reset DODGE RAM SRT-10 2006 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2838 of 5267

When Monitored:

When the ignition is turned from

OFFposition toRUNposition and/or the ignition is turned fromSTART

position toRUNposition.

Set Condition:

This DTC is set when there is less than 3.0 volts present at the transmissioncontrol output circuits located in

the Powertrain Control Module (PCM) when the Transmission Control Systemrequest the power up of those

circuits.Note: Due to the integration of the Transmission Control Module and the Powertrain Control

Module, both systems have their own power and ground circuits..

Possible Causes

RELATED TIPM DTCS

(T515) TRANSMISSION CONTROL CIRCUIT SHORT TO GROUND

(T515) TRANSMISSION CONTROL CIRCUIT OPEN

POWERTRAIN CONTROL MODULE

Always perform the 42RLE Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Control Output circuit is used to supply power to the Transmission Solenoid/TRS Assembly and to

the PCM when in normal operating mode. The purpose of the Transmission Output circuit is to allow the Transmis-

sion Control System to turn off the power to the Transmission Solenoid/TRSAssembly in event that the transmission

should need to be placed into “limp-in” mode due to a DTC.

After a PCM reset, (ignition switch turned to the run position, or after cranking the engine) the Transmission Control

System verifies that the Transmission Output circuit is open by checking for voltage on the Transmission Output

circuits before the Transmission Control System request for the circuit to be powered up. The request is sent by a

direct circuit control from the PCM tothe TIPM. If the Transmission Control System detects less that 3.0 volts when

the output is commanded on, the DTC will set.Note: Inadequate Transmission Control Output voltage can also

cause DTCs P0846, P0869, or P0871 to set. Repairing the P0882 fault should also eliminate the related

DTCs.

Diagnostic Test

1.CHECK IF THE DTC P0882 IS CURRENT

With the scan tool, Check the STARTS SINCE SET counter for P0882.

NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter equal to 0?

Ye s>>

Go To 2

No>>

Go To 5

2.CHECK FOR TIPM RELATED DTCS

With the scan tool, check TIPM DTCs.

Are there any TIPM TCM Power Control circuit DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 3

Page 2842 of 5267

When Monitored:

When the ignition is turned from

OFFposition toRUNposition and/or the ignition is turned fromSTART

position toRUNposition.

Set Condition:

This DTC is set if the Powertrain Control Module senses greater than 3.0 volts on the Transmission Control

Relay Output circuits prior to a request from the PCM to TIPM to energize theTransmission Output circuits.

Possible Causes

TIPM DTCS PRESENT

(T515) TRANSMISSION CONTROL CIRCUIT SHORT TO VOLTAGE

(T16) TRANSMISSION CONTROL OUTPUT CIRCUIT SHORT VOLTAGE

TRANSMISSION SOLENOID/TRS ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the 42RLE Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Control Output circuit is used to supply power to the Transmission Solenoid/TRS Assembly and to

the PCM when in normal operating mode. The purpose of the Transmission Output circuit is to allow the Transmis-

sion Control System to turn off the power to the Transmission Solenoid/TRSAssembly in event that the transmission

should need to be placed into “limp-in” mode due to a DTC.

After a PCM reset, (ignition switch turned to the run position, or after cranking the engine) the Transmission Control

System verifies that the Transmission Output circuit is open by checking for voltage on the Transmission Output

circuits before the Transmission Control System request for the circuit to be powered up. The request is sent by a

direct circuit control from the PCM tothe TIPM. If voltage is detected on the Transmission Output circuits before the

request is sent, the DTC will set.

Diagnostic Test

1.CHECK FOR TCM TIPM DTCS

With the scan tool under TIPM, check for TCM Power Control circuit DTCs.

Are there any TIPM TCM Power Control circuit DTCS present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK TO SEE IF DTC P0883 IS CURRENT

With the scan tool, check the STARTS SINCE SET counter.

NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter set to 0?

Ye s>>

Go To 3

No>>

Go To 6

Page 2845 of 5267

P0884-POWER UP AT SPEED

For a complete wiring diagramRefer to Section 8W.

When Monitored:

One time after each controller reset. Note: the Transmission Control Module is integrated with Powertrain Con-

trol Module. The Transmission Control Module has separate powers and grounds specifically to its portion of

the PCM.

Set Condition:

This DTC will set if the PCM powers up and senses the vehicle in a valid forward gear (no PRNDL DTCs) with

a output speed above 800 RPM, approximately 32 Kmh or 20 mph.

Possible Causes

INTERMITTENT POWER AND GROUND CIRCUITS

Always perform the 42RLE Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

If a vehicle loses power to the PCM, the vehicle will go to the 2nd gear mode since there is no power available to

control the transmission solenoids. However if power is restored, the PCMwill power-up and normal operation will

be restored. This DTC identifies that power to the PCM was restored when thegear selector was in a

Driveposi-

tion while the vehicle was moving at speeds above 32 Kmh (20 mph). If a customer shifts to Neutral and cycles the

ignition key and quickly shifts to

Drivewhile moving before the PCM comes out of its START ROUTINE, the DTC

can be set. Therefore it is critical that this DTC diagnosis repair procedure should only be used if the vehicle is

experiencing intermittent 2nd gear operation and subsequently a return to normal operation during normal driving.

The transmission will not be placed in Limp-in. This is an informational DTC to be used when attempting to diag-

nose an intermittent 2nd gear operation and subsequent return to normal transmission operation.

Diagnostic Test

1.CHECK THE POWER AND GROUND CIRCUITS

This DTC is set when the PCM is initialized while the vehicle is moving in a valid forward gear. This is usually

caused by a momentary loss of power to the Transmission portion of the PCM.

CAUTION: Do not probe the PCM harness connectors. Probing the PCM harness connectors will damage

the PCM terminals resulting in poor terminal to pin connection. Install Miller tool #8815 to perform diagno-

sis.

NOTE: Due to the integration of the Powertrain and Transmission Control Modules, the transmission part of

the PCM has its own specific power and ground circuits.

Check all of the Fused B(+), Fused Ignition Switch Output, and Ground circuits related to the PCM for an intermit-

tent open or short to ground.

Perform a wiggle test on all wiring and connectors pertaining to the PCM while looking for shorted or open circuits.

With the scan tool, check the DTC EVENT DATA to help identify the conditionsin which the DTC was set.

If there are no possible causes remaining, view repair.

Repair

Repair as necessary.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Page 2847 of 5267

When Monitored:

One time after a reset (ignition key turned to the RUN position or after cranking engine).

Set Condition:

A fault is set if voltage greater than 4.5 volts is detected for 7 msec on any of the pressure switch circuits

before the relay is energized. The transmission is placed in Limp-In. The MIL is on after 10 seconds. of vehicle

operation.

Possible Causes

(T47) 2/4 PRESSURE SWITCH SENSE CIRCUIT SHORT TO VOLTAGE

(T50) L/R PRESSURE SWITCH SENSE CIRCUIT SHORT TO VOLTAGE

(T9) OD PRESSURE SWITCH SENSE CIRCUIT SHORT TO VOLTAGE

POWERTRAIN CONTROL MODULE

Always perform the 42RLE Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

The transmission relay is used to supply power to the solenoid pack when in normal operating mode and to turn off

power to produce transmission

limp-inmode. The relay output (which supplies power to the solenoid pack) is fed

back to the controller. It is referred to as SWITCHED BATTERY. After a controller reset (ignition key turned to the

RUN position or after cranking engine), the controller verifies that the relay contacts are open by checking for no

voltage on Switched battery line (transmission control relay output) before the relay is energized. After switched

battery is verified for no voltage, the voltage of each of the solenoid packpressure switches is also checked. Since

the solenoid pack is not powered up, there should be no voltage on any of the pressure switches.

Diagnostic Test

1.CHECK TO SEE IF DTC P0890 IS PRESENT

With the scan tool, view DTCs.

Is the status Active for this DTC or is the STARTS SINCE SET counter set at 0?

Ye s>>

Go To 2

No>>

Go To 5

Page 2850 of 5267

P0897-TRANSMISSION FLUID DETERIORATED

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Each transition from full EMCC to partial EMCC for A/C bump prevention.

Set Condition:

DTC set if 20 occurrences of a turbine acceleration sum. Fault Set Time: 20 transitions from full EMCC to

partial EMCC. Transmission will not use partial EMCC. Established for A/Cbump prevention.

Possible Causes

WORN OUT/ BURNT TRANSAXLE FLUID

Always perform the 42RLE Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

To prevent a bump due to A/C clutch engagement, a temporary torque converter partial EMCC condition is estab-

lished prior to A/C clutch engagement. A message is received over the bus indicating that A/C clutch engagement

is imminent. Partial EMCC is then established and a reply message,

OK to engage A/C clutchis sent via the bus.

Partial EMCC will be held for 450 ms before returning to full EMCC. During the transition from full to partial EMCC,

a turbine acceleration sum is calculated, if this value exceeds a threshold value for several transitions, degraded

transmission fluid is indicated.

Diagnostic Test

1.WORN OUT/ BURNT TRANSMISSION FLUID

Turn the ignition off to the lock position.

Flush the Transmission Oil Cooler and lines, replace the Transmission OilFilter, refill with new Transmission Fluid,

start the engine, and adjust the fluid per the Service Information.

NOTE: The Transmission Cooler must be flushed before proceeding.

Allow the engine to idle for 10 minutes, in Park.

Turn the ignition off to the lock position.

Again, flush the Transmission Oil Cooler and lines, replace the Transmission Oil Filter, refill with new Transmission

Fluid, start the engine, and adjust the fluid per the Service Information.

With the scan tool, perform a Battery Disconnect.

NOTE: The Battery Disconnect must be done to re-enable EMCC during an A/C Clutch engagement.

NOTE: The vehicle may exhibit intermittent shudder during the first few hundred miles. The new Transmis-

sion Fluid will gradually penetrate the Torque Convertor Clutch frictionmaterial and the shudder should

disappear.

Erase the DTC and return the vehicle to the customer.

Did the DTC reset and/or does the vehicle still shudder after a few thousandmiles?

Ye s>>

Replace the Torque Converter per the Service Information.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 2852 of 5267

When Monitored:

Continuously with the ignition on, engine running, with the transmissionin gear.

Set Condition:

The PCM continuously monitors Actual Line Pressure and compares it to DesiredLinePressure.IftheActual

Line Pressure reading is more than 172.4 kPa (25 psi) higher than the Desired Line Pressure, but is less than

the highest Line Pressure ever used in the current gear, the DTC sets.

Possible Causes

RELATED DTC’S PRESENT

LINE PRESSURE CONNECTOR AND WIRING

INTERNAL TRANSMISSION

POWERTRAIN CONTROL MODULE

Always perform the 42RLE Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

Line pressure is electronically controlled by the Transmission Control System and is measured by the Line Pressure

Sensor (LPS). The desired line pressure is continuously being compared tothe actual line pressure and is regulated

by electronically changing the dutycycle of the Pressure Control Solenoid (PCS). (5% duty cycle = solenoid off =

max line pressure, 62% duty cycle =solenoid on = min line pressure).

The Transmission Control System calculates the desired line pressure based on inputs from the transmission and

engine. A calculated torque input to the transmission is used as the primary input of the desired line pressure cal-

culation and is called Torque Based Line Pressure. In addition, the line pressure is set to a preset level 827 to 931

kPa (120 to 135 psi) during shifts and in Park and Neutral to ensure consistent shift quality.

Diagnostic Test

1.DETERMINING IF RELATED DTCS ARE PRESENT

With the scan tool, check for other transmission DTCs.

Are there any other line pressure related DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom. Perform the test for P0934

and/or P0935 first if present.

No>>

Go To 2

2.COMPARE ACTUAL LINE PRESSURE TO DESIRED LINE PRESSURE

CAUTION: Apply Parking Brake

Start the engine.

CAUTION: Firmly apply the brakes.

With the scan tool, monitor the Line Pressure, Desired Line Pressure and the TPS degrees.

While firmly applying the brakes, place the shifter in reverse, then slowly press the accelerator pedal to a TPS

degree of 15°.

Compare the Line Pressure reading to the Desired Line Pressure reading on the scan tool.

Does the Line Pressure stay within ± 34 kPa or 5 psi of the Desired Line Pressure?

No>>

Go To 3

Ye s>>

Go To 5

Page 2855 of 5267

When Monitored:

Continuously with the ignition on and engine running.

Set Condition:

This DTC will set when the monitored Line Pressure Sensor voltage is less than or equal to 0.35 volts for 0.18

seconds.

Possible Causes

(F856) 5-VOLT SUPPLY CIRCUIT OPEN

(F856) 5-VOLT SUPPLY CIRCUIT SHORT TO GROUND

(T38) LINE PRESSURE SENSOR SIGNAL CIRCUIT SHORT TO GROUND

LINE PRESSURE SENSOR

POWERTRAIN CONTROL MODULE

Always perform the 42RLE Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

Line pressure is electronically controlled by the Transmission Control System and is measured by the Line Pressure

Sensor (LPS). The desired line pressure is continuously being compared tothe actual line pressure and is regulated

by electronically changing the dutycycle of the Pressure Control Solenoid (PCS). (5% duty cycle = solenoid off =

max line pressure, 62% duty cycle =solenoid on = min line pressure).

The Transmission Control System calculates the desired line pressure based on inputs from the transmission and

engine. A calculated torque input to the transmission is used as the primary input of the desired line pressure cal-

culation and is called Torque Based Line Pressure. In addition, the line pressure is set to a preset level 827 to 931

kPa (120 to 135 PSI) during shifts and in Park and Neutral to ensure consistent shift quality.

The monitored Line Pressure Sensor voltage should always be between 0.35 and 4.75 volts. Any monitored volt-

ages outside these parameters indicate an Line Pressure Sensor or wiring problem and will cause either DTC

P0934 or P0935 to set.

Diagnostic Test

1.CHECK IF DTC IS CURRENT

With the scan tool, check the STARTS SINCE SET counter for P0934.

NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter 2 or less?

Ye s>>

Go To 2

No>>

Go To 6

2.CHECK THE PCM AND WIRING

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator,Miller tool #8333 and the ElectronicTransmission Adapter kit.

Ignition on, engine not running.

With the scan tool, under Transmission Sensors, monitor the Line Pressure.

Using the Transmission Simulator, set the rotary switch to each of the 3 line pressure positions.

Page 2860 of 5267

When Monitored:

Continuously with ignition on and engine running.

Set Condition:

This DTC will set if the monitored Line Pressure Sensor voltage is greater than or equal to 4.75 volts for the

period of 0.18 seconds

Possible Causes

(T38) LINE PRESSURE SENSOR SIGNAL CIRCUIT OPEN

(K900) SENSOR GROUND CIRCUIT OPEN

(T38) LINE PRESSURE SENSOR SIGNAL CIRCUIT SHORT TO VOLTAGE

LINE PRESSURE SENSOR

POWERTRAIN CONTROL MODULE

Always perform the 42RLE Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

Theory of Operation

Line pressure is electronically controlled by the Transmission Control System and is measured by the Line Pressure

Sensor (LPS). The desired line pressure is continuously being compared tothe actual line pressure and is regulated

by electronically changing the dutycycle of the Pressure Control Solenoid (PCS). (5% duty cycle = solenoid off =

max line pressure, 62% duty cycle =solenoid on = min line pressure).

The Transmission Control System calculates the desired line pressure based on inputs from the transmission and

engine. A calculated torque input to the transmission is used as the primary input of the desired line pressure cal-

culation and is called Torque Based Line Pressure. In addition, the line pressure is set to a preset level 827 to 931

kPa (120 to 135 PSI) during shifts and in Park and Neutral to ensure consistent shift quality.

The monitored Line Pressure Sensor voltage should always be between 0.35 and 4.75 volts. Any monitored volt-

ages outside these parameters indicate an Line Pressure Sensor or wiring problem and will cause either DTC

P0934 or P0935 to set.

Diagnostic Test

1.CHECK TO SEE IF DTC IS CURRENT

With the scan tool, Check the STARTS SINCE SET counter for P0935.

NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter 2 or less?

Ye s>>

Go To 2

No>>

Go To 6

2.CHECK THE PCM AND WIRING

Turn the ignition off to the lock position.

Remove the Starter Relay.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator,Miller tool #8333 and the ElectronicTransmission Adapter kit.

Ignition on, engine not running.

With the scan tool, monitor the Line Pressure.

Using the Transmission Simulator, set the rotary switch to each of the 3 line pressure positions.

Page 2869 of 5267

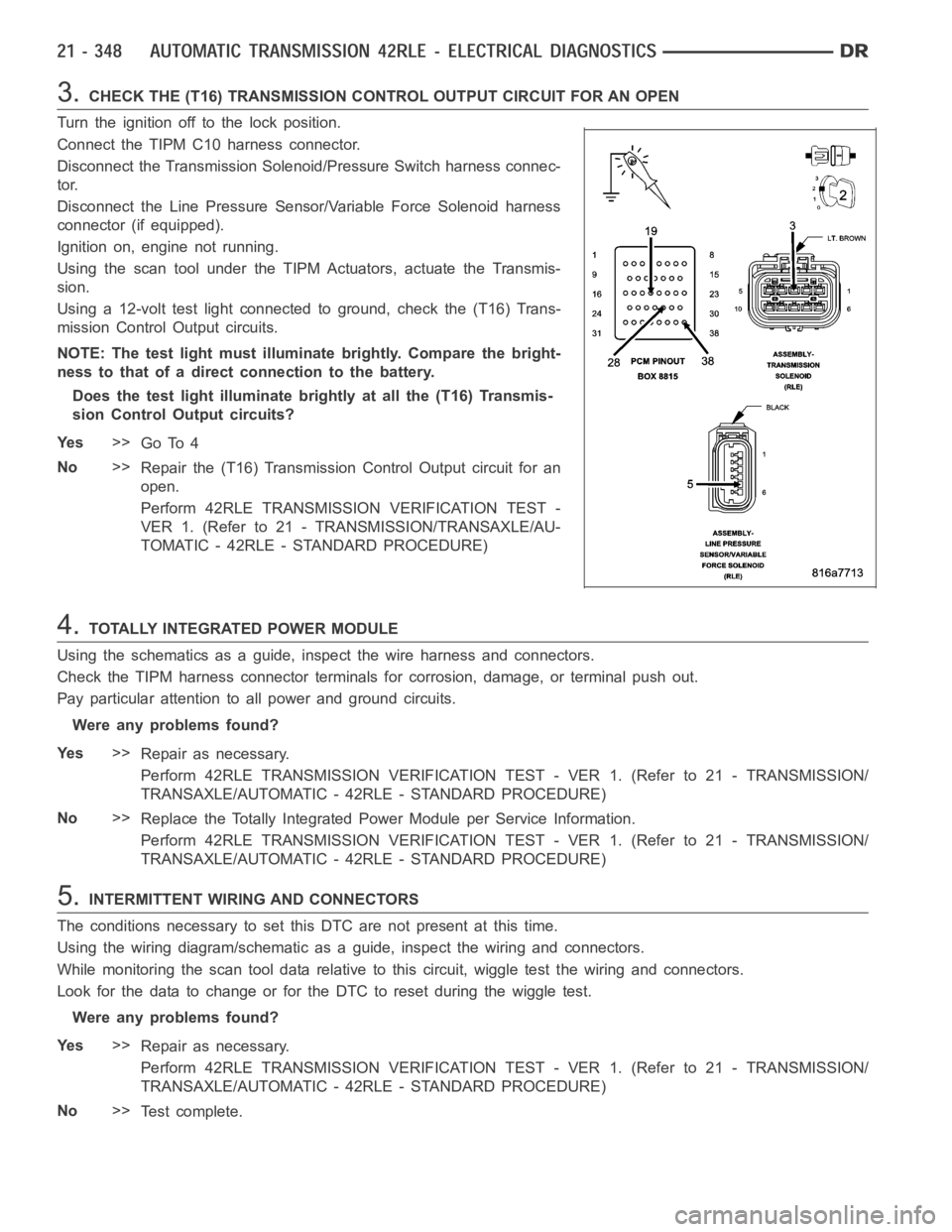

3.CHECK THE (T16) TRANSMISSION CONTROL OUTPUT CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Connect the TIPM C10 harness connector.

Disconnect the Transmission Solenoid/Pressure Switch harness connec-

tor.

Disconnect the Line Pressure Sensor/Variable Force Solenoid harness

connector (if equipped).

Ignition on, engine not running.

Using the scan tool under the TIPM Actuators, actuate the Transmis-

sion.

Using a 12-volt test light connected to ground, check the (T16) Trans-

mission Control Output circuits.

NOTE: The test light must illuminate brightly. Compare the bright-

ness to that of a direct connection to the battery.

Does the test light illuminate brightly at all the (T16) Transmis-

sion Control Output circuits?

Ye s>>

Go To 4

No>>

Repair the (T16) Transmission Control Output circuit for an

open.

Perform 42RLE TRANSMISSION VERIFICATION TEST -

VER 1. (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 42RLE - STANDARD PROCEDURE)

4.TOTALLY INTEGRATED POWER MODULE

Using the schematics as a guide, inspect the wire harness and connectors.

Check the TIPM harness connector terminals for corrosion, damage, or terminal push out.

Pay particular attention to all power and ground circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

5.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .

Page 2872 of 5267

3.TOTALLY INTEGRATED POWER MODULE

Using the schematics as a guide, inspect the wire harness and connectors.

Check the TIPM harness connector terminals for corrosion, damage, or terminal push out

Pay particular attention to all power and ground circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

4.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform 42RLE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 42RLE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .