change time DODGE RAM SRT-10 2006 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3745 of 5267

Theory of Operation

The transmission throttle valve cable has been replace by the transmission throttle valve actuator (TTVA). The TTVA

consists of an electric DC motor, two potentiometers, and a gear drive system. The TTVA is mechanically connected

to the transmission throttle valve in the valve body by the “D” shaped opening in the bottom of the TTVA shaft.

The Transmission Throttle Valve Actuator (TTVA) does not require any mechanical adjustments. All changes in throt-

tle valve position are controlled by the Engine Control Module (ECM).

The TTVA does require an initialization period after the actuator has beenremoved or replaced. After the actuator

has been removed or replaced, move the ignition to the ON position for thirty (30) seconds. This will allow the ECM

sufficient time to perform the internal calibration procedures to learn the TTVA’s current “zero” position.

When Monitored:

Continuously with the ignition on.

Set Condition:

The current detected on the TTVA circuit is greater than a threshold for a calibrated amount of time or the

feedback to the controller does not match the intended state.

Possible Causes

(F856) 5 VOLT SUPPLY CIRCUIT OPEN

(K314) TTVA MOTOR (+) CIRCUIT OPEN

(K315) TTVA MOTOR (-) CIRCUIT OPEN

(K314) TTVA MOTOR (+) CIRCUIT SHORT TO GROUND

(K315) TTVA MOTOR (-) CIRCUIT SHORT TO GROUND

(K314) TTVA MOTOR (+) CIRCUIT SHORT TO VOLTAGE

(K315) TTVA MOTOR (-) CIRCUIT SHORT TO VOLTAGE

(K314) TTVA MOTOR (+) CIRCUIT SHORT TO ANOTHER CIRCUIT

(K315) TTVA MOTOR (-) CIRCUIT SHORT TO ANOTHER CIRCUIT

INTERNAL TRANSMISSION

TRANSMISSION THROTTLE VALVE ACTUATOR

ENGINE CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Diagnostic Test

1.CHECK IF THE DTC IS CURRENT

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Record the Freeze Frame data for the reported DTC.

With the scan tool, erase DTCs.

Turn the ignition off to the lock position.

Using the Freeze Frame data recorded earlier, try to duplicate the conditions in which the DTC originally set.

NOTE: It may be necessary to road test the vehicle to duplicate the originalset conditions.

With the scan tool, read Engine DTCs.

Did the DTC reset?

Ye s>>

Go To 2

No>>

Go To 12

Page 3869 of 5267

OPERATION

Compensation is required for performance variations of two of the input devices. Though the slope of the transfer

functions is tightly controlled, offset may vary due to various environmental factors or manufacturing tolerances.

The pressure transducer is affected by barometric pressure as well as temperature. Calibration of the zero pressure

offset is required to compensate for shifting output due to these factors.

Normal calibration will be performed when sump temperature is above 50 degrees F, or in the absence of sump

temperature data, after the first 10 minutes of vehicle operation. Calibration of the pressure transducer offset occurs

each time the output shaft speed falls below 200 RPM. Calibration shall be repeated each 3 seconds the output

shaft speed is below 200 RPM. A 0.5 second pulse of 95% duty cycle is applied to the governor pressure solenoid

valve and the transducer output is read during this pulse. Averaging of thetransducer signal isnecessary to reject

electrical noise.

Under cold conditions (below 50 degrees F sump), the governor pressure solenoid valve response may be too slow

to guarantee 0 psi during the 0.5 second calibration pulse. Calibration pulses are continued during this period, how-

ever the transducer output valves are discarded. Transducer offset must be read at key-on, under conditions which

promote a stable reading. This value is retained and becomes the offset during the

coldperiod of operation.

GOVERNOR PRESSURE SOLENOID VALVE

The inlet side of the solenoid valve is exposed to normal transmission linepressure. The outlet side of the valve

leads to the valve body governor circuit.

The solenoid valve regulates line pressure to produce governor pressure.Theaveragecurrentsuppliedtothesole-

noid controls governor pressure. One amp current produces zero kPa/psi governor pressure. Zero amps sets the

maximum governor pressure.

The powertrain control module (PCM) turns on the trans control relay whichsupplies electrical power to the solenoid

valve. Operating voltage is 12 volts (DC). The PCM controls the ground sideof the solenoid using the governor

pressure solenoidcontrol circuit.

GOVERNOR PRESSURE SENSOR

The sensor output signal provides the necessary feedback to the PCM. This feedback is needed to adequately

control governor pressure.

GOVERNOR BODY AND TRANSFER PLATE

The transfer plate channels line pressure to the solenoid valve through the governor body. It also channels governor

pressure from the solenoid valve to the governor circuit. It is the solenoid valve that develops the necessary gov-

ernor pressure.

GOVERNOR PRESSURE CURVES

LOW TRANSMISSION FLUID TEMPERATURE

When the transmission fluid is cold the conventional governor can delay shifts, resulting in higher than normal shift

speeds and harsh shifts. The electronically controlled low temperature governor pressure curve is higher than nor-

mal to make the transmission shift at normal speeds and sooner. The PCM usesa temperature sensor in the trans-

mission oil sump to determine when low temperature governor pressure is needed.

NORMAL OPERATION

Normal operation is refined through the increased computing power of the PCM and through access to data on

engine operating conditions provided by the PCM that were not available with the previous stand-alone electronic

module. This facilitated the development of a load adaptive shift strategy - the ability to alter the shift schedule in

response to vehicle load condition. One manifestation of this capabilityis grade

huntingprevention - the ability of

the transmission logic to delay an upshift on a grade if the engine does not have sufficient power to maintain speed

in the higher gear. The 3-2 downshift and the potential for hunting betweengears occurs with a heavily loaded

vehicle or on steep grades. When hunting occurs, it is very objectionable because shifts are frequent and accom-

panied by large changes in noise and acceleration.

Page 3870 of 5267

WIDE OPEN THROTTLE OPERATION

In wide-open throttle (WOT) mode, adaptive memory in the PCM assures that up-shifts occur at the preprogrammed

optimum speed. WOT operation is determined from the throttle position sensor, which is also a part of the emission

control system. The initial setting for the WOT upshift is below the optimum engine speed. As WOT shifts are

repeated, the PCM learns the time required to complete the shifts by comparing the engine speed when the shifts

occur to the optimum speed. After each shift, the PCM adjusts the shift point until the optimum speed is reached.

The PCM also considers vehicle loading, grade and engine performance changes due to high altitude in determining

when to make WOT shifts. It does this by measuring vehicle and engine acceleration and then factoring in the shift

time.

TRANSFER CASE LOW RANGE OPERATION

On four-wheel drive vehicles operating in low range, the engine can accelerate to its peak more rapidly than in

Normal range, resulting in delayed shifts and undesirable engine

flare.The low range governor pressure curve is

also higher than normal to initiate upshifts sooner. The PCM compares electronic vehicle speed signal used by the

speedometer to the transmission output shaft speed signal to determine when the transfer case is in low range.

REMOVAL

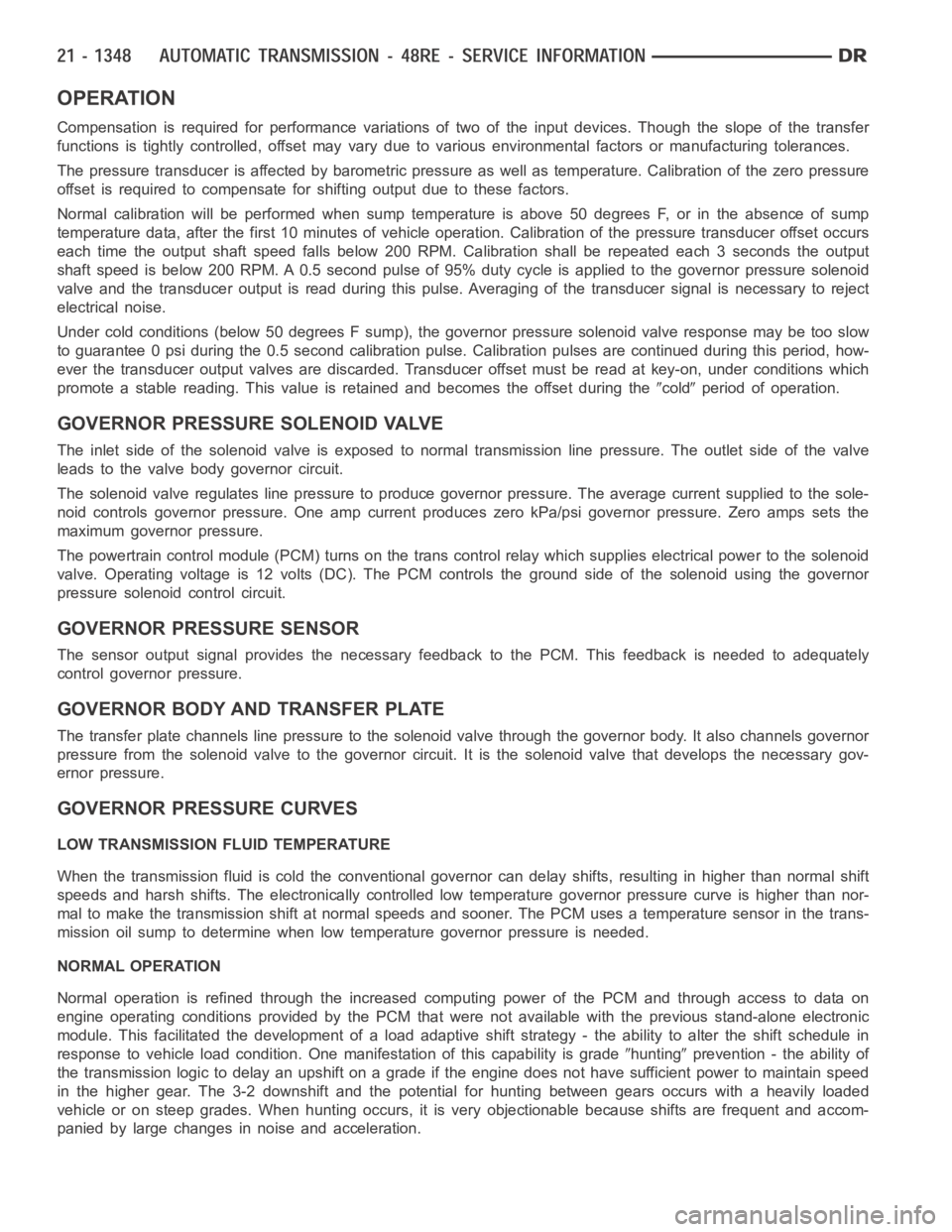

1. Hoist and support vehicle on safety stands.

2. Remove transmission fluid pan and filter.

3. Disengage wire connectors from pressure sensor

(1) and solenoid (2).

4. Remove screws holding pressure solenoid retainer

(1) to governor body (2).

5. Separate solenoid retainer from governor.

Page 3947 of 5267

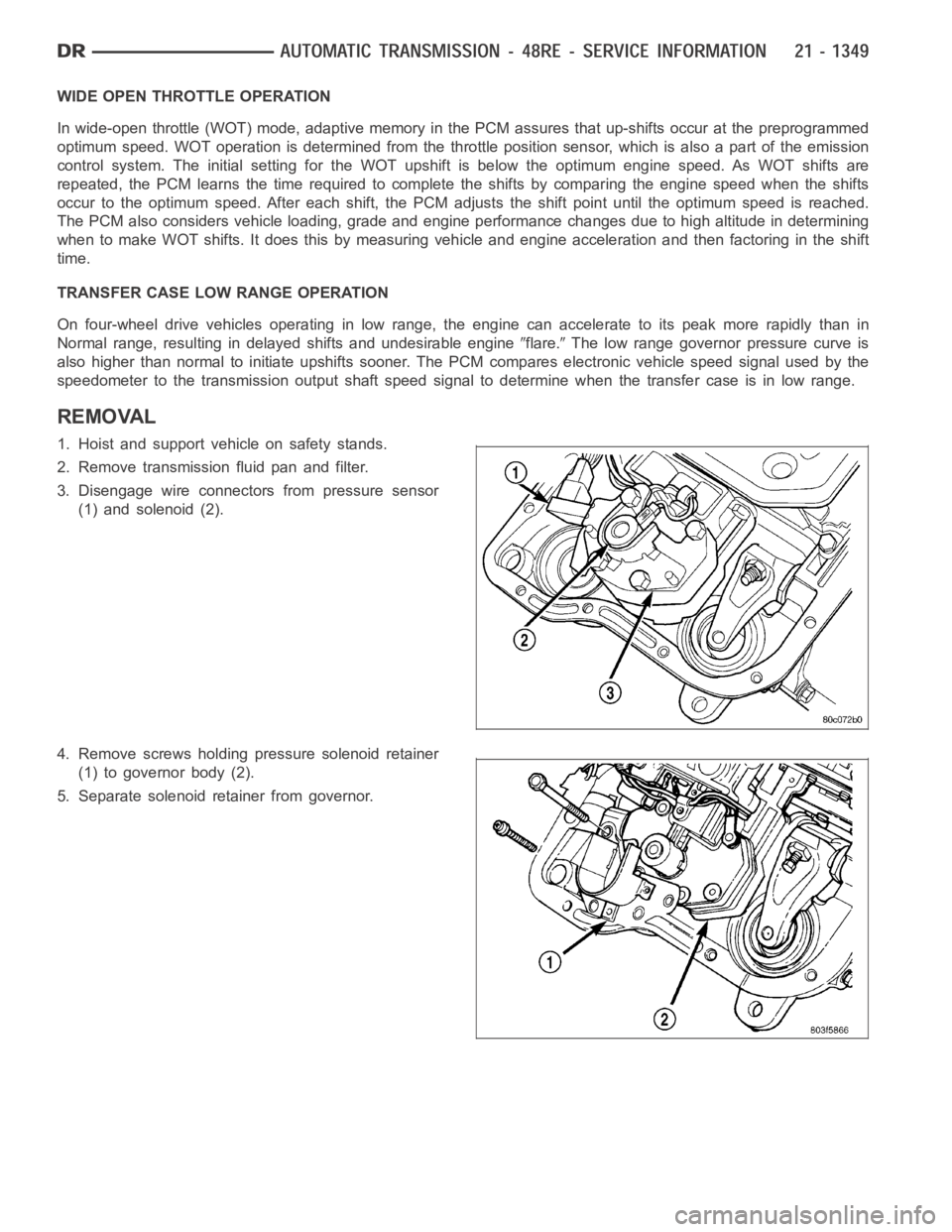

4. Rotate the TTVA (1) to the transmission case and

install the bolts (2) to hold the TTVA to the trans-

mission.

5. Tighten the bolts to 8.5 Nꞏm (75 in.lbs.).

6. Initialize the TTVA (Refer to 21 - TRANSMISSION/

AUTOMATIC - 48RE/THROTTLE VALVE ACTUA-

TOR - ADJUSTMENTS).

ADJUSTMENTS

ADJUSTMENT

The Transmission Throttle Valve Actuator (TTVA) does not require any mechanical adjustments. All changes in throt-

tle valve position are controlled by the Engine Control Module (ECM).

The TTVA does require an initialization period after the actuator has beenremoved or replaced. After the actuator

has been removed or replaced, move the iginition to the ON position for thirty (30) seconds. This will allow the ECM

sufficient time to perform the internal calibration procedures to learn the TTVA’s current “zero” position. Once this is

done, check the ECM for diagnostic trouble codes (DTCs). If no DTCs are set relating to the TTVA, the TTVA is fully

calibrated and ready for use.

Page 4026 of 5267

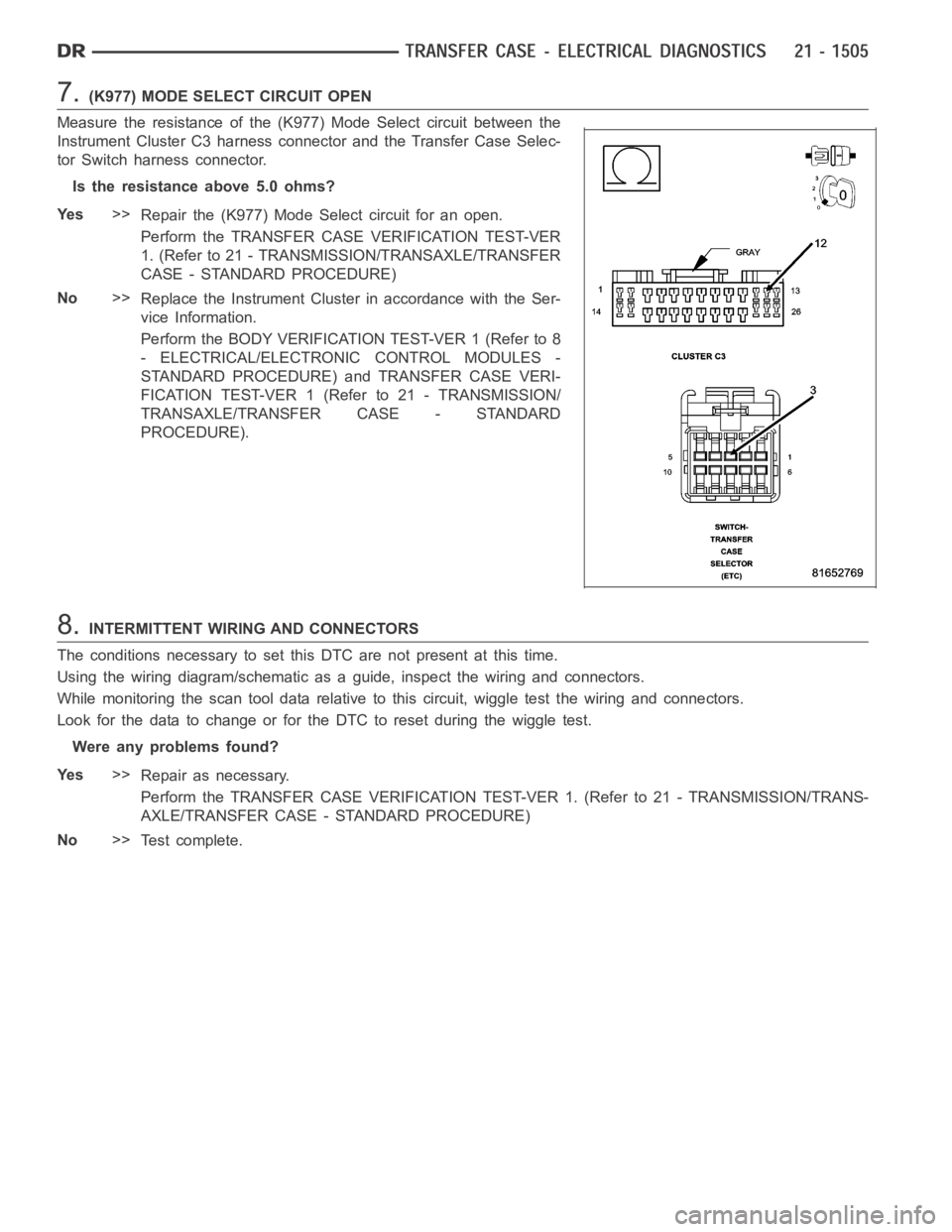

7.(K977) MODE SELECT CIRCUIT OPEN

Measure the resistance of the (K977) Mode Select circuit between the

Instrument Cluster C3 harness connector and the Transfer Case Selec-

tor Switch harness connector.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the (K977) Mode Select circuit for an open.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Replace the Instrument Cluster in accordance with the Ser-

vice Information.

Perform the BODY VERIFICATION TEST-VER 1 (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE) and TRANSFER CASE VERI-

FICATION TEST-VER 1 (Refer to 21 - TRANSMISSION/

TRANSAXLE/TRANSFER CASE - STANDARD

PROCEDURE).

8.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the TRANSFER CASE VERIFICATION TEST-VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/TRANSFER CASE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .

Page 4031 of 5267

7.INSTRUMENT CLUSTER

Repair

Replace the Instrument Cluster in accordance with the Service Information.

Perform the BODY VERIFICATION TEST-VER 1 (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE) and TRANSFER CASE VERIFICATION TEST-VER 1 (Refer to

21 - TRANSMISSION/TRANSAXLE/TRANSFER CASE - STANDARD PROCEDURE).

8.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the TRANSFER CASE VERIFICATION TEST-VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/TRANSFER CASE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .

Page 4035 of 5267

6.(D201) MODE SENSOR A CIRCUIT SHORTED TO GROUND

Measure the resistance between ground and the (D201) Mode Sensor A

circuit.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the (D201) Mode Sensor A circuit for a short to

ground.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go to 7

7.(D201) MODE SENSOR A CIRCUIT SHORTED TO (G180) TIPM SENSOR RETURN CIRCUIT

Measure the resistance between the (D201) Mode Sensor A circuit and

the (G180) TIPM Sensor Return circuit in the TIPM C4 harness connec-

tor.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the (D201) Mode Sensor A circuit for a short to the

(G180) TIPM Sensor Return circuit.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module in accordance

with the Service Information.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

8.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the TRANSFER CASE VERIFICATION TEST-VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/TRANSFER CASE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .

Page 4040 of 5267

7.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the TRANSFER CASE VERIFICATION TEST-VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/TRANSFER CASE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .

Page 4043 of 5267

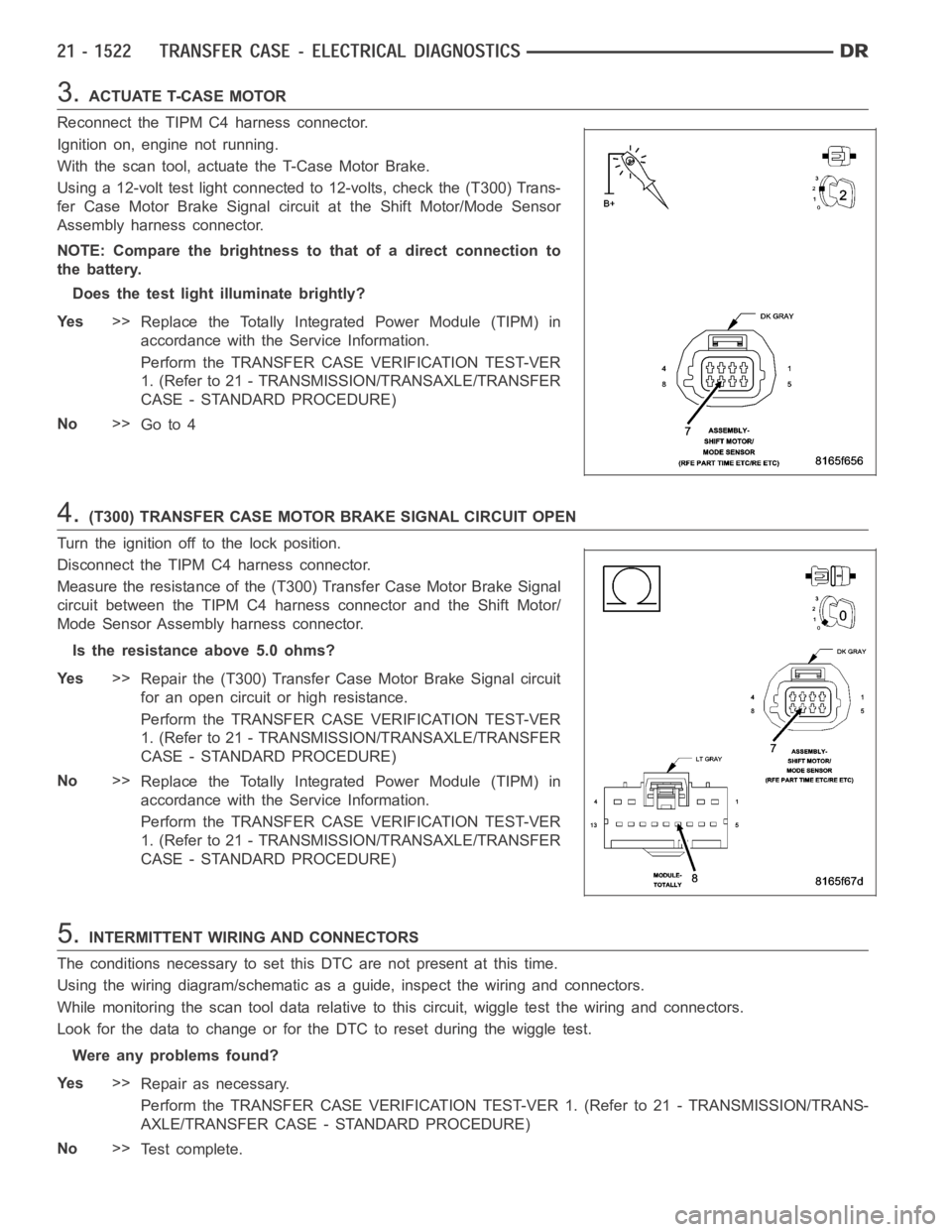

3.ACTUATE T-CASE MOTOR

Reconnect the TIPM C4 harness connector.

Ignition on, engine not running.

With the scan tool, actuate the T-Case Motor Brake.

Using a 12-volt test light connected to 12-volts, check the (T300) Trans-

fer Case Motor Brake Signal circuit at the Shift Motor/Mode Sensor

Assembly harness connector.

NOTE: Compare the brightness to that of a direct connection to

the battery.

Does the test light illuminate brightly?

Ye s>>

Replace the Totally Integrated Power Module (TIPM) in

accordance with the Service Information.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go to 4

4.(T300) TRANSFER CASE MOTOR BRAKE SIGNAL CIRCUIT OPEN

Turn the ignition off to the lock position.

Disconnect the TIPM C4 harness connector.

Measure the resistance of the (T300) Transfer Case Motor Brake Signal

circuit between the TIPM C4 harness connector and the Shift Motor/

Mode Sensor Assembly harness connector.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the (T300) Transfer Case Motor Brake Signal circuit

for an open circuit or high resistance.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module (TIPM) in

accordance with the Service Information.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

5.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the TRANSFER CASE VERIFICATION TEST-VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/TRANSFER CASE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .

Page 4046 of 5267

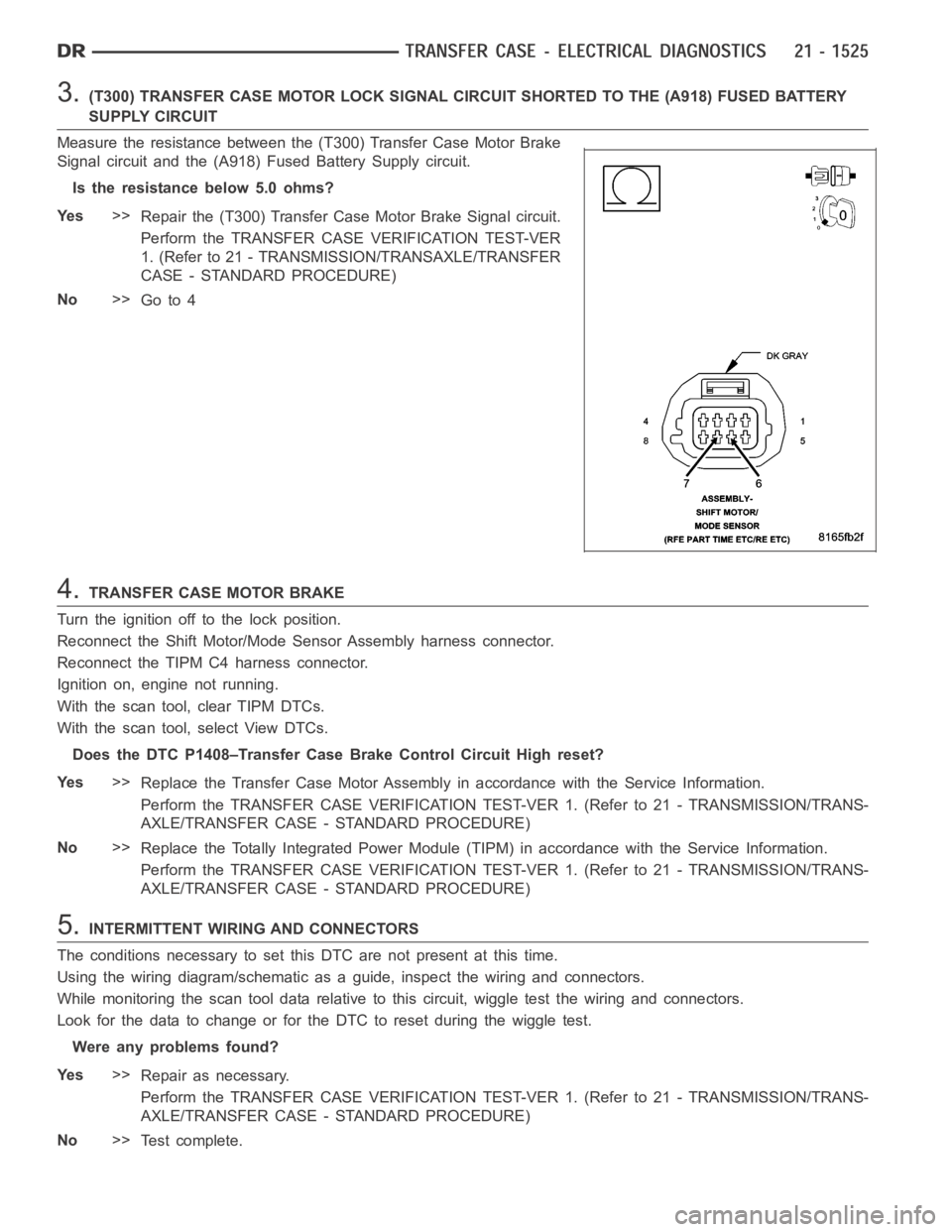

3.(T300) TRANSFER CASE MOTOR LOCK SIGNAL CIRCUIT SHORTED TO THE (A918) FUSEDBATTERY

SUPPLY CIRCUIT

Measure the resistance between the (T300) Transfer Case Motor Brake

Signal circuit and the (A918) Fused Battery Supply circuit.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the (T300) Transfer Case Motor Brake Signal circuit.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go to 4

4.TRANSFER CASE MOTOR BRAKE

Turn the ignition off to the lock position.

Reconnect the Shift Motor/Mode Sensor Assembly harness connector.

Reconnect the TIPM C4 harness connector.

Ignition on, engine not running.

With the scan tool, clear TIPM DTCs.

With the scan tool, select View DTCs.

Does the DTC P1408–Transfer Case Brake Control Circuit High reset?

Ye s>>

Replace the Transfer Case Motor Assembly in accordance with the Service Information.

Perform the TRANSFER CASE VERIFICATION TEST-VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/TRANSFER CASE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module (TIPM) in accordance with theService Information.

Perform the TRANSFER CASE VERIFICATION TEST-VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/TRANSFER CASE - STANDARD PROCEDURE)

5.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the TRANSFER CASE VERIFICATION TEST-VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/TRANSFER CASE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .