DODGE TOWN AND COUNTRY 2001 Service Manual

TOWN AND COUNTRY 2001

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56921/w960_56921-0.png

DODGE TOWN AND COUNTRY 2001 Service Manual

Trending: tires, mirror, airbag off, immobilizer, oil change, hood release, key fob battery

Page 1921 of 2321

(13) Apply a coat of epoxy to the exposed ends of

the support squares (Fig. 12).

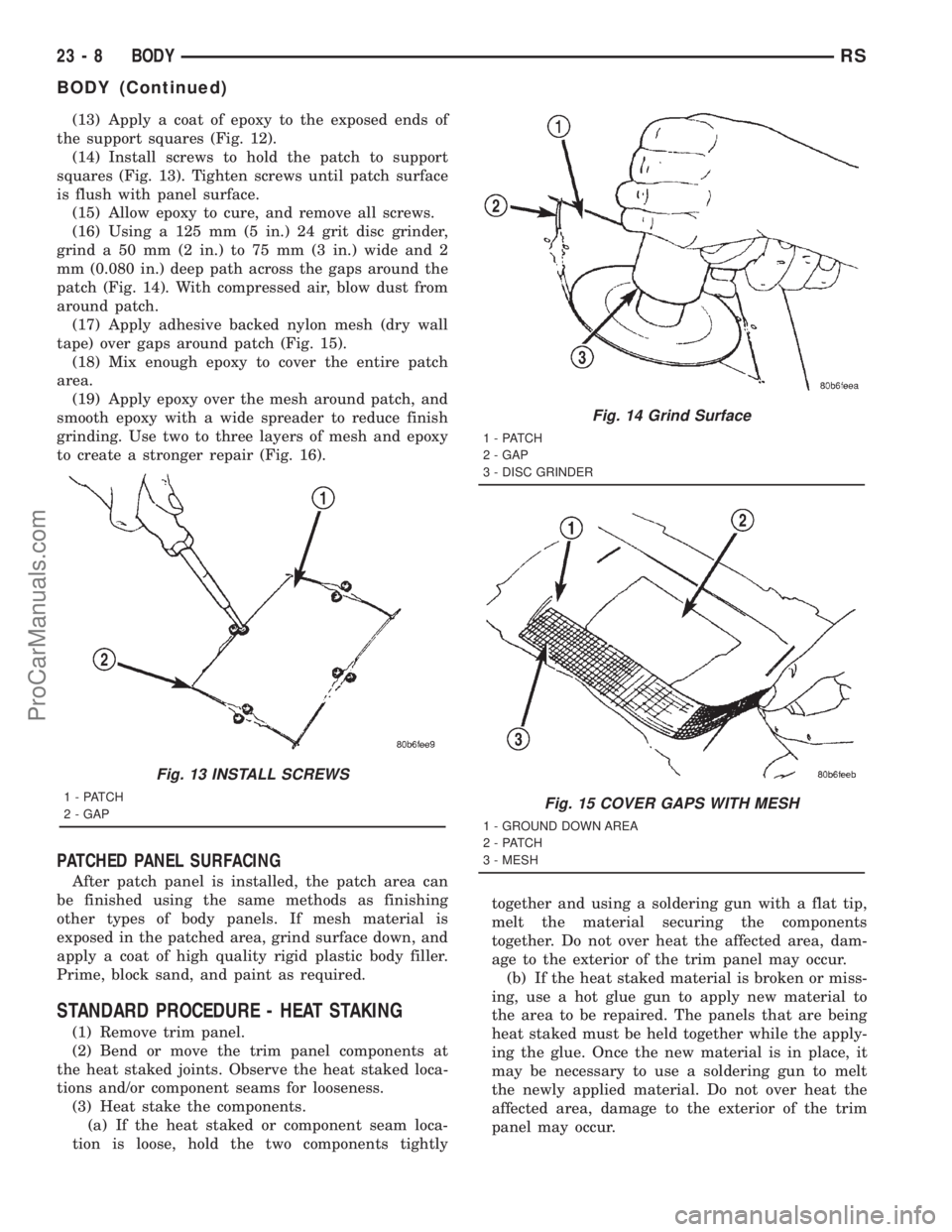

(14) Install screws to hold the patch to support

squares (Fig. 13). Tighten screws until patch surface

is flush with panel surface.

(15) Allow epoxy to cure, and remove all screws.

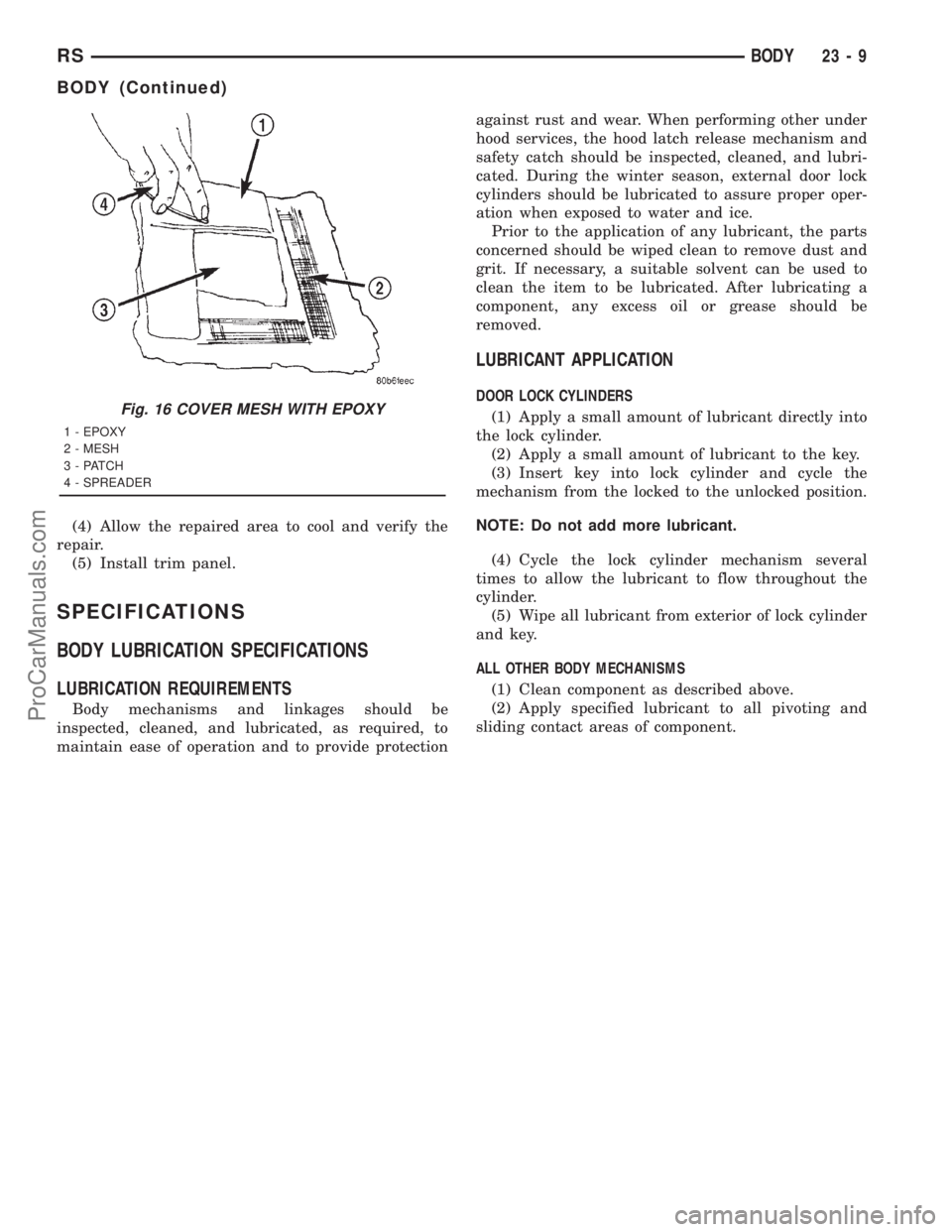

(16) Using a 125 mm (5 in.) 24 grit disc grinder,

grind a 50 mm (2 in.) to 75 mm (3 in.) wide and 2

mm (0.080 in.) deep path across the gaps around the

patch (Fig. 14). With compressed air, blow dust from

around patch.

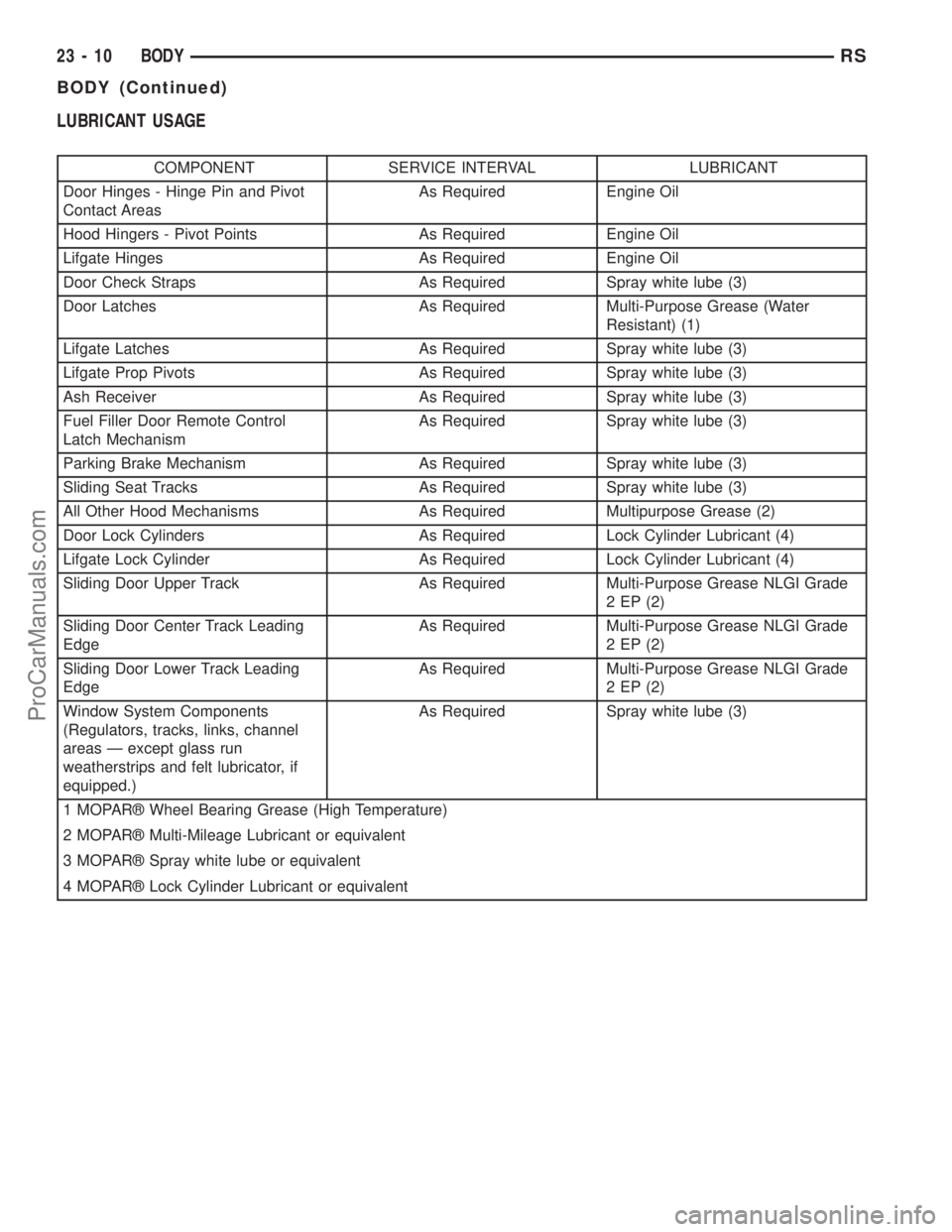

(17) Apply adhesive backed nylon mesh (dry wall

tape) over gaps around patch (Fig. 15).

(18) Mix enough epoxy to cover the entire patch

area.

(19) Apply epoxy over the mesh around patch, and

smooth epoxy with a wide spreader to reduce finish

grinding. Use two to three layers of mesh and epoxy

to create a stronger repair (Fig. 16).

PATCHED PANEL SURFACING

After patch panel is installed, the patch area can

be finished using the same methods as finishing

other types of body panels. If mesh material is

exposed in the patched area, grind surface down, and

apply a coat of high quality rigid plastic body filler.

Prime, block sand, and paint as required.

STANDARD PROCEDURE - HEAT STAKING

(1) Remove trim panel.

(2) Bend or move the trim panel components at

the heat staked joints. Observe the heat staked loca-

tions and/or component seams for looseness.

(3) Heat stake the components.

(a) If the heat staked or component seam loca-

tion is loose, hold the two components tightlytogether and using a soldering gun with a flat tip,

melt the material securing the components

together. Do not over heat the affected area, dam-

age to the exterior of the trim panel may occur.

(b) If the heat staked material is broken or miss-

ing, use a hot glue gun to apply new material to

the area to be repaired. The panels that are being

heat staked must be held together while the apply-

ing the glue. Once the new material is in place, it

may be necessary to use a soldering gun to melt

the newly applied material. Do not over heat the

affected area, damage to the exterior of the trim

panel may occur.

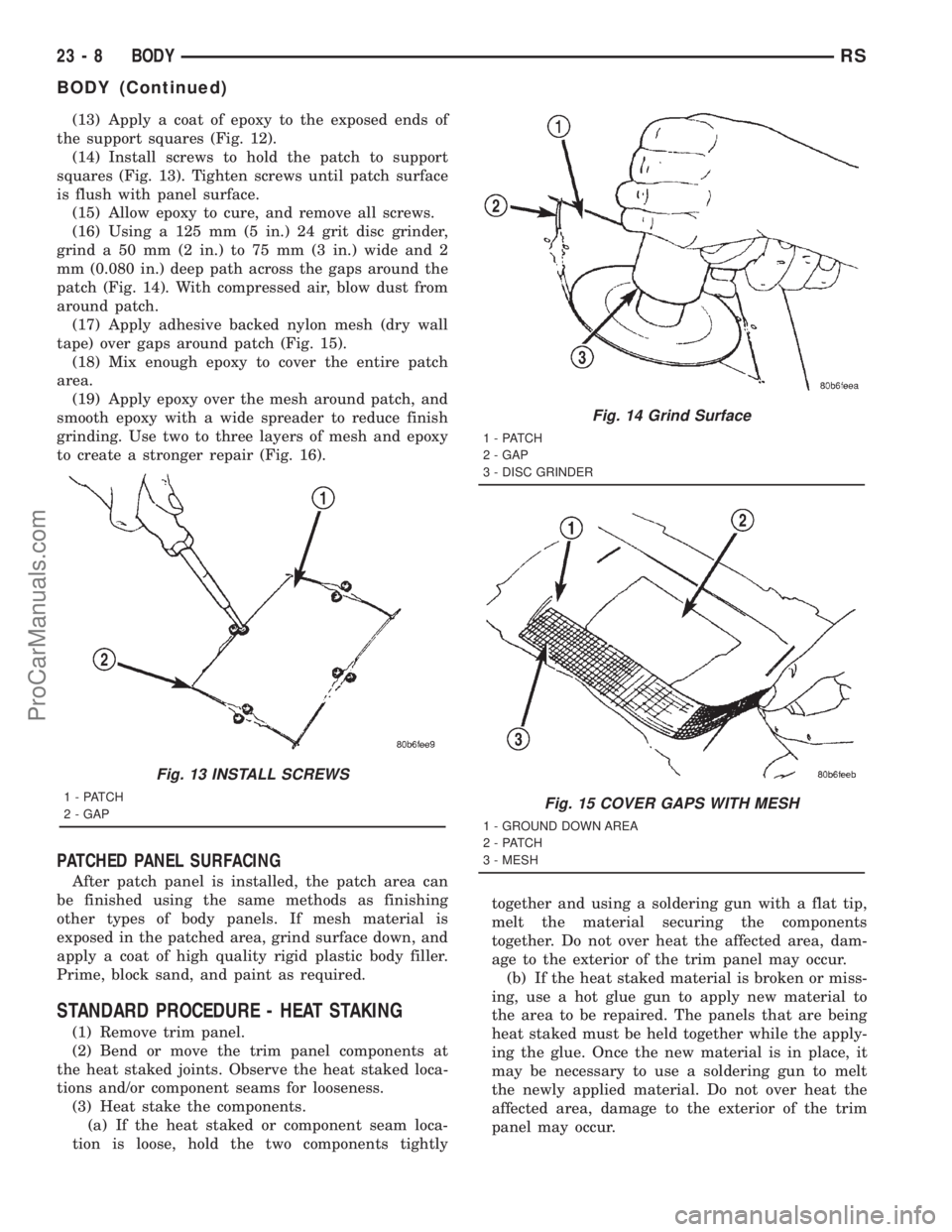

Fig. 13 INSTALL SCREWS

1 - PATCH

2 - GAP

Fig. 14 Grind Surface

1 - PATCH

2 - GAP

3 - DISC GRINDER

Fig. 15 COVER GAPS WITH MESH

1 - GROUND DOWN AREA

2 - PATCH

3 - MESH

23 - 8 BODYRS

BODY (Continued)

ProCarManuals.com

Page 1922 of 2321

(4) Allow the repaired area to cool and verify the

repair.

(5) Install trim panel.

SPECIFICATIONS

BODY LUBRICATION SPECIFICATIONS

LUBRICATION REQUIREMENTS

Body mechanisms and linkages should be

inspected, cleaned, and lubricated, as required, to

maintain ease of operation and to provide protectionagainst rust and wear. When performing other under

hood services, the hood latch release mechanism and

safety catch should be inspected, cleaned, and lubri-

cated. During the winter season, external door lock

cylinders should be lubricated to assure proper oper-

ation when exposed to water and ice.

Prior to the application of any lubricant, the parts

concerned should be wiped clean to remove dust and

grit. If necessary, a suitable solvent can be used to

clean the item to be lubricated. After lubricating a

component, any excess oil or grease should be

removed.

LUBRICANT APPLICATION

DOOR LOCK CYLINDERS

(1) Apply a small amount of lubricant directly into

the lock cylinder.

(2) Apply a small amount of lubricant to the key.

(3) Insert key into lock cylinder and cycle the

mechanism from the locked to the unlocked position.

NOTE: Do not add more lubricant.

(4) Cycle the lock cylinder mechanism several

times to allow the lubricant to flow throughout the

cylinder.

(5) Wipe all lubricant from exterior of lock cylinder

and key.

ALL OTHER BODY MECHANISMS

(1) Clean component as described above.

(2) Apply specified lubricant to all pivoting and

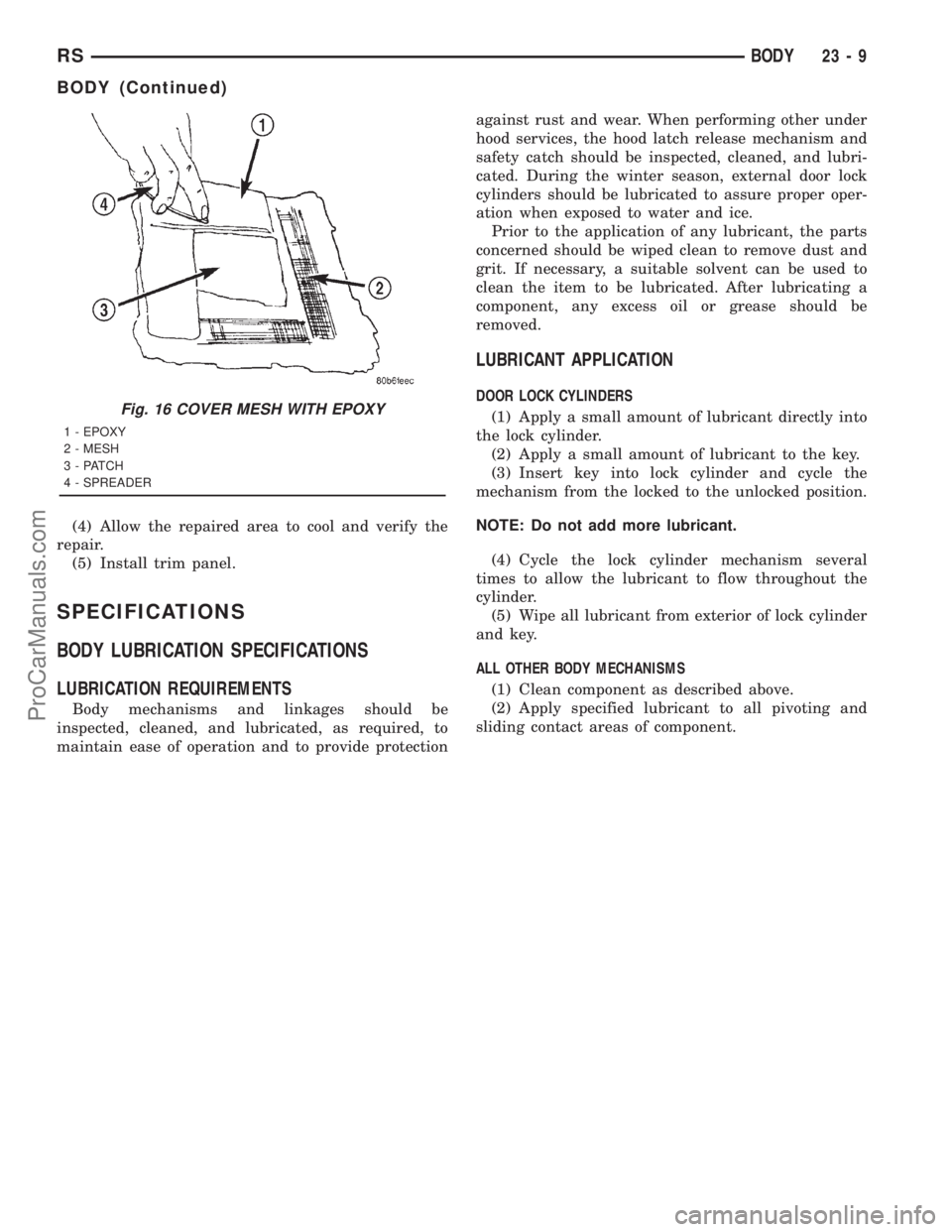

sliding contact areas of component.Fig. 16 COVER MESH WITH EPOXY

1 - EPOXY

2 - MESH

3 - PATCH

4 - SPREADER

RSBODY23-9

BODY (Continued)

ProCarManuals.com

Page 1923 of 2321

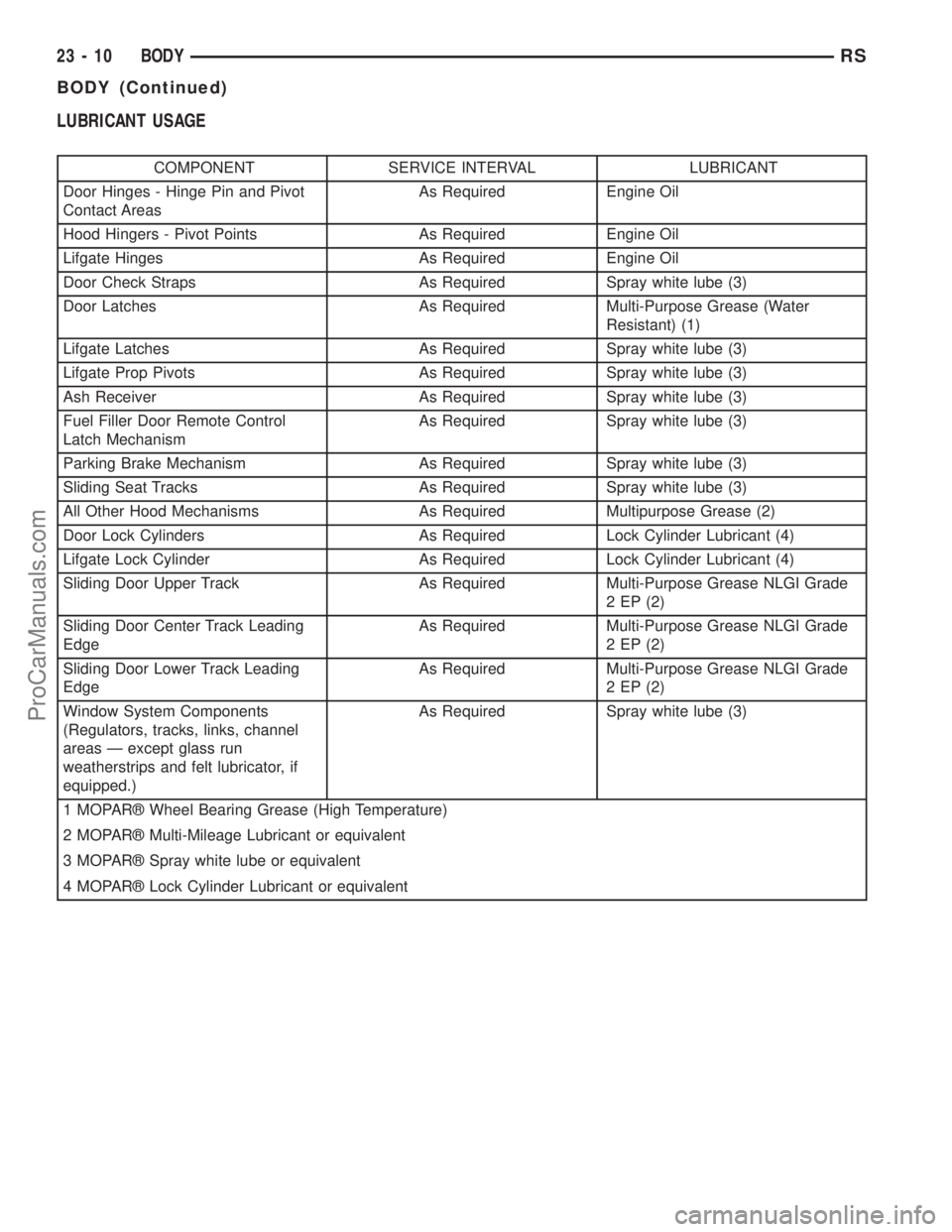

LUBRICANT USAGE

COMPONENT SERVICE INTERVAL LUBRICANT

Door Hinges - Hinge Pin and Pivot

Contact AreasAs Required Engine Oil

Hood Hingers - Pivot Points As Required Engine Oil

Lifgate Hinges As Required Engine Oil

Door Check Straps As Required Spray white lube (3)

Door Latches As Required Multi-Purpose Grease (Water

Resistant) (1)

Lifgate Latches As Required Spray white lube (3)

Lifgate Prop Pivots As Required Spray white lube (3)

Ash Receiver As Required Spray white lube (3)

Fuel Filler Door Remote Control

Latch MechanismAs Required Spray white lube (3)

Parking Brake Mechanism As Required Spray white lube (3)

Sliding Seat Tracks As Required Spray white lube (3)

All Other Hood Mechanisms As Required Multipurpose Grease (2)

Door Lock Cylinders As Required Lock Cylinder Lubricant (4)

Lifgate Lock Cylinder As Required Lock Cylinder Lubricant (4)

Sliding Door Upper Track As Required Multi-Purpose Grease NLGI Grade

2 EP (2)

Sliding Door Center Track Leading

EdgeAs Required Multi-Purpose Grease NLGI Grade

2 EP (2)

Sliding Door Lower Track Leading

EdgeAs Required Multi-Purpose Grease NLGI Grade

2 EP (2)

Window System Components

(Regulators, tracks, links, channel

areas Ð except glass run

weatherstrips and felt lubricator, if

equipped.)As Required Spray white lube (3)

1 MOPARž Wheel Bearing Grease (High Temperature)

2 MOPARž Multi-Mileage Lubricant or equivalent

3 MOPARž Spray white lube or equivalent

4 MOPARž Lock Cylinder Lubricant or equivalent

23 - 10 BODYRS

BODY (Continued)

ProCarManuals.com

Page 1924 of 2321

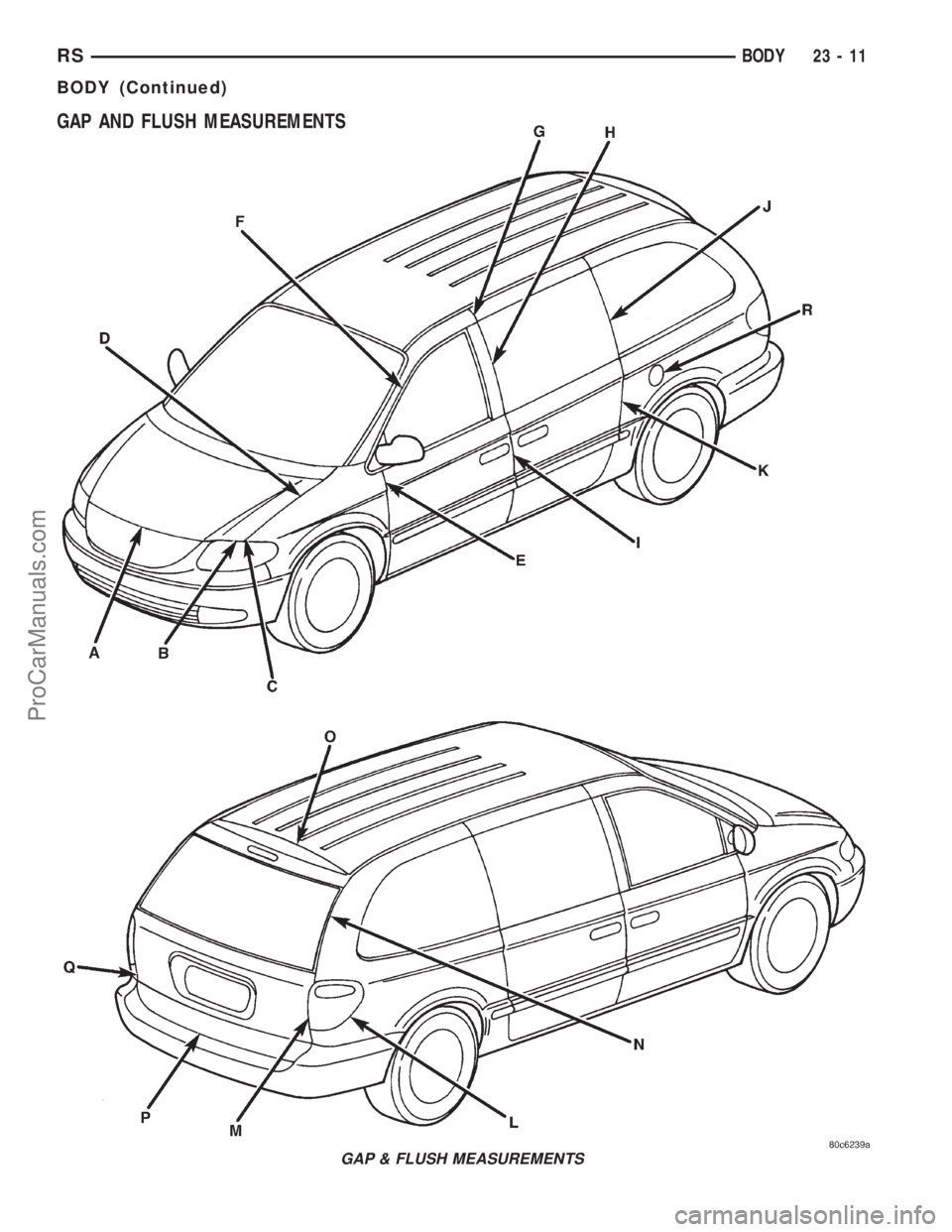

GAP AND FLUSH MEASUREMENTS

GAP & FLUSH MEASUREMENTS

RSBODY23-11

BODY (Continued)

ProCarManuals.com

Page 1925 of 2321

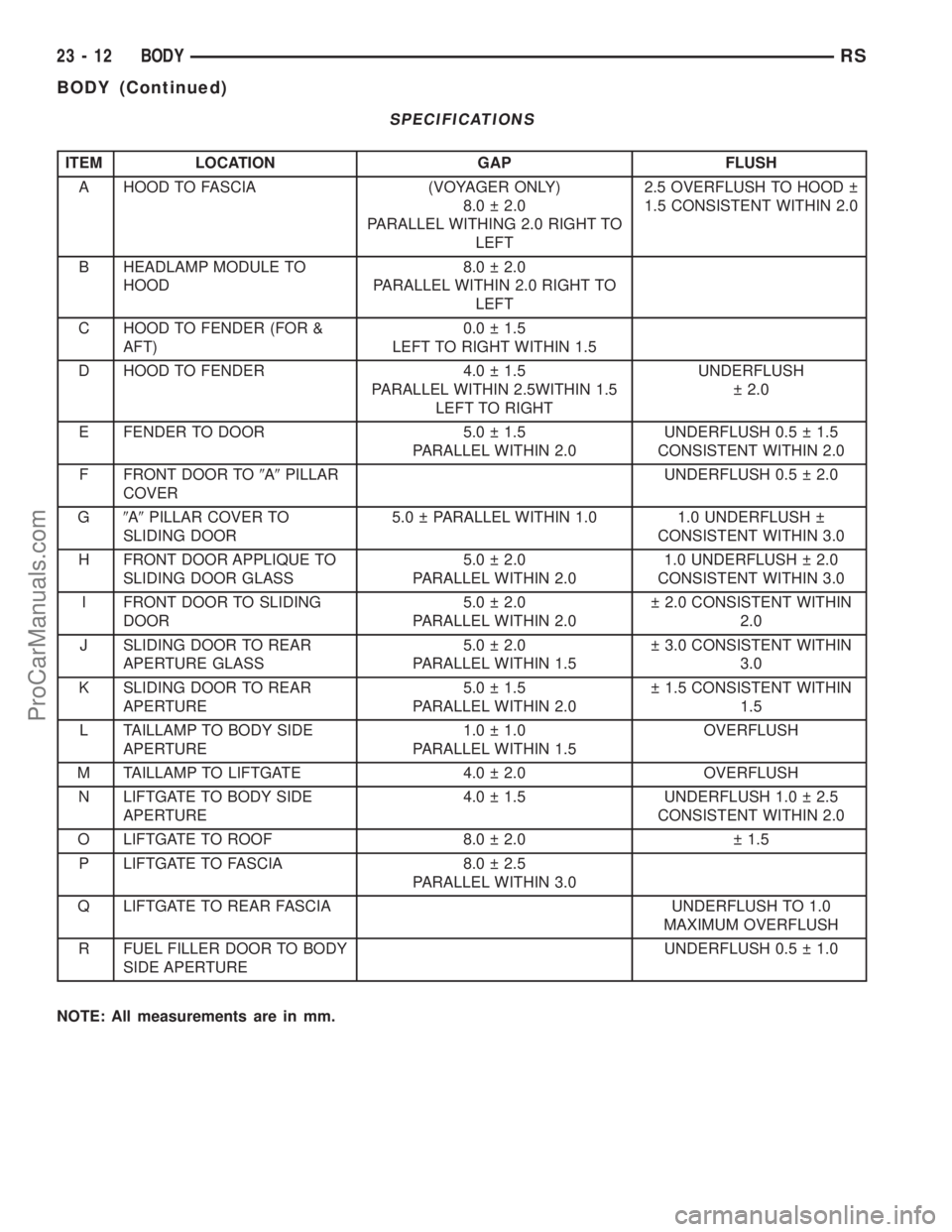

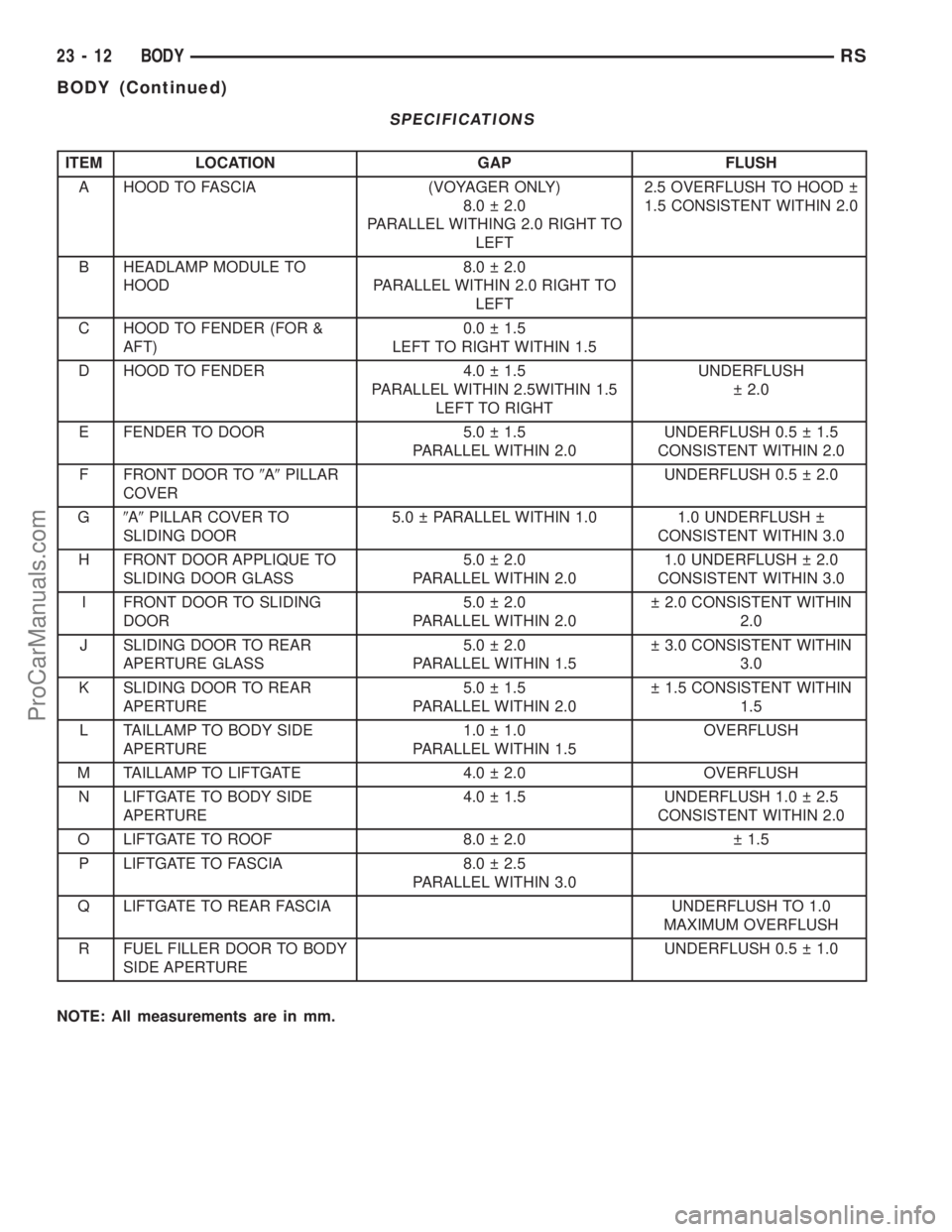

SPECIFICATIONS

ITEM LOCATION GAP FLUSH

A HOOD TO FASCIA (VOYAGER ONLY)

8.0 2.0

PARALLEL WITHING 2.0 RIGHT TO

LEFT2.5 OVERFLUSH TO HOOD

1.5 CONSISTENT WITHIN 2.0

B HEADLAMP MODULE TO

HOOD8.0 2.0

PARALLEL WITHIN 2.0 RIGHT TO

LEFT

C HOOD TO FENDER (FOR &

AFT)0.0 1.5

LEFT TO RIGHT WITHIN 1.5

D HOOD TO FENDER 4.0 1.5

PARALLEL WITHIN 2.5WITHIN 1.5

LEFT TO RIGHTUNDERFLUSH

2.0

E FENDER TO DOOR 5.0 1.5

PARALLEL WITHIN 2.0UNDERFLUSH 0.5 1.5

CONSISTENT WITHIN 2.0

F FRONT DOOR TO9A9PILLAR

COVERUNDERFLUSH 0.5 2.0

G9A9PILLAR COVER TO

SLIDING DOOR5.0 PARALLEL WITHIN 1.0 1.0 UNDERFLUSH

CONSISTENT WITHIN 3.0

H FRONT DOOR APPLIQUE TO

SLIDING DOOR GLASS5.0 2.0

PARALLEL WITHIN 2.01.0 UNDERFLUSH 2.0

CONSISTENT WITHIN 3.0

I FRONT DOOR TO SLIDING

DOOR5.0 2.0

PARALLEL WITHIN 2.0 2.0 CONSISTENT WITHIN

2.0

J SLIDING DOOR TO REAR

APERTURE GLASS5.0 2.0

PARALLEL WITHIN 1.5 3.0 CONSISTENT WITHIN

3.0

K SLIDING DOOR TO REAR

APERTURE5.0 1.5

PARALLEL WITHIN 2.0 1.5 CONSISTENT WITHIN

1.5

L TAILLAMP TO BODY SIDE

APERTURE1.0 1.0

PARALLEL WITHIN 1.5OVERFLUSH

M TAILLAMP TO LIFTGATE 4.0 2.0 OVERFLUSH

N LIFTGATE TO BODY SIDE

APERTURE4.0 1.5 UNDERFLUSH 1.0 2.5

CONSISTENT WITHIN 2.0

O LIFTGATE TO ROOF 8.0 2.0 1.5

P LIFTGATE TO FASCIA 8.0 2.5

PARALLEL WITHIN 3.0

Q LIFTGATE TO REAR FASCIA UNDERFLUSH TO 1.0

MAXIMUM OVERFLUSH

R FUEL FILLER DOOR TO BODY

SIDE APERTUREUNDERFLUSH 0.5 1.0

NOTE: All measurements are in mm.

23 - 12 BODYRS

BODY (Continued)

ProCarManuals.com

Page 1926 of 2321

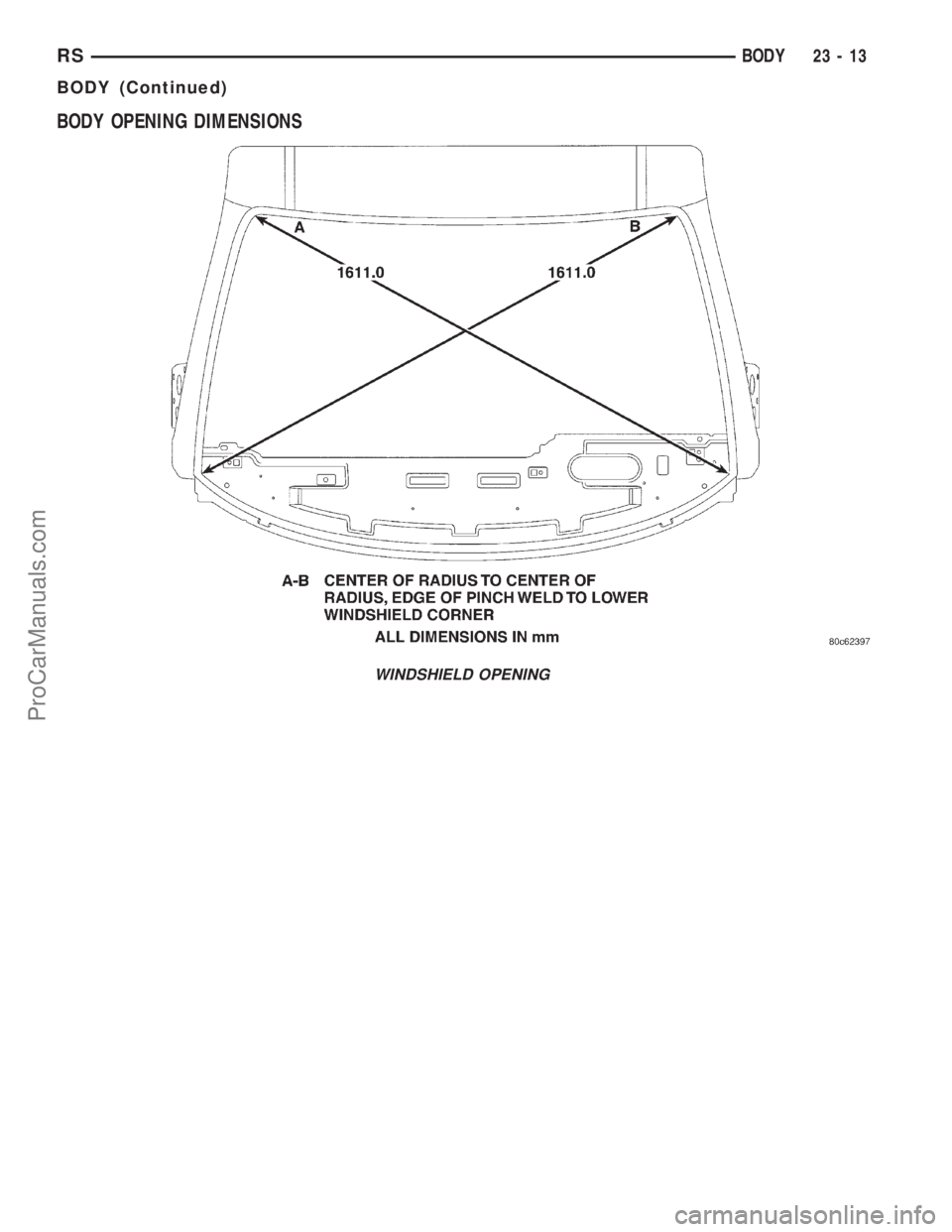

BODY OPENING DIMENSIONS

WINDSHIELD OPENING

RSBODY23-13

BODY (Continued)

ProCarManuals.com

Page 1927 of 2321

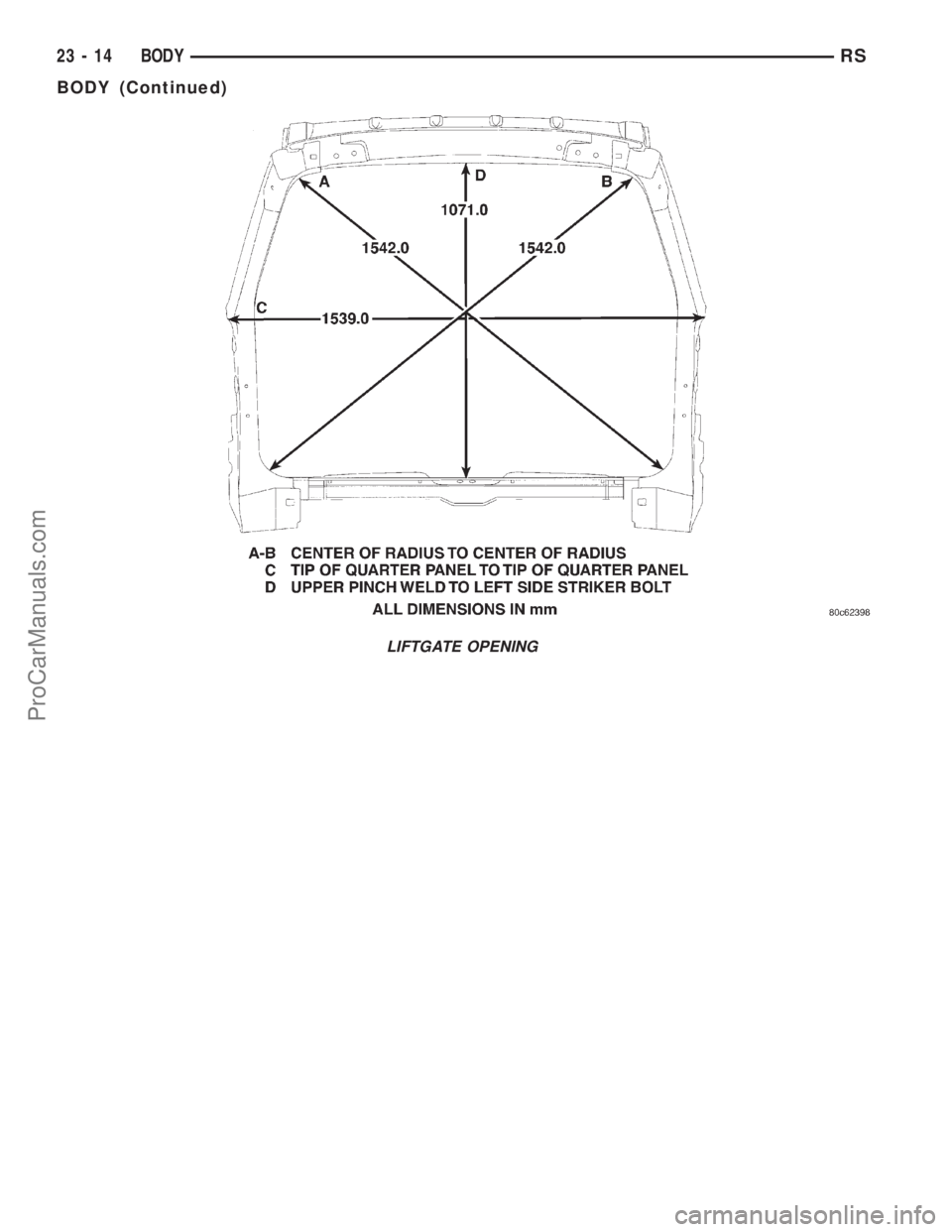

LIFTGATE OPENING

23 - 14 BODYRS

BODY (Continued)

ProCarManuals.com

Page 1928 of 2321

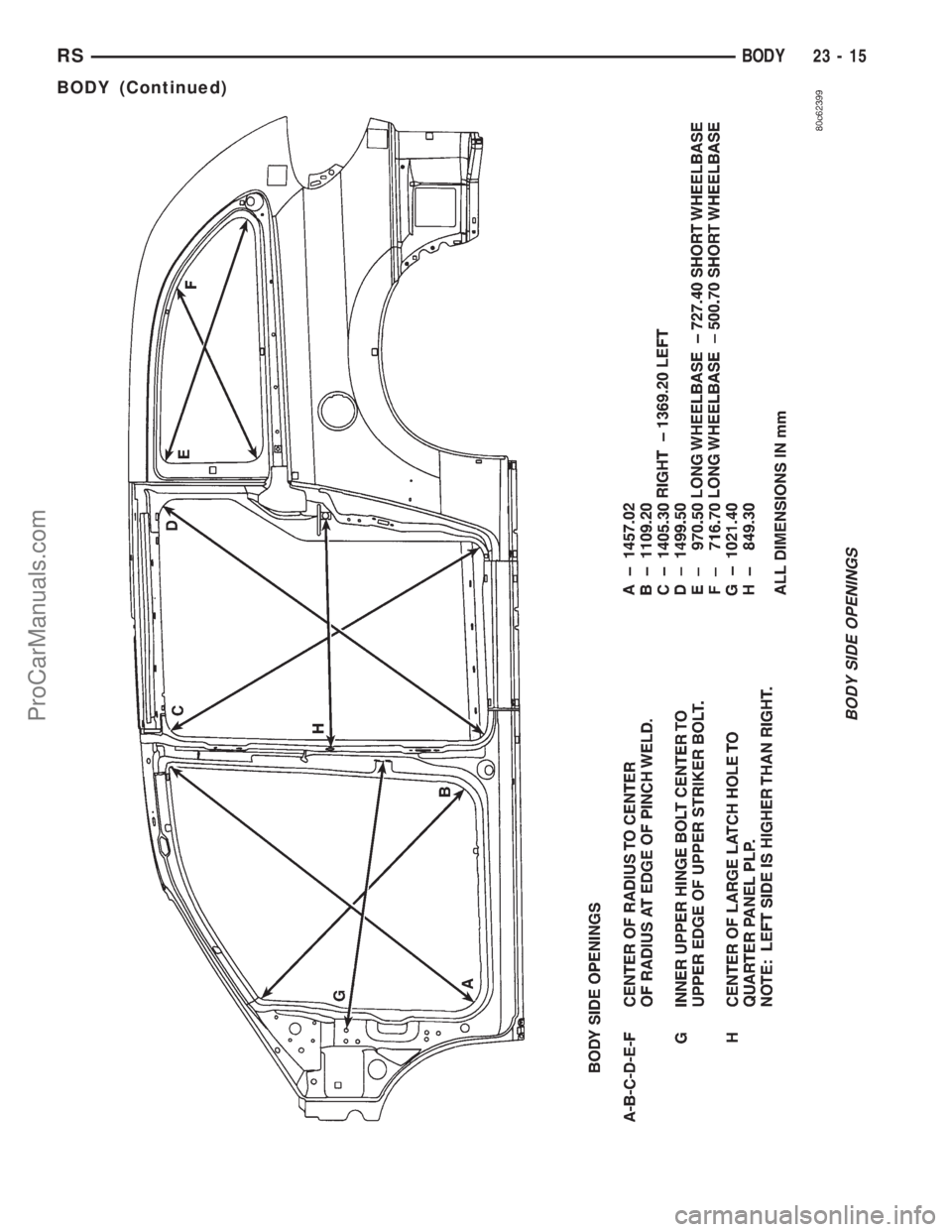

BODY SIDE OPENINGS

RSBODY23-15

BODY (Continued)

ProCarManuals.com

Page 1929 of 2321

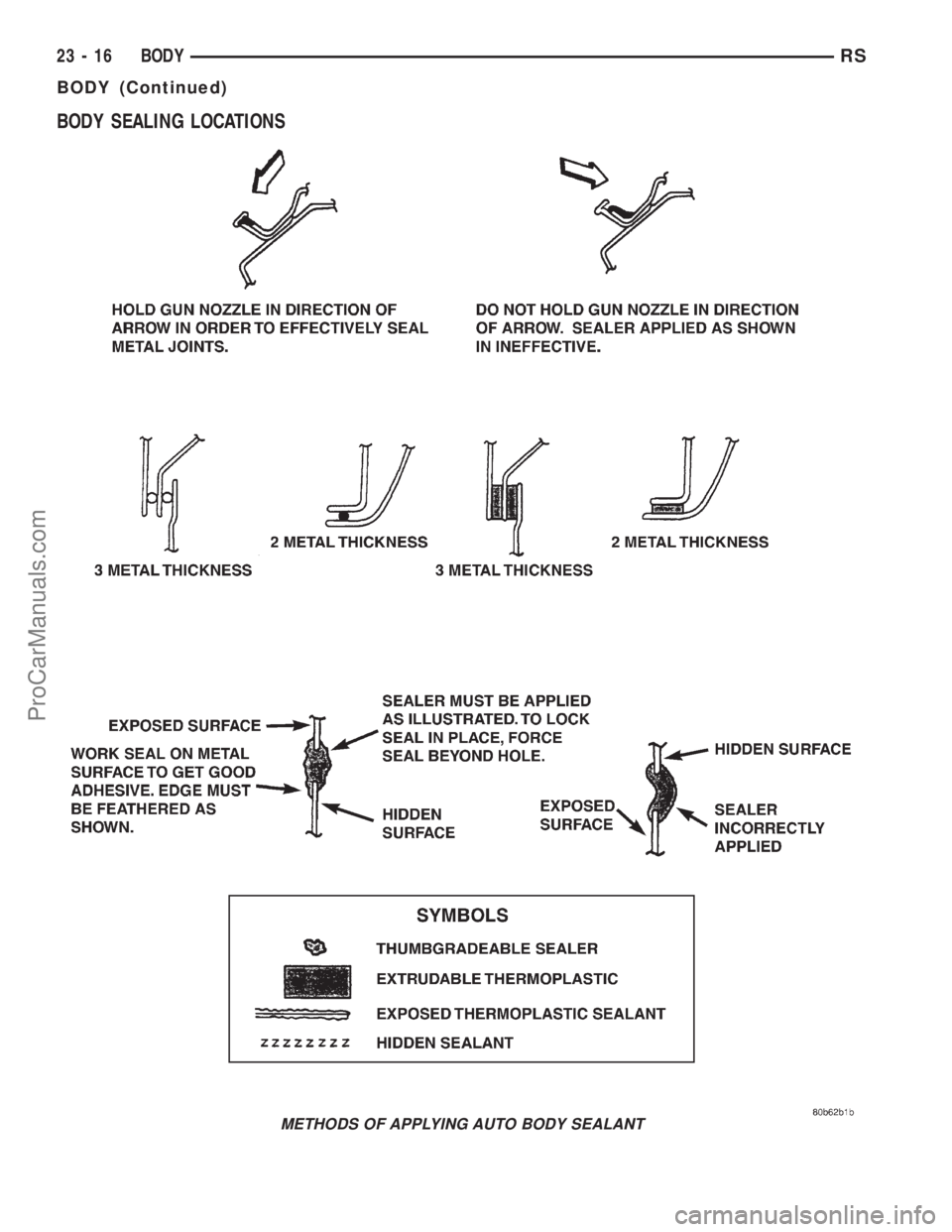

BODY SEALING LOCATIONS

METHODS OF APPLYING AUTO BODY SEALANT

23 - 16 BODYRS

BODY (Continued)

ProCarManuals.com

Page 1930 of 2321

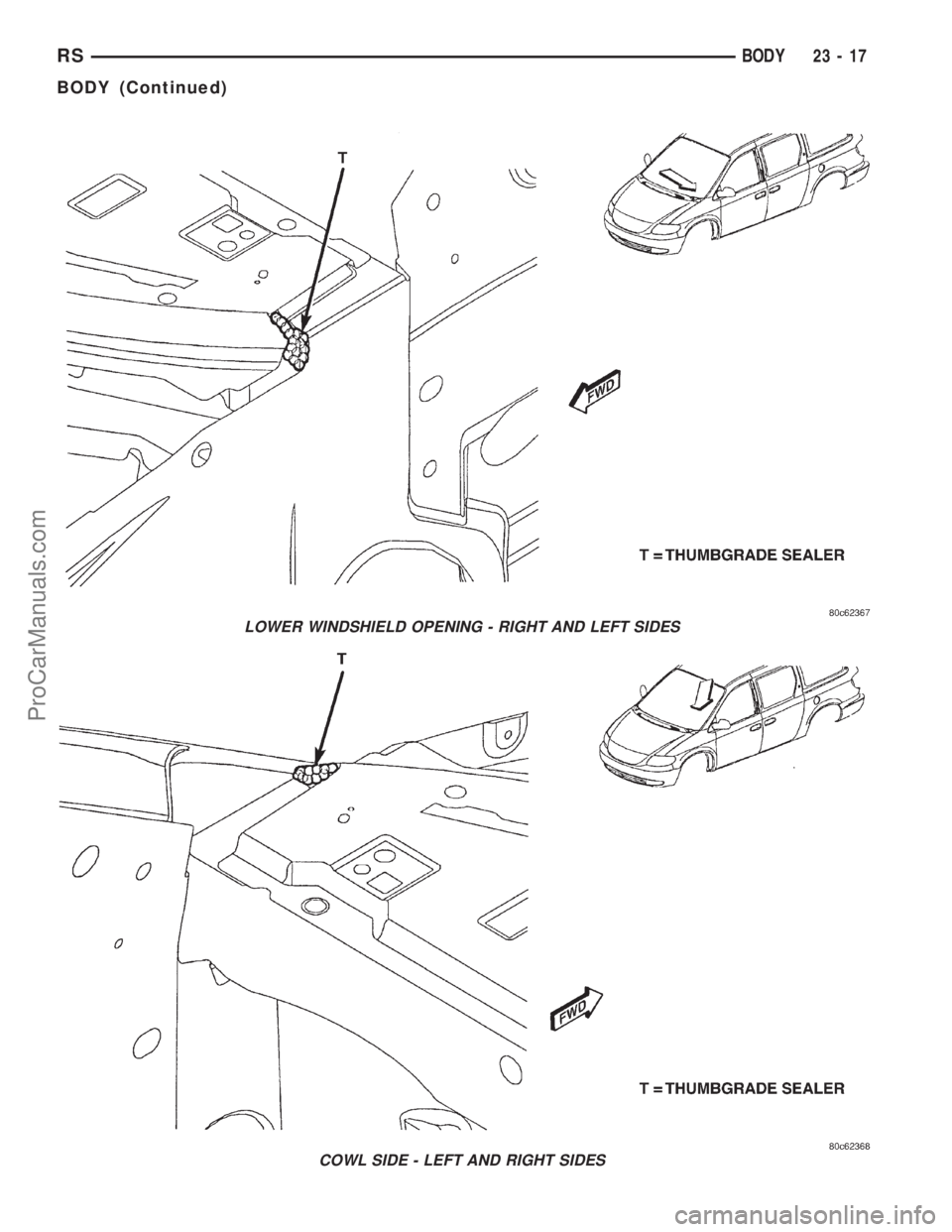

LOWER WINDSHIELD OPENING - RIGHT AND LEFT SIDES

COWL SIDE - LEFT AND RIGHT SIDES

RSBODY23-17

BODY (Continued)

ProCarManuals.com

Trending: steering, seat memory, jacking points, windshield wipers, parking brake, height adjustment, hood open