check engine DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2006 of 5267

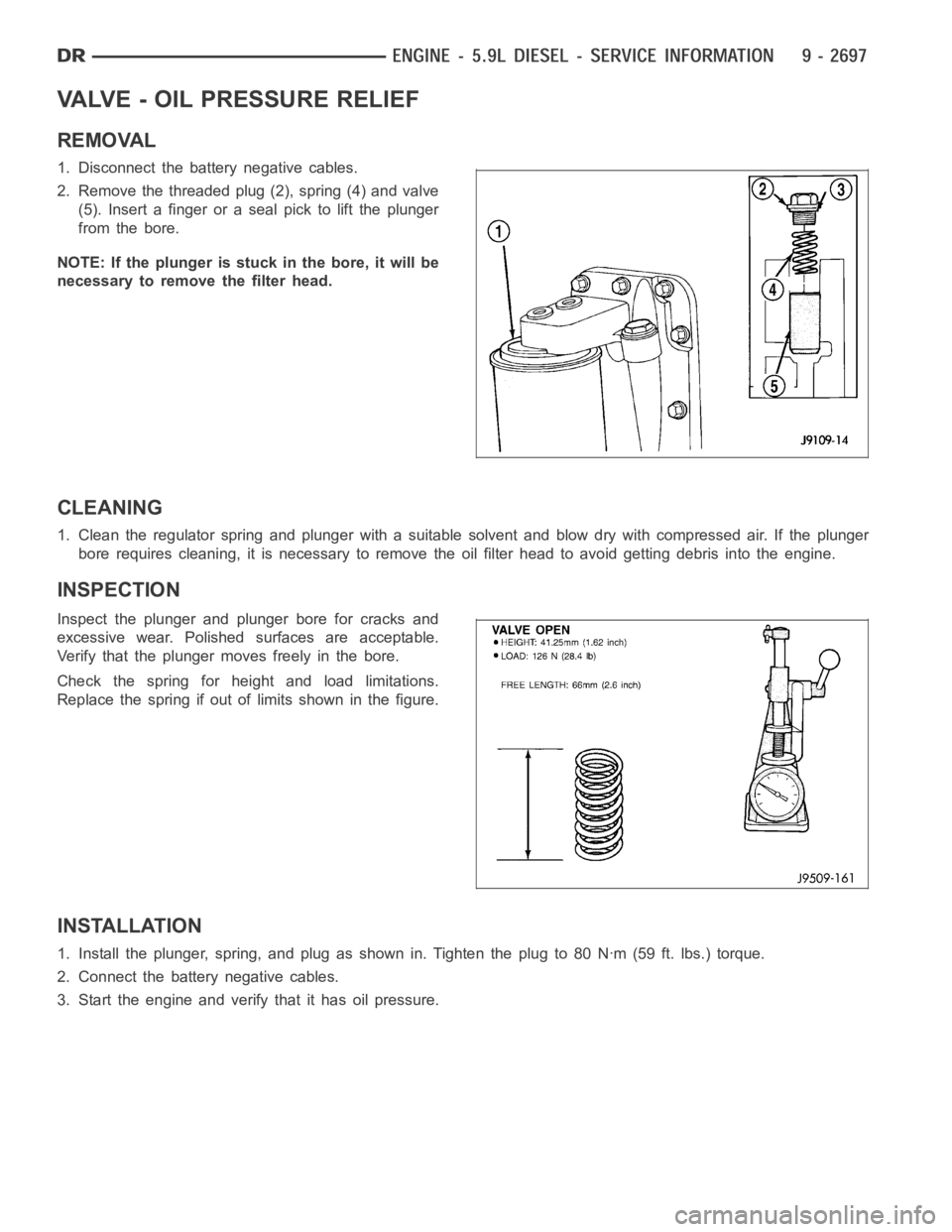

VALVE - OIL PRESSURE RELIEF

REMOVAL

1. Disconnect the battery negative cables.

2. Remove the threaded plug (2), spring (4) and valve

(5). Insert a finger or a seal pick to lift the plunger

from the bore.

NOTE: If the plunger is stuck in the bore, it will be

necessary to remove the filter head.

CLEANING

1. Clean the regulator spring and plunger with a suitable solvent and blow dry with compressed air. If the plunger

bore requires cleaning, it is necessaryto remove the oil filter head to avoid getting debris into the engine.

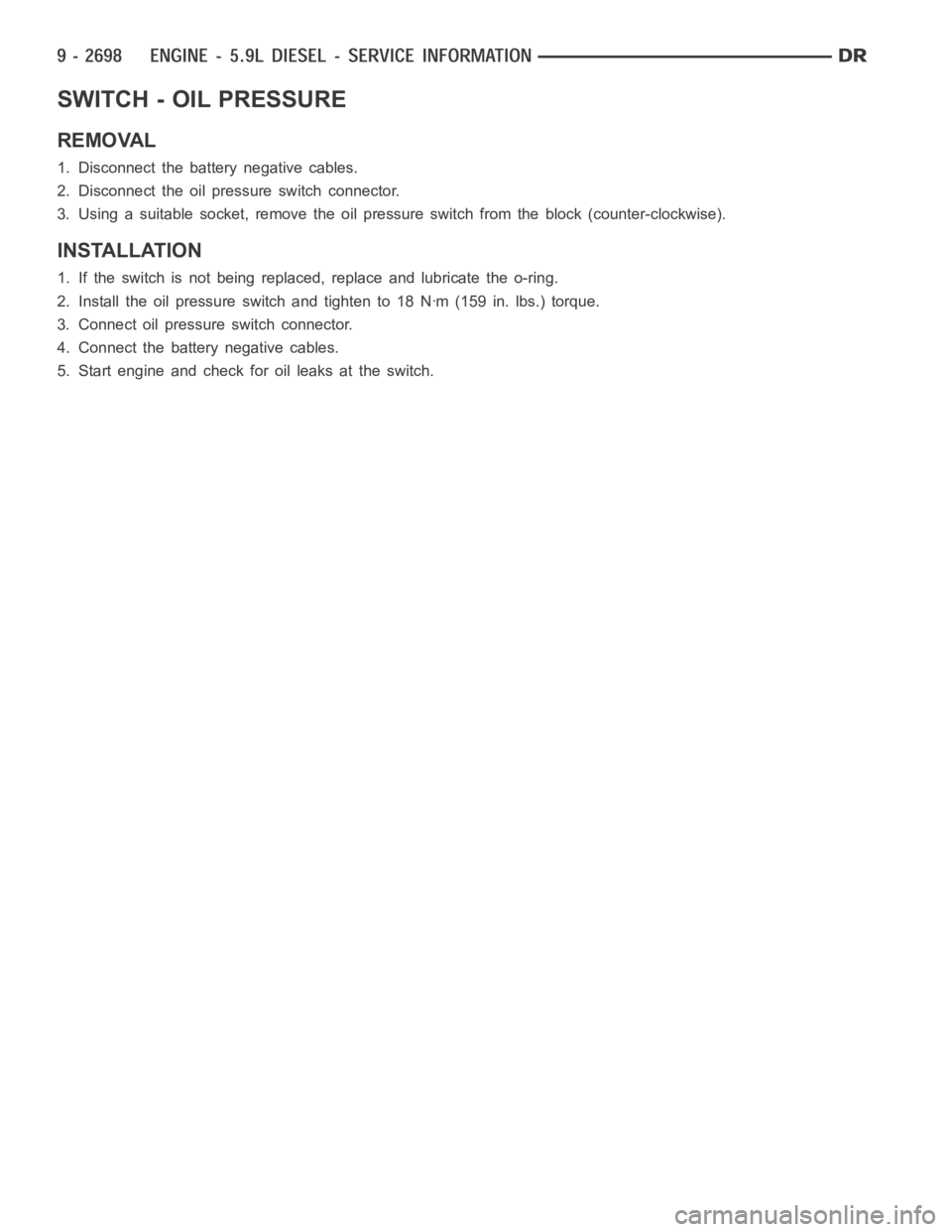

INSPECTION

Inspect the plunger and plunger bore for cracks and

excessive wear. Polished surfaces are acceptable.

Verify that the plunger moves freely in the bore.

Check the spring for height and load limitations.

Replace the spring if out of limits shown in the figure.

INSTALLATION

1. Install the plunger, spring, and plug as shown in. Tighten the plug to 80 Nꞏm (59 ft. lbs.) torque.

2. Connect the battery negative cables.

3. Start the engine and verify that it has oil pressure.

Page 2007 of 5267

SWITCH - OIL PRESSURE

REMOVAL

1. Disconnect the battery negative cables.

2. Disconnect the oil pressure switch connector.

3. Usingasuitablesocket,removetheoil pressure switch from the block (counter-clockwise).

INSTALLATION

1. If the switch is not being replaced, replace and lubricate the o-ring.

2. Install the oil pressure switch and tighten to 18 Nꞏm (159 in. lbs.) torque.

3. Connect oil pressure switch connector.

4. Connect the battery negative cables.

5. Start engine and check for oil leaks at the switch.

Page 2010 of 5267

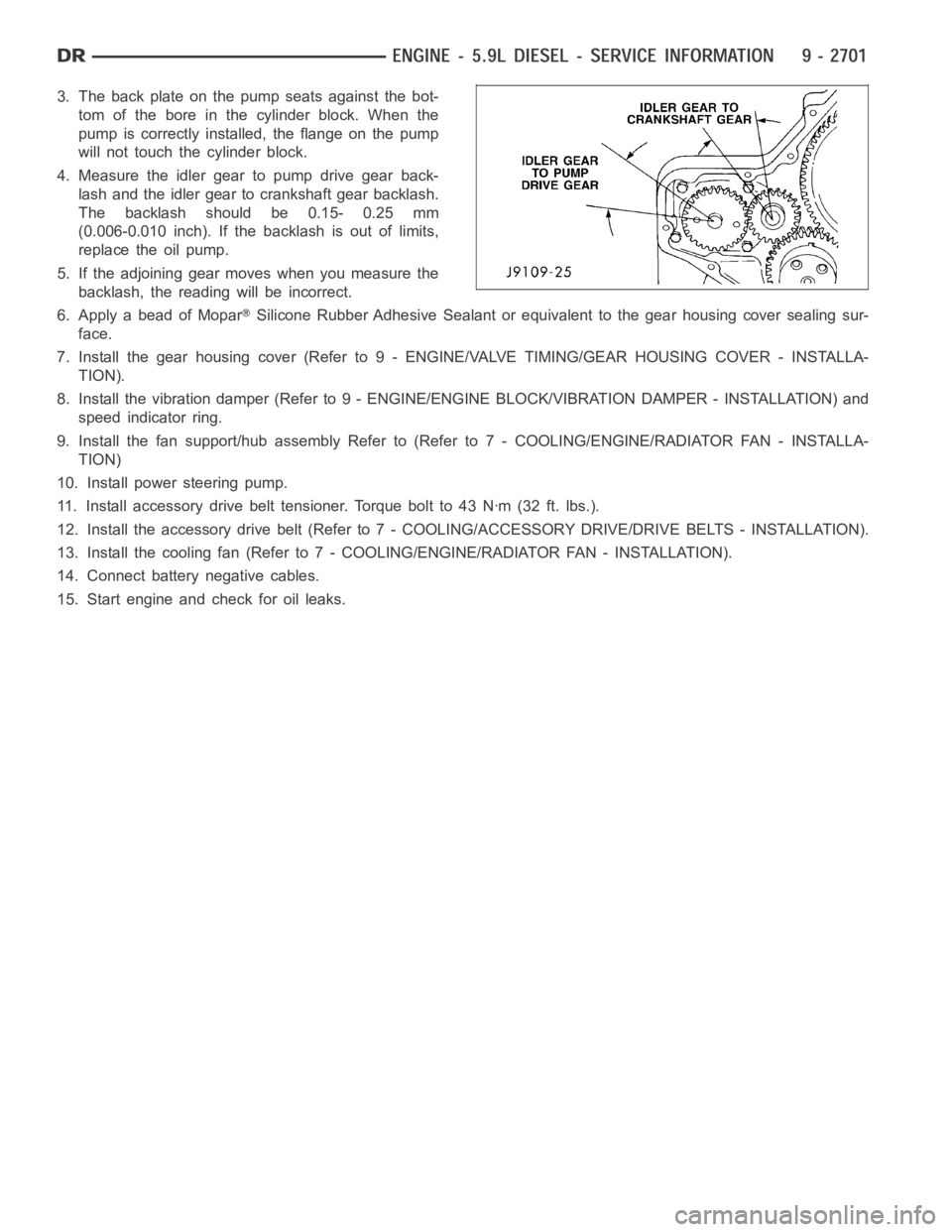

3. The back plate on the pump seats against the bot-

tom of the bore in the cylinder block. When the

pump is correctly installed, the flange on the pump

will not touch the cylinder block.

4. Measure the idler gear to pump drive gear back-

lash and the idler gear to crankshaft gear backlash.

The backlash should be 0.15- 0.25 mm

(0.006-0.010 inch). If the backlash is out of limits,

replace the oil pump.

5. If the adjoining gear moves when you measure the

backlash, the reading will be incorrect.

6. Apply a bead of Mopar

Silicone Rubber Adhesive Sealant or equivalent to the gear housing cover sealing sur-

face.

7. Install the gear housing cover (Refer to 9 - ENGINE/VALVE TIMING/GEAR HOUSING COVER - INSTALLA-

TION).

8. Install the vibration damper (Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION DAMPER - INSTALLATION) and

speed indicator ring.

9. Install the fan support/hub assemblyRefer to (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION)

10. Install power steering pump.

11. Install accessory drive belt tensioner. Torque bolt to 43 Nꞏm (32 ft. lbs.).

12. Install the accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

13. Install the cooling fan (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - INSTALLATION).

14. Connect battery negative cables.

15. Start engine and check for oil leaks.

Page 2014 of 5267

10. Connect the exhaust pipe to the turbocharger and tighten the bolts to 11Nꞏm (100 ft. lbs.) torque.

11. Connect the wastegate command valve connector.

12. Lower the vehicle.

13.Pre-lube the turbocharger.Pour 50 to 60 cc (2 to 3 oz.) clean engine oil in the oil supply line fitting on the

turbo. Rotate the turbocharger impeller by hand to distrubute the oil thoroughly.

14. Install and tighten the oil supply line fitting nut to 24 Nꞏm (18 ft. lbs.) torque.

15. Position the charge air cooler inlet pipe to the turbocharger. With theclamp in position, tighten the clamp nut to

11 Nꞏm (95 in. lbs.) torque.

16. Position the air inlet hose to the turbocharger. Tighten the clamp to 4 Nꞏm (35 in. lbs.) torque.

17. Connect the battery negative cables.

18. Start the engine to check for leaks.

Page 2020 of 5267

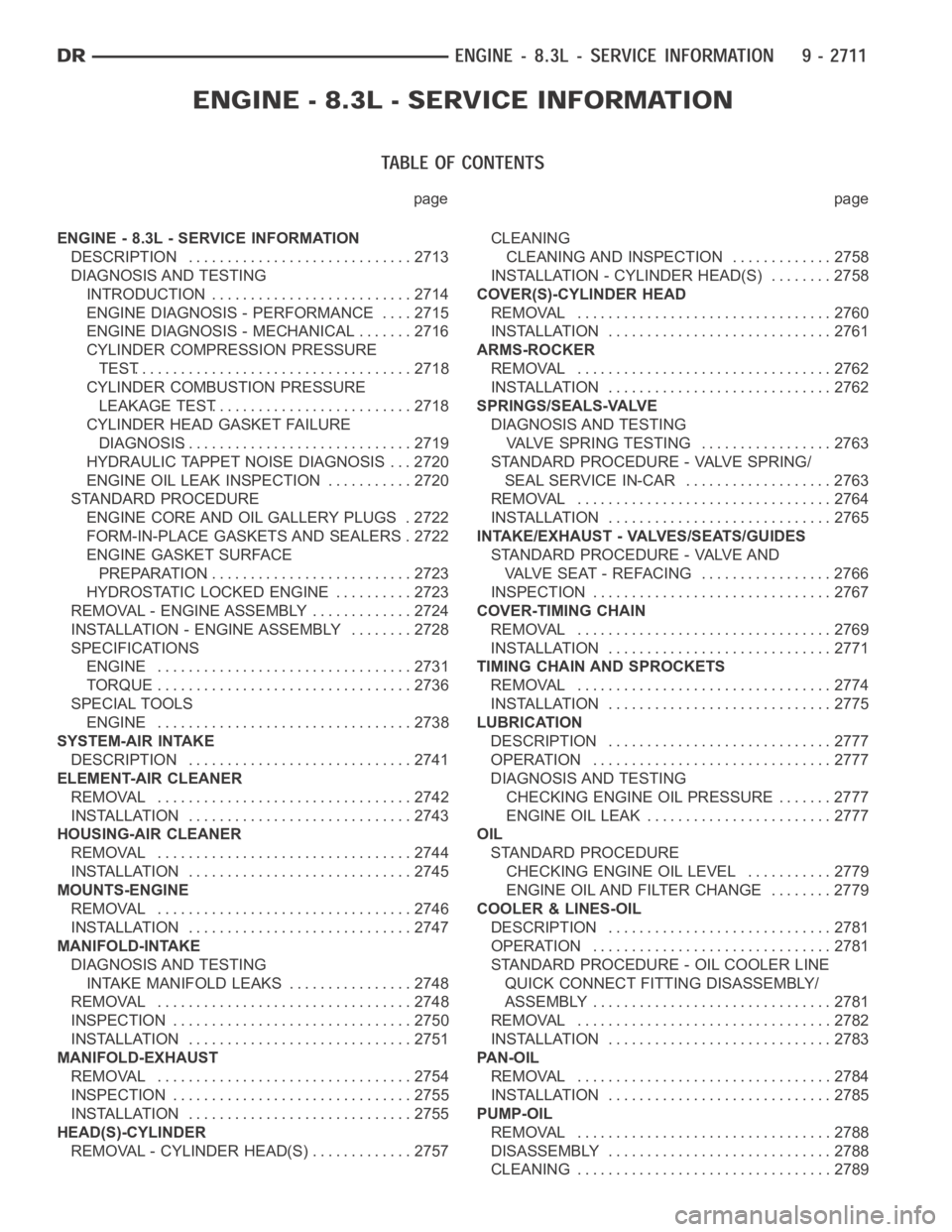

page page

ENGINE - 8.3L - SERVICE INFORMATION

DESCRIPTION ............................. 2713

DIAGNOSIS AND TESTING

INTRODUCTION . ......................... 2714

ENGINE DIAGNOSIS - PERFORMANCE .... 2715

ENGINE DIAGNOSIS - MECHANICAL ....... 2716

CYLINDER COMPRESSION PRESSURE

TEST.................................... 2718

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST.......................... 2718

CYLINDER HEAD GASKET FAILURE

DIAGNOSIS.............................. 2719

HYDRAULIC TAPPET NOISE DIAGNOSIS . . . 2720

ENGINE OIL LEAK INSPECTION ........... 2720

STANDARD PROCEDURE

ENGINE CORE AND OIL GALLERY PLUGS . 2722

FORM-IN-PLACE GASKETS AND SEALERS . 2722

ENGINE GASKET SURFACE

PREPARATION........................... 2723

HYDROSTATIC LOCKED ENGINE .......... 2723

REMOVAL - ENGINE ASSEMBLY . . ........... 2724

INSTALLATION - ENGINE ASSEMBLY ........ 2728

SPECIFICATIONS

ENGINE ................................. 2731

TORQUE ................................. 2736

SPECIAL TOOLS

ENGINE ................................. 2738

SYSTEM-AIR INTAKE

DESCRIPTION ............................. 2741

ELEMENT-AIR CLEANER

REMOVAL ................................. 2742

INSTALLATION ............................. 2743

HOUSING-AIR CLEANER

REMOVAL ................................. 2744

INSTALLATION ............................. 2745

MOUNTS-ENGINE

REMOVAL ................................. 2746

INSTALLATION ............................. 2747

MANIFOLD-INTAKE

DIAGNOSIS AND TESTING

INTAKE MANIFOLD LEAKS ................ 2748

REMOVAL ................................. 2748

INSPECTION ............................... 2750

INSTALLATION ............................. 2751

MANIFOLD-EXHAUST

REMOVAL ................................. 2754

INSPECTION ............................... 2755

INSTALLATION ............................. 2755

HEAD(S)-CYLINDER

REMOVAL - CYLINDER HEAD(S) ............. 2757CLEANING

CLEANING AND INSPECTION............. 2758

INSTALLATION - CYLINDER HEAD(S) ........ 2758

COVER(S)-CYLINDER HEAD

REMOVAL ................................. 2760

INSTALLATION ............................. 2761

ARMS-ROCKER

REMOVAL ................................. 2762

INSTALLATION ............................. 2762

SPRINGS/SEALS-VALVE

DIAGNOSIS AND TESTING

VALVE SPRING TESTING ................. 2763

STANDARD PROCEDURE - VALVE SPRING/

SEAL SERVICE IN-CAR ................... 2763

REMOVAL ................................. 2764

INSTALLATION ............................. 2765

INTAKE/EXHAUST - VALVES/SEATS/GUIDES

STANDARD PROCEDURE - VALVE AND

VALVE SEAT - REFACING ................. 2766

INSPECTION............................... 2767

COVER-TIMING CHAIN

REMOVAL ................................. 2769

INSTALLATION ............................. 2771

TIMING CHAIN AND SPROCKETS

REMOVAL ................................. 2774

INSTALLATION ............................. 2775

LUBRICATION

DESCRIPTION ............................. 2777

OPERATION ............................... 2777

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE ....... 2777

ENGINE OIL LEAK ........................ 2777

OIL

STANDARD PROCEDURE

CHECKING ENGINE OIL LEVEL........... 2779

ENGINE OILAND FILTER CHANGE ........ 2779

COOLER & LINES-OIL

DESCRIPTION ............................. 2781

OPERATION ............................... 2781

STANDARD PROCEDURE - OIL COOLER LINE

QUICK CONNECT FITTING DISASSEMBLY/

ASSEMBLY............................... 2781

REMOVAL ................................. 2782

INSTALLATION ............................. 2783

PAN-OIL

REMOVAL ................................. 2784

INSTALLATION ............................. 2785

PUMP-OIL

REMOVAL ................................. 2788

DISASSEMBLY . ............................ 2788

CLEANING ................................. 2789

Page 2024 of 5267

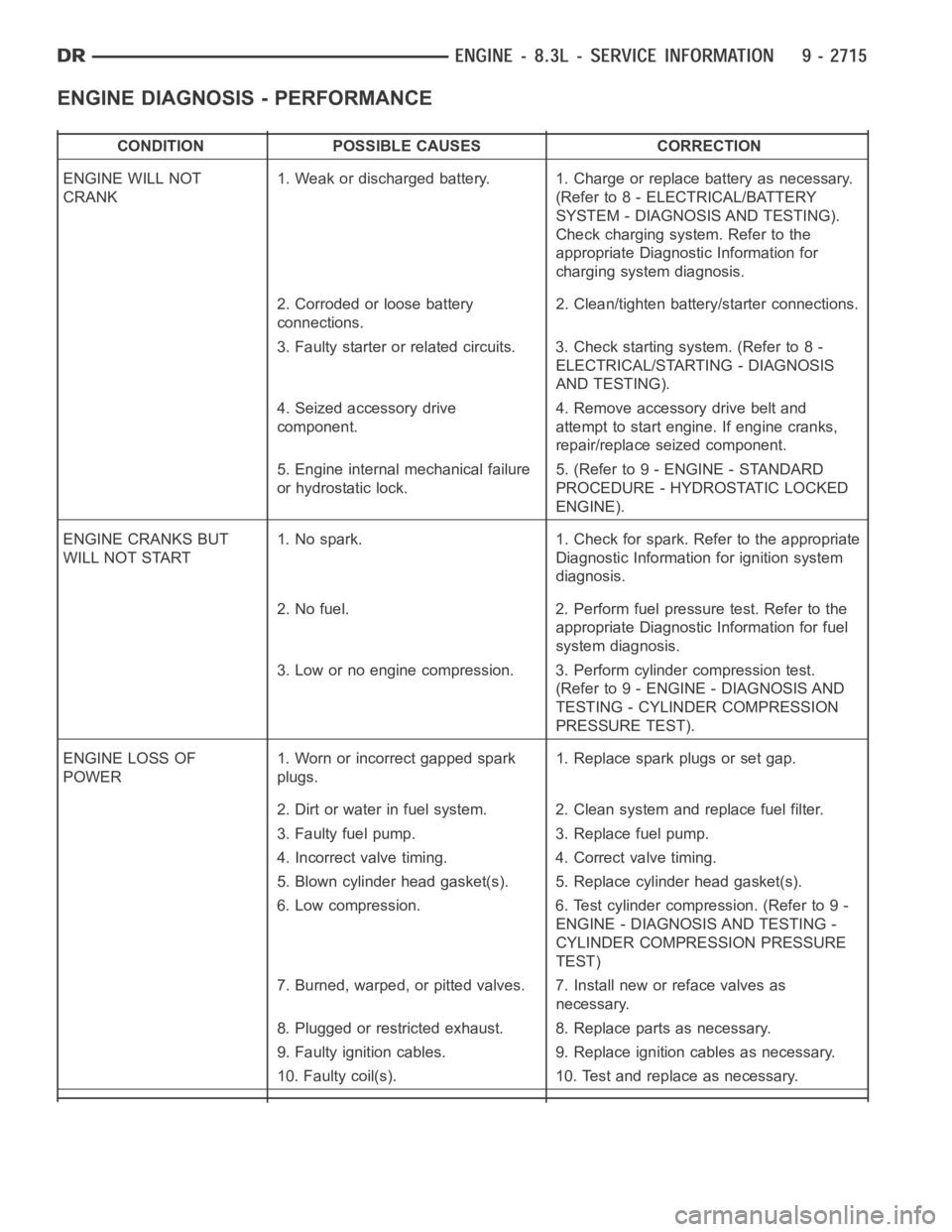

ENGINE DIAGNOSIS - PERFORMANCE

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WILL NOT

CRANK1. Weak or discharged battery. 1. Charge or replace battery as necessary.

(Refer to 8 - ELECTRICAL/BATTERY

SYSTEM - DIAGNOSIS AND TESTING).

Check charging system. Refer to the

appropriate Diagnostic Information for

charging system diagnosis.

2. Corroded or loose battery

connections.2. Clean/tighten battery/starter connections.

3. Faulty starter or related circuits. 3. Check starting system. (Refer to8-

ELECTRICAL/STARTING - DIAGNOSIS

AND TESTING).

4. Seized accessory drive

component.4. Remove accessory drive belt and

attempt to start engine. If engine cranks,

repair/replace seized component.

5. Engine internal mechanical failure

or hydrostatic lock.5. (Refer to 9 - ENGINE - STANDARD

PROCEDURE - HYDROSTATIC LOCKED

ENGINE).

ENGINE CRANKS BUT

WILL NOT START1. No spark. 1. Check for spark. Refer to the appropriate

Diagnostic Information for ignition system

diagnosis.

2. No fuel. 2. Perform fuel pressure test. Refer to the

appropriate Diagnostic Information for fuel

system diagnosis.

3. Low or no engine compression. 3. Perform cylinder compression test.

(Refer to 9 - ENGINE - DIAGNOSIS AND

TESTING - CYLINDER COMPRESSION

PRESSURE TEST).

ENGINE LOSS OF

POWER1. Worn or incorrect gapped spark

plugs.1. Replace spark plugs or set gap.

2. Dirt or water in fuel system. 2. Clean system and replace fuel filter.

3. Faulty fuel pump. 3. Replace fuel pump.

4. Incorrect valve timing. 4. Correct valve timing.

5. Blown cylinder head gasket(s). 5. Replace cylinder head gasket(s).

6. Low compression. 6. Test cylinder compression. (Refer to 9 -

ENGINE - DIAGNOSIS AND TESTING -

CYLINDER COMPRESSION PRESSURE

TEST)

7. Burned, warped, or pitted valves. 7. Install new or reface valves as

necessary.

8. Plugged or restricted exhaust. 8. Replace parts as necessary.

9. Faulty ignition cables. 9. Replace ignition cables as necessary.

10. Faulty coil(s). 10. Test and replace as necessary.

Page 2025 of 5267

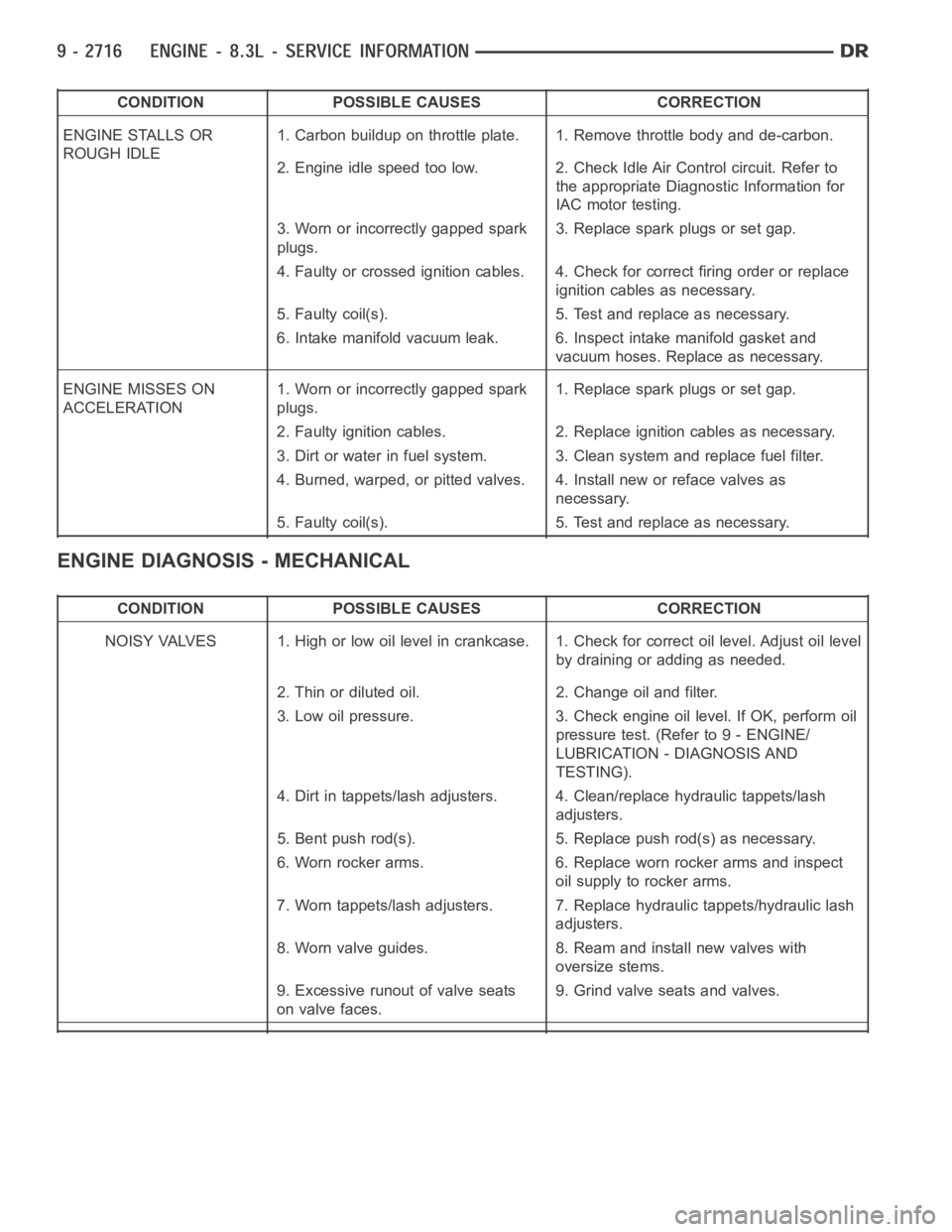

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE STALLS OR

ROUGH IDLE1. Carbon buildup on throttle plate. 1. Remove throttle body and de-carbon.

2. Engine idle speed too low. 2. Check Idle Air Control circuit. Refer to

the appropriate Diagnostic Information for

IAC motor testing.

3. Worn or incorrectly gapped spark

plugs.3. Replace spark plugs or set gap.

4. Faulty or crossed ignition cables. 4. Check for correct firing order or replace

ignition cables as necessary.

5. Faulty coil(s). 5. Test and replace as necessary.

6. Intake manifold vacuum leak. 6. Inspect intake manifold gasket and

vacuum hoses. Replace as necessary.

ENGINE MISSES ON

ACCELERATION1. Worn or incorrectly gapped spark

plugs.1. Replace spark plugs or set gap.

2. Faulty ignition cables. 2. Replace ignition cables as necessary.

3. Dirt or water in fuel system. 3. Clean system and replace fuel filter.

4. Burned, warped, or pitted valves. 4. Install new or reface valves as

necessary.

5. Faulty coil(s). 5. Test and replace as necessary.

ENGINE DIAGNOSIS - MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES 1. High or low oil level incrankcase. 1. Check for correct oil level. Adjust oil level

by draining or adding as needed.

2. Thin or diluted oil. 2. Change oil and filter.

3. Low oil pressure. 3. Check engine oil level. If OK, perform oil

pressure test. (Refer to 9 - ENGINE/

LUBRICATION - DIAGNOSIS AND

TESTING).

4. Dirt in tappets/lash adjusters. 4. Clean/replace hydraulic tappets/lash

adjusters.

5. Bent push rod(s). 5. Replace push rod(s) as necessary.

6. Worn rocker arms. 6. Replace worn rocker arms and inspect

oil supply to rocker arms.

7. Worn tappets/lash adjusters. 7. Replace hydraulic tappets/hydrauliclash

adjusters.

8. Worn valve guides. 8. Ream and install new valves with

oversize stems.

9. Excessive runout of valve seats

on valve faces.9. Grind valve seats and valves.

Page 2026 of 5267

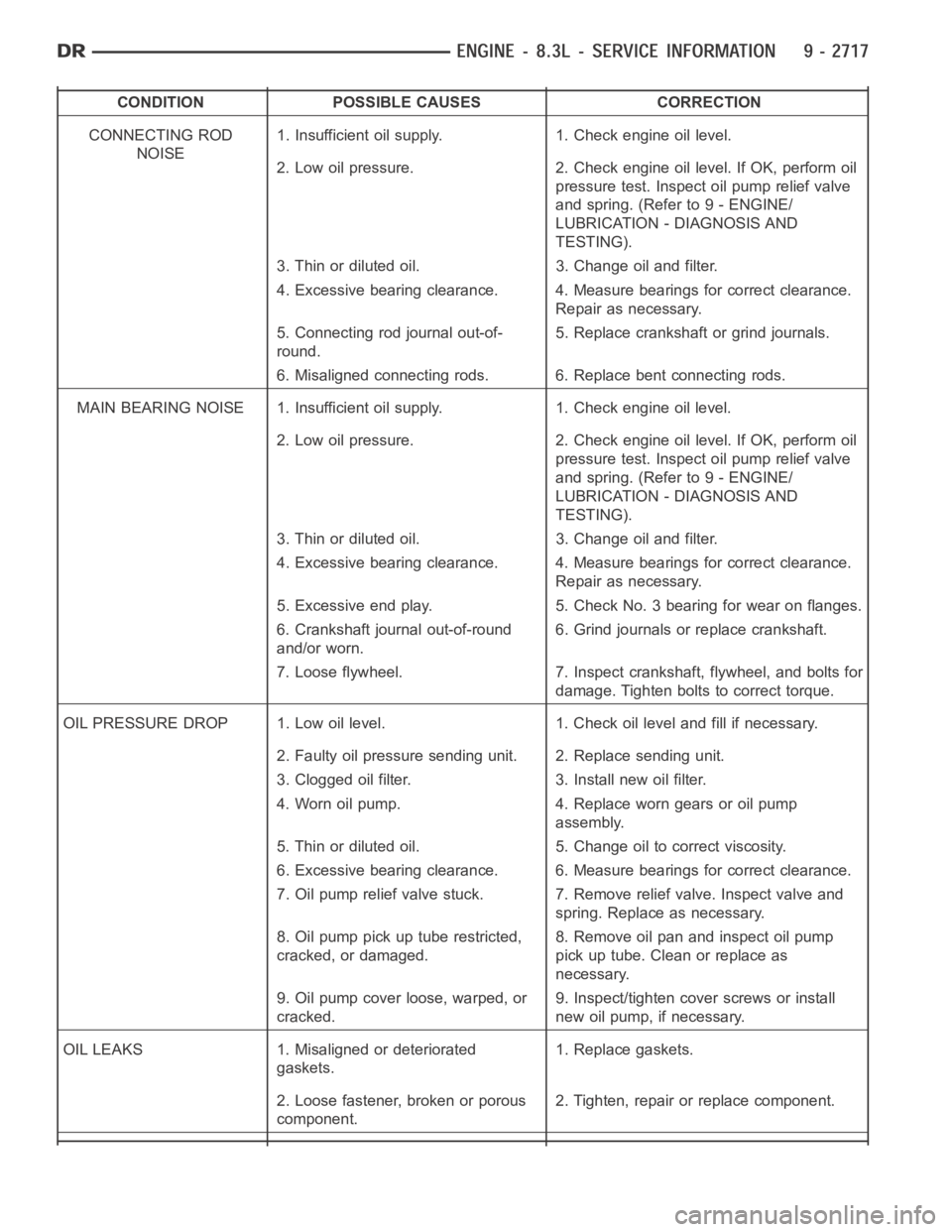

CONDITION POSSIBLE CAUSES CORRECTION

CONNECTING ROD

NOISE1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. If OK, perform oil

pressure test. Inspect oil pump relief valve

and spring. (Refer to 9 - ENGINE/

LUBRICATION - DIAGNOSIS AND

TESTING).

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Measure bearings for correct clearance.

Repair as necessary.

5. Connecting rod journal out-of-

round.5. Replace crankshaft or grind journals.

6. Misaligned connecting rods. 6. Replace bent connecting rods.

MAIN BEARING NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. If OK, perform oil

pressure test. Inspect oil pump relief valve

and spring. (Refer to 9 - ENGINE/

LUBRICATION - DIAGNOSIS AND

TESTING).

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Measure bearings for correct clearance.

Repair as necessary.

5. Excessive end play. 5. Check No. 3 bearing for wear on flanges.

6. Crankshaft journal out-of-round

and/or worn.6. Grind journals or replace crankshaft.

7. Loose flywheel. 7. Inspect crankshaft, flywheel, and bolts for

damage. Tighten bolts to correct torque.

OIL PRESSURE DROP 1. Low oil level. 1. Check oil level and fill if necessary.

2. Faulty oil pressure sending unit. 2. Replace sending unit.

3. Clogged oil filter. 3. Install new oil filter.

4. Worn oil pump. 4. Replace worn gears or oil pump

assembly.

5. Thin or diluted oil. 5. Change oil to correct viscosity.

6. Excessive bearing clearance. 6. Measure bearings for correct clearance.

7. Oil pump relief valve stuck. 7. Remove relief valve. Inspect valve and

spring. Replace as necessary.

8. Oil pump pick up tube restricted,

cracked, or damaged.8. Remove oil pan and inspect oil pump

pick up tube. Clean or replace as

necessary.

9. Oil pump cover loose, warped, or

cracked.9. Inspect/tighten cover screws or install

new oil pump, if necessary.

OIL LEAKS 1. Misaligned or deteriorated

gaskets.1. Replace gaskets.

2. Loose fastener, broken or porous

component.2. Tighten, repair or replace component.

Page 2027 of 5267

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE OIL

CONSUMPTION OR

SPARK PLUGS OIL

FOULED1. PCV system malfunction. 1. Check and repair PCV system as

necessary.

2. Defective valve stem seal(s). 2. Repair or replace seal(s).

3. Worn or broken piston rings. 3. Hone cylinder bores. Install new rings.

4. Scuffed pistons/cylinder walls. 4. Hone cylinder bores and replace pistons

as necessary.

5. Carbon in oil control ring groove. 5. Remove rings and de-carbon piston.

6. Worn valve guides. 6. Ream and install new valves with

oversize stems.

7. Piston rings fitted too tightly in

grooves.7. Remove piston rings. Check ring end

gap and side clearance. Replace as

necessary.

CYLINDER COMPRESSION PRESSURE TEST

The results of a cylinder compressionpressure test can be utilized to diagnose several engine malfunctions.

Ensurethebatteryiscompletelychargedandtheenginestartermotorisingood operating condition. Otherwise the

indicated compression pressures may not be valid for diagnosis purposes.

1. Check engine oil level and add oil if necessary.

2. Drive the vehicle until engine reaches normal operating temperature. Select a route free from traffic and other

forms of congestion, observe all traffic laws, and accelerate through thegears several times briskly.

3. Remove the Auto Shut Down (ASD) relay from the Power Distribution Center(PDC).

4. Disconnect ignition cables from spark plugs.

5. Remove all spark plugs from engine. As spark plugs are being removed, check electrodes for abnormal firing

indicators fouled, hot, oily, etc. Record cylinder number of spark plug for future reference.

6. Be sure throttle blade is fully open during the compression check.

7. Insert compression gauge adaptor Special Tool 8116 or the equivalent, into the No. 1 spark plug hole in cylinder

head. Connect the 0-500 psi (Blue) pressure transducer (Special Tool CH7059) with cable adaptors to the scan

tool. For Special Tool identification, (Refer to 9 - ENGINE - SPECIAL TOOLS).

8. Crank engine until maximum pressure is reached on gauge. Record this pressure as No. 1 cylinder pressure.

9. Repeat the previous step for all remaining cylinders.

10. Compression should not be less than 689 kPa (100 psi) and not vary more than 25 percent from cylinder to

cylinder.

11. If one or more cylinders have abnormally low compression pressures, repeat the compression test.

12. If the same cylinder or cylinders repeat an abnormally low reading on the second compression test, it could

indicate the existence of a problem in the cylinder in question.The recommended compression pressures

are to be used only as a guide to diagnosing engine problems. An engine should not be disassembled

to determine the cause of low compression unless some malfunction is present.

CYLINDER COMBUSTIONPRESSURE LEAKAGE TEST

The combustion pressure leakage test provides an accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

Exhaust and intake valve leaks (improper seating).

Leaks between adjacent cylinders or into water jacket.

Any causes for combustion/compression pressure loss.

WARNING: Do not remove the cooling system pressure cap with the system hot and under pressure

because serious burns from coolant can occur.

1. Check the coolant level and fill as required. DO NOT install the pressurecap.

2. Start and operate the engine until it attains normal operating temperature, then turn the engine OFF.

Page 2028 of 5267

3. Clean spark plug recesses with compressed air.

4. Remove the spark plugs.

5. Remove the oil fill cap.

6. Remove the air cleaner.

7. Calibrate the tester according to the manufacturer’s instructions. The shop air source for testing should maintain

483 kPa (70 psi) minimum, 1,379 kPa (200 psi) maximum, with 552 kPa (80 psi) recommended.

8. Perform the test procedures on each cylinder according to the tester manufacturer’s instructions. While testing,

listen for pressurized air escaping through the throttle body, tailpipe and oil filler cap opening. Check for bubbles

in the coolant pressure bottle.

All gauge pressure indications should be equal, with no more than 25 percent leakage per cylinder.

FOR EXAMPLE:At 552 kPa (80 psi) input pressure, a minimum of 414 kPa (60 psi) should be maintained in the

cylinder.

CYLINDER HEAD GASKET FAILURE DIAGNOSIS

A cylinder head gasket leak can be located between adjacent cylinders, between a cylinder and the adjacent water

jacket, or an external coolant leak may be present.

Possible indications of the cylinder head gasket leaking between adjacent cylinders are:

Loss of engine power

Engine misfiring

Poor fuel economy

Possible indications of the cylinder head gasket leaking between a cylinder and an adjacent water jacket are:

Engine overheating

Loss of coolant

Excessive steam (white smoke) emitting from exhaust

Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is leaking between adjacentcylinders, follow the procedures in Cyl-

inder Compression Pressure Test in this section. An engine cylinder head gasket leaking between adjacent cylinders

will result in approximately a 50-70% reduction in compression pressure.Cylinders adjacent to each other will both

have low compression.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: Use extreme caution when the engine is operating with coolant pressure cap removed.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure cap. Start the engine andallow it to warm up until thermostat

opens.

If a large combustion/compression pressure leak exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: With cooling system tester in place, pressure will build up fast.Excessive pressure built up, by

continuous engine operation, must be released to a safe pressure point. Never permit pressure to exceed

138 kpa (20 psi).

Install Cooling System Tester 7700 or equivalent to pressure cap neck. Start the engine and observe the tester’s

pressure gauge. If gauge pulsates with every power stroke of a cylinder a combustion pressure leak is evident.