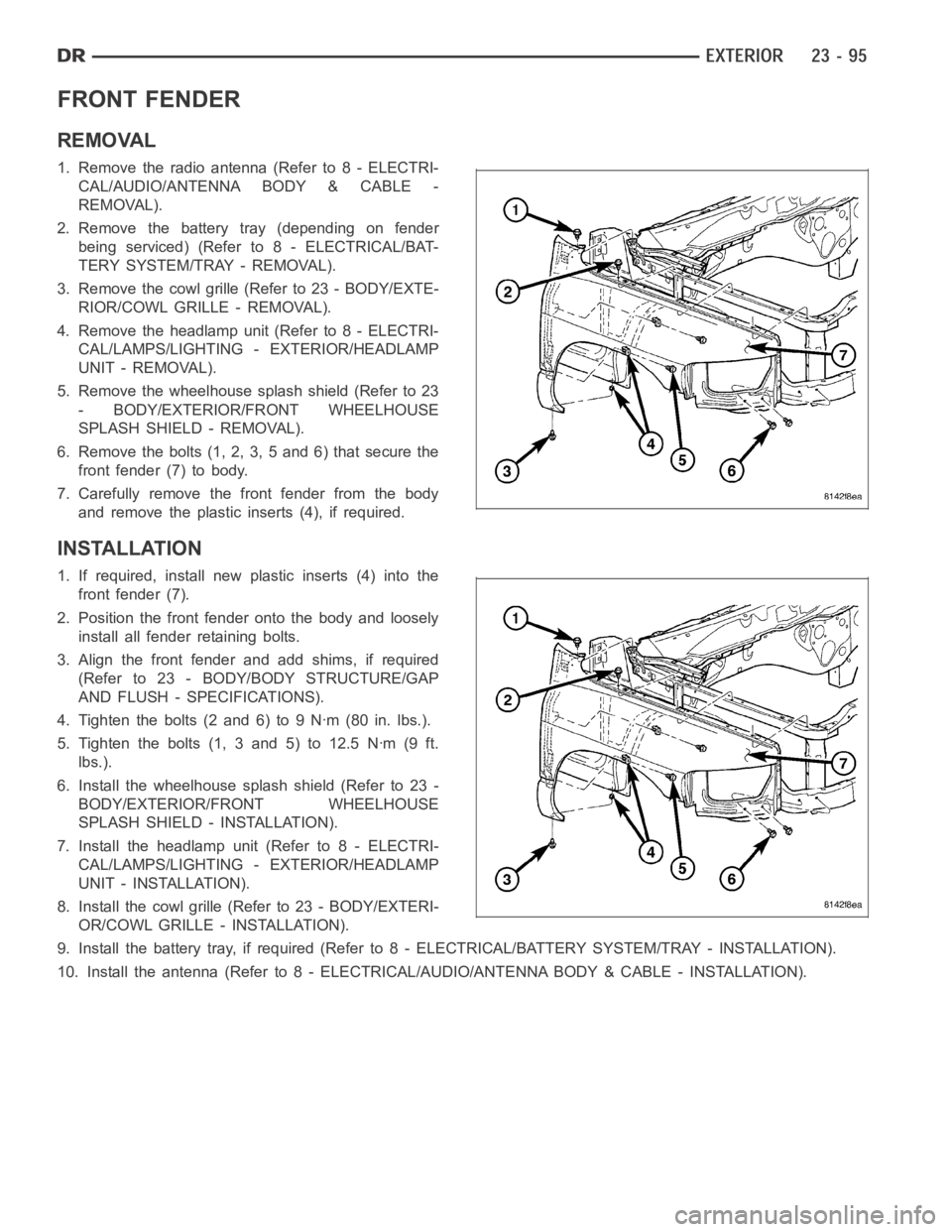

FRONT FENDER

REMOVAL

1. Remove the radio antenna (Refer to 8 - ELECTRI-

CAL/AUDIO/ANTENNA BODY & CABLE -

REMOVAL).

2. Remove the battery tray (depending on fender

beingserviced)(Referto8-ELECTRICAL/BAT-

TERY SYSTEM/TRAY - REMOVAL).

3. Remove the cowl grille (Refer to 23 - BODY/EXTE-

RIOR/COWL GRILLE - REMOVAL).

4. Remove the headlamp unit (Refer to 8 - ELECTRI-

CAL/LAMPS/LIGHTING - EXTERIOR/HEADLAMP

UNIT - REMOVAL).

5. Remove the wheelhouse splash shield (Refer to 23

- BODY/EXTERIOR/FRONT WHEELHOUSE

SPLASH SHIELD - REMOVAL).

6. Remove the bolts (1, 2, 3, 5 and 6) that secure the

front fender (7) to body.

7. Carefully remove the front fender from the body

and remove the plastic inserts (4), if required.

INSTALLATION

1. If required, install new plastic inserts (4) into the

front fender (7).

2. Position the front fender onto the body and loosely

install all fender retaining bolts.

3. Align the front fender and add shims, if required

(Refer to 23 - BODY/BODY STRUCTURE/GAP

AND FLUSH - SPECIFICATIONS).

4. Tighten the bolts (2 and 6) to 9 Nꞏm (80 in. lbs.).

5. Tighten the bolts (1, 3 and 5) to 12.5 Nꞏm (9 ft.

lbs.).

6. Install the wheelhouse splash shield (Refer to 23 -

BODY/EXTERIOR/FRONT WHEELHOUSE

SPLASH SHIELD - INSTALLATION).

7. Install the headlamp unit (Refer to 8 - ELECTRI-

CAL/LAMPS/LIGHTING - EXTERIOR/HEADLAMP

UNIT - INSTALLATION).

8. Install the cowl grille (Refer to 23 - BODY/EXTERI-

OR/COWL GRILLE - INSTALLATION).

9. Install the battery tray, if required (Refer to 8 - ELECTRICAL/BATTERY SYSTEM/TRAY - INSTALLATION).

10. Install the antenna (Refer to 8 - ELECTRICAL/AUDIO/ANTENNA BODY & CABLE - INSTALLATION).

Page 4436 of 5267

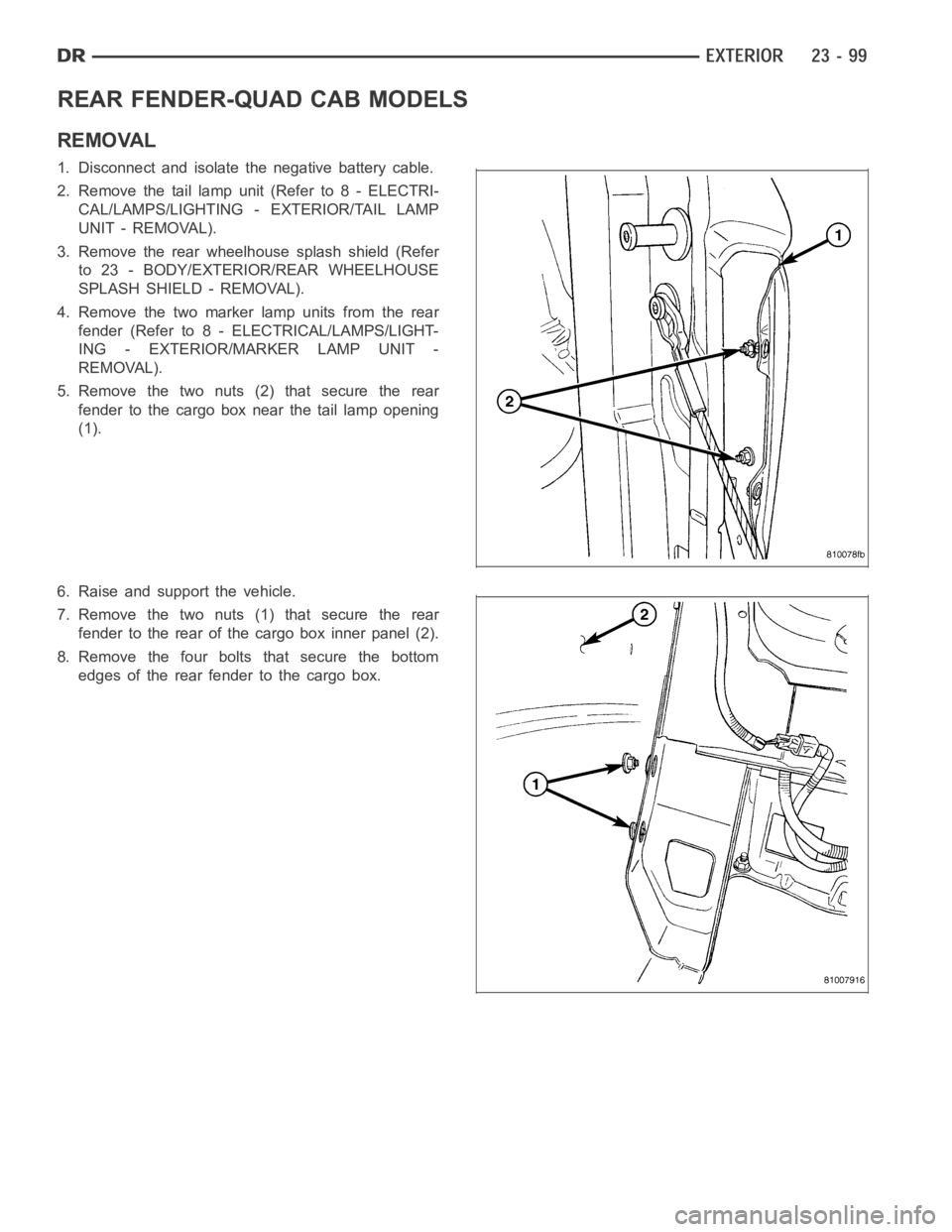

REAR FENDER-QUAD CAB MODELS

REMOVAL

1. Disconnect and isolate the negative battery cable.

2. Remove the tail lamp unit (Refer to 8 - ELECTRI-

CAL/LAMPS/LIGHTING - EXTERIOR/TAIL LAMP

UNIT - REMOVAL).

3. Remove the rear wheelhouse splash shield (Refer

to 23 - BODY/EXTERIOR/REAR WHEELHOUSE

SPLASH SHIELD - REMOVAL).

4. Remove the two marker lamp units from the rear

fender (Refer to 8 - ELECTRICAL/LAMPS/LIGHT-

ING - EXTERIOR/MARKER LAMP UNIT -

REMOVAL).

5. Remove the two nuts (2) that secure the rear

fender to the cargo box near the tail lamp opening

(1).

6. Raise and support the vehicle.

7. Remove the two nuts (1) that secure the rear

fender to the rear of the cargo box inner panel (2).

8. Remove the four bolts that secure the bottom

edges of the rear fender to the cargo box.

Page 4439 of 5267

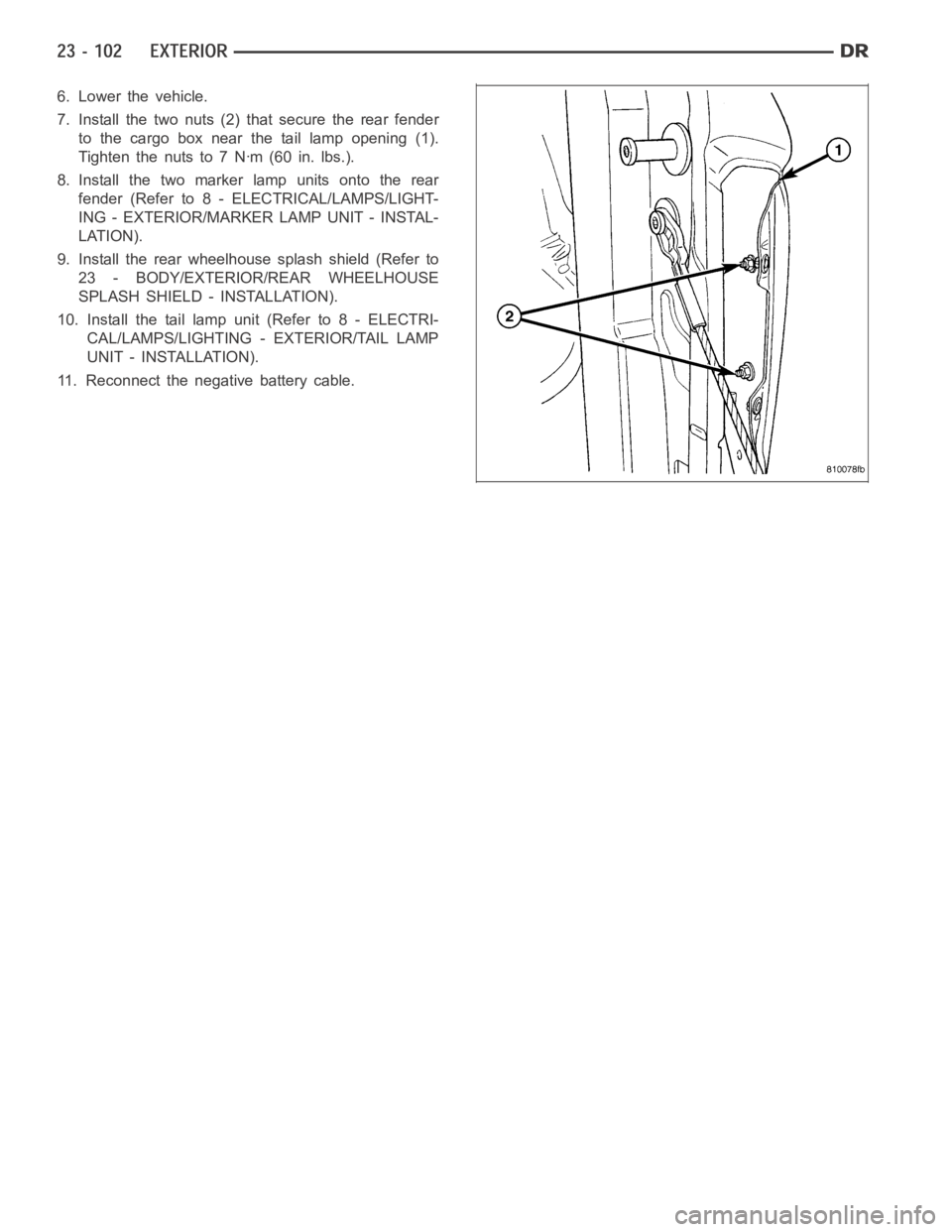

6. Lower the vehicle.

7. Install the two nuts (2) that secure the rear fender

to the cargo box near the tail lamp opening (1).

Tightenthenutsto7Nꞏm(60in.lbs.).

8. Install the two marker lamp units onto the rear

fender (Refer to 8 - ELECTRICAL/LAMPS/LIGHT-

ING - EXTERIOR/MARKER LAMP UNIT - INSTAL-

LATION).

9. Install the rear wheelhouse splash shield (Refer to

23 - BODY/EXTERIOR/REAR WHEELHOUSE

SPLASH SHIELD - INSTALLATION).

10. Install the tail lamp unit (Refer to 8 - ELECTRI-

CAL/LAMPS/LIGHTING - EXTERIOR/TAIL LAMP

UNIT - INSTALLATION).

11. Reconnect the negative battery cable.

Page 4469 of 5267

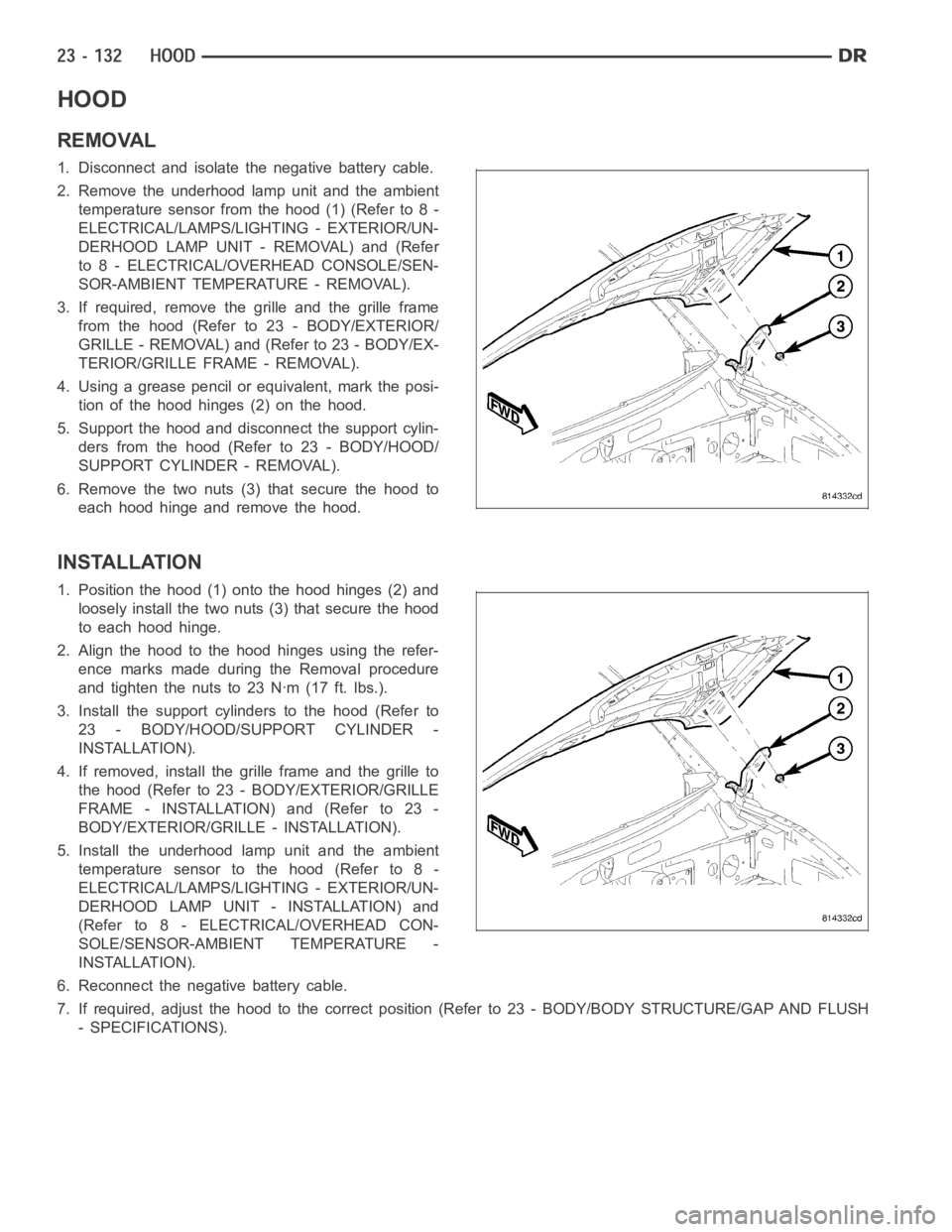

HOOD

REMOVAL

1. Disconnect and isolate the negative battery cable.

2. Remove the underhood lamp unit and the ambient

temperature sensor from the hood (1) (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/UN-

DERHOOD LAMP UNIT - REMOVAL) and (Refer

to 8 - ELECTRICAL/OVERHEAD CONSOLE/SEN-

SOR-AMBIENT TEMPERATURE - REMOVAL).

3. If required, remove the grille and the grille frame

from the hood (Refer to 23 - BODY/EXTERIOR/

GRILLE - REMOVAL) and (Refer to 23 - BODY/EX-

TERIOR/GRILLE FRAME - REMOVAL).

4. Using a grease pencil or equivalent, mark the posi-

tion of the hood hinges (2) on the hood.

5. Support the hood and disconnect the support cylin-

ders from the hood (Refer to 23 - BODY/HOOD/

SUPPORT CYLINDER - REMOVAL).

6. Remove the two nuts (3) that secure the hood to

each hood hinge and remove the hood.

INSTALLATION

1. Position the hood (1) onto the hood hinges (2) and

loosely install the two nuts (3) that secure the hood

to each hood hinge.

2. Align the hood to the hood hinges using the refer-

ence marks made during the Removal procedure

and tighten the nuts to 23 Nꞏm (17 ft. lbs.).

3. Install the support cylinders to the hood (Refer to

23 - BODY/HOOD/SUPPORT CYLINDER -

INSTALLATION).

4. If removed, install the grille frame and the grille to

the hood (Refer to 23 - BODY/EXTERIOR/GRILLE

FRAME - INSTALLATION) and (Refer to 23 -

BODY/EXTERIOR/GRILLE - INSTALLATION).

5. Install the underhood lamp unit and the ambient

temperature sensor to the hood (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/UN-

DERHOOD LAMP UNIT - INSTALLATION) and

(Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE/SENSOR-AMBIENT TEMPERATURE -

INSTALLATION).

6. Reconnect the negative battery cable.

7. If required, adjust the hood to the correct position (Refer to 23 - BODY/BODY STRUCTURE/GAP AND FLUSH

- SPECIFICATIONS).

Page 4539 of 5267

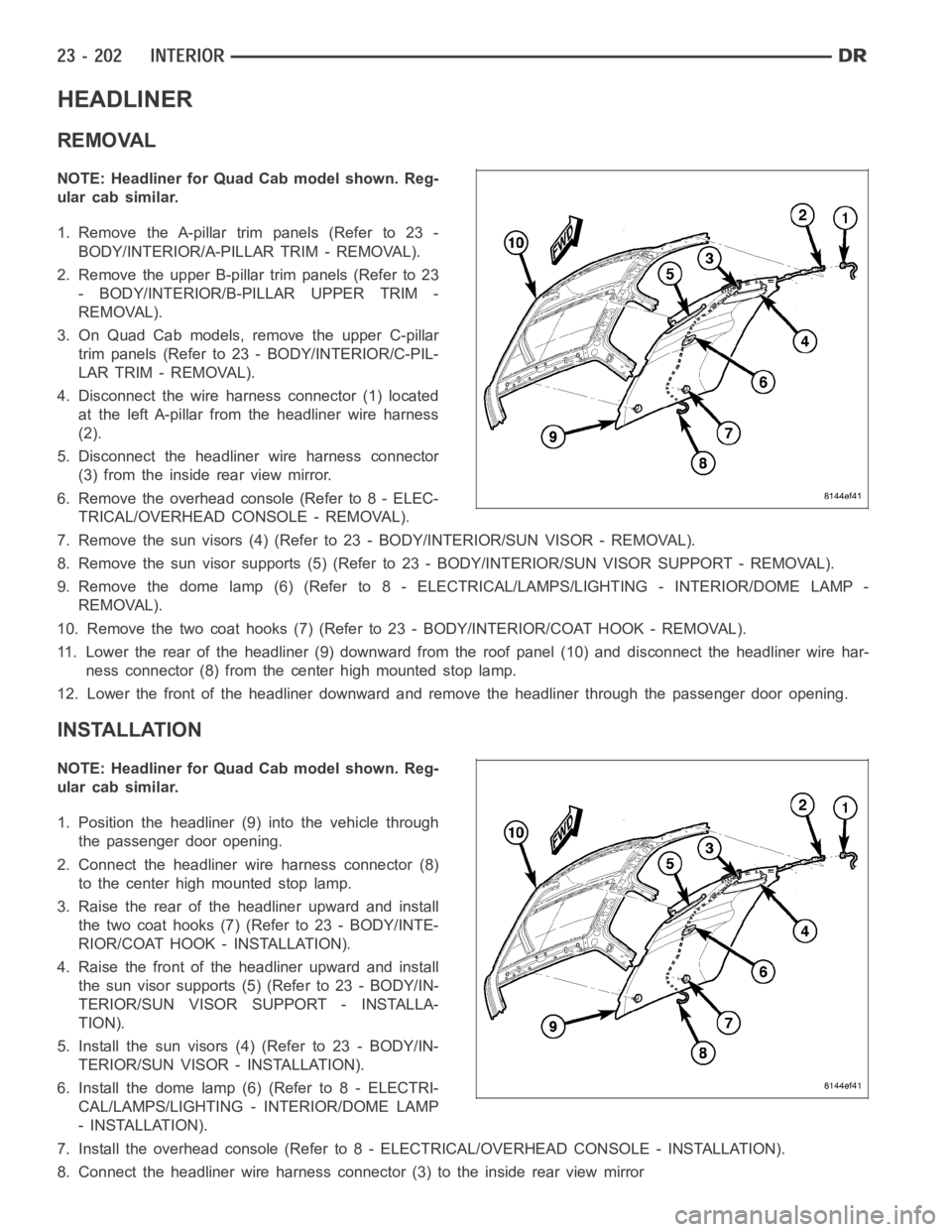

HEADLINER

REMOVAL

NOTE: Headliner for Quad Cab model shown. Reg-

ular cab similar.

1. Remove the A-pillar trim panels (Refer to 23 -

BODY/INTERIOR/A-PILLAR TRIM - REMOVAL).

2. Remove the upper B-pillar trim panels (Refer to 23

- BODY/INTERIOR/B-PILLAR UPPER TRIM -

REMOVAL).

3. On Quad Cab models, remove the upper C-pillar

trim panels (Refer to 23 - BODY/INTERIOR/C-PIL-

LAR TRIM - REMOVAL).

4. Disconnect the wire harness connector (1) located

at the left A-pillar from the headliner wire harness

(2).

5. Disconnect the headliner wire harness connector

(3) from the inside rear view mirror.

6. Remove the overhead console (Refer to 8 - ELEC-

TRICAL/OVERHEAD CONSOLE - REMOVAL).

7. Remove the sun visors (4) (Refer to 23 - BODY/INTERIOR/SUN VISOR - REMOVAL).

8. Remove the sun visor supports (5) (Refer to 23 - BODY/INTERIOR/SUN VISORSUPPORT - REMOVAL).

9. Remove the dome lamp (6) (Refer to 8 -ELECTRICAL/LAMPS/LIGHTING - INTERIOR/DOME LAMP -

REMOVAL).

10. Remove the two coat hooks (7) (Refer to 23 - BODY/INTERIOR/COAT HOOK - REMOVAL).

11. Lower the rear of the headliner (9) downward from the roof panel (10) anddisconnect the headliner wire har-

ness connector (8) from the center high mounted stop lamp.

12. Lower the front of the headliner downward and remove the headliner through the passenger door opening.

INSTALLATION

NOTE: Headliner for Quad Cab model shown. Reg-

ular cab similar.

1. Position the headliner (9) into the vehicle through

the passenger door opening.

2. Connect the headliner wire harness connector (8)

to the center high mounted stop lamp.

3. Raise the rear of the headliner upward and install

the two coat hooks (7) (Refer to 23 - BODY/INTE-

RIOR/COAT HOOK - INSTALLATION).

4. Raise the front of the headliner upward and install

the sun visor supports (5) (Refer to 23 - BODY/IN-

TERIOR/SUN VISOR SUPPORT - INSTALLA-

TION).

5. Install the sun visors (4) (Refer to 23 - BODY/IN-

TERIOR/SUN VISOR - INSTALLATION).

6. Install the dome lamp (6) (Refer to 8 - ELECTRI-

CAL/LAMPS/LIGHTING - INTERIOR/DOME LAMP

- INSTALLATION).

7. Install the overhead console (Refer to 8 - ELECTRICAL/OVERHEAD CONSOLE-INSTALLATION).

8. Connect the headliner wire harness connector (3) to the inside rear viewmirror

Page 4553 of 5267

PA I N T

SPECIFICATIONS

PA I N T C O D E S

CAUTION: Due to possible late model change of paint colors, always check each vehicle for its paint

code(s) (Refer to VEHICLE DATA/VEHICLE INFORMATION/VEHICLE CERTIFICATION LABEL - DESCRIPTION)

or (Refer to VEHICLE DATA/VEHICLE INFORMATION/BODY CODE PLATE - DESCRIPTION) and (Refer to 23 -

BODY/PAINT/PAINT CODE - DESCRIPTION).

EXTERIOR COLORS

EXTERIOR COLOR DAIMLERCHRYSLER CODE

Inferno Red Crystal Pearlcoat ARH/ARJ

Flame Red Clearcoat PR4

Light Khaki Clearcoat AJC

Atlantic Blue Pearlcoat ZBJ

Patriot Blue Pearlcoat WBT/WB7

Bright Silver Metallic Clearcoat WSB/WS2

Mineral Gray Metallic Clearcoat CDM

Black Clearcoat DX8

Bright White Clearcoat GW7

INTERIOR COLORS

INTERIOR COLOR DAIMLERCHRYSLER CODE

Medium Slate Gray D5

Khaki J3