DODGE RAM SRT-10 2006 Service Repair Manual

RAM SRT-10 2006

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56917/w960_56917-0.png

DODGE RAM SRT-10 2006 Service Repair Manual

Trending: air filter, phone, jump start terminals, tires, heating, child restraint, radiator

Page 4691 of 5267

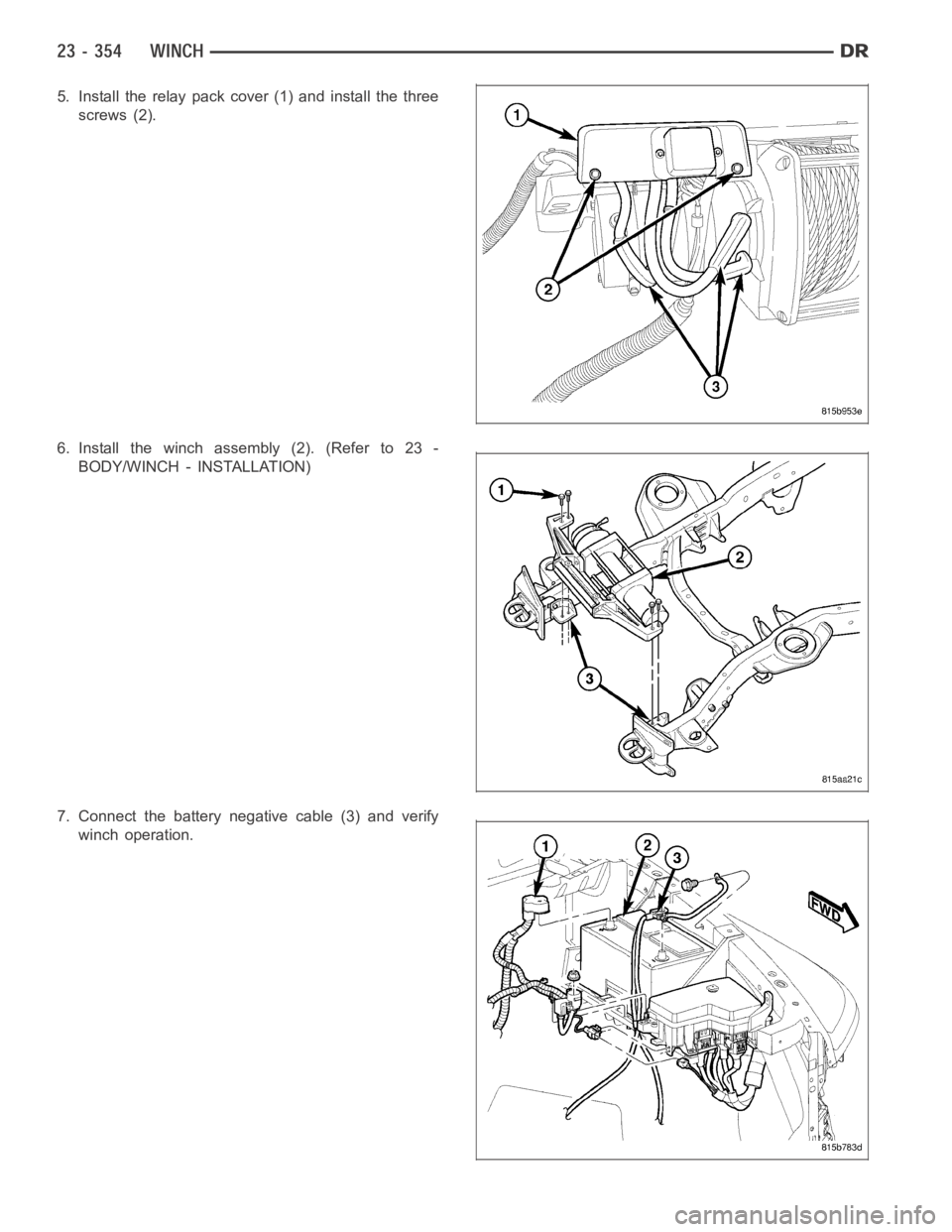

5. Install the relay pack cover (1) and install the three

screws (2).

6. Install the winch assembly (2). (Refer to 23 -

BODY/WINCH - INSTALLATION)

7. Connect the battery negative cable (3) and verify

winch operation.

Page 4692 of 5267

WIRE ROPE

REMOVAL

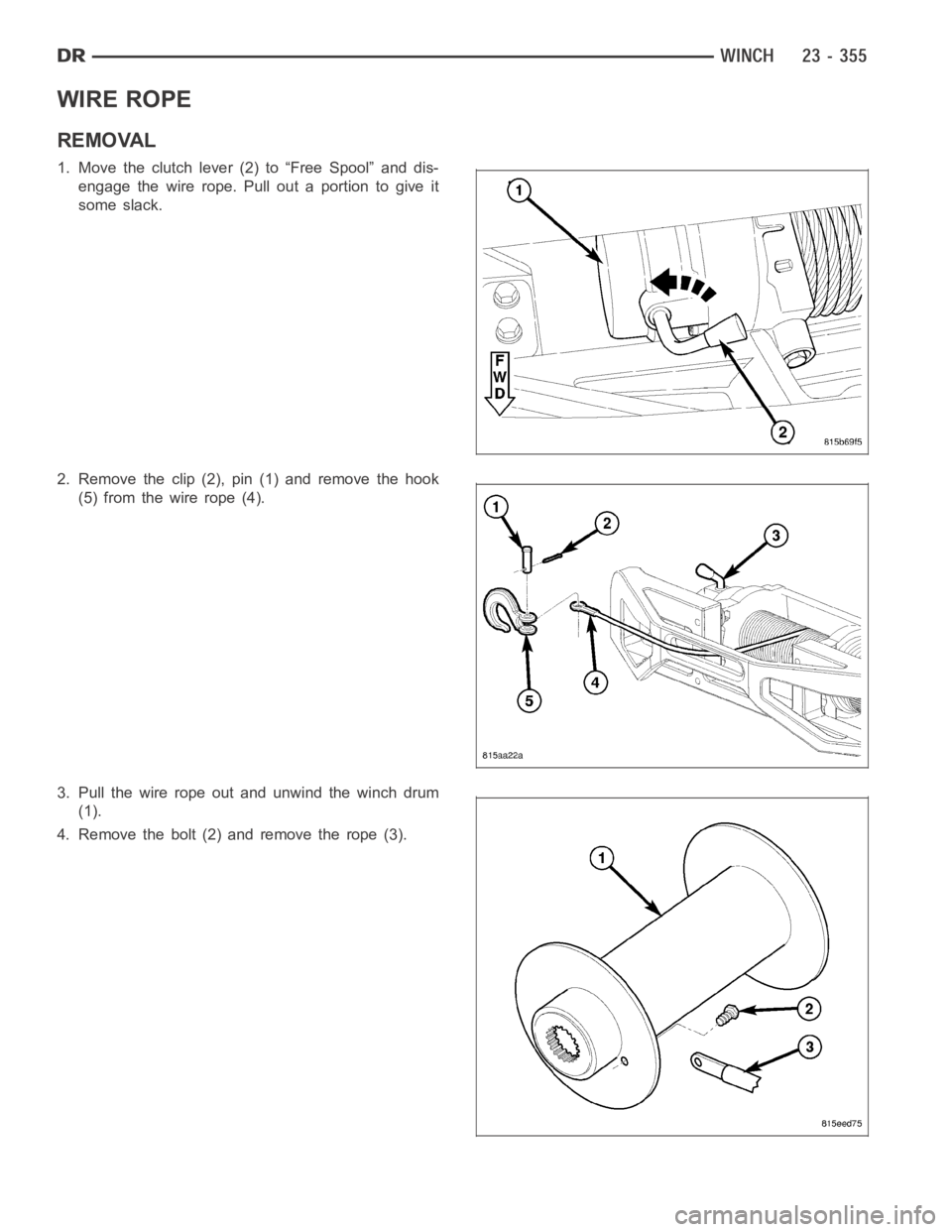

1. Move the clutch lever (2) to “Free Spool” and dis-

engage the wire rope. Pull out a portion to give it

some slack.

2. Remove the clip (2), pin (1) and remove the hook

(5) from the wire rope (4).

3. Pull the wire rope out and unwind the winch drum

(1).

4. Remove the bolt (2) and remove the rope (3).

Page 4693 of 5267

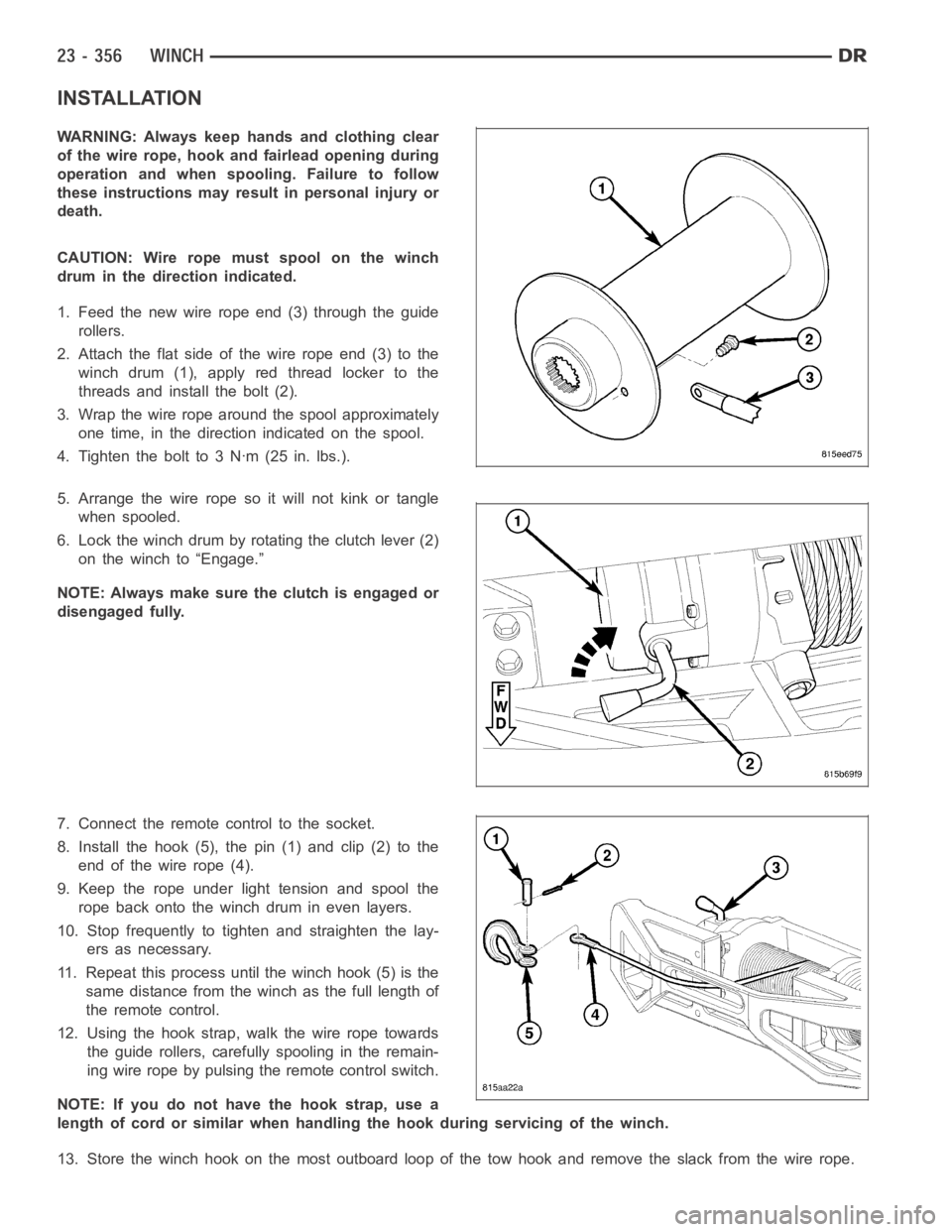

INSTALLATION

WARNING: Always keep hands and clothing clear

of the wire rope, hook and fairlead opening during

operation and when spooling. Failure to follow

these instructions may result in personal injury or

death.

CAUTION: Wire rope must spool on the winch

drum in the direction indicated.

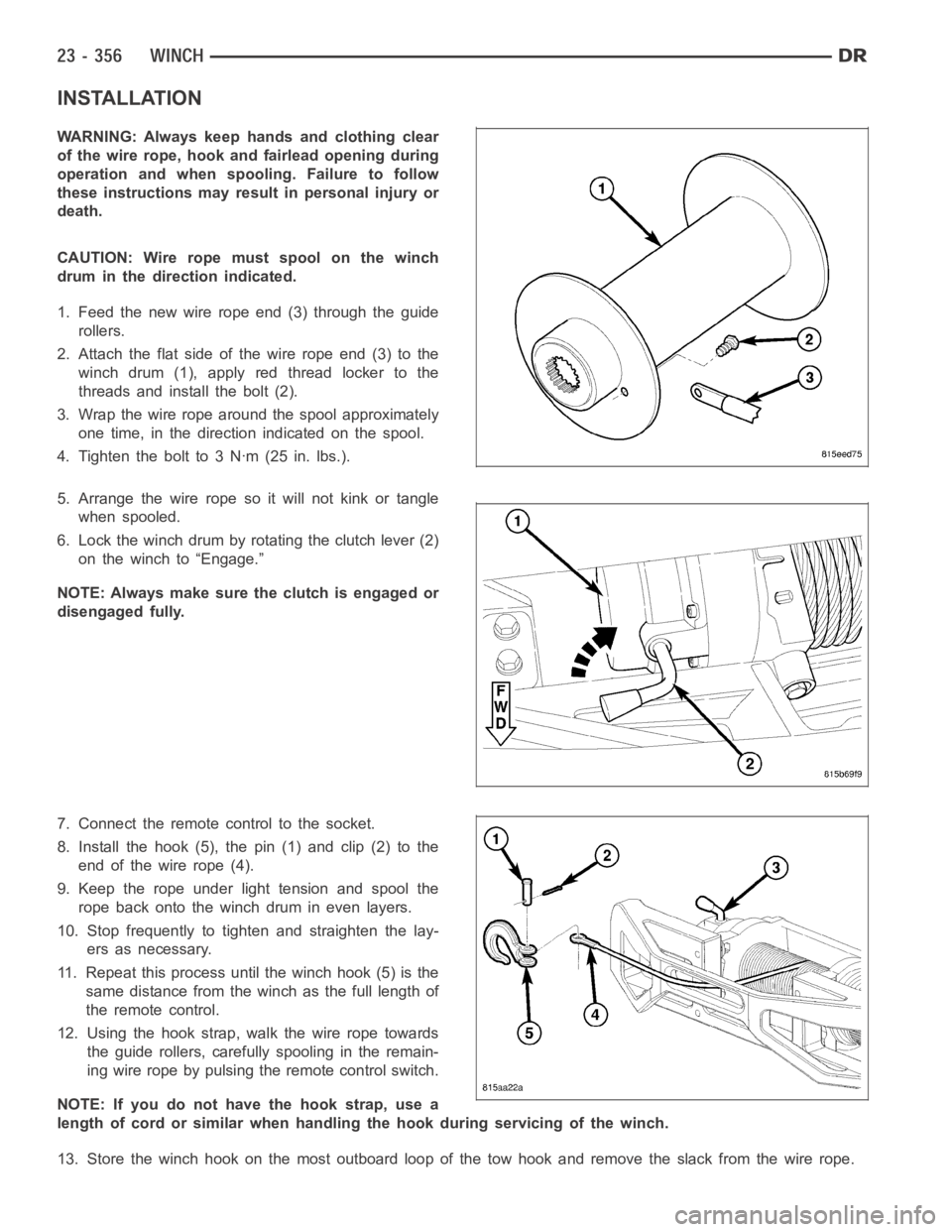

1. Feed the new wire rope end (3) through the guide

rollers.

2. Attach the flat side of the wire rope end (3) to the

winch drum (1), apply red thread locker to the

threads and install the bolt (2).

3. Wrap the wire rope around the spool approximately

one time, in the direction indicated on the spool.

4. Tighten the bolt to 3 Nꞏm (25 in. lbs.).

5. Arrange the wire rope so it will not kink or tangle

when spooled.

6. Lock the winch drum by rotating the clutch lever (2)

on the winch to “Engage.”

NOTE: Always make sure the clutch is engaged or

disengaged fully.

7. Connect the remote control to the socket.

8. Install the hook (5), the pin (1) and clip (2) to the

end of the wire rope (4).

9. Keep the rope under light tension and spool the

rope back onto the winch drum in even layers.

10. Stop frequently to tighten and straighten the lay-

ers as necessary.

11. Repeat this process until the winch hook (5) is the

same distance from the winch as the full length of

theremotecontrol.

12. Using the hook strap, walk the wire rope towards

the guide rollers, carefully spooling in the remain-

ing wire rope by pulsing the remote control switch.

NOTE: If you do not have the hook strap, use a

length of cord or similar when handling the hook during servicing of the winch.

13. Store the winch hook on the most outboard loop of the tow hook and remove the slack from the wire rope.

Page 4694 of 5267

WIRE ROPE GUIDE ROLLERS

REMOVAL

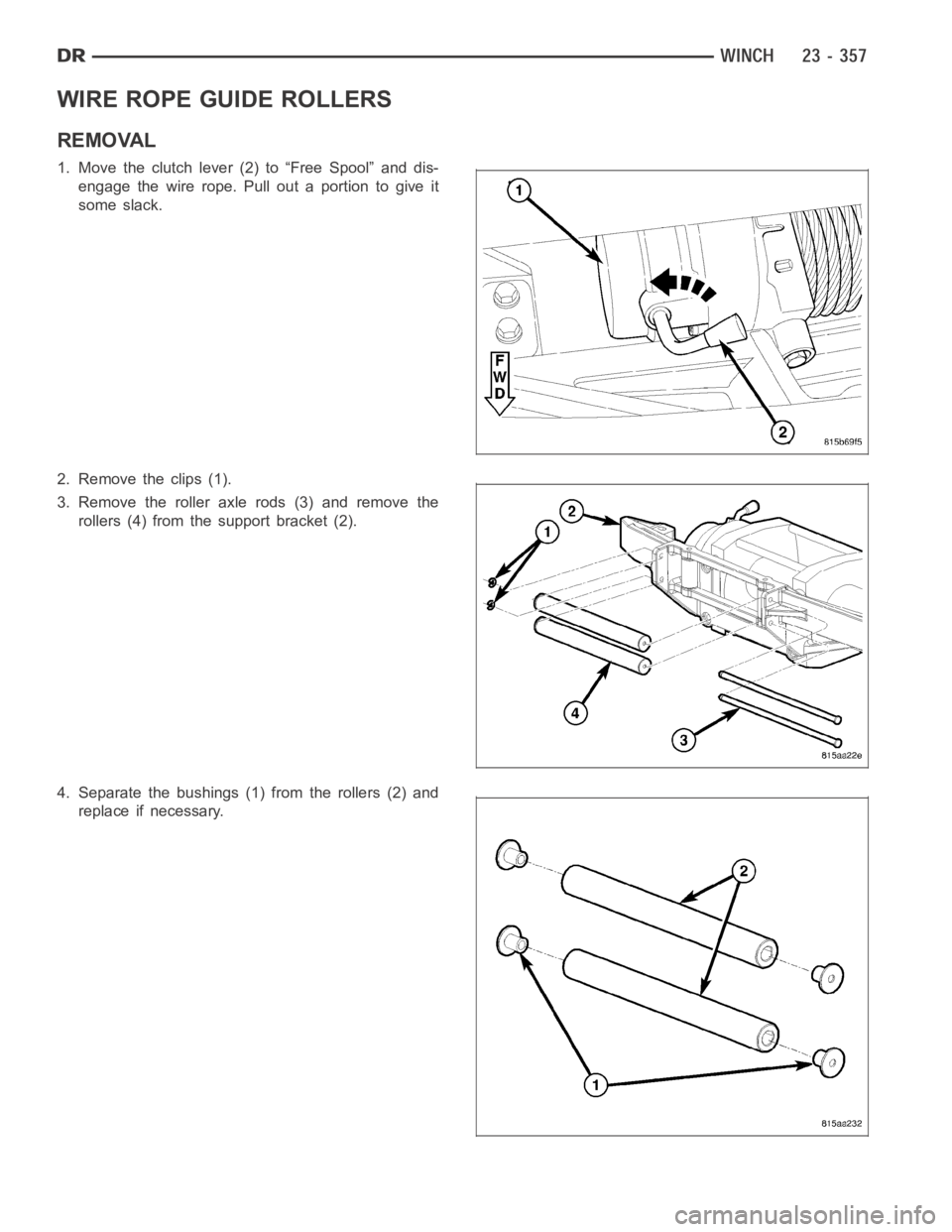

1. Move the clutch lever (2) to “Free Spool” and dis-

engage the wire rope. Pull out a portion to give it

some slack.

2. Remove the clips (1).

3. Remove the roller axle rods (3) and remove the

rollers (4) from the support bracket (2).

4. Separate the bushings (1) from the rollers (2) and

replace if necessary.

Page 4695 of 5267

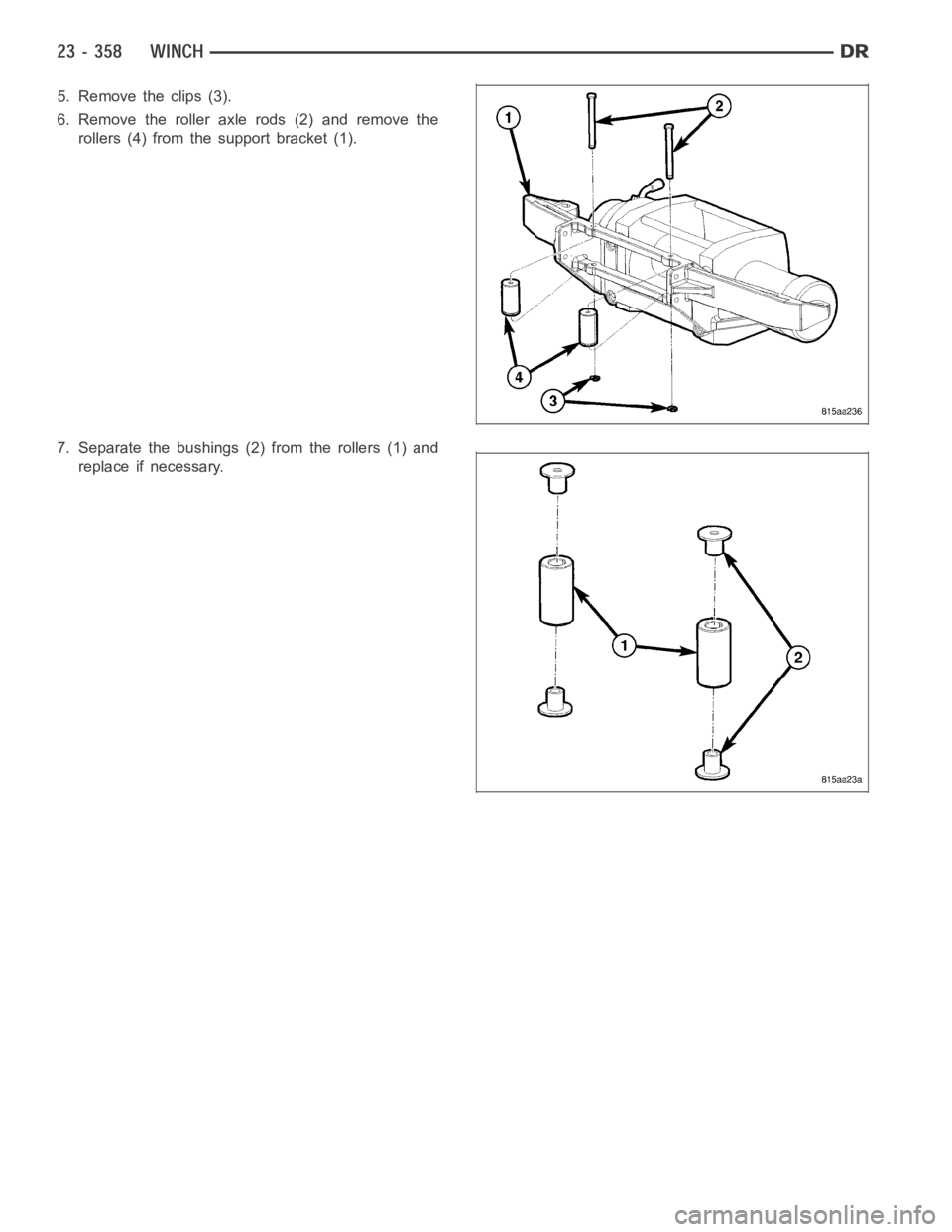

5. Remove the clips (3).

6. Remove the roller axle rods (2) and remove the

rollers (4) from the support bracket (1).

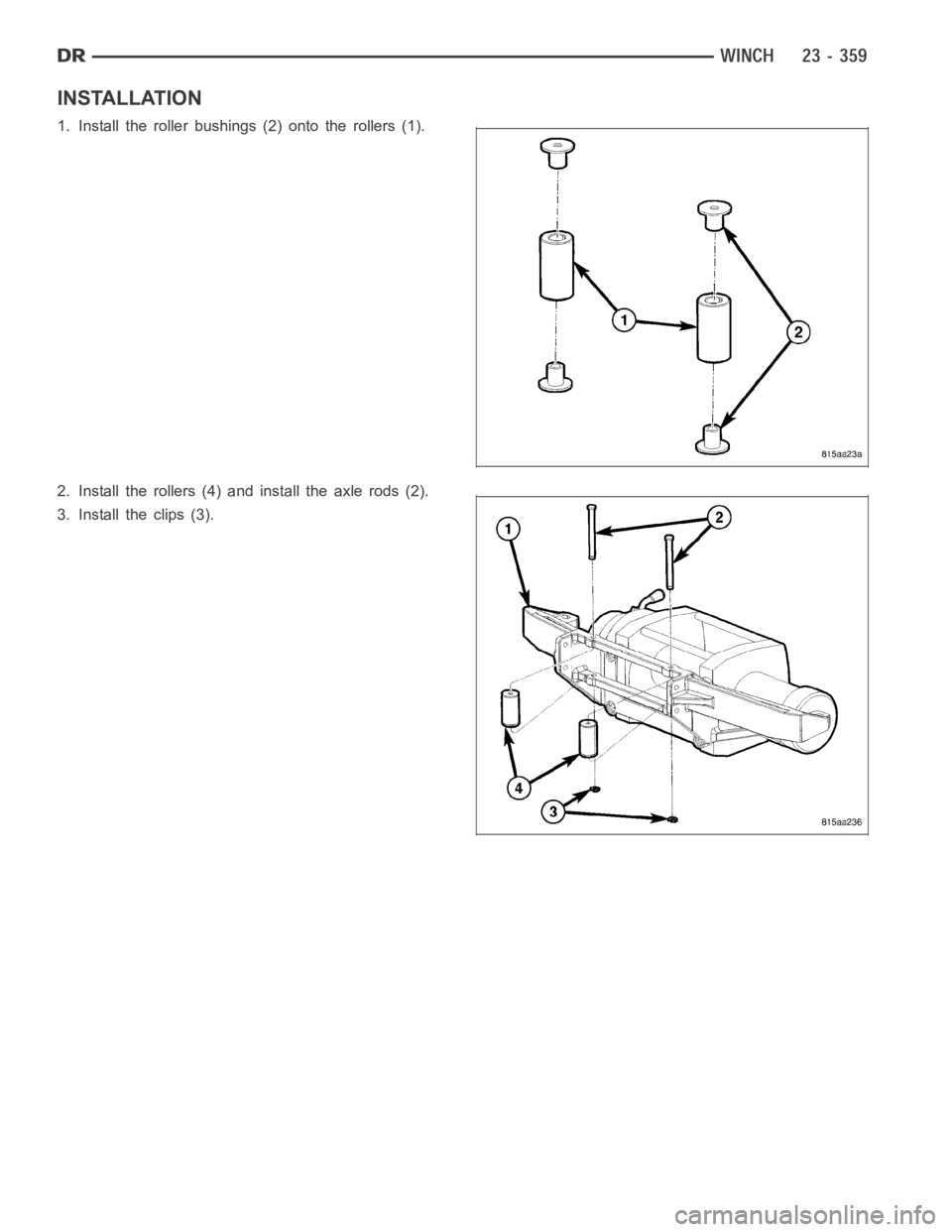

7. Separate the bushings (2) from the rollers (1) and

replace if necessary.

Page 4696 of 5267

INSTALLATION

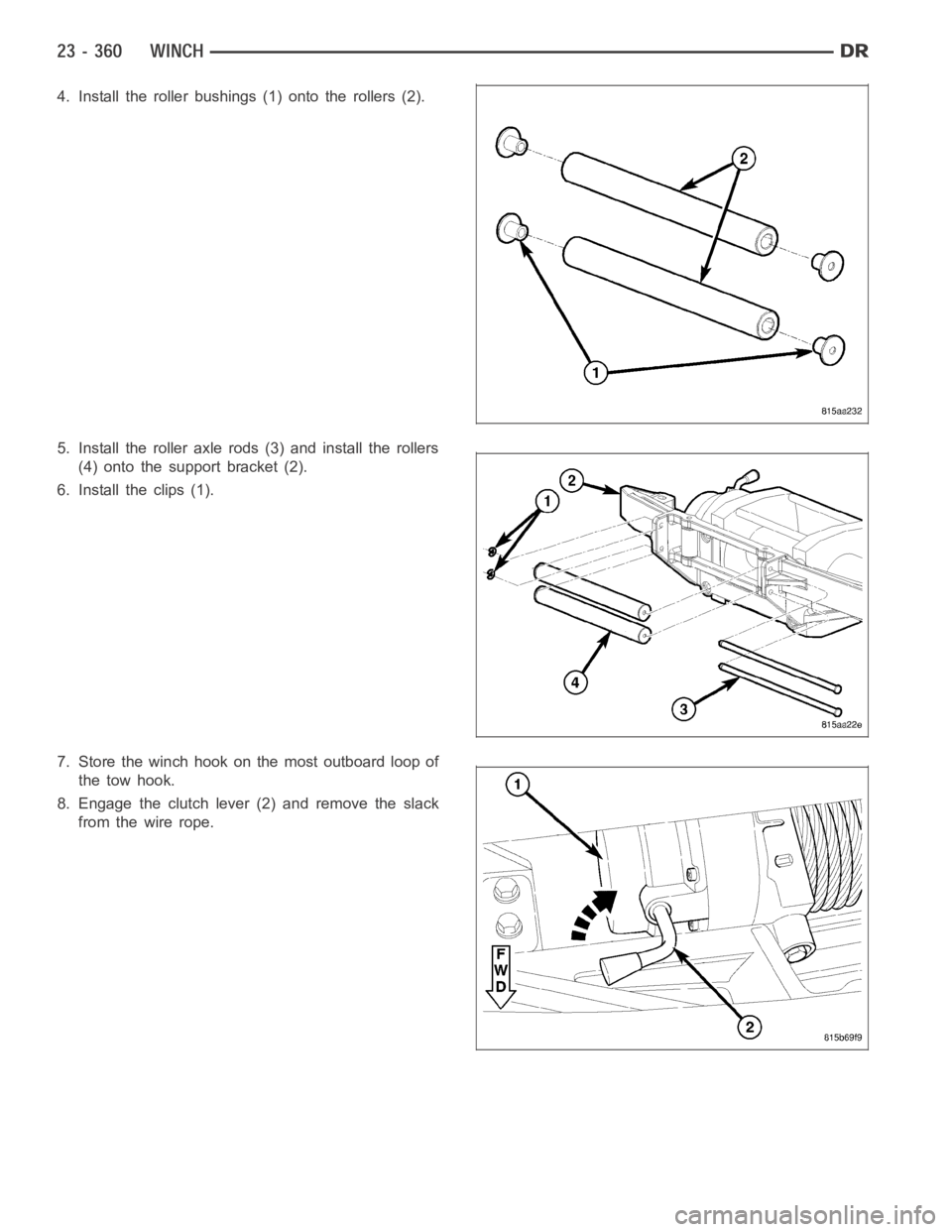

1. Install the roller bushings (2) onto the rollers (1).

2. Install the rollers (4) and install the axle rods (2).

3. Install the clips (3).

Page 4697 of 5267

4. Install the roller bushings (1) onto the rollers (2).

5. Install the roller axle rods (3) and install the rollers

(4) onto the support bracket (2).

6. Install the clips (1).

7. Store the winch hook on the most outboard loop of

the tow hook.

8. Engage the clutch lever (2) and remove the slack

fromthewirerope.

Page 4698 of 5267

page page

GAP AND FLUSH

SPECIFICATIONS ............................ 362

OPENING DIMENSIONS

SPECIFICATIONS ............................ 367

SEALER LOCATIONS

SPECIFICATIONS ............................ 370STRUCTURAL ADHESIVE LOCATIONS

SPECIFICATIONS ............................ 387

WELD LOCATIONS

SPECIFICATIONS ............................ 395

Page 4699 of 5267

GAP AND FLUSH

SPECIFICATIONS

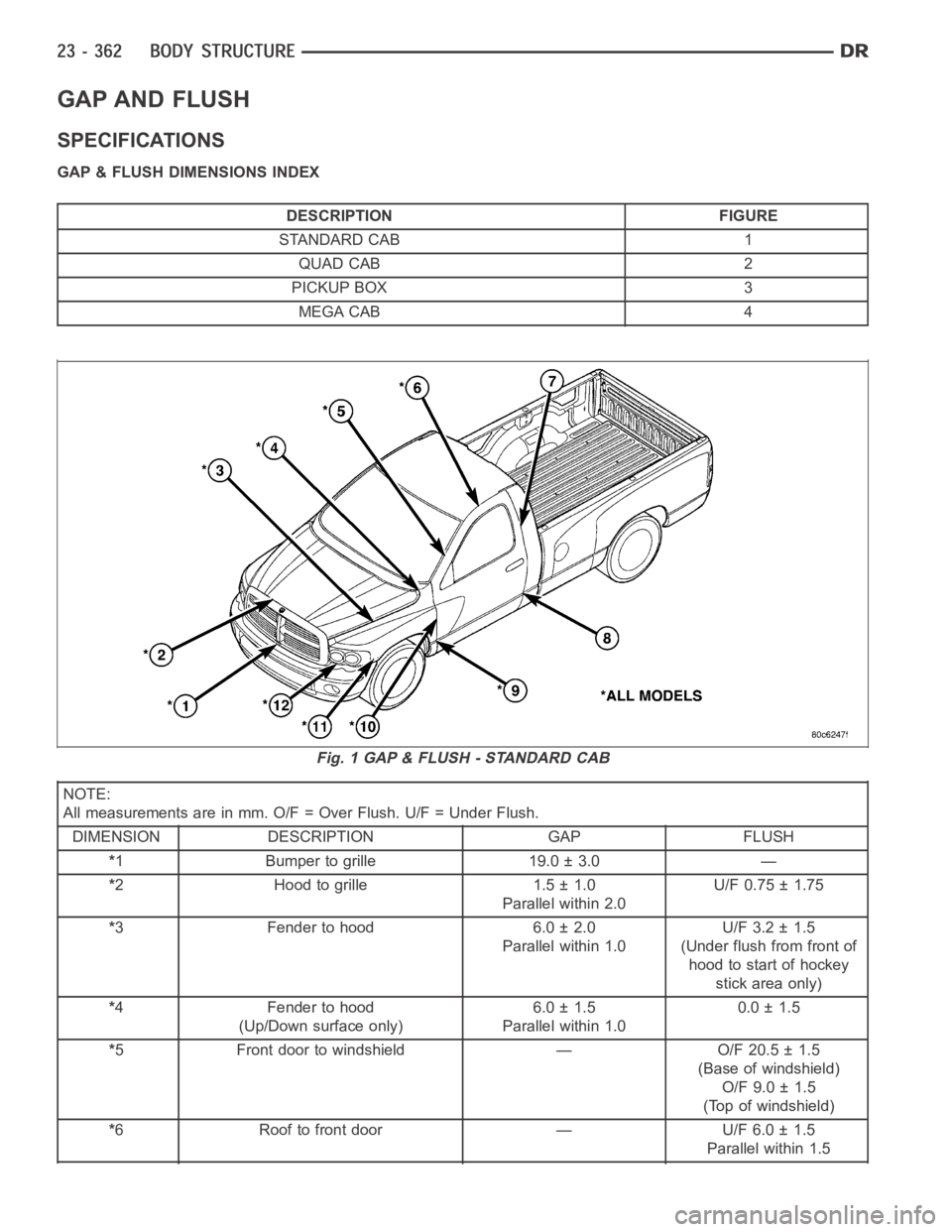

GAP & FLUSH DIMENSIONS INDEX

DESCRIPTION FIGURE

STANDARD CAB 1

QUAD CAB 2

PICKUP BOX 3

MEGA CAB 4

NOTE:

All measurements are in mm. O/F = Over Flush. U/F = Under Flush.

DIMENSION DESCRIPTION GAP FLUSH

*1 Bumper to grille 19.0 ± 3.0 —

*2 Hood to grille 1.5 ± 1.0

Parallel within 2.0U/F 0.75 ± 1.75

*3 Fender to hood 6.0 ± 2.0

Parallel within 1.0U/F 3.2 ± 1.5

(Under flush from front of

hood to start of hockey

stick area only)

*4 Fender to hood

(Up/Down surface only)6.0 ± 1.5

Parallel within 1.00.0 ± 1.5

*5 Front door to windshield — O/F 20.5 ± 1.5

(Base of windshield)

O/F 9.0 ± 1.5

(Top of windshield)

*6 Roof to front door — U/F 6.0 ± 1.5

Parallel within 1.5

Fig. 1 GAP & FLUSH - STANDARD CAB

Page 4700 of 5267

NOTE:

All measurements are in mm. O/F = Over Flush. U/F = Under Flush.

DIMENSION DESCRIPTION GAP FLUSH

7 Quarter to front door 5.0 ± 1.5

Parallel within 1.00.0 ± 1.5

8 Front door to quarter character line

alignment— Up/Down 0.0 ± 1.5

*9 Front door to fender character line

alignment— Up/Down 0.0 ± 1.5

*10 Front door to fender 5.0 ± 1.5

Parallel within 1.00.0 ± 1.5

*11 Bumper to fender 19.0 ± 3.0

Parallel within 3.0O/F 5.0 ± 5.0 (SLT)

O/F 14.0 ± 5.0 (SPORT)

*12 Bumper to headlamp 19.0 ± 4.0 —

*ALLMODELS

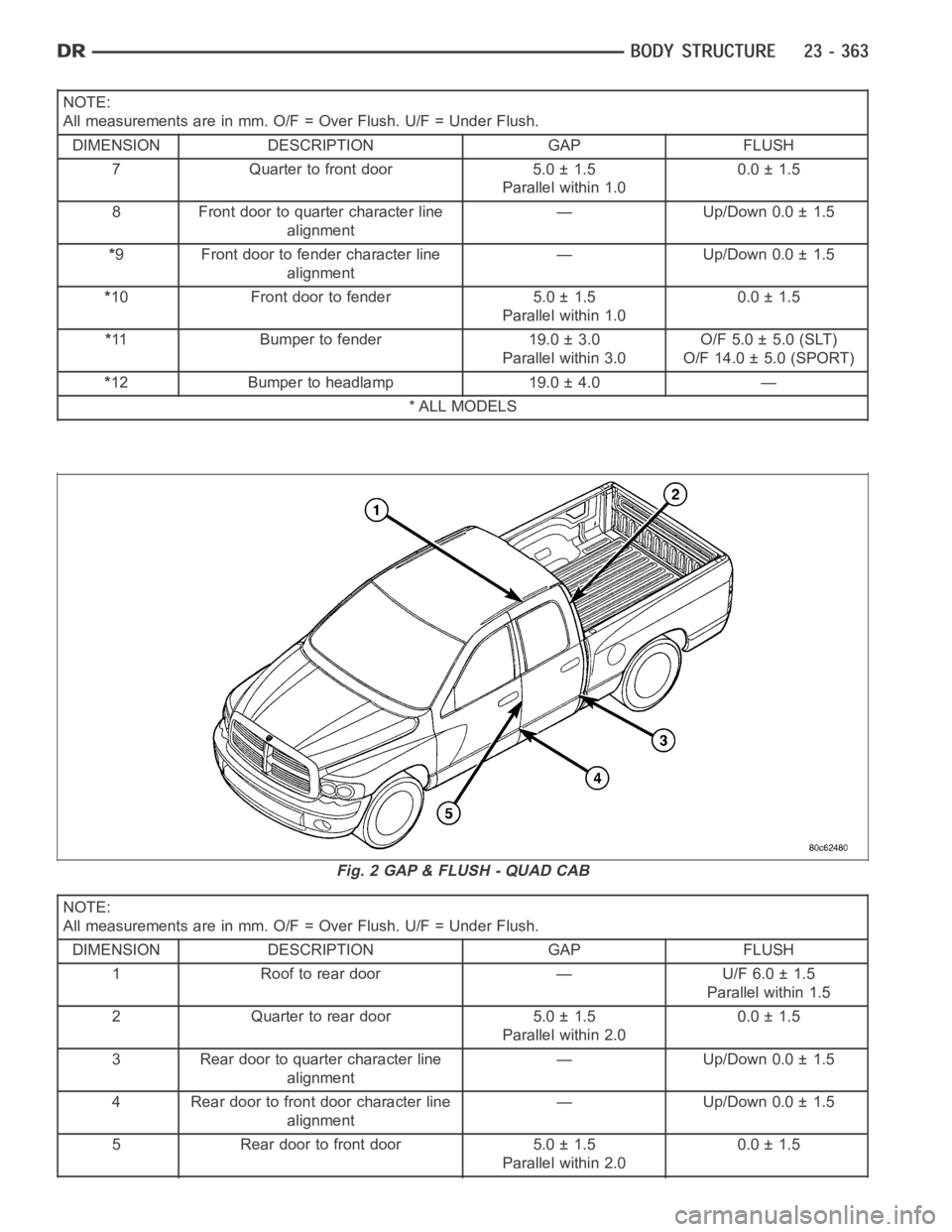

NOTE:

All measurements are in mm. O/F = Over Flush. U/F = Under Flush.

DIMENSION DESCRIPTION GAP FLUSH

1 Roof to rear door — U/F 6.0 ± 1.5

Parallel within 1.5

2 Quarter to rear door 5.0 ± 1.5

Parallel within 2.00.0 ± 1.5

3 Rear door to quarter character line

alignment— Up/Down 0.0 ± 1.5

4 Rear door to front door character line

alignment— Up/Down 0.0 ± 1.5

5 Rear door to front door 5.0 ± 1.5

Parallel within 2.00.0 ± 1.5

Fig. 2 GAP & FLUSH - QUAD CAB

Trending: air condition, instrument cluster, child restraint, low oil pressure, oil temperature, seats, height