DODGE TOWN AND COUNTRY 2001 Service Manual

Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 121 of 2321

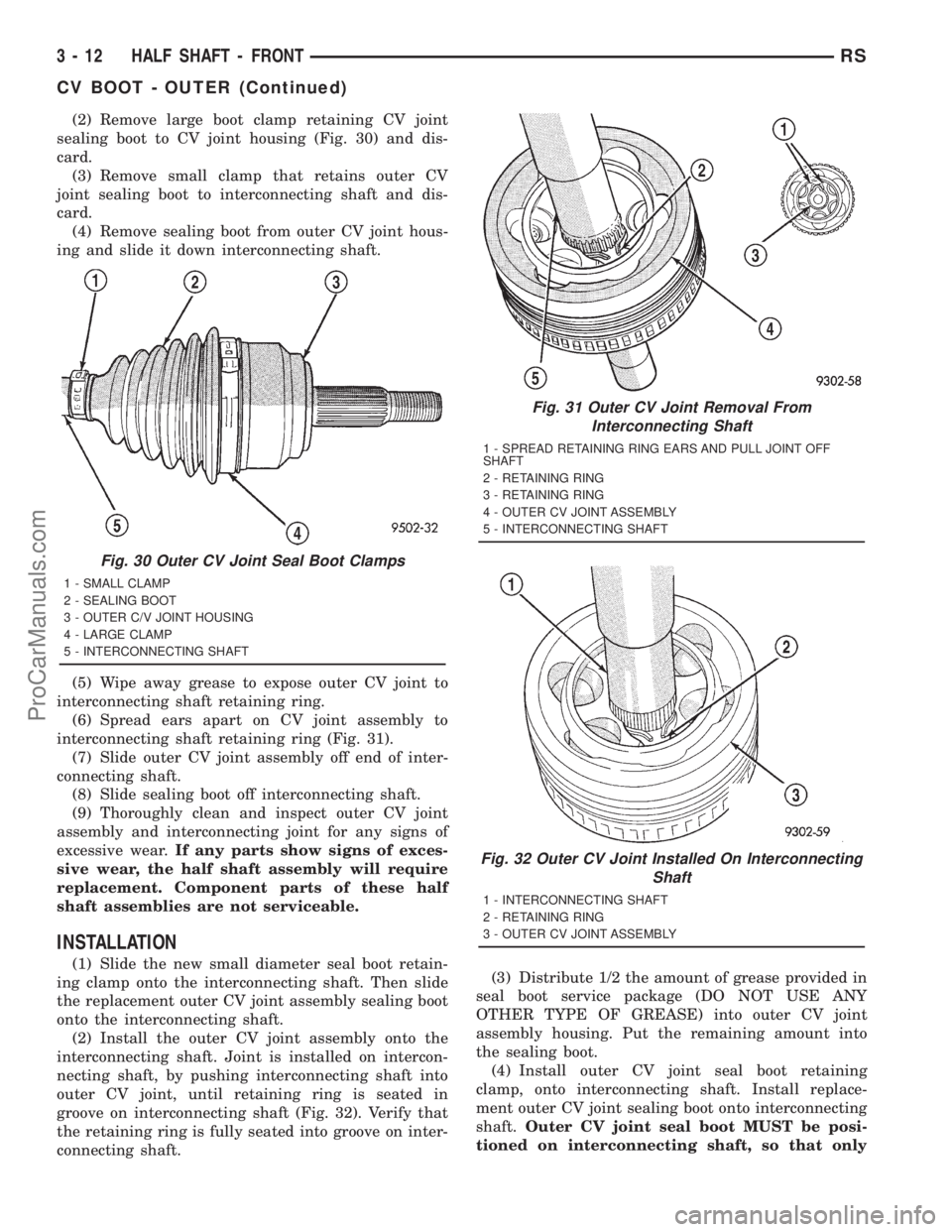

(2) Remove large boot clamp retaining CV joint

sealing boot to CV joint housing (Fig. 30) and dis-

card.

(3) Remove small clamp that retains outer CV

joint sealing boot to interconnecting shaft and dis-

card.

(4) Remove sealing boot from outer CV joint hous-

ing and slide it down interconnecting shaft.

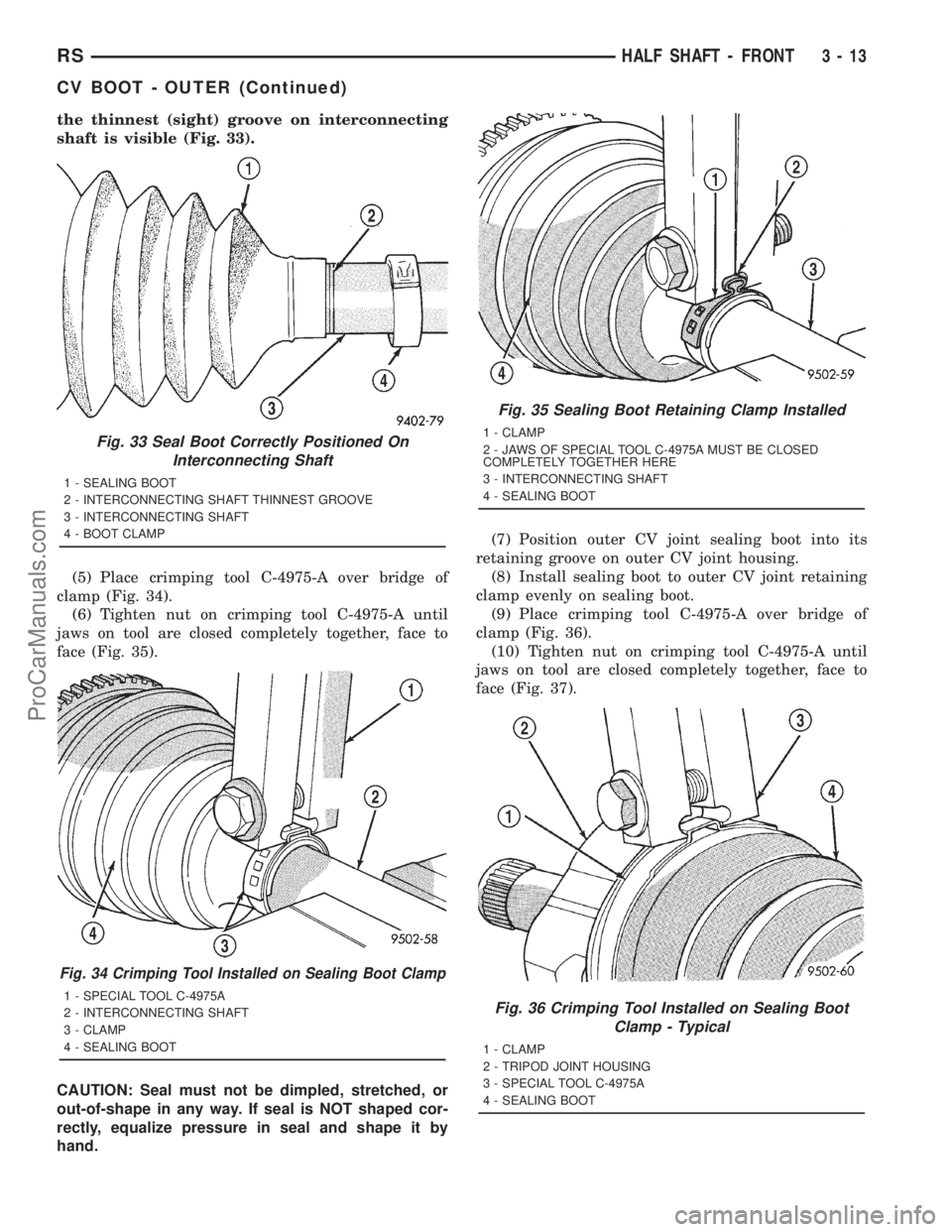

(5) Wipe away grease to expose outer CV joint to

interconnecting shaft retaining ring.

(6) Spread ears apart on CV joint assembly to

interconnecting shaft retaining ring (Fig. 31).

(7) Slide outer CV joint assembly off end of inter-

connecting shaft.

(8) Slide sealing boot off interconnecting shaft.

(9) Thoroughly clean and inspect outer CV joint

assembly and interconnecting joint for any signs of

excessive wear.If any parts show signs of exces-

sive wear, the half shaft assembly will require

replacement. Component parts of these half

shaft assemblies are not serviceable.

INSTALLATION

(1) Slide the new small diameter seal boot retain-

ing clamp onto the interconnecting shaft. Then slide

the replacement outer CV joint assembly sealing boot

onto the interconnecting shaft.

(2) Install the outer CV joint assembly onto the

interconnecting shaft. Joint is installed on intercon-

necting shaft, by pushing interconnecting shaft into

outer CV joint, until retaining ring is seated in

groove on interconnecting shaft (Fig. 32). Verify that

the retaining ring is fully seated into groove on inter-

connecting shaft.(3) Distribute 1/2 the amount of grease provided in

seal boot service package (DO NOT USE ANY

OTHER TYPE OF GREASE) into outer CV joint

assembly housing. Put the remaining amount into

the sealing boot.

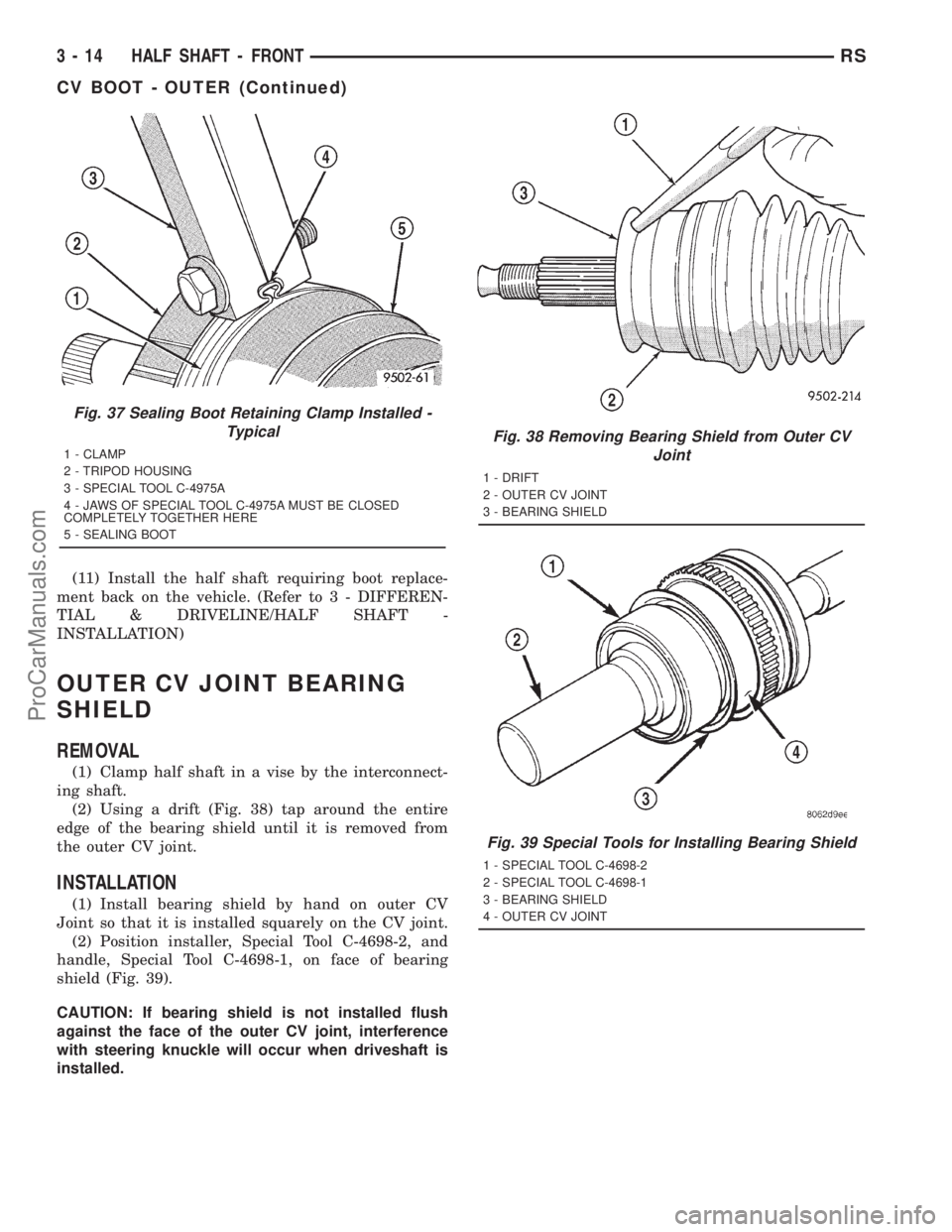

(4) Install outer CV joint seal boot retaining

clamp, onto interconnecting shaft. Install replace-

ment outer CV joint sealing boot onto interconnecting

shaft.Outer CV joint seal boot MUST be posi-

tioned on interconnecting shaft, so that only

Fig. 30 Outer CV Joint Seal Boot Clamps

1 - SMALL CLAMP

2 - SEALING BOOT

3 - OUTER C/V JOINT HOUSING

4 - LARGE CLAMP

5 - INTERCONNECTING SHAFT

Fig. 31 Outer CV Joint Removal From

Interconnecting Shaft

1 - SPREAD RETAINING RING EARS AND PULL JOINT OFF

SHAFT

2 - RETAINING RING

3 - RETAINING RING

4 - OUTER CV JOINT ASSEMBLY

5 - INTERCONNECTING SHAFT

Fig. 32 Outer CV Joint Installed On Interconnecting

Shaft

1 - INTERCONNECTING SHAFT

2 - RETAINING RING

3 - OUTER CV JOINT ASSEMBLY

3 - 12 HALF SHAFT - FRONTRS

CV BOOT - OUTER (Continued)

ProCarManuals.com

Page 122 of 2321

the thinnest (sight) groove on interconnecting

shaft is visible (Fig. 33).

(5) Place crimping tool C-4975-A over bridge of

clamp (Fig. 34).

(6) Tighten nut on crimping tool C-4975-A until

jaws on tool are closed completely together, face to

face (Fig. 35).

CAUTION: Seal must not be dimpled, stretched, or

out-of-shape in any way. If seal is NOT shaped cor-

rectly, equalize pressure in seal and shape it by

hand.(7) Position outer CV joint sealing boot into its

retaining groove on outer CV joint housing.

(8) Install sealing boot to outer CV joint retaining

clamp evenly on sealing boot.

(9) Place crimping tool C-4975-A over bridge of

clamp (Fig. 36).

(10) Tighten nut on crimping tool C-4975-A until

jaws on tool are closed completely together, face to

face (Fig. 37).

Fig. 33 Seal Boot Correctly Positioned On

Interconnecting Shaft

1 - SEALING BOOT

2 - INTERCONNECTING SHAFT THINNEST GROOVE

3 - INTERCONNECTING SHAFT

4 - BOOT CLAMP

Fig. 34 Crimping Tool Installed on Sealing Boot Clamp

1 - SPECIAL TOOL C-4975A

2 - INTERCONNECTING SHAFT

3 - CLAMP

4 - SEALING BOOT

Fig. 35 Sealing Boot Retaining Clamp Installed

1 - CLAMP

2 - JAWS OF SPECIAL TOOL C-4975A MUST BE CLOSED

COMPLETELY TOGETHER HERE

3 - INTERCONNECTING SHAFT

4 - SEALING BOOT

Fig. 36 Crimping Tool Installed on Sealing Boot

Clamp - Typical

1 - CLAMP

2 - TRIPOD JOINT HOUSING

3 - SPECIAL TOOL C-4975A

4 - SEALING BOOT

RSHALF SHAFT - FRONT3-13

CV BOOT - OUTER (Continued)

ProCarManuals.com

Page 123 of 2321

(11) Install the half shaft requiring boot replace-

ment back on the vehicle. (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/HALF SHAFT -

INSTALLATION)

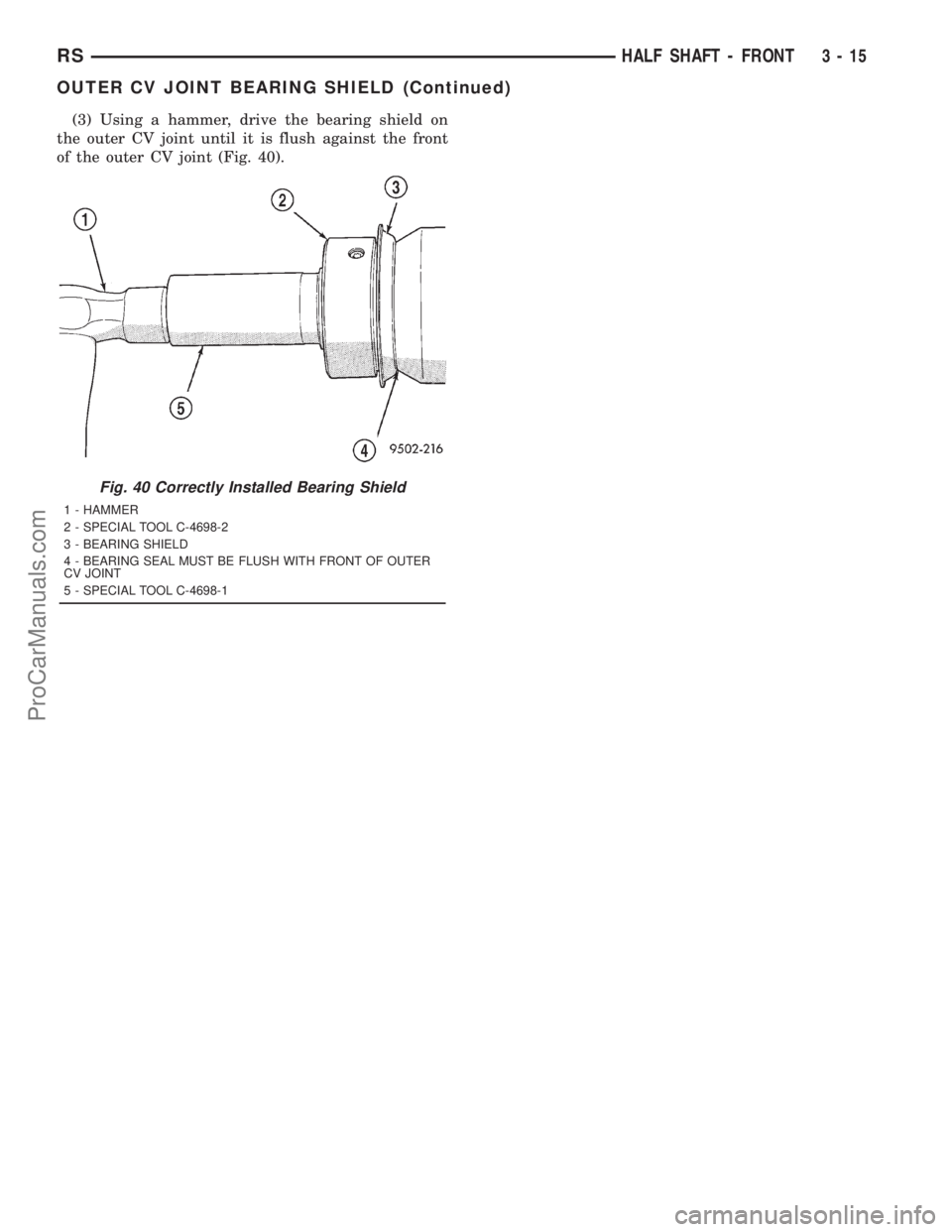

OUTER CV JOINT BEARING

SHIELD

REMOVAL

(1) Clamp half shaft in a vise by the interconnect-

ing shaft.

(2) Using a drift (Fig. 38) tap around the entire

edge of the bearing shield until it is removed from

the outer CV joint.

INSTALLATION

(1) Install bearing shield by hand on outer CV

Joint so that it is installed squarely on the CV joint.

(2) Position installer, Special Tool C-4698-2, and

handle, Special Tool C-4698-1, on face of bearing

shield (Fig. 39).

CAUTION: If bearing shield is not installed flush

against the face of the outer CV joint, interference

with steering knuckle will occur when driveshaft is

installed.

Fig. 37 Sealing Boot Retaining Clamp Installed -

Typical

1 - CLAMP

2 - TRIPOD HOUSING

3 - SPECIAL TOOL C-4975A

4 - JAWS OF SPECIAL TOOL C-4975A MUST BE CLOSED

COMPLETELY TOGETHER HERE

5 - SEALING BOOT

Fig. 38 Removing Bearing Shield from Outer CV

Joint

1 - DRIFT

2 - OUTER CV JOINT

3 - BEARING SHIELD

Fig. 39 Special Tools for Installing Bearing Shield

1 - SPECIAL TOOL C-4698-2

2 - SPECIAL TOOL C-4698-1

3 - BEARING SHIELD

4 - OUTER CV JOINT

3 - 14 HALF SHAFT - FRONTRS

CV BOOT - OUTER (Continued)

ProCarManuals.com

Page 124 of 2321

(3) Using a hammer, drive the bearing shield on

the outer CV joint until it is flush against the front

of the outer CV joint (Fig. 40).

Fig. 40 Correctly Installed Bearing Shield

1 - HAMMER

2 - SPECIAL TOOL C-4698-2

3 - BEARING SHIELD

4 - BEARING SEAL MUST BE FLUSH WITH FRONT OF OUTER

CV JOINT

5 - SPECIAL TOOL C-4698-1

RSHALF SHAFT - FRONT3-15

OUTER CV JOINT BEARING SHIELD (Continued)

ProCarManuals.com

Page 125 of 2321

HALF SHAFT - REAR

TABLE OF CONTENTS

page page

HALF SHAFT - REAR

DESCRIPTION...........................16

DIAGNOSIS AND TESTING.................16

HALF SHAFT..........................16

REMOVAL..............................16INSTALLATION...........................17

SPECIFICATIONS........................18

CV BOOT - INNER/OUTER

REMOVAL..............................18

INSTALLATION...........................20

HALF SHAFT - REAR

DESCRIPTION

The inner and outer joints of both half shaft

assemblies are tripod joints. The tripod joints are

true constant velocity (CV) joint assemblies, which

allow for the changes in half shaft length through

the jounce and rebound travel of the rear suspension.

On vehicles equipped with ABS brakes, the outer

CV joint is equipped with a tone wheel used to deter-

mine vehicle speed for ABS brake operation.

The inner tripod joint of both half shafts is bolted

rear differential assembly's output flanges. The outer

CV joint has a stub shaft that is splined into the

wheel hub and retained by a steel hub nut.

DIAGNOSIS AND TESTING - HALF SHAFT

VEHICLE INSPECTION

(1) Check for grease in the vicinity of the inboard

tripod joint and outboard CV joint; this is a sign of

inner or outer joint seal boot or seal boot clamp dam-

age.

(2) A light film of grease may appear on the right

inner tripod joint seal boot; this is considered normal

and should not require replacement of the seal boot.

NOISE AND/OR VIBRATION IN TURNS

A clicking noise and/or a vibration in turns could

be caused by one of the following conditions:

²Damaged outer CV or inner tripod joint seal

boot or seal boot clamps. This will result in the loss

and/or contamination of the joint grease, resulting in

inadequate lubrication of the joint.

²Noise may also be caused by another component

of the vehicle coming in contact with the half shafts.

CLUNKING NOISE DURING ACCELERATION

This noise may be a result of one of the following

conditions:²A torn seal boot on the inner or outer joint of the

half shaft assembly.

²A loose or missing clamp on the inner or outer

joint of the half shaft assembly.

²A damaged or worn half shaft CV joint.

SHUDDER OR VIBRATION DURING ACCELERATION

This problem could be a result of:

²A worn or damaged half shaft inner tripod joint.

²A sticking tripod joint spider assembly (inner tri-

pod joint only).

²Improper wheel alignment. (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE)

VIBRATION AT HIGHWAY SPEEDS

This problem could be a result of:

²Foreign material (mud, etc.) packed on the back-

side of the wheel(s).

²Out of balance tires or wheels. (Refer to 22 -

TIRES/WHEELS - STANDARD PROCEDURE)

²Improper tire and/or wheel runout. (Refer to 22 -

TIRES/WHEELS - DIAGNOSIS AND TESTING)

REMOVAL

(1) Lift vehicle on hoist so that the wheels hang

freely.

(2) Remove rear wheel.

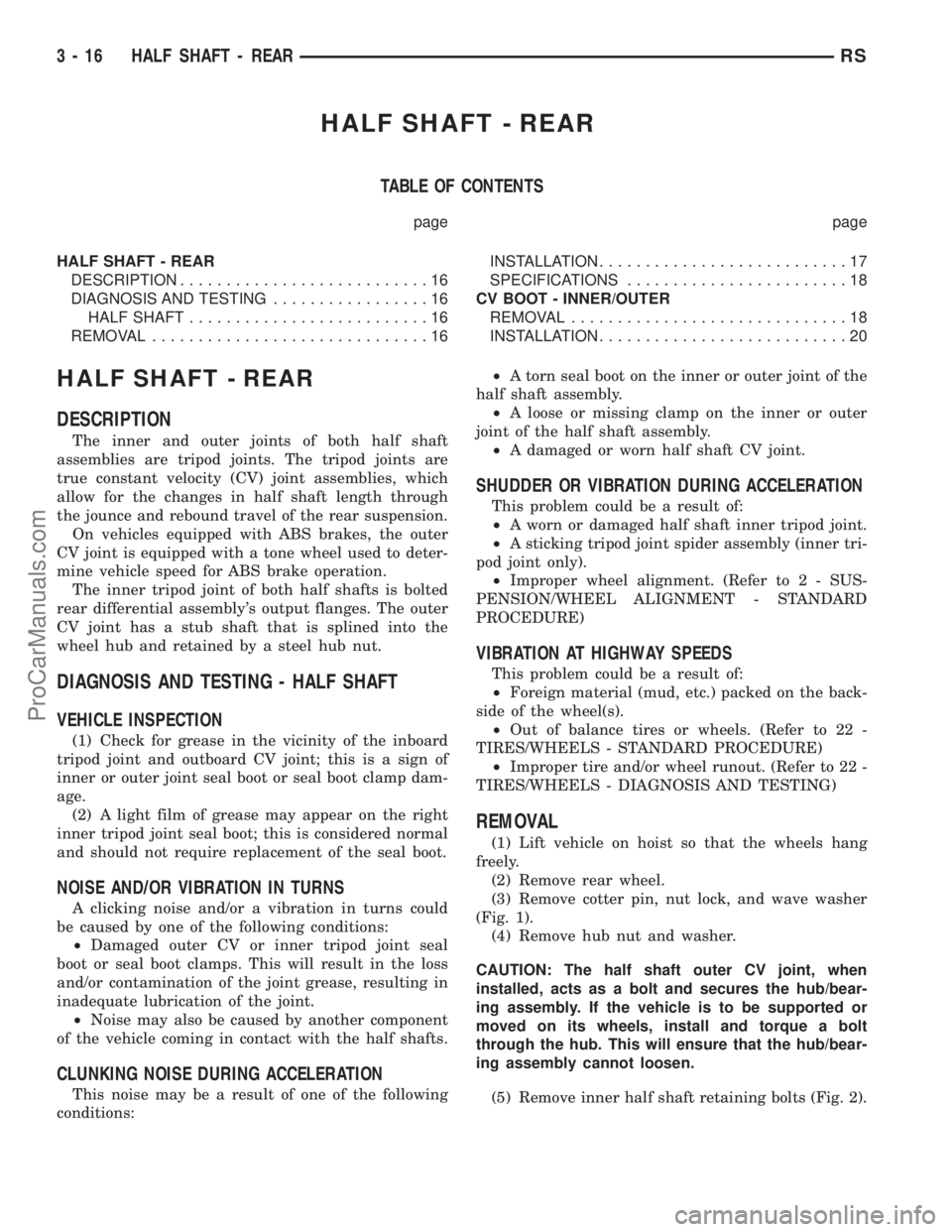

(3) Remove cotter pin, nut lock, and wave washer

(Fig. 1).

(4) Remove hub nut and washer.

CAUTION: The half shaft outer CV joint, when

installed, acts as a bolt and secures the hub/bear-

ing assembly. If the vehicle is to be supported or

moved on its wheels, install and torque a bolt

through the hub. This will ensure that the hub/bear-

ing assembly cannot loosen.

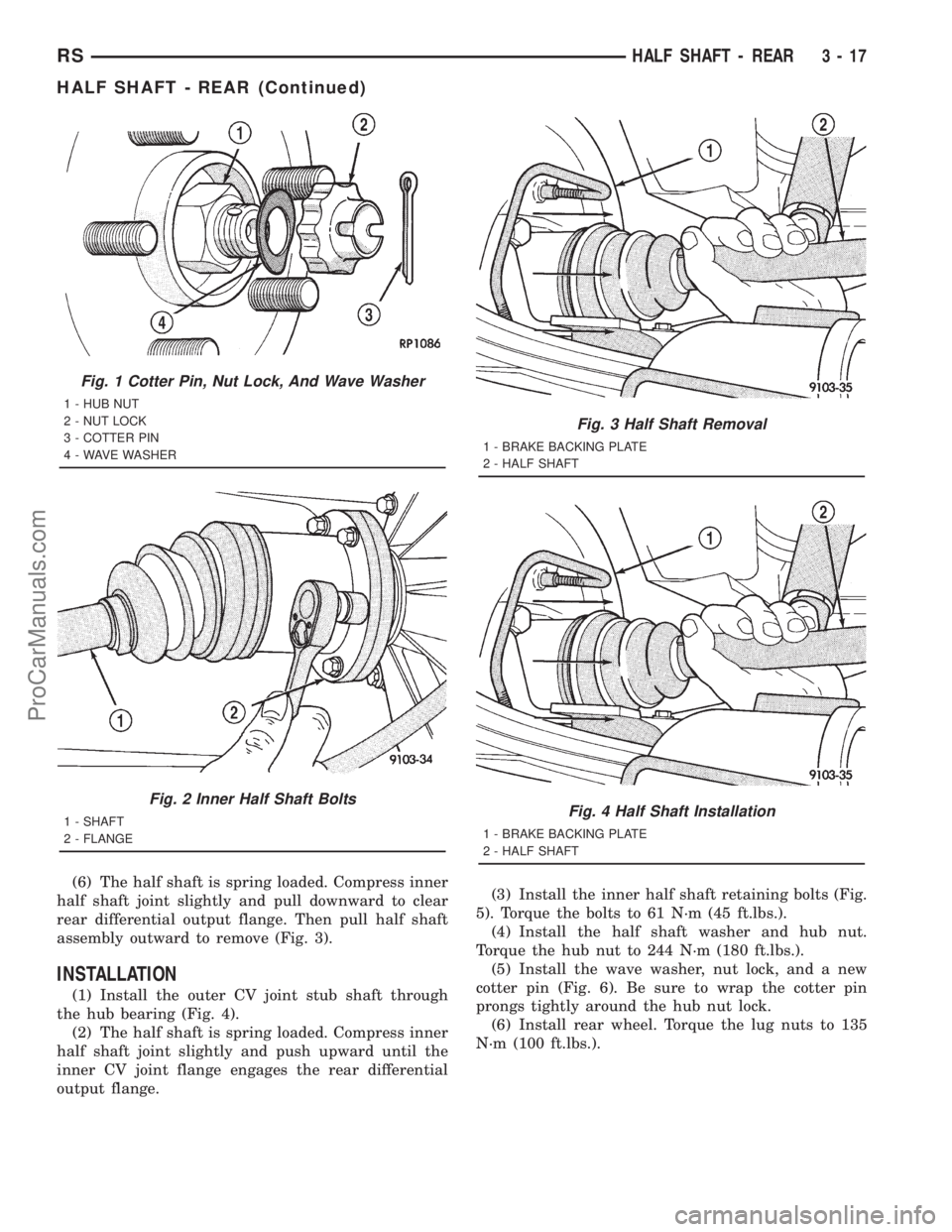

(5) Remove inner half shaft retaining bolts (Fig. 2).

3 - 16 HALF SHAFT - REARRS

ProCarManuals.com

Page 126 of 2321

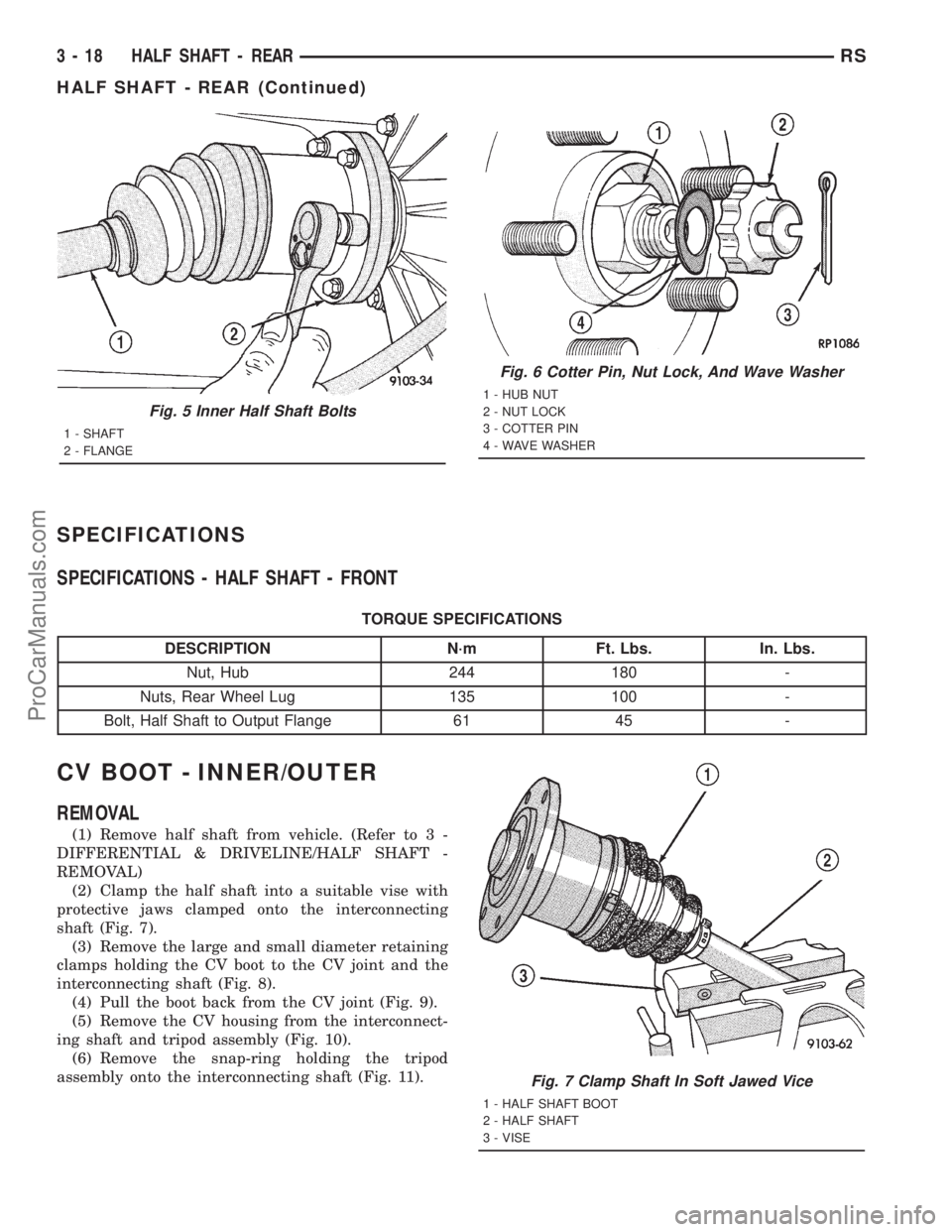

(6) The half shaft is spring loaded. Compress inner

half shaft joint slightly and pull downward to clear

rear differential output flange. Then pull half shaft

assembly outward to remove (Fig. 3).

INSTALLATION

(1) Install the outer CV joint stub shaft through

the hub bearing (Fig. 4).

(2) The half shaft is spring loaded. Compress inner

half shaft joint slightly and push upward until the

inner CV joint flange engages the rear differential

output flange.(3) Install the inner half shaft retaining bolts (Fig.

5). Torque the bolts to 61 N´m (45 ft.lbs.).

(4) Install the half shaft washer and hub nut.

Torque the hub nut to 244 N´m (180 ft.lbs.).

(5) Install the wave washer, nut lock, and a new

cotter pin (Fig. 6). Be sure to wrap the cotter pin

prongs tightly around the hub nut lock.

(6) Install rear wheel. Torque the lug nuts to 135

N´m (100 ft.lbs.).

Fig. 1 Cotter Pin, Nut Lock, And Wave Washer

1 - HUB NUT

2 - NUT LOCK

3 - COTTER PIN

4 - WAVE WASHER

Fig. 2 Inner Half Shaft Bolts

1 - SHAFT

2 - FLANGE

Fig. 3 Half Shaft Removal

1 - BRAKE BACKING PLATE

2 - HALF SHAFT

Fig. 4 Half Shaft Installation

1 - BRAKE BACKING PLATE

2 - HALF SHAFT

RSHALF SHAFT - REAR3-17

HALF SHAFT - REAR (Continued)

ProCarManuals.com

Page 127 of 2321

SPECIFICATIONS

SPECIFICATIONS - HALF SHAFT - FRONT

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Nut, Hub 244 180 -

Nuts, Rear Wheel Lug 135 100 -

Bolt, Half Shaft to Output Flange 61 45 -

CV BOOT - INNER/OUTER

REMOVAL

(1) Remove half shaft from vehicle. (Refer to 3 -

DIFFERENTIAL & DRIVELINE/HALF SHAFT -

REMOVAL)

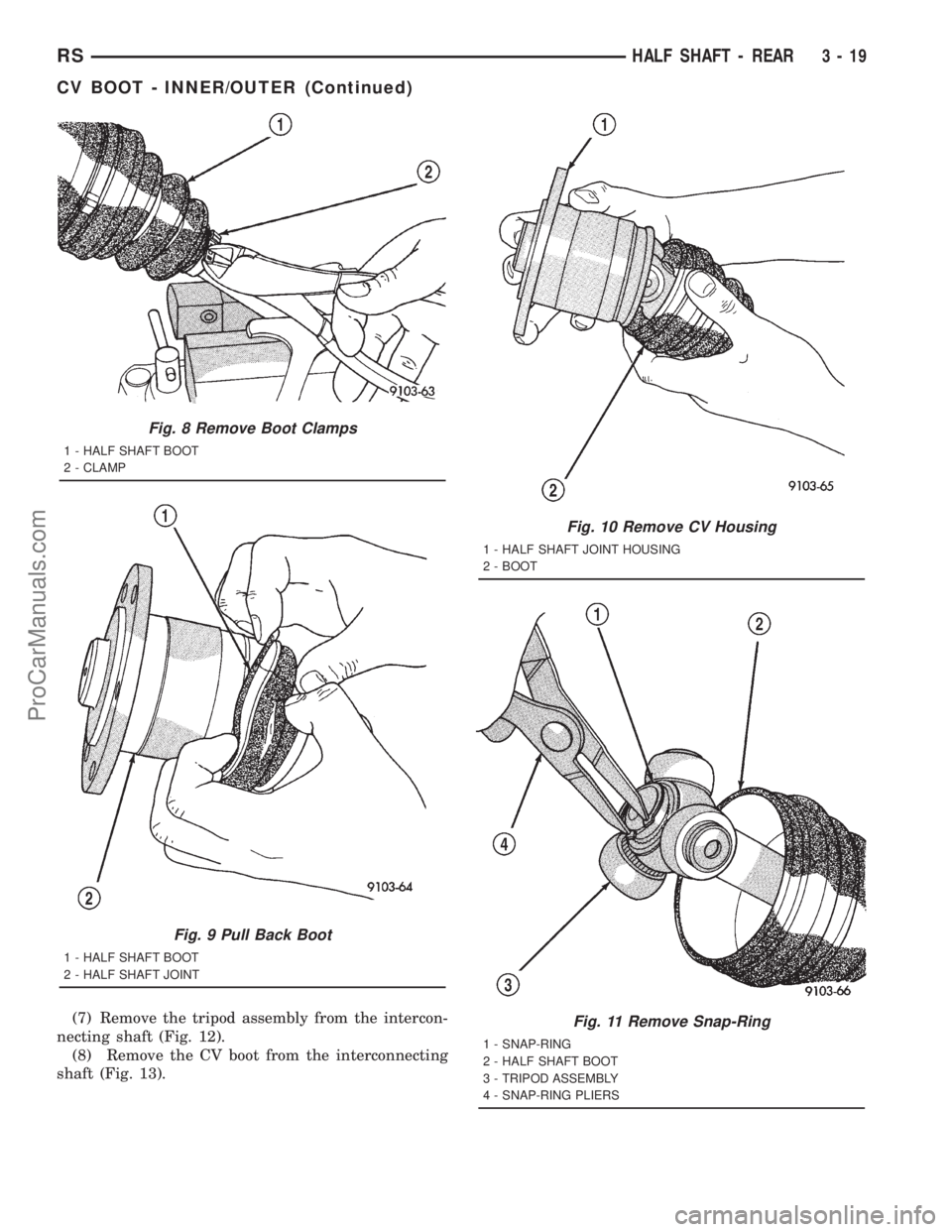

(2) Clamp the half shaft into a suitable vise with

protective jaws clamped onto the interconnecting

shaft (Fig. 7).

(3) Remove the large and small diameter retaining

clamps holding the CV boot to the CV joint and the

interconnecting shaft (Fig. 8).

(4) Pull the boot back from the CV joint (Fig. 9).

(5) Remove the CV housing from the interconnect-

ing shaft and tripod assembly (Fig. 10).

(6) Remove the snap-ring holding the tripod

assembly onto the interconnecting shaft (Fig. 11).

Fig. 5 Inner Half Shaft Bolts

1 - SHAFT

2 - FLANGE

Fig. 6 Cotter Pin, Nut Lock, And Wave Washer

1 - HUB NUT

2 - NUT LOCK

3 - COTTER PIN

4 - WAVE WASHER

Fig. 7 Clamp Shaft In Soft Jawed Vice

1 - HALF SHAFT BOOT

2 - HALF SHAFT

3 - VISE

3 - 18 HALF SHAFT - REARRS

HALF SHAFT - REAR (Continued)

ProCarManuals.com

Page 128 of 2321

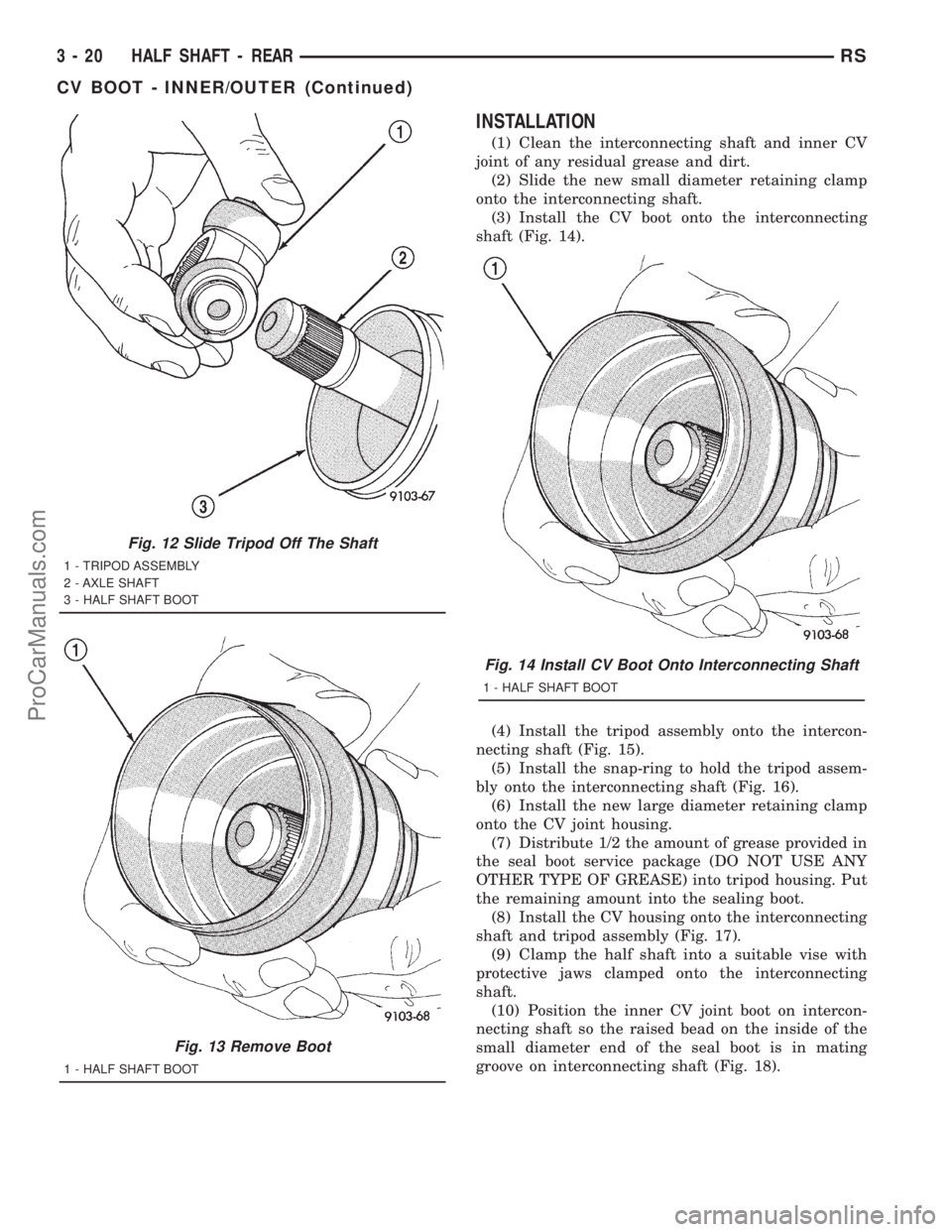

(7) Remove the tripod assembly from the intercon-

necting shaft (Fig. 12).

(8) Remove the CV boot from the interconnecting

shaft (Fig. 13).

Fig. 8 Remove Boot Clamps

1 - HALF SHAFT BOOT

2 - CLAMP

Fig. 9 Pull Back Boot

1 - HALF SHAFT BOOT

2 - HALF SHAFT JOINT

Fig. 10 Remove CV Housing

1 - HALF SHAFT JOINT HOUSING

2 - BOOT

Fig. 11 Remove Snap-Ring

1 - SNAP-RING

2 - HALF SHAFT BOOT

3 - TRIPOD ASSEMBLY

4 - SNAP-RING PLIERS

RSHALF SHAFT - REAR3-19

CV BOOT - INNER/OUTER (Continued)

ProCarManuals.com

Page 129 of 2321

INSTALLATION

(1) Clean the interconnecting shaft and inner CV

joint of any residual grease and dirt.

(2) Slide the new small diameter retaining clamp

onto the interconnecting shaft.

(3) Install the CV boot onto the interconnecting

shaft (Fig. 14).

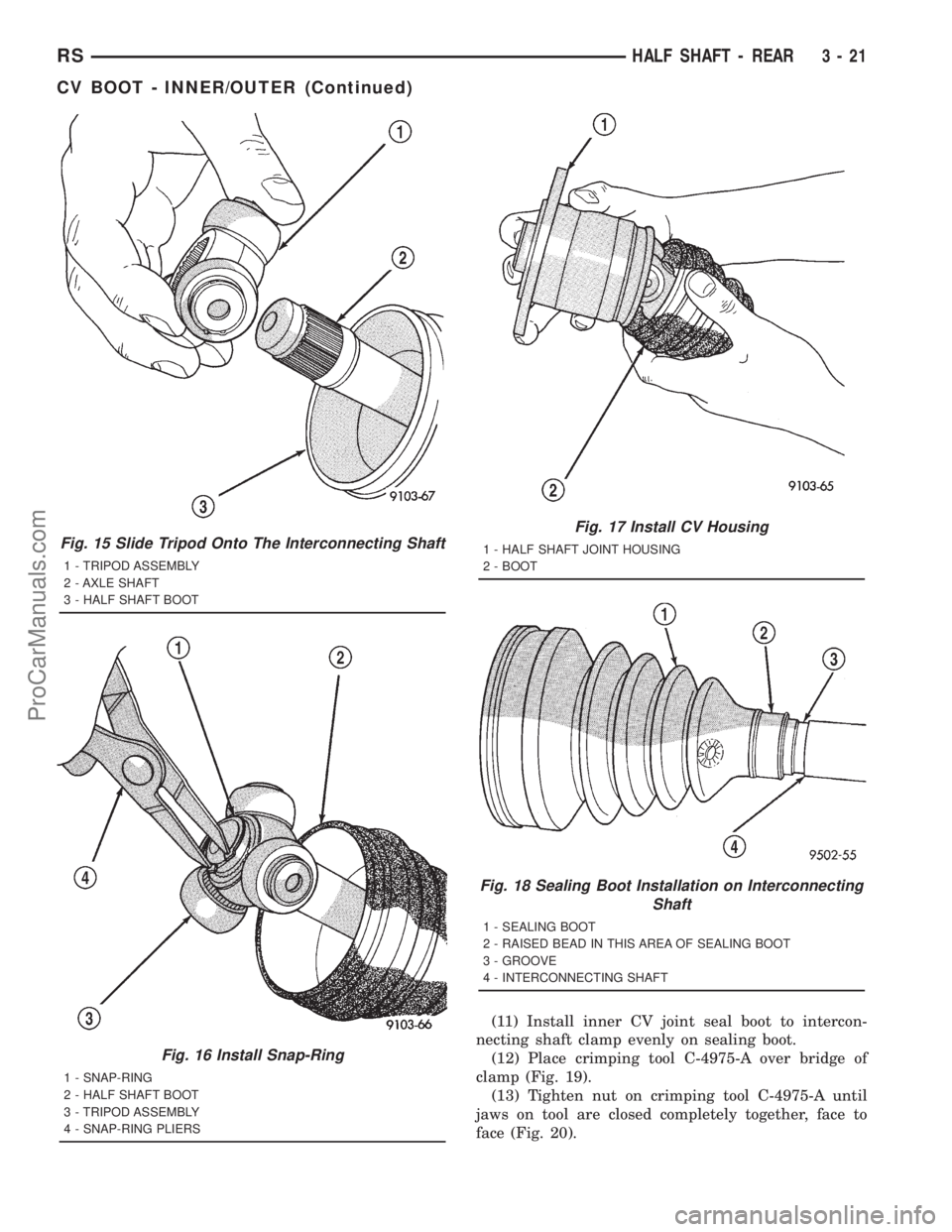

(4) Install the tripod assembly onto the intercon-

necting shaft (Fig. 15).

(5) Install the snap-ring to hold the tripod assem-

bly onto the interconnecting shaft (Fig. 16).

(6) Install the new large diameter retaining clamp

onto the CV joint housing.

(7) Distribute 1/2 the amount of grease provided in

the seal boot service package (DO NOT USE ANY

OTHER TYPE OF GREASE) into tripod housing. Put

the remaining amount into the sealing boot.

(8) Install the CV housing onto the interconnecting

shaft and tripod assembly (Fig. 17).

(9) Clamp the half shaft into a suitable vise with

protective jaws clamped onto the interconnecting

shaft.

(10) Position the inner CV joint boot on intercon-

necting shaft so the raised bead on the inside of the

small diameter end of the seal boot is in mating

groove on interconnecting shaft (Fig. 18).

Fig. 12 Slide Tripod Off The Shaft

1 - TRIPOD ASSEMBLY

2 - AXLE SHAFT

3 - HALF SHAFT BOOT

Fig. 13 Remove Boot

1 - HALF SHAFT BOOT

Fig. 14 Install CV Boot Onto Interconnecting Shaft

1 - HALF SHAFT BOOT

3 - 20 HALF SHAFT - REARRS

CV BOOT - INNER/OUTER (Continued)

ProCarManuals.com

Page 130 of 2321

(11) Install inner CV joint seal boot to intercon-

necting shaft clamp evenly on sealing boot.

(12) Place crimping tool C-4975-A over bridge of

clamp (Fig. 19).

(13) Tighten nut on crimping tool C-4975-A until

jaws on tool are closed completely together, face to

face (Fig. 20).

Fig. 15 Slide Tripod Onto The Interconnecting Shaft

1 - TRIPOD ASSEMBLY

2 - AXLE SHAFT

3 - HALF SHAFT BOOT

Fig. 16 Install Snap-Ring

1 - SNAP-RING

2 - HALF SHAFT BOOT

3 - TRIPOD ASSEMBLY

4 - SNAP-RING PLIERS

Fig. 17 Install CV Housing

1 - HALF SHAFT JOINT HOUSING

2 - BOOT

Fig. 18 Sealing Boot Installation on Interconnecting

Shaft

1 - SEALING BOOT

2 - RAISED BEAD IN THIS AREA OF SEALING BOOT

3 - GROOVE

4 - INTERCONNECTING SHAFT

RSHALF SHAFT - REAR3-21

CV BOOT - INNER/OUTER (Continued)

ProCarManuals.com