change time DODGE RAM SRT-10 2006 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3693 of 5267

Theory of Operation

The 3-4 Solenoid is used the engage the gear change from 3rd gear to 4th gear.

The solenoids used in transmission applications are attached to valves which can be classified as normally open or

normally closed. The normally open solenoid valve is defined as a valve which allows hydraulic flow when no cur-

rent or voltage is applied to the solenoid. The normally closed solenoid valve is defined as a valve which does not

allow hydraulic flow when no current or voltage is applied to the solenoid.These valves perform hydraulic control

functions for the transmission and must therefore be durable and tolerantof dirt particles. For these reasons, the

valves have hardened steel poppets and ball valves. The solenoids operatethe valves directly, which means that

the solenoids must have very high outputs to close the valves against the sizable flow areas and line pressures

found in current transmissions. Fastresponse time is also necessary to ensure accurate control.

When Monitored:

Continuously with ignition on.

Set Condition:

This code will set if the voltage detected on the 3-4 Shift Solenoid Controlcircuit at the ECM is different then

the expected voltage. Note: To clear this DTC it is necessary to drive the vehicle at a sustained speed which

would allow the TCC and/or Overdrive Clutch to operate

Possible Causes

TRANSMISSION CONTROL DTC PRESENT

(T9) 3-4 SOLENOID CONTROL CIRCUIT SHORT TO VOLTAGE

(T9) 3-4 SOLENOID CONTROL CIRCUIT SHORT TO ANOTHER CIRCUIT

3-4 SOLENOID

ENGINE CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Diagnostic Test

1.CHECK IF ANY TRANSMISSION CONTROL DTCS ARE PRESENT

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Are there any Transmission Control DTC’s present?

Ye s>>

Refer to the Transmission category, (Refer to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 48RE

- DIAGNOSIS AND TESTING) and perform the appropriate symptom(s).

No>>

Go To 2

2.CHECK IF THE DTC IS CURRENT

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Record the Freeze Frame data for the reported DTC.

With the scan tool, erase DTCs.

Turn the ignition off to the lock position.

Using the Freeze Frame data recorded earlier, try to duplicate the conditions in which the DTC originally set.

NOTE: It may be necessary to road test the vehicle to duplicate the originalset conditions.

With the scan tool, read Engine DTCs.

Did the DTC reset?

Ye s>>

Go To 3

No>>

Go To 7

Page 3699 of 5267

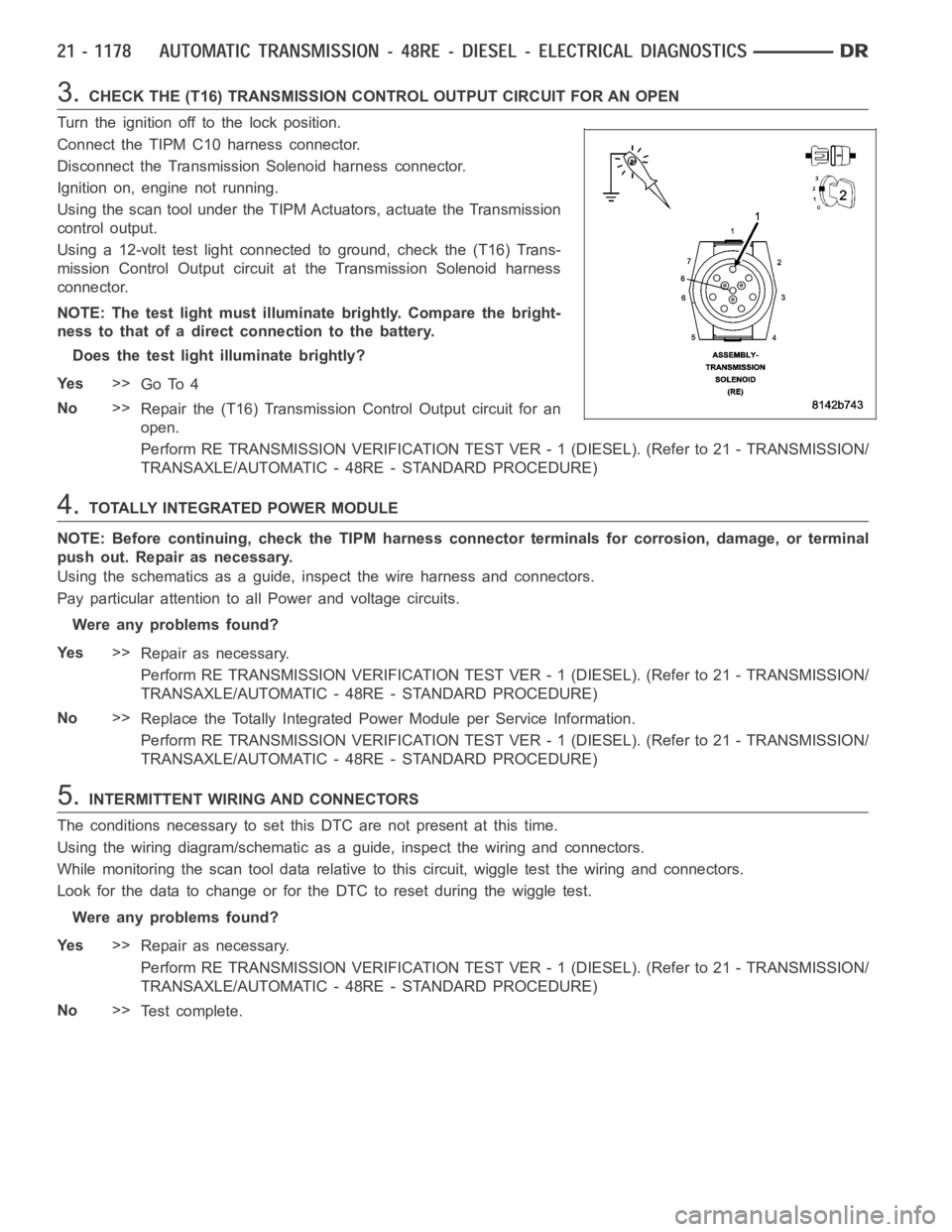

3.CHECK THE (T16) TRANSMISSION CONTROL OUTPUT CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Connect the TIPM C10 harness connector.

Disconnect the Transmission Solenoid harness connector.

Ignition on, engine not running.

Using the scan tool under the TIPM Actuators, actuate the Transmission

control output.

Using a 12-volt test light connected to ground, check the (T16) Trans-

mission Control Output circuit at the Transmission Solenoid harness

connector.

NOTE: The test light must illuminate brightly. Compare the bright-

ness to that of a direct connection to the battery.

Does the test light illuminate brightly?

Ye s>>

Go To 4

No>>

Repair the (T16) Transmission Control Output circuit for an

open.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (DIESEL). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

4.TOTALLY INTEGRATED POWER MODULE

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to allPower and voltage circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (DIESEL). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (DIESEL). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

5.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (DIESEL). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .

Page 3702 of 5267

3.TOTALLY INTEGRATED POWER MODULE

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to allPower and voltage circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (DIESEL). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (DIESEL). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

4.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (DIESEL). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .

Page 3705 of 5267

4.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (DIESEL). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .

Page 3716 of 5267

Theory of Operation

The transmission throttle valve cable has been replace by the transmission throttle valve actuator (TTVA). The TTVA

consists of an electric DC motor, two potentiometers, and a gear drive system. The TTVA is mechanically connected

to the transmission throttle valve in the valve body by the “D” shaped opening in the bottom of the TTVA shaft.

The Transmission Throttle Valve Actuator (TTVA) does not require any mechanical adjustments. All changes in throt-

tle valve position are controlled by the Engine Control Module (ECM).

The TTVA does require an initialization period after the actuator has beenremoved or replaced. After the actuator

has been removed or replaced, move the ignition to the ON position for thirty (30) seconds. This will allow the ECM

sufficient time to perform the internal calibration procedures to learn the TTVA’s current “zero” position.

When Monitored:

Continuously with the ignition on.

Set Condition:

When the Engine Control Module (ECM) detects the monitored Transmission Throttle Valve Position Sensor

voltage drops below a predetermined value.

Possible Causes

(K312) TTVA POSITION SENSOR SIGNAL CIRCUIT OPEN

(K312) TTVA POSITION SENSOR SIGNAL CIRCUIT SHORT TO GROUND

(K312) TTVA POSITION SENSOR SIGNAL CIRCUIT SHORT TO ANOTHER CIRCUIT

(F856) 5 VOLT SUPPLY CIRCUIT OPEN

(F856) 5 VOLT SUPPLY CIRCUIT SHORT TO GROUND

(F856) 5 VOLT SUPPLY CIRCUIT SHORT TO ANOTHER CIRCUIT

TRANSMISSION THROTTLE VALVE ACTUATOR

ENGINE CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Diagnostic Test

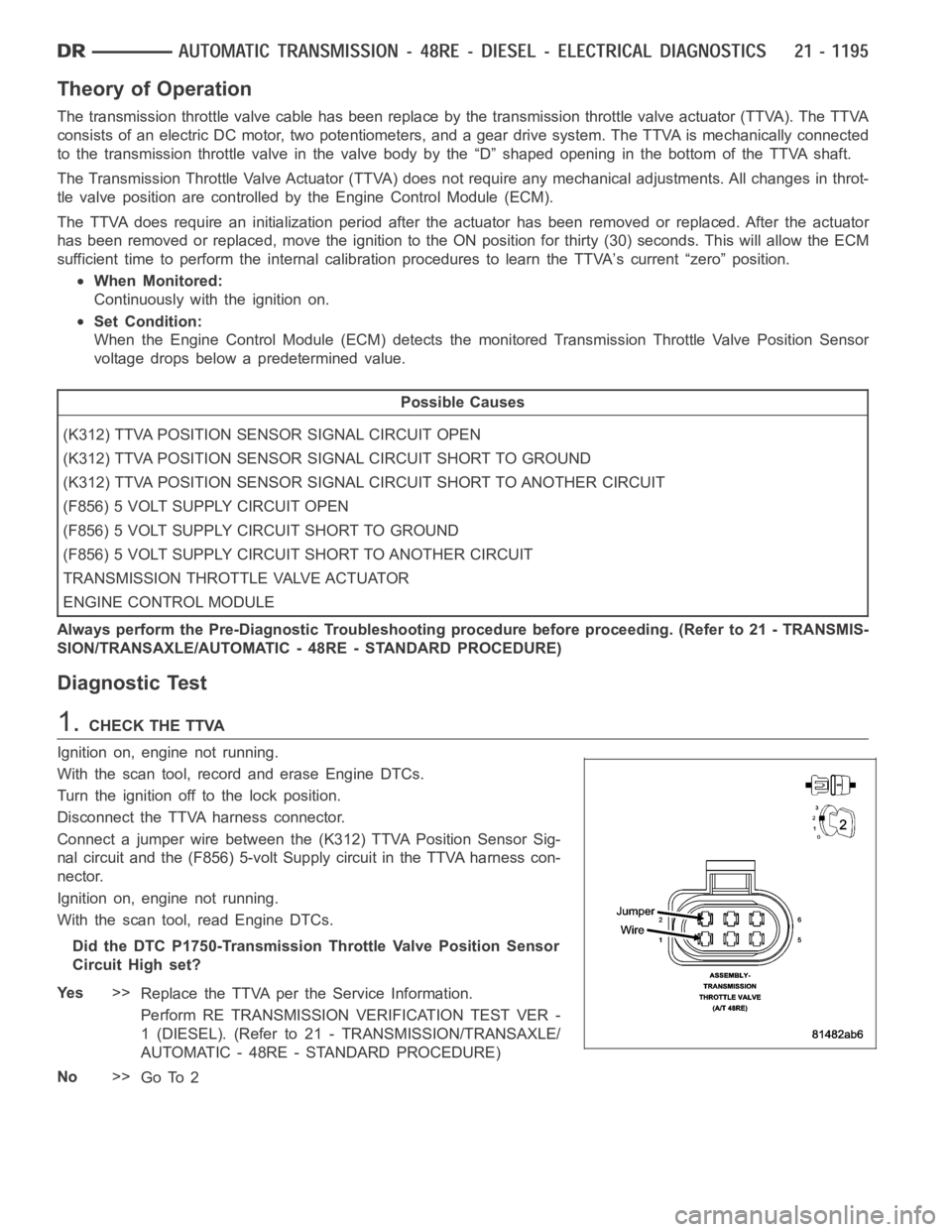

1.CHECK THE TTVA

Ignition on, engine not running.

With the scan tool, record and erase Engine DTCs.

Turn the ignition off to the lock position.

Disconnect the TTVA harness connector.

Connect a jumper wire between the (K312) TTVA Position Sensor Sig-

nal circuit and the (F856) 5-volt Supply circuit in the TTVA harness con-

nector.

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Did the DTC P1750-Transmission Throttle Valve Position Sensor

Circuit High set?

Ye s>>

Replace the TTVA per the Service Information.

Perform RE TRANSMISSION VERIFICATION TEST VER -

1 (DIESEL). (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Go To 2

Page 3722 of 5267

Theory of Operation

The transmission throttle valve cable has been replace by the transmission throttle valve actuator (TTVA). The TTVA

consists of an electric DC motor, two potentiometers, and a gear drive system. The TTVA is mechanically connected

to the transmission throttle valve in the valve body by the “D” shaped opening in the bottom of the TTVA shaft.

The Transmission Throttle Valve Actuator (TTVA) does not require any mechanical adjustments. All changes in throt-

tle valve position are controlled by the Engine Control Module (ECM).

The TTVA does require an initialization period after the actuator has beenremoved or replaced. After the actuator

has been removed or replaced, move the ignition to the ON position for thirty (30) seconds. This will allow the ECM

sufficient time to perform the internal calibration procedures to learn the TTVA’s current “zero” position.

When Monitored:

Continuously with the ignition on.

Set Condition:

When the Engine Control Module (ECM) detects the monitored Transmission Throttle Valve Position Sensor

voltage rises above a predetermined value.

Possible Causes

(K312) TTVA POSITION SENSOR SIGNAL CIRCUIT SHORT TO VOLTAGE

(K312) TTVA POSITION SENSOR SIGNAL CIRCUIT SHORT TO ANOTHER CIRCUIT

(K900) SENSOR GROUND CIRCUIT OPEN

TRANSMISSION THROTTLE VALVE ACTUATOR

ENGINE CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Diagnostic Test

1.CHECK IF THE DTC IS CURRENT

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Record the Freeze Frame data for the reported DTC.

With the scan tool, erase DTCs.

Turn the ignition off to the lock position.

Using the Freeze Frame data recorded earlier, try to duplicate the conditions in which the DTC originally set.

NOTE: It may be necessary to road test the vehicle to duplicate the originalset conditions.

With the scan tool, read Engine DTCs.

Did the DTC reset?

Ye s>>

Go To 2

No>>

Go To 7

2.CHECK THE TTVA

With the scan tool, record and erase Engine DTCs.

Turn the ignition off to the lock position.

Disconnect the TTVA harness connector.

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Did the DTC Transmission Throttle Valve Position Sensor Circuit High set?

Ye s>>

Go To 4

No>>

Go To 3

Page 3727 of 5267

For a complete wiring diagramRefer to Section 8W

Theory of Operation

The transmission throttle valve cable has been replace by the transmission throttle valve actuator (TTVA). The TTVA

consists of an electric DC motor, two potentiometers, and a gear drive system. The TTVA is mechanically connected

to the transmission throttle valve in the valve body by the “D” shaped opening in the bottom of the TTVA shaft.

The Transmission Throttle Valve Actuator (TTVA) does not require any mechanical adjustments. All changes in throt-

tle valve position are controlled by the Engine Control Module (ECM).

The TTVA does require an initialization period after the actuator has beenremoved or replaced. After the actuator

has been removed or replaced, move the ignition to the ON position for thirty (30) seconds. This will allow the ECM

sufficient time to perform the internal calibration procedures to learn the TTVA’s current “zero” position.

When Monitored:

Ignition on and with or without engine running with transmission in the park or neutral position. Note: Not mon-

itored when either the engine is cranking or while vehicle is moving.

Set Condition:

Each time the ignition is cycled to the on position, the ECM commands a TTVA internal calibration procedure

(autozero) to determine the zero position. If the TTVA does not reach a calibrated minimum position in a pre-

determined amount of time, the DTC will set.

Possible Causes

TRANSMISSION THROTTLE VALVE ACTUATOR BINDING

TRANSMISSION THROTTLE VALVE COMPONENTS

TRANSMISSION THROTTLE VALVE ACTUATOR

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Diagnostic Test

1.CHECK IF THE DTC IS CURRENT

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Record the Freeze Frame data for the reported DTC.

With the scan tool, erase DTCs.

Turn the ignition off to the lock position.

Using the Freeze Frame data recorded earlier, try to duplicate the conditions in which the DTC originally set.

NOTE: It may be necessary to road test the vehicle to duplicate the originalset conditions.

With the scan tool, read Engine DTCs.

Did the DTC reset?

Ye s>>

Go To 2

No>>

Go To 5

Page 3730 of 5267

Theory of Operation

The transmission throttle valve cable has been replace by the transmission throttle valve actuator (TTVA). The TTVA

consists of an electric DC motor, two potentiometers, and a gear drive system. The TTVA is mechanically connected

to the transmission throttle valve in the valve body by the “D” shaped opening in the bottom of the TTVA shaft.

The Transmission Throttle Valve Actuator (TTVA) does not require any mechanical adjustments. All changes in throt-

tle valve position are controlled by the Engine Control Module (ECM).

The TTVA does require an initialization period after the actuator has beenremoved or replaced. After the actuator

has been removed or replaced, move the ignition to the ON position for thirty (30) seconds. This will allow the ECM

sufficient time to perform the internal calibration procedures to learn the TTVA’s current “zero” position.

When Monitored:

Ignition on and with or without engine running with transmission in the park or neutral position. Note: Not mon-

itored when either the engine is cranking or while vehicle is moving.

Set Condition:

Each time the ignition is cycled to the on position, the ECM commands a TTVA internal calibration procedure

(autozero) to determine the zero position. After completion of the autozero procedure, the TTVA is instructed to

perform a span check to record the minimum and maximum span positions. ThisDTC will set if the minimum

total span is not achieved.

Possible Causes

TRANSMISSION THROTTLE VALVE ACTUATOR BINDING

TRANSMISSION THROTTLE VALVE

INTERNAL TRANSMISSION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Diagnostic Test

1.CHECK IF THE DTC IS CURRENT

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Record the Freeze Frame data for the reported DTC.

With the scan tool, erase DTCs.

Turn the ignition off to the lock position.

Using the Freeze Frame data recorded earlier, try to duplicate the conditions in which the DTC originally set.

NOTE: It may be necessary to road test the vehicle to duplicate the originalset conditions.

With the scan tool, read Engine DTCs.

Did the DTC reset?

Ye s>>

Go To 2

No>>

Go To 5

2.CHECK TTVA FOR SIGNS OF DAMAGE

Turn the ignition off to the lock position.

Visually inspect the TTVA shaft for any signs of external damage or improperly mounted.

NOTE: It is not necessary to remove the TTVA to perform this procedure.

Is the TTVA damaged or improperly mounted?

Ye s>>

Repair as necessary.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (DIESEL). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Go To 3

Page 3733 of 5267

Theory of Operation

The transmission throttle valve cable has been replace by the transmission throttle valve actuator (TTVA). The TTVA

consists of an electric DC motor, two potentiometers, and a gear drive system. The TTVA is mechanically connected

to the transmission throttle valve in the valve body by the “D” shaped opening in the bottom of the TTVA shaft.

The Transmission Throttle Valve Actuator (TTVA) does not require any mechanical adjustments. All changes in throt-

tle valve position are controlled by the Engine Control Module (ECM).

The TTVA does require an initialization period after the actuator has beenremoved or replaced. After the actuator

has been removed or replaced, move the ignition to the ON position for thirty (30) seconds. This will allow the ECM

sufficient time to perform the internal calibration procedures to learn the TTVA’s current “zero” position.

When Monitored:

Ignition on, engine running in a valid forward gear with a throttle openinggreater than 50% and the transmis-

sion in overdrive.

Set Condition:

When the Governor pressure is below a minimum threshold when conditions indicate that the Governor pres-

sure should be high. This DTC indicates that the TTVA is working properly electronically but mechanically the

output shaft is not moving the Throttle Valve in the transmission.

Possible Causes

BROKEN OR STRIPPED LINKAGE BETWEEN THE TTVA OUTPUT SHAFT AND THE THROTTLE VALVE

TRANSMISSION THROTTLE VALVE ACTUATOR

TRANSMISSION THROTTLE VALVE COMPONENTS

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Diagnostic Test

1.CHECK FOR GOVERNOR PRESSURE DTCS

Ignition on, engine not running.

With the scan tool, check Engine DTCs.

Are there any Governor Pressure related DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom(s).

No>>

Go To 2

2.CHECK TTVA FOR SIGNS OF DAMAGE

Turn the ignition off to the lock position.

Visually inspect the TTVA shaft for any signs of external damage or improperly mounted.

NOTE: It is not necessary to remove the TTVA to perform this procedure.

Is the TTVA damaged or improperly mounted?

Ye s>>

Repair as necessary.

Perform RE TRANSMISSION VERIFICATION TEST VER - 1 (DIESEL). (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

No>>

Go To 3

Page 3736 of 5267

Theory of Operation

The transmission throttle valve cable has been replace by the transmission throttle valve actuator (TTVA). The TTVA

consists of an electric DC motor, two potentiometers, and a gear drive system. The TTVA is mechanically connected

to the transmission throttle valve in the valve body by the “D” shaped opening in the bottom of the TTVA shaft.

The Transmission Throttle Valve Actuator (TTVA) does not require any mechanical adjustments. All changes in throt-

tle valve position are controlled by the Engine Control Module (ECM).

The TTVA does require an initialization period after the actuator has beenremoved or replaced. After the actuator

has been removed or replaced, move the ignition to the ON position for thirty (30) seconds. This will allow the ECM

sufficient time to perform the internal calibration procedures to learn the TTVA’s current “zero” position.

When Monitored:

Continuously with the ignition on.

Set Condition:

The monitored TTVA position sensor does not indicate a change in position when the TTVA is commanded to

change the position.

Possible Causes

(F856) 5 VOLT SUPPLY CIRCUIT OPEN

(K314) TTVA MOTOR (+) CIRCUIT OPEN

(K315) TTVA MOTOR (-) CIRCUIT OPEN

(K314) TTVA MOTOR (+) CIRCUIT SHORT TO GROUND

(K315) TTVA MOTOR (-) CIRCUIT SHORT TO GROUND

(K314) TTVA MOTOR (+) CIRCUIT SHORT TO VOLTAGE

(K315) TTVA MOTOR (-) CIRCUIT SHORT TO VOLTAGE

(K314) TTVA MOTOR (+) CIRCUIT SHORT TO ANOTHER CIRCUIT

(K315) TTVA MOTOR (-) CIRCUIT SHORT TO ANOTHER CIRCUIT

TRANSMISSION THROTTLE VALVE COMPONENTS

TRANSMISSION THROTTLE VALVE ACTUATOR

ENGINE CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Diagnostic Test

1.CHECK IF THE DTC IS CURRENT

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Record the Freeze Frame data for the reported DTC.

With the scan tool, erase DTCs.

Turn the ignition off to the lock position.

Using the Freeze Frame data recorded earlier, try to duplicate the conditions in which the DTC originally set.

NOTE: It may be necessary to road test the vehicle to duplicate the originalset conditions.

With the scan tool, read Engine DTCs.

Did the DTC reset?

Ye s>>

Go To 2

No>>

Go To 16