ABS DODGE RAM SRT-10 2006 Service Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3933 of 5267

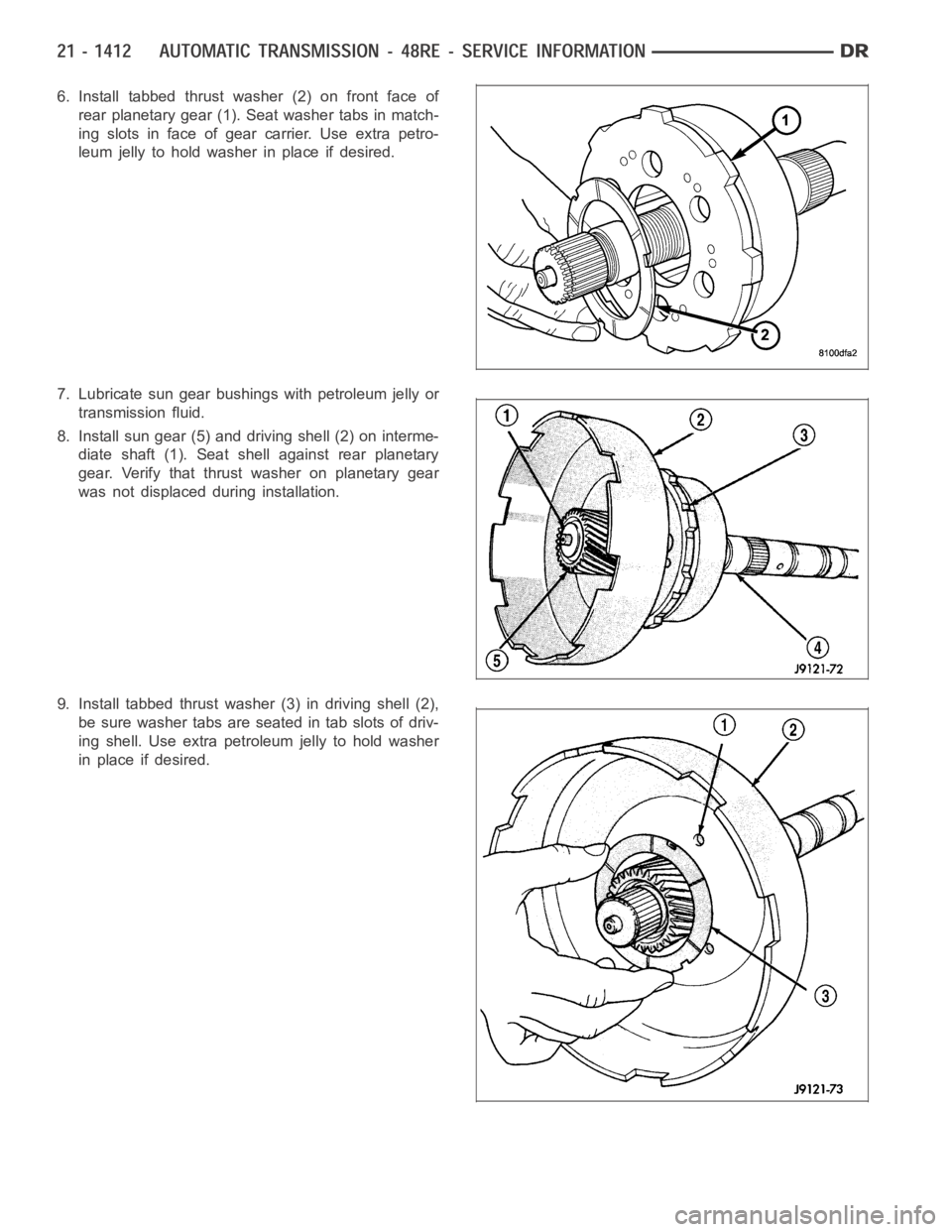

6. Install tabbed thrust washer (2) on front face of

rear planetary gear (1). Seat washer tabs in match-

ing slots in face of gear carrier. Use extra petro-

leum jelly to hold washer in place if desired.

7. Lubricate sun gear bushings with petroleum jelly or

transmission fluid.

8. Install sun gear (5) and driving shell (2) on interme-

diate shaft (1). Seat shell against rear planetary

gear. Verify that thrust washer on planetary gear

was not displaced during installation.

9. Install tabbed thrust washer (3) in driving shell (2),

be sure washer tabs are seated in tab slots of driv-

ing shell. Use extra petroleum jelly to hold washer

in place if desired.

Page 3934 of 5267

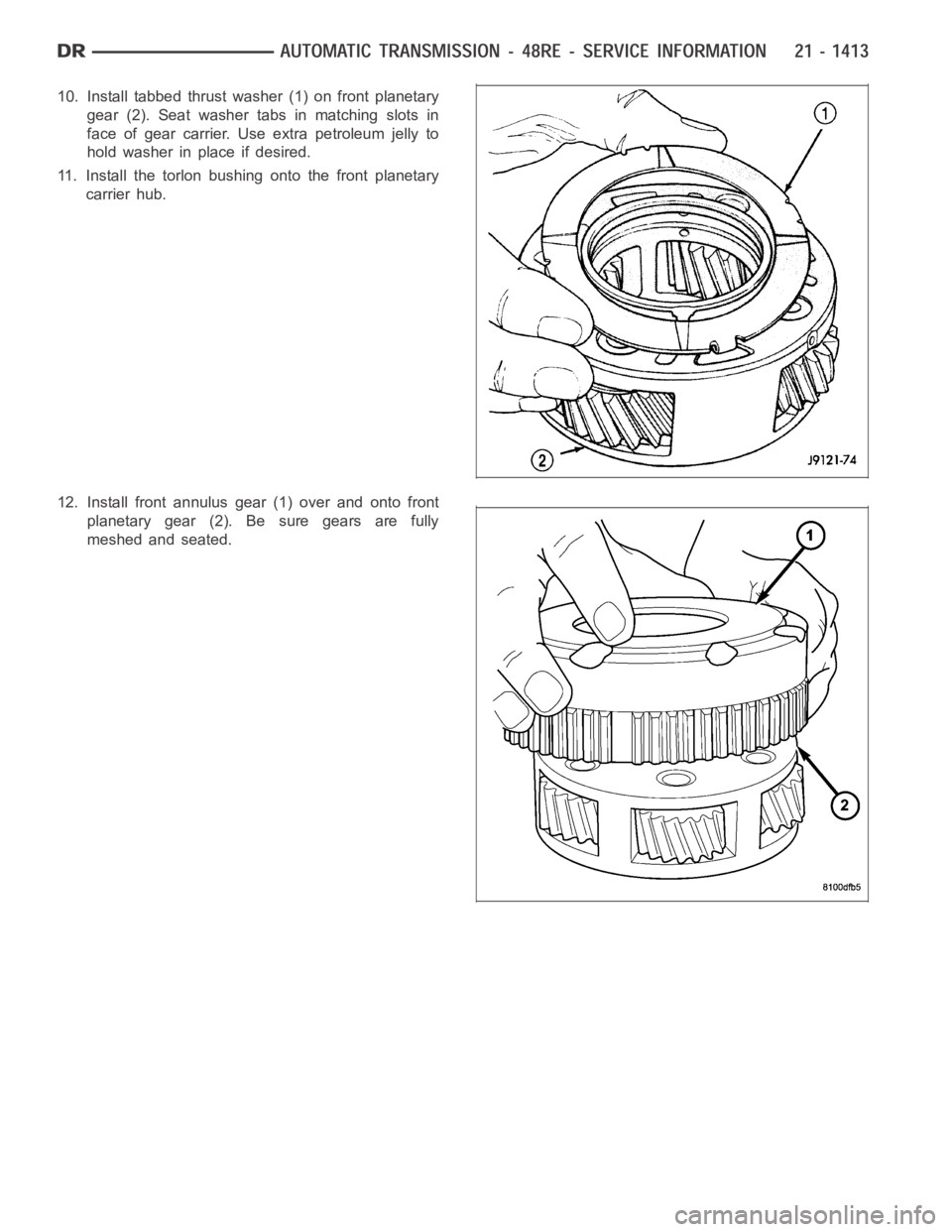

10. Install tabbed thrust washer (1) on front planetary

gear (2). Seat washer tabs in matching slots in

face of gear carrier. Use extra petroleum jelly to

hold washer in place if desired.

11. Install the torlon bushing onto the front planetary

carrier hub.

12. Install front annulus gear (1) over and onto front

planetary gear (2). Be sure gears are fully

meshed and seated.

Page 4000 of 5267

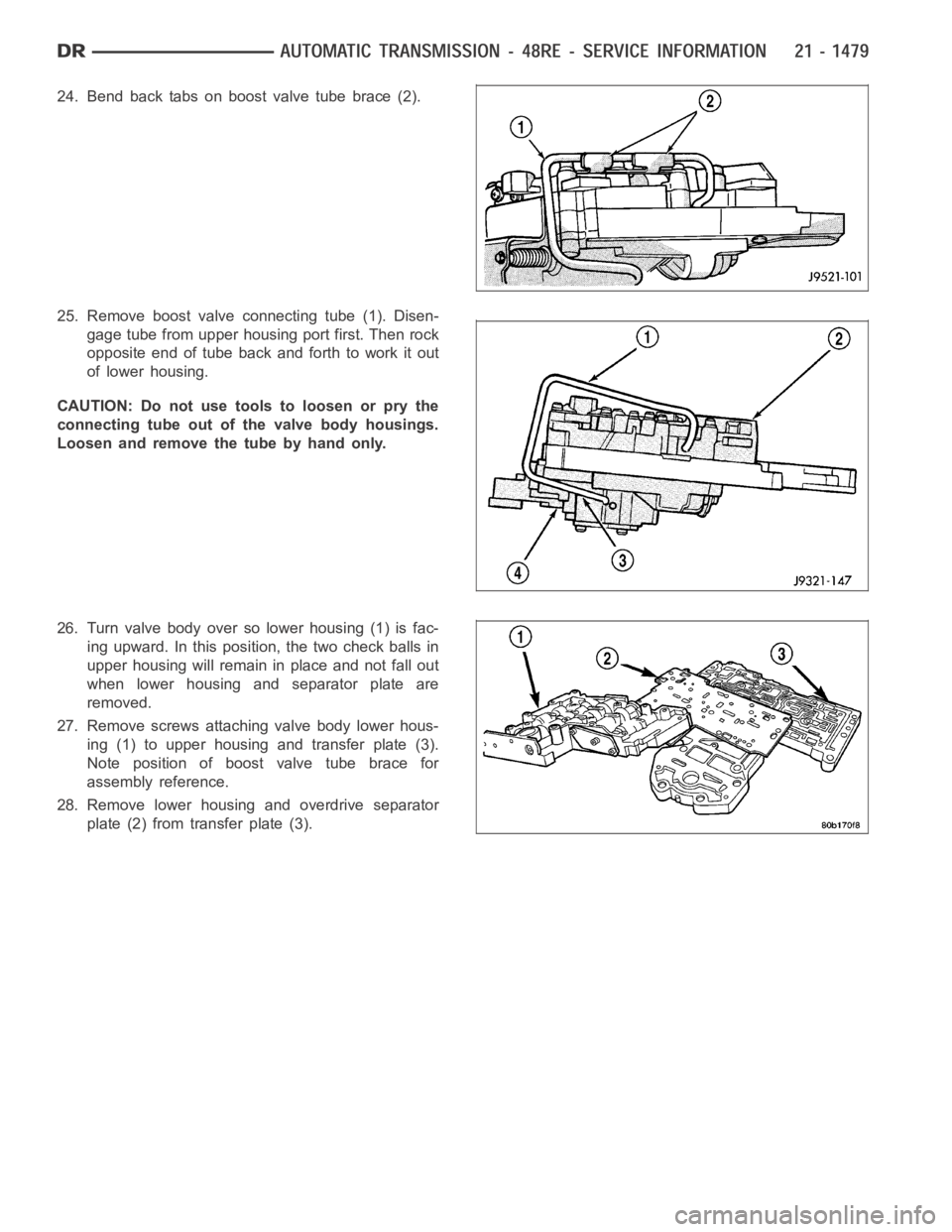

24. Bend back tabs on boost valve tube brace (2).

25. Remove boost valve connecting tube (1). Disen-

gage tube from upper housing port first. Then rock

opposite end of tube back and forth to work it out

of lower housing.

CAUTION: Do not use tools to loosen or pry the

connecting tube out of the valve body housings.

Loosen and remove the tube by hand only.

26. Turn valve body over so lower housing (1) is fac-

ing upward. In this position, the two check balls in

upper housing will remain in place and not fall out

when lower housing and separator plate are

removed.

27. Remove screws attaching valve body lower hous-

ing (1) to upper housing and transfer plate (3).

Note position of boost valve tube brace for

assembly reference.

28. Remove lower housing and overdrive separator

plate (2) from transfer plate (3).

Page 4015 of 5267

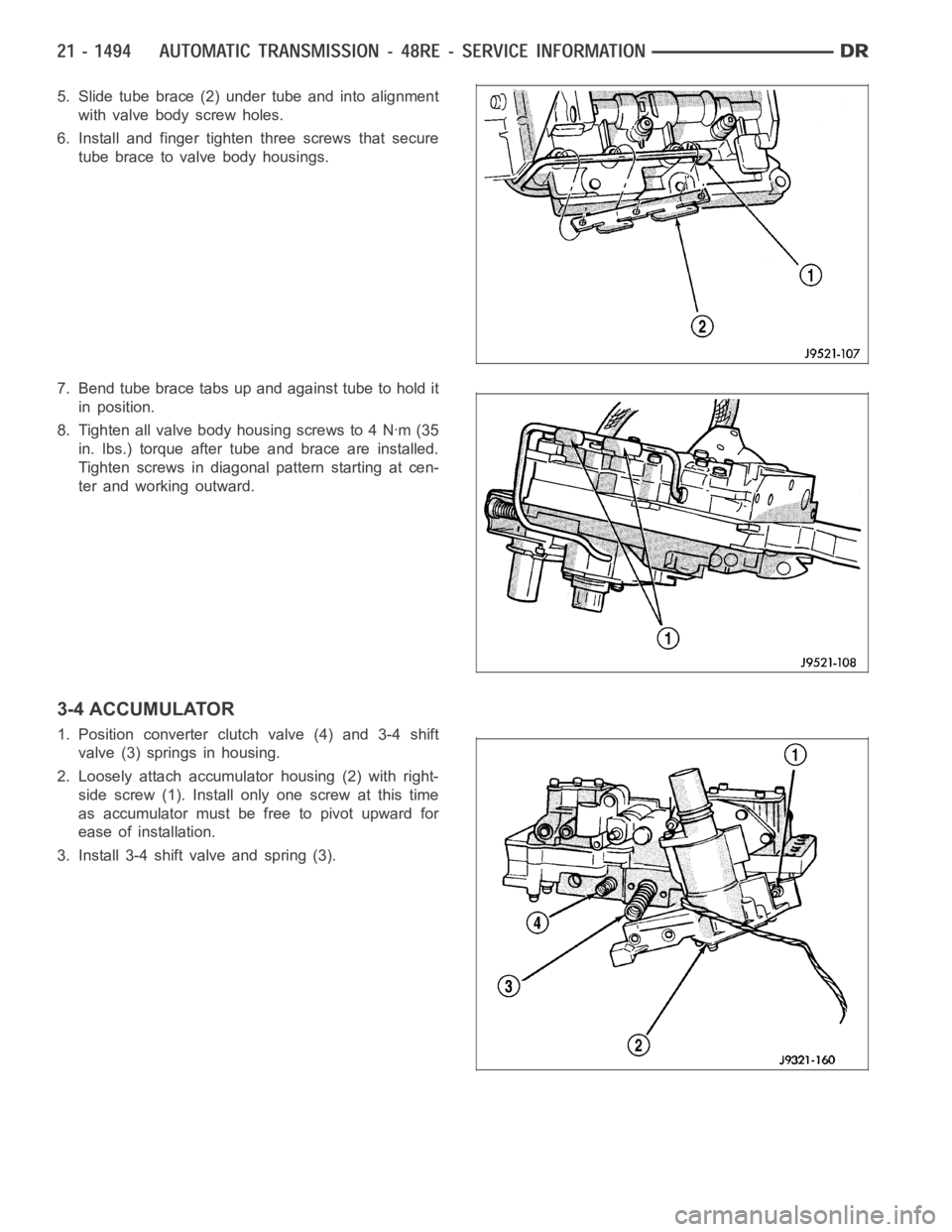

5. Slide tube brace (2) under tube and into alignment

with valve body screw holes.

6. Install and finger tighten three screws that secure

tube brace to valve body housings.

7. Bend tube brace tabs up and against tube to hold it

in position.

8. Tighten all valve body housing screws to 4 Nꞏm (35

in. lbs.) torque after tube and brace are installed.

Tighten screws in diagonal pattern starting at cen-

ter and working outward.

3-4 ACCUMULATOR

1. Position converter clutch valve (4) and 3-4 shift

valve (3) springs in housing.

2. Loosely attach accumulator housing (2) with right-

side screw (1). Install only one screw at this time

as accumulator must be free to pivot upward for

ease of installation.

3. Install 3-4 shift valve and spring (3).

Page 4106 of 5267

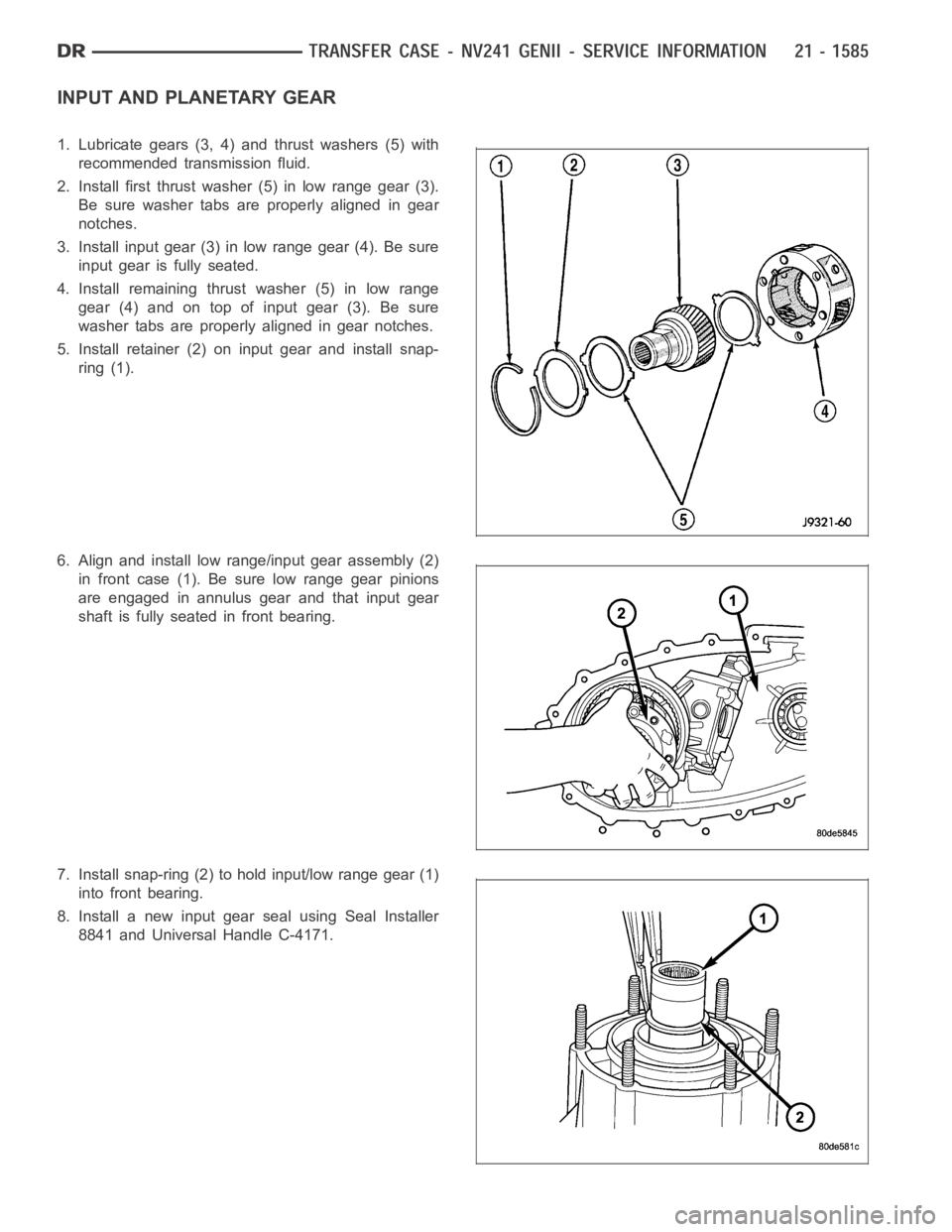

INPUT AND PLANETARY GEAR

1. Lubricate gears (3, 4) and thrust washers (5) with

recommended transmission fluid.

2. Install first thrust washer (5) in low range gear (3).

Be sure washer tabs are properly aligned in gear

notches.

3. Install input gear (3) in low range gear (4). Be sure

input gear is fully seated.

4. Install remaining thrust washer (5) in low range

gear (4) and on top of input gear (3). Be sure

washer tabs are properly aligned in gear notches.

5. Install retainer (2) on input gear and install snap-

ring (1).

6. Align and install low range/input gear assembly (2)

in front case (1). Be sure low range gear pinions

are engaged in annulus gear and that input gear

shaft is fully seated in front bearing.

7. Install snap-ring (2) to hold input/low range gear (1)

into front bearing.

8. Install a new input gear seal using Seal Installer

8841 and Universal Handle C-4171.

Page 4152 of 5267

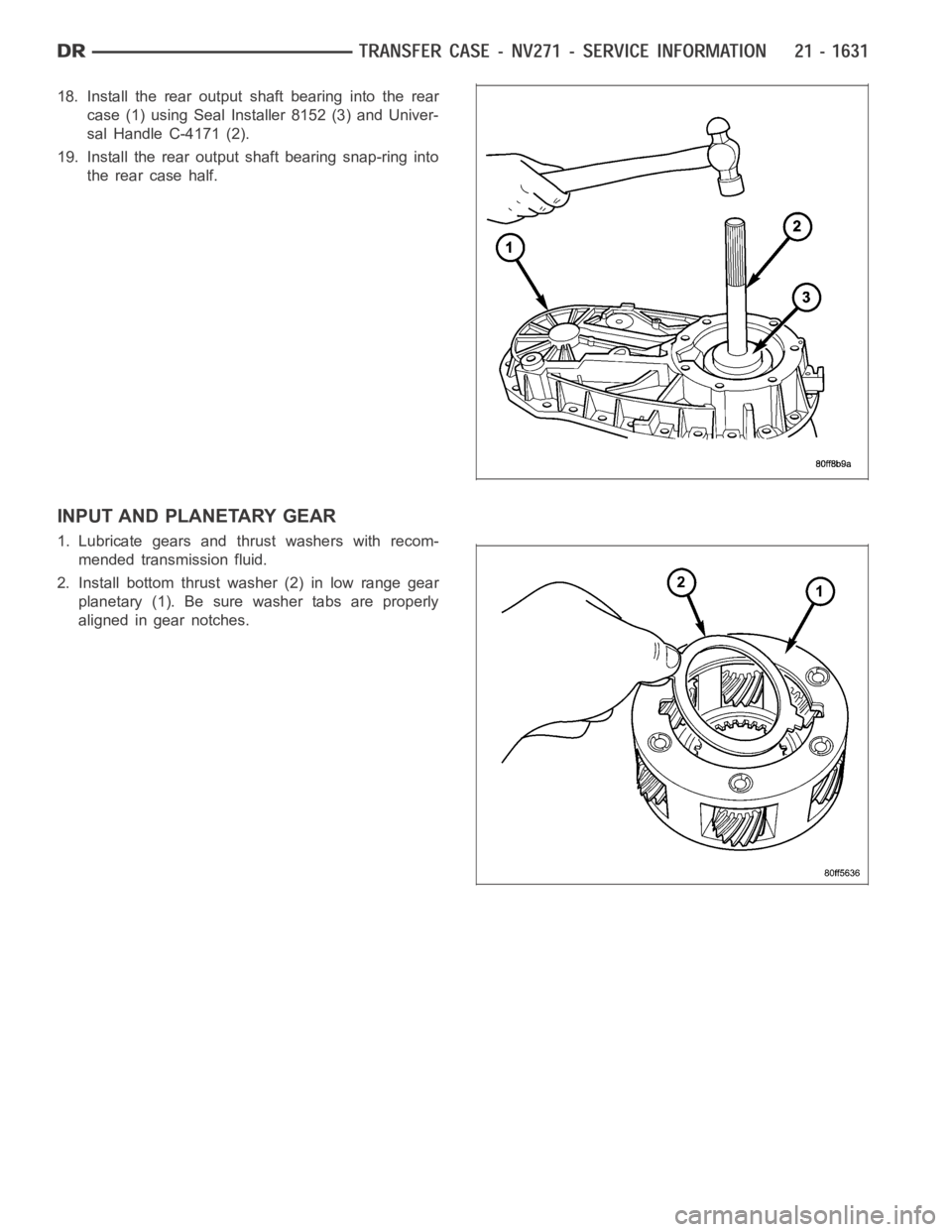

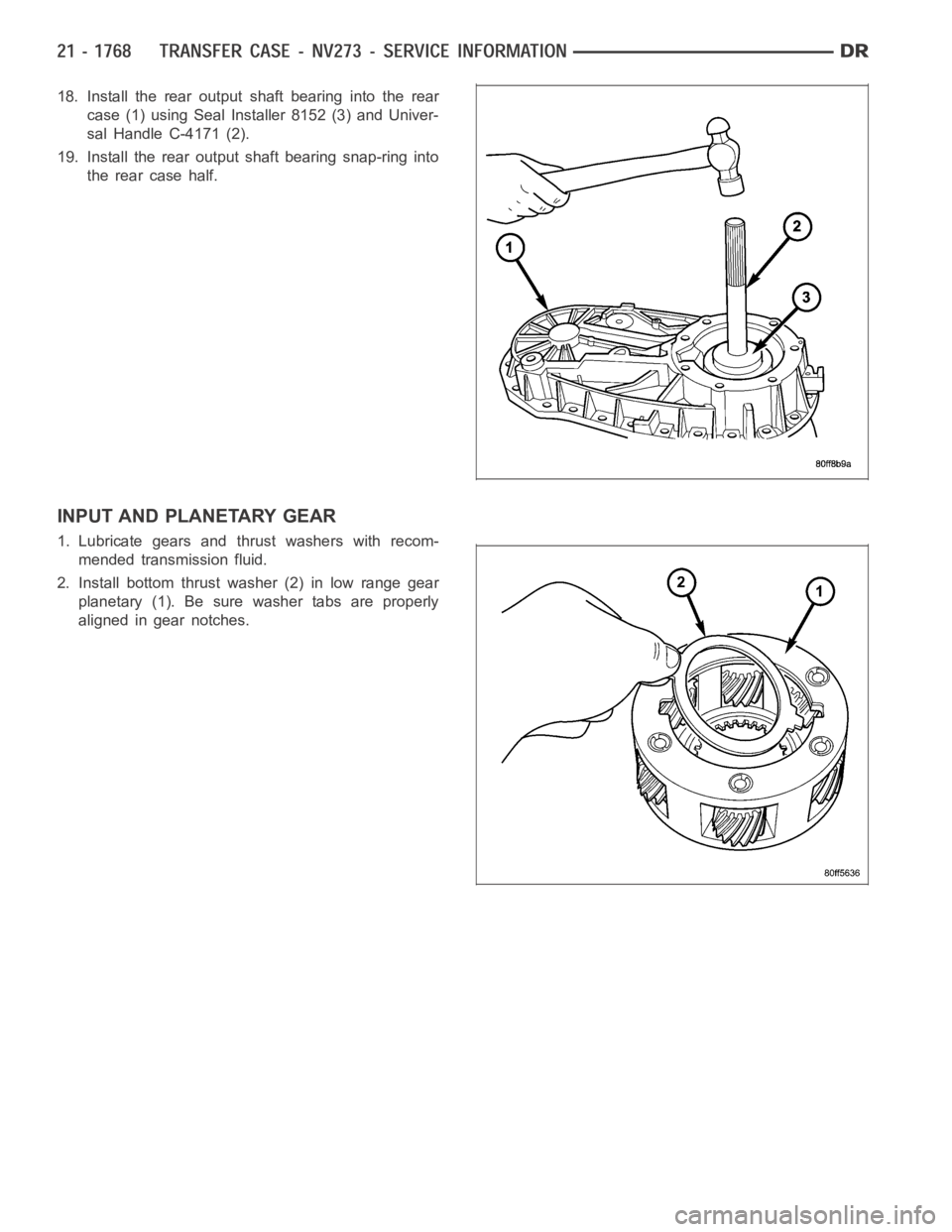

18. Install the rear output shaft bearing into the rear

case (1) using Seal Installer 8152 (3) and Univer-

sal Handle C-4171 (2).

19. Install the rear output shaft bearing snap-ring into

the rear case half.

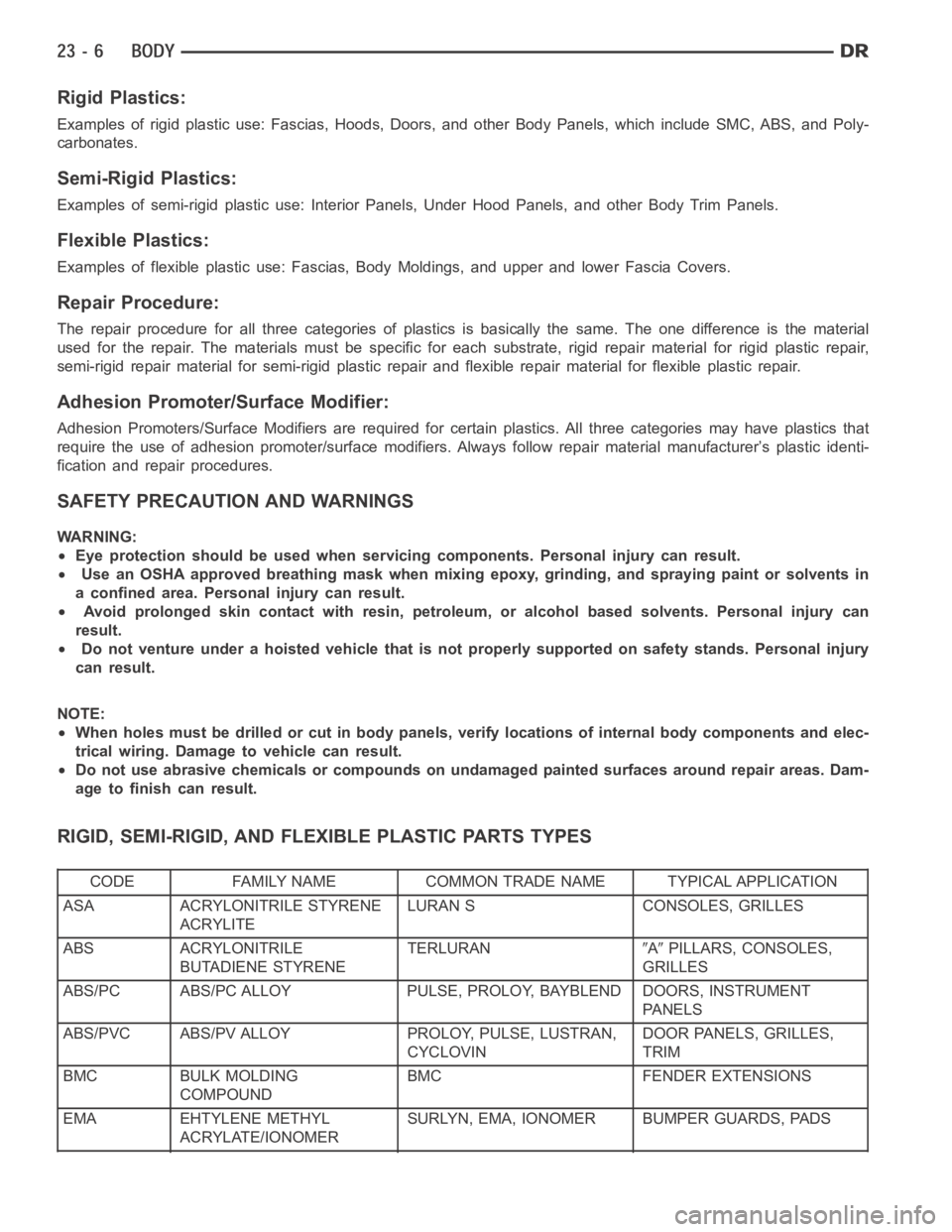

INPUT AND PLANETARY GEAR

1. Lubricate gears and thrust washers with recom-

mended transmission fluid.

2. Install bottom thrust washer (2) in low range gear

planetary (1). Be sure washer tabs are properly

aligned in gear notches.

Page 4198 of 5267

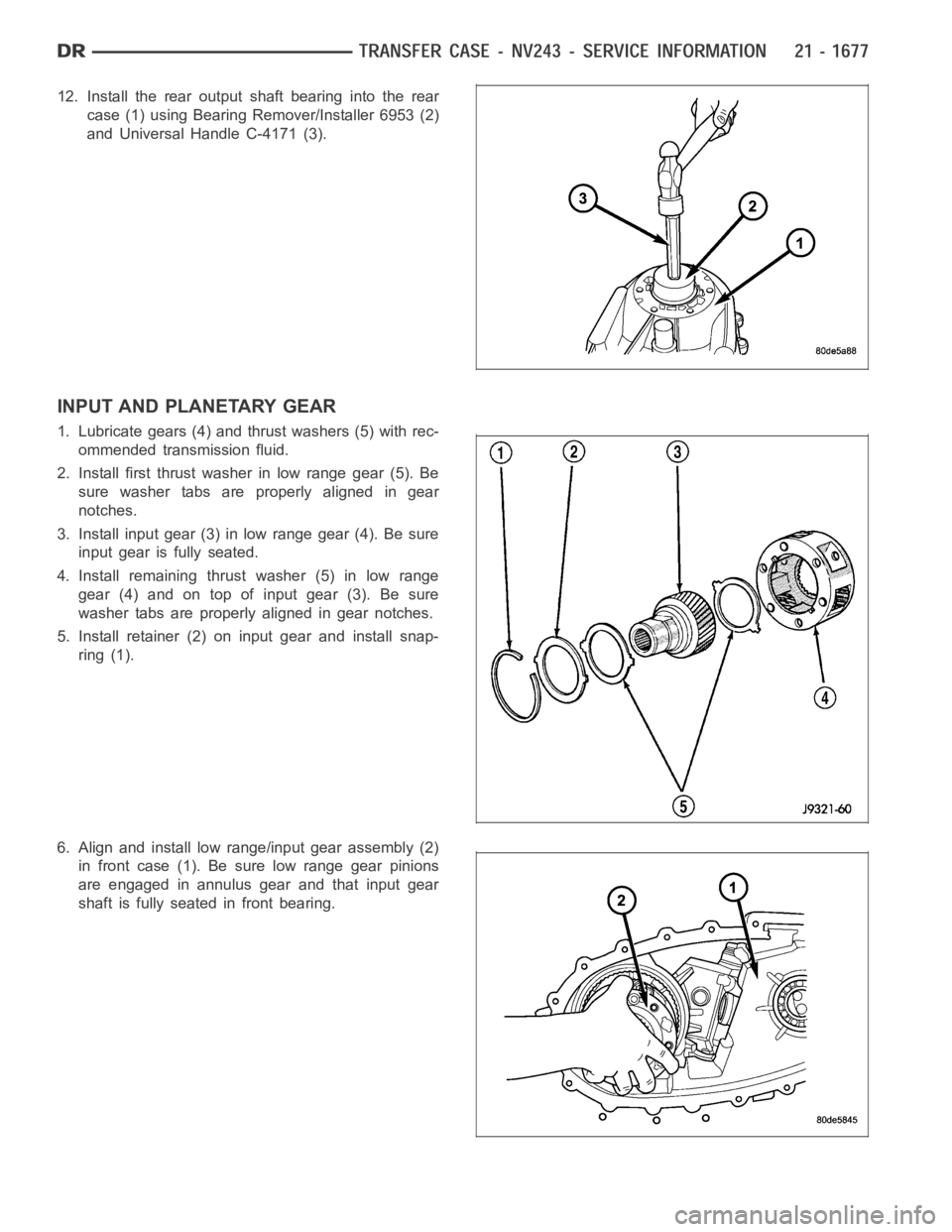

12. Install the rear output shaft bearing into the rear

case (1) using Bearing Remover/Installer 6953 (2)

and Universal Handle C-4171 (3).

INPUT AND PLANETARY GEAR

1. Lubricate gears (4) and thrust washers (5) with rec-

ommended transmission fluid.

2. Install first thrust washer in low range gear (5). Be

sure washer tabs are properly aligned in gear

notches.

3. Install input gear (3) in low range gear (4). Be sure

input gear is fully seated.

4. Install remaining thrust washer (5) in low range

gear (4) and on top of input gear (3). Be sure

washer tabs are properly aligned in gear notches.

5. Install retainer (2) on input gear and install snap-

ring (1).

6. Align and install low range/input gear assembly (2)

in front case (1). Be sure low range gear pinions

are engaged in annulus gear and that input gear

shaft is fully seated in front bearing.

Page 4241 of 5267

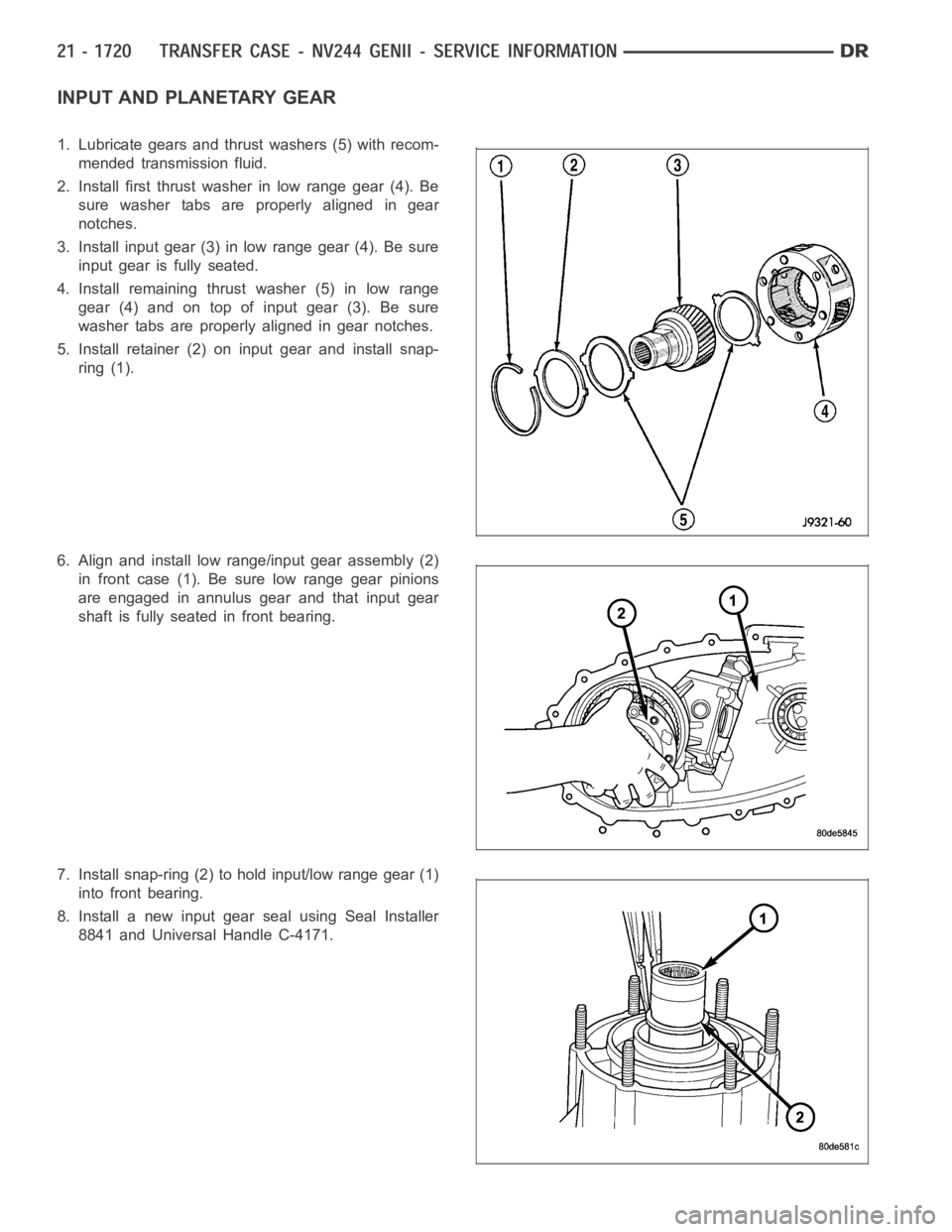

INPUT AND PLANETARY GEAR

1. Lubricate gears and thrust washers (5) with recom-

mended transmission fluid.

2. Install first thrust washer in low range gear (4). Be

sure washer tabs are properly aligned in gear

notches.

3. Install input gear (3) in low range gear (4). Be sure

input gear is fully seated.

4. Install remaining thrust washer (5) in low range

gear (4) and on top of input gear (3). Be sure

washer tabs are properly aligned in gear notches.

5. Install retainer (2) on input gear and install snap-

ring (1).

6. Align and install low range/input gear assembly (2)

in front case (1). Be sure low range gear pinions

are engaged in annulus gear and that input gear

shaft is fully seated in front bearing.

7. Install snap-ring (2) to hold input/low range gear (1)

into front bearing.

8. Install a new input gear seal using Seal Installer

8841 and Universal Handle C-4171.

Page 4289 of 5267

18. Install the rear output shaft bearing into the rear

case (1) using Seal Installer 8152 (3) and Univer-

sal Handle C-4171 (2).

19. Install the rear output shaft bearing snap-ring into

the rear case half.

INPUT AND PLANETARY GEAR

1. Lubricate gears and thrust washers with recom-

mended transmission fluid.

2. Install bottom thrust washer (2) in low range gear

planetary (1). Be sure washer tabs are properly

aligned in gear notches.

Page 4343 of 5267

Rigid Plastics:

Examples of rigid plastic use: Fascias, Hoods, Doors, and other Body Panels, which include SMC, ABS, and Poly-

carbonates.

Semi-Rigid Plastics:

Examples of semi-rigid plastic use: Interior Panels, Under Hood Panels, and other Body Trim Panels.

Flexible Plastics:

Examples of flexible plastic use: Fascias, Body Moldings, and upper and lower Fascia Covers.

Repair Procedure:

The repair procedure for all three categories of plastics is basically thesame. The one difference is the material

used for the repair. The materials must be specific for each substrate, rigid repair material for rigid plastic repair,

semi-rigid repair material for semi-rigid plastic repair and flexible repair material for flexible plastic repair.

Adhesion Promoter/Surface Modifier:

Adhesion Promoters/Surface Modifiers are required for certain plastics. All three categories may have plastics that

require the use of adhesion promoter/surface modifiers. Always follow repair material manufacturer’s plastic identi-

fication and repair procedures.

SAFETY PRECAUTION AND WARNINGS

WARNING:

Eye protection should be used when servicing components. Personal injurycan result.

Use an OSHA approved breathing mask when mixing epoxy, grinding, and spraying paint or solvents in

a confined area. Personal injury can result.

Avoid prolonged skin contact with resin, petroleum, or alcohol based solvents. Personal injury can

result.

Do not venture under a hoisted vehicle that is not properly supported on safety stands. Personal injury

can result.

NOTE:

When holes must be drilled or cut in bodypanels, verify locations of internal body components and elec-

trical wiring. Damage to vehicle can result.

Do not use abrasive chemicals or compounds on undamaged painted surfaces around repair areas. Dam-

age to finish can result.

RIGID, SEMI-RIGID, AND FLEXIBLE PLASTIC PARTS TYPES

CODE FAMILY NAME COMMON TRADE NAME TYPICAL APPLICATION

ASA ACRYLONITRILE STYRENE

ACRYLITELURAN S CONSOLES, GRILLES

ABS ACRYLONITRILE

BUTADIENE STYRENETERLURAN

APILLARS, CONSOLES,

GRILLES

ABS/PC ABS/PC ALLOY PULSE, PROLOY, BAYBLEND DOORS, INSTRUMENT

PA N E L S

ABS/PVC ABS/PV ALLOY PROLOY, PULSE, LUSTRAN,

CYCLOVINDOOR PANELS, GRILLES,

TRIM

BMC BULK MOLDING

COMPOUNDBMC FENDER EXTENSIONS

EMA EHTYLENE METHYL

ACRYLATE/IONOMERSURLYN, EMA, IONOMER BUMPER GUARDS, PADS