reset DODGE RAM SRT-10 2006 Service Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3261 of 5267

16.CHECK IF THE DTC RESETS

Reconnect all previously disconnected connectors.

With the scan tool, erase all transmission DTCs.

Test drive the vehicle. Using the DTC EVENT DATA recorded earlier, try to duplicate the conditions in which the

DTC originally set.

Does the DTC P0876 reset?

Ye s>>

Go To 17

No>>

Go To 18

17.CHECK FOR A CUT NO. 2 CHECK BALL

Remove the Valve Body per the Service Information.

Check the No. 2 check ball for cuts or damage.

Is the No. 2 check ball cut or damaged?

Ye s>>

Replace the No. 2 check ball. Check for excessive clutch debris in the oil pan. If excessive debris is

present, check the UD Clutch and repair as necessary.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Replace the Transmission Solenoid/TRS Assembly per the Service Information. Check for excessive

clutch debris in the oil pan. If excessive debris is present, check the UD Clutch and repair as necessary.

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE/TRANS SOLENOID/TRS

ASSY - REMOVAL)

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

18.CHECK FOR INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specifictothiscircuit.

Wiggle the wires while checking for shorted and open circuits.

With the scan tool, check the DTC EVENT DATA to help identify the conditionsin which the DTC was set.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 3263 of 5267

When Monitored:

When the ignition is turned from

OFFposition toRUNposition and/or the ignition is turned fromSTART

position toRUNposition.

Set Condition:

This DTC is set when there is less than 3.0 volts present at the transmissioncontrol output circuits located in

the Powertrain Control Module (PCM) when the Transmission Control Systemrequest the power up of those

circuits.Note: Due to the integration of the Transmission Control Module and the Powertrain Control

Module, both systems have their own power and ground circuits..

Possible Causes

RELATED TIPM DTCS

(T515) TRANSMISSION CONTROL CIRCUIT SHORT TO GROUND

(T515) TRANSMISSION CONTROL CIRCUIT OPEN

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Control Output circuit is used to supply power to the Transmission Solenoid/TRS Assembly and to

the PCM when in normal operating mode. The purpose of the Transmission Output circuit is to allow the Transmis-

sion Control System to turn off the power to the Transmission Solenoid/TRSAssembly in event that the transmission

should need to be placed into “limp-in” mode due to a DTC.

After a PCM reset, (ignition switch turned to the run position, or after cranking the engine) the Transmission Control

System verifies that the Transmission Output circuit is open by checking for voltage on the Transmission Output

circuits before the Transmission Control System request for the circuit to be powered up. The request is sent by a

direct circuit control from the PCM tothe TIPM. If the Transmission Control System detects less that 3.0 volts when

the output is commanded on, the DTC will set.Note: Inadequate Transmission Control Output voltage can also

cause DTCs P0846, P0869, P0871, P0876 or P0988 to set. Repairing the P0882 fault should also eliminate the

related DTCs.

Diagnostic Test

1.CHECK IF THE DTC P0882 IS CURRENT

With the scan tool, Check the STARTS SINCE SET counter for P0882.

NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter equal to 0?

Ye s>>

Go To 2

No>>

Go To 5

2.CHECK FOR TIPM RELATED DTCS

With the scan tool, check TIPM DTCs.

Are there any TCM TIPM DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 3

Page 3267 of 5267

When Monitored:

When the ignition is turned from

OFFposition toRUNposition and/or the ignition is turned fromSTART

position toRUNposition.

Set Condition:

This DTC is set if the Powertrain Control Module senses greater than 3.0 volts on the Transmission Control

Relay Output circuits prior to a request from the PCM to TIPM to energize theTransmission Output circuits.

Possible Causes

TIPM DTCS PRESENT

(T15) TRANSMISSION CONTROL CIRCUIT SHORT TO VOLTAGE

(T16) TRANSMISSION CONTROL OUTPUT CIRCUIT SHORT VOLTAGE

TRANSMISSION SOLENOID/TRS ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Control Output circuit is used to supply power to the Transmission Solenoid/TRS Assembly and to

the PCM when in normal operating mode. The purpose of the Transmission Output circuit is to allow the Transmis-

sion Control System to turn off the power to the Transmission Solenoid/TRSAssembly in event that the transmission

should need to be placed into “limp-in” mode due to a DTC.

After a PCM reset, (ignition switch turned to the run position, or after cranking the engine) the Transmission Control

System verifies that the Transmission Output circuit is open by checking for voltage on the Transmission Output

circuits before the Transmission Control System request for the circuit to be powered up. The request is sent by a

direct circuit control from the PCM tothe TIPM. If voltage is detected on the Transmission Output circuits before the

request is sent, the DTC will set.

Diagnostic Test

1.CHECK FOR TCM TIPM DTCS

With the scan tool under TIPM, check for TCM Power Input DTCs.

Are there any TIPM TCM Power Input DTCS present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK TO SEE IF DTC P0883 IS CURRENT

With the scan tool, check the STARTS SINCE SET counter.

NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter set to 0?

Ye s>>

Go To 3

No>>

Go To 6

Page 3273 of 5267

When Monitored:

When the ignition is turned from

OFFposition toRUNposition and/or the ignition is turned fromSTART

position toRUNposition.

Set Condition:

This DTC is set if the Powertrain Control Module senses voltage on any of thepressure switch inputs prior to

the Transmission Control Output circuit being energized.

Possible Causes

PRESSURE SWITCH SENSE CIRCUITS SHORT TO VOLTAGE

TRANSMISSION SOLENOID/TRS ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Totally Integrated Control Module (TIPM) replaces the Transmission control relay. The Transmission Control

Output circuit It is used to supply power to the solenoids and pressure switches (Transmission Solenoid/TRS

Assembly) when the transmission is in normal operating mode. When the Transmission Control Output circuit is off,

no power is supplied and the transmission.

Immediately after a controller reset (ignition key turned to the

runposition or after cranking engine), the TCM ver-

ifies that the Transmission Control Output circuits are open by checking for no voltage at the transmission control

output terminals at the PCM. After this is verified, the voltage at the pressure switches are checked. There should

be no voltage on the pressure switches at this time. The PCM will then activate the relay.

Diagnostic Test

1.CHECK FOR TIPM TCM DTCS

With the scan tool under TIPM, check for TCM Power Control DTCs.

Are there any TCM Power Control DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK TO SEE IF DTC P0890 IS PRESENT

With the scan tool, Check the STARTS SINCE SET counter for P0890.

NOTE: This counter only applies to the last DTC set.

Is the

Starts Since Setcounter set at 0?

Ye s>>

Go To 3

No>>

Go To 5

Page 3277 of 5267

When Monitored:

Continuously with the ignition on, engine running, with the transmissionin gear.

Set Condition:

The PCM continuously monitors Actual Line Pressure and compares it to DesiredLinePressure.IftheActual

Line Pressure reading is more than 172.4 kPa (25 psi) higher than the Desired Line Pressure, but is less than

the highest Line Pressure ever used in the current gear, the DTC sets.

Possible Causes

RELATED DTC’S PRESENT

LINE PRESSURE CONNECTOR AND WIRING

INTERNAL TRANSMISSION

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

Line pressure is electronically controlled by the Transmission Control System and is measured by the Line Pressure

Sensor (LPS). The desired line pressure is continuously being compared tothe actual line pressure and is regulated

by electronically changing the dutycycle of the Pressure Control Solenoid (PCS). (5% duty cycle = solenoid off =

max line pressure, 62% duty cycle =solenoid on = min line pressure).

The Transmission Control System calculates the desired line pressure based on inputs from the transmission and

engine. A calculated torque input to the transmission is used as the primary input of the desired line pressure cal-

culation and is called Torque Based Line Pressure. In addition, the line pressure is set to a preset level 827 to 931

kPa (120 to 135 psi) during shifts and in Park and Neutral to ensure consistent shift quality.

Diagnostic Test

1.DETERMINING IF RELATED DTCS ARE PRESENT

With the scan tool, check for other transmission DTCs.

Are there any other line pressure related DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom. Perform the test for P0934

and/or P0935 first if present.

No>>

Go To 2

2.COMPARE ACTUAL LINE PRESSURE TO DESIRED LINE PRESSURE

CAUTION: Apply Parking Brake

Start the engine.

CAUTION: Firmly apply the brakes.

With the scan tool, monitor the Line Pressure, Desired Line Pressure and the TPS degrees.

While firmly applying the brakes, place the shifter in reverse, then slowly press the accelerator pedal to a TPS

degree of 15°.

Compare the Line Pressure reading to the Desired Line Pressure reading on the scan tool.

Does the Line Pressure stay within ± 34 kPa or 5 psi of the Desired Line Pressure?

No>>

Go To 3

Ye s>>

Go To 5

Page 3280 of 5267

When Monitored:

Continuously with the ignition on and engine running.

Set Condition:

This DTC will set when the monitored Line Pressure Sensor voltage is less than or equal to 0.35 volts for 0.18

seconds.

Possible Causes

(F856) 5-VOLT SUPPLY CIRCUIT OPEN

(F856) 5-VOLT SUPPLY CIRCUIT SHORT TO GROUND

(T38) LINE PRESSURE SENSOR SIGNAL CIRCUIT SHORT TO GROUND

LINE PRESSURE SENSOR

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

Line pressure is electronically controlled by the Transmission Control System and is measured by the Line Pressure

Sensor (LPS). The desired line pressure is continuously being compared tothe actual line pressure and is regulated

by electronically changing the dutycycle of the Pressure Control Solenoid (PCS). (5% duty cycle = solenoid off =

max line pressure, 62% duty cycle =solenoid on = min line pressure).

The Transmission Control System calculates the desired line pressure based on inputs from the transmission and

engine. A calculated torque input to the transmission is used as the primary input of the desired line pressure cal-

culation and is called Torque Based Line Pressure. In addition, the line pressure is set to a preset level 827 to 931

kPa (120 to 135 psi) during shifts and in Park and Neutral to ensure consistent shift quality.

The monitored Line Pressure Sensor voltage should always be between 0.35 and 4.75 volts. Any monitored volt-

ages outside these parameters indicate an Line Pressure Sensor or wiring problem and will cause either DTC

P0934 or P0935 to set.

Diagnostic Test

1.CHECK IF DTC IS CURRENT

With the scan tool, check the STARTS SINCE SET counter for P0934.

NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter 2 or less?

Ye s>>

Go To 2

No>>

Go To 6

2.CHECK THE PCM AND WIRING

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the scan tool, under Transmission Sensors, monitor the Line Pressure.

Using the Transmission Simulator, set the rotary switch to each of the 3 line pressure positions.

Page 3285 of 5267

When Monitored:

Continuously with ignition on and engine running.

Set Condition:

This DTC will set if the monitored Line Pressure Sensor voltage is greater than or equal to 4.75 volts for the

period of 0.18 seconds

Possible Causes

(T38) LINE PRESSURE SENSOR SIGNAL CIRCUIT OPEN

(K900) SENSOR GROUND CIRCUIT OPEN

(T38) LINE PRESSURE SENSOR SIGNAL CIRCUIT SHORT TO VOLTAGE

LINE PRESSURE SENSOR

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

Line pressure is electronically controlled by the Transmission Control System and is measured by the Line Pressure

Sensor (LPS). The desired line pressure is continuously being compared tothe actual line pressure and is regulated

by electronically changing the dutycycle of the Pressure Control Solenoid (PCS). (5% duty cycle = solenoid off =

max line pressure, 62% duty cycle =solenoid on = min line pressure).

The Transmission Control System calculates the desired line pressure based on inputs from the transmission and

engine. A calculated torque input to the transmission is used as the primary input of the desired line pressure cal-

culation and is called Torque Based Line Pressure. In addition, the line pressure is set to a preset level 827 to 931

kPa (120 to 135 psi) during shifts and in Park and Neutral to ensure consistent shift quality.

The monitored Line Pressure Sensor voltage should always be between 0.35 and 4.75 volts. Any monitored volt-

ages outside these parameters indicate an Line Pressure Sensor or wiring problem and will cause either DTC

P0934 or P0935 to set.

Diagnostic Test

1.CHECK TO SEE IF DTC IS CURRENT

With the scan tool, Check the STARTS SINCE SET counter for P0935.

NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter 2 or less?

Ye s>>

Go To 2

No>>

Go To 6

2.CHECK THE PCM AND WIRING

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the scan tool, monitor the Line Pressure.

Using the Transmission Simulator, set the rotary switch to each of the 3 line pressure positions.

Page 3307 of 5267

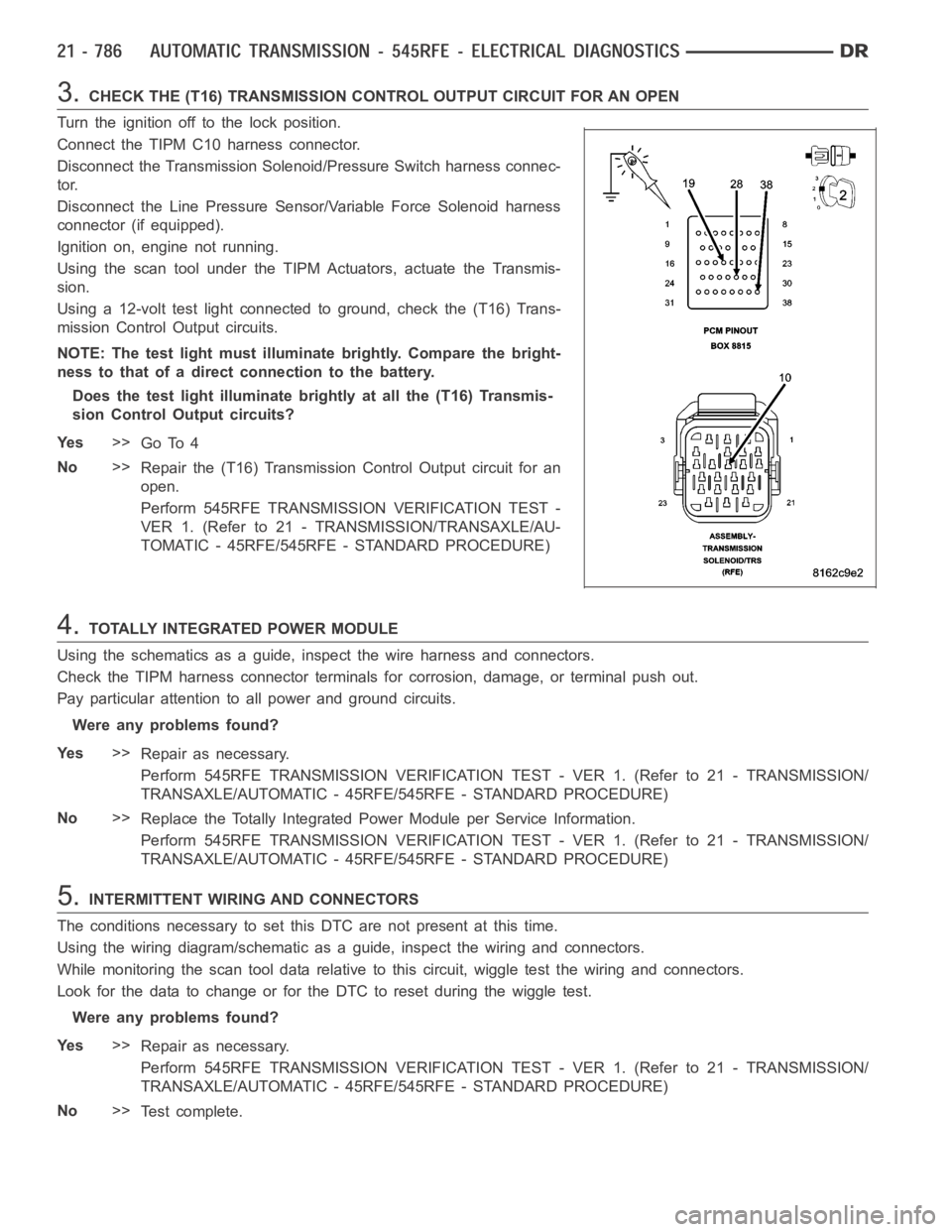

3.CHECK THE (T16) TRANSMISSION CONTROL OUTPUT CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Connect the TIPM C10 harness connector.

Disconnect the Transmission Solenoid/Pressure Switch harness connec-

tor.

Disconnect the Line Pressure Sensor/Variable Force Solenoid harness

connector (if equipped).

Ignition on, engine not running.

Using the scan tool under the TIPM Actuators, actuate the Transmis-

sion.

Using a 12-volt test light connected to ground, check the (T16) Trans-

mission Control Output circuits.

NOTE: The test light must illuminate brightly. Compare the bright-

ness to that of a direct connection to the battery.

Does the test light illuminate brightly at all the (T16) Transmis-

sion Control Output circuits?

Ye s>>

Go To 4

No>>

Repair the (T16) Transmission Control Output circuit for an

open.

Perform 545RFE TRANSMISSION VERIFICATION TEST -

VER 1. (Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

4.TOTALLY INTEGRATED POWER MODULE

Using the schematics as a guide, inspect the wire harness and connectors.

Check the TIPM harness connector terminals for corrosion, damage, or terminal push out.

Pay particular attention to all power and ground circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform 545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform 545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

5.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform 545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .

Page 3310 of 5267

4.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform 545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .

Page 3313 of 5267

3.TOTALLY INTEGRATED POWER MODULE

Using the schematics as a guide, inspect the wire harness and connectors.

Check the TIPM harness connector terminals for corrosion, damage, or terminal push out.

Pay particular attention to all power and ground circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform 545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform 545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

4.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform 545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .