light DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4062 of 5267

When Monitored:

The ignition on, with the T-Case Switch in a 4W/LO position.

Set Condition:

The TIPM detects the Front Axle Lock Control circuit is shorted low.

Possible Causes

(G304) FRONT AXLE LOCK CONTROL CIRCUIT SHORTED TO GROUND

FRONT AXLE DISCONNECT (FAD) MODULE

TOTALLY INTEGRATED POWER MODULE (TIPM)

Diagnostic Test

1.ACTIVE DTC

CAUTION: Before removing the TIPM harness connectors, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasingor installing the harness con-

nector.

Ignition on, engine not running.

With the scan tool, read the TIPM DTCs.

Is the status Active for this DTC?

Ye s>>

Go To 2

No>>

Go To 6

2.(G304) FRONT AXLE LOCK CONTROL CIRCUIT

Turn the ignition off to the lock position.

Disconnect the FAD harness connector.

Ignition on, engine not running.

With the scan tool, actuate the Front Axle Lock Control in the TIPM.

Using a 12-volt test light connected to 12-volts, check the (G304) Front Axle Lock Control circuit in the FAD harness

connector.

Does the test light illuminate brightly?

Ye s>>

Go To 5

No>>

Go To 3

Page 4070 of 5267

When Monitored:

The ignition on, with the T-Case Switch in 4W/LO position.

Set Condition:

The TIPM detects the Front Axle Lock Signal circuit is shorted low.

Possible Causes

(A880) FUSED B+ CIRCUIT OPEN

(G303) FRONT AXLE LOCK SIGNAL CIRCUIT OPEN

(G304) FRONT AXLE LOCK CONTROL CIRCUIT OPEN

FRONT AXLE DISCONNECT (FAD) MODULE

TOTALLY INTEGRATED POWER MODULE (TIPM)

Diagnostic Test

1.ACTIVE DTC

CAUTION: Before removing the TIPM harness connectors, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasingor installing the harness con-

nector.

Ignition on, engine not running.

With the scan tool, read the TIPM DTCs.

Is the DTC currently active?

Ye s>>

Go To 2

No>>

Go To 6

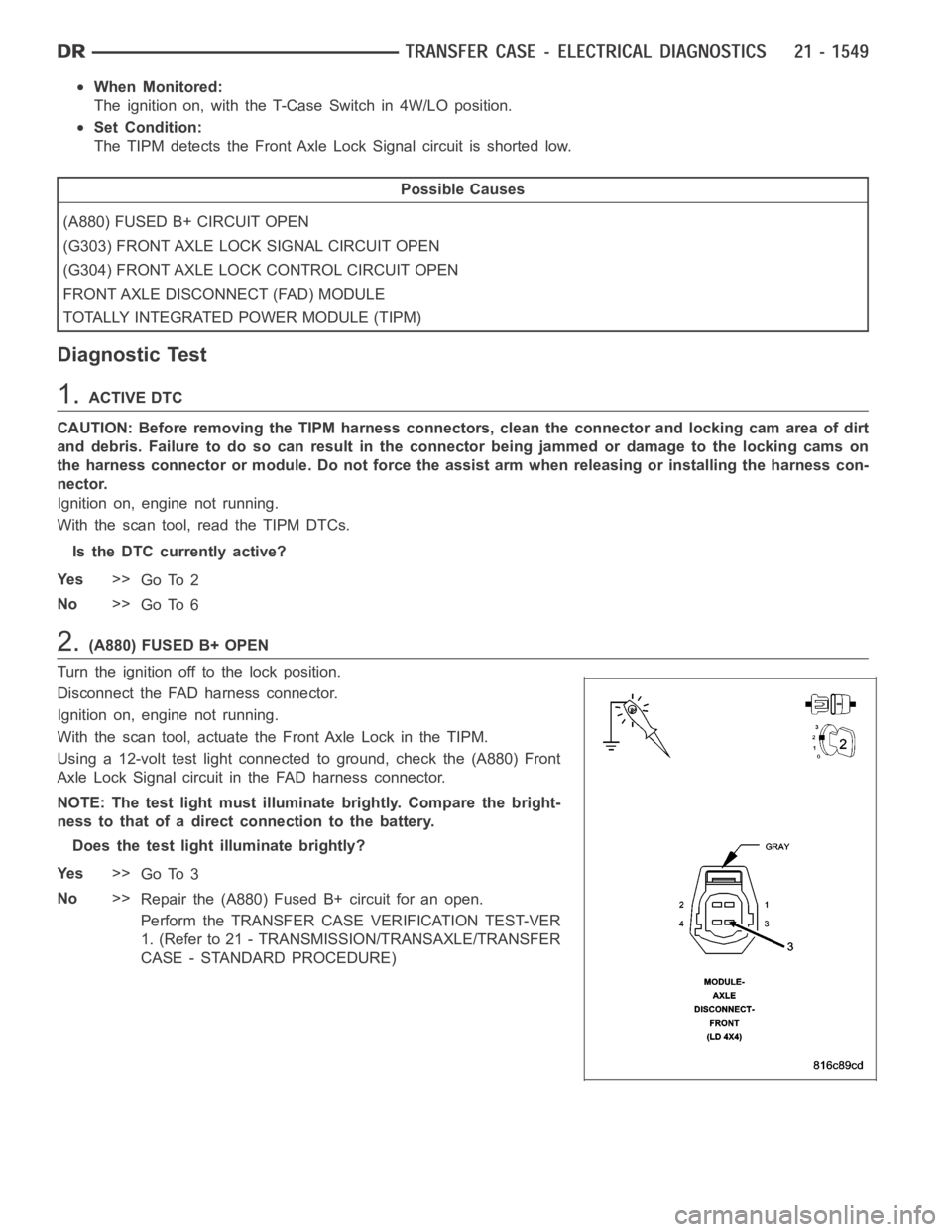

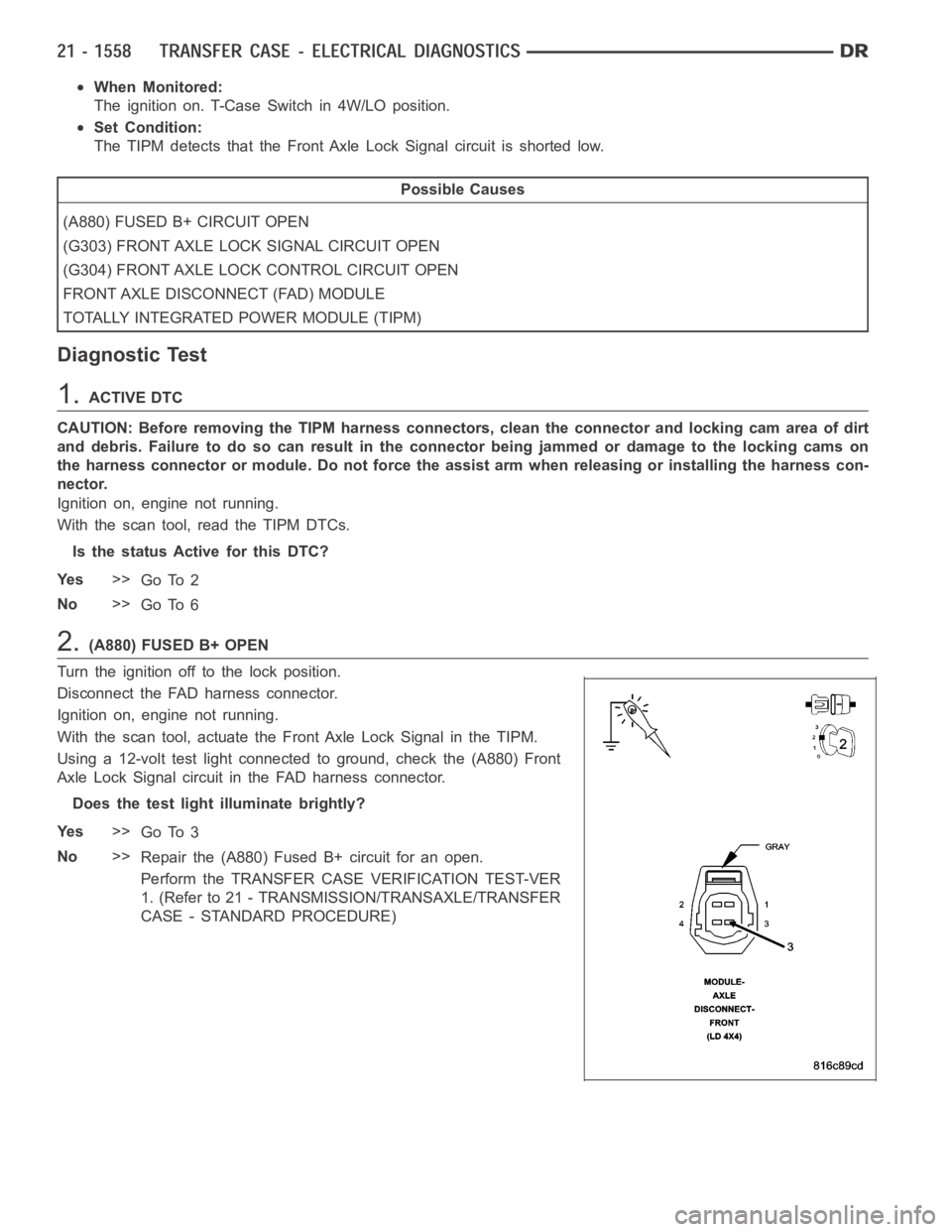

2.(A880) FUSED B+ OPEN

Turn the ignition off to the lock position.

Disconnect the FAD harness connector.

Ignition on, engine not running.

With the scan tool, actuate the Front Axle Lock in the TIPM.

Using a 12-volt test light connected to ground, check the (A880) Front

Axle Lock Signal circuit in the FAD harness connector.

NOTE: The test light must illuminate brightly. Compare the bright-

ness to that of a direct connection to the battery.

Does the test light illuminate brightly?

Ye s>>

Go To 3

No>>

Repair the (A880) Fused B+ circuit for an open.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

Page 4071 of 5267

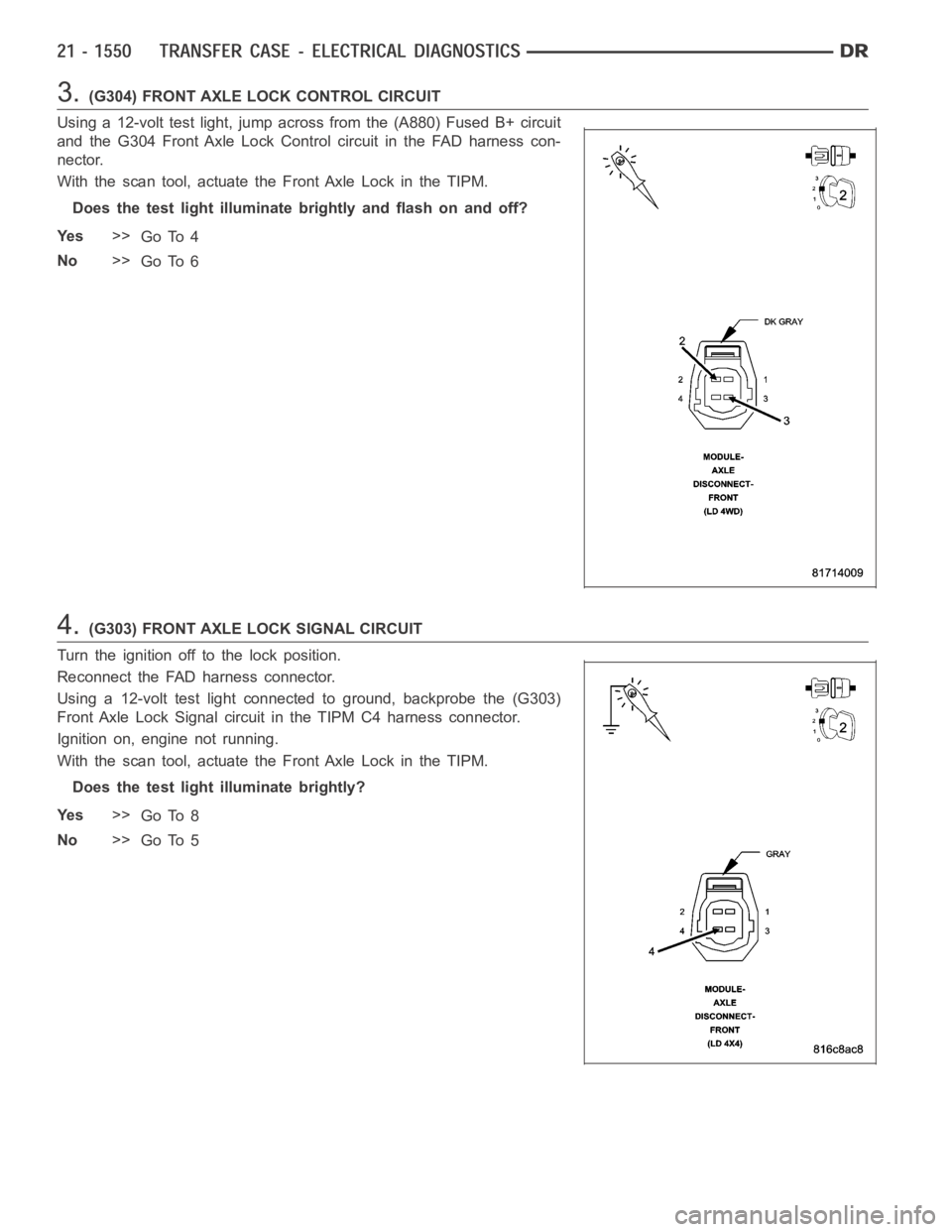

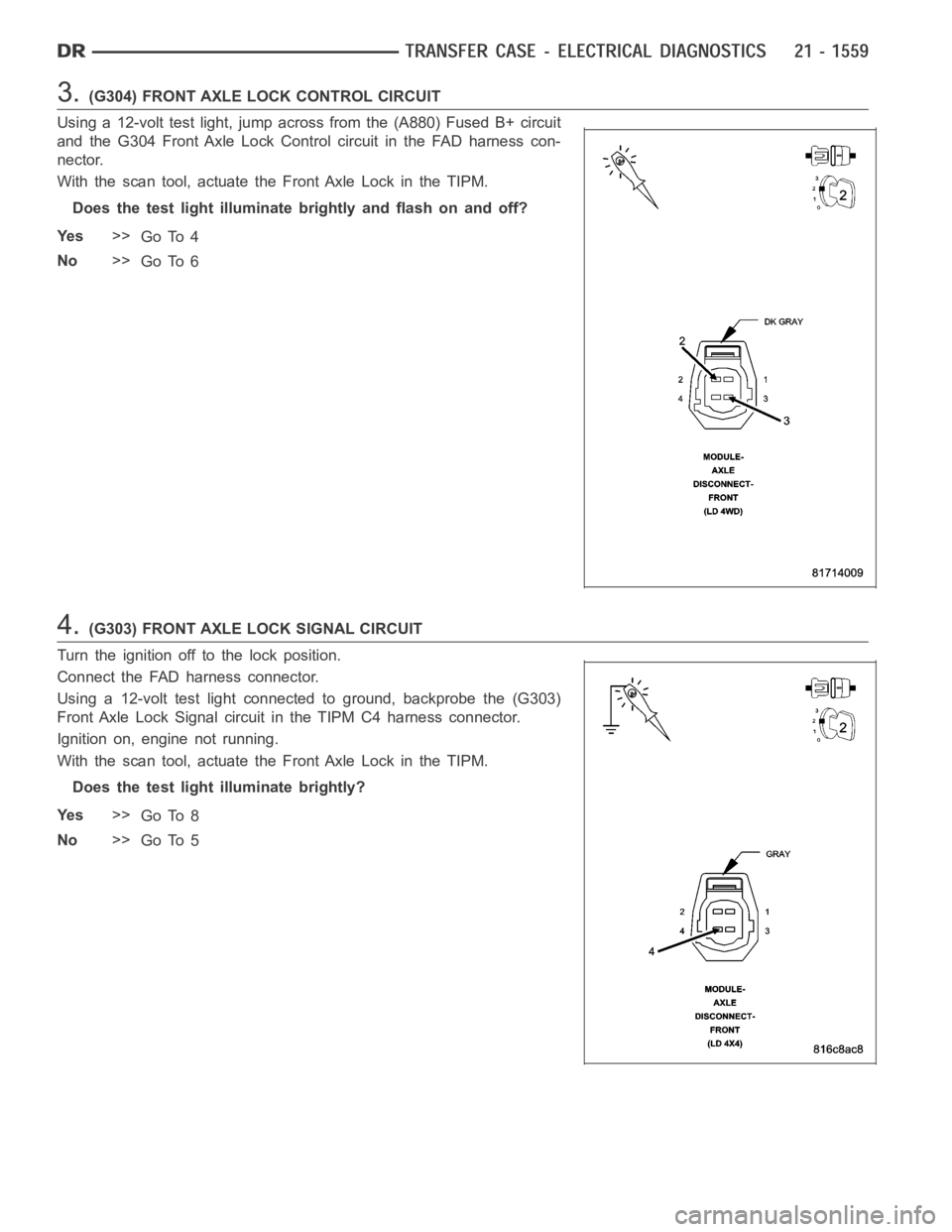

3.(G304) FRONT AXLE LOCK CONTROL CIRCUIT

Using a 12-volt test light, jump across from the (A880) Fused B+ circuit

and the G304 Front Axle Lock Control circuit in the FAD harness con-

nector.

With the scan tool, actuate the Front Axle Lock in the TIPM.

Does the test light illuminate brightly and flash on and off?

Ye s>>

Go To 4

No>>

Go To 6

4.(G303) FRONT AXLE LOCK SIGNAL CIRCUIT

Turn the ignition off to the lock position.

Reconnect the FAD harness connector.

Using a 12-volt test light connected to ground, backprobe the (G303)

Front Axle Lock Signal circuit in the TIPM C4 harness connector.

Ignition on, engine not running.

With the scan tool, actuate the Front Axle Lock in the TIPM.

Does the test light illuminate brightly?

Ye s>>

Go To 8

No>>

Go To 5

Page 4076 of 5267

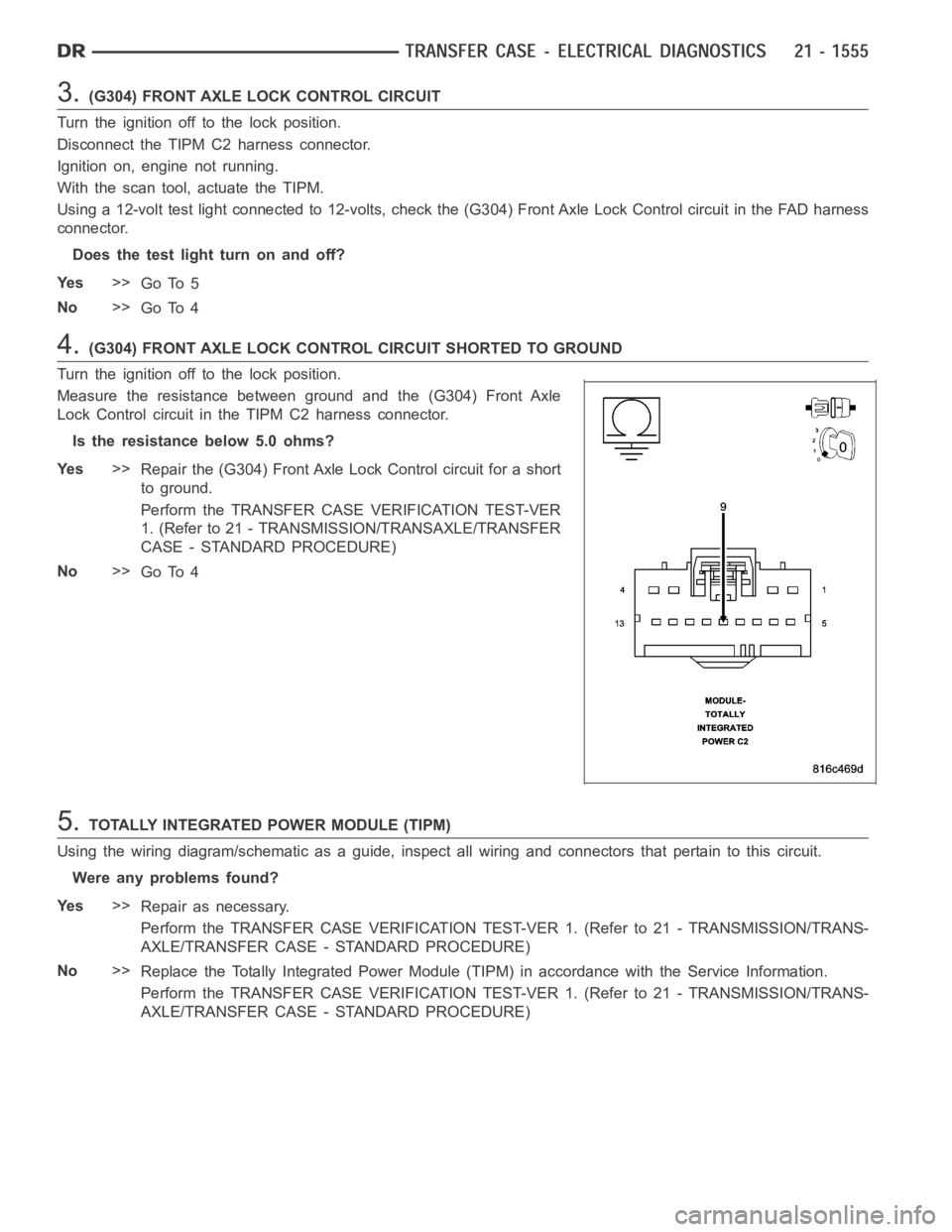

3.(G304) FRONT AXLE LOCK CONTROL CIRCUIT

Turn the ignition off to the lock position.

Disconnect the TIPM C2 harness connector.

Ignition on, engine not running.

With the scan tool, actuate the TIPM.

Using a 12-volt test light connected to 12-volts, check the (G304) Front Axle Lock Control circuit in the FAD harness

connector.

Does the test light turn on and off?

Ye s>>

Go To 5

No>>

Go To 4

4.(G304) FRONT AXLE LOCK CONTROL CIRCUIT SHORTED TO GROUND

Turn the ignition off to the lock position.

Measure the resistance between ground and the (G304) Front Axle

Lock Control circuit in the TIPM C2 harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the (G304) Front Axle Lock Control circuit for a short

to ground.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go To 4

5.TOTALLY INTEGRATED POWER MODULE (TIPM)

Using the wiring diagram/schematic as a guide, inspect all wiring and connectors that pertain to this circuit.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the TRANSFER CASE VERIFICATION TEST-VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/TRANSFER CASE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module (TIPM) in accordance with theService Information.

Perform the TRANSFER CASE VERIFICATION TEST-VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/TRANSFER CASE - STANDARD PROCEDURE)

Page 4079 of 5267

When Monitored:

The ignition on. T-Case Switch in 4W/LO position.

Set Condition:

The TIPM detects that the Front Axle Lock Signal circuit is shorted low.

Possible Causes

(A880) FUSED B+ CIRCUIT OPEN

(G303) FRONT AXLE LOCK SIGNAL CIRCUIT OPEN

(G304) FRONT AXLE LOCK CONTROL CIRCUIT OPEN

FRONT AXLE DISCONNECT (FAD) MODULE

TOTALLY INTEGRATED POWER MODULE (TIPM)

Diagnostic Test

1.ACTIVE DTC

CAUTION: Before removing the TIPM harness connectors, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasingor installing the harness con-

nector.

Ignition on, engine not running.

With the scan tool, read the TIPM DTCs.

Is the status Active for this DTC?

Ye s>>

Go To 2

No>>

Go To 6

2.(A880) FUSED B+ OPEN

Turn the ignition off to the lock position.

Disconnect the FAD harness connector.

Ignition on, engine not running.

With the scan tool, actuate the Front Axle Lock Signal in the TIPM.

Using a 12-volt test light connected to ground, check the (A880) Front

Axle Lock Signal circuit in the FAD harness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 3

No>>

Repair the (A880) Fused B+ circuit for an open.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

Page 4080 of 5267

3.(G304) FRONT AXLE LOCK CONTROL CIRCUIT

Using a 12-volt test light, jump across from the (A880) Fused B+ circuit

and the G304 Front Axle Lock Control circuit in the FAD harness con-

nector.

With the scan tool, actuate the Front Axle Lock in the TIPM.

Does the test light illuminate brightly and flash on and off?

Ye s>>

Go To 4

No>>

Go To 6

4.(G303) FRONT AXLE LOCK SIGNAL CIRCUIT

Turn the ignition off to the lock position.

Connect the FAD harness connector.

Using a 12-volt test light connected to ground, backprobe the (G303)

Front Axle Lock Signal circuit in the TIPM C4 harness connector.

Ignition on, engine not running.

With the scan tool, actuate the Front Axle Lock in the TIPM.

Does the test light illuminate brightly?

Ye s>>

Go To 8

No>>

Go To 5

Page 4216 of 5267

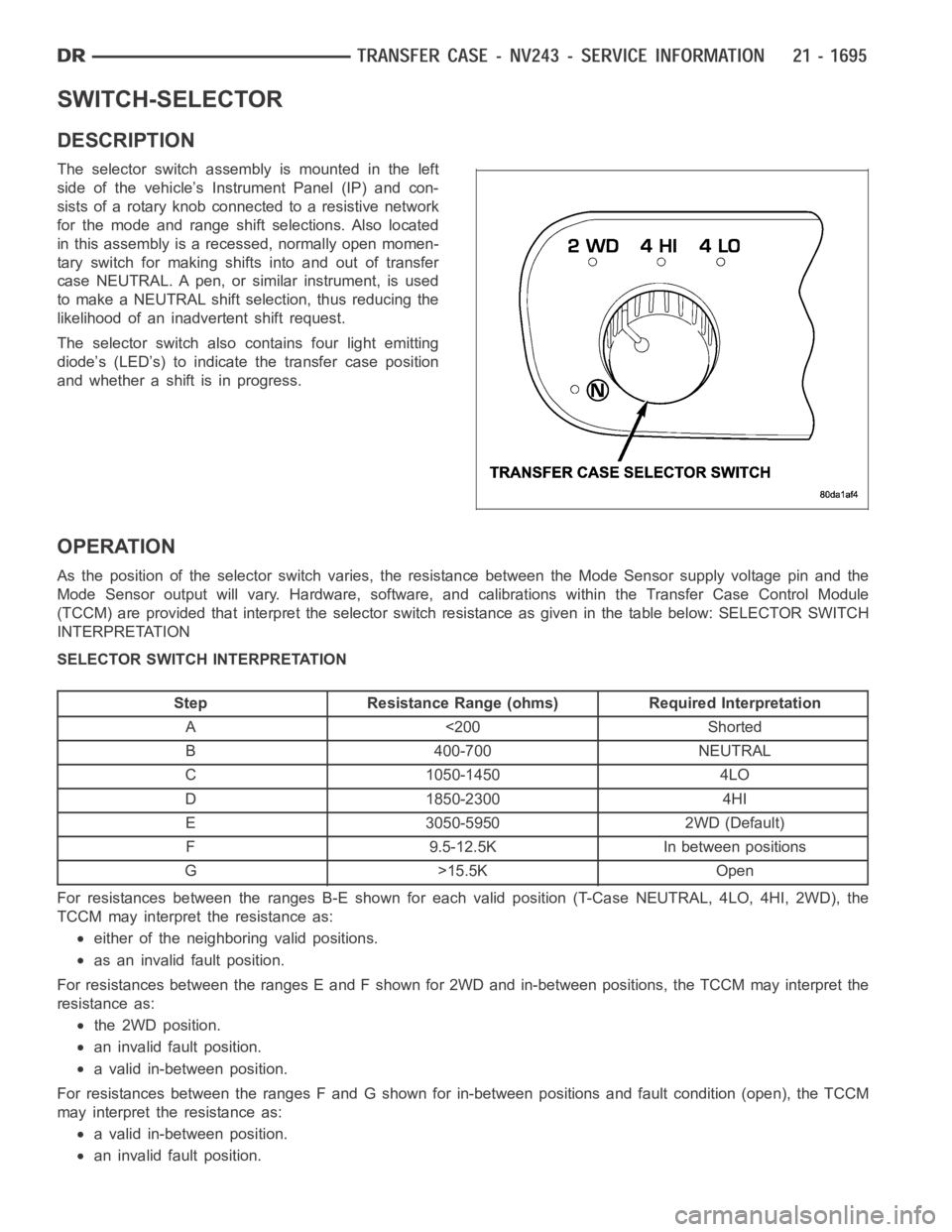

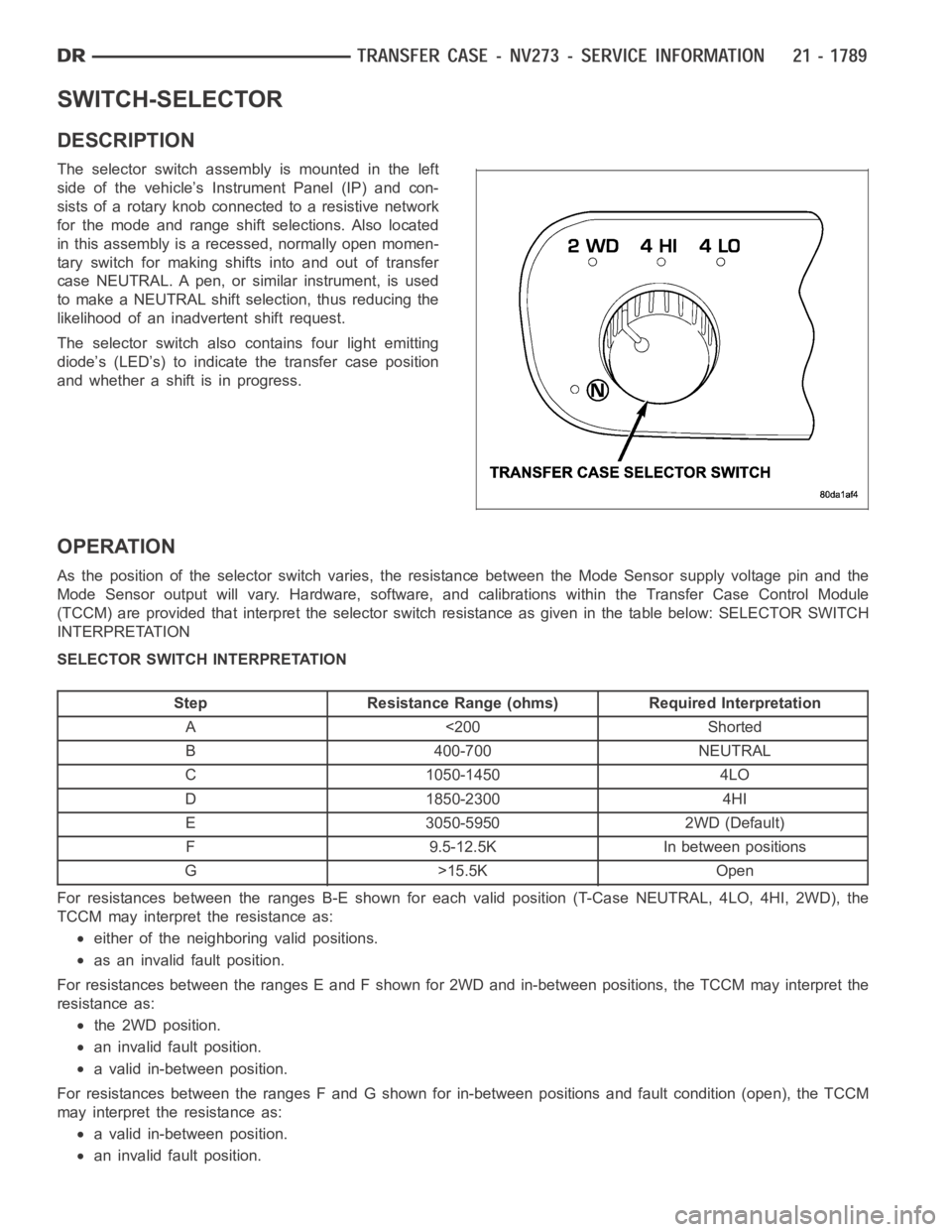

SWITCH-SELECTOR

DESCRIPTION

The selector switch assembly is mounted in the left

side of the vehicle’s Instrument Panel (IP) and con-

sists of a rotary knob connected to a resistive network

for the mode and range shift selections. Also located

in this assembly is a recessed, normally open momen-

tary switch for making shifts into and out of transfer

case NEUTRAL. A pen, or similar instrument, is used

to make a NEUTRAL shift selection, thus reducing the

likelihood of an inadvertent shift request.

The selector switch also contains four light emitting

diode’s (LED’s) to indicate the transfer case position

and whether a shift is in progress.

OPERATION

As the position of the selector switchvaries, the resistance between the Mode Sensor supply voltage pin and the

Mode Sensor output will vary. Hardware, software, and calibrations within the Transfer Case Control Module

(TCCM) are provided that interpret the selector switch resistance as giveninthetablebelow:SELECTORSWITCH

INTERPRETATION

SELECTOR SWITCH INTERPRETATION

Step Resistance Range (ohms) Required Interpretation

A <200 Shorted

B 400-700 NEUTRAL

C 1050-1450 4LO

D 1850-2300 4HI

E 3050-5950 2WD (Default)

F 9.5-12.5K In between positions

G>15.5KOpen

For resistances between the ranges B-E shown for each valid position (T-Case NEUTRAL, 4LO, 4HI, 2WD), the

TCCM may interpret the resistance as:

either of the neighboring valid positions.

as an invalid fault position.

For resistances between the ranges E and F shown for 2WD and in-between positions, the TCCM may interpret the

resistance as:

the 2WD position.

an invalid fault position.

a valid in-between position.

For resistances between the ranges F and G shown for in-between positions and fault condition (open), the TCCM

may interpret the resistance as:

a valid in-between position.

an invalid fault position.

Page 4260 of 5267

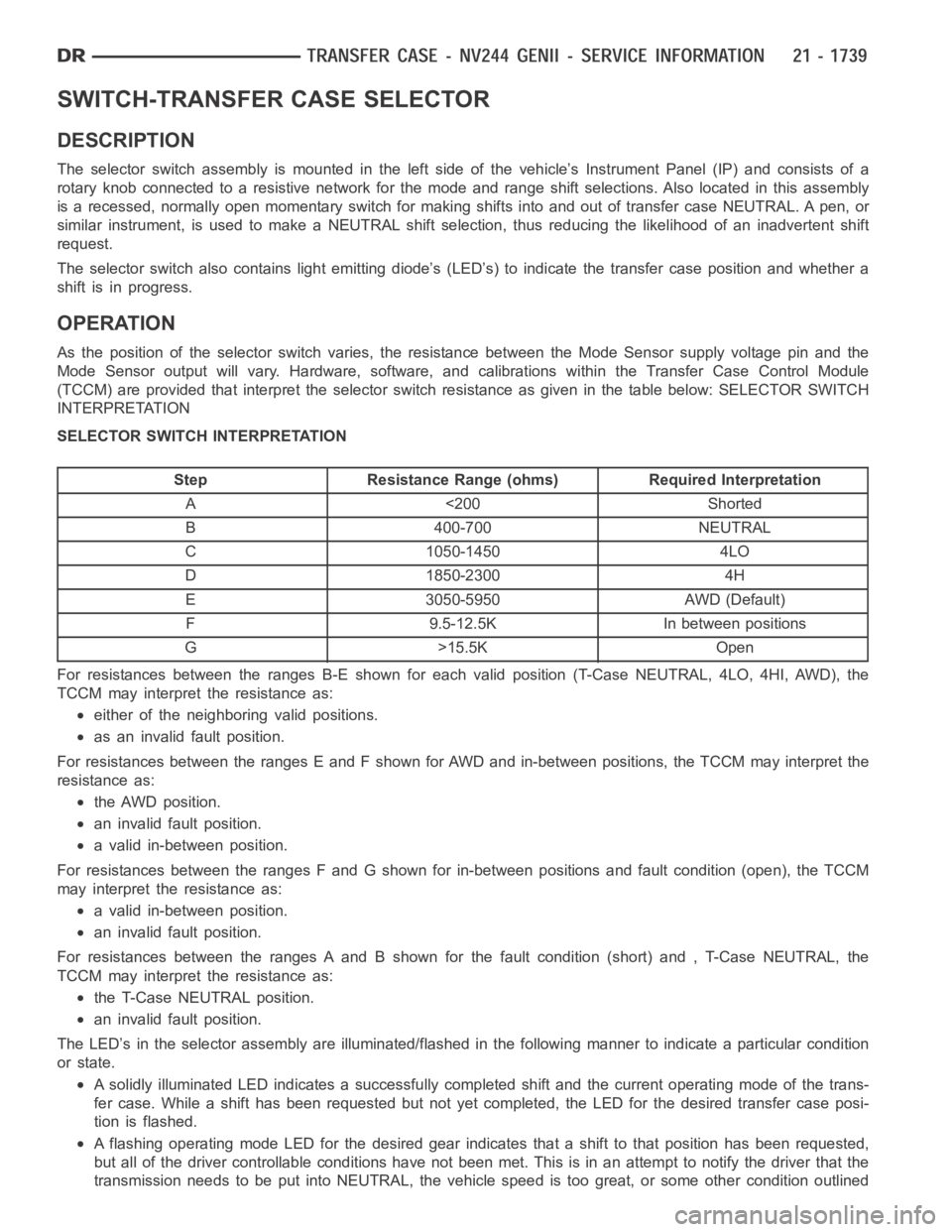

SWITCH-TRANSFER CASE SELECTOR

DESCRIPTION

The selector switch assembly is mounted in the left side of the vehicle’s Instrument Panel (IP) and consists of a

rotary knob connected to a resistive network for the mode and range shift selections. Also located in this assembly

is a recessed, normally open momentary switch for making shifts into and out of transfer case NEUTRAL. A pen, or

similar instrument, is used to make a NEUTRAL shift selection, thus reducing the likelihood of an inadvertent shift

request.

The selector switch also contains light emitting diode’s (LED’s) to indicate the transfer case position and whether a

shift is in progress.

OPERATION

As the position of the selector switchvaries, the resistance between the Mode Sensor supply voltage pin and the

Mode Sensor output will vary. Hardware, software, and calibrations within the Transfer Case Control Module

(TCCM) are provided that interpret the selector switch resistance as giveninthetablebelow:SELECTORSWITCH

INTERPRETATION

SELECTOR SWITCH INTERPRETATION

Step Resistance Range (ohms) Required Interpretation

A <200 Shorted

B 400-700 NEUTRAL

C 1050-1450 4LO

D 1850-2300 4H

E 3050-5950 AWD (Default)

F 9.5-12.5K In between positions

G>15.5KOpen

For resistances between the ranges B-E shown for each valid position (T-Case NEUTRAL, 4LO, 4HI, AWD), the

TCCM may interpret the resistance as:

either of the neighboring valid positions.

as an invalid fault position.

For resistances between the ranges E and F shown for AWD and in-between positions, the TCCM may interpret the

resistance as:

the AWD position.

an invalid fault position.

a valid in-between position.

For resistances between the ranges F and G shown for in-between positions and fault condition (open), the TCCM

may interpret the resistance as:

a valid in-between position.

an invalid fault position.

For resistances between the ranges A and B shown for the fault condition (short) and , T-Case NEUTRAL, the

TCCM may interpret the resistance as:

the T-Case NEUTRAL position.

an invalid fault position.

The LED’s in the selector assembly are illuminated/flashed in the following manner to indicate a particular condition

or state.

A solidly illuminated LED indicates asuccessfully completed shift and the current operating mode of the trans-

fer case. While a shift has been requested but not yet completed, the LED forthe desired transfer case posi-

tion is flashed.

A flashing operating mode LED for the desired gear indicates that a shift tothat position has been requested,

but all of the driver controllable conditions have not been met. This is in an attempt to notify the driver that the

transmission needs to be put into NEUTRAL, the vehicle speed is too great, or some other condition outlined

Page 4310 of 5267

SWITCH-SELECTOR

DESCRIPTION

The selector switch assembly is mounted in the left

side of the vehicle’s Instrument Panel (IP) and con-

sists of a rotary knob connected to a resistive network

for the mode and range shift selections. Also located

in this assembly is a recessed, normally open momen-

tary switch for making shifts into and out of transfer

case NEUTRAL. A pen, or similar instrument, is used

to make a NEUTRAL shift selection, thus reducing the

likelihood of an inadvertent shift request.

The selector switch also contains four light emitting

diode’s (LED’s) to indicate the transfer case position

and whether a shift is in progress.

OPERATION

As the position of the selector switchvaries, the resistance between the Mode Sensor supply voltage pin and the

Mode Sensor output will vary. Hardware, software, and calibrations within the Transfer Case Control Module

(TCCM) are provided that interpret the selector switch resistance as giveninthetablebelow:SELECTORSWITCH

INTERPRETATION

SELECTOR SWITCH INTERPRETATION

Step Resistance Range (ohms) Required Interpretation

A <200 Shorted

B 400-700 NEUTRAL

C 1050-1450 4LO

D 1850-2300 4HI

E 3050-5950 2WD (Default)

F 9.5-12.5K In between positions

G>15.5KOpen

For resistances between the ranges B-E shown for each valid position (T-Case NEUTRAL, 4LO, 4HI, 2WD), the

TCCM may interpret the resistance as:

either of the neighboring valid positions.

as an invalid fault position.

For resistances between the ranges E and F shown for 2WD and in-between positions, the TCCM may interpret the

resistance as:

the 2WD position.

an invalid fault position.

a valid in-between position.

For resistances between the ranges F and G shown for in-between positions and fault condition (open), the TCCM

may interpret the resistance as:

a valid in-between position.

an invalid fault position.

Page 4339 of 5267

BODY

WARNING

SAFETY PRECAUTIONS AND WARNINGS

WARNING: Use an OSHA approved breathing filter when spraying paint or solvents in a confined area. Per-

sonal injury can result.

Avoidprolongedskincontactwithpetroleumoralcohol–basedcleaningsolvents. Personal injury can

result.

Do not stand under a hoisted vehicle that is not properly supported on safety stands. Personal injury can

result.

CAUTION: When holes must be drilled or punched in an inner body panel, verify depth of space to the outer

body panel, electrical wiring, or other components. Damage to vehicle canresult.

Do not weld exterior panels unless combustible material on the interior ofvehicle is removed from the

repair area. Fire or hazardous conditions, can result.

Always have a fire extinguisher ready for use when welding.

Disconnect the negative (-) cable clamp from the battery when servicing electrical components that are

live when the ignition is OFF. Damage to electrical system can result.

Do not use abrasive chemicals or compounds on painted surfaces. Damage to finish can result.

Do not use harsh alkaline based cleaning solvents on painted or upholstered surfaces. Damage to finish

or color can result.

Do not hammer or pound on plastic trim panel when servicing interior trim. Plastic panels can break.

DIAGNOSIS AND TESTING

WAT E R L E A K S

Water leaks can be caused by poor sealing, improper body component alignment, body seam porosity, missing

plugs, or blocked drain holes. Centrifugal and gravitational force can cause water to drip from a location away from

the actual leak point, making leak detection difficult. All body sealing points should be water tight in normal wet-

driving conditions. Water flowing downward from the front of the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not always seal water tight under all conditions. At times, side glass or

door seals will allow water to enter the passenger compartment during highpressure washing or hard driving rain

(severe) conditions. Overcompensating on door or glass adjustments to stop a water leak that occurs under severe

conditions can cause premature sealwear and excessive closing or latching effort. After completing a repair, water

test vehicle to verify leak has stopped before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK TESTS

Verify that floor and body plugs are in place, body drains are clear, and body components are properly aligned and

sealed. If component alignment or sealing is necessary, refer to the appropriate section of this group for proper

procedures.

WATER LEAK TESTS

WARNING: Do not use electric shop lights or tools in water test area. Personal injury can result.

When the conditions causing a water leak have been determined, simulate the conditions as closely as possible.

Ifaleakoccurswiththevehicleparkedinasteadylightrain,floodtheleak area with an open-ended garden

hose.

If a leak occurs while driving at highway speeds in a steady rain, test the leak area with a reasonable velocity

stream or fan spray of water. Direct the spray in a direction comparable to actual conditions.

If a leak occurs when the vehicle is parked on an incline, hoist the end or sideofthevehicletosimulatethis

condition. This method can be used when the leak occurs when the vehicle accelerates, stops or turns. If the

leak occurs on acceleration, hoist the front of the vehicle. If the leak occurs when braking, hoist the back of the