cooling DODGE RAM SRT-10 2006 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1754 of 5267

27. Install power steering pump (Referto19-STEERING/PUMP-INSTALLATION).

28. Install radiator fan shroud.

29. Fill cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE).

30. Connect negative cable to battery.

Page 1755 of 5267

SHAFT - IDLER

REMOVAL

1. Remove the primary and secondary timing chains and sprockets (Refer to 9- ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL) .

NOTE: To remove the idler shaft, it is necessary to tap threads into the shaft, to install the removal tool.

2. Using a 12 mm X 1.75 tap, cut threads in the idler shaft center bore.

3. Cover the radiator core with a suitable cover.

CAUTION: Use care when removing the idler shaft, Do not strike the radiatorcooling fins with the slide

hammer.

4. Using Special Tool 8517 Slide Hammer, remove the idler shaft.

INSTALLATION

1. Thoroughly clean the idler shaft bore.

2. Position the idler shaft in the bore.

NOTE: The two lubrication holes in the idler shaft do not require any specialalignment.

NOTE: Before using the retaining bolt to install the idler shaft, coat the threads and the pilot on the idler

shaft, with clean engine oil.

3. Using the primary idler sprocket retaining bolt and washer, carefully draw the idler shaft into the bore until fully

seated.

4. Coat the idler shaft with clean engine oil.

5. Install the timing chains and sprockets (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION) .

Page 1766 of 5267

15. Connect the negative cable(s) to the battery.

16. Start the engine and check for any leaks.

REMOVAL

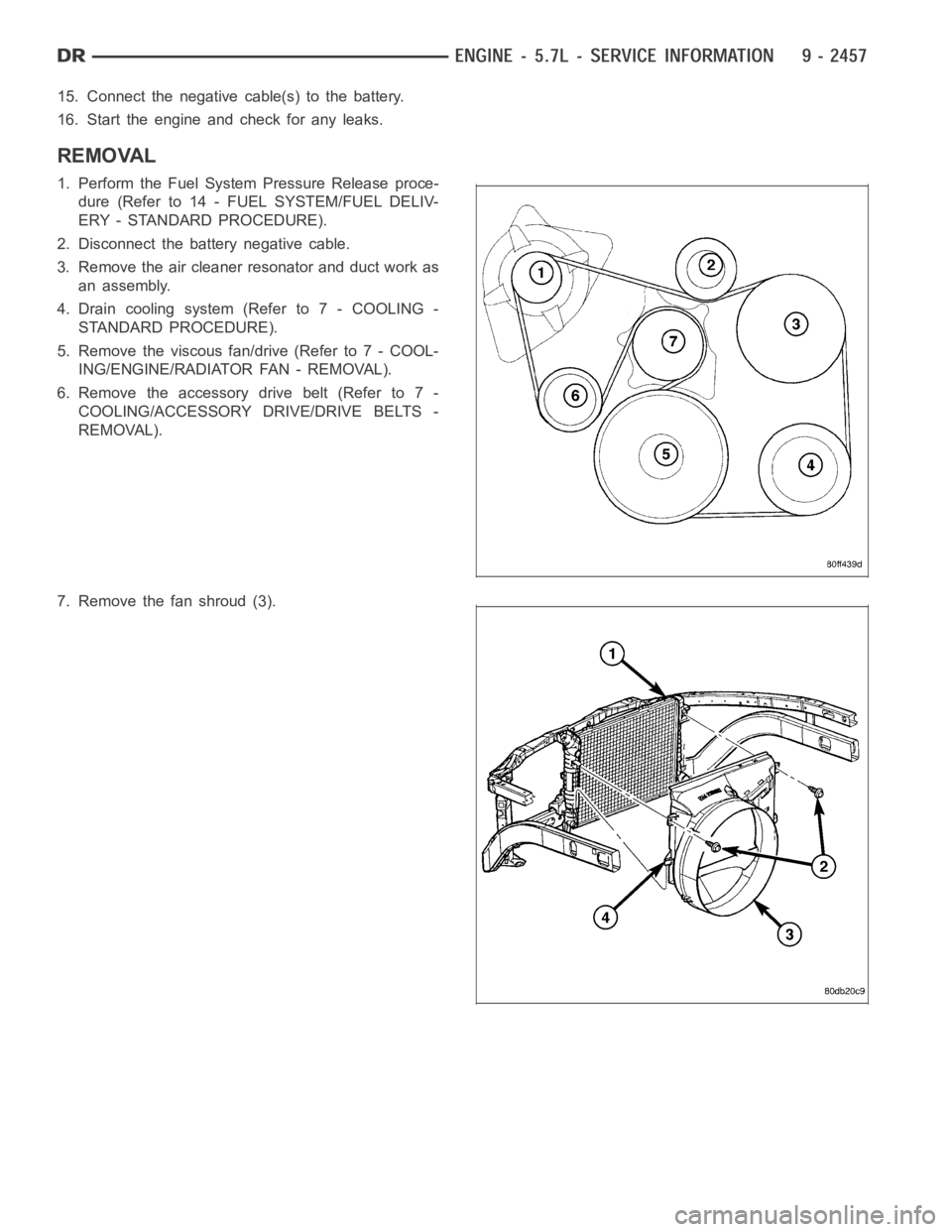

1. Perform the Fuel System Pressure Release proce-

dure (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

ERY - STANDARD PROCEDURE).

2. Disconnect the battery negative cable.

3. Remove the air cleaner resonator and duct work as

an assembly.

4. Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

5. Remove the viscous fan/drive (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - REMOVAL).

6. Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

7. Remove the fan shroud (3).

Page 1767 of 5267

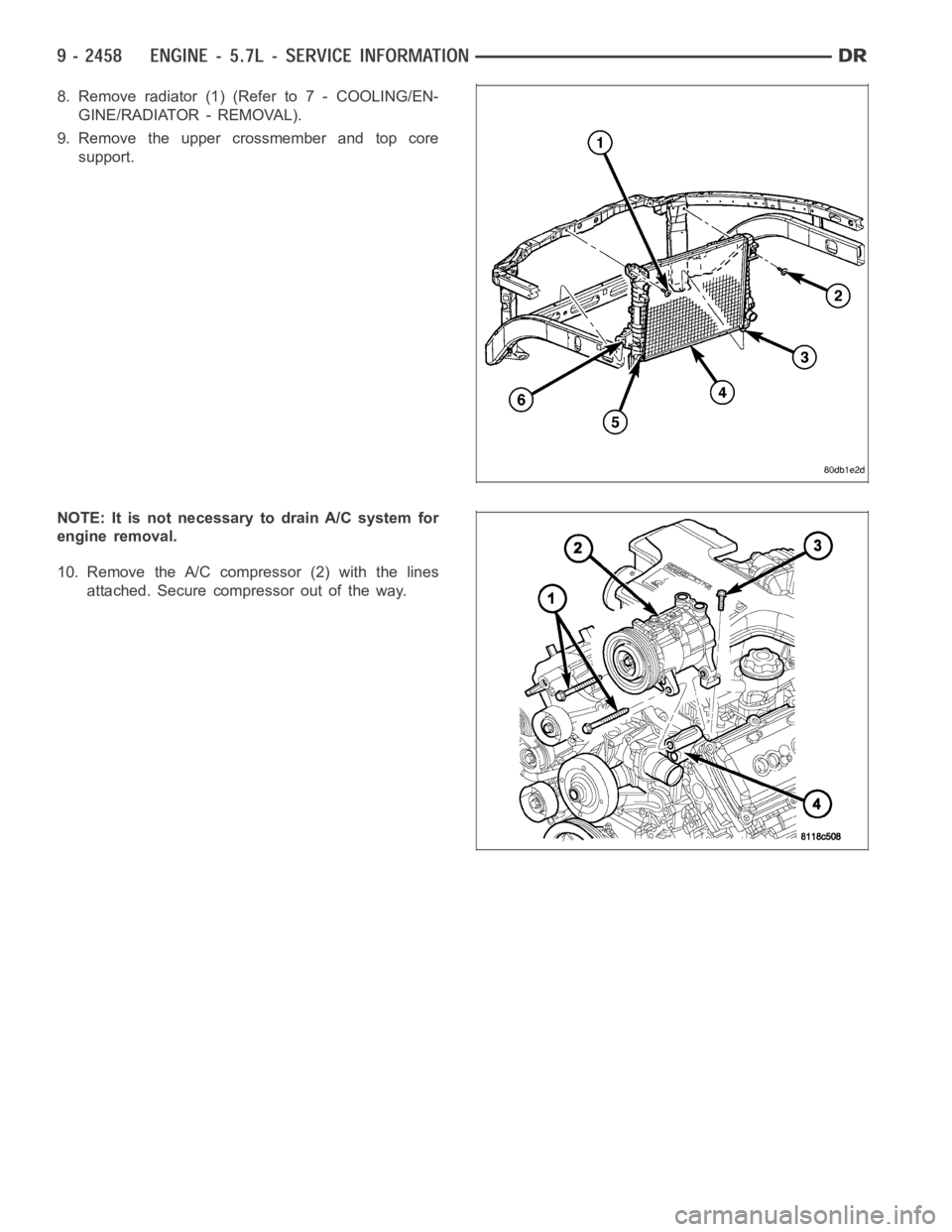

8. Remove radiator (1) (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

9. Remove the upper crossmember and top core

support.

NOTE: It is not necessary to drain A/C system for

engine removal.

10. Remove the A/C compressor (2) with the lines

attached. Secure compressor out of the way.

Page 1775 of 5267

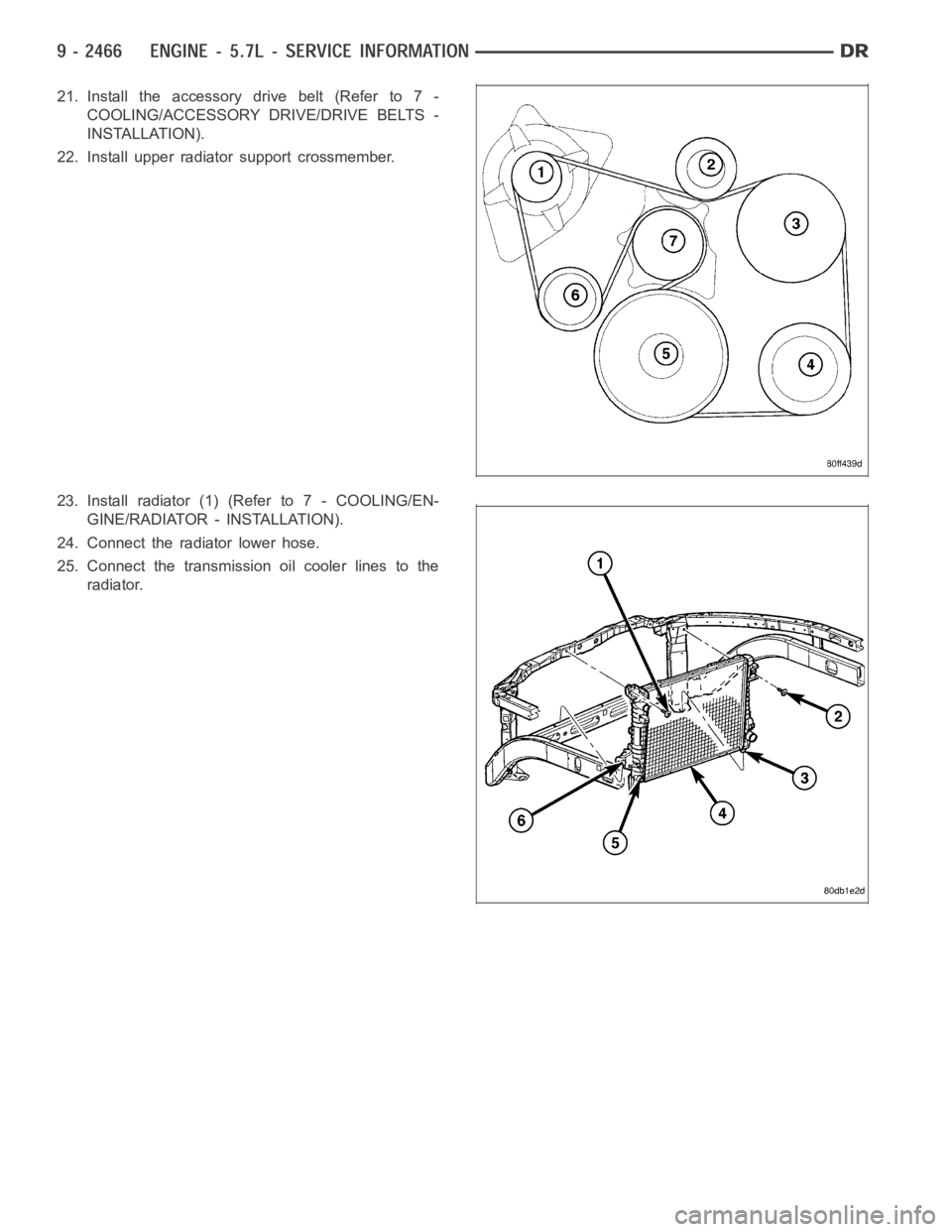

21. Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

22. Install upper radiator support crossmember.

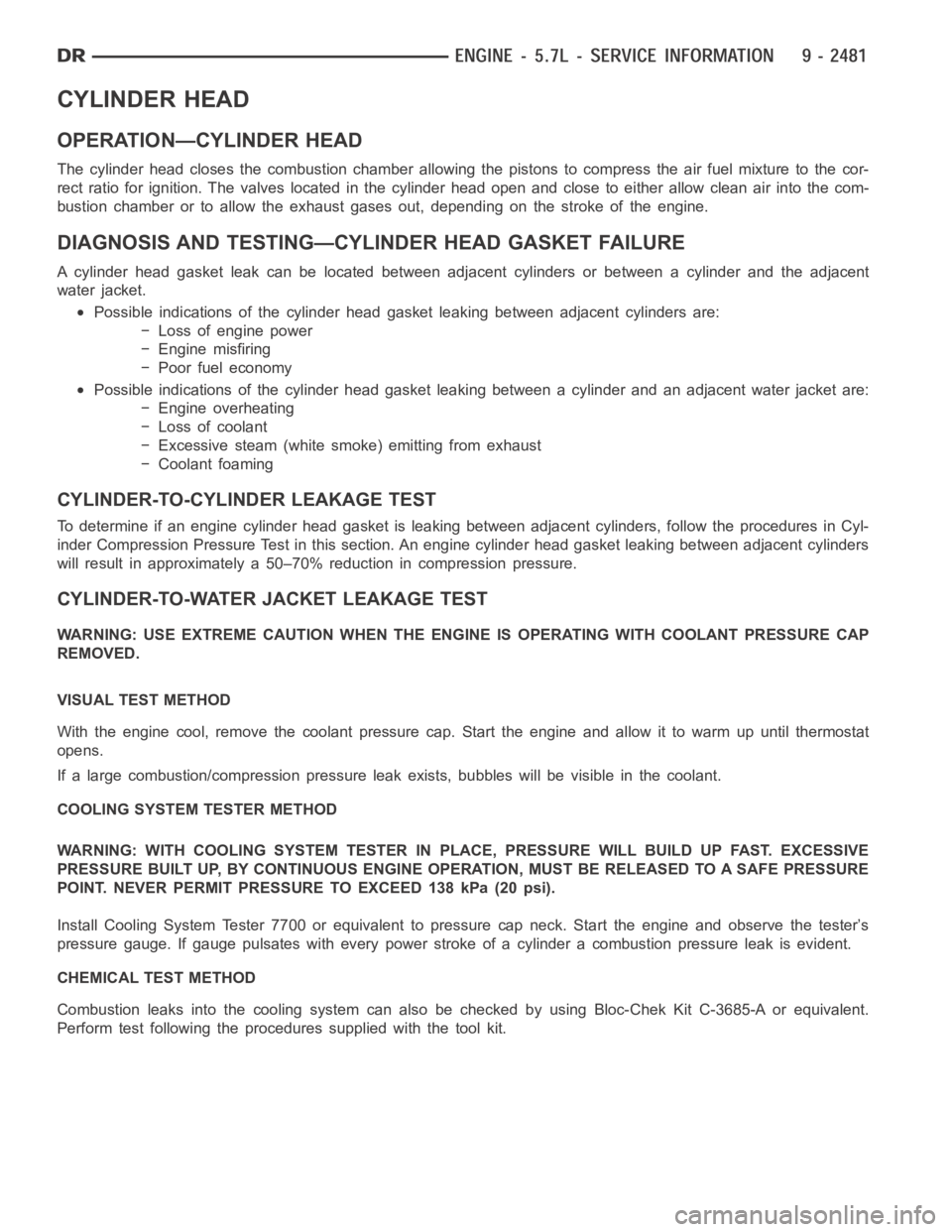

23. Install radiator (1) (Refer to 7 - COOLING/EN-

GINE/RADIATOR - INSTALLATION).

24. Connect the radiator lower hose.

25. Connect the transmission oil cooler lines to the

radiator.

Page 1776 of 5267

26. Install the fan shroud (3).

27. Install the fan (Refer to 7 - COOLING/ENGINE/

RADIATOR FAN - INSTALLATION).

28. Connect the radiator upper hose.

29. Install the washer bottle.

30. Connect the transmission cooler lines.

31. Install the air cleaner resonator and duct work..

32. Add engine oil to crankcase (Refer to LUBRICA-

TION & MAINTENANCE/FLUID TYPES - SPECI-

FICATIONS).

33. Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

34. Connect battery negative cable.

35. Start engine and inspect for leaks.

36. Road test vehicle.

SPECIFICATIONS

5.7L ENGINE

GENERAL DESCRIPTION

DESCRIPTION SPECIFICATION

Engine Type 90° V-8 OHV

Displacement 5.7 Liters

345 ( Cubic Inches)

Bore 99.5 mm (3.91 in.)

Stroke 90.9 mm (3.58 in.)

Compression Ratio 9.6:1

Firing Order 1-8-4-3-6-5-7-2

Lubrication Pressure Feed - Full Flow

Filtration

Cooling System Liquid Cooled - Forced

Circulation

Cylinder Block Cast Iron

Cylinder Head Aluminum

Crankshaft Nodular Iron

Camshaft Hollow Assembled Camshaft

Pistons Aluminum Alloy

Connecting Rods Powdered Metal

CYLINDER BLOCK

Page 1790 of 5267

CYLINDER HEAD

OPERATION—CYLINDER HEAD

The cylinder head closes the combustion chamber allowing the pistons to compress the air fuel mixture to the cor-

rect ratio for ignition. The valves located in the cylinder head open and close to either allow clean air into the com-

bustion chamber or to allow the exhaust gases out, depending on the stroke of the engine.

DIAGNOSIS AND TESTING—CYLINDER HEAD GASKET FAILURE

A cylinder head gasket leak can be located between adjacent cylinders or between a cylinder and the adjacent

water jacket.

Possible indications of the cylinder head gasket leaking between adjacent cylinders are:

− Loss of engine power

− Engine misfiring

− Poor fuel economy

Possible indications of the cylinder head gasket leaking between a cylinder and an adjacent water jacket are:

− Engine overheating

− Loss of coolant

− Excessive steam (white smoke) emitting from exhaust

− Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is leaking between adjacentcylinders, follow the procedures in Cyl-

inder Compression Pressure Test in this section. An engine cylinder head gasket leaking between adjacent cylinders

will result in approximately a 50–70% reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE ENGINE IS OPERATING WITH COOLANT PRESSURE CAP

REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure cap. Start the engine andallow it to warm up until thermostat

opens.

If a large combustion/compression pressure leak exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN PLACE, PRESSURE WILL BUILD UP FAST.EXCESSIVE

PRESSURE BUILT UP, BY CONTINUOUS ENGINE OPERATION, MUST BE RELEASED TO A SAFE PRESSURE

POINT. NEVER PERMIT PRESSURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to pressure cap neck. Start the engine and observe the tester’s

pressure gauge. If gauge pulsates with every power stroke of a cylinder a combustion pressure leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also be checked by using Bloc-Chek Kit C-3685-A or equivalent.

Perform test following the procedures supplied with the tool kit.

Page 1792 of 5267

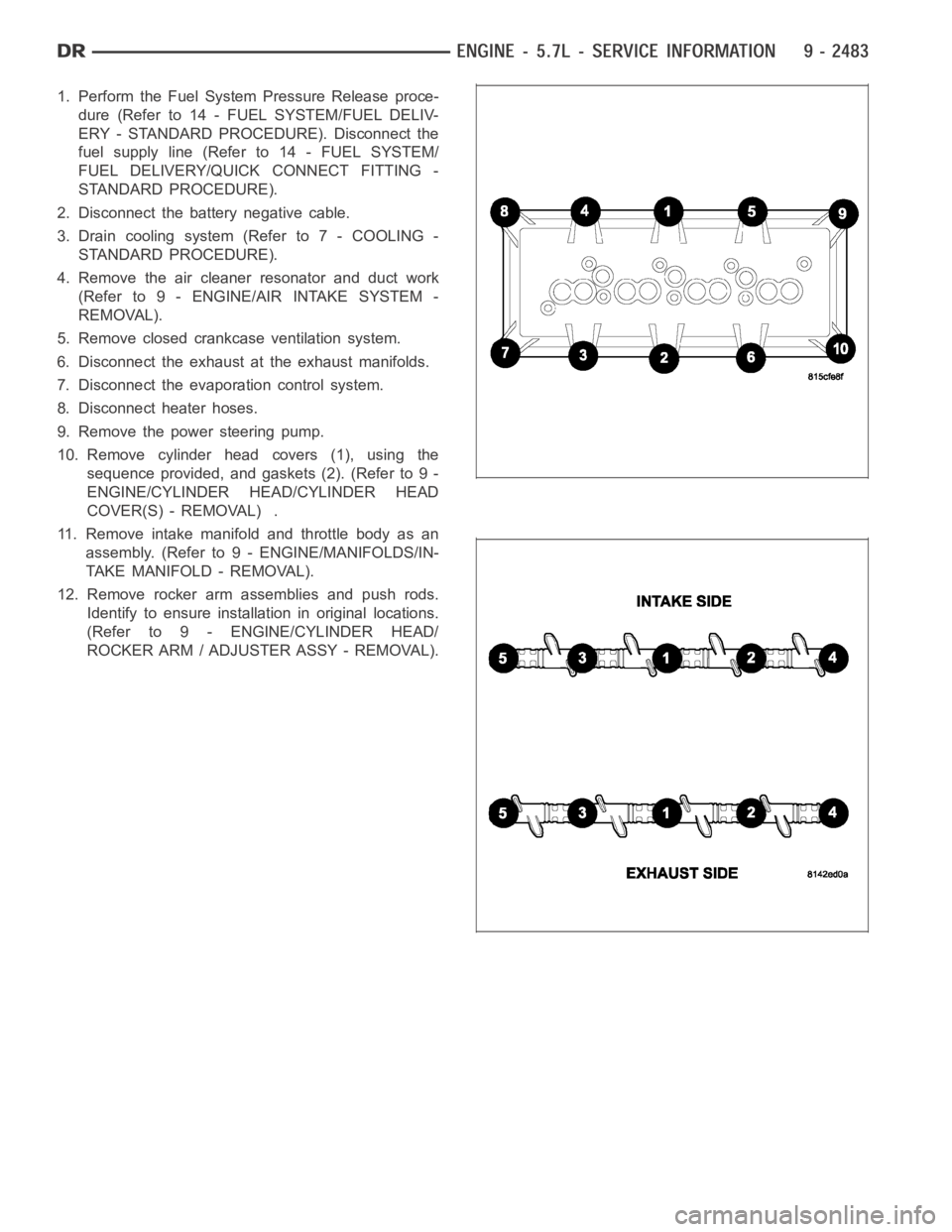

1. Perform the Fuel System Pressure Release proce-

dure (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

ERY - STANDARD PROCEDURE). Disconnect the

fuelsupplyline(Referto14-FUELSYSTEM/

FUEL DELIVERY/QUICK CONNECT FITTING -

STANDARD PROCEDURE).

2. Disconnect the battery negative cable.

3. Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

4. Remove the air cleaner resonator and duct work

(Refer to 9 - ENGINE/AIR INTAKE SYSTEM -

REMOVAL).

5. Remove closed crankcase ventilation system.

6. Disconnect the exhaust at the exhaust manifolds.

7. Disconnect the evaporation control system.

8. Disconnect heater hoses.

9. Remove the power steering pump.

10. Remove cylinder head covers (1), using the

sequence provided, and gaskets (2). (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL) .

11. Remove intake manifold and throttle body as an

assembly. (Refer to 9 - ENGINE/MANIFOLDS/IN-

TAKE MANIFOLD - REMOVAL).

12. Remove rocker arm assemblies and push rods.

Identify to ensure installation in original locations.

(Refer to 9 - ENGINE/CYLINDER HEAD/

ROCKER ARM / ADJUSTER ASSY - REMOVAL).

Page 1796 of 5267

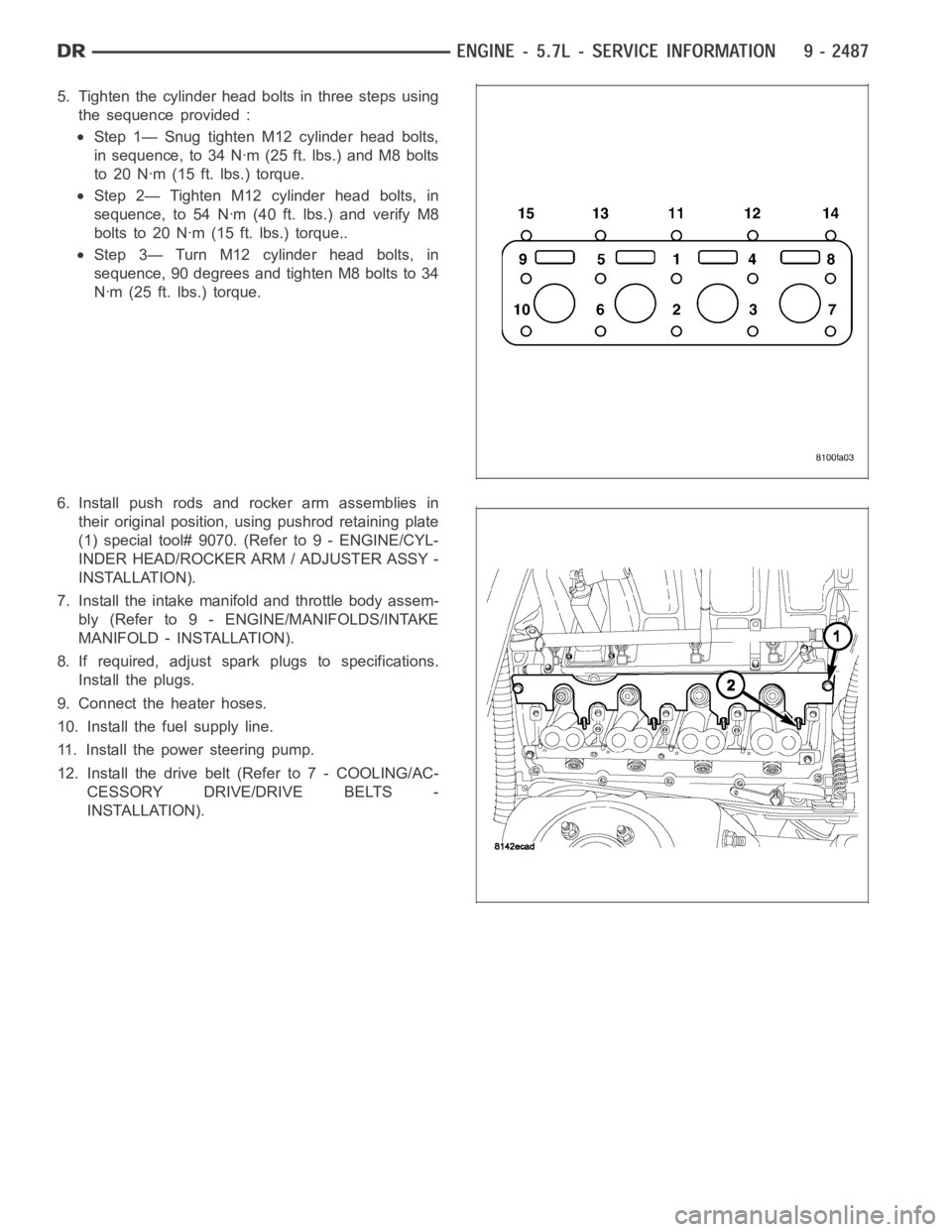

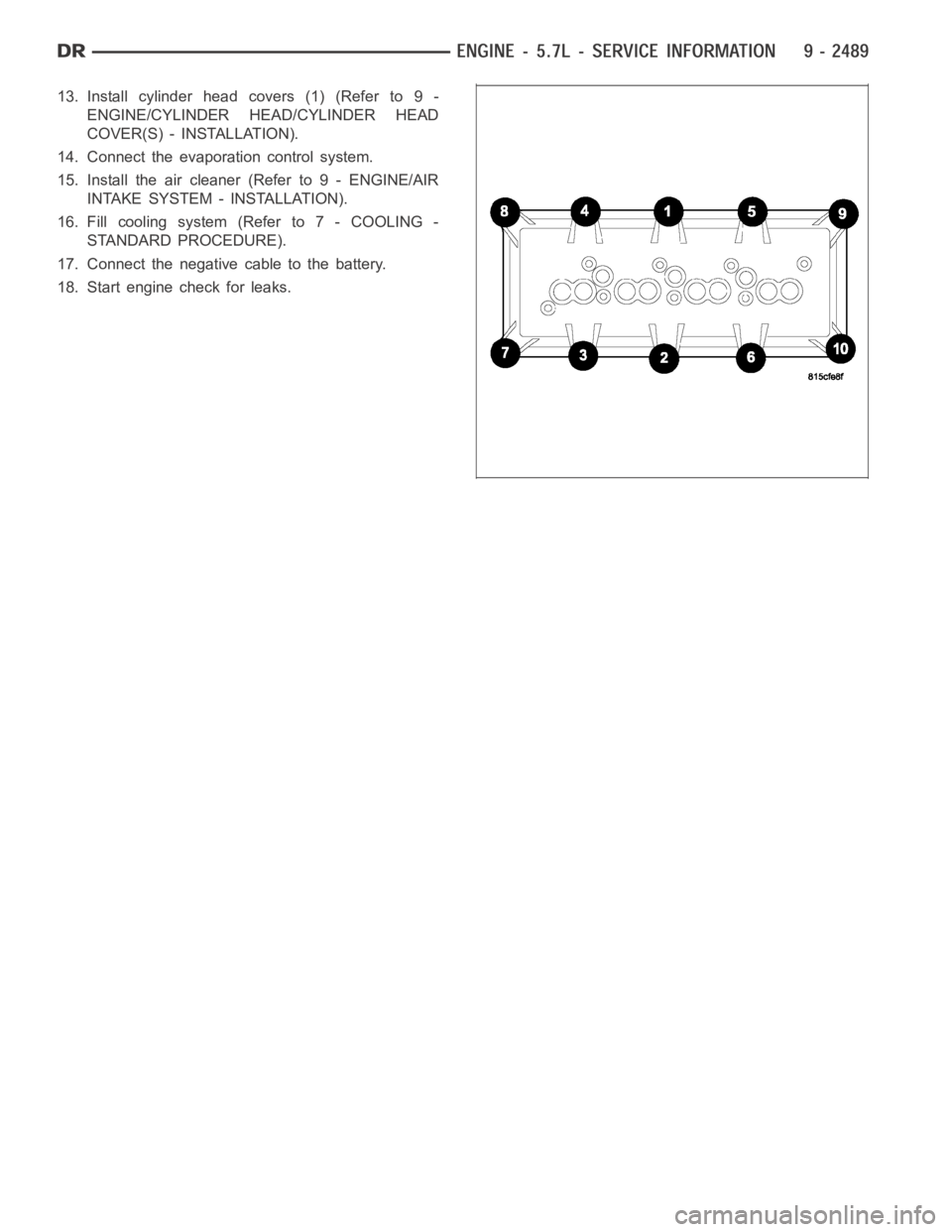

5. Tighten the cylinder head bolts in three steps using

the sequence provided :

Step 1— Snug tighten M12 cylinder head bolts,

in sequence, to 34 Nꞏm (25 ft. lbs.) and M8 bolts

to 20 Nꞏm (15 ft. lbs.) torque.

Step 2— Tighten M12 cylinder head bolts, in

sequence, to 54 Nꞏm (40 ft. lbs.) and verify M8

bolts to 20 Nꞏm (15 ft. lbs.) torque..

Step 3— Turn M12 cylinder head bolts, in

sequence, 90 degrees and tighten M8 bolts to 34

Nꞏm (25 ft. lbs.) torque.

6. Install push rods and rocker arm assemblies in

their original position, using pushrod retaining plate

(1) special tool# 9070. (Refer to 9 - ENGINE/CYL-

INDER HEAD/ROCKER ARM / ADJUSTER ASSY -

INSTALLATION).

7. Install the intake manifold and throttle body assem-

bly (Refer to 9 - ENGINE/MANIFOLDS/INTAKE

MANIFOLD - INSTALLATION).

8. If required, adjust spark plugs to specifications.

Install the plugs.

9. Connect the heater hoses.

10. Install the fuel supply line.

11. Install the power steering pump.

12. Install the drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

Page 1798 of 5267

13. Install cylinder head covers (1) (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

14. Connect the evaporation control system.

15. Install the air cleaner (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM - INSTALLATION).

16. Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

17. Connect the negative cable to the battery.

18. Start engine check for leaks.