light DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4885 of 5267

3.CHECK CONDENSER FAN MOTOR

Reconnect the TIPM C8 harness connector.

Ignition on, engine not running.

With the scan tool, actuate the Condenser Fan.

Using a 12-volt test light connected to ground, probe the (C123) Con-

denser Fan Control Output circuit at the Condenser Fan harness con-

nector.

Does the test light illuminate brightly and flash on and off?

Ye s>>

With the scan tool, de-actuate the Condenser Fan. Then,

replace the Condenser Fan Motor in accordance with the

Service Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

No>>

With the scan tool, de-actuate the Condenser Fan. Then,

Go To 4

4.INSPECT RELATED WIRING

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to all Power and Ground circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

No>>

Replace the Totally Integrated Power Module in accordance with the Service Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Page 4888 of 5267

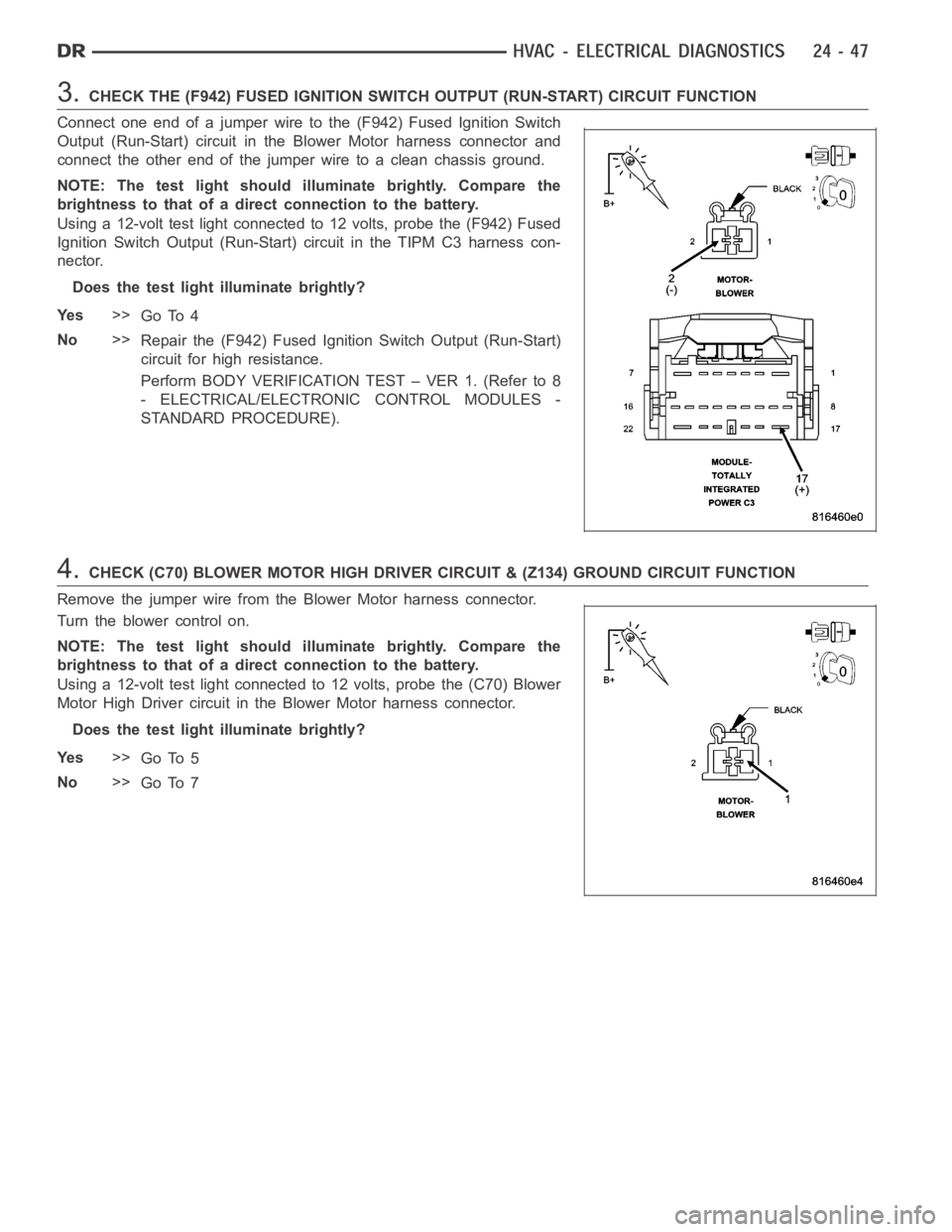

3.CHECK THE (F942) FUSED IGNITION SWITCH OUTPUT (RUN-START) CIRCUIT FUNCTION

Connect one end of a jumper wire to the (F942) Fused Ignition Switch

Output (Run-Start) circuit in the Blower Motor harness connector and

connect the other end of the jumper wire to a clean chassis ground.

NOTE: The test light should illuminate brightly. Compare the

brightness to that of a direct connection to the battery.

Using a 12-volt test light connected to 12 volts, probe the (F942) Fused

Ignition Switch Output (Run-Start) circuit in the TIPM C3 harness con-

nector.

Does the test light illuminate brightly?

Ye s>>

Go To 4

No>>

Repair the (F942) Fused Ignition Switch Output (Run-Start)

circuit for high resistance.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

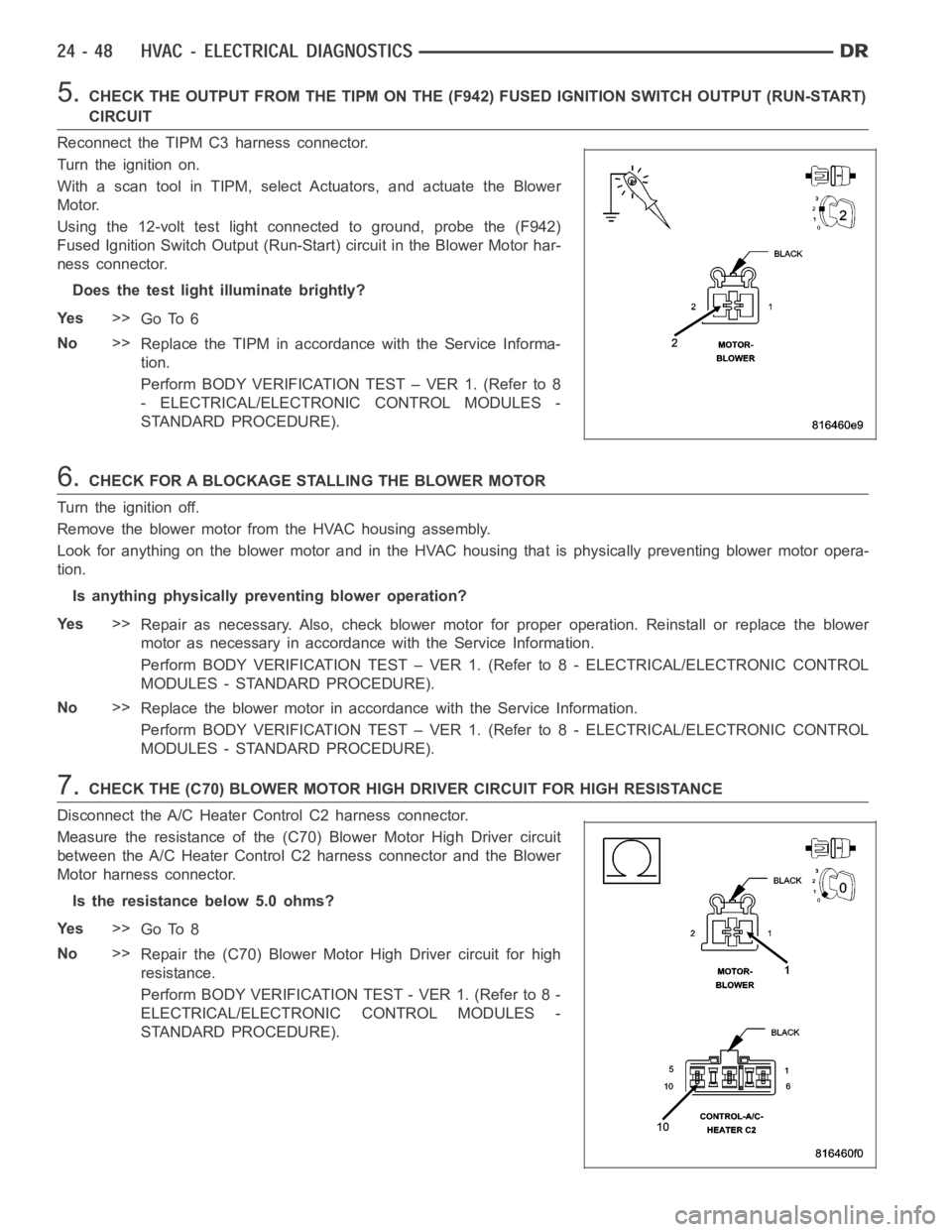

4.CHECK (C70) BLOWER MOTOR HIGH DRIVER CIRCUIT & (Z134) GROUND CIRCUIT FUNCTION

Remove the jumper wire from the Blower Motor harness connector.

Turn the blower control on.

NOTE: The test light should illuminate brightly. Compare the

brightness to that of a direct connection to the battery.

Using a 12-volt test light connected to 12 volts, probe the (C70) Blower

Motor High Driver circuit in the Blower Motor harness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 5

No>>

Go To 7

Page 4889 of 5267

5.CHECK THE OUTPUT FROM THE TIPM ON THE (F942) FUSED IGNITION SWITCH OUTPUT (RUN-START)

CIRCUIT

Reconnect the TIPM C3 harness connector.

Turn the ignition on.

With a scan tool in TIPM, select Actuators, and actuate the Blower

Motor.

Using the 12-volt test light connected to ground, probe the (F942)

Fused Ignition Switch Output (Run-Start) circuit in the Blower Motor har-

ness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 6

No>>

Replace the TIPM in accordance with the Service Informa-

tion.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

6.CHECK FOR A BLOCKAGE STALLING THE BLOWER MOTOR

Turn the ignition off.

Remove the blower motor from the HVAC housing assembly.

Look for anything on the blower motor and in the HVAC housing that is physically preventing blower motor opera-

tion.

Is anything physically preventing blower operation?

Ye s>>

Repair as necessary. Also, check blower motor for proper operation. Reinstall or replace the blower

motor as necessary in accordancewith the Service Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

No>>

Replace the blower motor in accordance with the Service Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

7.CHECK THE (C70) BLOWER MOTOR HIGH DRIVER CIRCUIT FOR HIGH RESISTANCE

Disconnect the A/C Heater Control C2 harness connector.

Measure the resistance of the (C70) Blower Motor High Driver circuit

between the A/C Heater Control C2 harness connector and the Blower

Motor harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 8

No>>

Repair the (C70) Blower Motor High Driver circuit for high

resistance.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

Page 4893 of 5267

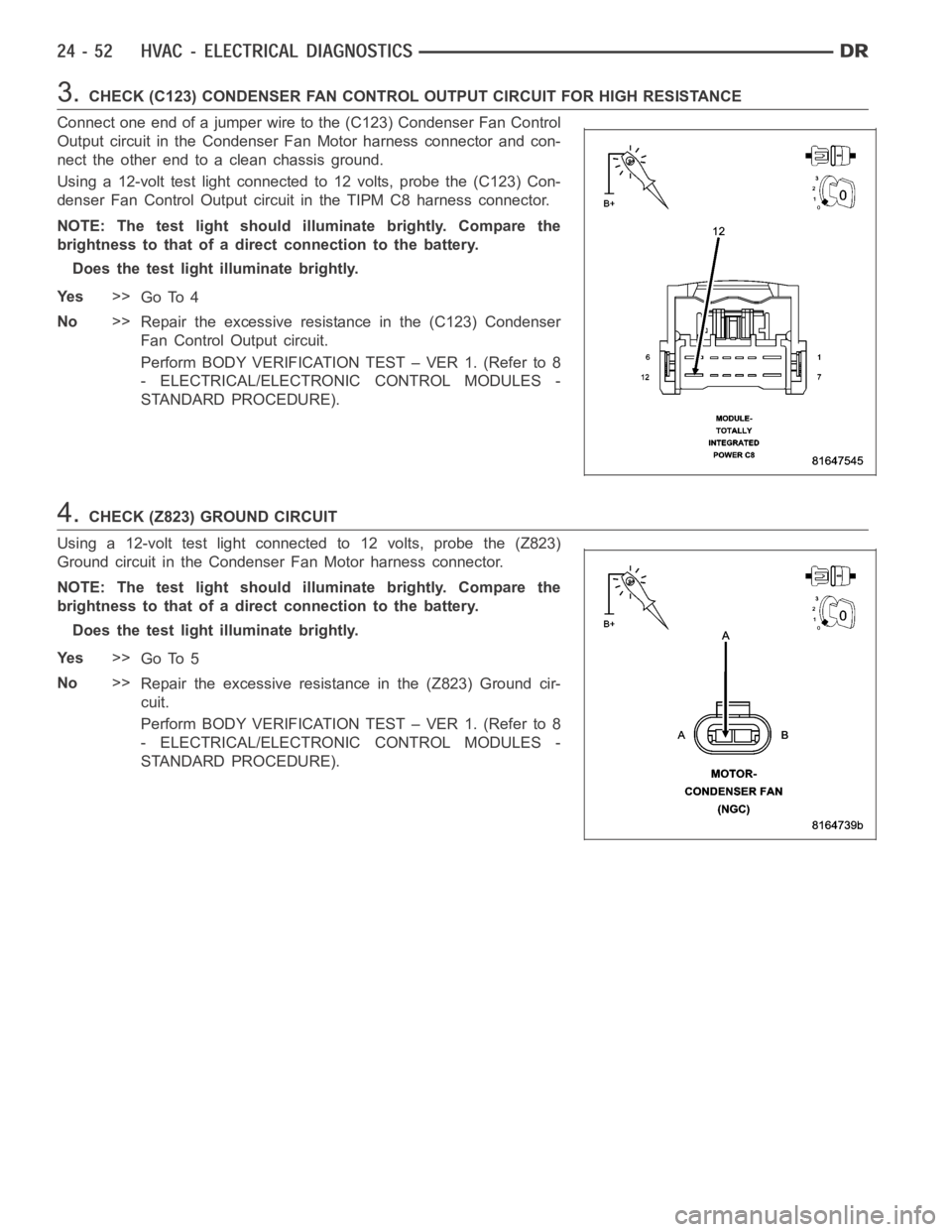

3.CHECK (C123) CONDENSER FAN CONTROL OUTPUT CIRCUIT FOR HIGH RESISTANCE

Connect one end of a jumper wire to the (C123) Condenser Fan Control

Output circuit in the Condenser Fan Motor harness connector and con-

nect the other end to a clean chassis ground.

Using a 12-volt test light connected to 12 volts, probe the (C123) Con-

denser Fan Control Output circuit in the TIPM C8 harness connector.

NOTE: The test light should illuminate brightly. Compare the

brightness to that of a direct connection to the battery.

Does the test light illuminate brightly.

Ye s>>

Go To 4

No>>

Repair the excessive resistance in the (C123) Condenser

Fan Control Output circuit.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

4.CHECK (Z823) GROUND CIRCUIT

Using a 12-volt test light connected to 12 volts, probe the (Z823)

Ground circuit in the Condenser Fan Motor harness connector.

NOTE: The test light should illuminate brightly. Compare the

brightness to that of a direct connection to the battery.

Does the test light illuminate brightly.

Ye s>>

Go To 5

No>>

Repair the excessive resistance in the (Z823) Ground cir-

cuit.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

Page 4894 of 5267

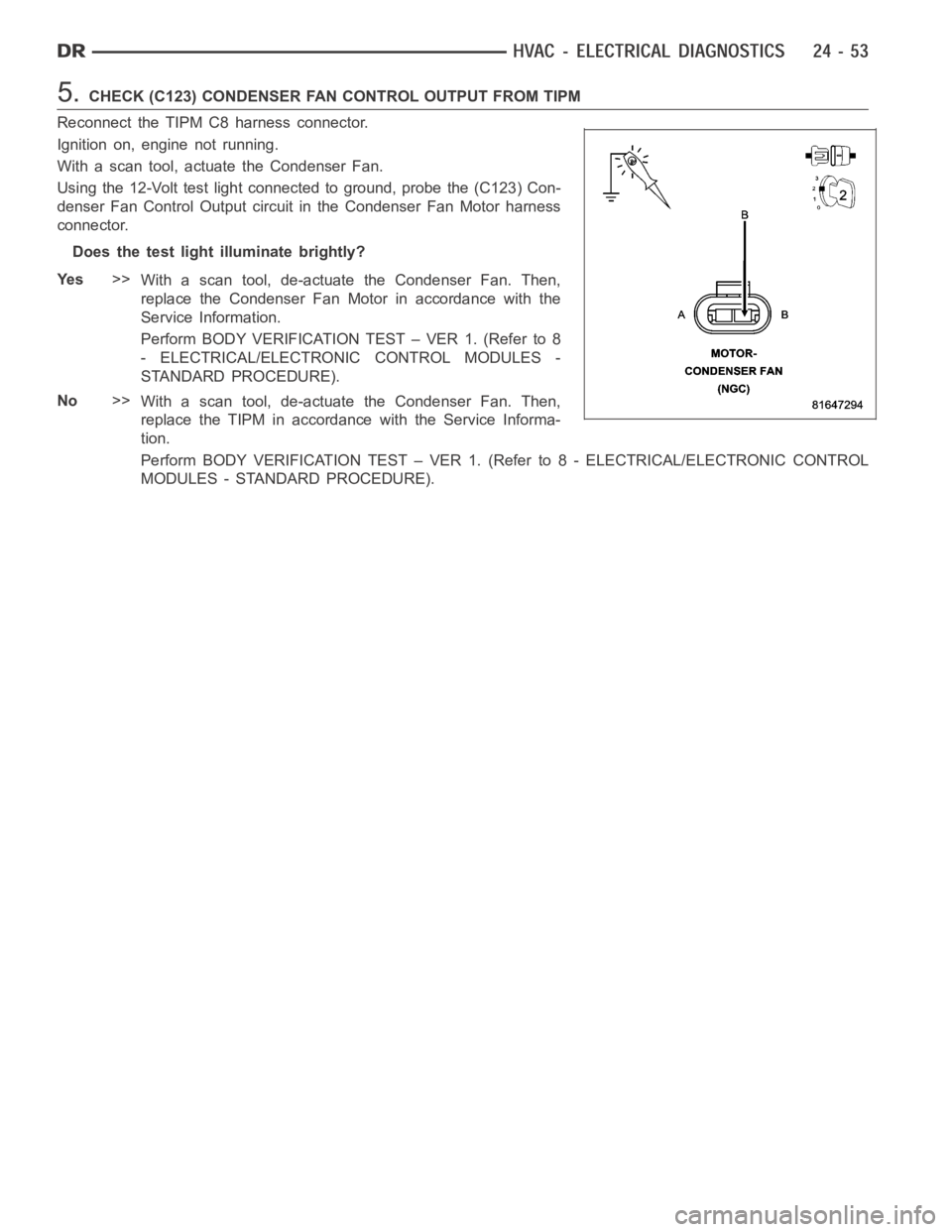

5.CHECK (C123) CONDENSER FAN CONTROL OUTPUT FROM TIPM

Reconnect the TIPM C8 harness connector.

Ignition on, engine not running.

With a scan tool, actuate the Condenser Fan.

Using the 12-Volt test light connected to ground, probe the (C123) Con-

denser Fan Control Output circuit in the Condenser Fan Motor harness

connector.

Does the test light illuminate brightly?

Ye s>>

With a scan tool, de-actuate the Condenser Fan. Then,

replace the Condenser Fan Motor in accordance with the

Service Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

No>>

With a scan tool, de-actuate the Condenser Fan. Then,

replace the TIPM in accordance with the Service Informa-

tion.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

Page 5043 of 5267

Possible Causes

(F942) FUSED IGNITION SWITCH OUTPUT (RUN-START) CIRCUIT OPEN

(C70) BLOWER MOTOR HIGH DRIVER CIRCUIT OPEN

(Z134) GROUND CIRCUIT OPEN

BLOWER MOTOR

A/C HEATER CONTROL

TIPM

Diagnostic Test

1.CHECK FOR DTCs IN THE TIPM

Turn the ignition on.

With the scan tool, read TIPM DTCs.

Does the scan tool display any DTCs?

Ye s>>

Diagnose and repair the DTC(s). Refer to the Table of Contents in the applicable section for the diag-

nostic procedure.

No>>

Go To 2

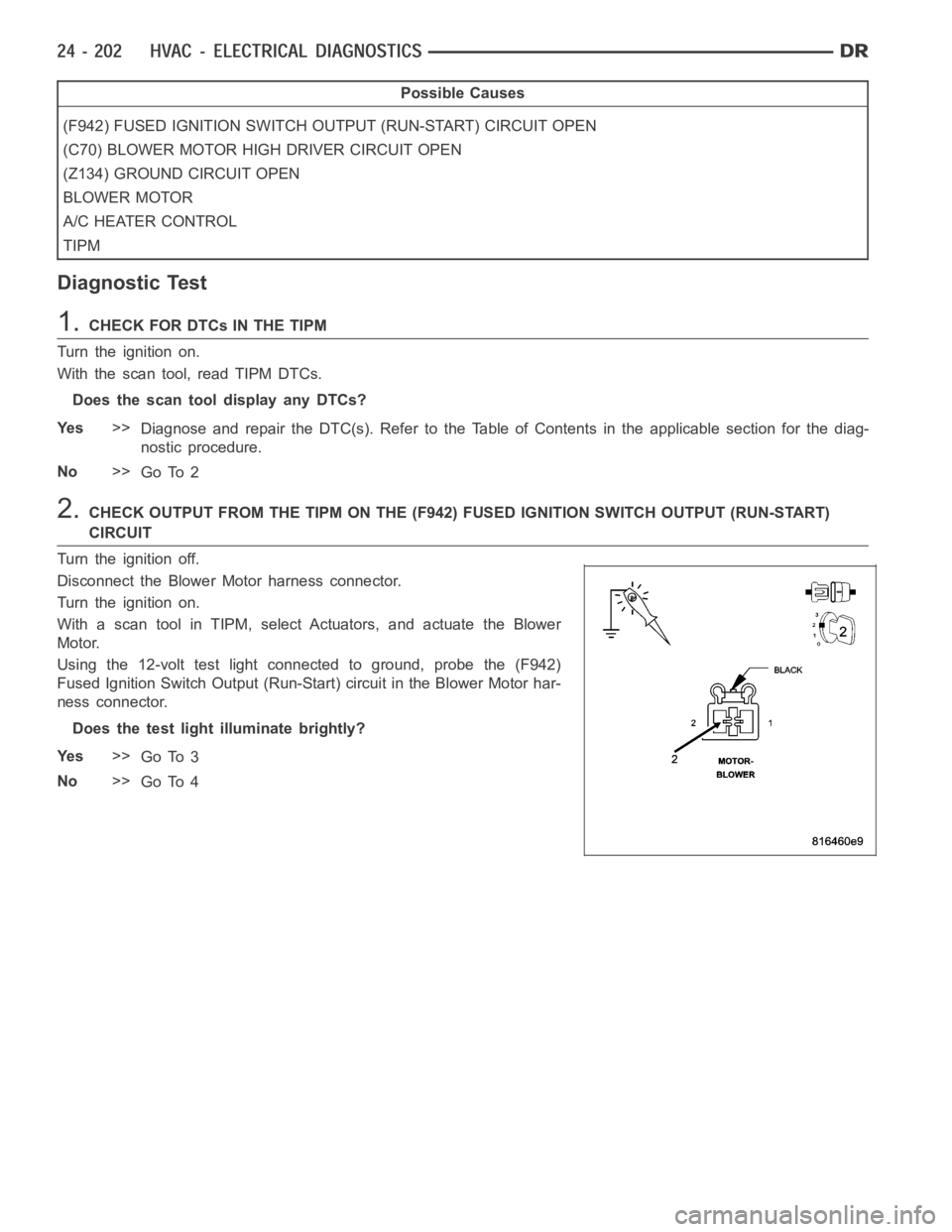

2.CHECK OUTPUT FROM THE TIPM ON THE (F942) FUSED IGNITION SWITCH OUTPUT (RUN-START)

CIRCUIT

Turn the ignition off.

Disconnect the Blower Motor harness connector.

Turn the ignition on.

With a scan tool in TIPM, select Actuators, and actuate the Blower

Motor.

Using the 12-volt test light connected to ground, probe the (F942)

Fused Ignition Switch Output (Run-Start) circuit in the Blower Motor har-

ness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 3

No>>

Go To 4

Page 5044 of 5267

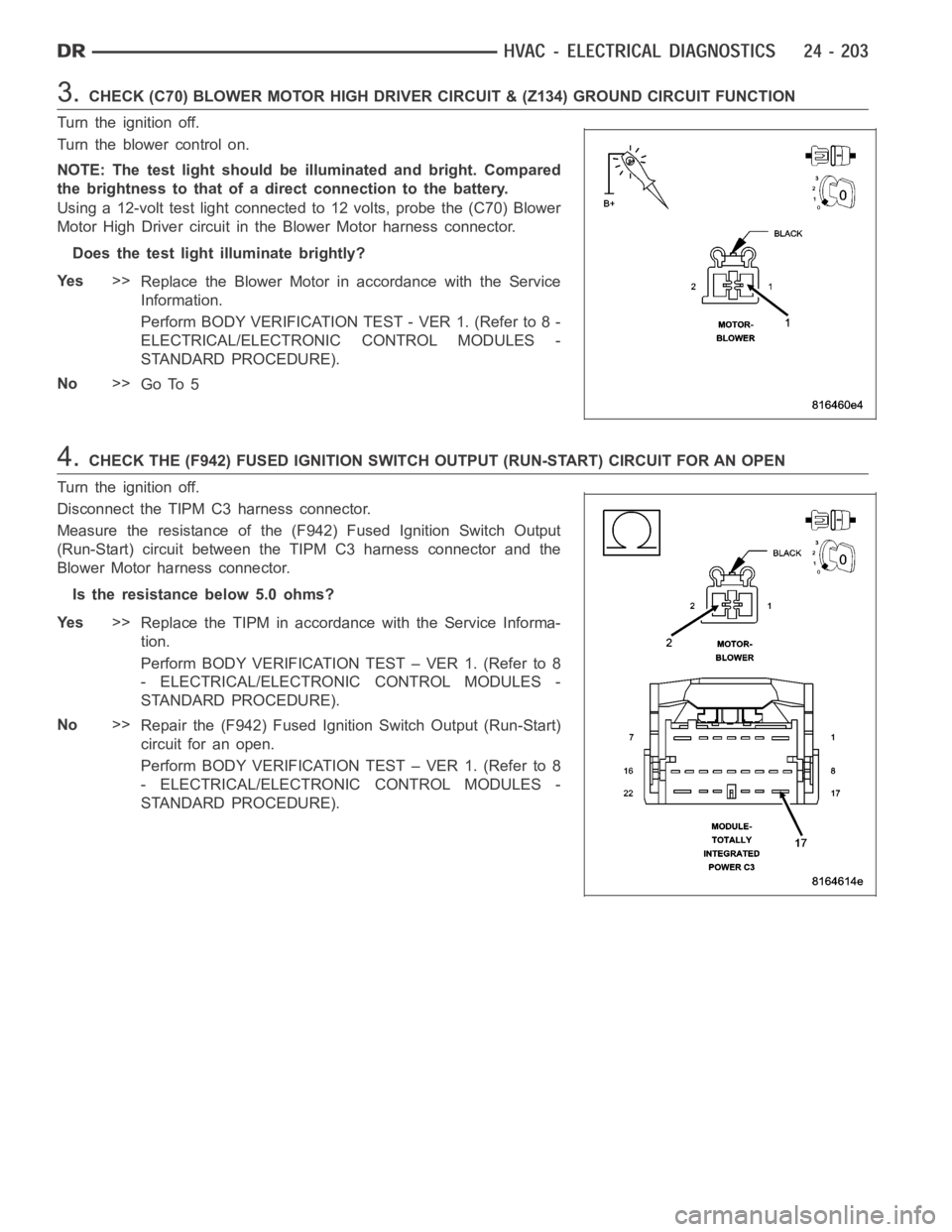

3.CHECK (C70) BLOWER MOTOR HIGH DRIVER CIRCUIT & (Z134) GROUND CIRCUIT FUNCTION

Turn the ignition off.

Turn the blower control on.

NOTE: The test light should be illuminated and bright. Compared

the brightness to that of a direct connection to the battery.

Using a 12-volt test light connected to 12 volts, probe the (C70) Blower

Motor High Driver circuit in the Blower Motor harness connector.

Does the test light illuminate brightly?

Ye s>>

Replace the Blower Motor in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

No>>

Go To 5

4.CHECK THE (F942) FUSED IGNITION SWITCH OUTPUT (RUN-START) CIRCUIT FOR AN OPEN

Turn the ignition off.

Disconnect the TIPM C3 harness connector.

Measure the resistance of the (F942) Fused Ignition Switch Output

(Run-Start) circuit between the TIPM C3 harness connector and the

Blower Motor harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Replace the TIPM in accordance with the Service Informa-

tion.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

No>>

Repair the (F942) Fused Ignition Switch Output (Run-Start)

circuit for an open.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

Page 5052 of 5267

DIAGNOSIS AND TESTING

HEATING-A/C SYSTEM DIAGNOSTICS

CAUTION: Do not exchange A/C Heater Controls from vehicle to vehicle. Software versions differ between

models and model years. Installing an A/C Heater Control with software that is incompatible for a given

vehicle can result in either improper or failed HVAC system operation.

ON-BOARD DIAGNOSTICS

The A/C-heater control communicates on the controller area network (CAN)B bus and is fully addressable with a

scan tool.

The A/C-heater control’s primary means of fault detection is through active and stored diagnostic trouble codes

(DTCs). Active DTCs are those which currently exist in the system. The condition causing the fault must be repaired

in order to clear this type of DTC. Stored DTCs are those which occurred in the system since the A/C-heater control

received the last clear diagnostic info message. DTCs must be read with a scan tool. Refer to 24 - HVAC - Elec-

trical Diagnostics for HVAC DTC diagnostic test procedures.

The A/C-heater control’s secondary means of fault detection is through system tests. These tests include the HVAC

System Test, the A/C Cooldown Test, Actuator Calibration, and Actuator DTC Detection. Refer to System Tests in

this Section for a detailed description of each test.

SYSTEM TESTS

HVAC System Test

The HVAC System Test, found in 24 - HVAC - Electrical Diagnostics, providesa starting point in the diagnostic

process by identifying the appropriate diagnostic procedure or system test to perform when diagnosing a given

symptom, condition, or DTC. It also provides a means for testing the entireHVAC system by utilizing the A/C-heater

control’s On-Board System Tests. The On-Board System Tests can also assistindiagnosingstoredDTCs.

A/CCOOLDOWNTEST

The A/C Cooldown Test:

is actuated with a scan tool.

tests A/C system performance based on evaporator temperature sensor input.

will fail if evaporator temperature isbelow 13°C (55°F) when initiating the test.

will pass if the evaporator temperature drops 11°C (20°F).

indicates an outcome by displaying one or more test status messages on the scan tool. These test status

messages will clear after paging back out of this test function. Therefore, is it important to note all of the mes-

sages before doing so.

will cause the A/C status indicator to flash while the test is running.

ACTUATOR CALIBRATION FUNCTION

The Actuator Calibration function:

is actuated with a scan tool.

clears all actuator related DTCs when the test is actuated.

homes and repositions door actuators.

monitors for door span faults. Door span faults (XXX Door Travel Range Too Large or XXX Door Travel Range

Too Small) will only display after calibration.

will cause the electric backlight (EBL) status indicator (if equipped) toflash while the test is running.

Page 5055 of 5267

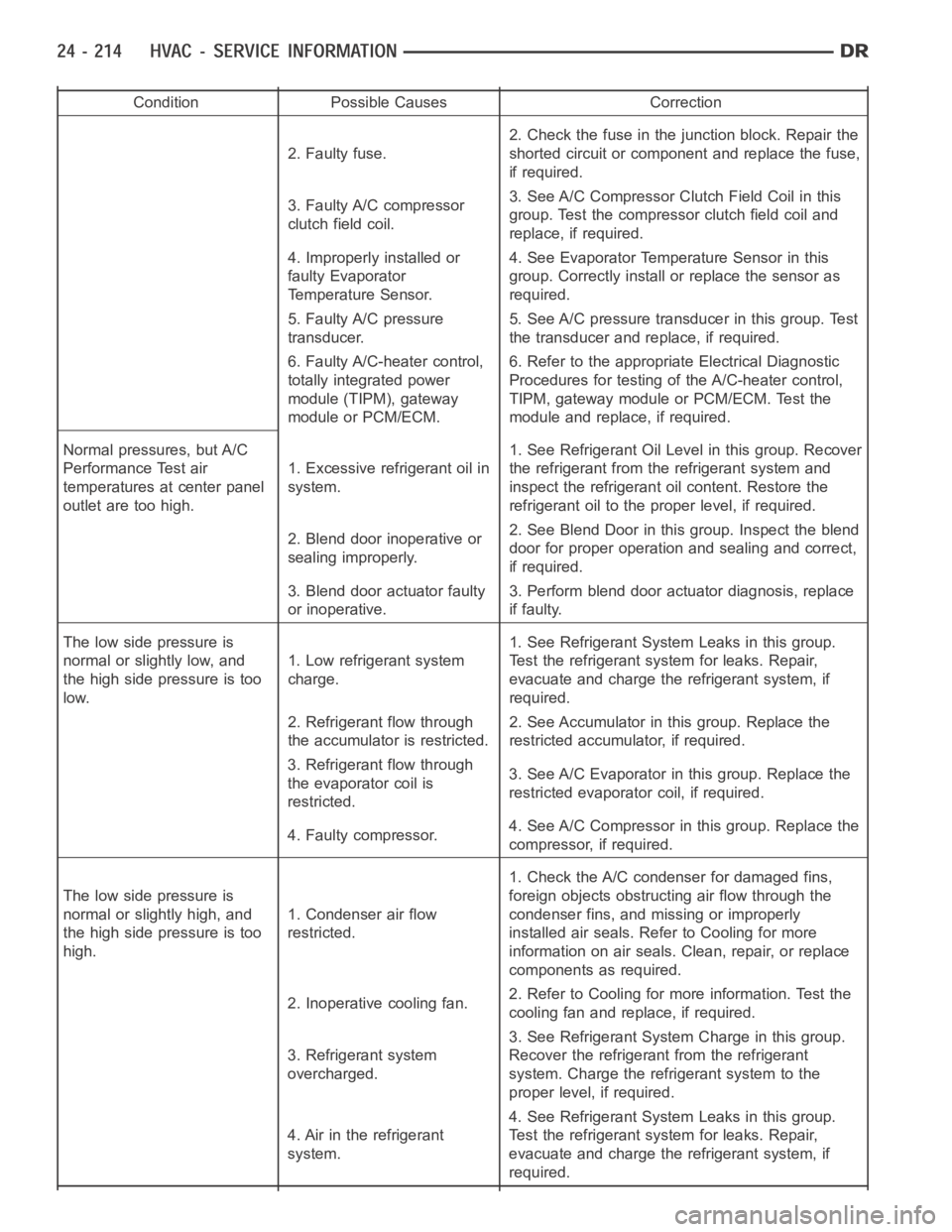

Condition Possible Causes Correction

2. Faulty fuse.2. Check the fuse in the junction block. Repair the

shorted circuit or component and replace the fuse,

if required.

3. Faulty A/C compressor

clutch field coil.3. See A/C Compressor Clutch Field Coil in this

group. Test the compressor clutch field coil and

replace, if required.

4. Improperly installed or

faulty Evaporator

Temperature Sensor.4. See Evaporator Temperature Sensor in this

group. Correctly install or replace the sensor as

required.

5. Faulty A/C pressure

transducer.5. See A/C pressure transducer in this group. Test

the transducer and replace, if required.

6. Faulty A/C-heater control,

totally integrated power

module (TIPM), gateway

module or PCM/ECM.6. Refer to the appropriate Electrical Diagnostic

Procedures for testing of the A/C-heater control,

TIPM, gateway module or PCM/ECM. Test the

module and replace, if required.

Normal pressures, but A/C

Performance Test air

temperatures at center panel

outlet are too high.1. Excessive refrigerant oil in

system.1. See Refrigerant Oil Level in this group. Recover

the refrigerant from the refrigerant system and

inspect the refrigerant oil content. Restore the

refrigerant oil to the proper level, if required.

2. Blend door inoperative or

sealing improperly.2. See Blend Door in this group. Inspect the blend

door for proper operation and sealing and correct,

if required.

3. Blend door actuator faulty

or inoperative.3. Perform blend door actuator diagnosis, replace

if faulty.

The low side pressure is

normal or slightly low, and

the high side pressure is too

low.1. Low refrigerant system

charge.1. See Refrigerant System Leaks in this group.

Test the refrigerant system for leaks. Repair,

evacuate and charge the refrigerant system, if

required.

2. Refrigerant flow through

the accumulator is restricted.2. See Accumulator in this group. Replace the

restricted accumulator, if required.

3. Refrigerant flow through

the evaporator coil is

restricted.3. See A/C Evaporator in this group. Replace the

restricted evaporator coil, if required.

4. Faulty compressor.4. See A/C Compressor in this group. Replace the

compressor, if required.

The low side pressure is

normal or slightly high, and

the high side pressure is too

high.1. Condenser air flow

restricted.1. Check the A/C condenser for damaged fins,

foreign objects obstructing air flow through the

condenser fins, and missing or improperly

installed air seals. Refer to Cooling for more

information on air seals. Clean, repair, or replace

components as required.

2. Inoperative cooling fan.2. Refer to Cooling for more information. Test the

cooling fan and replace, if required.

3. Refrigerant system

overcharged.3. See Refrigerant System Charge in this group.

Recover the refrigerant from the refrigerant

system. Charge the refrigerant system to the

proper level, if required.

4. Air in the refrigerant

system.4. See Refrigerant System Leaks in this group.

Test the refrigerant system for leaks. Repair,

evacuate and charge the refrigerant system, if

required.

Page 5056 of 5267

Condition Possible Causes Correction

5. Engine overheating.5. Refer to Cooling for more information. Test the

cooling system and repair, if required.

The low side pressure is too

high, and the high side

pressure is too low.1. Accessory drive belt

slipping.1. Refer to Cooling for more information. Inspect

the accessory drive belt condition and tension.

Tighten or replace the accessory drive belt, if

required.

2. Fixed orifice tube not

installed.2. See A/C Orifice Tube in this group. Replace the

liquid line, if required.

3. Faulty A/C compressor.3. See A/C Compressor in this group. Replace the

compressor, if required.

The low side pressure is too

low, and the high side

pressure is too high.1. Restricted refrigerant flow

through the refrigerant lines.1. See Liquid, Suction, and Discharge Line in this

group. Inspect the refrigerant lines for kinks, tight

bends or improper routing. Correct the routing or

replace the refrigerant line, if required.

2. Restricted refrigerant flow

through the fixed orifice

tube.2. See A/C Orifice Tube in this group. Replace the

liquid line, if required.

3. Restricted refrigerant flow

through the condenser.3. See A/C Condenser in this group. Replace the

restricted condenser, if required.

HEATER PERFORMANCE

Before performing the following tests, refer to Group 7 - Cooling for the procedures to check the engine coolant

level and flow, engine coolant reserve/recovery system operation, accessory drive belt condition and tension, radi-

ator air flow and the fan drive operation. Perform the HVAC System Test (refer to 24 - HVAC Electrical Diagnostics).

If any diagnostic trouble codes (DTCs) are found in the A/C-heater control, powertrain control module (PCM) or

engine control module (ECM) (depending on engine application), gateway module or totally integrated power module

(TIPM), repair as necessary.

MAXIMUM HEATER OUTPUT: TEST AND ACTION

Engine coolant is provided to the heater system through two heater hoses. With the engine idling at normal oper-

ating temperature, set the temperature control to maximum heat position,the mode control to the floor position, and

the blower motor control to the highest speed position. Using a test thermometer, check the temperature of the air

being discharged from the floor outlets. Compare the test thermometer reading to the Heater Temperature Refer-

ence chart.

HEATER TEMPERATURE REFERENCE

Ambient Air Temperature16° C

(60° F)21° C

(70° F)26° C

(80° F)32° C

(90° F)

Minimum Air Temperature at

Floor Outlet62° C

(144° F)64° C

(147° F)65° C

(150° F)67° C

(153° F)

If the heater outlet air temperature is below the minimum specification, refer to Group 7 - Cooling. Both of the heater

hoses should be hot to the touch. The coolant return heater hose should be slightly cooler than the coolant supply

heater hose. If the return hose is much cooler than the supply hose, locate and repair the engine coolant flow

obstruction in the cooling system. RefertoGroup7-Coolingformoreinformation.

OBSTRUCTED COOLANT FLOW

Possible locations or causes of obstructed coolant flow are as follows:

Faulty water pump.

Faulty thermostat.

Pinched or kinked heater hoses.