ignition DODGE RAM SRT-10 2006 Service Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 150 of 5267

When Monitored:

Ignition on.

Set Condition:

When the PCM recognizes the Primary 5-volt Supply circuit voltage is varying too much too quickly. One Trip

Fault. ETC light is flashing.

Possible Causes

(F855) PRIMARY 5-VOLT SUPPLY SHORTED TO GROUND

(F855) PRIMARY 5-VOLT SUPPLY SHORTED TO BATTERY VOLTAGE

(F855) PRIMARY 5-VOLT SUPPLY CIRCUIT OPEN

5-VOLT SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

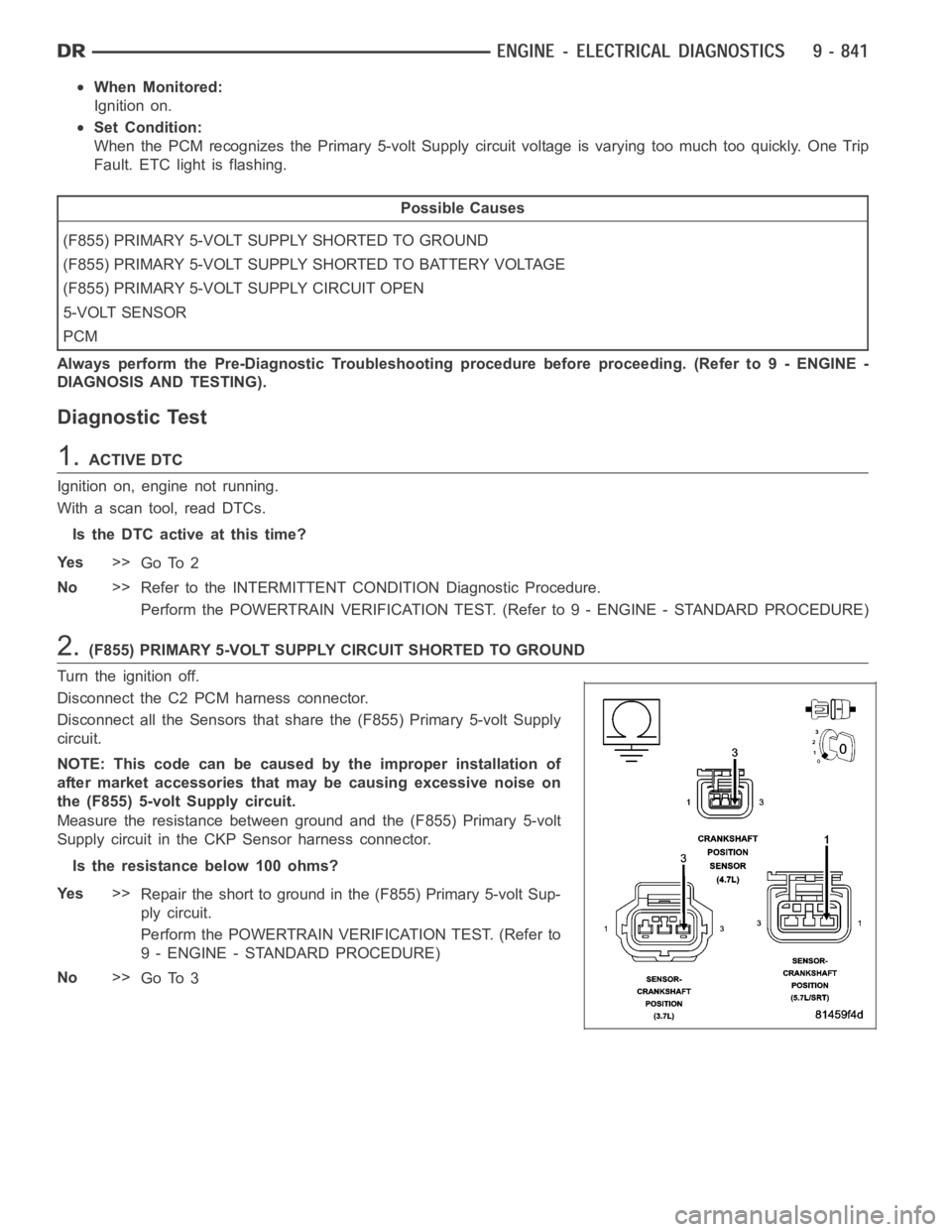

2.(F855) PRIMARY 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

Turn the ignition off.

Disconnect the C2 PCM harness connector.

Disconnect all the Sensors that share the (F855) Primary 5-volt Supply

circuit.

NOTE: This code can be caused by the improper installation of

after market accessories that may be causing excessive noise on

the (F855) 5-volt Supply circuit.

Measure the resistance between ground and the (F855) Primary 5-volt

Supply circuit in the CKP Sensor harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (F855) Primary 5-volt Sup-

ply circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 151 of 5267

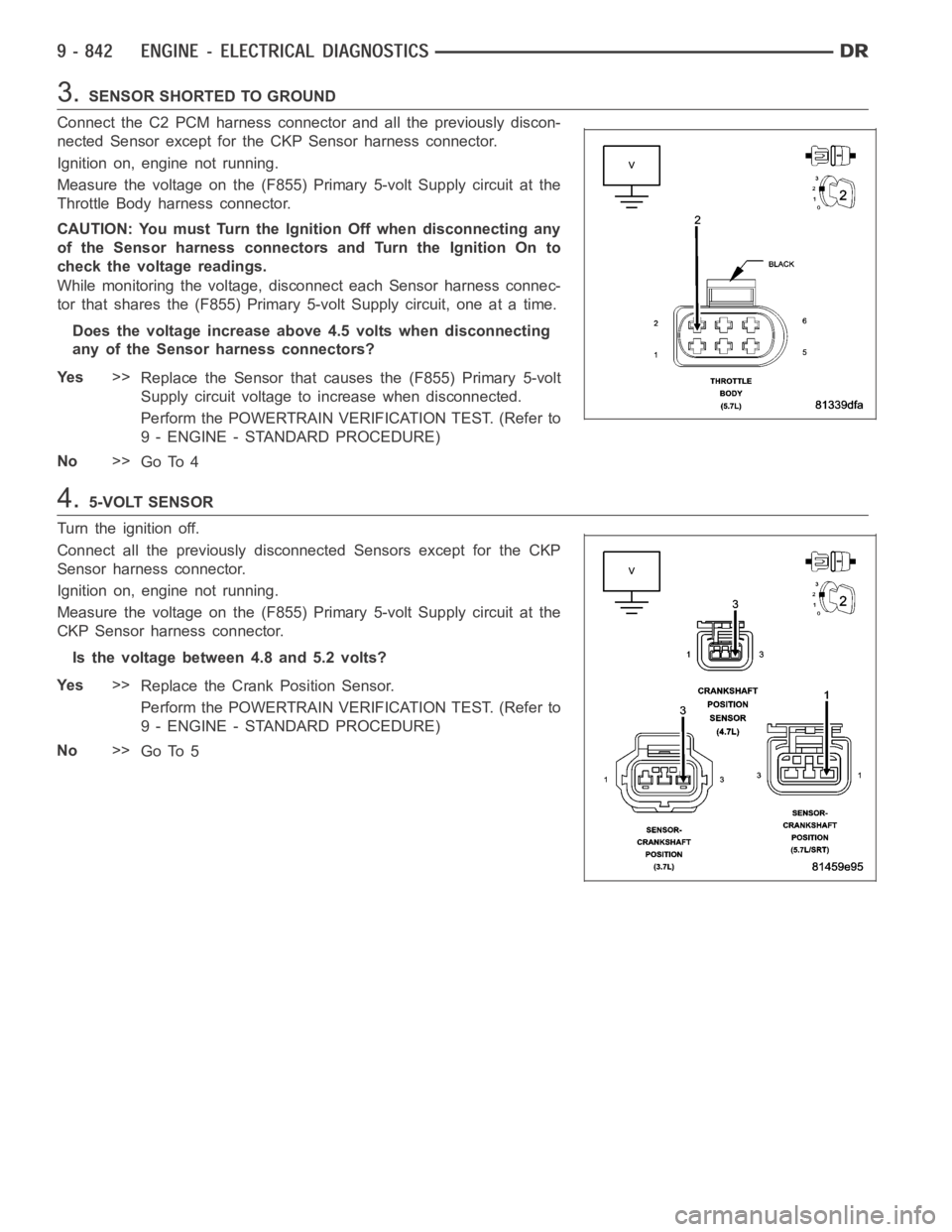

3.SENSOR SHORTED TO GROUND

Connect the C2 PCM harness connector and all the previously discon-

nected Sensor except for the CKP Sensor harness connector.

Ignition on, engine not running.

Measure the voltage on the (F855) Primary 5-volt Supply circuit at the

Throttle Body harness connector.

CAUTION: You must Turn the Ignition Off when disconnecting any

of the Sensor harness connectors and Turn the Ignition On to

check the voltage readings.

While monitoring the voltage, disconnect each Sensor harness connec-

tor that shares the (F855) Primary 5-volt Supply circuit, one at a time.

Does the voltage increase above 4.5 volts when disconnecting

any of the Sensor harness connectors?

Ye s>>

Replace the Sensor that causes the (F855) Primary 5-volt

Supply circuit voltage to increase when disconnected.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

4.5-VOLT SENSOR

Turn the ignition off.

Connect all the previously disconnected Sensors except for the CKP

Sensor harness connector.

Ignition on, engine not running.

Measure the voltage on the (F855) Primary 5-volt Supply circuit at the

CKP Sensor harness connector.

Is the voltage between 4.8 and 5.2 volts?

Ye s>>

Replace the Crank Position Sensor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

Page 152 of 5267

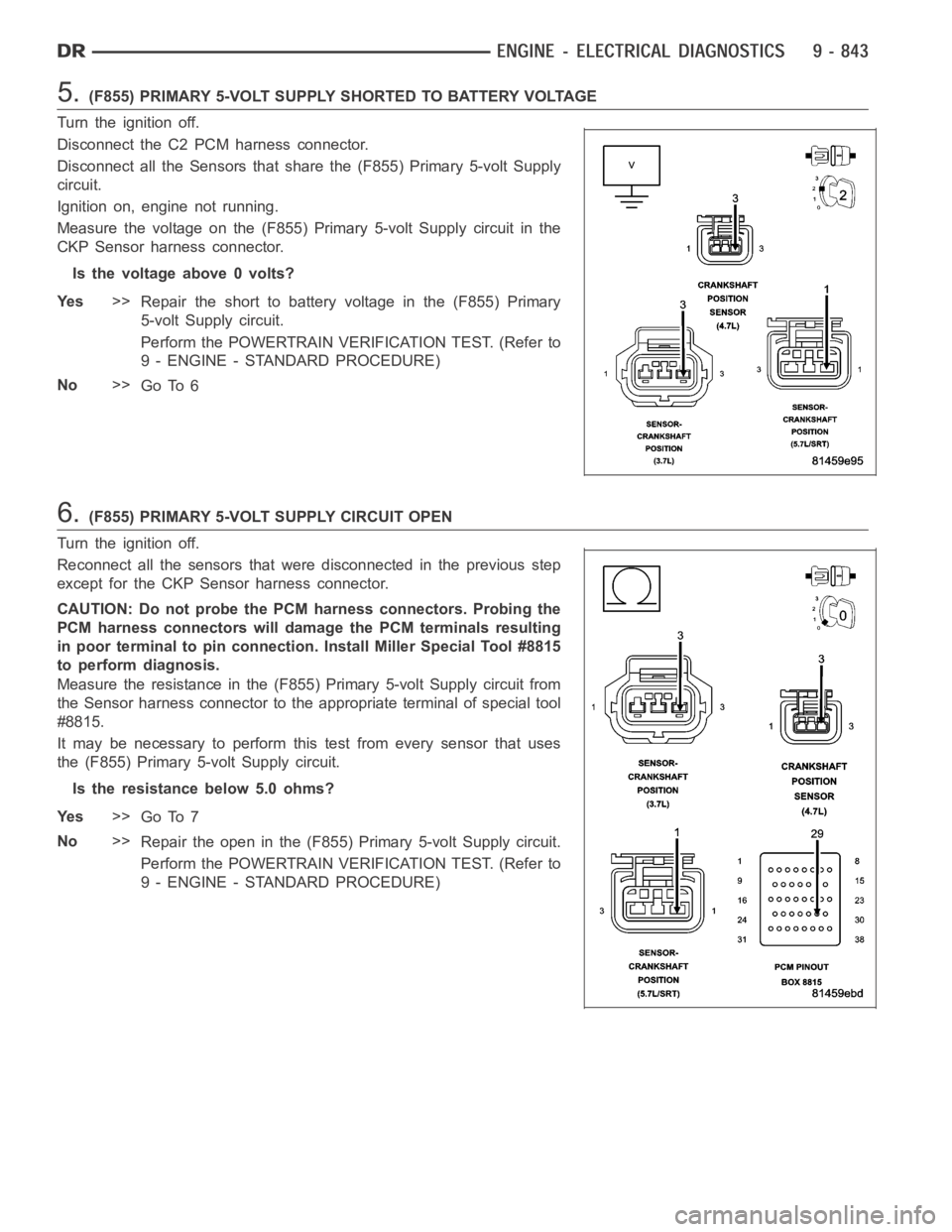

5.(F855) PRIMARY 5-VOLT SUPPLY SHORTED TO BATTERY VOLTAGE

Turn the ignition off.

Disconnect the C2 PCM harness connector.

Disconnect all the Sensors that share the (F855) Primary 5-volt Supply

circuit.

Ignition on, engine not running.

Measure the voltage on the (F855) Primary 5-volt Supply circuit in the

CKP Sensor harness connector.

Is the voltage above 0 volts?

Ye s>>

Repair the short to battery voltage in the (F855) Primary

5-volt Supply circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 6

6.(F855) PRIMARY 5-VOLT SUPPLY CIRCUIT OPEN

Turn the ignition off.

Reconnect all the sensors that were disconnected in the previous step

except for the CKP Sensor harness connector.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller Special Tool #8815

to perform diagnosis.

Measure the resistance in the (F855) Primary 5-volt Supply circuit from

the Sensor harness connector to the appropriate terminal of special tool

#8815.

It may be necessary to perform this test from every sensor that uses

the (F855) Primary 5-volt Supply circuit.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 7

No>>

Repair the open in the (F855) Primary 5-volt Supply circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 155 of 5267

When Monitored:

Ignition on.

Set Condition:

When the PCM recognizes the Auxiliary 5-volt Supply circuit voltage is varying too much too quickly. One Trip

Fault. ETC light is flashing.

Possible Causes

(F856) AUXILIARY 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

(F856) AUXILIARY 5-VOLT SUPPLY CIRCUIT SHORTED TO BATTERY VOLTAGE

(F856) AUXILIARY 5-VOLT SUPPLY CIRCUIT OPEN

5-VOLT SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

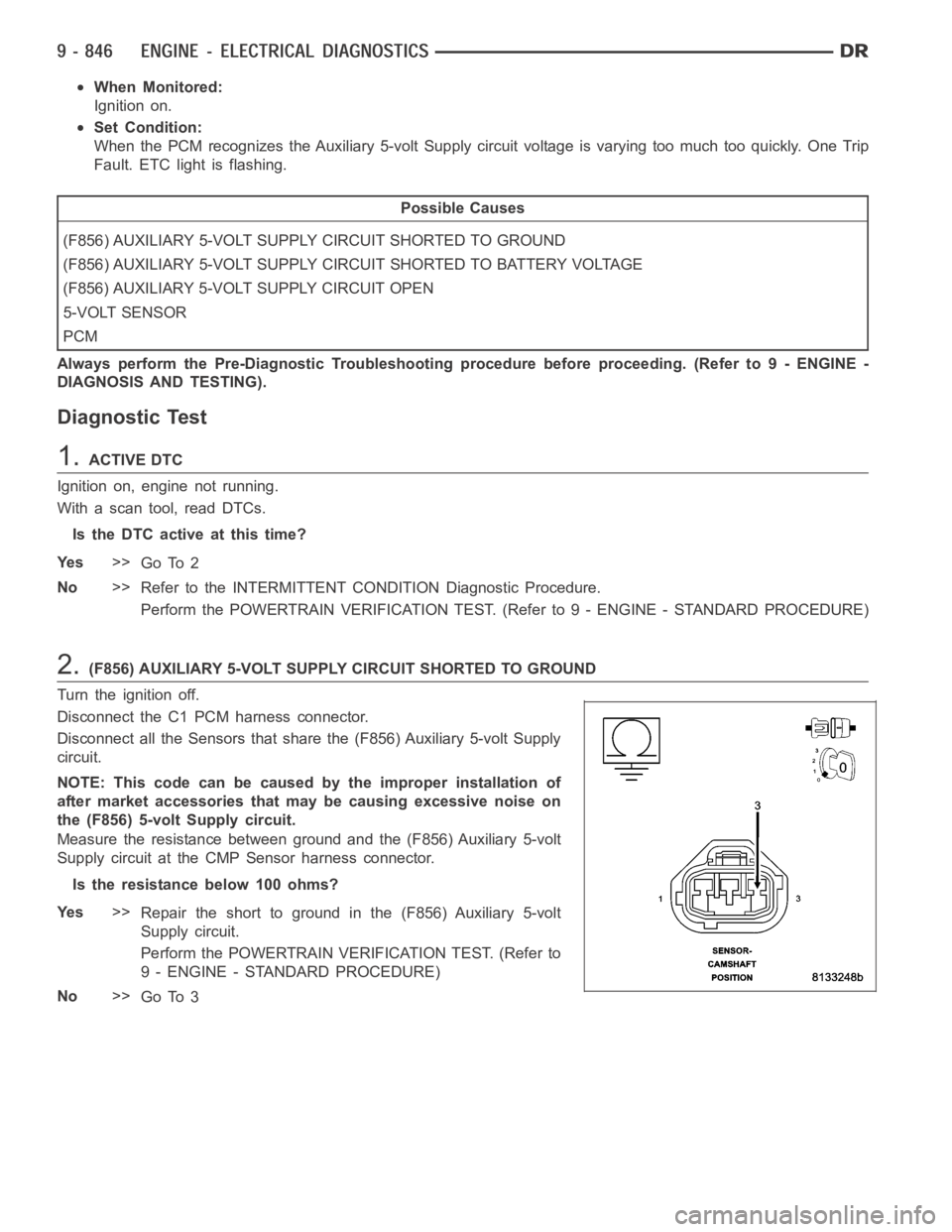

2.(F856) AUXILIARY 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

Turn the ignition off.

Disconnect the C1 PCM harness connector.

Disconnect all the Sensors that share the (F856) Auxiliary 5-volt Supply

circuit.

NOTE: This code can be caused by the improper installation of

after market accessories that may be causing excessive noise on

the (F856) 5-volt Supply circuit.

Measure the resistance between ground and the (F856) Auxiliary 5-volt

Supply circuit at the CMP Sensor harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (F856) Auxiliary 5-volt

Supply circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 156 of 5267

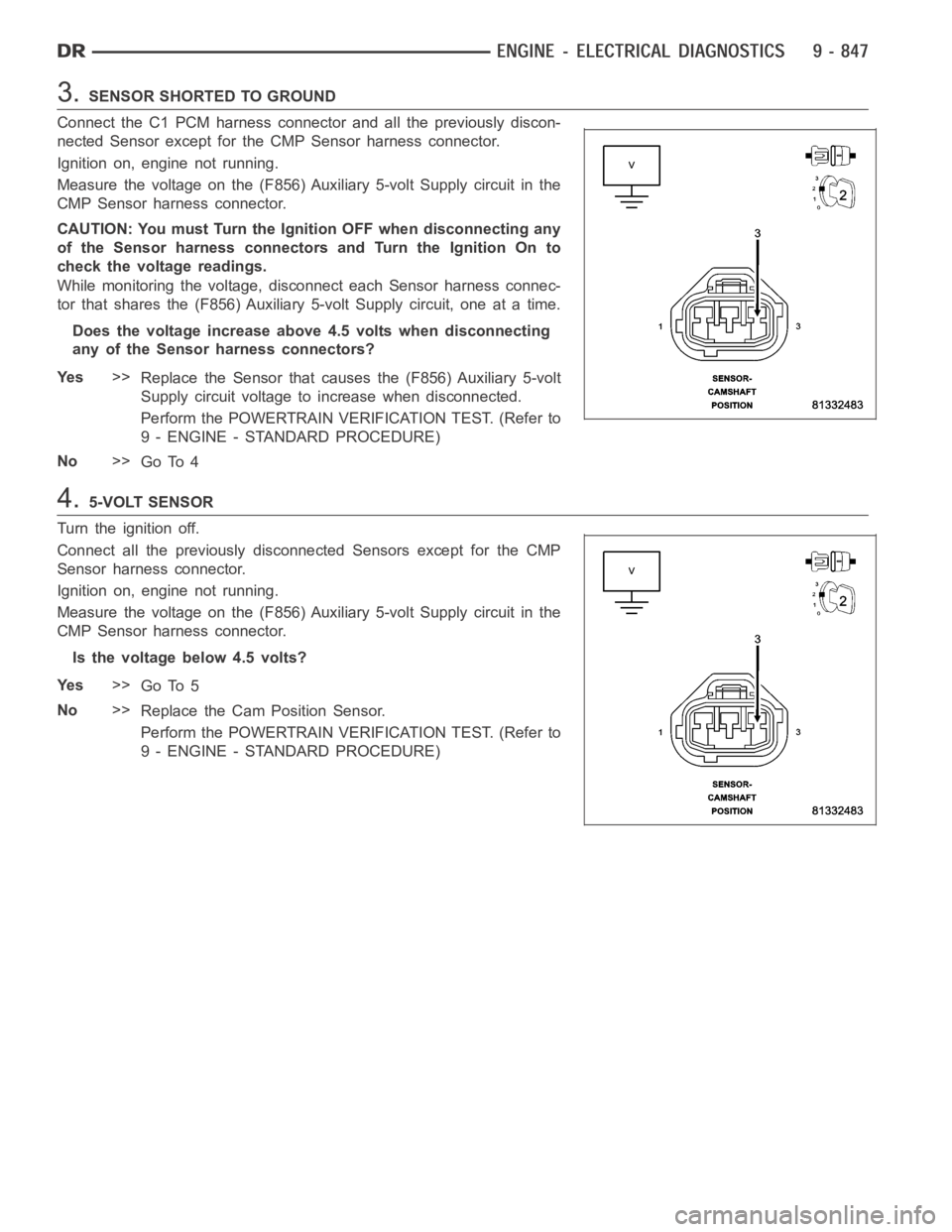

3.SENSOR SHORTED TO GROUND

Connect the C1 PCM harness connector and all the previously discon-

nected Sensor except for the CMP Sensor harness connector.

Ignition on, engine not running.

Measure the voltage on the (F856) Auxiliary 5-volt Supply circuit in the

CMP Sensor harness connector.

CAUTION: You must Turn the Ignition OFF when disconnecting any

of the Sensor harness connectors and Turn the Ignition On to

check the voltage readings.

While monitoring the voltage, disconnect each Sensor harness connec-

tor that shares the (F856) Auxiliary 5-volt Supply circuit, one at a time.

Does the voltage increase above 4.5 volts when disconnecting

any of the Sensor harness connectors?

Ye s>>

Replace the Sensor that causes the (F856) Auxiliary 5-volt

Supply circuit voltage to increase when disconnected.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

4.5-VOLT SENSOR

Turn the ignition off.

Connect all the previously disconnected Sensors except for the CMP

Sensor harness connector.

Ignition on, engine not running.

Measure the voltage on the (F856) Auxiliary 5-volt Supply circuit in the

CMP Sensor harness connector.

Is the voltage below 4.5 volts?

Ye s>>

Go To 5

No>>

Replace the Cam Position Sensor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 157 of 5267

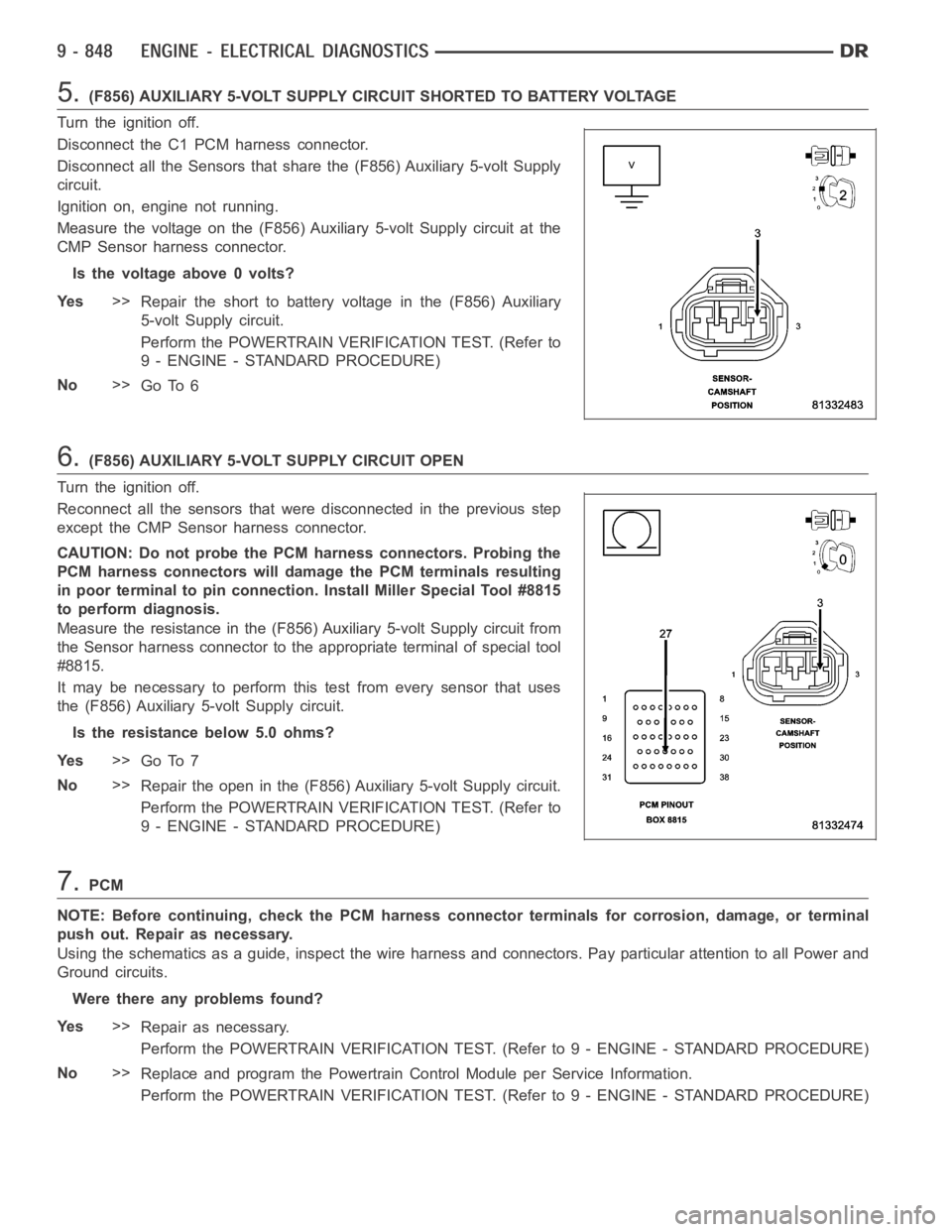

5.(F856) AUXILIARY 5-VOLT SUPPLY CIRCUIT SHORTED TO BATTERY VOLTAGE

Turn the ignition off.

Disconnect the C1 PCM harness connector.

Disconnect all the Sensors that share the (F856) Auxiliary 5-volt Supply

circuit.

Ignition on, engine not running.

Measure the voltage on the (F856) Auxiliary 5-volt Supply circuit at the

CMP Sensor harness connector.

Is the voltage above 0 volts?

Ye s>>

Repair the short to battery voltage in the (F856) Auxiliary

5-volt Supply circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 6

6.(F856) AUXILIARY 5-VOLT SUPPLY CIRCUIT OPEN

Turn the ignition off.

Reconnect all the sensors that were disconnected in the previous step

except the CMP Sensor harness connector.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller Special Tool #8815

to perform diagnosis.

Measure the resistance in the (F856) Auxiliary 5-volt Supply circuit from

the Sensor harness connector to the appropriate terminal of special tool

#8815.

It may be necessary to perform this test from every sensor that uses

the (F856) Auxiliary 5-volt Supply circuit.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 7

No>>

Repair the open in the (F856) Auxiliary 5-volt Supply circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

7.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 158 of 5267

P1696-EEPROM MEMORY WRITE DENIED/INVALID

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Continuously with the ignition on.

Set Condition:

An attempt to program/write to the internal EEPROM failed, Also checks at power down. One Trip Fault. Three

good trips to turn off the MIL.

Possible Causes

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.SCAN TOOL DISPLAYS A WRITE FAILURE

With a scan tool, perform the SRI Memory Test.

Does scan tool display Write Failure?

Ye s>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

2.SCAN TOOL DISPLAYS A WRITE REFUSED

With the a scan tool, perform the SRI Memory Test.

Does the scan tool display Write Refused?

Ye s>>

Go To 3

No>>

Go To 4

3.PCM REFUSED 2ND TEST

With a scan tool, perform the SRI Memory Test a third time.

NOTE: Retest the SRI Memory two more times.

Does the scan tool display Write Refused again?

Ye s>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

4.SCAN TOOL DISPLAYS SRI MILEAGE INVALID

With a scan tool, perform the SRI Memory Test.

Does the scan tool display SRI Mileage Invalid?

Ye s>>

Update the mileage and retest the SRI Memory.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

Page 160 of 5267

P1697-EMR (SRI) MILEAGE NOT STORED

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Continuously with the ignition on.

Set Condition:

An attempt to program/write to the internal EEPROM failed, Also checks at powerdown. One Trip Fault. Three

good trips to turn off the MIL.

Possible Causes

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.SCAN TOOL DISPLAYS A WRITE FAILURE

With a scan tool, perform the SRI Memory Test.

Does scan tool display Write Failure?

Ye s>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

2.SCAN TOOL DISPLAYS A WRITE REFUSED

With the a scan tool, perform the SRI Memory Test.

Does the scan tool display Write Refused?

Ye s>>

Go To 3

No>>

Go To 4

3.PCM REFUSED 2ND TEST

With a scan tool, perform the SRI Memory Test a third time.

NOTE: Retest the SRI Memory two more times.

Does the scan tool display Write Refused again?

Ye s>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

4.SCAN TOOL DISPLAYS SRI MILEAGE INVALID

With a scan tool, perform the SRI Memory Test.

Does the scan tool display SRI Mileage Invalid?

Ye s>>

Update the mileage and retest the SRI Memory.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

Page 163 of 5267

P2072-ELECTRONIC THROTTLE CONTROL SYSTEM - ICE BLOCKAGE

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Ignition on.

Set Condition:

The PCM recognizes the Throttle plate is stuck during extremely cold Ambient Temperature operation. The

throttle plate goes through a de-icing procedure. If the throttle blade still doesn’t move this fault sets. The MIL

will not illuminate. The vehicle willbe in Limp home condition, limiting rpm and vehicle speed.

Possible Causes

THROTTLE PLATE FROZEN

Diagnostic Test

1.THROTTLE BODY INSPECTION

Ignition on, engine not running.

With a scan tool, read DTCs and record the related Freeze Frame data.

NOTE: This DTC sets in extreme cold Ambient Temperatures with the throttleplatestuckbythetimethe

vehicle gets to the dealership the condition may be corrected.

NOTE: Diagnose any other DTCs that may also be set before continuing.

Turn the ignition off.

Remove the Air Cleaner Assembly from the Throttle Body.

Check for any signs of a foreign material (ice or dirt) on the Throttle Plateor in the bore causing the Throttle Plate

to stick.

Isthethrottlebladestillstuckbecauseitisfrozen?

Ye s>>

Allow the Throttle Body to thaw naturally in a room temperature climate.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 165 of 5267

Theory of Operation

This DTC sets when an unexpected high intake manifold air flow condition exists that can lead to increased engine

speed and puts the NGC into a High Air flow Protection limiting mode. The High Air flow Protection feature includes

RPM limits for when a Throttle and/or MAP sensor limp-in fault is present.

When Monitored:

During all drive modes

Set Condition:

If vacuum drops below 1.5

Hg with engine RPM greater than 2000 RPM and closed throttle. One Trip Fault.

Three good trips to turn off the MIL.

Possible Causes

VACUUM LEAK

RESISTANCE IN THE (F856) 5-VOLT SUPPLY CIRCUIT

(F856) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

RESISTANCE IN THE (K1) MAP SIGNAL CIRCUIT

(K1) MAP SIGNAL CIRCUIT SHORTED TO GROUND

RESISTANCE IN THE (F855) 5-VOLT SUPPLY CIRCUIT

(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

RESISTANCE IN THE (K22) TP SENSOR NO.1 SIGNAL CIRCUIT

(K22) TP SENSOR NO.1 SIGNAL CIRCUIT SHORTED TO GROUND

RESISTANCE IN THE (K900) SENSOR GROUND CIRCUIT

MAP SENSOR

THROTTLE POSITION SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: Diagnose any TP Sensor or MAP Sensor component DTCs before continuing.

NOTE: If the P0501 - No Vehicle Speed Signal is set long with this DTC, refer to the P0501 diagnostics

before continuing.

NOTE: The throttle plate and linkage should be free from binding and carbonbuild up.

NOTE: Make sure the throttle plate is at the idle position.

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)