DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 5091 of 5267

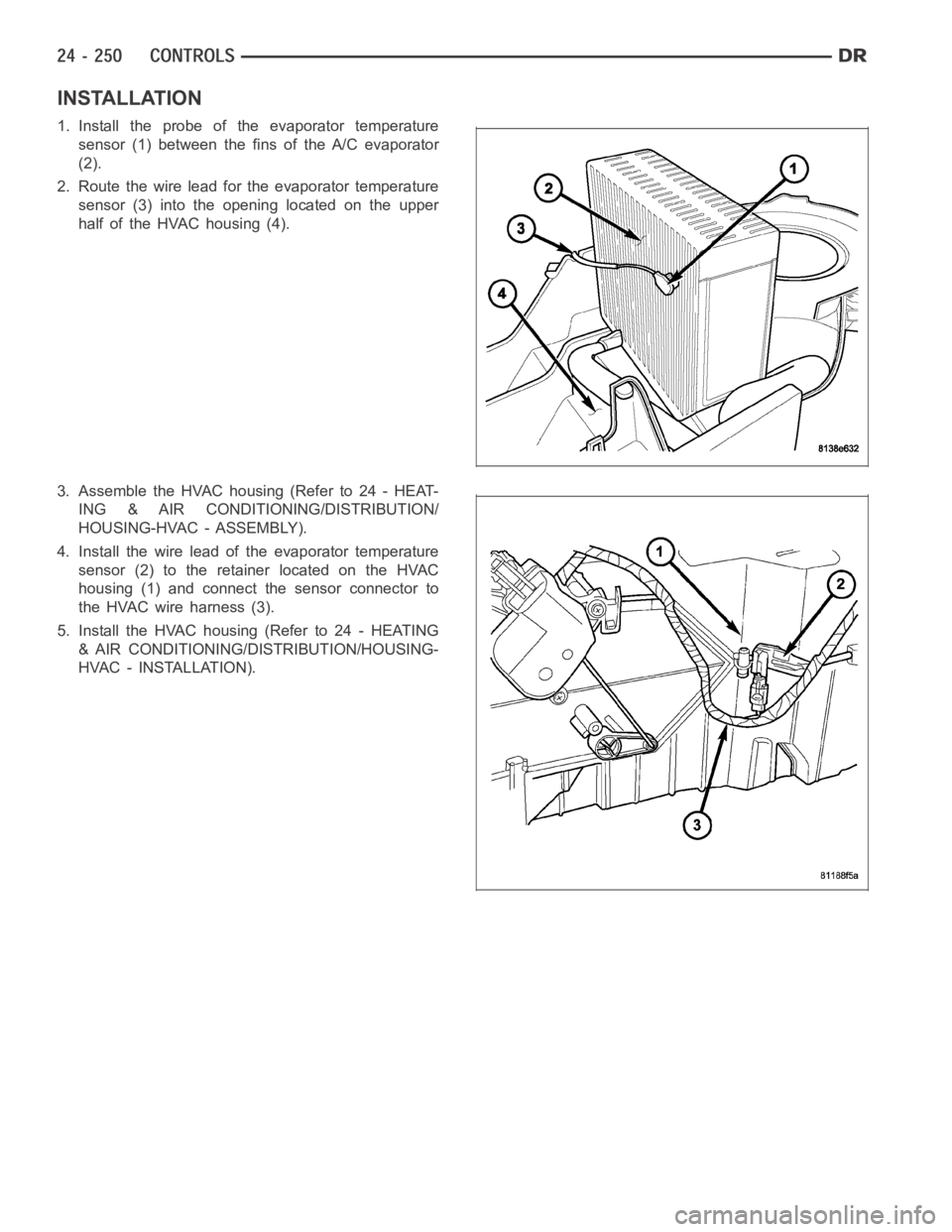

INSTALLATION

1. Install the probe of the evaporator temperature

sensor (1) between the fins of the A/C evaporator

(2).

2. Route the wire lead for the evaporator temperature

sensor (3) into the opening located on the upper

half of the HVAC housing (4).

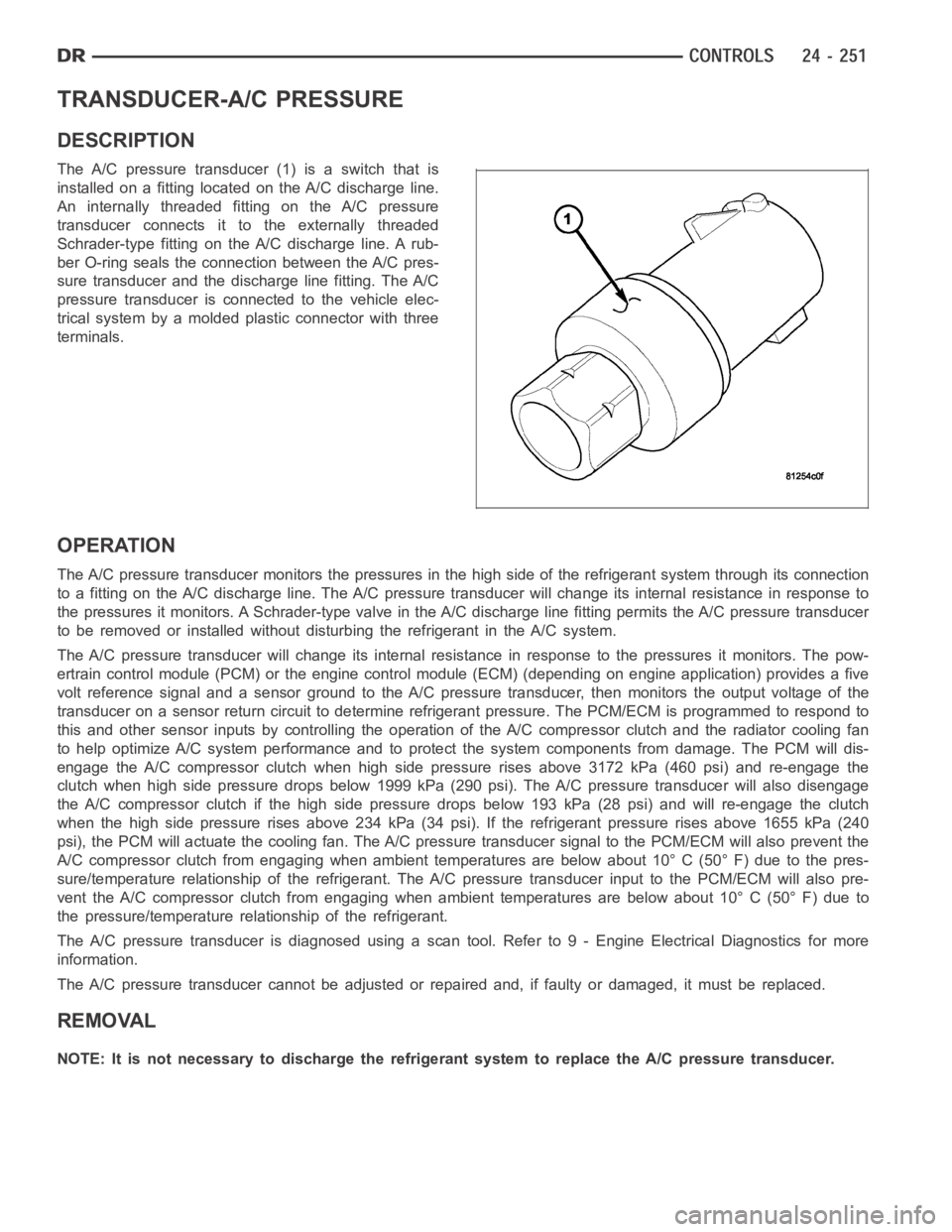

3. Assemble the HVAC housing (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/

HOUSING-HVAC - ASSEMBLY).

4. Install the wire lead of the evaporator temperature

sensor (2) to the retainer located on the HVAC

housing (1) and connect the sensor connector to

theHVACwireharness(3).

5. Install the HVAC housing (Refer to 24 - HEATING

& AIR CONDITIONING/DISTRIBUTION/HOUSING-

HVAC - INSTALLATION).

Page 5092 of 5267

TRANSDUCER-A/C PRESSURE

DESCRIPTION

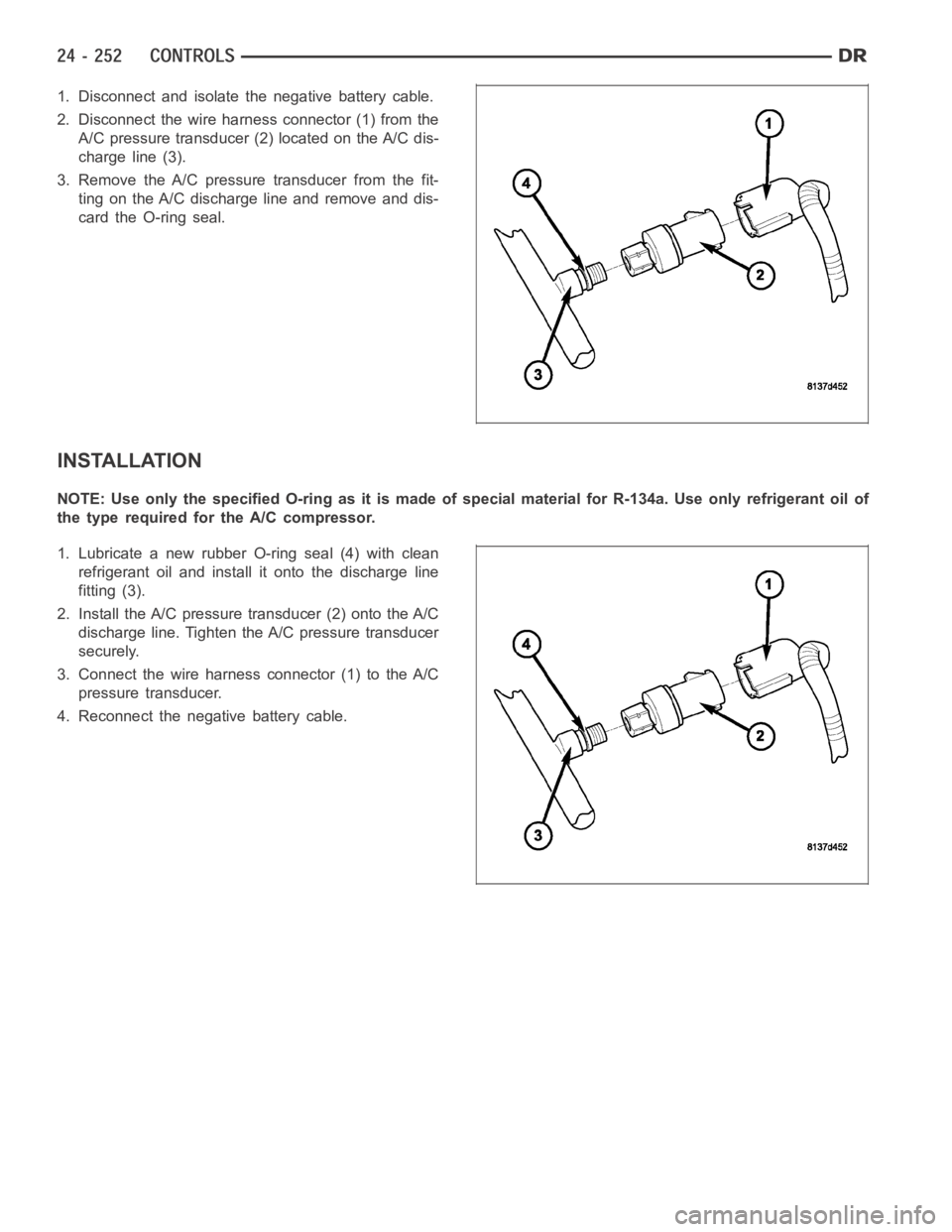

The A/C pressure transducer (1) is a switch that is

installed on a fitting located on the A/C discharge line.

An internally threaded fitting on the A/C pressure

transducer connects it to the externally threaded

Schrader-type fitting on the A/C discharge line. A rub-

ber O-ring seals the connection between the A/C pres-

sure transducer and the discharge line fitting. The A/C

pressure transducer is connected to the vehicle elec-

trical system by a molded plastic connector with three

terminals.

OPERATION

The A/C pressure transducer monitors the pressures in the high side of the refrigerant system through its connection

to a fitting on the A/C discharge line. The A/C pressure transducer will change its internal resistance in response to

the pressures it monitors. A Schrader-type valve in the A/C discharge linefitting permits the A/C pressure transducer

to be removed or installed without disturbing the refrigerant in the A/C system.

The A/C pressure transducer will change its internal resistance in response to the pressures it monitors. The pow-

ertrain control module (PCM) or the engine control module (ECM) (depending on engine application) provides a five

volt reference signal and a sensor ground to the A/C pressure transducer, then monitors the output voltage of the

transducer on a sensor return circuit to determine refrigerant pressure.The PCM/ECM is programmed to respond to

this and other sensor inputs by controlling the operation of the A/C compressor clutch and the radiator cooling fan

to help optimize A/C system performance and to protect the system components from damage. The PCM will dis-

engagetheA/Ccompressorclutchwhenhighsidepressurerisesabove3172kPa (460 psi) and re-engage the

clutch when high side pressure drops below 1999 kPa (290 psi). The A/C pressure transducer will also disengage

the A/C compressor clutch if the high side pressure drops below 193 kPa (28 psi) and will re-engage the clutch

when the high side pressure rises above 234 kPa (34 psi). If the refrigerantpressure rises above 1655 kPa (240

psi), the PCM will actuate the cooling fan. The A/C pressure transducer signal to the PCM/ECM will also prevent the

A/C compressor clutch from engaging when ambient temperatures are below about 10° C (50° F) due to the pres-

sure/temperature relationship of the refrigerant. The A/C pressure transducer input to the PCM/ECM will also pre-

vent the A/C compressor clutch from engaging when ambient temperatures are below about 10° C (50° F) due to

the pressure/temperature relationship of the refrigerant.

The A/C pressure transducer is diagnosed using a scan tool. Refer to 9 - Engine Electrical Diagnostics for more

information.

The A/C pressure transducer cannot be adjusted or repaired and, if faulty or damaged, it must be replaced.

REMOVAL

NOTE: It is not necessary to discharge the refrigerant system to replace the A/C pressure transducer.

Page 5093 of 5267

1. Disconnect and isolate the negative battery cable.

2. Disconnect the wire harness connector (1) from the

A/C pressure transducer (2) located on the A/C dis-

charge line (3).

3. Remove the A/C pressure transducer from the fit-

ting on the A/C discharge line and remove and dis-

card the O-ring seal.

INSTALLATION

NOTE:UseonlythespecifiedO-ringasitismadeofspecialmaterialforR-134a. Use only refrigerant oil of

the type required for the A/C compressor.

1. Lubricate a new rubber O-ring seal (4) with clean

refrigerant oil and install it onto the discharge line

fitting (3).

2. Install the A/C pressure transducer (2) onto the A/C

discharge line. Tighten the A/C pressure transducer

securely.

3. Connect the wire harness connector (1) to the A/C

pressure transducer.

4. Reconnect the negative battery cable.

Page 5094 of 5267

page page

DUCT-DEFROSTER

REMOVAL ................................... 254

INSTALLATION .............................. 255

DUCT-FLOOR CONSOLE

REMOVAL ................................... 256

INSTALLATION .............................. 256

DUCT-FLOOR DISTRIBUTION

REMOVAL ................................... 257

INSTALLATION .............................. 257

DUCT-INSTRUMENT PANEL

REMOVAL ................................... 258

INSTALLATION .............................. 259

DUCT-INSTRUMENT PANEL DEMISTER

REMOVAL ................................... 260

INSTALLATION .............................. 261

HOUSING-HVAC

DESCRIPTION ............................... 262

REMOVAL

HVAC HOUSING ASSEMBLY . . .............. 263AIR INLET HOUSING ....................... 264

DISASSEMBLY

HVAC HOUSING ........................... 265

AIR INLET HOUSING ....................... 270

ASSEMBLY

HVAC HOUSING ........................... 272

AIR INLET HOUSING ....................... 277

INSTALLATION

HVAC HOUSING ASSEMBLY ................ 277

AIR INLET HOUSING ....................... 278

MOTOR-BLOWER

DESCRIPTION ............................... 280

OPERATION ................................. 280

DIAGNOSIS AND TESTING

BLOWER MOTOR ......................... 280

REMOVAL ................................... 282

INSTALLATION .............................. 282

OUTLETS-AIR

DESCRIPTION ............................... 283

Page 5095 of 5267

DUCT-DEFROSTER

REMOVAL

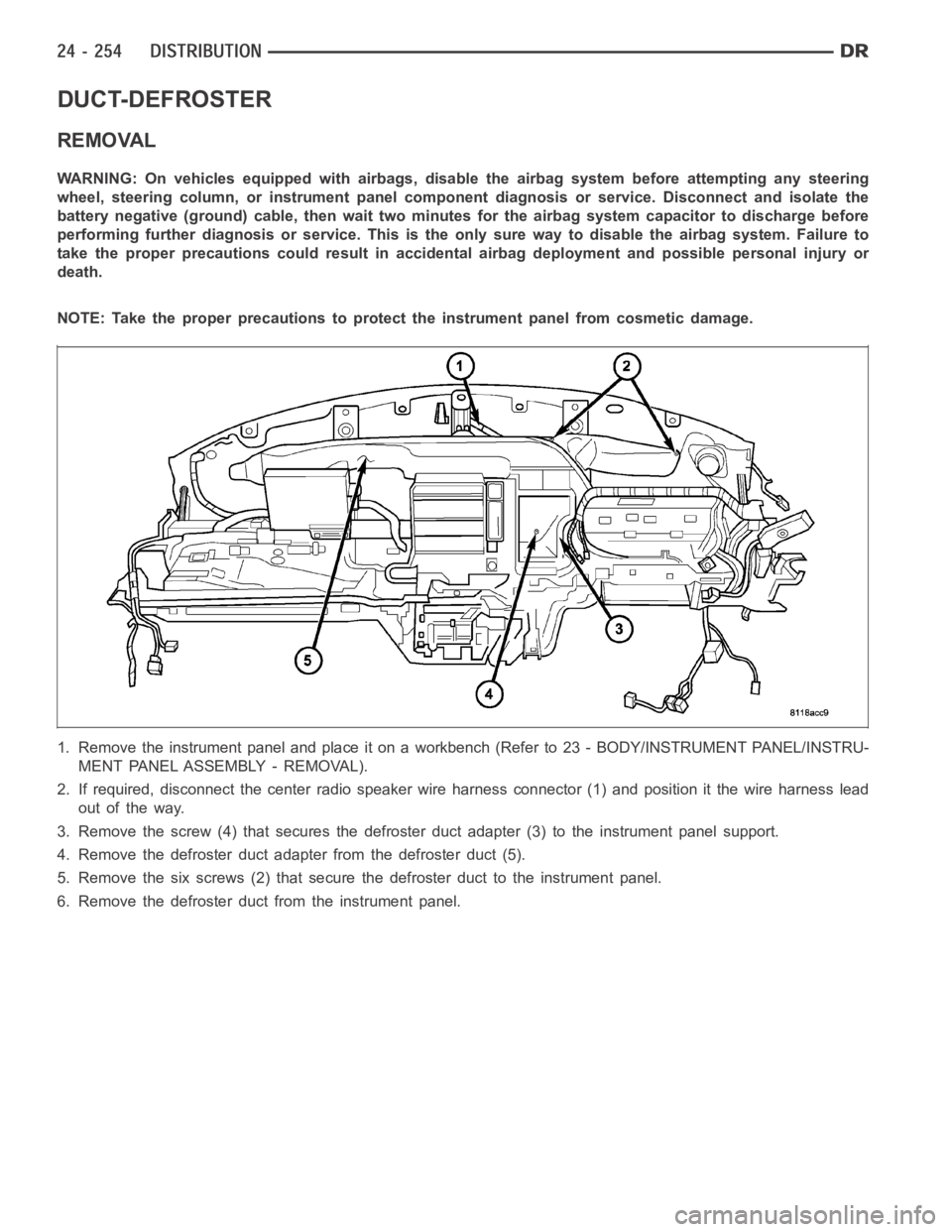

WARNING: On vehicles equipped with airbags, disable the airbag system before attempting any steering

wheel, steering column, or instrument panel component diagnosis or service. Disconnect and isolate the

battery negative (ground) cable, then wait two minutes for the airbag system capacitor to discharge before

performing further diagnosis or service. This is the only sure way to disable the airbag system. Failure to

take the proper precautions could result in accidental airbag deploymentand possible personal injury or

death.

NOTE: Take the proper precautions to protect the instrument panel from cosmetic damage.

1. Remove the instrument panel and place it on a workbench (Refer to 23 - BODY/INSTRUMENT PANEL/INSTRU-

MENT PANEL ASSEMBLY - REMOVAL).

2. If required, disconnect the center radio speaker wire harness connector (1) and position it the wire harness lead

out of the way.

3. Remove the screw (4) that secures the defroster duct adapter (3) to the instrument panel support.

4. Remove the defroster duct adapter from the defroster duct (5).

5. Remove the six screws (2) that secure the defroster duct to the instrument panel.

6. Remove the defroster duct from the instrument panel.

Page 5096 of 5267

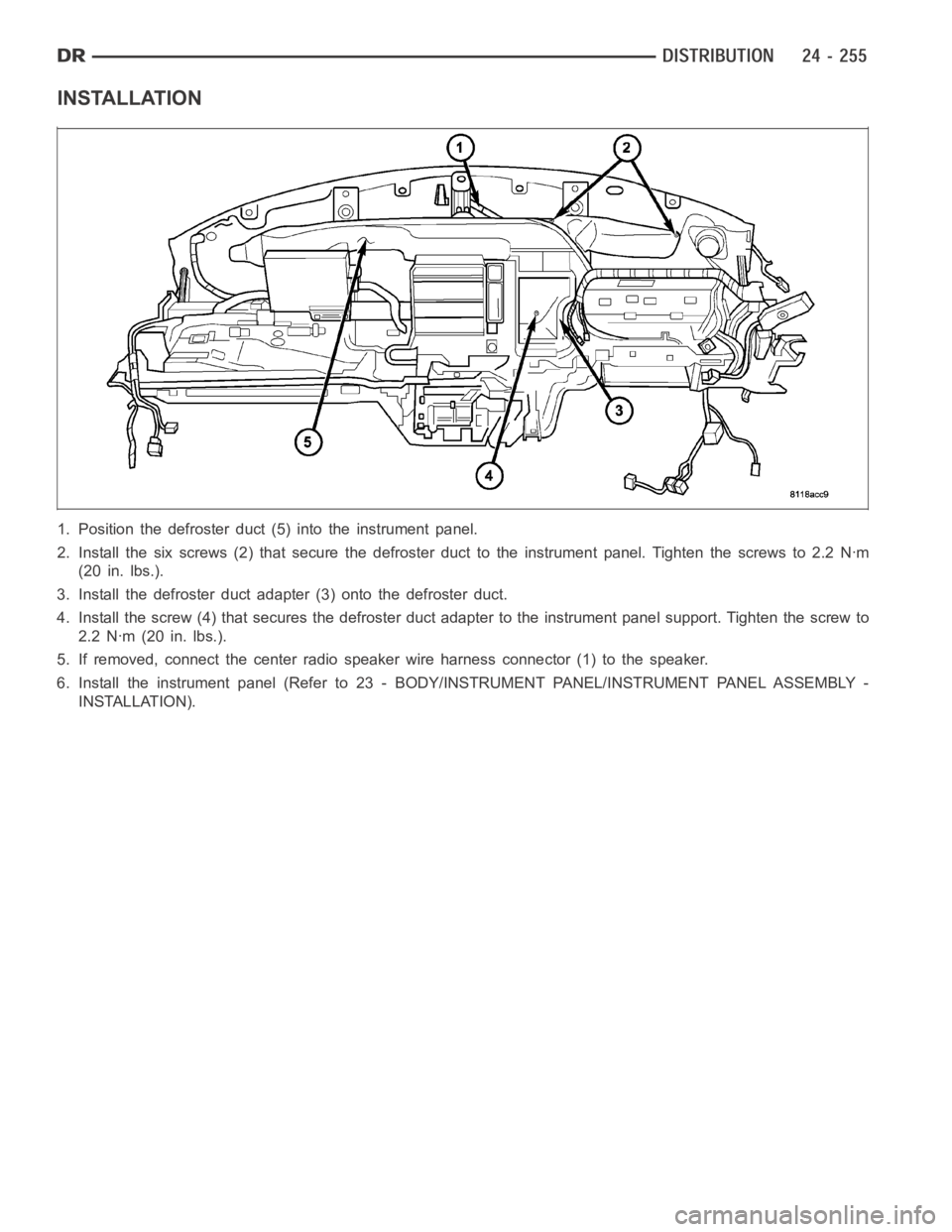

INSTALLATION

1. Position the defroster duct (5) into the instrument panel.

2. Install the six screws (2) that secure the defroster duct to the instrument panel. Tighten the screws to 2.2 Nꞏm

(20 in. lbs.).

3. Install the defroster duct adapter (3) onto the defroster duct.

4. Install the screw (4) that secures the defroster duct adapter to the instrument panel support. Tighten the screw to

2.2 Nꞏm (20 in. lbs.).

5. If removed, connect the center radiospeaker wire harness connector (1)to the speaker.

6. Install the instrument panel (Refer to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT PANEL ASSEMBLY -

INSTALLATION).

Page 5097 of 5267

DUCT-FLOOR CONSOLE

REMOVAL

NOTE: Illustration shown with seat cushions

removed from view for clarity.

1. Removethefloorconsole(Referto23-BODY/IN-

TERIOR/FLOOR CONSOLE - REMOVAL).

2. Slide the floor console duct (1) rearward and first

disconnect it from the floor distribution duct (3)

located on the bottom of the HVAC housing (4), then disconnect the floor duct from the rear duct (33) located

below the center seat.

3. If required, remove the rear duct from the center seat support.

INSTALLATION

NOTE: Illustration shown with seat cushions

removed from view for clarity.

1. If removed, install the rear duct (2) to the bottom of

the center seat support. Make sure the duct is fully

engaged to the rear outlets.

2. Install the floor console duct (1) onto the rear duct

and then slide it forward and connect it to the floor distribution duct (3) located at the bottom of the HVAC hous-

ing (4). Make sure all ducts are fully to each other.

3. Install the floor console (Refer to 23 - BODY/INTERIOR/FLOOR CONSOLE - INSTALLATION).

Page 5098 of 5267

DUCT-FLOOR DISTRIBUTION

REMOVAL

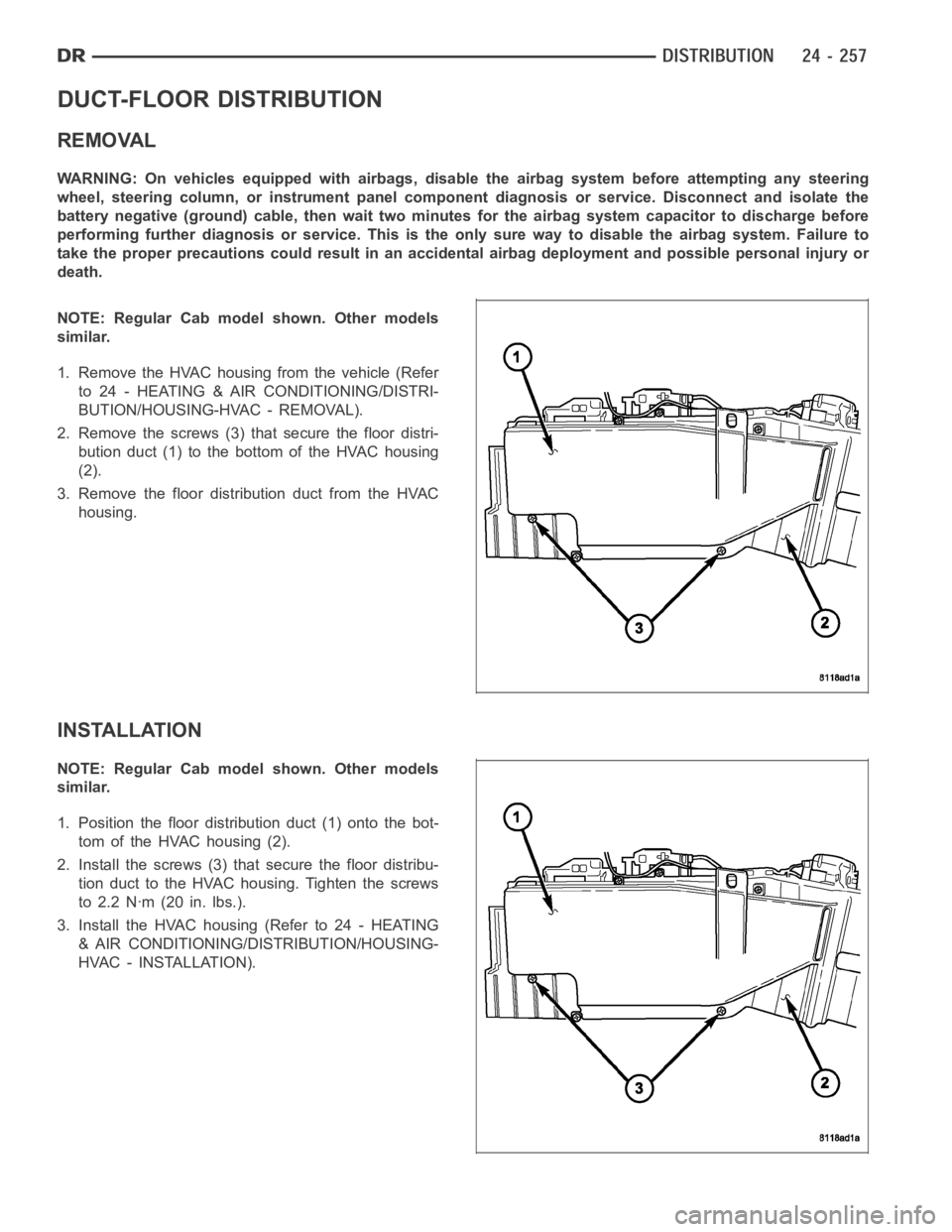

WARNING: On vehicles equipped with airbags, disable the airbag system before attempting any steering

wheel, steering column, or instrument panel component diagnosis or service. Disconnect and isolate the

battery negative (ground) cable, then wait two minutes for the airbag system capacitor to discharge before

performing further diagnosis or service. This is the only sure way to disable the airbag system. Failure to

take the proper precautions could result in an accidental airbag deployment and possible personal injury or

death.

NOTE: Regular Cab model shown. Other models

similar.

1. Remove the HVAC housing from the vehicle (Refer

to 24 - HEATING & AIR CONDITIONING/DISTRI-

BUTION/HOUSING-HVAC - REMOVAL).

2. Remove the screws (3) that secure the floor distri-

bution duct (1) to the bottom of the HVAC housing

(2).

3. Remove the floor distribution duct from the HVAC

housing.

INSTALLATION

NOTE: Regular Cab model shown. Other models

similar.

1. Position the floor distribution duct (1) onto the bot-

tom of the HVAC housing (2).

2. Install the screws (3) that secure the floor distribu-

tion duct to the HVAC housing. Tighten the screws

to 2.2 Nꞏm (20 in. lbs.).

3. Install the HVAC housing (Refer to 24 - HEATING

& AIR CONDITIONING/DISTRIBUTION/HOUSING-

HVAC - INSTALLATION).

Page 5099 of 5267

DUCT-INSTRUMENT PANEL

REMOVAL

WARNING: On vehicles equipped with airbags, disable the airbag system before attempting any steering

wheel, steering column, or instrument panel component diagnosis or service. Disconnect and isolate the

battery negative (ground) cable, then wait two minutes for the airbag system capacitor to discharge before

performing further diagnosis or service. This is the only sure way to disable the airbag system. Failure to

take the proper precautions could result in an accidental airbag deployment and possible personal injury or

death.

NOTE: Take the proper precautions to protect the instrument panel from cosmetic damage.

1. Remove the instrument panel and place it on a

workbench (Refer to 23 - BODY/INSTRUMENT

PANEL/INSTRUMENT PANEL ASSEMBLY -

REMOVAL).

2. Remove the radio (Refer to 8 - ELECTRICAL/AU-

DIO/RADIO - REMOVAL).

3. Remove the defroster duct (Refer to 24 - HEATING

& AIR CONDITIONING/DISTRIBUTION/DUCT-DE-

FROSTER - REMOVAL).

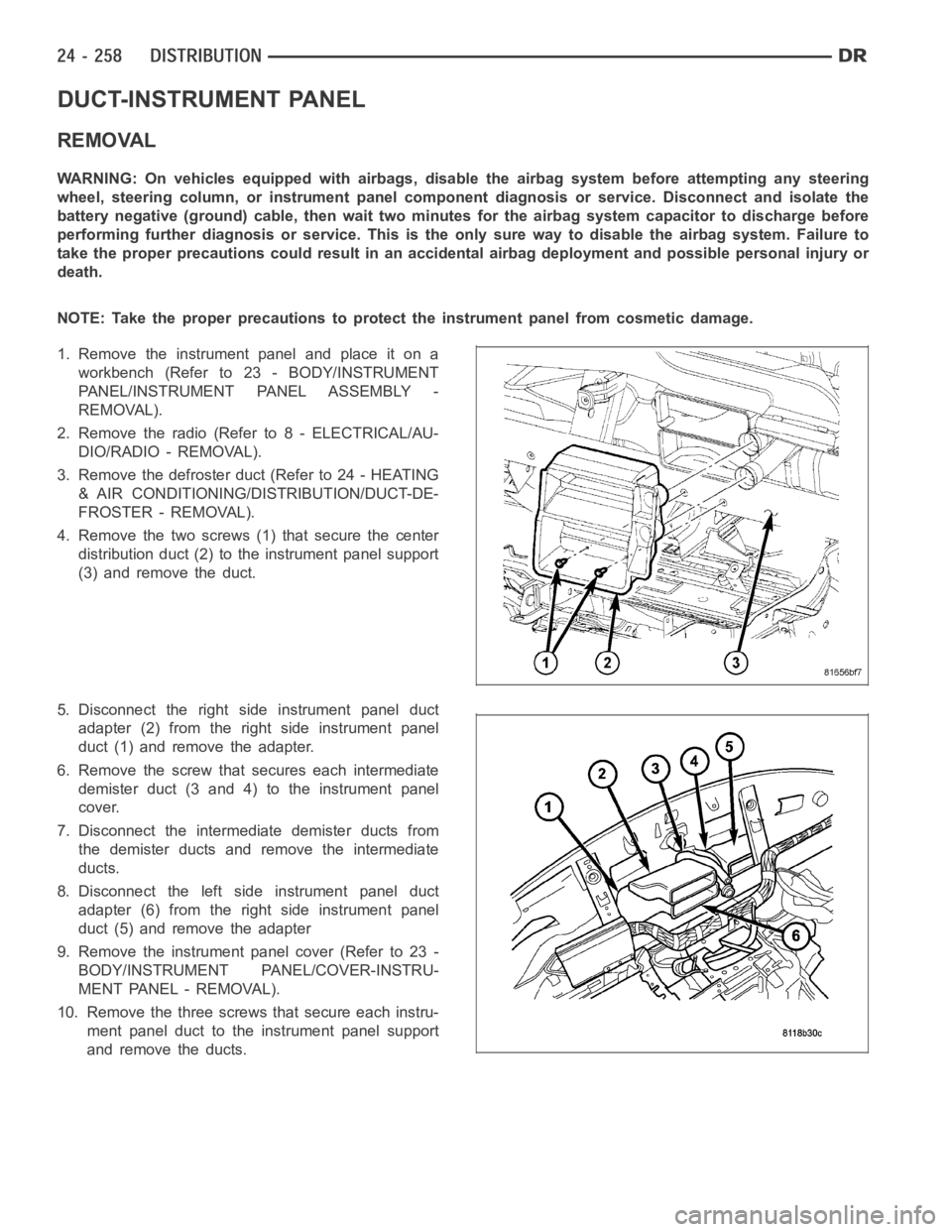

4. Remove the two screws (1) that secure the center

distribution duct (2) to the instrument panel support

(3) and remove the duct.

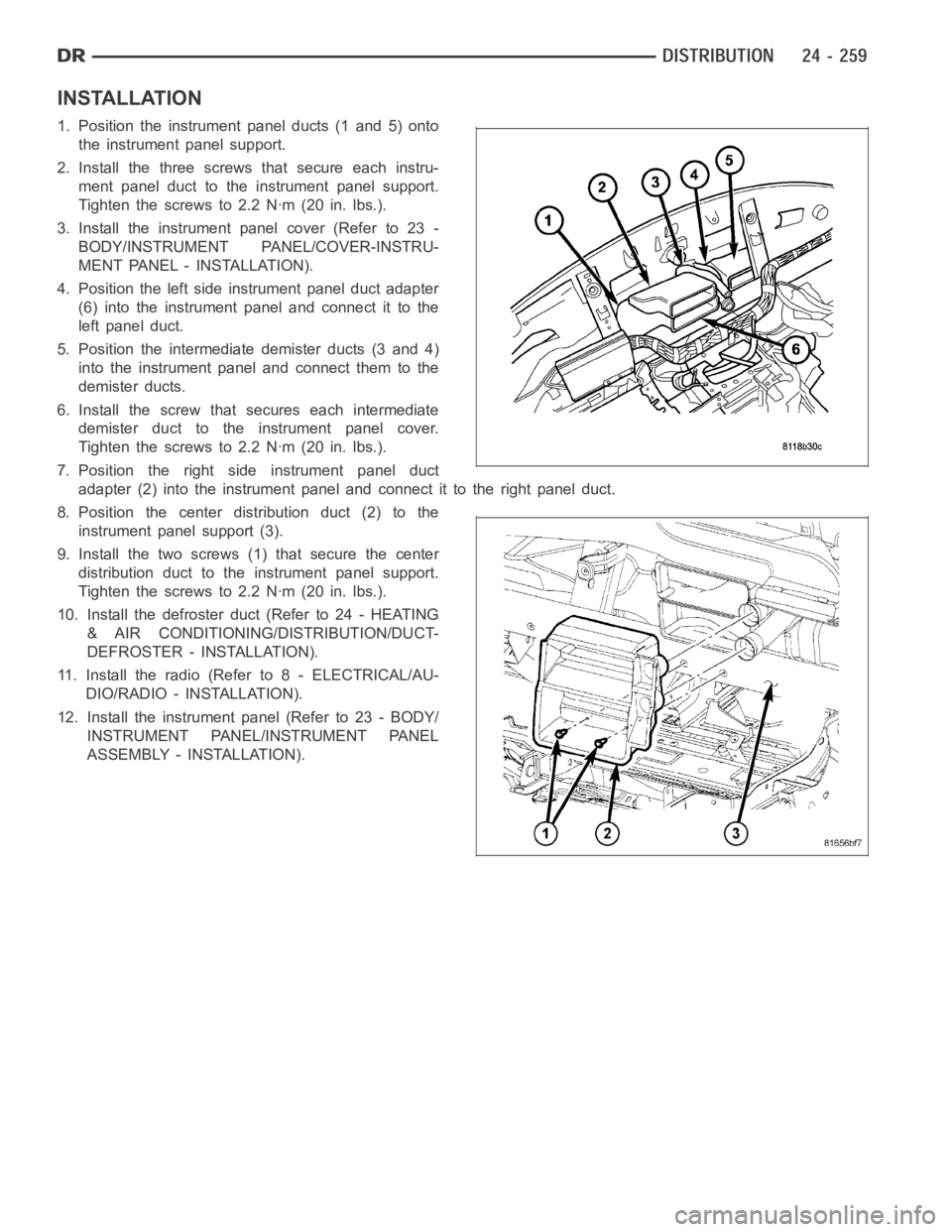

5. Disconnect the right side instrument panel duct

adapter (2) from the right side instrument panel

duct (1) and remove the adapter.

6. Remove the screw that secures each intermediate

demister duct (3 and 4) to the instrument panel

cover.

7. Disconnect the intermediate demister ducts from

the demister ducts and remove the intermediate

ducts.

8. Disconnect the left side instrument panel duct

adapter (6) from the right side instrument panel

duct (5) and remove the adapter

9. Remove the instrument panel cover (Refer to 23 -

BODY/INSTRUMENT PANEL/COVER-INSTRU-

MENT PANEL - REMOVAL).

10. Remove the three screws that secure each instru-

ment panel duct to the instrument panel support

and remove the ducts.

Page 5100 of 5267

INSTALLATION

1. Position the instrument panel ducts (1 and 5) onto

the instrument panel support.

2. Install the three screws that secure each instru-

ment panel duct to the instrument panel support.

Tighten the screws to 2.2 Nꞏm (20 in. lbs.).

3. Install the instrument panel cover (Refer to 23 -

BODY/INSTRUMENT PANEL/COVER-INSTRU-

MENT PANEL - INSTALLATION).

4. Position the left side instrument panel duct adapter

(6) into the instrument panel and connect it to the

left panel duct.

5. Position the intermediate demister ducts (3 and 4)

into the instrument panel and connect them to the

demister ducts.

6. Install the screw that secures each intermediate

demister duct to the instrument panel cover.

Tighten the screws to 2.2 Nꞏm (20 in. lbs.).

7. Position the right side instrument panel duct

adapter (2) into the instrument panel and connect it to the right panel duct.

8. Position the center distribution duct (2) to the

instrument panel support (3).

9. Install the two screws (1) that secure the center

distribution duct to the instrument panel support.

Tighten the screws to 2.2 Nꞏm (20 in. lbs.).

10. Install the defroster duct (Refer to 24 - HEATING

& AIR CONDITIONING/DISTRIBUTION/DUCT-

DEFROSTER - INSTALLATION).

11. Install the radio (Refer to 8 - ELECTRICAL/AU-

DIO/RADIO - INSTALLATION).

12. Install the instrument panel (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

ASSEMBLY - INSTALLATION).