light DODGE SPRINTER 2007 2.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2007, Model line: SPRINTER, Model: DODGE SPRINTER 2007 2.GPages: 393, PDF Size: 7.61 MB

Page 303 of 393

302 Practical hintsWhere will I find...?

5

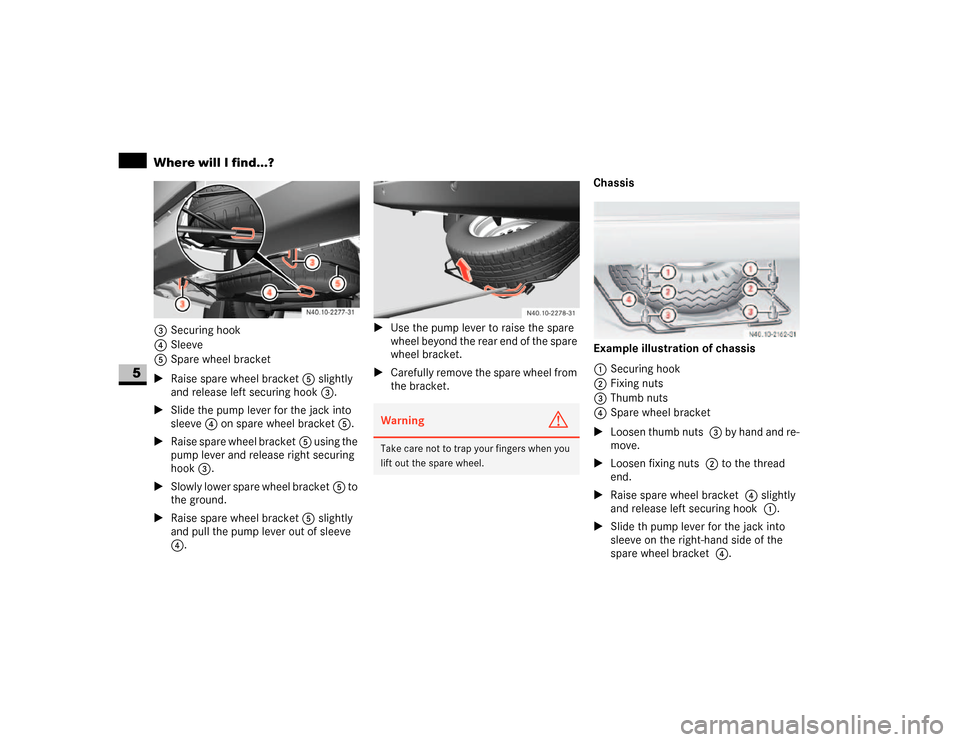

3Securing hook

4Sleeve

5Spare wheel bracket

\1Raise spare wheel bracket5 slightly

and release left securing hook3.

\1Slide the pump lever for the jack into

sleeve4 on spare wheel bracket5.

\1Raise spare wheel bracket5 using the

pump lever and release right securing

hook3.

\1Slowly lower spare wheel bracket5 to

the ground.

\1Raise spare wheel bracket5 slightly

and pull the pump lever out of sleeve

4.\1Use the pump lever to raise the spare

wheel beyond the rear end of the spare

wheel bracket.

\1Carefully remove the spare wheel from

the bracket.Chassis

Example illustration of chassis

1Securing hook

2Fixing nuts

3Thumb nuts

4Spare wheel bracket

\1Loosen thumb nuts 3 by hand and re-

move.

\1Loosen fixing nuts 2 to the thread

end.

\1Raise spare wheel bracket 4 slightly

and release left securing hook 1.

\1Slide th pump lever for the jack into

sleeve on the right-hand side of the

spare wheel bracket 4.

Warning

G

Take care not to trap your fingers when you

lift out the spare wheel.

Page 304 of 393

303 Practical hints

Where will I find...?

5

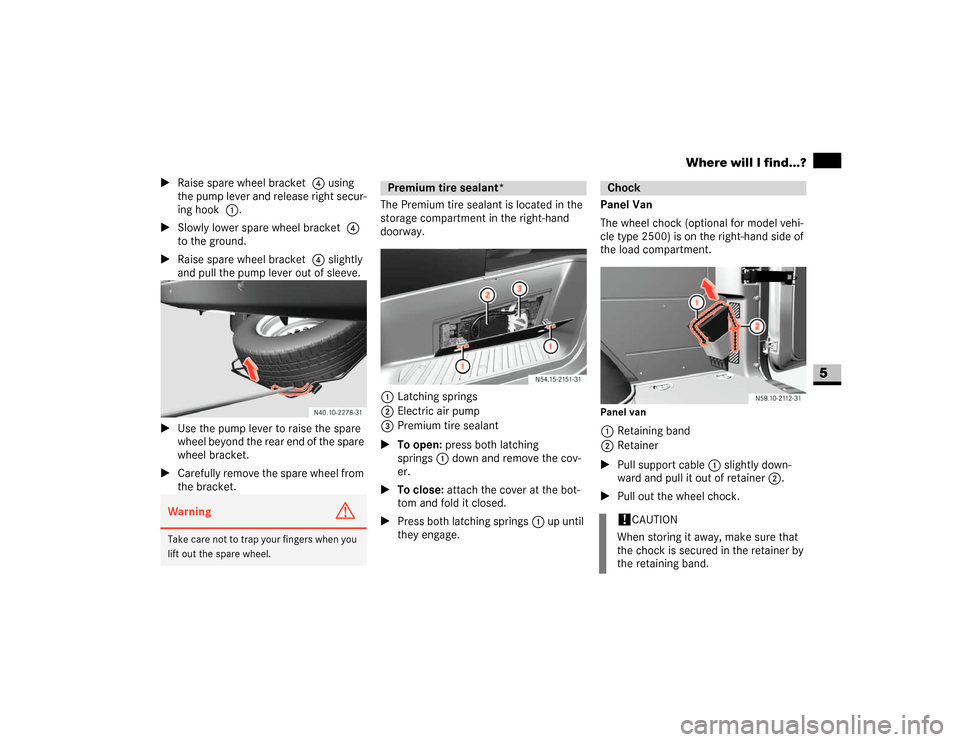

\1Raise spare wheel bracket 4 using

the pump lever and release right secur-

ing hook 1.

\1Slowly lower spare wheel bracket 4

to the ground.

\1Raise spare wheel bracket 4 slightly

and pull the pump lever out of sleeve.

\1Use the pump lever to raise the spare

wheel beyond the rear end of the spare

wheel bracket.

\1Carefully remove the spare wheel from

the bracket.The Premium tire sealant is located in the

storage compartment in the right-hand

doorway.

1Latching springs

2Electric air pump

3Premium tire sealant

\1To open: press both latching

springs1 down and remove the cov-

er.

\1To close: attach the cover at the bot-

tom and fold it closed.

\1Press both latching springs1 up until

they engage.Panel Van

The wheel chock (optional for model vehi-

cle type 2500) is on the right-hand side of

the load compartment.

Panel van1Retaining band

2Retainer

\1Pull support cable 1 slightly down-

ward and pull it out of retainer 2.

\1Pull out the wheel chock.

Warning

G

Take care not to trap your fingers when you

lift out the spare wheel.

Premium tire sealant*

Chock!

CAUTION

When storing it away, make sure that

the chock is secured in the retainer by

the retaining band.

Page 307 of 393

306 Practical hintsChanging bulbs

5

\3 Changing bulbsBulbs and lights are an important aspect of

vehicle safety. For this reason, make sure

that all bulbs are in working order at all

times.

\4Switch off the lights to avoid a short cir-

cuit.

\4Only touch new bulbs with a clean lint-

free cloth or something similar. Do not

work with wet or greasy fingers.

\4Only fit 12 V bulbs of the same type as

before and of the correct wattage.

\4Have the headlamp setting checked

regularly.\4If the newly installed bulb does not light

up either, visit an authorized Sprinter

Dealer.

\4Have the following LEDs and bulbs

changed at an authorized Sprinter

Dealer:

\4The additional turn signals in the

exterior mirrors

\4The third brake lamp (cargo and

passenger vans only)*

\4The bi-xenon headlamps*

\4The foglamps* Before changing bulbs

Warning

G

Bulbs and bulb holders can become very

hot. For this reason, allow the light to cool

down before changing the bulb.

Keep bulbs out of the reach of children.

Never use a bulb which has been dropped.

Such a bulb may explode and injure you.

H7 bulbs are pressurized and may explode

when changed. You should therefore wear

eye protection and gloves when you are

changing them.

Page 308 of 393

307 Practical hints

Changing bulbs

5

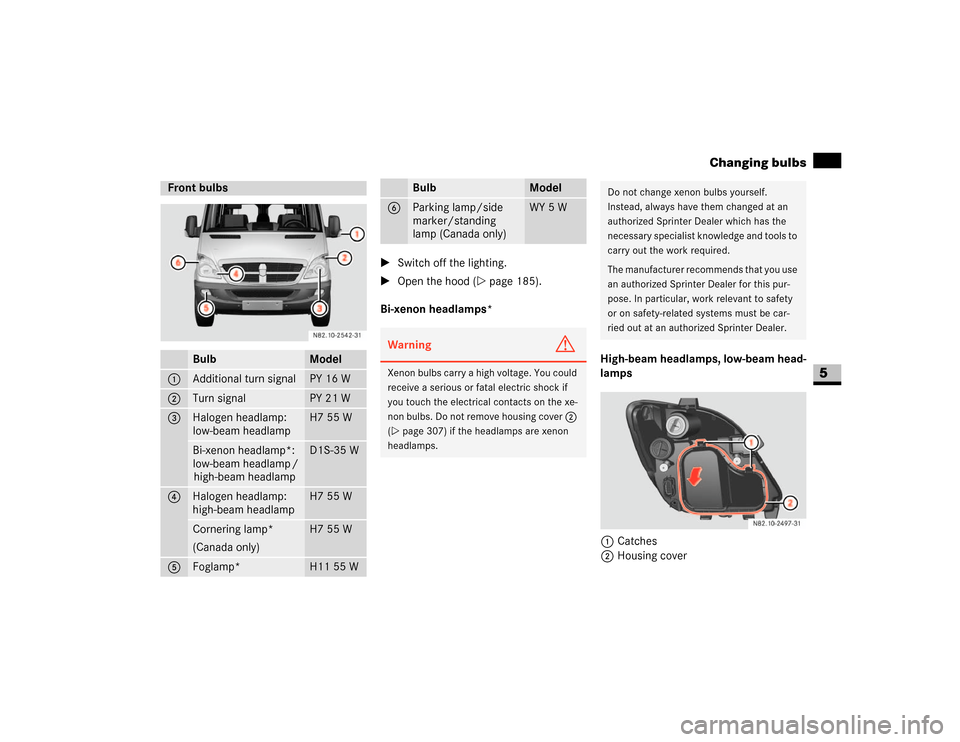

\1Switch off the lighting.

\1Open the hood (\2page 185).

Bi-xenon headlamps*

High-beam headlamps, low-beam head-

lamps

1Catches

2Housing cover

Front bulbs

Bulb

Model

1

Additional turn signal

PY 16 W

2

Turn signal

PY 21 W

3

Halogen headlamp:

low-beam headlamp

H7 55 W

Bi-xenon headlamp*:

low-beam headlamp /

high-beam headlamp

D1S-35 W

4

Halogen headlamp:

high-beam headlamp

H7 55 W

Cornering lamp*

(Canada only)

H7 55 W

5

Foglamp*

H11 55 W

6

Parking lamp/side

marker/standing

lamp (Canada only)

WY 5 W

Warning

G

Xenon bulbs carry a high voltage. You could

receive a serious or fatal electric shock if

you touch the electrical contacts on the xe-

non bulbs. Do not remove housing cover 2

(\2page 307) if the headlamps are xenon

headlamps.

Bulb

Model

Do not change xenon bulbs yourself.

Instead, always have them changed at an

authorized Sprinter Dealer which has the

necessary specialist knowledge and tools to

carry out the work required.

The manufacturer recommends that you use

an authorized Sprinter Dealer for this pur-

pose. In particular, work relevant to safety

or on safety-related systems must be car-

ried out at an authorized Sprinter Dealer.

Page 311 of 393

310 Practical hintsChanging bulbs

5

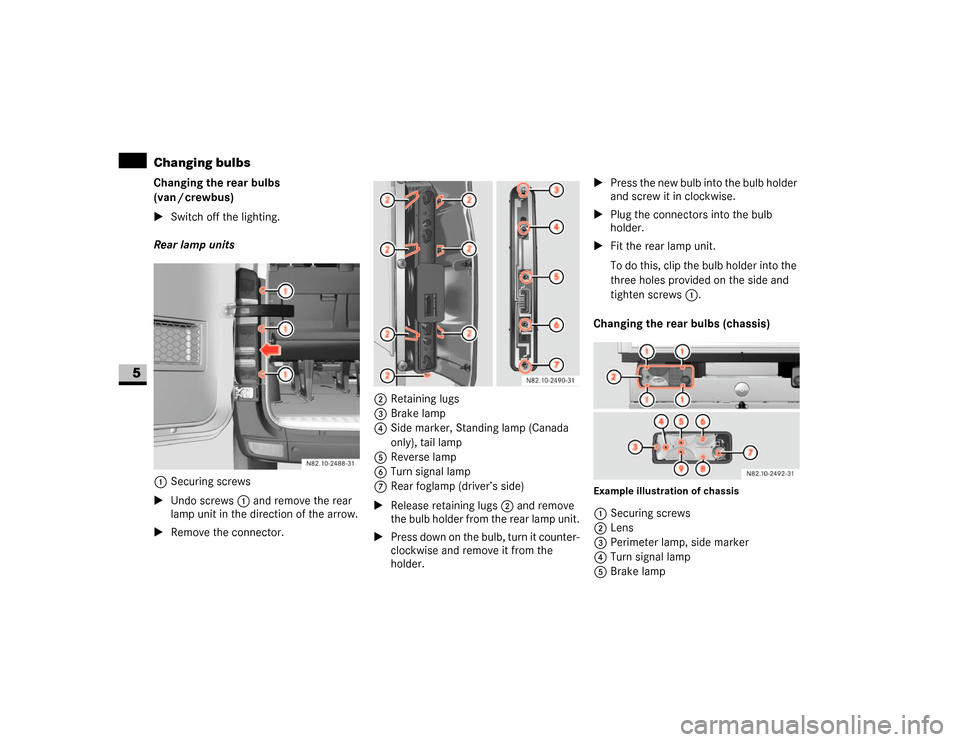

Changing the rear bulbs

(van / crewbus)

\1Switch off the lighting.

Rear lamp units

1Securing screws

\1Undo screws1 and remove the rear

lamp unit in the direction of the arrow.

\1Remove the connector.2Retaining lugs

3Brake lamp

4Side marker, Standing lamp (Canada

only), tail lamp

5Reverse lamp

6Turn signal lamp

7Rear foglamp (driver’s side)

\1Release retaining lugs2 and remove

the bulb holder from the rear lamp unit.

\1Press down on the bulb, turn it counter-

clockwise and remove it from the

holder.\1Press the new bulb into the bulb holder

and screw it in clockwise.

\1Plug the connectors into the bulb

holder.

\1Fit the rear lamp unit.

To do this, clip the bulb holder into the

three holes provided on the side and

tighten screws1.

Changing the rear bulbs (chassis)

Example illustration of chassis1Securing screws

2Lens

3Perimeter lamp, side marker

4Turn signal lamp

5Brake lamp

Page 312 of 393

311 Practical hints

Changing bulbs

5

6Tail lamp

7Rear foglamp (driver’s side)

8License plate lamp

9Reverse lamp

\1Switch off the lighting.

\1Undo screws1 and remove lens 2.

\1Press the bulb into the bulb holder and

screw it out in a counterclockwise di-

rection.

\1Press the new bulb into the bulb holder

and screw it in clockwise.

\1Replace lens2 and retighten

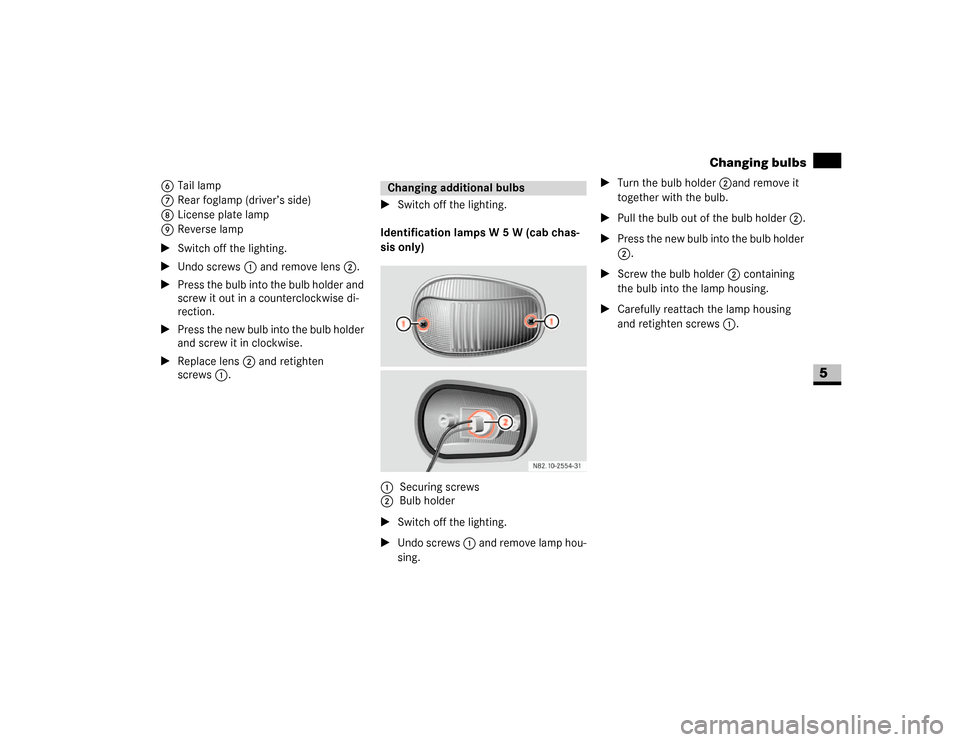

screws1.\1Switch off the lighting.

Identification lamps W 5 W (cab chas-

sis only)

\1Switch off the lighting.

\1Undo screws 1 and remove lamp hou-

sing.\1Turn the bulb holder 2and remove it

together with the bulb.

\1Pull the bulb out of the bulb holder 2.

\1Press the new bulb into the bulb holder

2.

\1Screw the bulb holder 2 containing

the bulb into the lamp housing.

\1Carefully reattach the lamp housing

and retighten screws 1.

Changing additional bulbs

1Securing screws

2Bulb holder

Page 315 of 393

314 Practical hintsChanging bulbs

5

Interior lamp K18WInterior lamp1Lamp housing

2Festoon lamp\1Switch off the lighting.

\1Press in the latching springs of lamp

housing1 using a suitable tool, for ex-

ample a screwdriver.

\1Pry off lamp housing1.

\1Remove bulb2 from the bulb holder.

\1Insert new bulb2.

\1Align lamp housing1 on the right and

engage it. N82.20-2079-31

!

CAUTION

Have the interior lamps in the overhead

control panel changed at an authorized

Sprinter Dealer which has the neces-

sary specialist knowledge and tools to

carry out the work required.

The manufacturer recommends that

you use an authorized Sprinter Dealer

for this purpose.

You could damage the overhead con-

trol panel.

Page 318 of 393

317 Practical hints

Fuel system

5

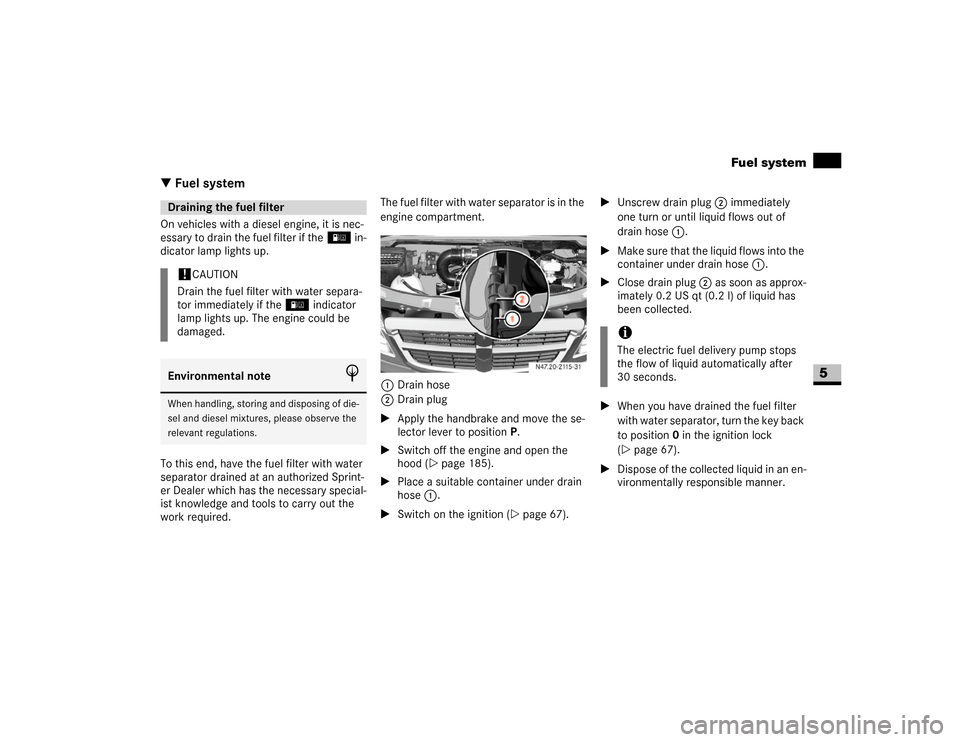

\3 Fuel systemOn vehicles with a diesel engine, it is nec-

essary to drain the fuel filter if the/ in-

dicator lamp lights up.

To this end, have the fuel filter with water

separator drained at an authorized Sprint-

er Dealer which has the necessary special-

ist knowledge and tools to carry out the

work required.The fuel filter with water separator is in the

engine compartment.

1Drain hose

2Drain plug

\1Apply the handbrake and move the se-

lector lever to positionP.

\1Switch off the engine and open the

hood (\2page 185).

\1Place a suitable container under drain

hose1.

\1Switch on the ignition (\2page 67).\1Unscrew drain plug2 immediately

one turn or until liquid flows out of

drain hose1.

\1Make sure that the liquid flows into the

container under drain hose 1.

\1Close drain plug 2 as soon as approx-

imately 0.2 US qt (0.2 l) of liquid has

been collected.

\1When you have drained the fuel filter

with water separator, turn the key back

to position0 in the ignition lock

(\2page 67).

\1Dispose of the collected liquid in an en-

vironmentally responsible manner.Draining the fuel filter!

CAUTION

Drain the fuel filter with water separa-

tor immediately if the/ indicator

lamp lights up. The engine could be

damaged.

Environmental note

H

When handling, storing and disposing of die-

sel and diesel mixtures, please observe the

relevant regulations.

iThe electric fuel delivery pump stops

the flow of liquid automatically after

30 seconds.

Page 325 of 393

324 Practical hintsFlat tire

5

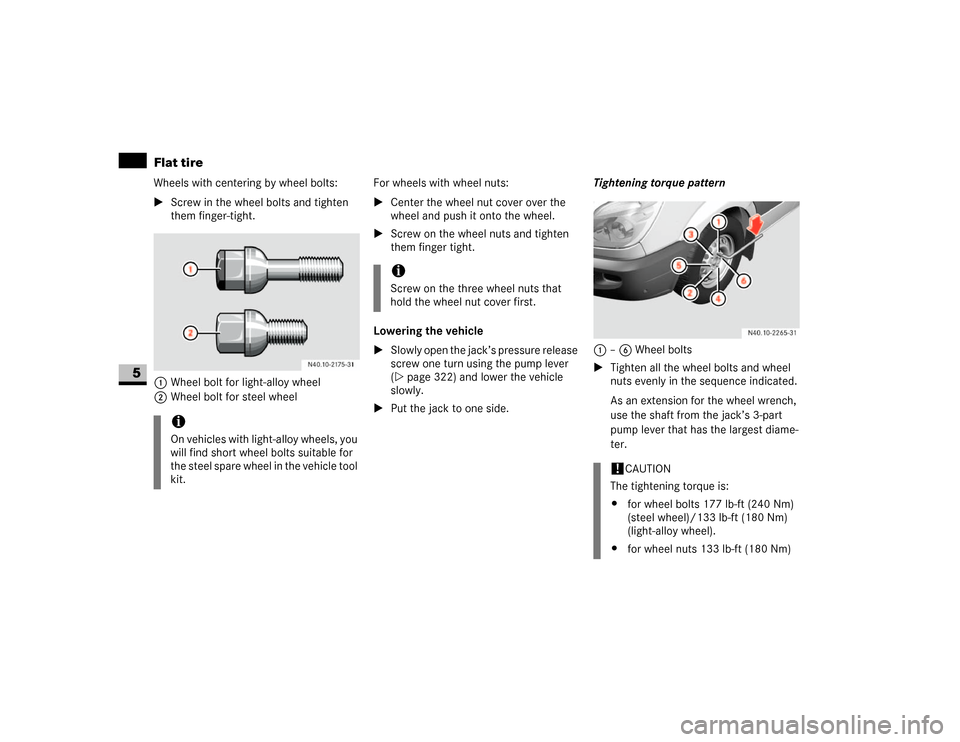

Wheels with centering by wheel bolts:

\1Screw in the wheel bolts and tighten

them finger-tight.

1Wheel bolt for light-alloy wheel

2Wheel bolt for steel wheelor wheels with wheel nuts:

For wheels with wheel nuts:

\1Center the wheel nut cover over the

wheel and push it onto the wheel.

\1Screw on the wheel nuts and tighten

them finger tight.

Lowering the vehicle

\1Slowly open the jack’s pressure release

screw one turn using the pump lever

(\2page 322) and lower the vehicle

slowly.

\1Put the jack to one side.Tightening torque pattern

1 – 6 Wheel bolts

\1Tighten all the wheel bolts and wheel

nuts evenly in the sequence indicated.

As an extension for the wheel wrench,

use the shaft from the jack’s 3-part

pump lever that has the largest diame-

ter.

iOn vehicles with light-alloy wheels, you

will find short wheel bolts suitable for

the steel spare wheel in the vehicle tool

kit.N40.10-2175-31

iScrew on the three wheel nuts that

hold the wheel nut cover first.

!

CAUTION

The tightening torque is:

\4for wheel bolts 177 lb-ft (240 Nm)

(steel wheel)/133 lb-ft (180 Nm)

(light-alloy wheel).

\4for wheel nuts 133 lb-ft (180 Nm)

Page 326 of 393

325 Practical hints

Flat tire

5

\1For wheels with wheel bolts attach the

wheel cover.

Vehicles with wheel caps:

Make sure that the opening in the

wheel cap is positioned over the tire

vent.

Vehicles with center caps:

Make sure that the retaining lugs of the

hub cap are positioned over the bolts.

\1Compress the piston of the hydraulic

jack and close the pressure release

screw.

\1Store the jack and the remaining vehi-

cle tools.

\1Place the defective wheel in the spare

wheel bracket after changing the wheel

(\2page 301).

\1Check the tire pressure (\2page 210).

\1Retighten the wheel bolts and wheel

nuts to the specified tightening torque

once the vehicle has been driven for 30

miles (50 km).

iGive the middle of the center cap a

knock to engage it on the wheel.

Warning

G

For safety reasons, you must observe the

following after changing a wheel:

\4Have the tightening torque checked:

\4for wheel bolts 177 lb-ft (240 Nm)

(steel wheel)/133 lb-ft (180 Nm)

(light-alloy wheel) or

\4for wheel nuts

133 lb-ft (180 Nm).

The wheels could otherwise come loose.

\4Check the tire pressure and correct it if

necessary

\4Have the wheel bolts or wheel nuts re-

tightened after 30 miles (50 km) to a

torque of:

\4177 lb-ft (240 Nm) (steel wheel)/

133 lb-ft (180 Nm) (light-alloy

wheel) for wheel bolts or

\4133 lb-ft (180 Nm) for wheel nuts.

\4Have the direction of tire rotation cor-

rected, if reversed, as soon as possible

at an authorized Sprinter Dealer. The ve-

hicle handling characteristics could oth-

erwise be affected.Warning

G

Loose wheel nuts or bolts could cause the

vehicle to lose a wheel while it is in motion.

This would jeopardize the operating and

road safety of the vehicle. You could lose

control of the vehicle as a result, cause an

accident and injure yourself or others.

If new or repainted wheels are mounted, the

wheel bolts or wheel nuts must be retight-

ened again after approximately 600 to 3000

miles (about 1000 to 5000 km).