change time DODGE RAM SRT-10 2006 Service Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4265 of 5267

TRANSFER CASE - NV273 - SERVICE INFORMATION

DESCRIPTION

The NV273 is an electronically controlled part-time transfer case with a low range gear reduction system. The

NV273 has three operating ranges plus a NEUTRAL position. The low range system provides a gear reduction ratio

for increased low speed torque capability.

The geartrain is mounted in two aluminum case halves attached with bolts. The mainshaft front and rear bearings

are mounted in aluminum case halves.

OPERATING RANGES

Transfer case operating ranges are:

2WD (2-wheel drive).

4HI (4-wheel drive).

4LO (4-wheel drive low range).

NEUTRAL.

The 2WD range is for use on any road surface at any time.

The 4HI and 4LO ranges are for off road use only. They are not for use on hard surface roads. The only exception

being when the road surface is wet or slippery or covered by ice and snow.

The low range reduction gear system is operative in 4LO range only. This range is for extra pulling power in off road

situations. Low range reduction ratio is 2.72:1.

SHIFT MECHANISM

Operating ranges are selected with a dash mounted shift selector switch. The shift selector switch provides a input

to the Transfer Case Control Module (TCCM) to indicate the driver’s desireto change operating ranges. The TCCM

uses this input, along with input from the transfer case mounted mode sensor and information from the vehicle’s

bus, to determine if a shift is permitted. If the TCCM decides the shift is permitted, the TCCM controls the shift

motor, mounted to the exterior of the transfer case, to perform the shift.

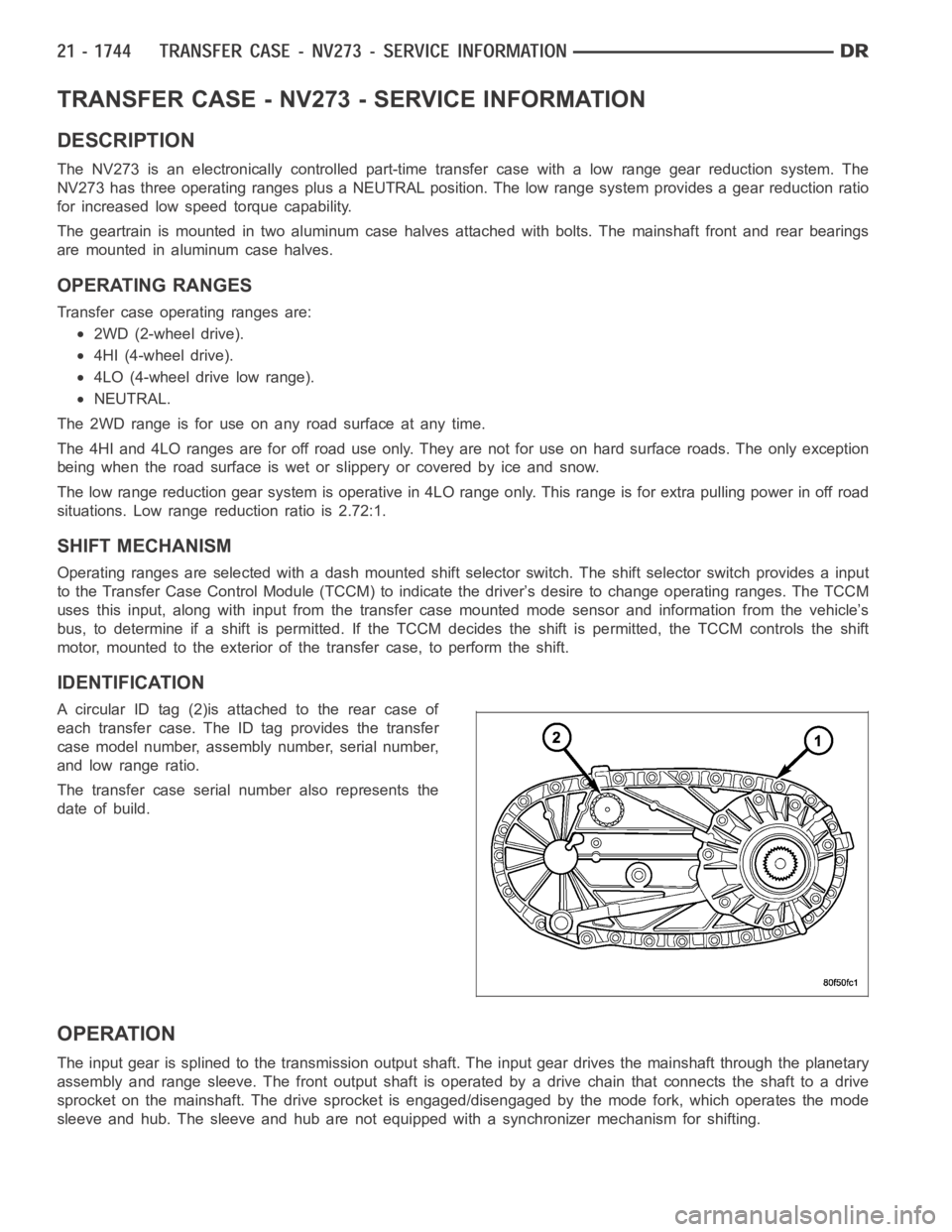

IDENTIFICATION

A circular ID tag (2)is attached to the rear case of

each transfer case. The ID tag provides the transfer

case model number, assembly number, serial number,

and low range ratio.

The transfer case serial number also represents the

date of build.

OPERATION

The input gear is splined to the transmission output shaft. The input gear drives the mainshaft through the planetary

assembly and range sleeve. The front output shaft is operated by a drive chain that connects the shaft to a drive

sprocket on the mainshaft. The drive sprocket is engaged/disengaged by themodefork,whichoperatesthemode

sleeve and hub. The sleeve and hub are not equipped with a synchronizer mechanism for shifting.

Page 4559 of 5267

SEATS

WARNING

WARNINGS - RESTRAINT SYSTEM

WARNING: To avoid personal injury or death, during and following any seat beltorchildrestraintanchor

service, carefully inspect all seat belts, buckles, mounting hardware, retractors, tether straps, and anchors

for proper installation, operation, or damage. Replace any belt that is cut, frayed, or torn. Straighten any

belt that is twisted. Tighten any loose fasteners. Replace any belt that has a damaged or ineffective buckle

or retractor. Replace any belt that has a bent or damaged latch plate or anchor plate. Replace any child

restraint anchor or the unit to which the anchor is integral that has been bent or damaged. Never attempt to

repair a seat belt or child restraint component. Always replace damaged orineffective seat belt and child

restraint components with the correct, new and unused replacement parts listed in the DaimlerChrysler

Mopar

Parts Catalog.

WARNING: To avoid personal injury or death, on vehicles equipped with airbags, disable the supplemental

restraint system before attempting any steering wheel, steering column,airbag, seat belt tensioner, impact

sensor, or instrument panel component diagnosis or service. Disconnect and isolate the battery negative

(ground) cable, then wait two minutes for the system capacitor to discharge before performing further diag-

nosis or service. This is the only sure way to disable the supplemental restraint system. Failure to take the

proper precautions could result in accidental airbag deployment.

WARNING: To avoid personal injury or death on vehicles equipped with airbags, before performing any

welding operations disconnect and isolate the battery negative (ground)cable and disconnect all wire har-

ness connectors from the Occupant Restraint Controller (ORC). Failure totake the proper precautions could

result in accidental airbag deployment and other possible damage to the supplemental restraint system cir-

cuits and components.

WARNING: To avoid personal injury or death, do not attempt to dismantle an airbag unit or tamper with its

inflator. Do not puncture, incinerate, or bring into contact with electricity. Do not store at temperatures

exceeding 93° C (200° F). An airbag inflator unit may contain sodium azide and potassium nitrate. These

materials are poisonous and extremely flammable. Contact with acid, water, or heavy metals may produce

harmful and irritating gases (sodium hydroxide is formed in the presence of moisture) or combustible com-

pounds. An airbag inflator unit may also contain a gas canister pressurizedtoover2500psi.

WARNING: To avoid personal injury or death, when handling a seat belt tensioner retractor, proper care

should be exercised to keep fingers out from under the retractor cover and away from the seat belt webbing

where it exits from the retractor cover.

WARNING: To avoid personal injury or death, replace all restraint system components only with parts spec-

ified in the DaimlerChrysler Mopar

Parts Catalog. Substitute parts may appear interchangeable, but internal

differences may result in inferior occupant protection.

WARNING: To avoid personal injury or death, the fasteners, screws, and bolts originally used for the

restraint system components must never be replaced with any substitutes.These fasteners have special

coatings and are specifically designed for the restraint system. Any timea new fastener is needed, replace

it with the correct fasteners provided in the service package or specifiedin the DaimlerChrysler Mopar

Parts Catalog.

WARNING: To avoid personal injury or death, when a steering column has an airbag unit attached, never

place the column on the floor or any other surface with the steering wheel orairbag unit face down.

Page 4853 of 5267

Theory of Operation

The A/C Heater Control drives the Passenger Blend Door Actuator via the (C33) Passenger Blend Door Driver cir-

cuit and the (C34) Common Door Driver circuit. All of the door actuators share the (C34) Common Door Driver

circuit. Inside the A/C Heater Control, each door actuator has its own unique driver, but all share a single common

door driver circuit. Due to the shared circuitry similar DTCs can set at thesame time for multiple actuators depend-

ing upon the location of the open circuit and the direction the actuator is moving when the open is present.

When Monitored:

During actuator calibration.

Set Condition:

If Passenger Blend Door Actuator’s electrical circuit is open. This DTC has a maturing time of 5 seconds and

a de-maturing time of 10 seconds. If the DTC’s status changes from active tostored it will stay in memory for

100 ignition cycles.

Possible Causes

(C33) PASSENGER BLEND DOOR DRIVER CIRCUIT OPEN

(C34) COMMON DOOR DRIVER CIRCUIT OPEN

PASSENGER BLEND DOOR ACTUATOR

A/C HEATER CONTROL

NOTE: This DTC must be active for the results of this test to be valid. Do not perform this test if this DTC

is stored. Refer to HVAC System Test for stored DTC test procedures.

Diagnostic Test

1.CHECK FOR ACTIVE CONTROL CIRCUIT/PERFORMANCE DTCs

Turn the ignition on.

With the scan tool, read active HVAC DTCs.

Does the scan tool display any active: XXXX CONTROL CIRCUIT/PERFORMANCE DTCs?

Ye s>>

Diagnose and repair the DTC(s). Refer to the Table of Contents in this Section for a complete list of

HVAC related symptoms.

No>>

Go To 2

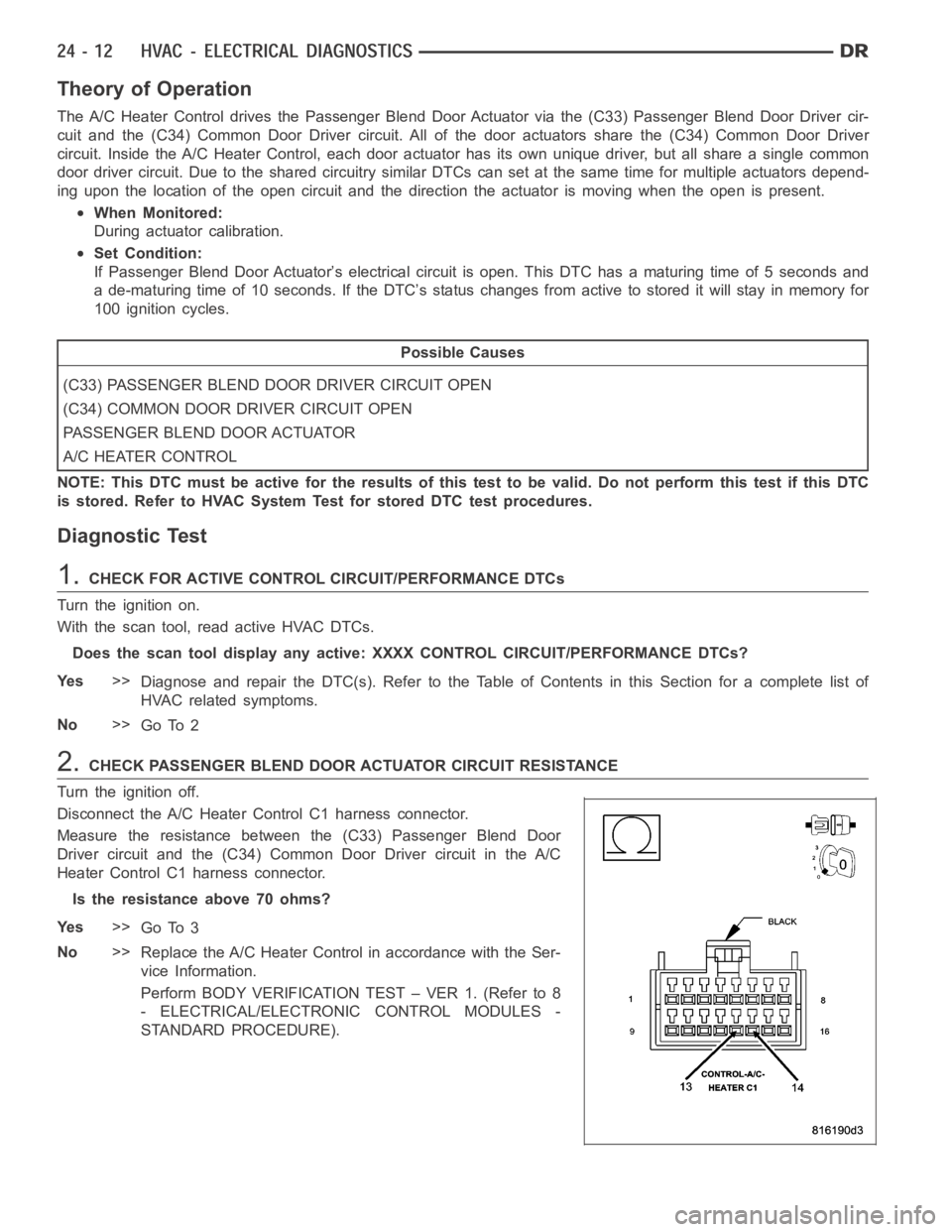

2.CHECK PASSENGER BLEND DOOR ACTUATOR CIRCUIT RESISTANCE

Turn the ignition off.

Disconnect the A/C Heater Control C1 harness connector.

Measure the resistance between the (C33) Passenger Blend Door

Driver circuit and the (C34) Common Door Driver circuit in the A/C

Heater Control C1 harness connector.

Is the resistance above 70 ohms?

Ye s>>

Go To 3

No>>

Replace the A/C Heater Control in accordance with the Ser-

vice Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

Page 4859 of 5267

B10A2–LEFT BLEND DOOR CONTROL CIRCUIT/PERFORMANCE (DUAL-ZONE)

For a complete wiring diagramRefer to Section 8W.

Theory of Operation

The A/C Heater Control monitors the door driver circuits during actuator operation for shorts to ground, shorts to

battery, and shorts to other door driver circuits. If detected, the A/C Heater Control reports these types of faults as

Control Circuit/Performance DTCs. It is important to note that Control Circuit/Performance DTCs do not indicate

where or what type of short is present and that additional system testing isnecessary to provide more details about

the reported fault.

When Monitored:

When actuator movement is requested.

Set Condition:

If the A/C Heater Control detects an excessive current draw on any of the door driver circuits while attempting

to drive this actuator. This DTC has a maturing time of 5 seconds and a de-maturing time of 10 seconds. If the

DTC’s status changes from active to stored, it will stay in memory for 100 ignition cycles.

Possible Causes

DOOR DRIVER CIRCUIT(S) SHORTED

NOTE:TheDTCmustbeactivefortheresultsofthistesttobevalid.Donotperform this test if the DTC is

stored. Refer to HVAC System Test for stored DTC test procedures.

Diagnostic Test

1.RUN THE ACTUATOR DTC DETECTION TEST

Turn the ignition on.

With the scan tool in HVAC, erase DTCs.

With the scan tool, select System Tests and then select Actuator DTC Detection. When the test is complete, select

View DTCs.

Repair

Diagnose and repair the DTC(s). If multiple DTCs are present, beginning with the passenger blend door,

diagnose and repair all short high DTCs and then all short low DTCs. Refer tothe Table of Contents in

this Section for a complete list of HVAC related symptoms.

Page 4868 of 5267

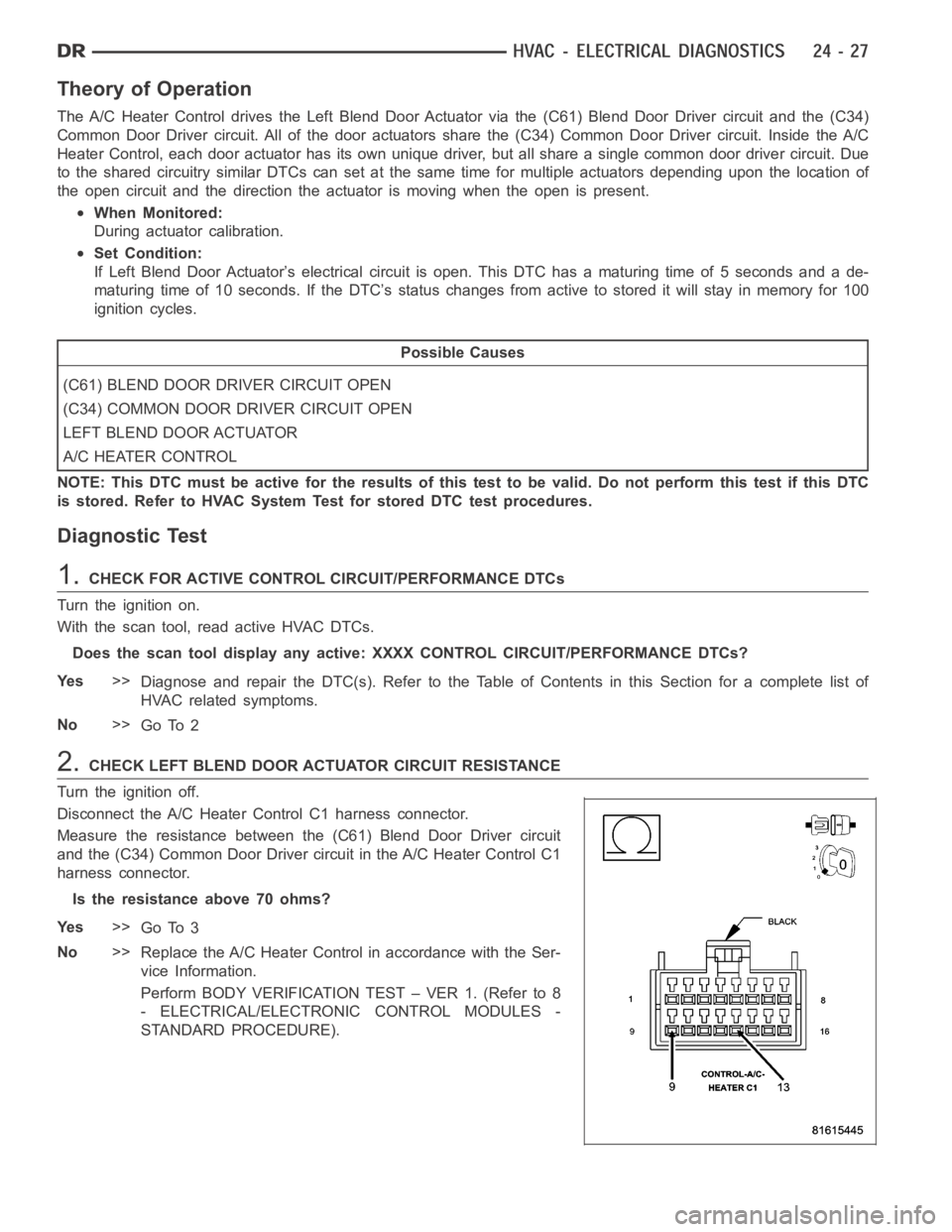

Theory of Operation

The A/C Heater Control drives the Left Blend Door Actuator via the (C61) Blend Door Driver circuit and the (C34)

Common Door Driver circuit. All of the door actuators share the (C34) Common Door Driver circuit. Inside the A/C

Heater Control, each door actuator has its own unique driver, but all sharea single common door driver circuit. Due

to the shared circuitry similar DTCs can set at the same time for multiple actuators depending upon the location of

the open circuit and the direction the actuator is moving when the open is present.

When Monitored:

During actuator calibration.

Set Condition:

If Left Blend Door Actuator’s electrical circuit is open. This DTC has a maturingtimeof5secondsandade-

maturing time of 10 seconds. If the DTC’s status changes from active to stored it will stay in memory for 100

ignition cycles.

Possible Causes

(C61) BLEND DOOR DRIVER CIRCUIT OPEN

(C34) COMMON DOOR DRIVER CIRCUIT OPEN

LEFT BLEND DOOR ACTUATOR

A/C HEATER CONTROL

NOTE: This DTC must be active for the results of this test to be valid. Do not perform this test if this DTC

is stored. Refer to HVAC System Test for stored DTC test procedures.

Diagnostic Test

1.CHECK FOR ACTIVE CONTROL CIRCUIT/PERFORMANCE DTCs

Turn the ignition on.

With the scan tool, read active HVAC DTCs.

Does the scan tool display any active: XXXX CONTROL CIRCUIT/PERFORMANCE DTCs?

Ye s>>

Diagnose and repair the DTC(s). Refer to the Table of Contents in this Section for a complete list of

HVAC related symptoms.

No>>

Go To 2

2.CHECK LEFT BLEND DOOR ACTUATOR CIRCUIT RESISTANCE

Turn the ignition off.

Disconnect the A/C Heater Control C1 harness connector.

Measure the resistance between the (C61) Blend Door Driver circuit

and the (C34) Common Door Driver circuit in the A/C Heater Control C1

harness connector.

Is the resistance above 70 ohms?

Ye s>>

Go To 3

No>>

Replace the A/C Heater Control in accordance with the Ser-

vice Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

Page 4874 of 5267

B10A9–RIGHT BLEND DOOR CONTROL CIRCUIT/PERFORMANCE (DUAL-ZONE)

For a complete wiring diagramRefer to Section 8W.

Theory of Operation

The A/C Heater Control monitors the door driver circuits during actuator operation for shorts to ground, shorts to

battery, and shorts to other door driver circuits. If detected, the A/C Heater Control reports these types of faults as

Control Circuit/Performance DTCs. It is important to note that Control Circuit/Performance DTCs do not indicate

where or what type of short is present and that additional system testing isnecessary to provide more details about

the reported fault.

When Monitored:

When actuator movement is requested.

Set Condition:

If the A/C Heater Control detects an excessive current draw on any of the door driver circuits while attempting

to drive this actuator. This DTC has a maturing time of 5 seconds and a de-maturing time of 10 seconds. If the

DTC’s status changes from active to stored, it will stay in memory for 100 ignition cycles.

Possible Causes

DOOR DRIVER CIRCUIT(S) SHORTED

NOTE:TheDTCmustbeactivefortheresultsofthistesttobevalid.Donotperform this test if the DTC is

stored. Refer to HVAC System Test for stored DTC test procedures.

Diagnostic Test

1.RUN THE ACTUATOR DTC DETECTION TEST

Turn the ignition on.

With the scan tool in HVAC, erase DTCs.

With the scan tool, select System Tests and then select Actuator DTC Detection. When the test is complete, select

View DTCs.

Repair

Diagnose and repair the DTC(s). If multiple DTCs are present, beginning with the passenger blend door,

diagnose and repair all short high DTCs and then all short low DTCs. Refer tothe Table of Contents in

this Section for a complete list of HVAC related symptoms.

Page 4902 of 5267

B104C–BLEND DOOR CONTROL CIRCUIT/PERFORMANCE (SINGLE-ZONE)

For a complete wiring diagramRefer to Section 8W.

Theory of Operation

The A/C Heater Control monitors the door driver circuits during actuator operation for shorts to ground, shorts to

battery, and shorts to other door driver circuits. If detected, the A/C Heater Control reports these types of faults as

Control Circuit/Performance DTCs. It is important to note that Control Circuit/Performance DTCs do not indicate

where or what type of short is present and that additional system testing isnecessary to provide more details about

the reported fault.

When Monitored:

With the ignition on.

Set Condition:

If the A/C Heater Control detects a short on any of the door driver circuits while attempting to drive this actua-

tor. This DTC has a maturing time of 5 seconds and a de-maturing time of 10 seconds. If the DTC’s status

changes from active to stored, it will stay in memory for 100 ignition cycles.

Possible Causes

DOOR DRIVER CIRCUIT(S) SHORTED

NOTE:TheDTCmustbeactivefortheresultsofthistesttobevalid.Donotperform this test if the DTC is

stored. Refer to HVAC System Test for stored DTC test procedures.

Diagnostic Test

1.RUN THE ACTUATOR DTC DETECTION TEST

Turn the ignition on.

With the scan tool in HVAC, erase DTCs.

Turn the ignition off, wait 10 seconds, and then turn the ignition on.

With the scan tool, select System Tests and then select Actuator DTC Detection. When the test is complete, select

View DTCs.

Repair

Diagnose and repair the DTC(s). If multiple DTCs are present, beginning with the common circuits, diag-

nose and repair all short high DTCs and then all short low DTCs. Refer to the Table of Contents in this

Section for a complete list of HVAC related symptoms.

Page 4911 of 5267

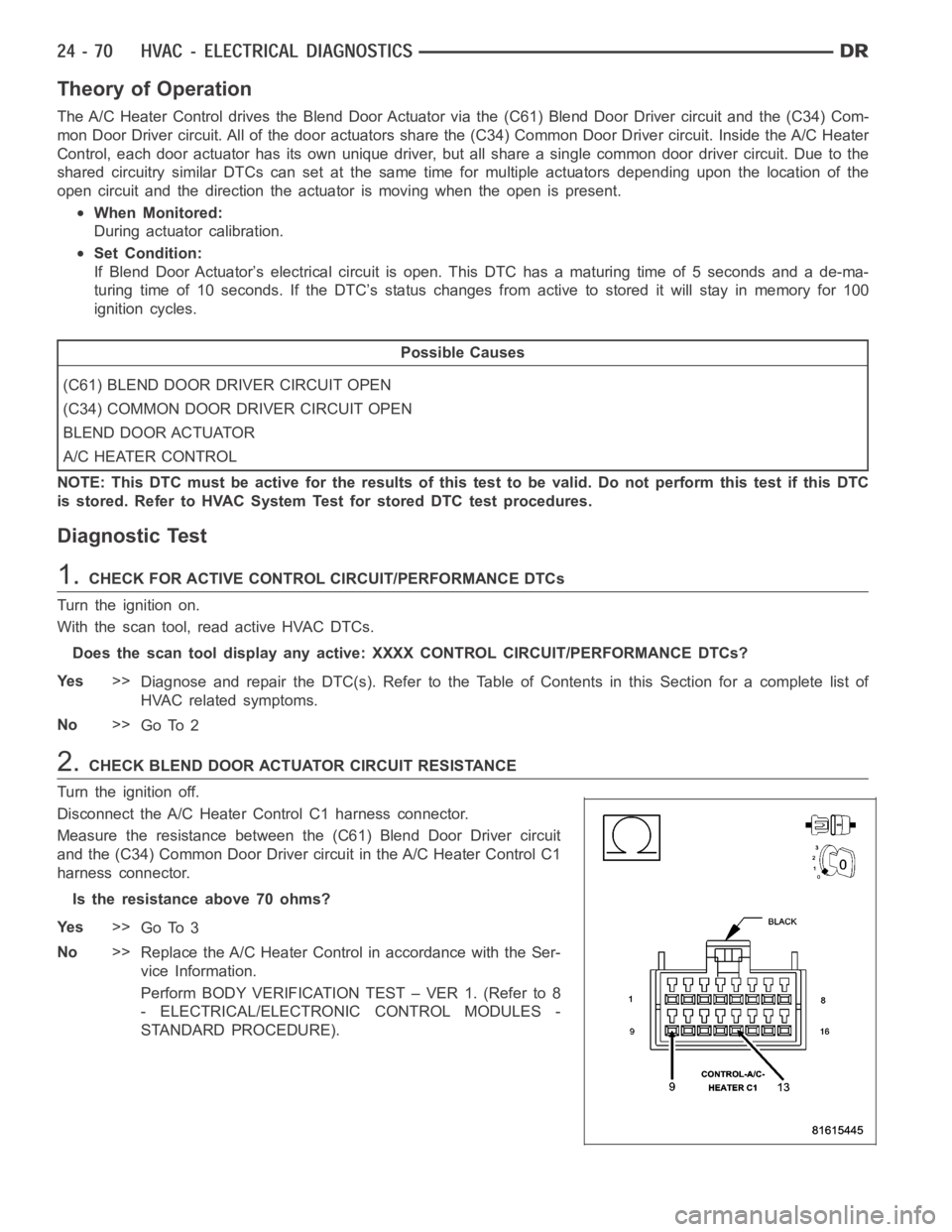

Theory of Operation

The A/C Heater Control drives the Blend Door Actuator via the (C61) Blend Door Driver circuit and the (C34) Com-

mon Door Driver circuit. All of the door actuators share the (C34) Common Door Driver circuit. Inside the A/C Heater

Control, each door actuator has its own unique driver, but all share a single common door driver circuit. Due to the

shared circuitry similar DTCs can set at the same time for multiple actuators depending upon the location of the

open circuit and the direction the actuator is moving when the open is present.

When Monitored:

During actuator calibration.

Set Condition:

If Blend Door Actuator’s electrical circuit is open. This DTC has a maturingtimeof5secondsandade-ma-

turing time of 10 seconds. If the DTC’s status changes from active to storedit will stay in memory for 100

ignition cycles.

Possible Causes

(C61) BLEND DOOR DRIVER CIRCUIT OPEN

(C34) COMMON DOOR DRIVER CIRCUIT OPEN

BLEND DOOR ACTUATOR

A/C HEATER CONTROL

NOTE: This DTC must be active for the results of this test to be valid. Do not perform this test if this DTC

is stored. Refer to HVAC System Test for stored DTC test procedures.

Diagnostic Test

1.CHECK FOR ACTIVE CONTROL CIRCUIT/PERFORMANCE DTCs

Turn the ignition on.

With the scan tool, read active HVAC DTCs.

Does the scan tool display any active: XXXX CONTROL CIRCUIT/PERFORMANCE DTCs?

Ye s>>

Diagnose and repair the DTC(s). Refer to the Table of Contents in this Section for a complete list of

HVAC related symptoms.

No>>

Go To 2

2.CHECK BLEND DOOR ACTUATOR CIRCUIT RESISTANCE

Turn the ignition off.

Disconnect the A/C Heater Control C1 harness connector.

Measure the resistance between the (C61) Blend Door Driver circuit

and the (C34) Common Door Driver circuit in the A/C Heater Control C1

harness connector.

Is the resistance above 70 ohms?

Ye s>>

Go To 3

No>>

Replace the A/C Heater Control in accordance with the Ser-

vice Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

Page 4920 of 5267

Theory of Operation

The A/C Heater Control drives the Recirculation Door Actuator via the (C32) Recirculation Door Driver circuit and

the (C34) Common Door Driver circuit. All of the door actuators share the (C34) Common Door Driver. Inside the

A/C Heater Control, each door actuator has its own unique driver, but all share a single common door driver circuit.

Due to the shared circuitry similar DTCs can set at the same time for multiple actuators depending upon the location

of the open circuit and the direction the actuator is moving when the open ispresent.

When Monitored:

During actuator calibration.

Set Condition:

If Recirculation Door Actuator’s electrical circuit is open. This DTC hasa maturing time of 5 seconds and a

de-maturing time of 10 seconds. If the DTC’s status changes from active to stored it will stay in memory for

100 ignition cycles.

Possible Causes

(C32) RECIRCULATION DOOR DRIVER CIRCUIT OPEN

(C34) COMMON DOOR DRIVER CIRCUIT OPEN

RECIRCULATION DOOR ACTUATOR

A/C HEATER CONTROL

NOTE: This DTC must be active for the results of this test to be valid. Do not perform this test if this DTC

is stored. Refer to HVAC System Test for stored DTC test procedures.

Diagnostic Test

1.CHECK FOR ACTIVE CONTROL CIRCUIT/PERFORMANCE DTCs

Turn the ignition on.

With the scan tool, read active HVAC DTCs.

Does the scan tool display any active: XXXX CONTROL CIRCUIT/PERFORMANCE DTCs?

Ye s>>

Diagnose and repair the DTC(s). Refer to the Table of Contents in this Section for a complete list of

HVAC related symptoms.

No>>

Go To 2

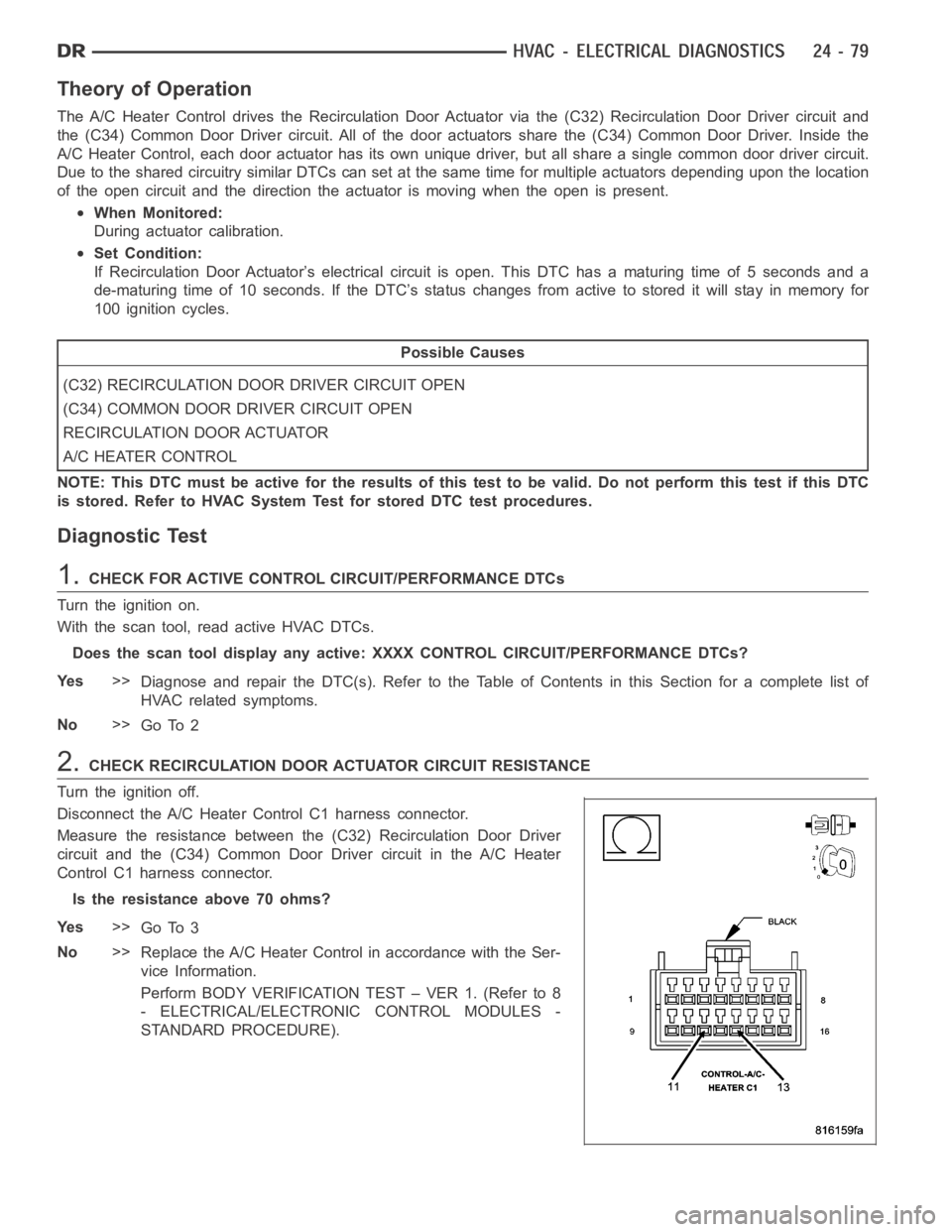

2.CHECK RECIRCULATION DOOR ACTUATOR CIRCUIT RESISTANCE

Turn the ignition off.

Disconnect the A/C Heater Control C1 harness connector.

Measure the resistance between the (C32) Recirculation Door Driver

circuit and the (C34) Common Door Driver circuit in the A/C Heater

Control C1 harness connector.

Is the resistance above 70 ohms?

Ye s>>

Go To 3

No>>

Replace the A/C Heater Control in accordance with the Ser-

vice Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

Page 4923 of 5267

Theory of Operation

The A/C Heater Control drives the Recirculation Door Actuator via the (C32) Recirculation Door Driver circuit and

the (C34) Common Door Driver circuit. All of the door actuators share the (C34) Common Door Driver. Inside the

A/C Heater Control, each door actuator has its own unique driver, but all share a single common door driver circuit.

Due to the shared circuitry similar DTCs can set at the same time for multiple actuators depending upon the location

of the open circuit and the direction the actuator is moving when the open ispresent.

When Monitored:

During actuator calibration.

Set Condition:

If Recirculation Door Actuator’s electrical circuit is open. This DTC hasa maturing time of 5 seconds and a

de-maturing time of 10 seconds. If the DTC’s status changes from active to stored it will stay in memory for

100 ignition cycles.

Possible Causes

(C32) RECIRCULATION DOOR DRIVER CIRCUIT OPEN

(C34) COMMON DOOR DRIVER CIRCUIT OPEN

RECIRCULATION DOOR ACTUATOR

A/C HEATER CONTROL

NOTE: This DTC must be active for the results of this test to be valid. Do not perform this test if this DTC

is stored. Refer to HVAC System Test for stored DTC test procedures.

Diagnostic Test

1.CHECK FOR ACTIVE CONTROL CIRCUIT/PERFORMANCE DTCs

Turn the ignition on.

With the scan tool, read active HVAC DTCs.

Does the scan tool display any active: XXXX CONTROL CIRCUIT/PERFORMANCE DTCs?

Ye s>>

Diagnose and repair the DTC(s). Refer to the Table of Contents in this Section for a complete list of

HVAC related symptoms.

No>>

Go To 2

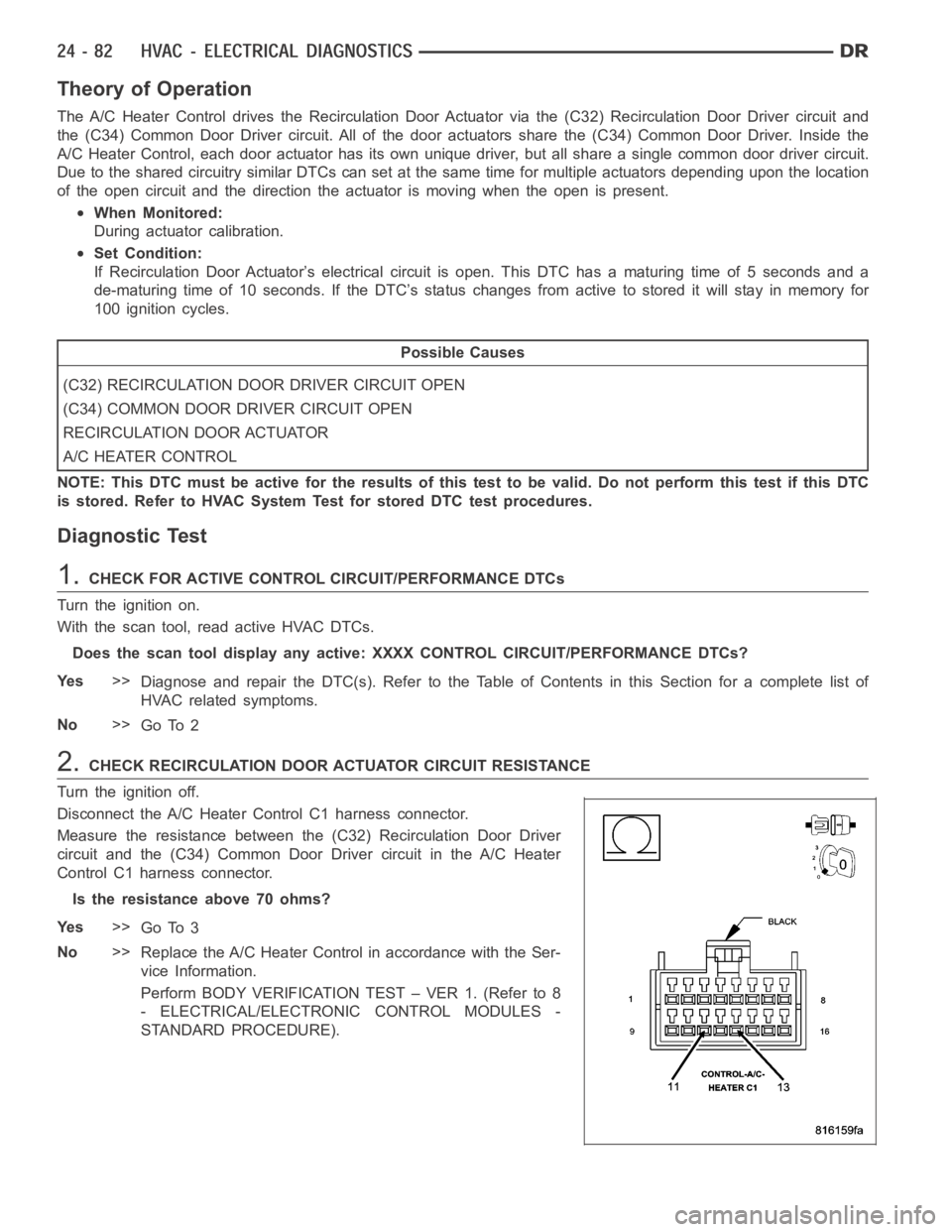

2.CHECK RECIRCULATION DOOR ACTUATOR CIRCUIT RESISTANCE

Turn the ignition off.

Disconnect the A/C Heater Control C1 harness connector.

Measure the resistance between the (C32) Recirculation Door Driver

circuit and the (C34) Common Door Driver circuit in the A/C Heater

Control C1 harness connector.

Is the resistance above 70 ohms?

Ye s>>

Go To 3

No>>

Replace the A/C Heater Control in accordance with the Ser-

vice Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).