check engine DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1640 of 5267

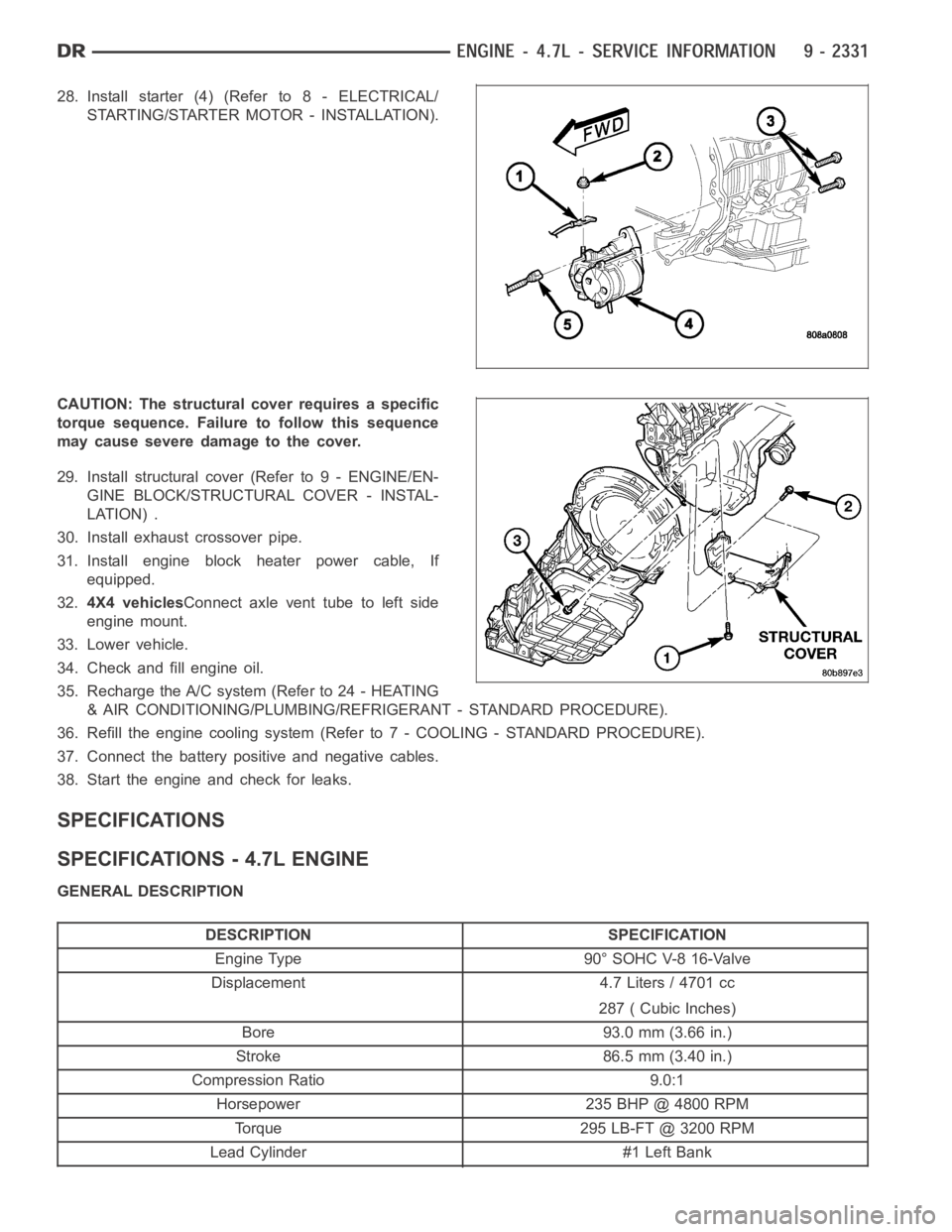

28. Install starter (4) (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - INSTALLATION).

CAUTION: The structural cover requires a specific

torque sequence. Failure to follow this sequence

may cause severe damage to the cover.

29. Install structural cover (Refer to 9 - ENGINE/EN-

GINE BLOCK/STRUCTURAL COVER - INSTAL-

LATION) .

30. Install exhaust crossover pipe.

31. Install engine block heater power cable, If

equipped.

32.4X4 vehiclesConnect axle vent tube to left side

engine mount.

33. Lower vehicle.

34. Check and fill engine oil.

35. Recharge the A/C system (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/REFRIGERANT - STANDARD PROCEDURE).

36. Refill the engine cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE).

37. Connect the battery positive and negative cables.

38. Start the engine and check for leaks.

SPECIFICATIONS

SPECIFICATIONS - 4.7L ENGINE

GENERAL DESCRIPTION

DESCRIPTION SPECIFICATION

Engine Type 90° SOHC V-8 16-Valve

Displacement 4.7 Liters / 4701 cc

287 ( Cubic Inches)

Bore 93.0 mm (3.66 in.)

Stroke 86.5 mm (3.40 in.)

Compression Ratio 9.0:1

Horsepower 235 BHP @ 4800 RPM

Torque 295 LB-FT @ 3200 RPM

Lead Cylinder #1 Left Bank

Page 1654 of 5267

Install Cooling System Tester Special Tool # 7700 or equivalent to pressure cap neck. Start the engine and observe

the tester’s pressure gauge. If gauge pulsates with every power stroke of acylinder a combustion pressure leak is

evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also be checked by using Bloc-Chek Kit Special Tool # C-3685-A or

equivalent. Perform test following the procedures supplied with the toolkit.

REMOVAL

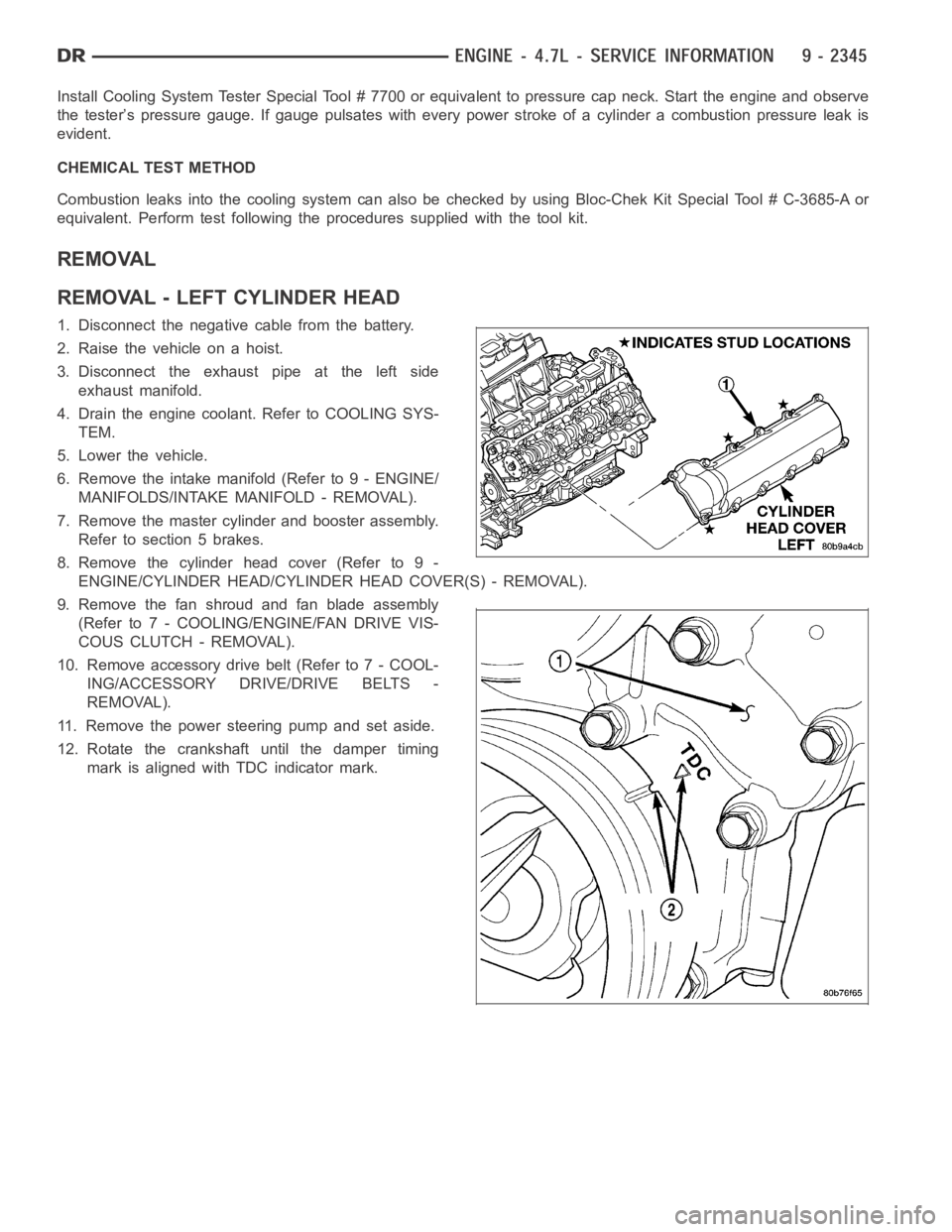

REMOVAL - LEFT CYLINDER HEAD

1. Disconnect the negative cable from the battery.

2. Raise the vehicle on a hoist.

3. Disconnect the exhaust pipe at the left side

exhaust manifold.

4. Drain the engine coolant. Refer to COOLING SYS-

TEM.

5. Lower the vehicle.

6. Remove the intake manifold (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - REMOVAL).

7. Remove the master cylinder and booster assembly.

Refer to section 5 brakes.

8. Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) - REMOVAL).

9. Remove the fan shroud and fan blade assembly

(Refer to 7 - COOLING/ENGINE/FAN DRIVE VIS-

COUS CLUTCH - REMOVAL).

10. Remove accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

11. Remove the power steering pump and set aside.

12. Rotate the crankshaft until the damper timing

mark is aligned with TDC indicator mark.

Page 1662 of 5267

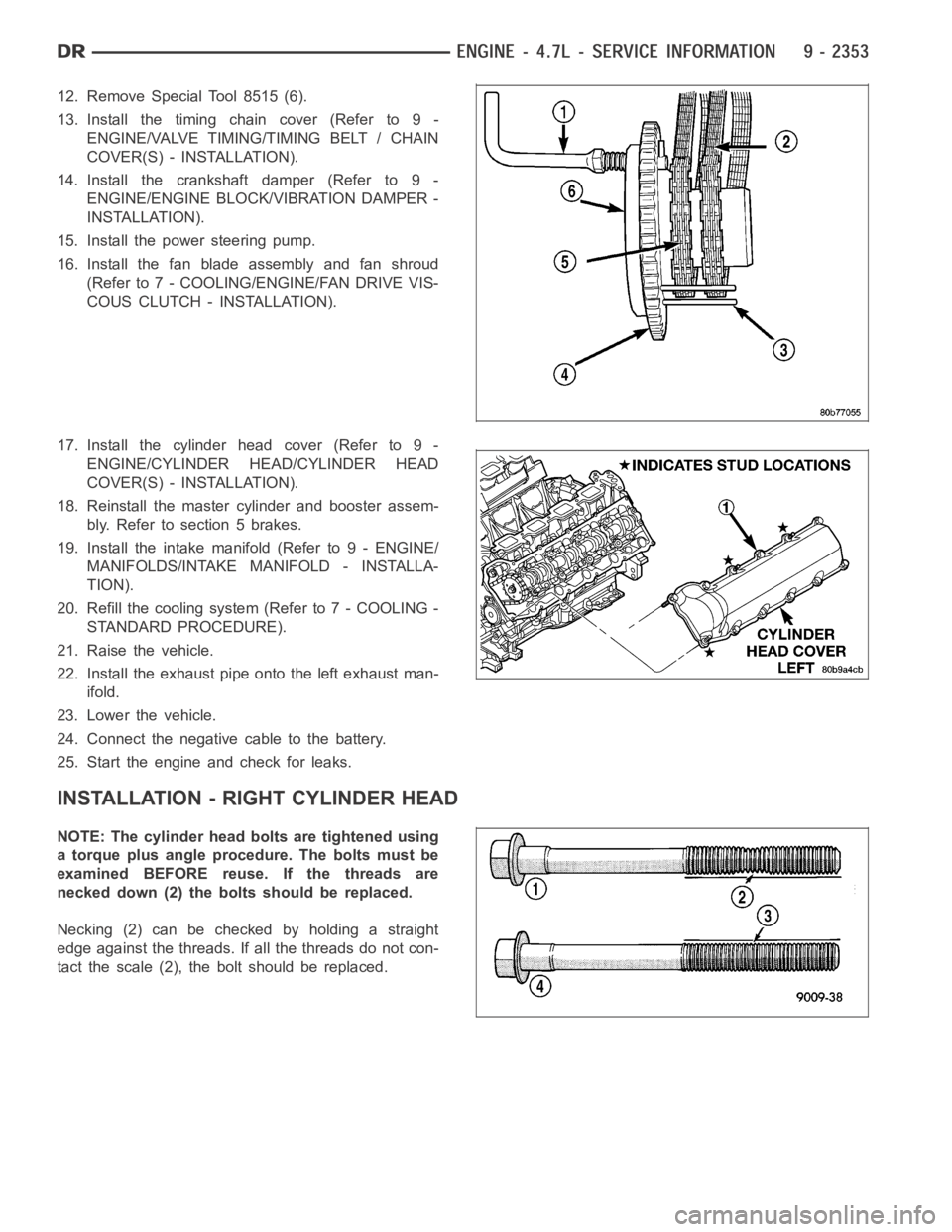

12. Remove Special Tool 8515 (6).

13. Install the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

14. Install the crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

15. Install the power steering pump.

16. Install the fan blade assembly and fan shroud

(Refer to 7 - COOLING/ENGINE/FAN DRIVE VIS-

COUS CLUTCH - INSTALLATION).

17. Install the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

18. Reinstall the master cylinder and booster assem-

bly.Refertosection5brakes.

19. Install the intake manifold (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - INSTALLA-

TION).

20. Refill the cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

21. Raise the vehicle.

22. Install the exhaust pipe onto the left exhaust man-

ifold.

23. Lower the vehicle.

24. Connect the negative cable to the battery.

25. Start the engine and check for leaks.

INSTALLATION - RIGHT CYLINDER HEAD

NOTE: The cylinder head bolts are tightened using

a torque plus angle procedure. The bolts must be

examined BEFORE reuse. If the threads are

necked down (2) the bolts should be replaced.

Necking(2)canbecheckedbyholdingastraight

edge against the threads. If all the threads do not con-

tactthescale(2),theboltshouldbereplaced.

Page 1665 of 5267

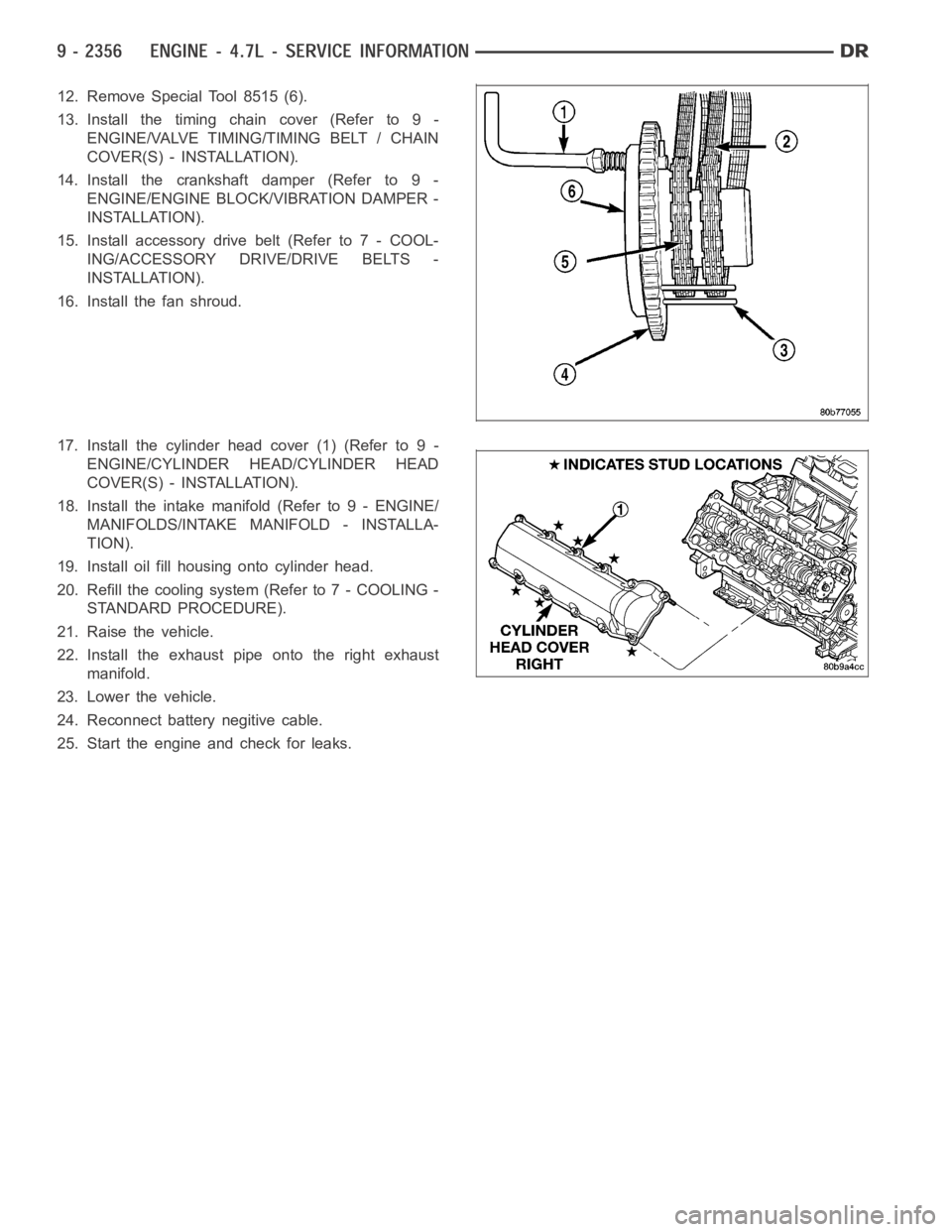

12. Remove Special Tool 8515 (6).

13. Install the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

14. Install the crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

15. Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

16. Install the fan shroud.

17. Install the cylinder head cover (1) (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

18. Install the intake manifold (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - INSTALLA-

TION).

19. Install oil fill housing onto cylinder head.

20. Refill the cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

21. Raise the vehicle.

22. Install the exhaust pipe onto the right exhaust

manifold.

23. Lower the vehicle.

24. Reconnect battery negitive cable.

25. Start the engine and check for leaks.

Page 1680 of 5267

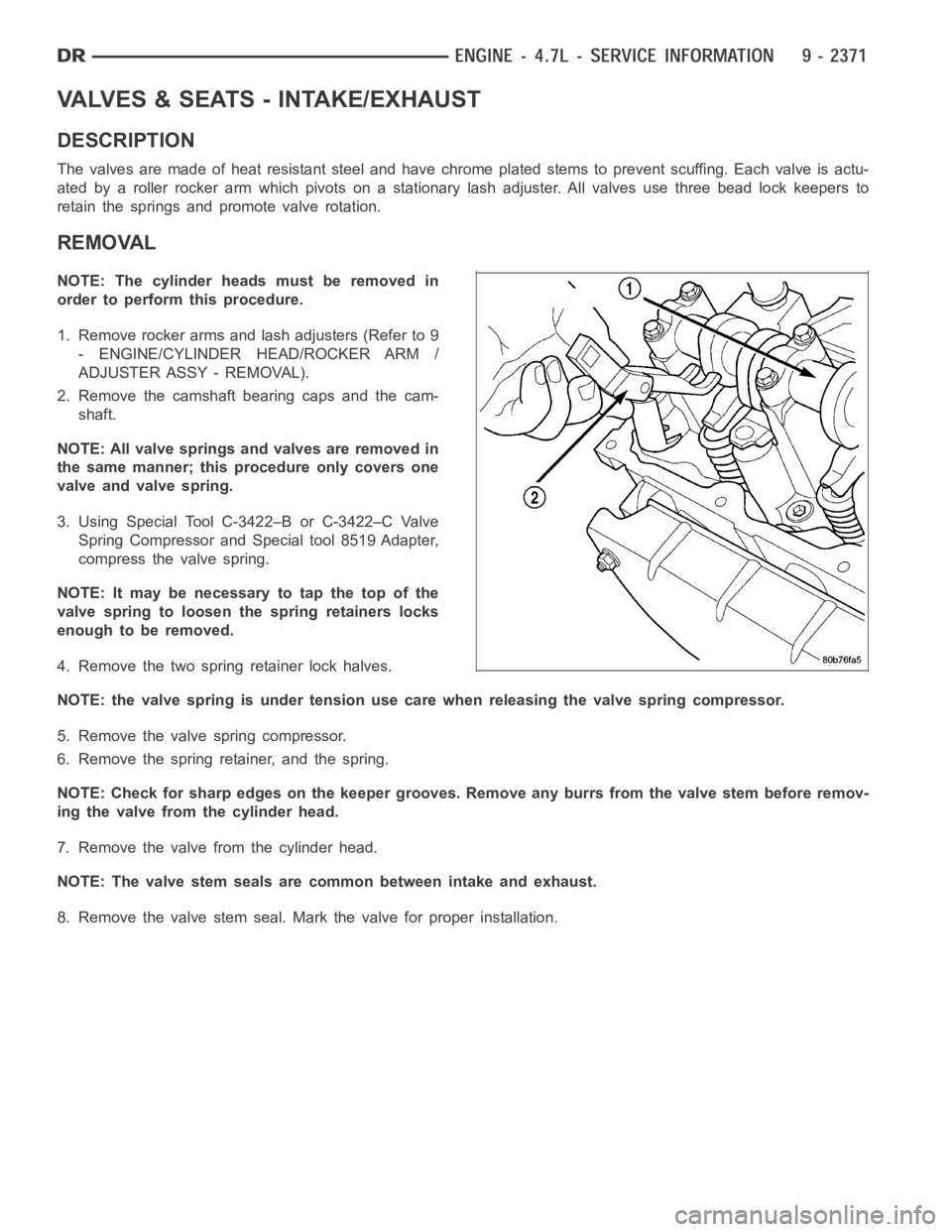

VALVES & SEATS - INTAKE/EXHAUST

DESCRIPTION

The valves are made of heat resistant steel and have chrome plated stems to prevent scuffing. Each valve is actu-

ated by a roller rocker arm which pivots on a stationary lash adjuster. All valves use three bead lock keepers to

retain the springs and promote valve rotation.

REMOVAL

NOTE: The cylinder heads must be removed in

order to perform this procedure.

1. Remove rocker arms and lash adjusters (Refer to 9

- ENGINE/CYLINDER HEAD/ROCKER ARM /

ADJUSTER ASSY - REMOVAL).

2. Remove the camshaft bearing caps and the cam-

shaft.

NOTE: All valve springs and valves are removed in

the same manner; this procedure only covers one

valve and valve spring.

3. Using Special Tool C-3422–B or C-3422–C Valve

Spring Compressor and Special tool 8519 Adapter,

compress the valve spring.

NOTE: It may be necessary to tap the top of the

valve spring to loosen the spring retainers locks

enough to be removed.

4. Remove the two spring retainer lock halves.

NOTE: the valve spring is under tension use care when releasing the valve spring compressor.

5. Remove the valve spring compressor.

6. Remove the spring retainer, and the spring.

NOTE: Check for sharp edges on the keeper grooves. Remove any burrs from thevalvestembeforeremov-

ing the valve from the cylinder head.

7. Remove the valve from the cylinder head.

NOTE: The valve stem seals are common between intake and exhaust.

8. Remove the valve stem seal. Mark the valve for proper installation.

Page 1683 of 5267

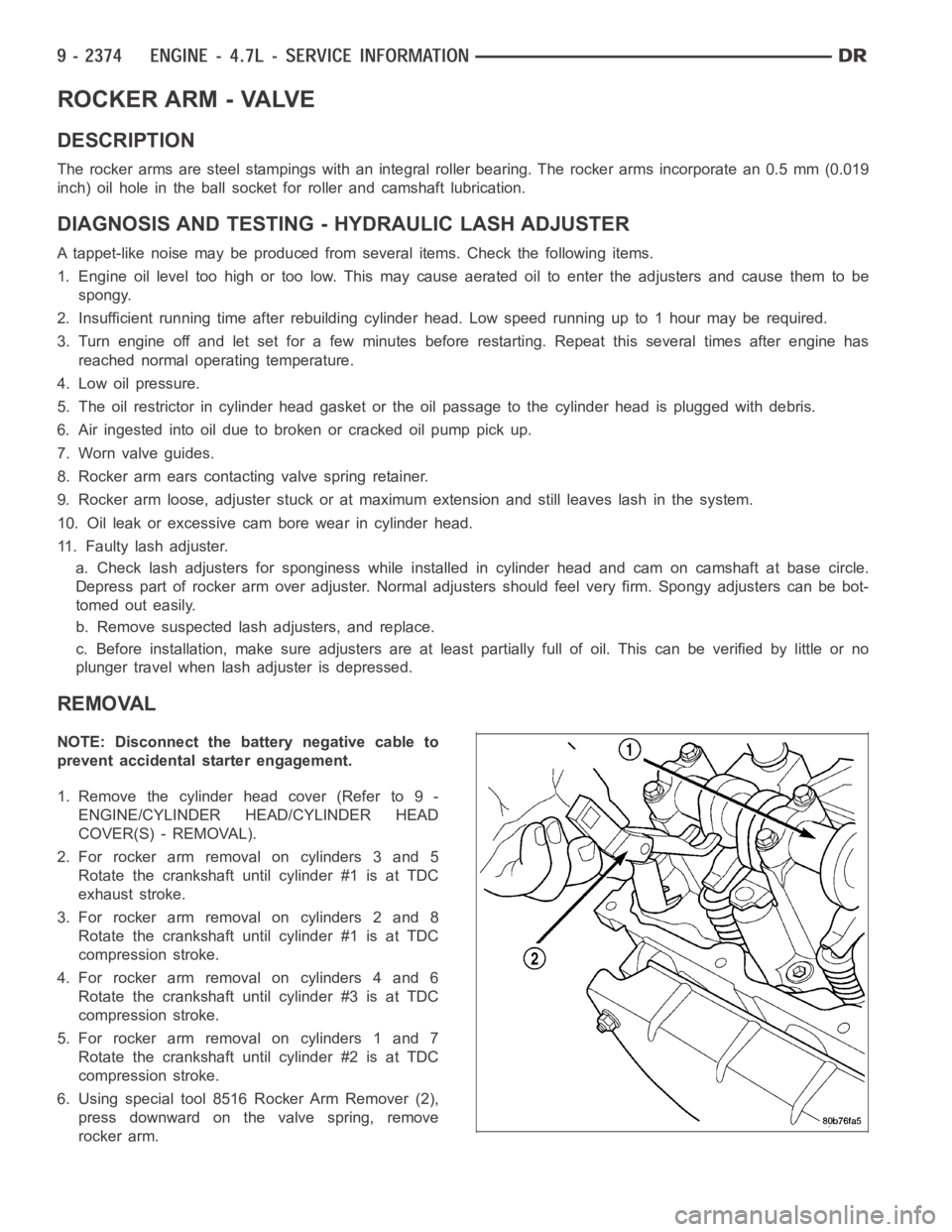

ROCKER ARM - VALVE

DESCRIPTION

The rocker arms are steel stampings with an integral roller bearing. The rocker arms incorporate an 0.5 mm (0.019

inch) oil hole in the ball socket forroller and camshaft lubrication.

DIAGNOSIS AND TESTING - HYDRAULIC LASH ADJUSTER

A tappet-like noise may be produced from several items. Check the followingitems.

1. Engine oil level too high or too low. This may cause aerated oil to enter the adjusters and cause them to be

spongy.

2. Insufficient running time after rebuilding cylinder head. Low speed runningupto1hourmayberequired.

3. Turn engine off and let set for a few minutes before restarting. Repeat this several times after engine has

reached normal operating temperature.

4. Low oil pressure.

5. The oil restrictor in cylinder head gasket or the oil passage to the cylinder head is plugged with debris.

6. Airingestedintooilduetobrokenorcrackedoilpumppickup.

7. Worn valve guides.

8. Rocker arm ears contacting valve spring retainer.

9. Rocker arm loose, adjuster stuck or at maximum extension and still leaves lash in the system.

10. Oil leak or excessive cam bore wear in cylinder head.

11. Faulty lash adjuster.

a. Check lash adjusters for sponginess while installed in cylinder head and cam on camshaft at base circle.

Depress part of rocker arm over adjuster. Normal adjusters should feel very firm. Spongy adjusters can be bot-

tomed out easily.

b. Remove suspected lash adjusters, and replace.

c. Before installation, make sure adjusters are at least partially full ofoil. This can be verified by little or no

plunger travel when lash adjuster is depressed.

REMOVAL

NOTE: Disconnect the battery negative cable to

prevent accidental starter engagement.

1. Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

2. For rocker arm removal on cylinders 3 and 5

Rotate the crankshaft until cylinder #1 is at TDC

exhaust stroke.

3. For rocker arm removal on cylinders 2 and 8

Rotate the crankshaft until cylinder #1 is at TDC

compression stroke.

4. For rocker arm removal on cylinders 4 and 6

Rotate the crankshaft until cylinder #3 is at TDC

compression stroke.

5. For rocker arm removal on cylinders 1 and 7

Rotate the crankshaft until cylinder #2 is at TDC

compression stroke.

6. Using special tool 8516 Rocker Arm Remover (2),

press downward on the valve spring, remove

rocker arm.

Page 1688 of 5267

ENGINE BLOCK

DESCRIPTION

The cylinder block is made of cast iron.The block is a closed deck design with the left bank forward. To provide

high rigidity and improved NVH an enhanced compacted graphite bedplate isbolted to the block. The block design

allows coolant flow between the cylinders bores, and an internal coolant bypass to a single poppet inlet thermostat

is included in the cast aluminum front cover.

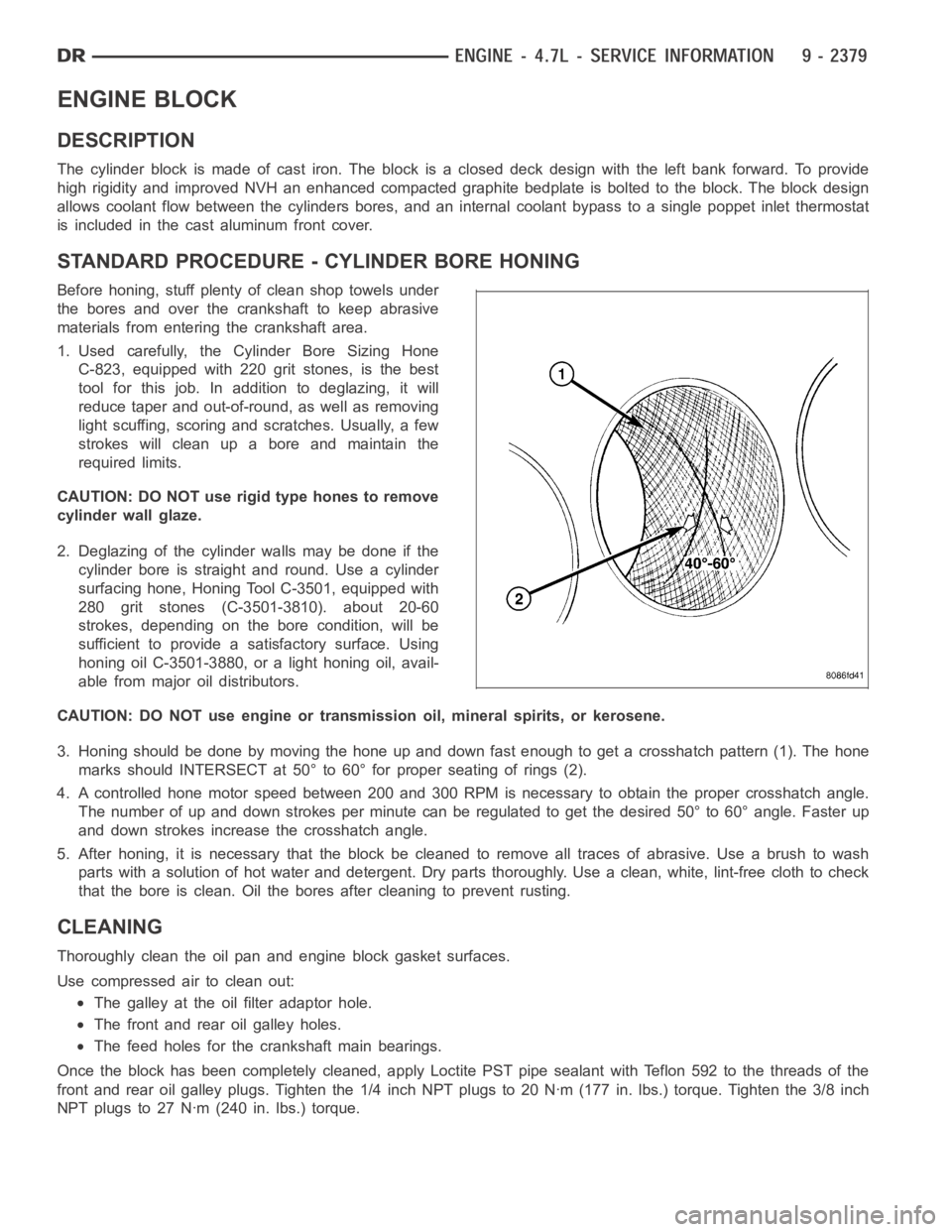

STANDARD PROCEDURE - CYLINDER BORE HONING

Before honing, stuff plenty of clean shop towels under

the bores and over the crankshaft to keep abrasive

materials from entering the crankshaft area.

1. Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best

tool for this job. In addition to deglazing, it will

reduce taper and out-of-round, as well as removing

light scuffing, scoring and scratches. Usually, a few

strokes will clean up a bore and maintain the

required limits.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

2. Deglazing of the cylinder walls may be done if the

cylinder bore is straight and round. Use a cylinder

surfacing hone, Honing Tool C-3501, equipped with

280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be

sufficient to provide a satisfactory surface. Using

honing oil C-3501-3880, or a light honing oil, avail-

able from major oil distributors.

CAUTION: DO NOT use engine or transmission oil, mineral spirits, or kerosene.

3. Honing should be done by moving the hone up and down fast enough to get a crosshatch pattern (1). The hone

marks should INTERSECT at 50° to 60° for proper seating of rings (2).

4. A controlled hone motor speed between 200 and 300 RPM is necessary to obtain the proper crosshatch angle.

The number of up and down strokes per minute can be regulated to get the desired 50° to 60° angle. Faster up

and down strokes increase the crosshatch angle.

5. After honing, it is necessary that the block be cleaned to remove all traces of abrasive. Use a brush to wash

parts with a solution of hot water and detergent. Dry parts thoroughly. Usea clean, white, lint-free cloth to check

that the bore is clean. Oil the bores after cleaning to prevent rusting.

CLEANING

Thoroughly clean the oil pan and engine block gasket surfaces.

Use compressed air to clean out:

The galley at the oil filter adaptor hole.

The front and rear oil galley holes.

The feed holes for the crankshaft main bearings.

Once the block has been completely cleaned, apply Loctite PST pipe sealantwith Teflon 592 to the threads of the

front and rear oil galley plugs. Tighten the 1/4 inch NPT plugs to 20 Nꞏm (177in. lbs.) torque. Tighten the 3/8 inch

NPT plugs to 27 Nꞏm (240 in. lbs.) torque.

Page 1702 of 5267

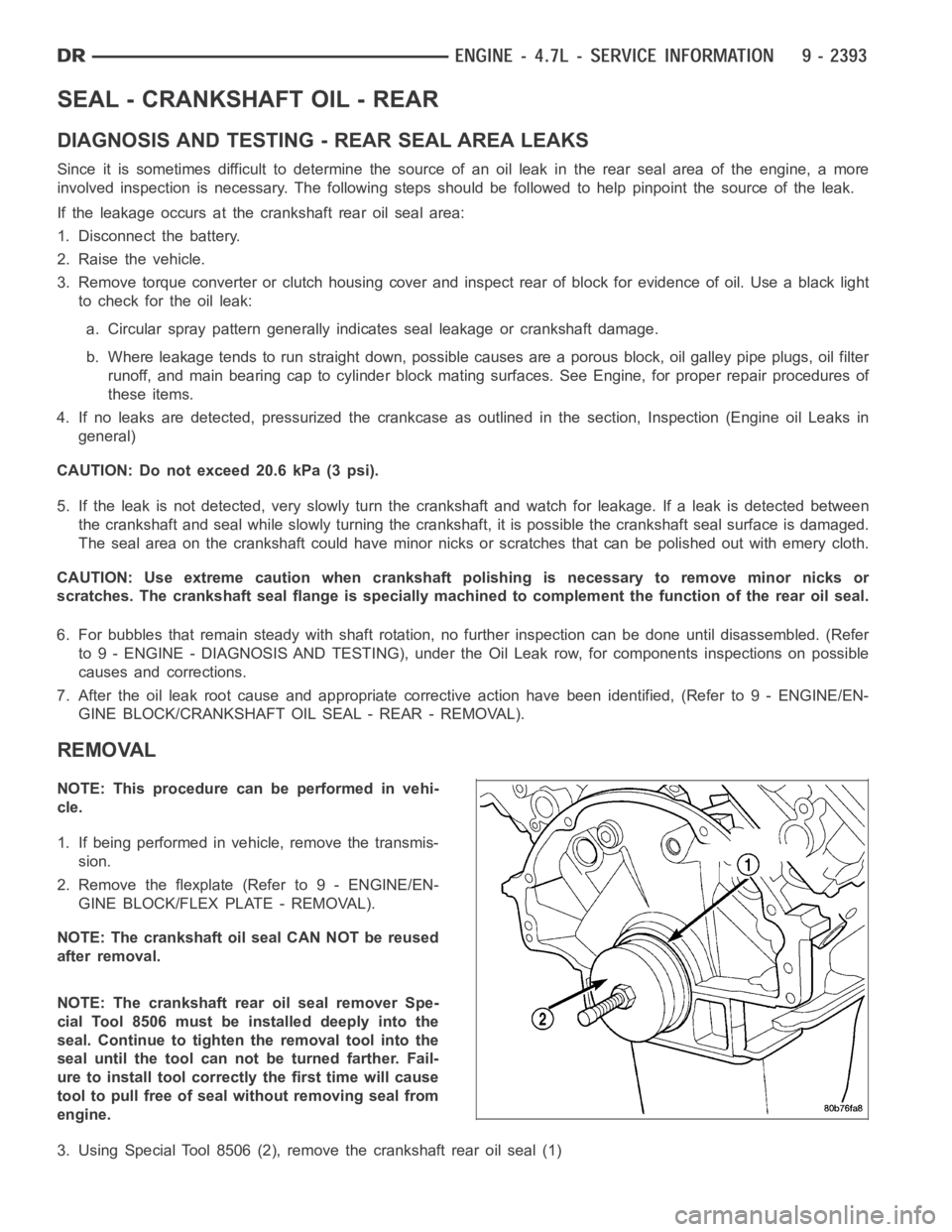

SEAL - CRANKSHAFT OIL - REAR

DIAGNOSIS AND TESTING - REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the source of an oil leak in therear seal area of the engine, a more

involved inspection is necessary. The following steps should be followedto help pinpoint the source of the leak.

If the leakage occurs at the crankshaft rear oil seal area:

1. Disconnect the battery.

2. Raise the vehicle.

3. Remove torque converter or clutch housing cover and inspect rear of block for evidence of oil. Use a black light

to check for the oil leak:

a. Circular spray pattern generally indicates seal leakage or crankshaftdamage.

b. Where leakage tends to run straight down, possible causes are a porous block, oil galley pipe plugs, oil filter

runoff, and main bearing cap to cylinder block mating surfaces. See Engine, for proper repair procedures of

these items.

4. If no leaks are detected, pressurized the crankcase as outlined in the section, Inspection (Engine oil Leaks in

general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

5. If the leak is not detected, very slowly turn the crankshaft and watch forleakage. If a leak is detected between

the crankshaft and seal while slowly turning the crankshaft, it is possible the crankshaft seal surface is damaged.

The seal area on the crankshaft could have minor nicks or scratches that canbe polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially machined to complement the function of the rear oil seal.

6. For bubbles that remain steady with shaft rotation, no further inspection can be done until disassembled. (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING), under the Oil Leak row, for components inspections on possible

causes and corrections.

7. After the oil leak root cause and appropriate corrective action have been identified, (Refer to 9 - ENGINE/EN-

GINE BLOCK/CRANKSHAFT OIL SEAL - REAR - REMOVAL).

REMOVAL

NOTE: This procedure can be performed in vehi-

cle.

1. If being performed in vehicle, remove the transmis-

sion.

2. Remove the flexplate (Refer to 9 - ENGINE/EN-

GINE BLOCK/FLEX PLATE - REMOVAL).

NOTE: The crankshaft oil seal CAN NOT be reused

after removal.

NOTE: The crankshaft rear oil seal remover Spe-

cial Tool 8506 must be installed deeply into the

seal. Continue to tighten the removal tool into the

seal until the tool can not be turned farther. Fail-

ure to install tool correctly the first time will cause

tool to pull free of seal without removing seal from

engine.

3. Using Special Tool 8506 (2), remove the crankshaft rear oil seal (1)

Page 1707 of 5267

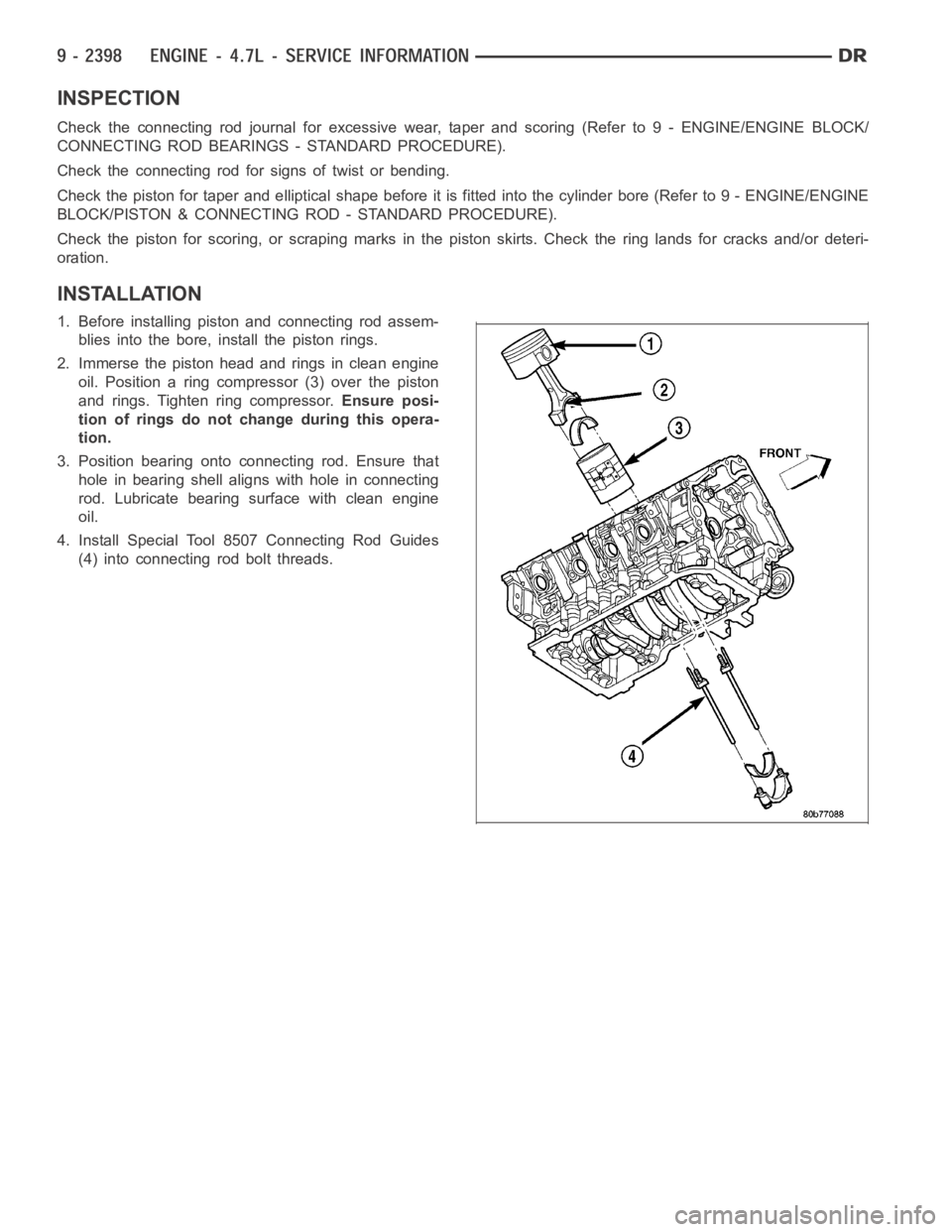

INSPECTION

Check the connecting rod journal for excessive wear, taper and scoring (Refer to 9 - ENGINE/ENGINE BLOCK/

CONNECTING ROD BEARINGS - STANDARD PROCEDURE).

Check the connecting rod for signs of twist or bending.

Check the piston for taper and elliptical shape before it is fitted into thecylinder bore (Refer to 9 - ENGINE/ENGINE

BLOCK/PISTON & CONNECTING ROD - STANDARD PROCEDURE).

Check the piston for scoring, or scraping marks in the piston skirts. Checkthe ring lands for cracks and/or deteri-

oration.

INSTALLATION

1. Before installing piston and connecting rod assem-

blies into the bore, install the piston rings.

2. Immerse the piston head and rings in clean engine

oil. Position a ring compressor (3) over the piston

and rings. Tighten ring compressor.Ensure posi-

tion of rings do not change during this opera-

tion.

3. Position bearing onto connecting rod. Ensure that

hole in bearing shell aligns with hole in connecting

rod. Lubricate bearing surface with clean engine

oil.

4. Install Special Tool 8507 Connecting Rod Guides

(4) into connecting rod bolt threads.

Page 1721 of 5267

Engine Lubrication Flow Chart—Block: Table 1

FROM TO

Oil Pickup Tube Oil Pump

Oil Pump Oil Filter

Oil Filter Block Main Oil Gallery

Block Main Oil Gallery 1. Crankshaft Main Journal

2. Left Cylinder Head*

3. Right Cylinder Head*

Crankshaft Main Journals Crankshaft Rod Journals

Crankshaft Number One Main Journal 1.Front Timing Chain Idler Shaft

2.Both Secondary Chain Tensioners

Left Cylinder Head See Table 2

Right Cylinder Head See Table 2

* The cylinder head gaskets have an oil restricter to control oil flow to thecylinder heads.

Engine Lubrication Flow Chart—Cylinder Heads: Table 2

FROM TO

Cylinder Head Oil Port (in bolt hole) Diagonal Cross Drilling to Main Oil Gallery

Main Oil Gallery (drilled through headfrom rear to front) 1. Base of Camshaft Towers

2. Lash Adjuster Towers

Base of Camshaft Towers Vertical Drilling Through Tower to Camshaft Bearings**

Lash Adjuster Towers Diagonal Drillings to Hydraulic Lash Adjuster Pockets

** The number three camshaft bearing journal feeds oil into the hollow camshaft tubes. Oil is routed to the intake

lobes, which have oil passages drilled into them to lubricate the rocker arms.

DIAGNOSIS AND TESTING

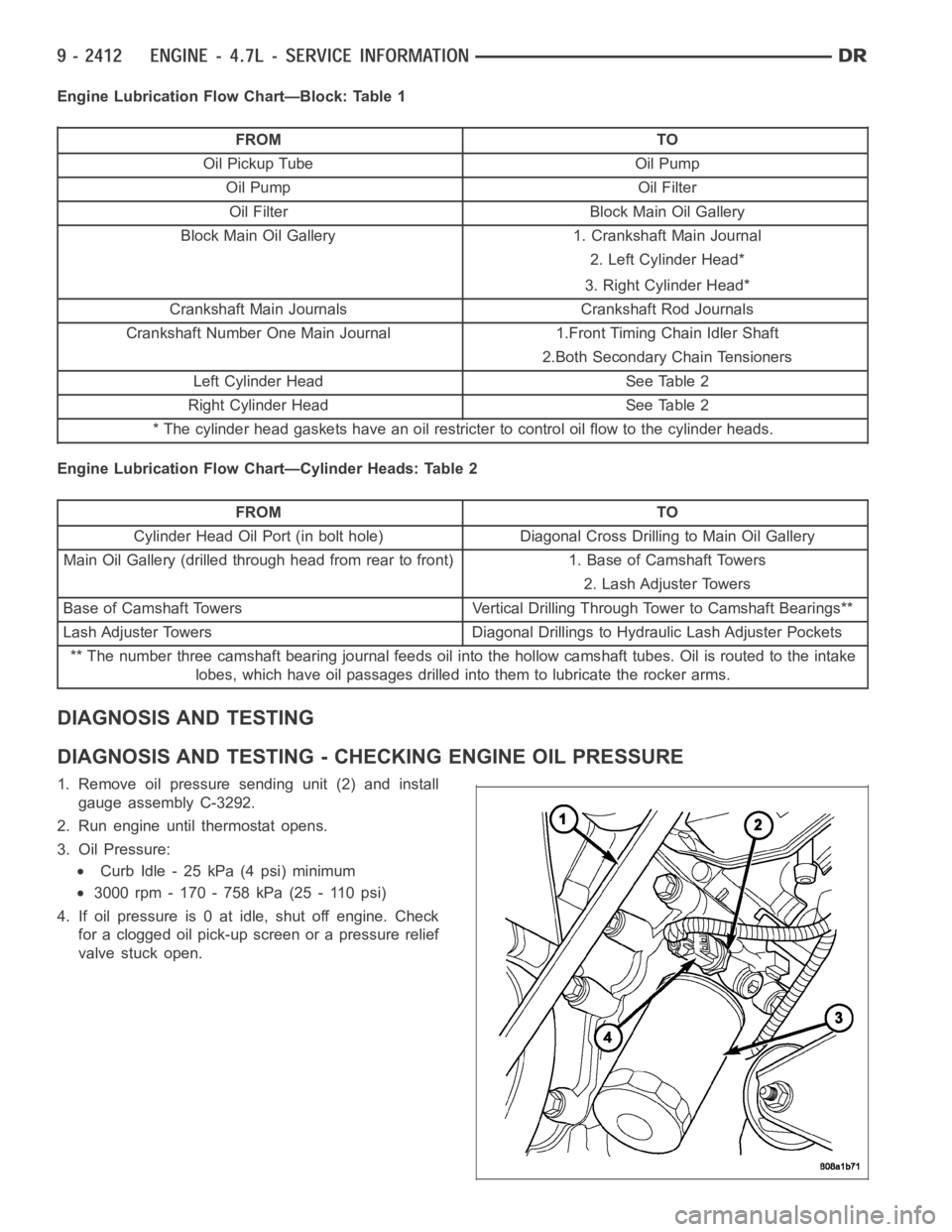

DIAGNOSIS AND TESTING - CHECKING ENGINE OIL PRESSURE

1. Remove oil pressure sending unit (2) and install

gauge assembly C-3292.

2. Run engine until thermostat opens.

3. Oil Pressure:

Curb Idle - 25 kPa (4 psi) minimum

3000 rpm - 170 - 758 kPa (25 - 110 psi)

4. If oil pressure is 0 at idle, shut off engine. Check

for a clogged oil pick-up screen or a pressure relief

valve stuck open.