check engine DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1587 of 5267

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

Begin with a thorough visual inspection of the engine, particularly at thearea of the suspected leak. If an oil leak

source is not readily identifiable, thefollowingstepsshouldbefollowed:

1. Do not clean or degrease the engine at this time because some solvents maycause rubber to swell, temporarily

stopping the leak.

2. Add an oil soluble dye (use as recommended by manufacturer). Start the engine and let idle for approximately 15

minutes. Check the oil dipstick to make sure the dye is thoroughly mixed as indicated with a bright yellow color

under a black light.

3. Using a black light, inspect the entire engine for fluorescent dye, particularly at the suspected area of oil leak. If

the oil leak is found and identified, repair per service manual instructions.

4. If dye is not observed, drive the vehicle at various speeds for approximately 24 km (15 miles), and repeat inspec-

tion.If the oil leak source is not positively identified at this time, proceed with the air leak detection test method.

Air Leak Detection Test Method

1. Disconnect the breather cap to air cleaner hose at the breather cap end. Cap or plug breather cap nipple.

2. Remove the PCV valve from the cylinder head cover. Cap or plug the PCV valvegrommet.

3. Attach an air hose with pressure gauge and regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to more than 20.6 kPa (3 PSI) of test pressure.

4. Gradually apply air pressure from 1 psi to 2.5 psi maximum while applyingsoapy water at the suspected source.

Adjust the regulator to the suitable test pressure that provide the best bubbles which will pinpoint the leak

source. If the oil leak is detected and identified, repair per service manual procedures.

5. If the leakage occurs at the rear oil seal area, refer to the section, Inspection for Rear Seal Area Leak.

6. If no leaks are detected, turn off the air supply and remove the air hose and all plugs and caps. Install the PCV

valve and breather cap hose.

7. Clean the oil off the suspect oil leak area using a suitable solvent. Drive the vehicle at various speeds approx-

imately 24 km (15 miles). Inspect the engine for signs of an oil leak by usinga black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the source of an oil leak in therear seal area of the engine, a more

involved inspection is necessary. The following steps should be followedto help pinpoint the source of the leak.

If the leakage occurs at the crankshaft rear oil seal area:

1. Disconnect the battery.

2. Raise the vehicle.

3. Remove torque converter or clutch housing cover and inspect rear of block for evidence of oil. Use a black light

to check for the oil leak:

a. Circular spray pattern generally indicates seal leakage or crankshaftdamage.

b. Where leakage tends to run straight down, possible causes are a porous block, oil galley pipe plugs, oil filter

runoff, and main bearing cap to cylinder block mating surfaces.

4. If no leaks are detected, pressurize the crankcase as outlined in the, Inspection (Engine oil Leaks in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

5. If the leak is not detected, very slowly turn the crankshaft and watch forleakage. If a leak is detected between

the crankshaft and seal while slowly turning the crankshaft, it is possible the crankshaft seal surface is damaged.

The seal area on the crankshaft could have minor nicks or scratches that canbe polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially machined to complement the function of the rear oil seal.

6. For bubbles that remain steady with shaft rotation, no further inspection can be done until disassembled.

Page 1588 of 5267

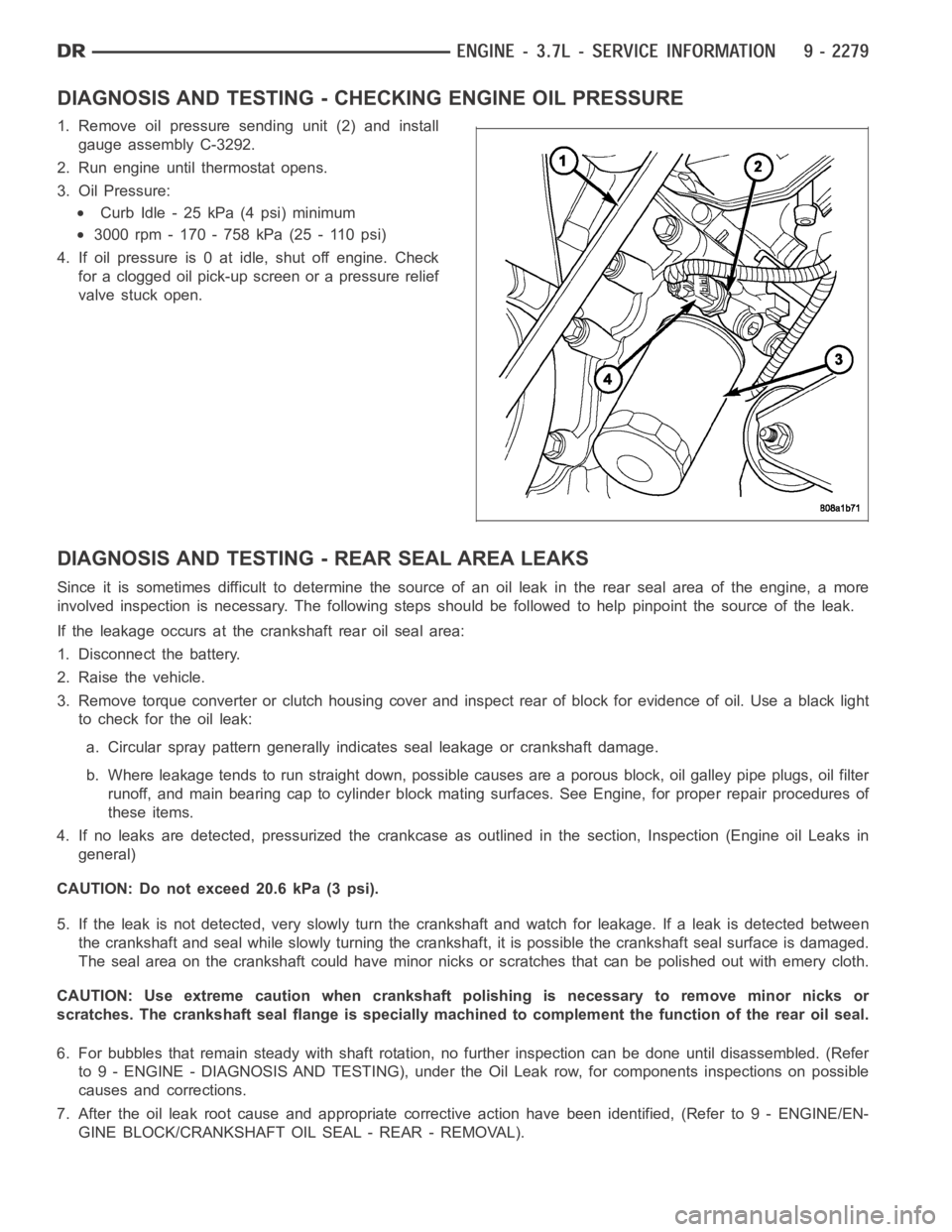

DIAGNOSIS AND TESTING - CHECKING ENGINE OIL PRESSURE

1. Remove oil pressure sending unit (2) and install

gauge assembly C-3292.

2. Run engine until thermostat opens.

3. Oil Pressure:

Curb Idle - 25 kPa (4 psi) minimum

3000 rpm - 170 - 758 kPa (25 - 110 psi)

4. If oil pressure is 0 at idle, shut off engine. Check

for a clogged oil pick-up screen or a pressure relief

valve stuck open.

DIAGNOSIS AND TESTING - REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the source of an oil leak in therear seal area of the engine, a more

involved inspection is necessary. The following steps should be followedto help pinpoint the source of the leak.

If the leakage occurs at the crankshaft rear oil seal area:

1. Disconnect the battery.

2. Raise the vehicle.

3. Remove torque converter or clutch housing cover and inspect rear of block for evidence of oil. Use a black light

to check for the oil leak:

a. Circular spray pattern generally indicates seal leakage or crankshaftdamage.

b. Where leakage tends to run straight down, possible causes are a porous block, oil galley pipe plugs, oil filter

runoff, and main bearing cap to cylinder block mating surfaces. See Engine, for proper repair procedures of

these items.

4. If no leaks are detected, pressurized the crankcase as outlined in the section, Inspection (Engine oil Leaks in

general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

5. If the leak is not detected, very slowly turn the crankshaft and watch forleakage. If a leak is detected between

the crankshaft and seal while slowly turning the crankshaft, it is possible the crankshaft seal surface is damaged.

The seal area on the crankshaft could have minor nicks or scratches that canbe polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially machined to complement the function of the rear oil seal.

6. For bubbles that remain steady with shaft rotation, no further inspection can be done until disassembled. (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING), under the Oil Leak row, for components inspections on possible

causes and corrections.

7. After the oil leak root cause and appropriate corrective action have been identified, (Refer to 9 - ENGINE/EN-

GINE BLOCK/CRANKSHAFT OIL SEAL - REAR - REMOVAL).

Page 1590 of 5267

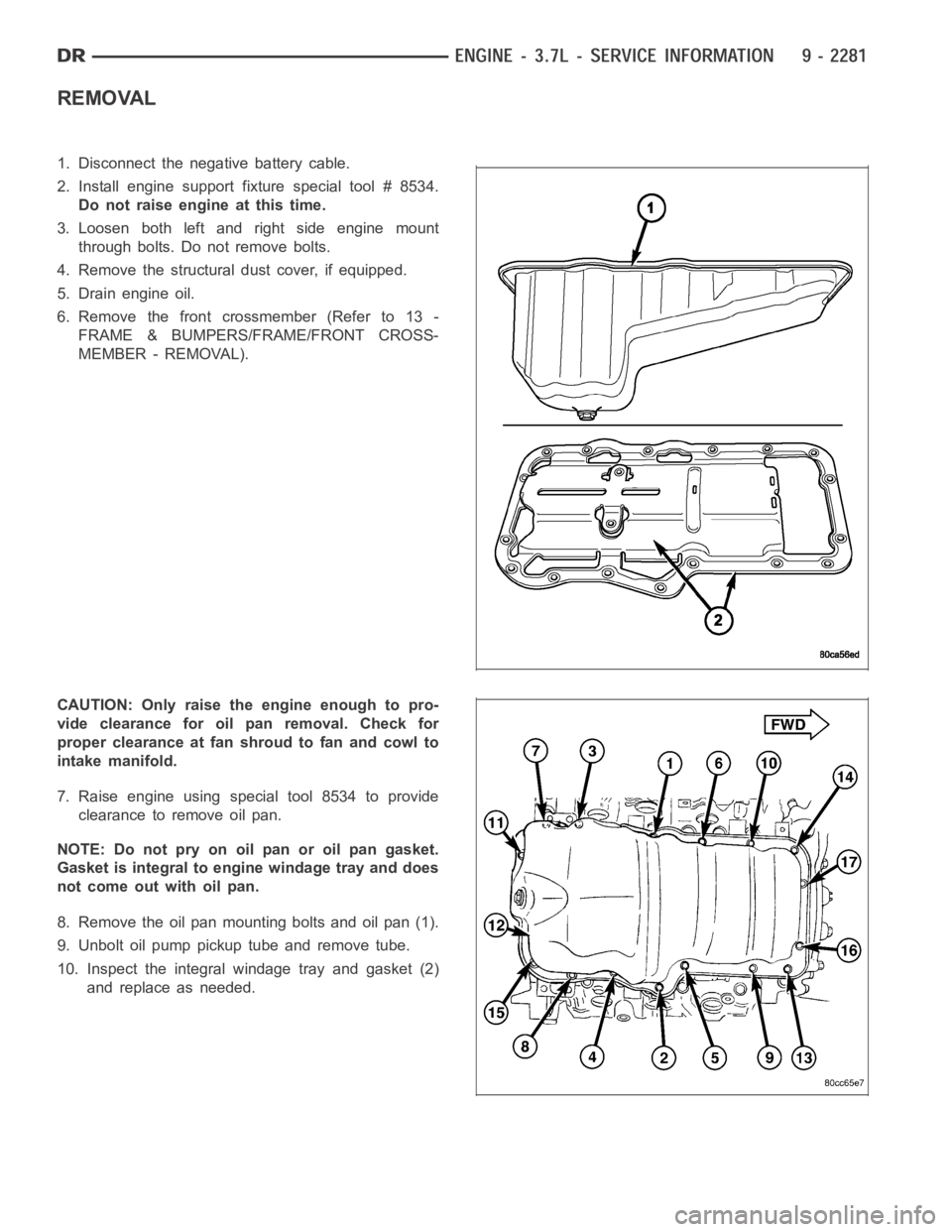

REMOVAL

1. Disconnect the negative battery cable.

2. Install engine support fixture special tool # 8534.

Do not raise engine at this time.

3. Loosen both left and right side engine mount

through bolts. Do not remove bolts.

4. Remove the structural dust cover, if equipped.

5. Drain engine oil.

6. Remove the front crossmember (Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - REMOVAL).

CAUTION: Only raise the engine enough to pro-

vide clearance for oil pan removal. Check for

proper clearance at fan shroud to fan and cowl to

intake manifold.

7. Raise engine using special tool 8534 to provide

clearance to remove oil pan.

NOTE:Donotpryonoilpanoroilpangasket.

Gasket is integral to engine windage tray and does

not come out with oil pan.

8. Remove the oil pan mounting bolts and oil pan (1).

9. Unbolt oil pump pickup tube and remove tube.

10. Inspect the integral windage tray and gasket (2)

and replace as needed.

Page 1592 of 5267

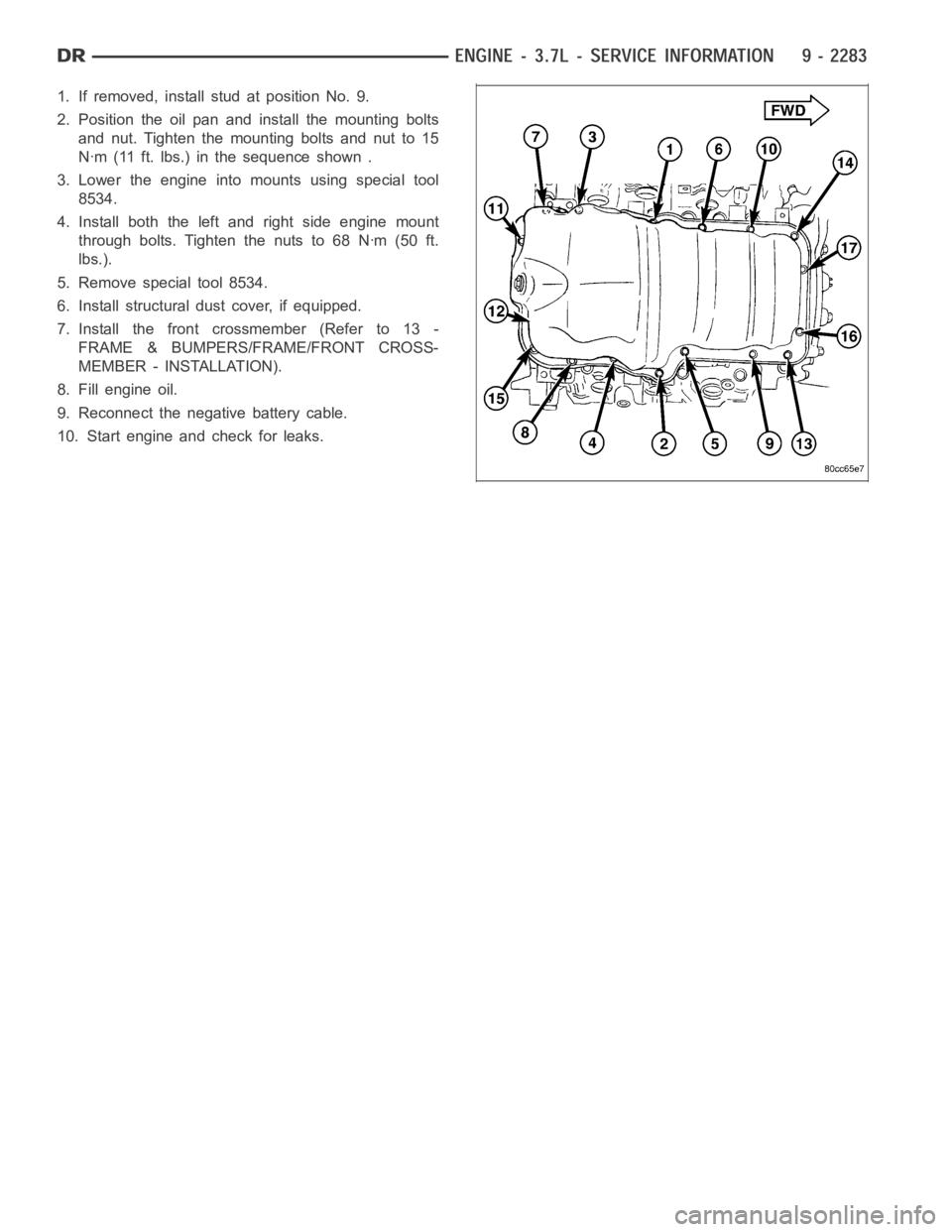

1. If removed, install stud at position No. 9.

2. Position the oil pan and install the mounting bolts

and nut. Tighten the mounting bolts and nut to 15

Nꞏm (11 ft. lbs.) in the sequence shown .

3. Lower the engine into mounts using special tool

8534.

4. Install both the left and right side engine mount

through bolts. Tighten the nuts to 68 Nꞏm (50 ft.

lbs.).

5. Remove special tool 8534.

6. Install structural dust cover, if equipped.

7. Install the front crossmember (Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - INSTALLATION).

8. Fill engine oil.

9. Reconnect the negative battery cable.

10. Start engine and check for leaks.

Page 1593 of 5267

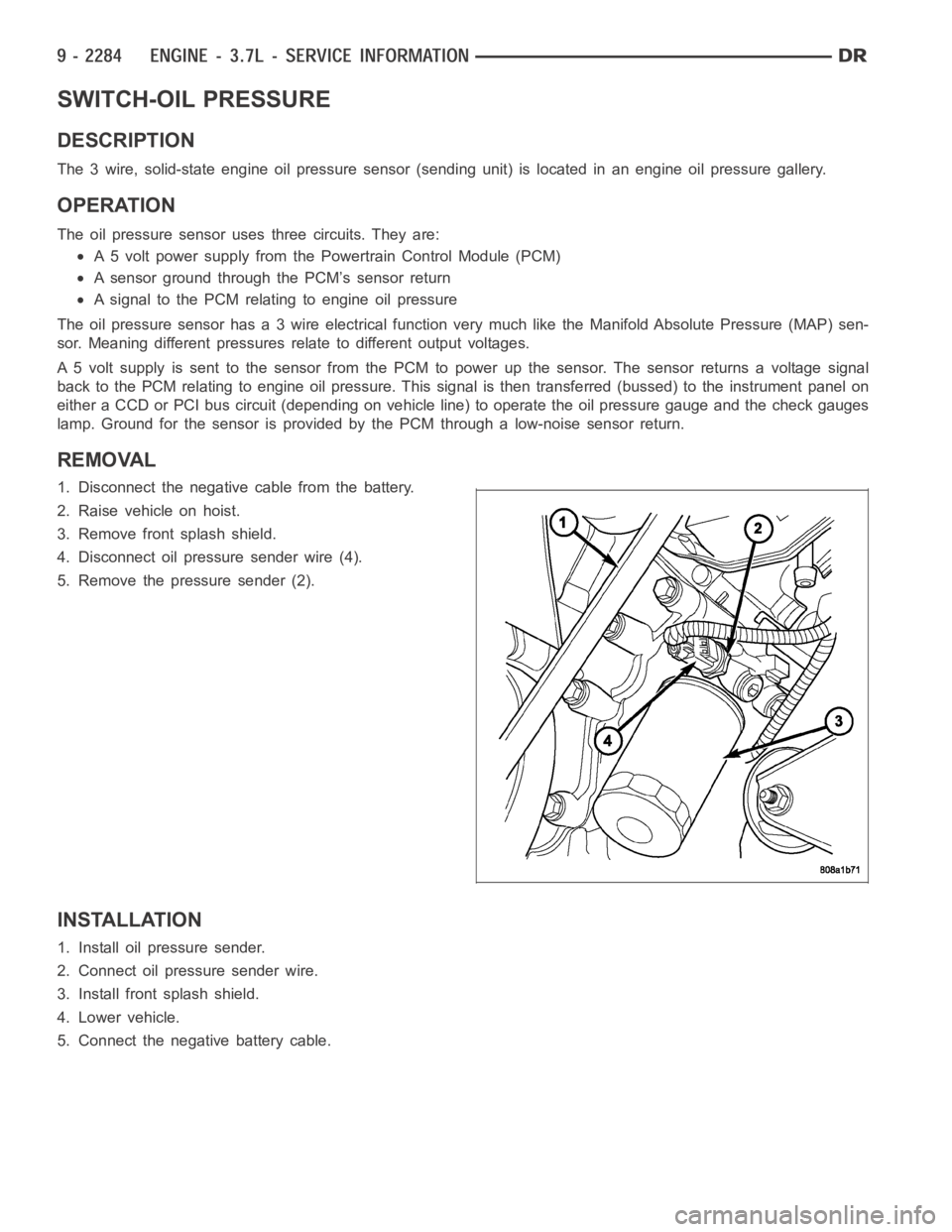

SWITCH-OIL PRESSURE

DESCRIPTION

The 3 wire, solid-state engine oil pressure sensor (sending unit) is located in an engine oil pressure gallery.

OPERATION

The oil pressure sensor uses three circuits. They are:

A 5 volt power supply from the Powertrain Control Module (PCM)

A sensor ground through the PCM’s sensor return

A signal to the PCM relating to engine oil pressure

The oil pressure sensor has a 3 wire electrical function very much like the Manifold Absolute Pressure (MAP) sen-

sor. Meaning different pressures relate to different output voltages.

A 5 volt supply is sent to the sensor from the PCM to power up the sensor. The sensor returns a voltage signal

back to the PCM relating to engine oil pressure. This signal is then transferred (bussed) to the instrument panel on

either a CCD or PCI bus circuit (depending on vehicle line) to operate the oil pressure gauge and the check gauges

lamp. Ground for the sensor is provided by the PCM through a low-noise sensor return.

REMOVAL

1. Disconnect the negative cable from the battery.

2. Raise vehicle on hoist.

3. Remove front splash shield.

4. Disconnect oil pressure sender wire (4).

5. Remove the pressure sender (2).

INSTALLATION

1. Install oil pressure sender.

2. Connect oil pressure sender wire.

3. Install front splash shield.

4. Lower vehicle.

5. Connect the negative battery cable.

Page 1598 of 5267

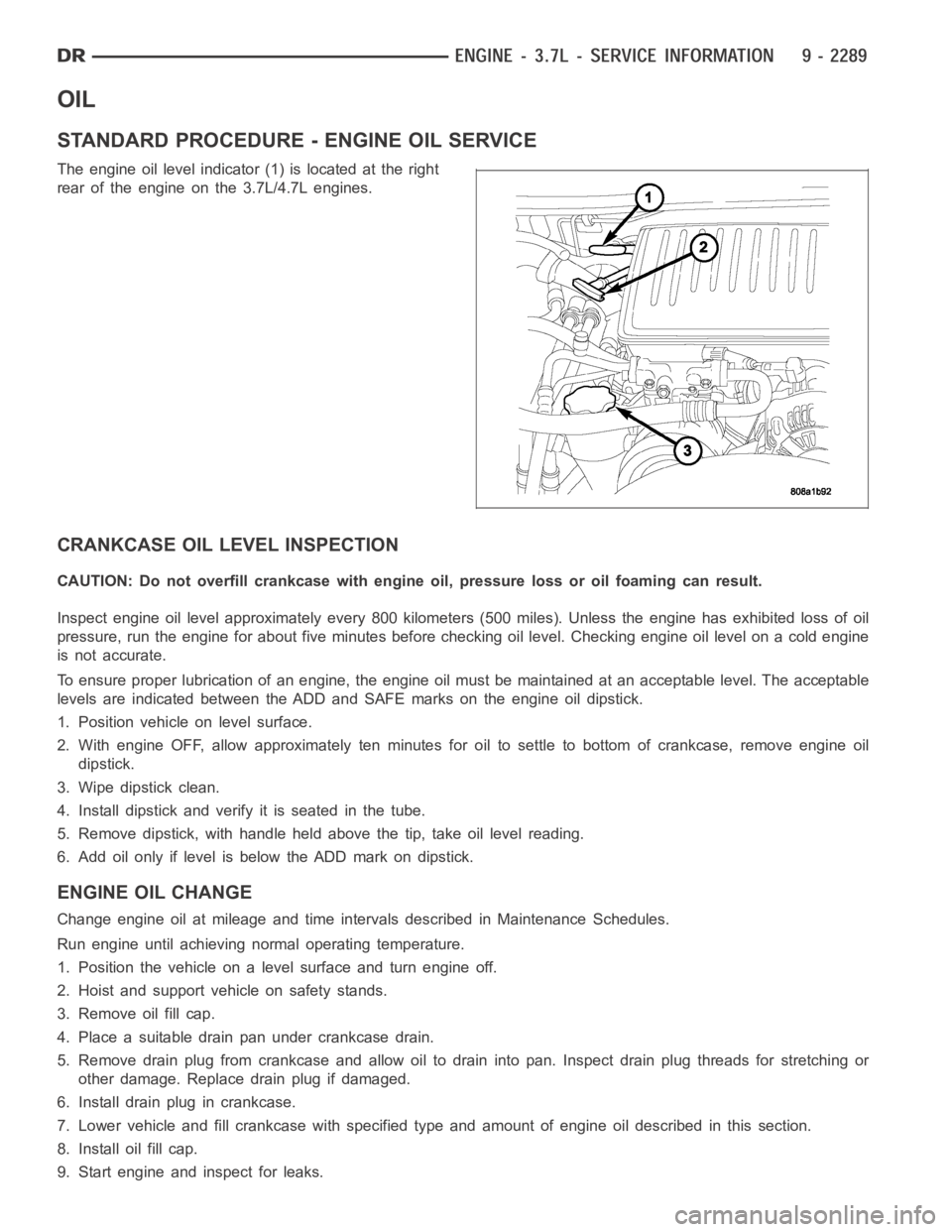

OIL

STANDARD PROCEDURE - ENGINE OIL SERVICE

The engine oil level indicator (1) is located at the right

rear of the engine on the 3.7L/4.7L engines.

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil, pressure loss or oil foaming can result.

Inspect engine oil level approximately every 800 kilometers (500 miles).Unless the engine has exhibited loss of oil

pressure, run the engine for about five minutes before checking oil level.Checking engine oil level on a cold engine

is not accurate.

To ensure proper lubrication of an engine, the engine oil must be maintained at an acceptable level. The acceptable

levels are indicated between the ADD and SAFE marks on the engine oil dipstick.

1. Position vehicle on level surface.

2. With engine OFF, allow approximately ten minutes for oil to settle to bottom of crankcase, remove engine oil

dipstick.

3. Wipe dipstick clean.

4. Install dipstick and verify it is seated in the tube.

5. Remove dipstick, with handle held above the tip, take oil level reading.

6. Add oil only if level is below the ADD mark on dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals described in Maintenance Schedules.

Run engine until achieving normal operating temperature.

1. Position the vehicle on a level surface and turn engine off.

2. Hoist and support vehicle on safety stands.

3. Remove oil fill cap.

4. Place a suitable drain pan under crankcase drain.

5. Remove drain plug from crankcase and allow oil to drain into pan. Inspectdrain plug threads for stretching or

other damage. Replace drain plug if damaged.

6. Install drain plug in crankcase.

7. Lower vehicle and fill crankcase with specified type and amount of engine oil described in this section.

8. Install oil fill cap.

9. Start engine and inspect for leaks.

Page 1621 of 5267

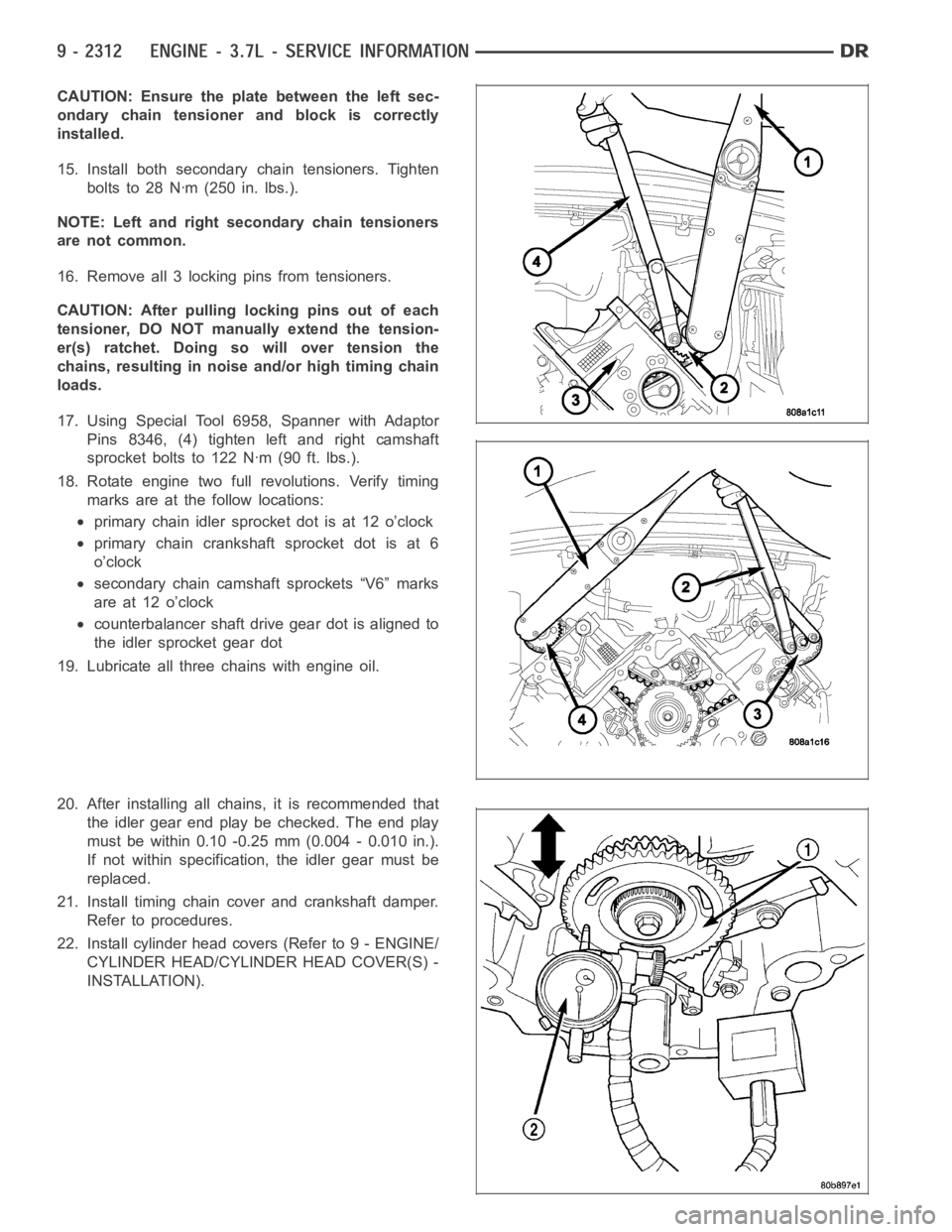

CAUTION: Ensure the plate between the left sec-

ondary chain tensioner and block is correctly

installed.

15. Install both secondary chain tensioners. Tighten

boltsto28Nꞏm(250in.lbs.).

NOTE: Left and right secondary chain tensioners

are not common.

16. Remove all 3 locking pins from tensioners.

CAUTION: After pulling locking pins out of each

tensioner, DO NOT manually extend the tension-

er(s) ratchet. Doing so will over tension the

chains, resulting in noise and/or high timing chain

loads.

17. Using Special Tool 6958, Spanner with Adaptor

Pins 8346, (4) tighten left and right camshaft

sprocket bolts to 122 Nꞏm (90 ft. lbs.).

18. Rotate engine two full revolutions. Verify timing

marks are at the follow locations:

primary chain idler sprocket dot is at 12 o’clock

primary chain crankshaft sprocket dot is at 6

o’clock

secondary chain camshaft sprockets “V6” marks

are at 12 o’clock

counterbalancer shaft drive gear dot is aligned to

the idler sprocket gear dot

19. Lubricate all three chains with engine oil.

20. After installing all chains, it is recommended that

the idler gear end play be checked. The end play

must be within 0.10 -0.25 mm (0.004 - 0.010 in.).

If not within specification, the idler gear must be

replaced.

21. Install timing chain cover and crankshaft damper.

Refer to procedures.

22. Install cylinder head covers (Refer to 9 - ENGINE/

CYLINDER HEAD/CYLINDER HEAD COVER(S) -

INSTALLATION).

Page 1624 of 5267

INSTALLATION ............................. 2394

FLEX PLATE

REMOVAL ................................. 2395

INSTALLATION ............................. 2395

ROD - PISTON & CONNECTING

DESCRIPTION ............................. 2396

STANDARD PROCEDURE - PISTON FITTING . 2396

REMOVAL ................................. 2397

CLEANING ................................. 2397

INSPECTION ............................... 2398

INSTALLATION ............................. 2398

RINGS - PISTON

STANDARD PROCEDURE - PISTON RING

FITTING .................................. 2400

DAMPER - CRANKSHAFT

REMOVAL ................................. 2403

INSTALLATION ............................. 2404

COVER - STRUCTURAL

DESCRIPTION ............................. 2405

OPERATION ............................... 2405

REMOVAL ................................. 2405

INSTALLATION ............................. 2405

MOUNT - FRONT

REMOVAL ................................. 2406

INSTALLATION ............................. 2408

MOUNT - REAR

REMOVAL ................................. 2410

INSTALLATION ............................. 2410

LUBRICATION

DESCRIPTION .............................. 2411

OPERATION ................................ 2411

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - CHECKING

ENGINE OIL PRESSURE.................. 2412

DIAGNOSIS AND TESTING - ENGINE OIL

LEAK.................................... 2413

OIL

STANDARD PROCEDURE - ENGINE OIL

SERVICE ................................. 2414

FILTER - ENGINE OIL

REMOVAL ................................. 2416

INSTALLATION ............................. 2416

PAN - ENGINE OIL

REMOVAL ................................. 2417

INSTALLATION ............................. 2417

SWITCH - OIL PRESSURE

DESCRIPTION

DESCRIPTION ........................... 2418DESCRIPTION ........................... 2418

OPERATION

OPERATION ............................. 2418

OPERATION ............................. 2418

REMOVAL ................................. 2419

INSTALLATION ............................. 2419

PUMP - ENGINE OIL

REMOVAL ................................. 2420

DISASSEMBLY . ............................ 2420

CLEANING ................................. 2420

INSPECTION............................... 2420

ASSEMBLY................................ 2422

INSTALLATION ............................. 2422

MANIFOLD - INTAKE

DESCRIPTION ............................. 2423

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKAGE ..................... 2423

REMOVAL ................................. 2423

CLEANING ................................. 2424

INSPECTION............................... 2424

INSTALLATION ............................. 2425

MANIFOLD - EXHAUST

DESCRIPTION ............................. 2426

REMOVAL ................................. 2426

CLEANING ................................. 2428

INSPECTION............................... 2428

INSTALLATION ............................. 2428

VALVE TIMING

DESCRIPTION - TIMING DRIVE SYSTEM ..... 2430

OPERATION - TIMING DRIVE SYSTEM....... 2430

STANDARD PROCEDURE

STANDARD PROCEDURE - MEASURING

TIMING CHAIN WEAR..................... 2431

STANDARD PROCEDURE - ENGINE TIMING

- VERIFICATION.......................... 2431

COVER - TIMING

REMOVAL ................................. 2436

INSTALLATION ............................. 2437

TIMING CHAIN & SPROCKETS

REMOVAL ................................. 2438

INSPECTION............................... 2441

INSTALLATION ............................. 2442

SHAFT - IDLER

REMOVAL ................................. 2446

INSTALLATION ............................. 2446

Page 1627 of 5267

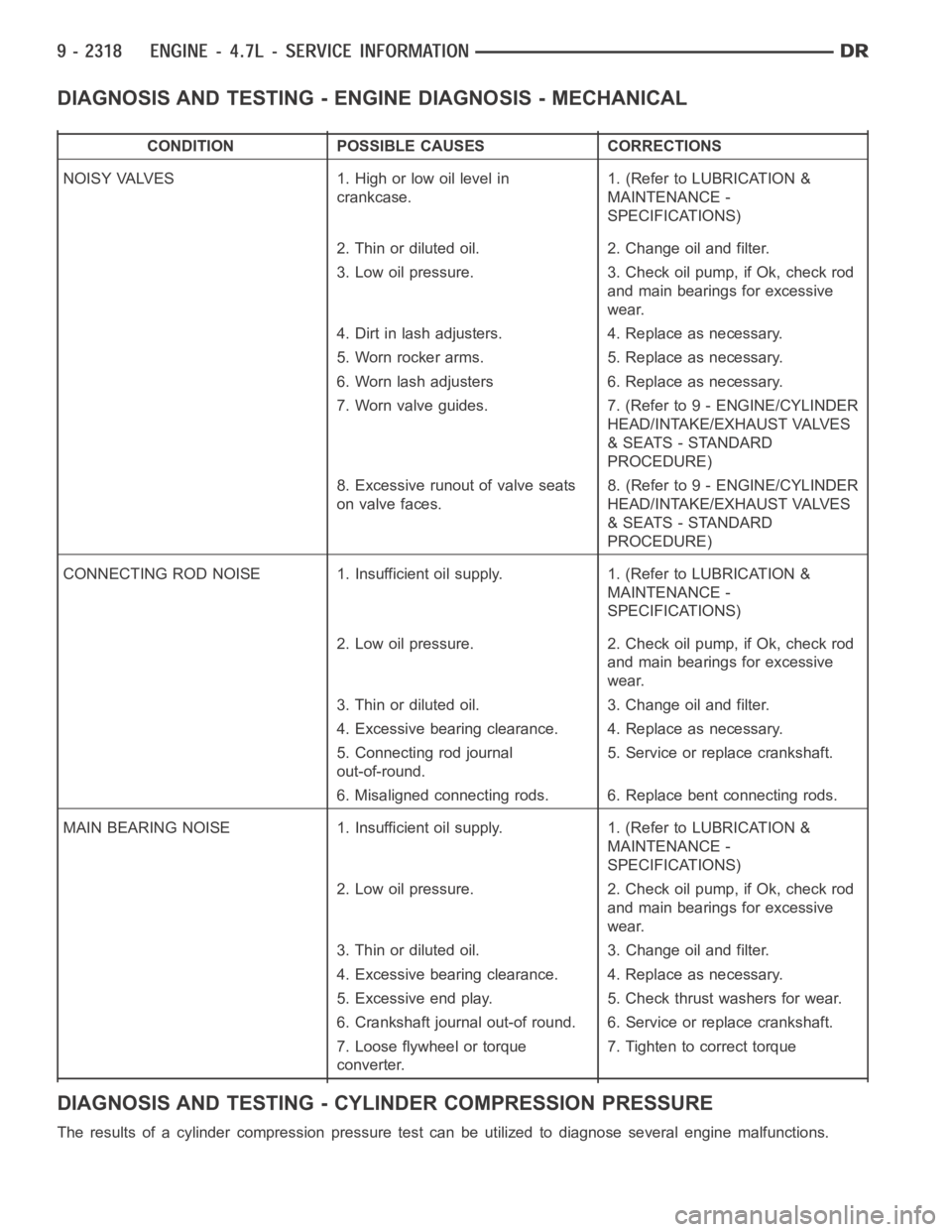

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTIONS

NOISY VALVES 1. High or low oil level in

crankcase.1. (Refer to LUBRICATION &

MAINTENANCE -

SPECIFICATIONS)

2. Thin or diluted oil. 2. Change oil and filter.

3. Low oil pressure. 3. Check oil pump, if Ok, check rod

and main bearings for excessive

wear.

4. Dirt in lash adjusters. 4. Replace as necessary.

5. Worn rocker arms. 5. Replace as necessary.

6. Worn lash adjusters 6. Replace as necessary.

7. Worn valve guides. 7. (Refer to 9 - ENGINE/CYLINDER

HEAD/INTAKE/EXHAUST VALVES

& SEATS - STANDARD

PROCEDURE)

8. Excessive runout of valve seats

on valve faces.8. (Refer to 9 - ENGINE/CYLINDER

HEAD/INTAKE/EXHAUST VALVES

& SEATS - STANDARD

PROCEDURE)

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. (Refer to LUBRICATION&

MAINTENANCE -

SPECIFICATIONS)

2. Low oil pressure. 2. Check oil pump, if Ok, check rod

and main bearings for excessive

wear.

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Replace as necessary.

5. Connecting rod journal

out-of-round.5. Service or replace crankshaft.

6. Misaligned connecting rods. 6. Replace bent connecting rods.

MAIN BEARING NOISE 1. Insufficient oil supply. 1. (Refer to LUBRICATION &

MAINTENANCE -

SPECIFICATIONS)

2. Low oil pressure. 2. Check oil pump, if Ok, check rod

and main bearings for excessive

wear.

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Replace as necessary.

5. Excessive end play. 5. Check thrust washers for wear.

6. Crankshaft journal out-of round. 6. Service or replace crankshaft.

7. Loose flywheel or torque

converter.7. Tighten to correct torque

DIAGNOSIS AND TESTING - CYLINDER COMPRESSION PRESSURE

The results of a cylinder compressionpressure test can be utilized to diagnose several engine malfunctions.

Page 1628 of 5267

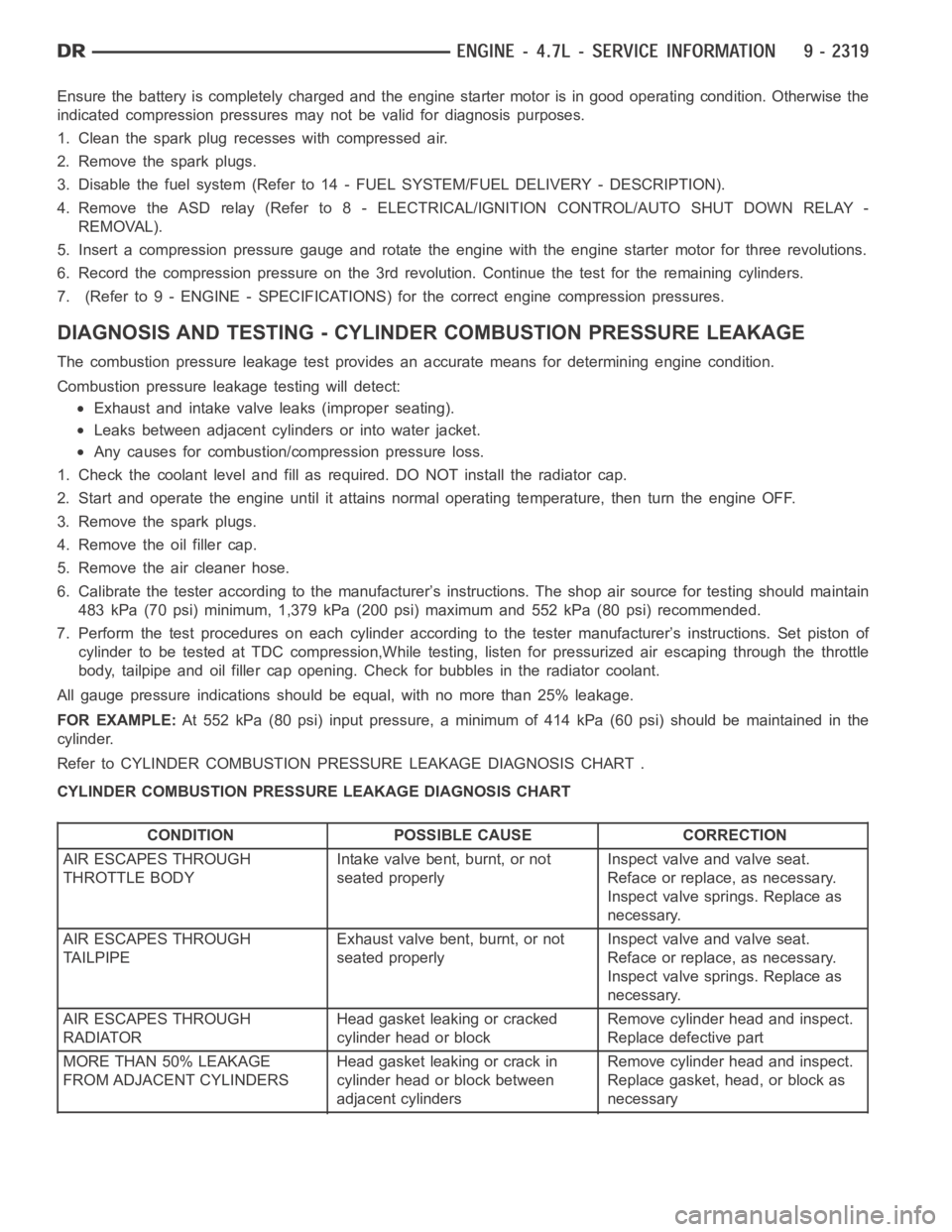

Ensurethebatteryiscompletelychargedandtheenginestartermotorisingood operating condition. Otherwise the

indicated compression pressures may not be valid for diagnosis purposes.

1. Clean the spark plug recesses with compressed air.

2. Remove the spark plugs.

3. Disable the fuel system (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY - DESCRIPTION).

4. Remove the ASD relay (Refer to 8 - ELECTRICAL/IGNITION CONTROL/AUTO SHUTDOWNRELAY-

REMOVAL).

5. Insert a compression pressure gauge and rotate the engine with the engine starter motor for three revolutions.

6. Record the compression pressure on the 3rd revolution. Continue the test for the remaining cylinders.

7. (Refer to 9 - ENGINE - SPECIFICATIONS) for the correct engine compression pressures.

DIAGNOSIS AND TESTING - CYLINDERCOMBUSTION PRESSURE LEAKAGE

The combustion pressure leakage test provides an accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

Exhaust and intake valve leaks (improper seating).

Leaks between adjacent cylinders or into water jacket.

Any causes for combustion/compression pressure loss.

1. Check the coolant level and fill as required. DO NOT install the radiatorcap.

2. Start and operate the engine until it attains normal operating temperature, then turn the engine OFF.

3. Remove the spark plugs.

4. Remove the oil filler cap.

5. Remove the air cleaner hose.

6. Calibrate the tester according to the manufacturer’s instructions. The shop air source for testing should maintain

483 kPa (70 psi) minimum, 1,379 kPa (200 psi) maximum and 552 kPa (80 psi) recommended.

7. Perform the test procedures on each cylinder according to the tester manufacturer’s instructions. Set piston of

cylinder to be tested at TDC compression,While testing, listen for pressurized air escaping through the throttle

body, tailpipe and oil filler cap opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal, with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pressure, a minimum of 414 kPa (60 psi) should be maintained in the

cylinder.

Refer to CYLINDER COMBUSTION PRESSURE LEAKAGE DIAGNOSIS CHART .

CYLINDER COMBUSTION PRESSURE LEAKAGE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

AIR ESCAPES THROUGH

THROTTLE BODYIntake valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary.

Inspect valve springs. Replace as

necessary.

AIR ESCAPES THROUGH

TAILPIPEExhaust valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary.

Inspect valve springs. Replace as

necessary.

AIR ESCAPES THROUGH

RADIATORHead gasket leaking or cracked

cylinder head or blockRemove cylinder head and inspect.

Replace defective part

MORE THAN 50% LEAKAGE

FROM ADJACENT CYLINDERSHead gasket leaking or crack in

cylinder head or block between

adjacent cylindersRemove cylinder head and inspect.

Replace gasket, head, or block as

necessary