DODGE TOWN AND COUNTRY 2001 Service Manual

TOWN AND COUNTRY 2001

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56921/w960_56921-0.png

DODGE TOWN AND COUNTRY 2001 Service Manual

Trending: air filter, checking oil, air condition, radio, wheel torque, towing, diagnostic menu

Page 1881 of 2321

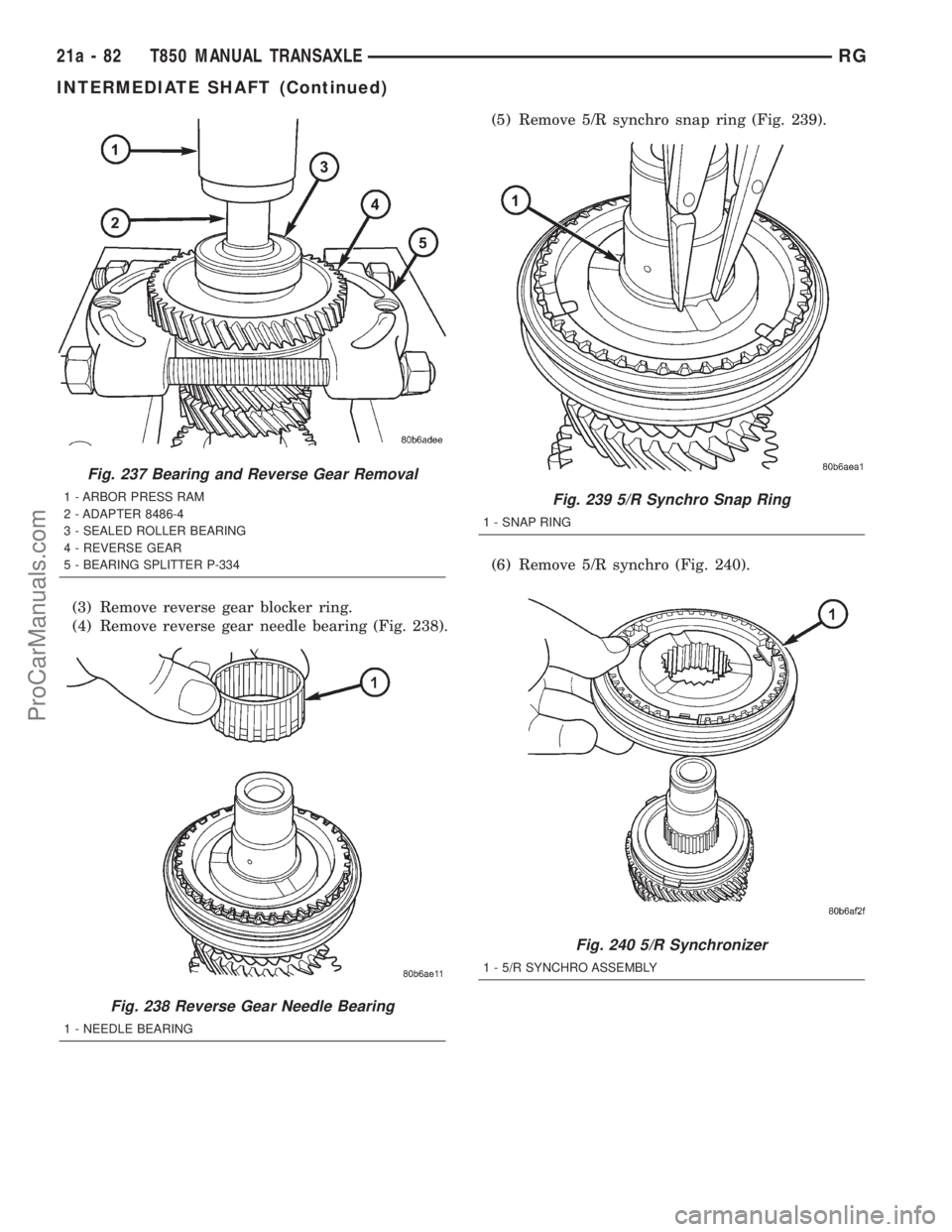

(3) Remove reverse gear blocker ring.

(4) Remove reverse gear needle bearing (Fig. 238).(5) Remove 5/R synchro snap ring (Fig. 239).

(6) Remove 5/R synchro (Fig. 240).

Fig. 237 Bearing and Reverse Gear Removal

1 - ARBOR PRESS RAM

2 - ADAPTER 8486-4

3 - SEALED ROLLER BEARING

4 - REVERSE GEAR

5 - BEARING SPLITTER P-334

Fig. 238 Reverse Gear Needle Bearing

1 - NEEDLE BEARING

Fig. 239 5/R Synchro Snap Ring

1 - SNAP RING

Fig. 240 5/R Synchronizer

1 - 5/R SYNCHRO ASSEMBLY

21a - 82 T850 MANUAL TRANSAXLERG

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Page 1882 of 2321

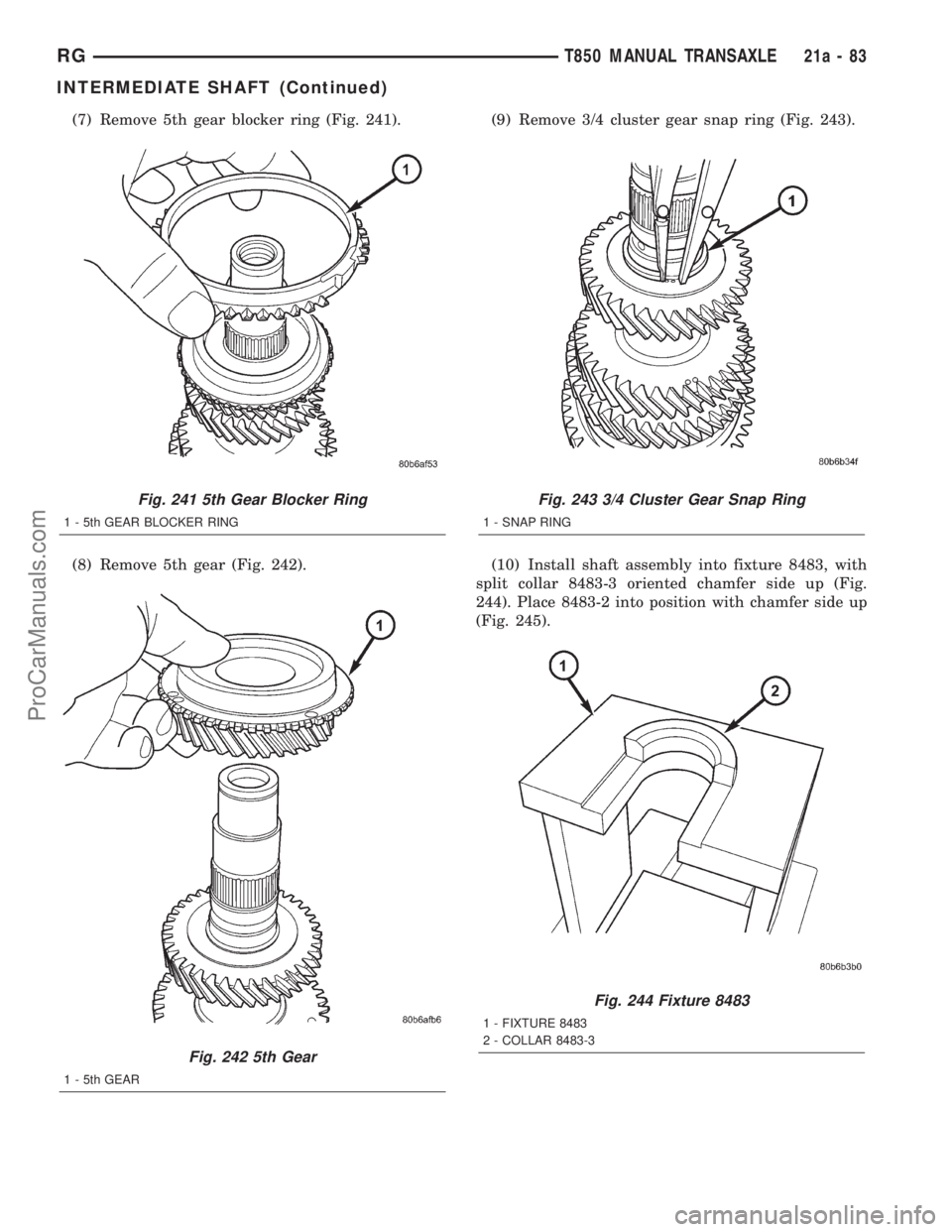

(7) Remove 5th gear blocker ring (Fig. 241).

(8) Remove 5th gear (Fig. 242).(9) Remove 3/4 cluster gear snap ring (Fig. 243).

(10) Install shaft assembly into fixture 8483, with

split collar 8483-3 oriented chamfer side up (Fig.

244). Place 8483-2 into position with chamfer side up

(Fig. 245).

Fig. 241 5th Gear Blocker Ring

1 - 5th GEAR BLOCKER RING

Fig. 242 5th Gear

1 - 5th GEAR

Fig. 243 3/4 Cluster Gear Snap Ring

1 - SNAP RING

Fig. 244 Fixture 8483

1 - FIXTURE 8483

2 - COLLAR 8483-3

RGT850 MANUAL TRANSAXLE21a-83

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Page 1883 of 2321

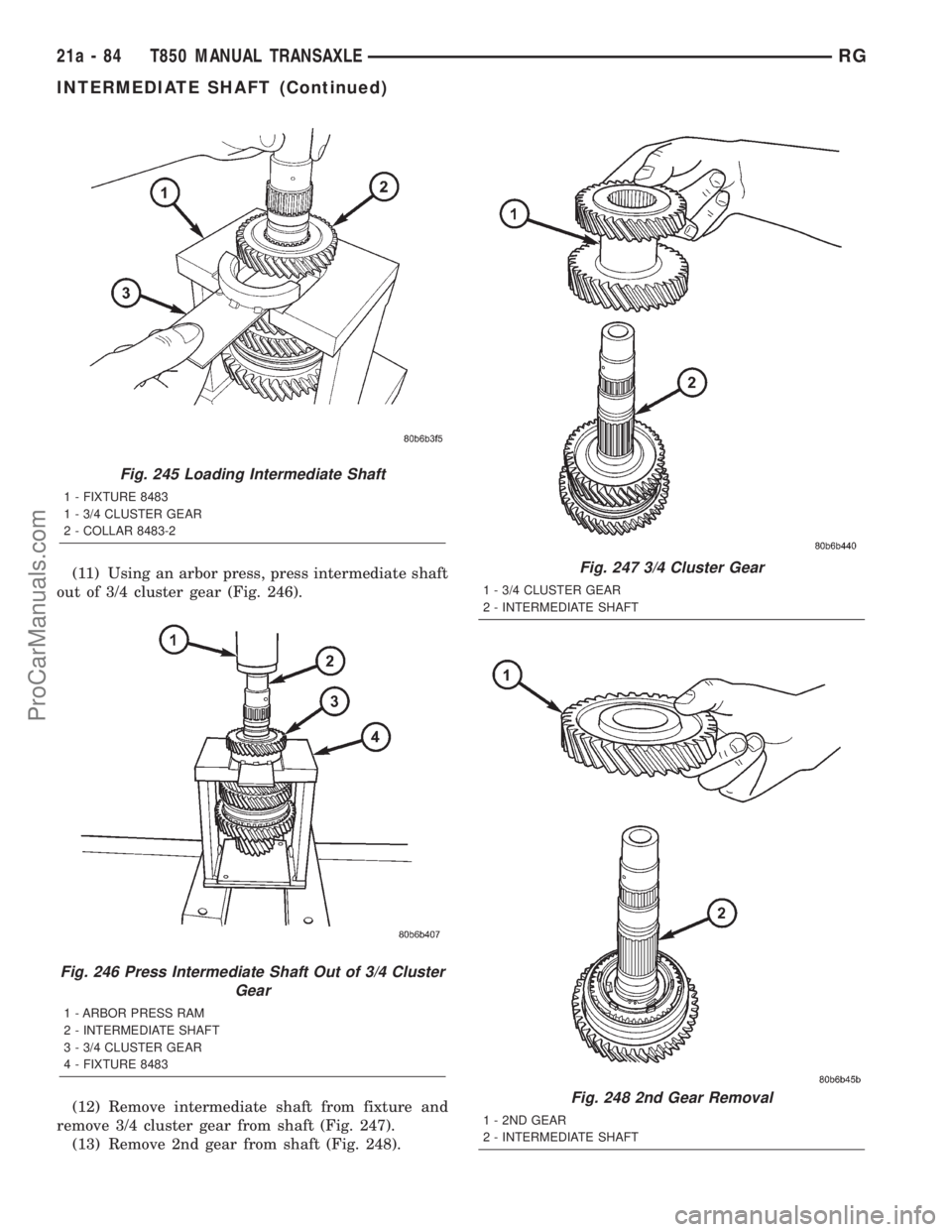

(11) Using an arbor press, press intermediate shaft

out of 3/4 cluster gear (Fig. 246).

(12) Remove intermediate shaft from fixture and

remove 3/4 cluster gear from shaft (Fig. 247).

(13) Remove 2nd gear from shaft (Fig. 248).

Fig. 245 Loading Intermediate Shaft

1 - FIXTURE 8483

1 - 3/4 CLUSTER GEAR

2 - COLLAR 8483-2

Fig. 246 Press Intermediate Shaft Out of 3/4 Cluster

Gear

1 - ARBOR PRESS RAM

2 - INTERMEDIATE SHAFT

3 - 3/4 CLUSTER GEAR

4 - FIXTURE 8483

Fig. 247 3/4 Cluster Gear

1 - 3/4 CLUSTER GEAR

2 - INTERMEDIATE SHAFT

Fig. 248 2nd Gear Removal

1 - 2ND GEAR

2 - INTERMEDIATE SHAFT

21a - 84 T850 MANUAL TRANSAXLERG

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Page 1884 of 2321

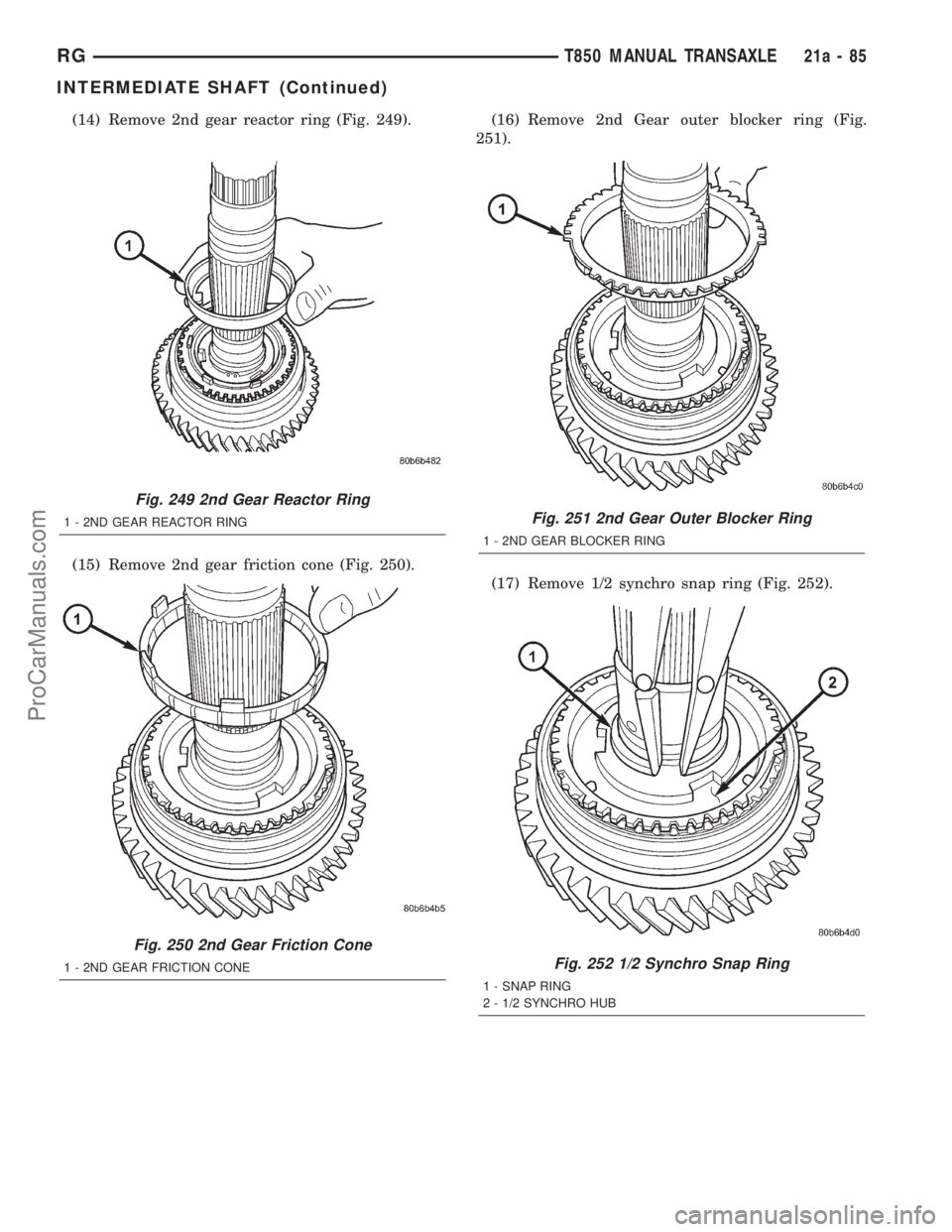

(14) Remove 2nd gear reactor ring (Fig. 249).

(15) Remove 2nd gear friction cone (Fig. 250).(16) Remove 2nd Gear outer blocker ring (Fig.

251).

(17) Remove 1/2 synchro snap ring (Fig. 252).

Fig. 249 2nd Gear Reactor Ring

1 - 2ND GEAR REACTOR RING

Fig. 250 2nd Gear Friction Cone

1 - 2ND GEAR FRICTION CONE

Fig. 251 2nd Gear Outer Blocker Ring

1 - 2ND GEAR BLOCKER RING

Fig. 252 1/2 Synchro Snap Ring

1 - SNAP RING

2 - 1/2 SYNCHRO HUB

RGT850 MANUAL TRANSAXLE21a-85

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Page 1885 of 2321

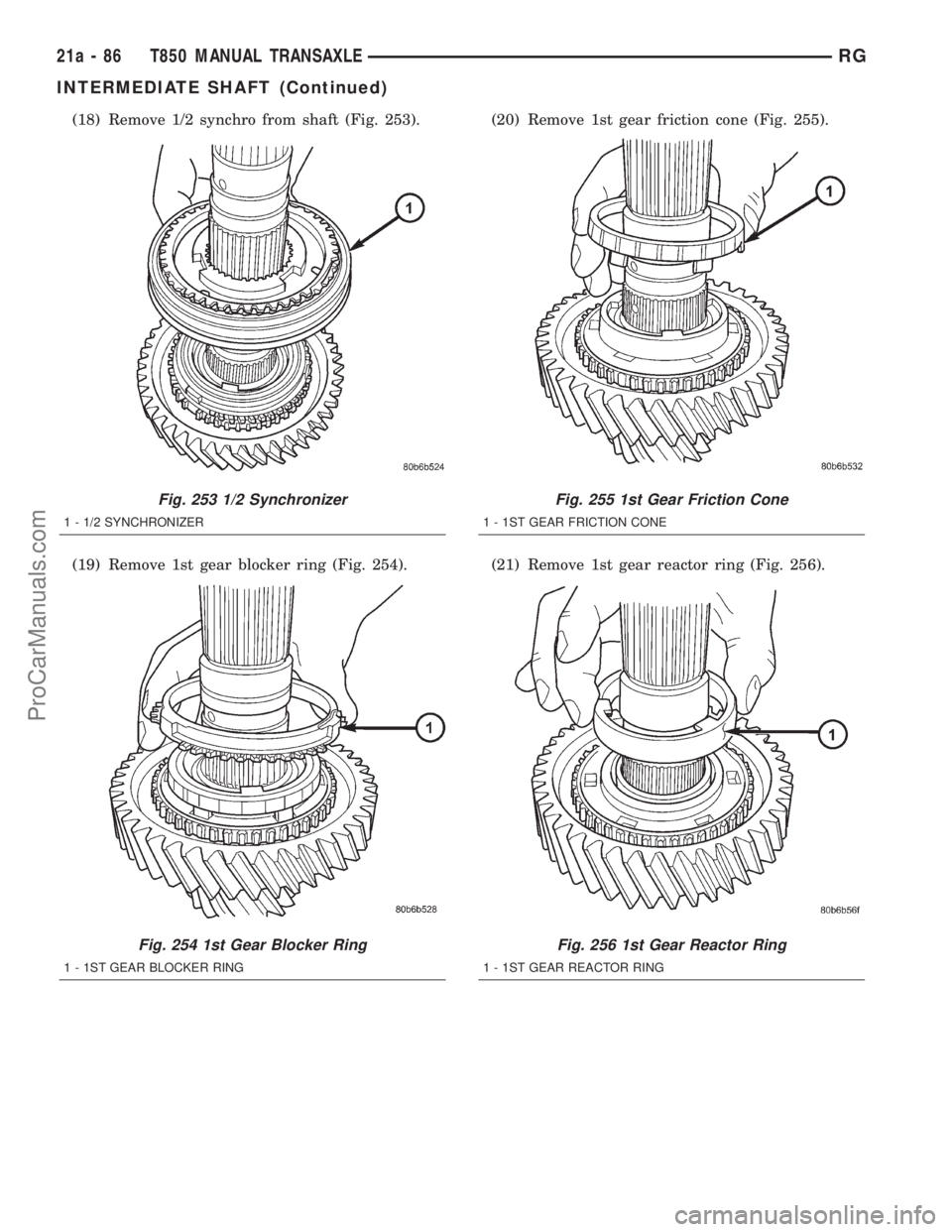

(18) Remove 1/2 synchro from shaft (Fig. 253).

(19) Remove 1st gear blocker ring (Fig. 254).(20) Remove 1st gear friction cone (Fig. 255).

(21) Remove 1st gear reactor ring (Fig. 256).

Fig. 253 1/2 Synchronizer

1 - 1/2 SYNCHRONIZER

Fig. 254 1st Gear Blocker Ring

1 - 1ST GEAR BLOCKER RING

Fig. 255 1st Gear Friction Cone

1 - 1ST GEAR FRICTION CONE

Fig. 256 1st Gear Reactor Ring

1 - 1ST GEAR REACTOR RING

21a - 86 T850 MANUAL TRANSAXLERG

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Page 1886 of 2321

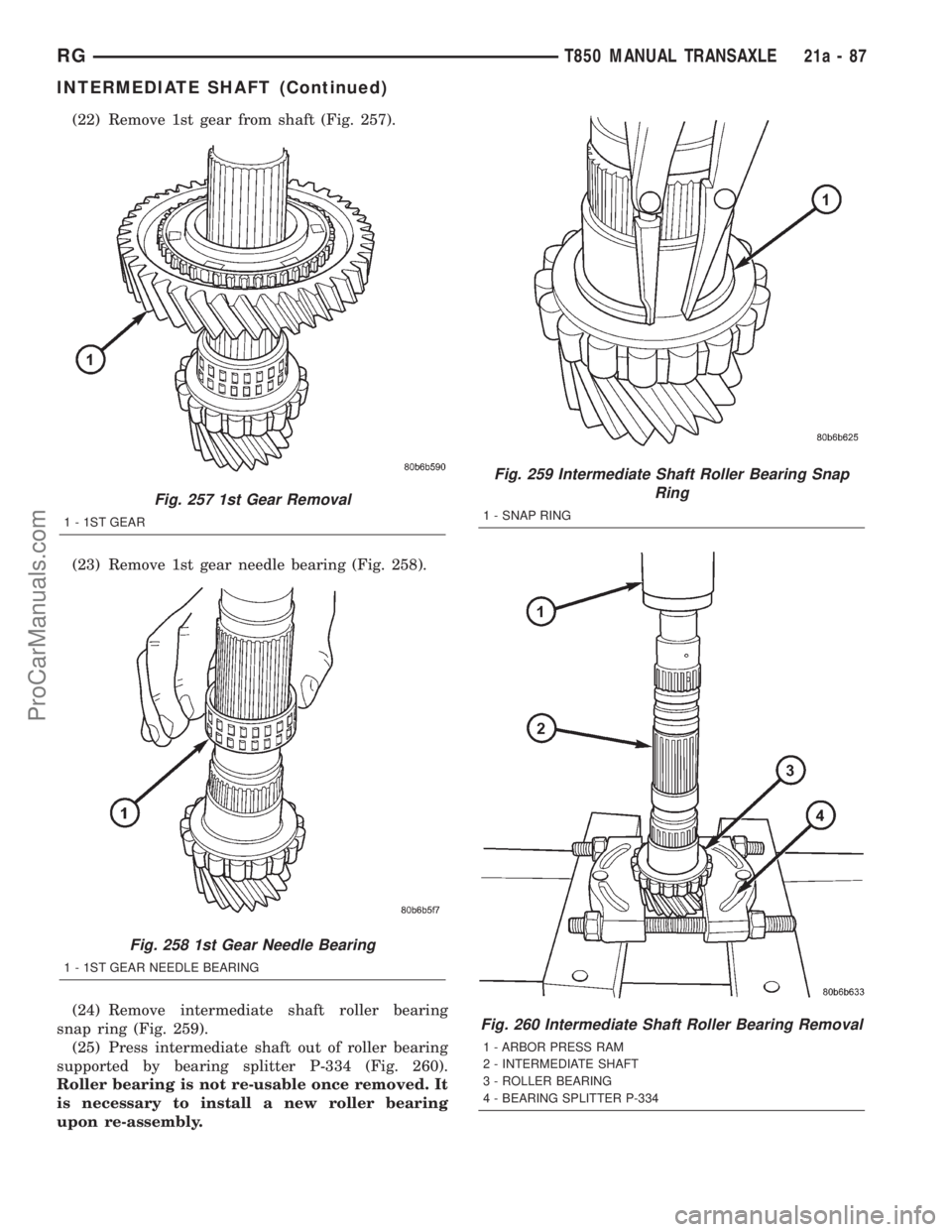

(22) Remove 1st gear from shaft (Fig. 257).

(23) Remove 1st gear needle bearing (Fig. 258).

(24) Remove intermediate shaft roller bearing

snap ring (Fig. 259).

(25) Press intermediate shaft out of roller bearing

supported by bearing splitter P-334 (Fig. 260).

Roller bearing is not re-usable once removed. It

is necessary to install a new roller bearing

upon re-assembly.

Fig. 257 1st Gear Removal

1 - 1ST GEAR

Fig. 258 1st Gear Needle Bearing

1 - 1ST GEAR NEEDLE BEARING

Fig. 259 Intermediate Shaft Roller Bearing Snap

Ring

1 - SNAP RING

Fig. 260 Intermediate Shaft Roller Bearing Removal

1 - ARBOR PRESS RAM

2 - INTERMEDIATE SHAFT

3 - ROLLER BEARING

4 - BEARING SPLITTER P-334

RGT850 MANUAL TRANSAXLE21a-87

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Page 1887 of 2321

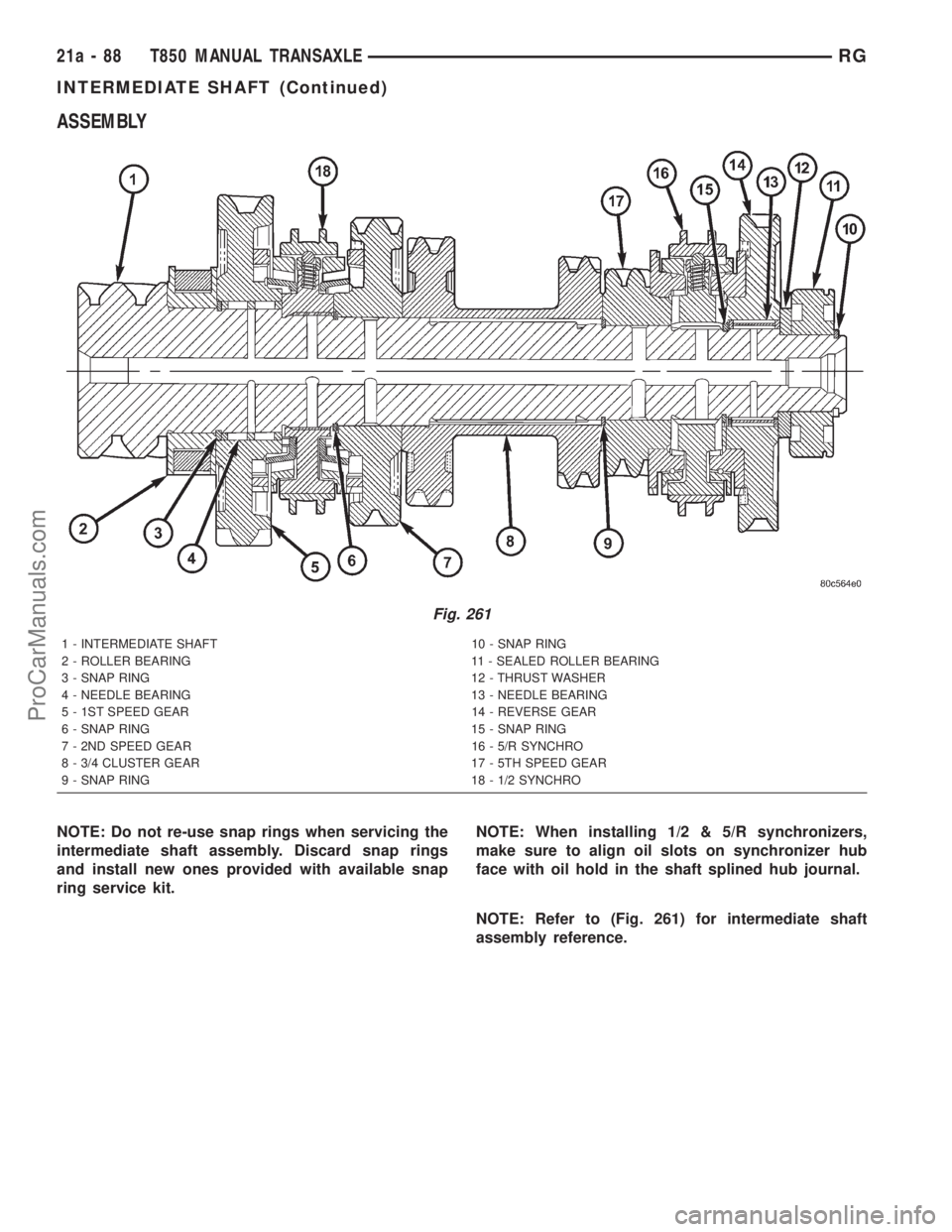

ASSEMBLY

NOTE: Do not re-use snap rings when servicing the

intermediate shaft assembly. Discard snap rings

and install new ones provided with available snap

ring service kit.NOTE: When installing 1/2 & 5/R synchronizers,

make sure to align oil slots on synchronizer hub

face with oil hold in the shaft splined hub journal.

NOTE: Refer to (Fig. 261) for intermediate shaft

assembly reference.

1 - INTERMEDIATE SHAFT 10 - SNAP RING

2 - ROLLER BEARING 11 - SEALED ROLLER BEARING

3 - SNAP RING 12 - THRUST WASHER

4 - NEEDLE BEARING 13 - NEEDLE BEARING

5 - 1ST SPEED GEAR 14 - REVERSE GEAR

6 - SNAP RING 15 - SNAP RING

7 - 2ND SPEED GEAR 16 - 5/R SYNCHRO

8 - 3/4 CLUSTER GEAR 17 - 5TH SPEED GEAR

9 - SNAP RING 18 - 1/2 SYNCHRO

Fig. 261

21a - 88 T850 MANUAL TRANSAXLERG

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Page 1888 of 2321

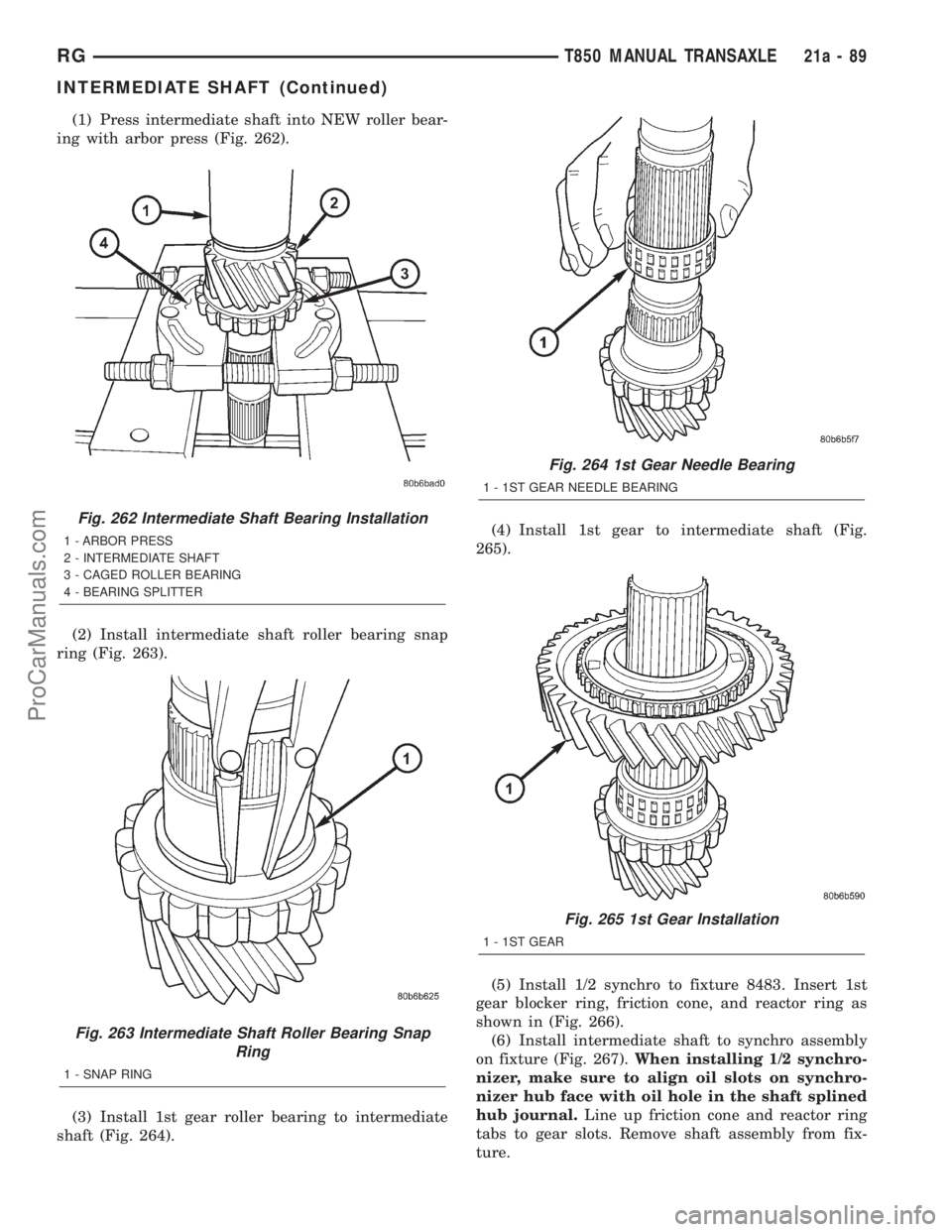

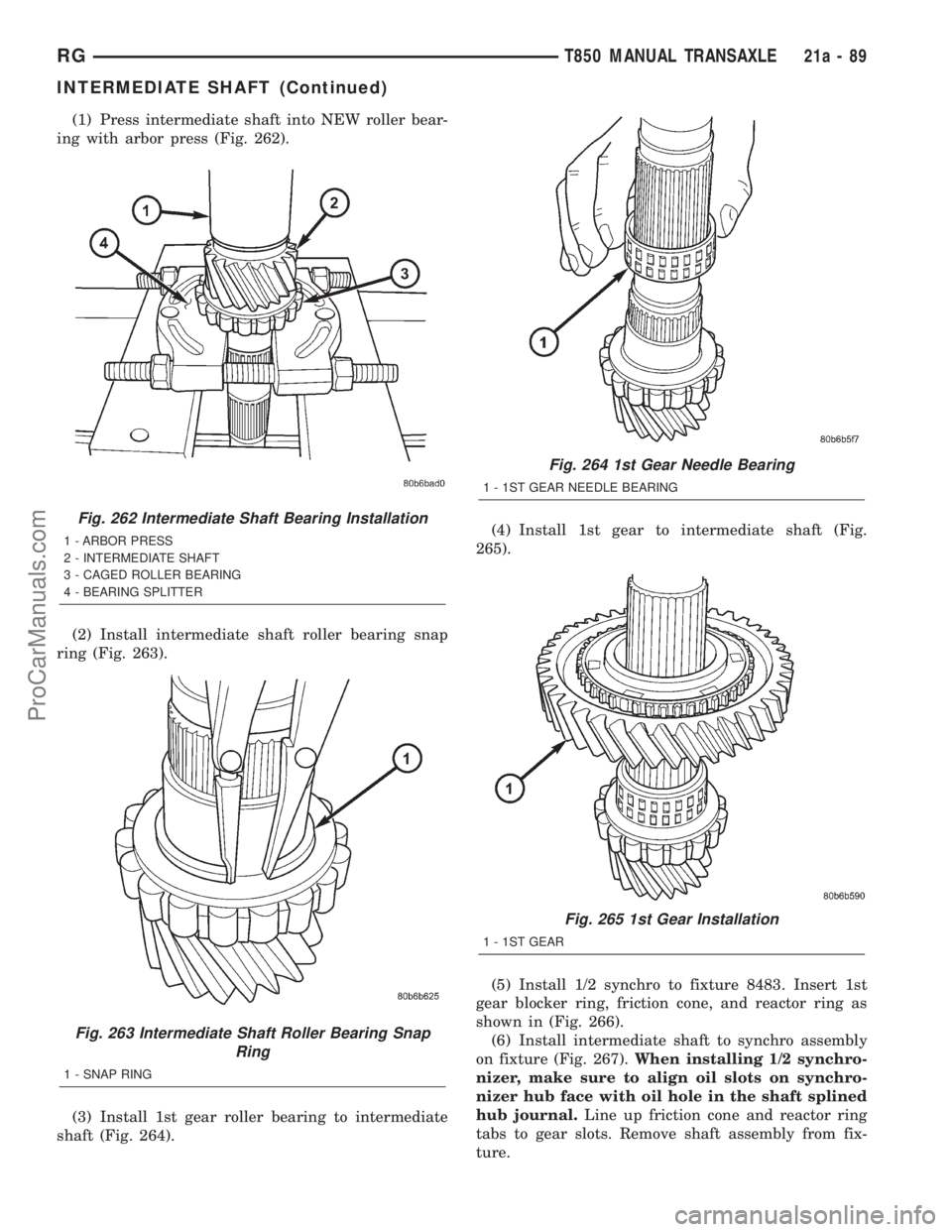

(1) Press intermediate shaft into NEW roller bear-

ing with arbor press (Fig. 262).

(2) Install intermediate shaft roller bearing snap

ring (Fig. 263).

(3) Install 1st gear roller bearing to intermediate

shaft (Fig. 264).(4) Install 1st gear to intermediate shaft (Fig.

265).

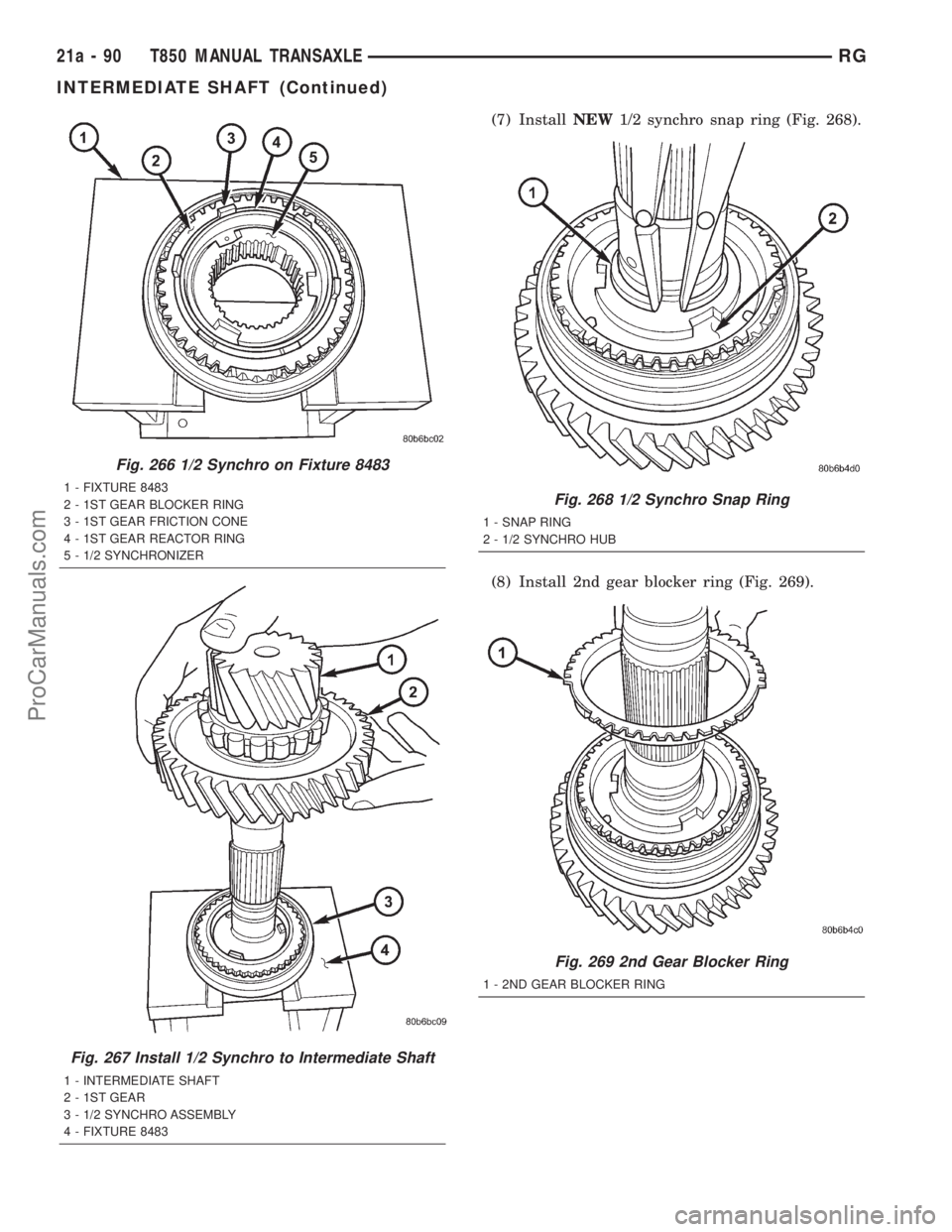

(5) Install 1/2 synchro to fixture 8483. Insert 1st

gear blocker ring, friction cone, and reactor ring as

shown in (Fig. 266).

(6) Install intermediate shaft to synchro assembly

on fixture (Fig. 267).When installing 1/2 synchro-

nizer, make sure to align oil slots on synchro-

nizer hub face with oil hole in the shaft splined

hub journal.Line up friction cone and reactor ring

tabs to gear slots. Remove shaft assembly from fix-

ture.

Fig. 262 Intermediate Shaft Bearing Installation

1 - ARBOR PRESS

2 - INTERMEDIATE SHAFT

3 - CAGED ROLLER BEARING

4 - BEARING SPLITTER

Fig. 263 Intermediate Shaft Roller Bearing Snap

Ring

1 - SNAP RING

Fig. 264 1st Gear Needle Bearing

1 - 1ST GEAR NEEDLE BEARING

Fig. 265 1st Gear Installation

1 - 1ST GEAR

RGT850 MANUAL TRANSAXLE21a-89

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Page 1889 of 2321

(7) InstallNEW1/2 synchro snap ring (Fig. 268).

(8) Install 2nd gear blocker ring (Fig. 269).

Fig. 266 1/2 Synchro on Fixture 8483

1 - FIXTURE 8483

2 - 1ST GEAR BLOCKER RING

3 - 1ST GEAR FRICTION CONE

4 - 1ST GEAR REACTOR RING

5 - 1/2 SYNCHRONIZER

Fig. 267 Install 1/2 Synchro to Intermediate Shaft

1 - INTERMEDIATE SHAFT

2 - 1ST GEAR

3 - 1/2 SYNCHRO ASSEMBLY

4 - FIXTURE 8483

Fig. 268 1/2 Synchro Snap Ring

1 - SNAP RING

2 - 1/2 SYNCHRO HUB

Fig. 269 2nd Gear Blocker Ring

1 - 2ND GEAR BLOCKER RING

21a - 90 T850 MANUAL TRANSAXLERG

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Page 1890 of 2321

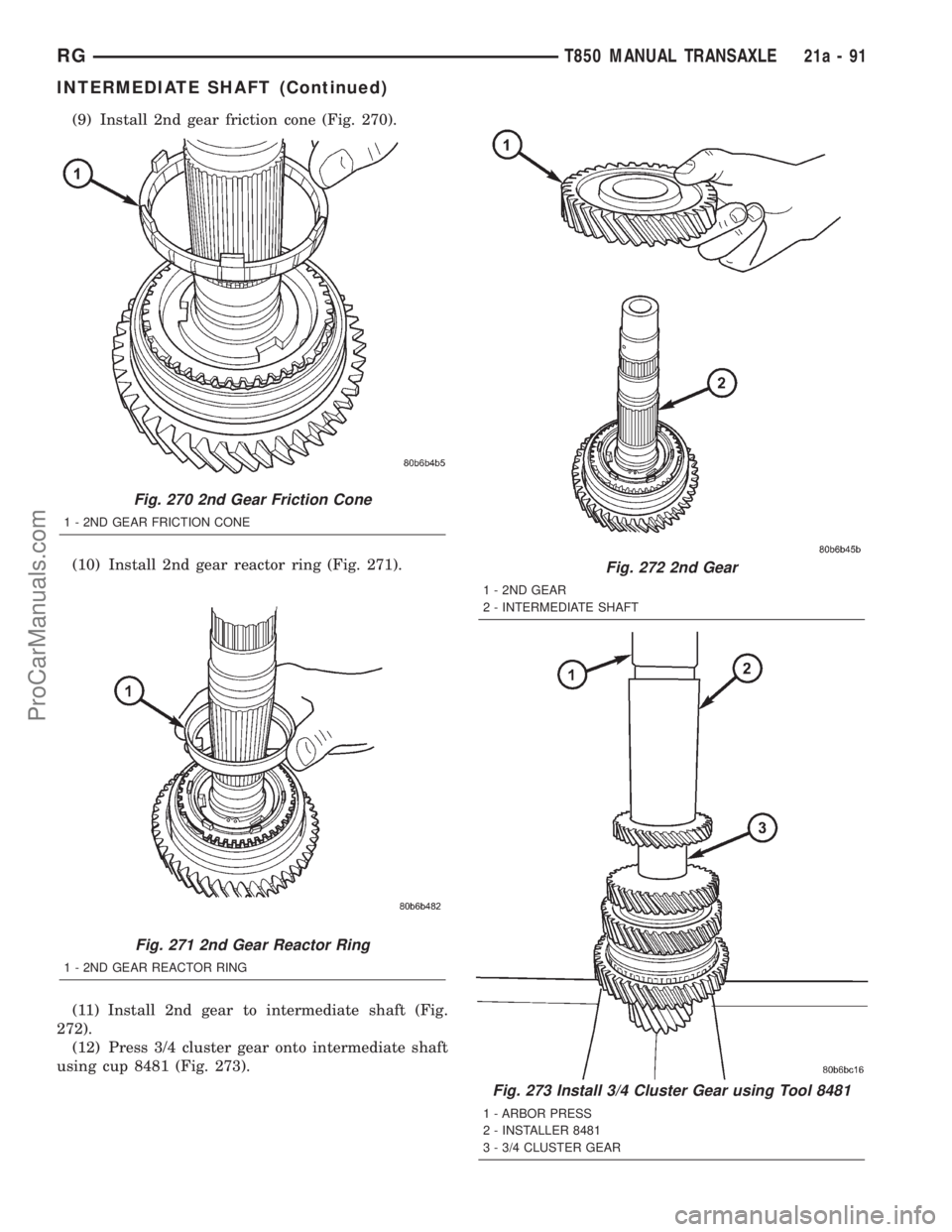

(9) Install 2nd gear friction cone (Fig. 270).

(10) Install 2nd gear reactor ring (Fig. 271).

(11) Install 2nd gear to intermediate shaft (Fig.

272).

(12) Press 3/4 cluster gear onto intermediate shaft

using cup 8481 (Fig. 273).

Fig. 270 2nd Gear Friction Cone

1 - 2ND GEAR FRICTION CONE

Fig. 271 2nd Gear Reactor Ring

1 - 2ND GEAR REACTOR RING

Fig. 272 2nd Gear

1 - 2ND GEAR

2 - INTERMEDIATE SHAFT

Fig. 273 Install 3/4 Cluster Gear using Tool 8481

1 - ARBOR PRESS

2 - INSTALLER 8481

3 - 3/4 CLUSTER GEAR

RGT850 MANUAL TRANSAXLE21a-91

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Trending: engine oil, airbag, automatic transmission fluid, park assist, fuel tank capacity, boot, low oil pressure