technical data DODGE SPRINTER 2007 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2007, Model line: SPRINTER, Model: DODGE SPRINTER 2007 2.GPages: 393, PDF Size: 7.61 MB

Page 362 of 393

361 *Technical data

Service products and capacities

6

At temperatures below 14 °F (–10 °C) a

certain quantity of fuel flow improver may

be added. These substances may only be

mixed within the vehicle’s fuel tank.

Engine power may drop according to the

proportion of fuel flow improver. For this

reason, keep the percentage of fuel flow

improver to the minimum necessitated by

the ambient temperature.

Adding kerosene to diesel fuel is not rec-

ommended even at low temperatures.

Do not blend other specific fuel additives

with diesel fuel except for fuel flow improv-

er. They only result in unnecessary cost,

and may be harmful to the engine opera-

tion.Flow improvers

The effectiveness of flow improvers cannot

be guaranteed with all fuels. Observe the

mixing ratio and comply with the handling

instructions given from the manufacturer.

!

CAUTION

Do not fill the tank with gasoline.

Do not mix diesel fuel with gasoline or

kerosene. The fuel system and engine

will otherwise be damaged, which is

not covered by the Sprinter warranty.

Warning

G

Under no circumstances should gasoline be

mixed with diesel fuel.

Due to the high pressure and high tempera-

ture in the injection system, there is a risk of

fire and explosion.

In addition, there is a risk of engine damage.

Always follow basic safety rules when work-

ing with any combustible material.

Page 363 of 393

362 *Technical dataService products and capacities

6

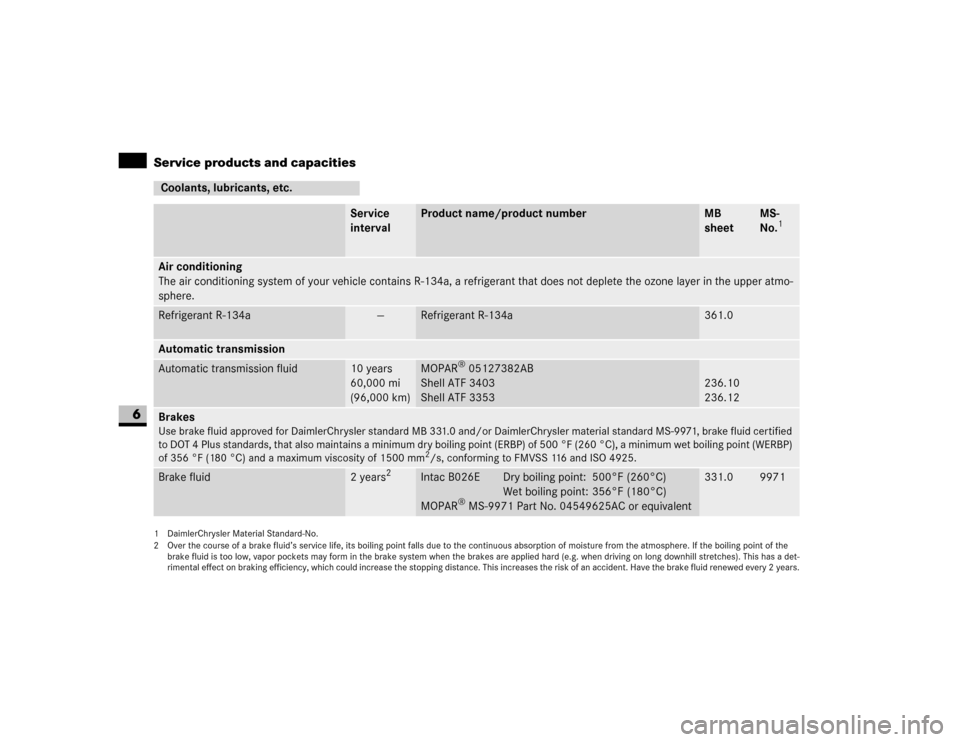

Coolants, lubricants, etc.

Service

interval

Product name/product number

MB

sheet

MS-

No.

1

Air conditioning

The air conditioning system of your vehicle contains R-134a, a refrigerant that does not deplete the ozone layer in the upper atmo-

sphere.Refrigerant R-134a

—

Refrigerant R-134a

361.0

Automatic transmissionAutomatic transmission fluid

10 years

60,000 mi

(96,000 km)

MOPAR

® 05127382AB

Shell ATF 3403

Shell ATF 3353

236.10

236.12

BrakesUse brake fluid approved for DaimlerChrysler standard MB 331.0 and/or DaimlerChrysler material standard MS-9971, brake fluid certified

to DOT 4 Plus standards, that also maintains a minimum dry boiling point (ERBP) of 500 °F (260°C), a minimum wet boiling point (WERBP)

of 356 °F (180 °C) and a maximum viscosity of 1500 mm

2/s, conforming to FMVSS 116 and ISO 4925.

Brake fluid

2 years

2

Intac B026E Dry boiling point: 500°F (260°C)

Wet boiling point: 356°F (180°C)

MOPAR

® MS-9971 Part No. 04549625AC or equivalent

331.0

9971

1 DaimlerChrysler Material Standard-No.

2 Over the course of a brake fluid’s service life, its boiling point falls due to the continuous absorption of moisture from the atmosphere. If the boiling point of the

brake fluid is too low, vapor pockets may form in the brake system when the brakes are applied hard (e.g. when driving on long downhill stretches). This has a det-

rimental effect on braking efficiency, which could increase the stopping distance. This increases the risk of an accident. Have the brake fluid renewed every 2 years.

Page 364 of 393

363 *Technical data

Service products and capacities

6

Service interval

Product name/product number

MB

sheet

MS-

No.

1

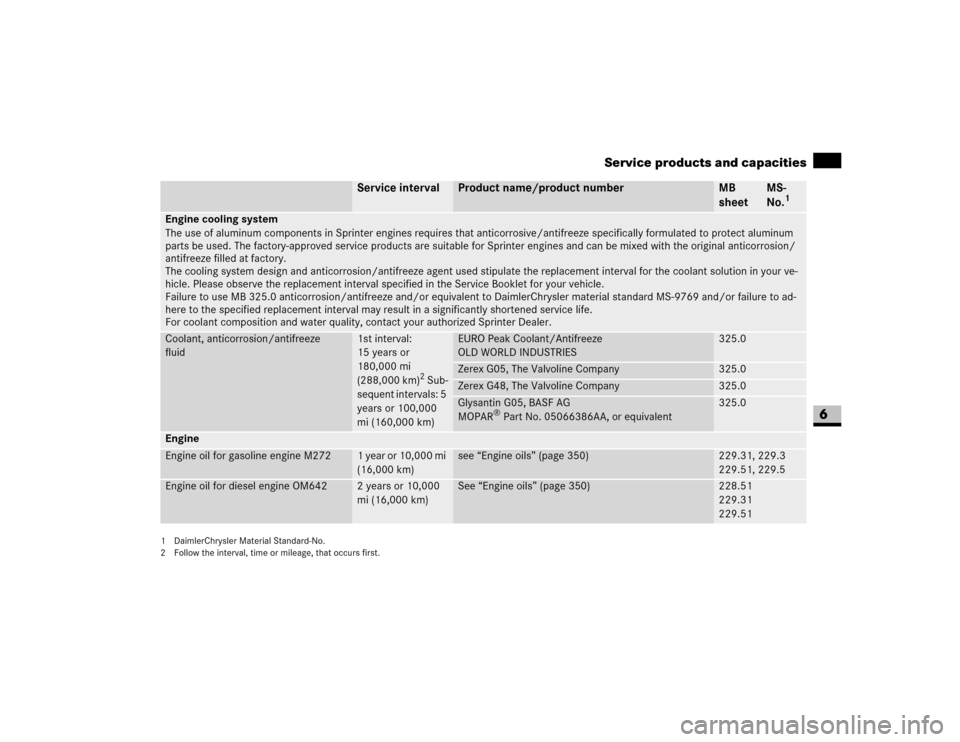

Engine cooling system

The use of aluminum components in Sprinter engines requires that anticorrosive/antifreeze specifically formulated to protect aluminum

parts be used. The factory-approved service products are suitable for Sprinter engines and can be mixed with the original anticorrosion/

antifreeze filled at factory.

The cooling system design and anticorrosion/antifreeze agent used stipulate the replacement interval for the coolant solution in your ve-

hicle. Please observe the replacement interval specified in the Service Booklet for your vehicle.

Failure to use MB 325.0 anticorrosion/antifreeze and/or equivalent to DaimlerChrysler material standard MS-9769 and/or failure to ad-

here to the specified replacement interval may result in a significantly shortened service life.

For coolant composition and water quality, contact your authorized Sprinter Dealer.Coolant, anticorrosion/antifreeze

fluid

1st interval:

15 years or

180,000 mi

(288,000 km)

2 Sub-

sequent intervals: 5

years or 100,000

mi (160,000 km)

EURO Peak Coolant/Antifreeze

OLD WORLD INDUSTRIES

325.0

Zerex G05, The Valvoline Company

325.0

Zerex G48, The Valvoline Company

325.0

Glysantin G05, BASF AG

MOPAR

® Part No. 05066386AA, or equivalent

325.0

EngineEngine oil for gasoline engine M272

1 year or 10,000 mi

(16,000 km)

see “Engine oils” (page 350)

229.31, 229.3

229.51, 229.5

Engine oil for diesel engine OM642

2 years or 10,000

mi (16,000 km)

See “Engine oils” (page 350)

228.51

229.31

229.51

1 DaimlerChrysler Material Standard-No.

2 Follow the interval, time or mileage, that occurs first.

Page 365 of 393

364 *Technical dataService products and capacities

6

Service interval

Product name/product number

MB

sheet

MS-

No.

1

Power steering

Power steering, no fluid service required.Power steering fluid

—

Mobil ATF+4, Exxon Mobil Corporation, or equiva-

lent

236.3

9602

MOPAR

® Part No. 05013457AA, or equivalent

–

Rear axleGear oil

10 years or

180,000 mi

(288,000 km)

2

BP Energear Hyep DC 80W-90

Mobil Delvac Synthetic Gear Oil 75W-90

235.20

235.8

8985

MOPAR

® Part No. 04874469

3

–

1 DaimlerChrysler Material Standard-No.

2 Follow the interval, time or mileage, that occurs first.

3 Synthetic automotive gear lubricant without fricition modifier.

Page 366 of 393

365 *Technical data

Service products and capacities

6

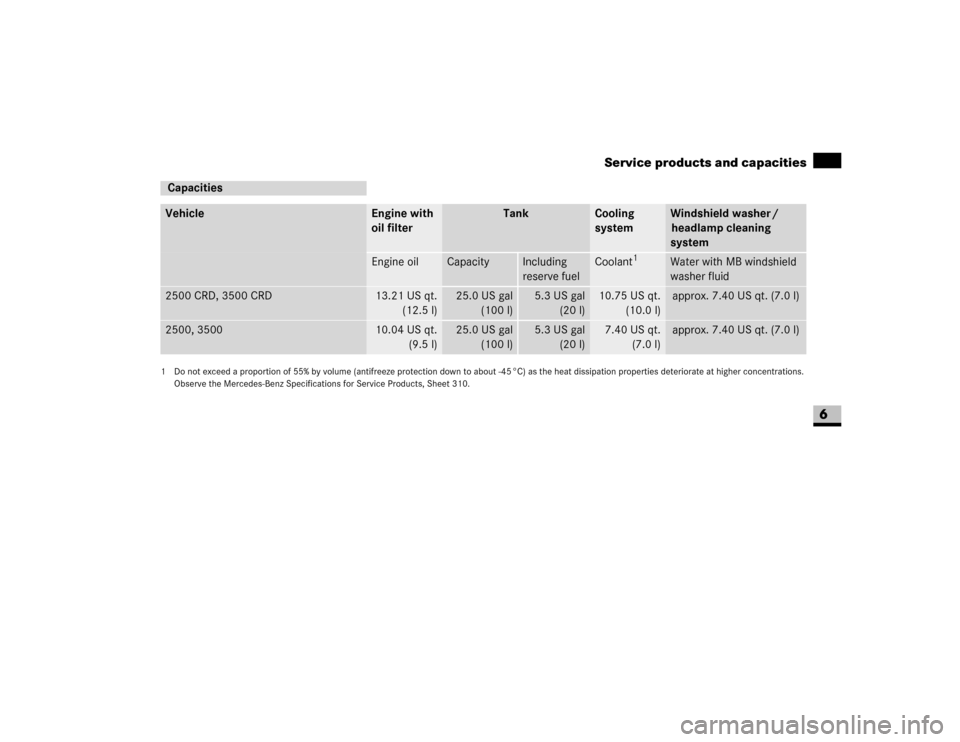

CapacitiesVehicle

Engine with

oil filter

Tank

Cooling

system

Windshield washer /

headlamp cleaning

system

Engine oil

Capacity

Including

reserve fuel

Coolant

1

1 Do not exceed a proportion of 55% by volume (antifreeze protection down to about -45 °C) as the heat dissipation properties deteriorate at higher concentrations.

Observe the Mercedes-Benz Specifications for Service Products, Sheet 310.

Water with MB windshield

washer fluid

2500 CRD, 3500 CRD

13.21 US qt.

(12.5 l)

25.0 US gal

(100 l)

5.3 US gal

(20 l)

10.75 US qt.

(10.0 l)

approx. 7.40 US qt. (7.0 l)

2500, 3500

10.04 US qt.

(9.5 l)

25.0 US gal

(100 l)

5.3 US gal

(20 l)

7.40 US qt.

(7.0 l)

approx. 7.40 US qt. (7.0 l)

Page 367 of 393

366 *Technical dataService products and capacities

6

The vehicle will use more fuel than usual in

the following conditions:

\4at very low temperatures

\4in urban traffic

\4on short trips

\4when towing a trailer

\4when driving with a heavy load

\4in mountainous terrain

Fuel consumptionEnvironmental note

H

A vehicle’s CO

2 emissions and fuel con-

sumption depend on:

\4efficient use of fuel by the engine

\4the style of driving adopted

\4other non-technical factors such as en-

vironmental influences or road condi-

tions

Page 368 of 393

367 *Technical data

Rims and tires

6

\3 Rims and tires

!

CAUTION

Only use tires which have been tested

and approved for your Sprinter vehicle

by the vehicle manufacturer. Tires ap-

proved by the vehicle manufacturer are

developed to provide the best possible

performance in conjunction with the

driving safety systems on your Sprinter

vehicle such as ABS, BAS, ASR or ESP

®.

Using tires other than those approved

by the vehicle manufacturer may result

in damage that is not covered by the

Sprinter warranty.

Using tires other than those approved

by the vehicle manufacturer can have

detrimental effects, such as

\4poor handling characteristics

\4increased noise

\4increased fuel consumption

Moreover, tires and rims not approved

by the vehicle manufacturer may, un-

der load, exhibit dimensional variations

and different tire deformation charac-

teristics that could cause them to come

into contact with the vehicle body or

axle parts. Damage to the tires or the

vehicle may be the result.

Warning

G

Loose wheel nuts or bolts could cause the

vehicle to lose a wheel while it is in motion.

This would jeopardize the operating and

road safety of the vehicle. You could lose

control of the vehicle as a result, cause an

accident an injure yourself or others.

If a wheel was replaced or new wheel nuts

are used, the wheel bolts or wheel nuts must

be retightened to the specified tightening

torque after 30 miles (50 km).

If new or repainted wheels are mounted, the

wheel bolts or wheel nuts must be retight-

ened again to the specified tightening

torque after approximately 600 to 3000

miles (about 1000 to 5000 km).

iFurther information on tires and rims is

available at any authorized Sprinter

Dealer. A placard with the recommend-

ed tire inflation pressures is located on

\4the driver’s door B-pillar for vehi-

cles with a gross weight capacity

less than 10,000 lbs (4500 kg)

(\2page 375)

\4on a label below the driver’s seat on

an outward facing position of the

mounting pillar for vehicles with a

gross weight capacity above

10,000 lbs (4500 kg) (\2page 375)

The tire inflation pressure should be

checked regularly and should only be

adjusted on cold tires.

Page 369 of 393

368 *Technical dataRims and tires

6

Vehicle Model Type

2500

3500

Rims (steel)

6.5 J x 16

5.5 J x 16

Rims (light alloy)

6.5 J x 16

–

Wheel offset

2.13 in (54 mm)

–

Half dual spacing

4.82 in (122.5 mm)

Wheel fixture

Wheel bolts

Wheel nuts

Tightening torque (steel wheel)

177 lb-ft (240 Nm)

133 lb-ft (180 Nm)

Tightening torque (light-alloy wheel)

133 lb-ft (180 Nm)

-

Summer tires

–

–

All-season tires

1

1 Radial-ply tires

LT 245/75 R16 120/116L

LT 215/85 R16 115/112N

LT 215/85 R16 115/112Q

LT 245/75 R16 120/116N

Winter tires

2

2 Radial-ply tires

LT 245/75 R16 120/116L M+S .

LT 215/85 R16 115/112N M+S .

LT 245/75 R16 120/116N M+S .

Page 370 of 393

369 *Technical data

Tire inflation pressure

6

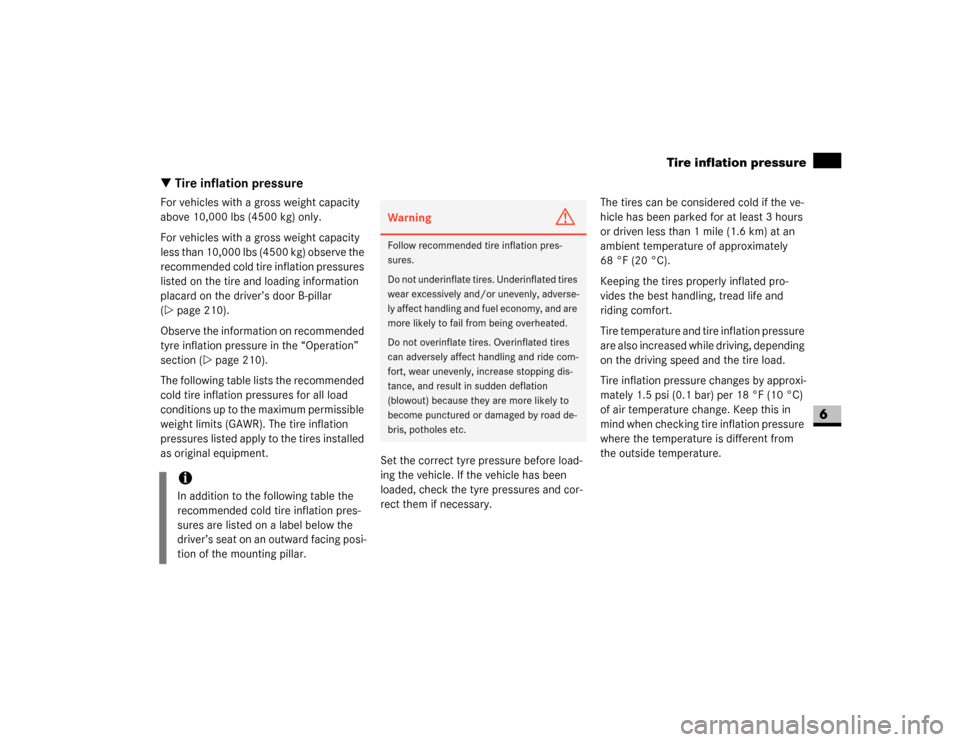

\3 Tire inflation pressureFor vehicles with a gross weight capacity

above 10,000 lbs (4500 kg) only.

For vehicles with a gross weight capacity

less than 10,000 lbs (4500 kg) observe the

recommended cold tire inflation pressures

listed on the tire and loading information

placard on the driver’s door B-pillar

(\2page 210).

Observe the information on recommended

tyre inflation pressure in the “Operation”

section (\2page 210).

The following table lists the recommended

cold tire inflation pressures for all load

conditions up to the maximum permissible

weight limits (GAWR). The tire inflation

pressures listed apply to the tires installed

as original equipment.

Set the correct tyre pressure before load-

ing the vehicle. If the vehicle has been

loaded, check the tyre pressures and cor-

rect them if necessary.The tires can be considered cold if the ve-

hicle has been parked for at least 3 hours

or driven less than 1 mile (1.6 km) at an

ambient temperature of approximately

68 °F (20 °C).

Keeping the tires properly inflated pro-

vides the best handling, tread life and

riding comfort.

Tire temperature and tire inflation pressure

are also increased while driving, depending

on the driving speed and the tire load.

Tire inflation pressure changes by approxi-

mately 1.5 psi (0.1 bar) per 18 °F (10 °C)

of air temperature change. Keep this in

mind when checking tire inflation pressure

where the temperature is different from

the outside temperature.

iIn addition to the following table the

recommended cold tire inflation pres-

sures are listed on a label below the

driver’s seat on an outward facing posi-

tion of the mounting pillar.

Warning

G

Follow recommended tire inflation pres-

sures.

Do not underinflate tires. Underinflated tires

wear excessively and/or unevenly, adverse-

ly affect handling and fuel economy, and are

more likely to fail from being overheated.

Do not overinflate tires. Overinflated tires

can adversely affect handling and ride com-

fort, wear unevenly, increase stopping dis-

tance, and result in sudden deflation

(blowout) because they are more likely to

become punctured or damaged by road de-

bris, potholes etc.

Page 371 of 393

370 *Technical dataTire inflation pressure

6

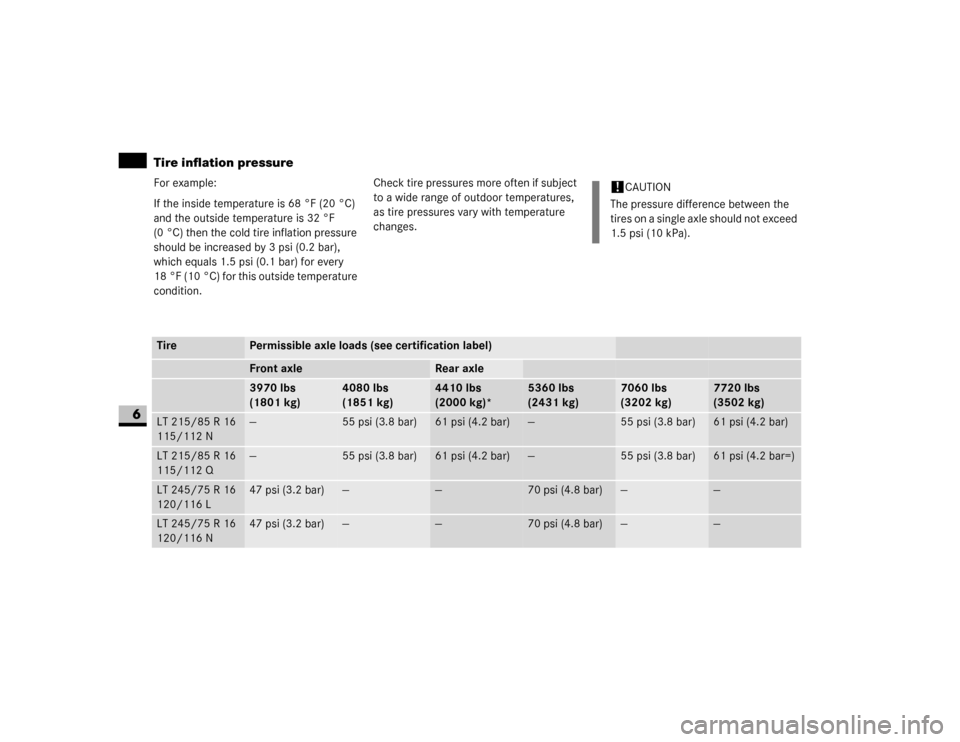

For example:

If the inside temperature is 68 °F (20 °C)

and the outside temperature is 32 °F

(0 °C) then the cold tire inflation pressure

should be increased by 3 psi (0.2 bar),

which equals 1.5 psi (0.1 bar) for every

18 °F (10 °C) for this outside temperature

condition.Check tire pressures more often if subject

to a wide range of outdoor temperatures,

as tire pressures vary with temperature

changes.

!

CAUTION

The pressure difference between the

tires on a single axle should not exceed

1.5psi (10kPa).

Tire

Permissible axle loads (see certification label)Front axle

Rear axle

3970 lbs

(1801 kg)

4080 lbs

(1851 kg)

4410 lbs

(2000 kg)*

5360 lbs

(2431 kg)

7060 lbs

(3202 kg)

7720 lbs

(3502 kg)

LT 215/85 R 16

115/112 N

—

55 psi (3.8 bar)

61 psi (4.2 bar)

—

55 psi (3.8 bar)

61 psi (4.2 bar)

LT 215/85 R 16

115/112 Q

—

55 psi (3.8 bar)

61 psi (4.2 bar)

—

55 psi (3.8 bar)

61 psi (4.2 bar=)

LT 245/75 R 16

120/116 L

47 psi (3.2 bar)

—

—

70 psi (4.8 bar)

—

—

LT 245/75 R 16

120/116 N

47 psi (3.2 bar)

—

—

70 psi (4.8 bar)

—

—